Entropy Generation Analysis and Radiated Heat Transfer in MHD (Al2O3-Cu/Water) Hybrid Nanofluid Flow

Abstract

:1. Introduction

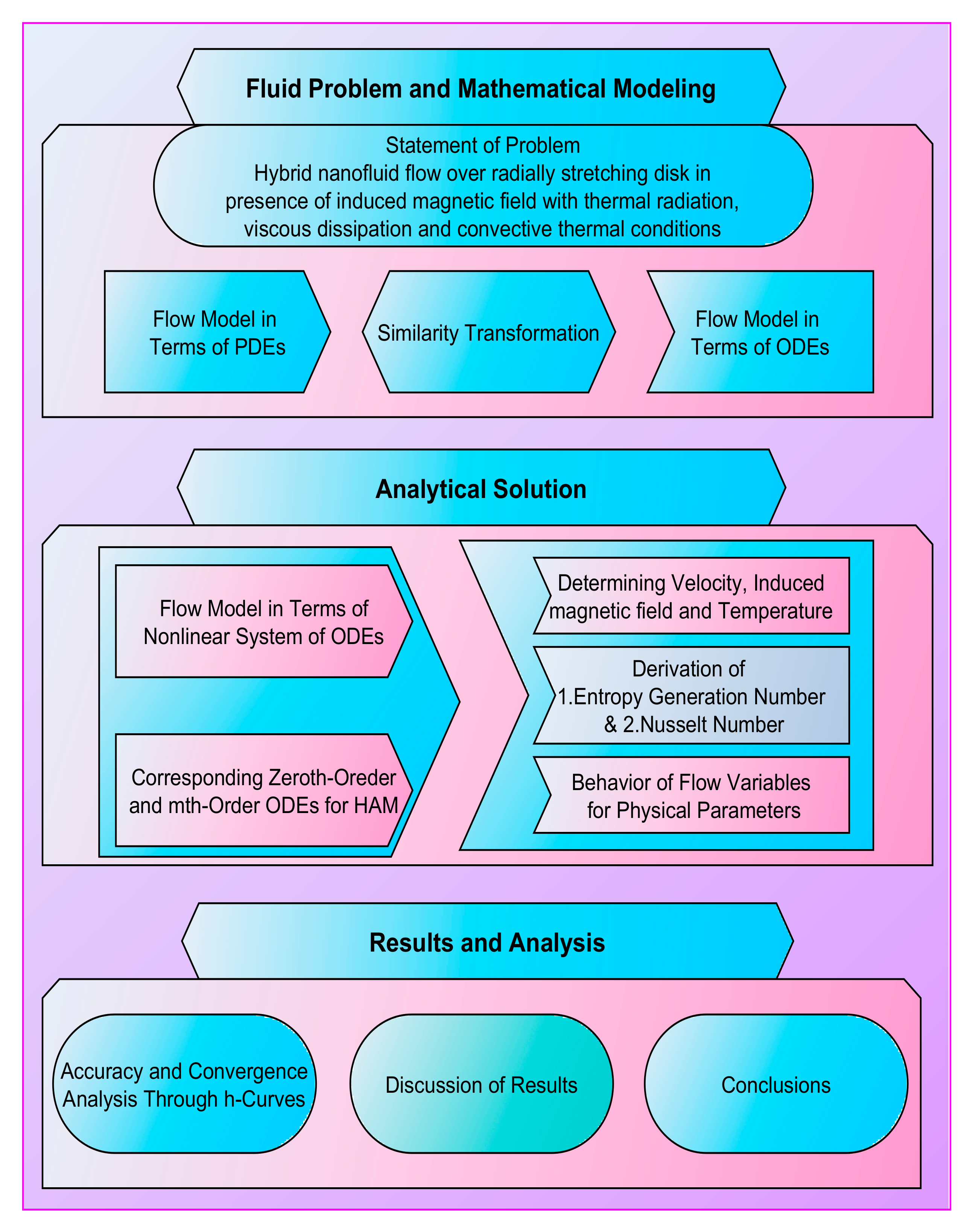

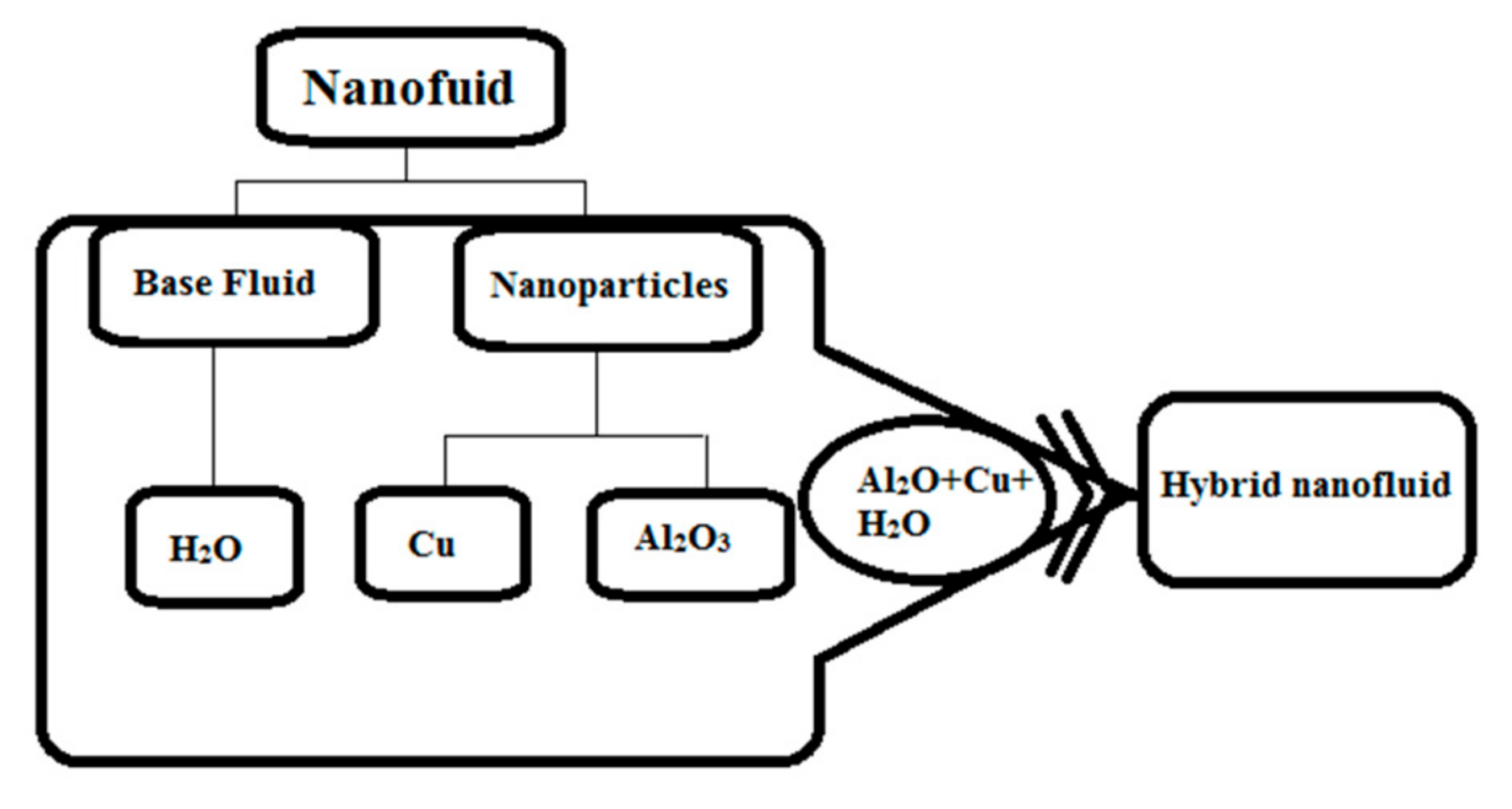

2. Modeling and Problem

3. Homotopy Analysis Method and Convergence of Solutions

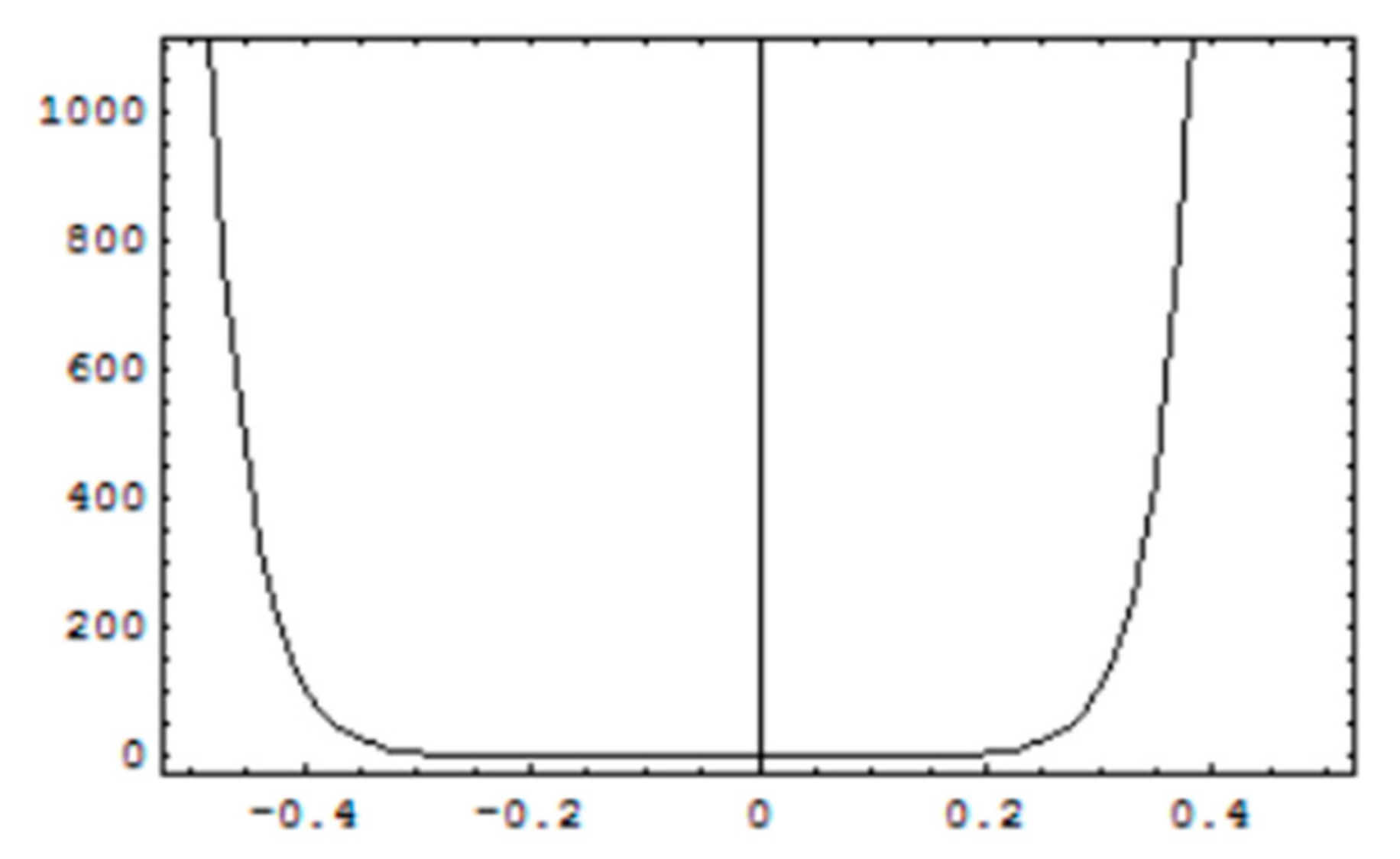

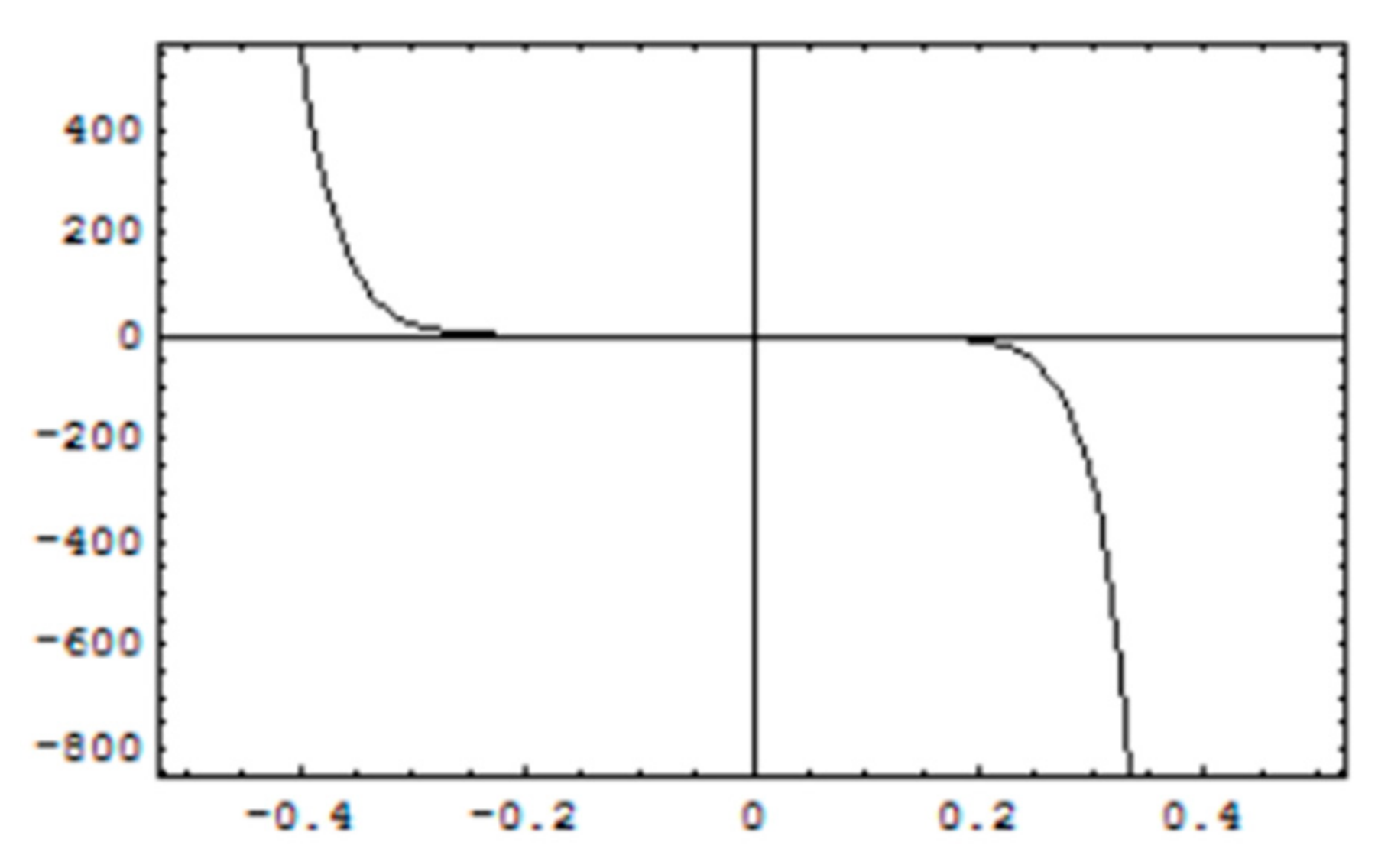

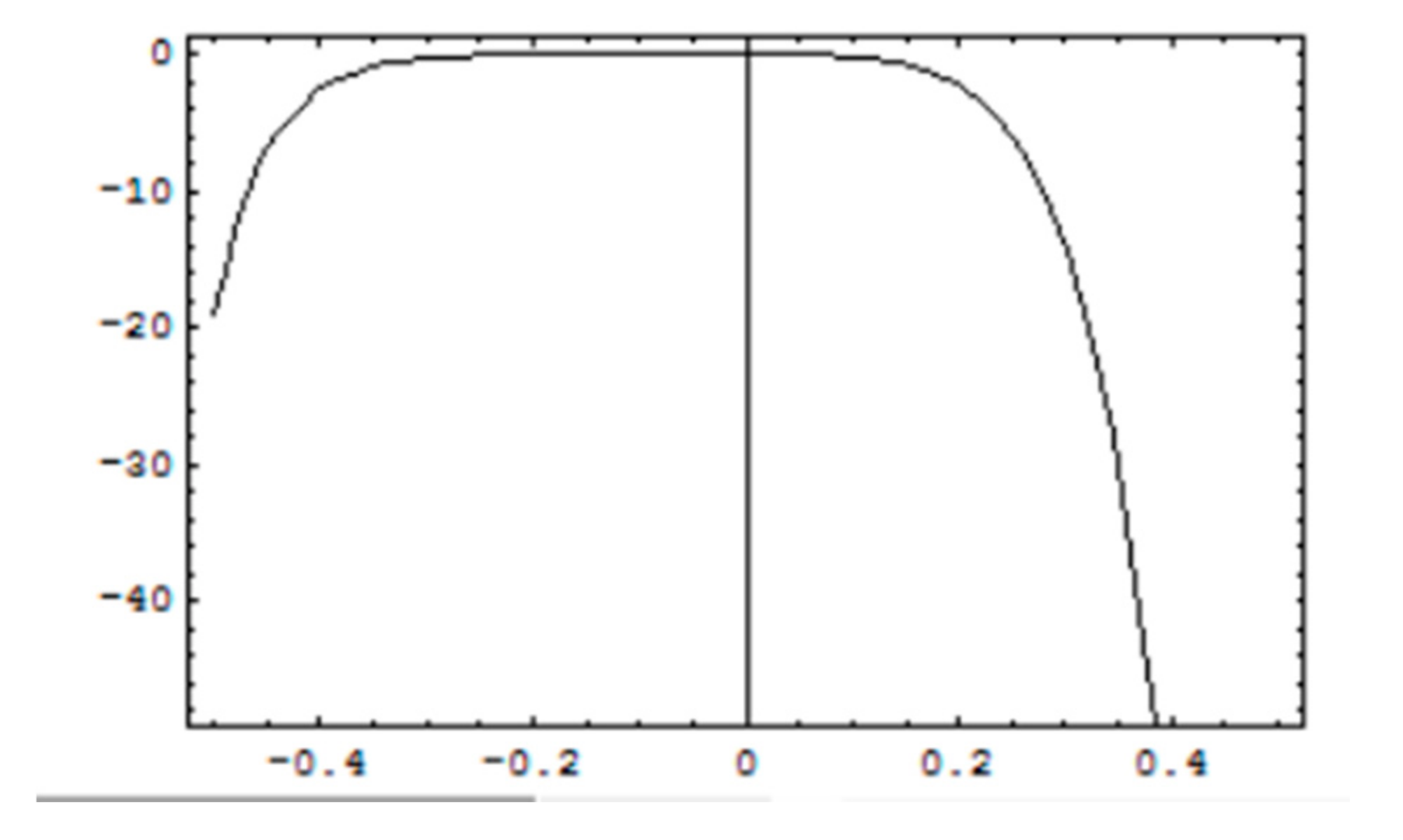

3.1. Convergence-Control Parameters

3.2. Convergence of Solutions

4. Discussion of Results

5. Concluding Remarks

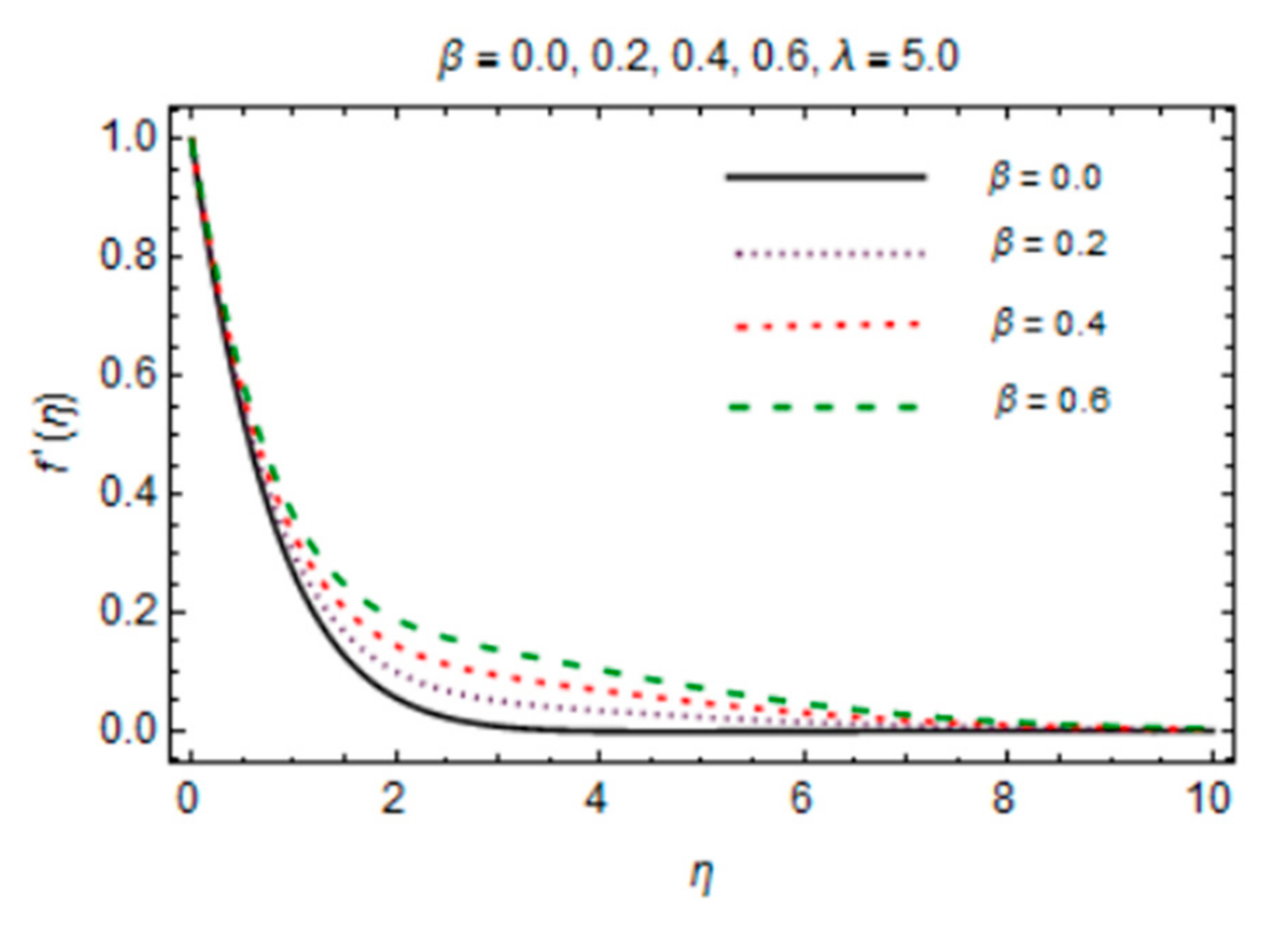

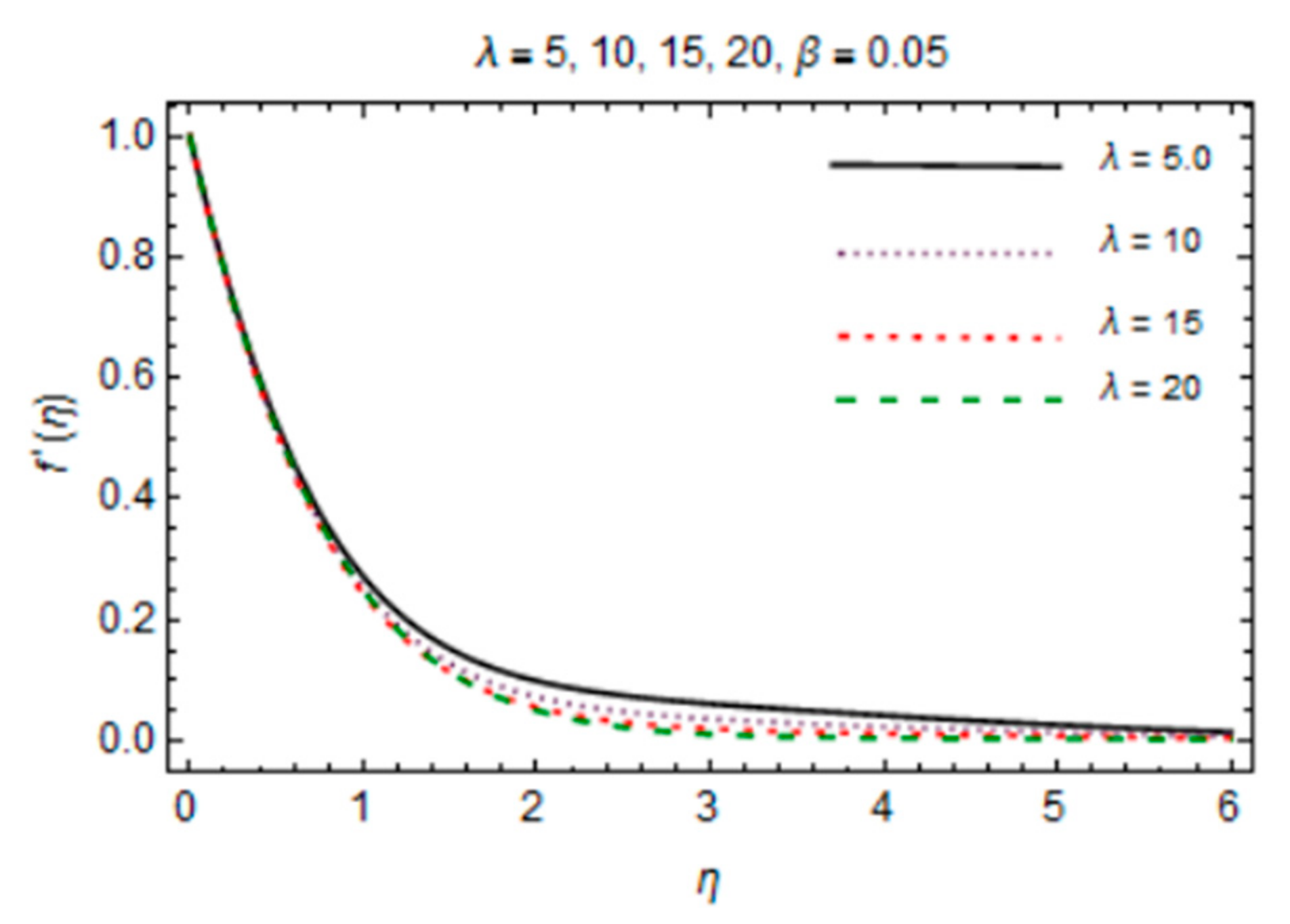

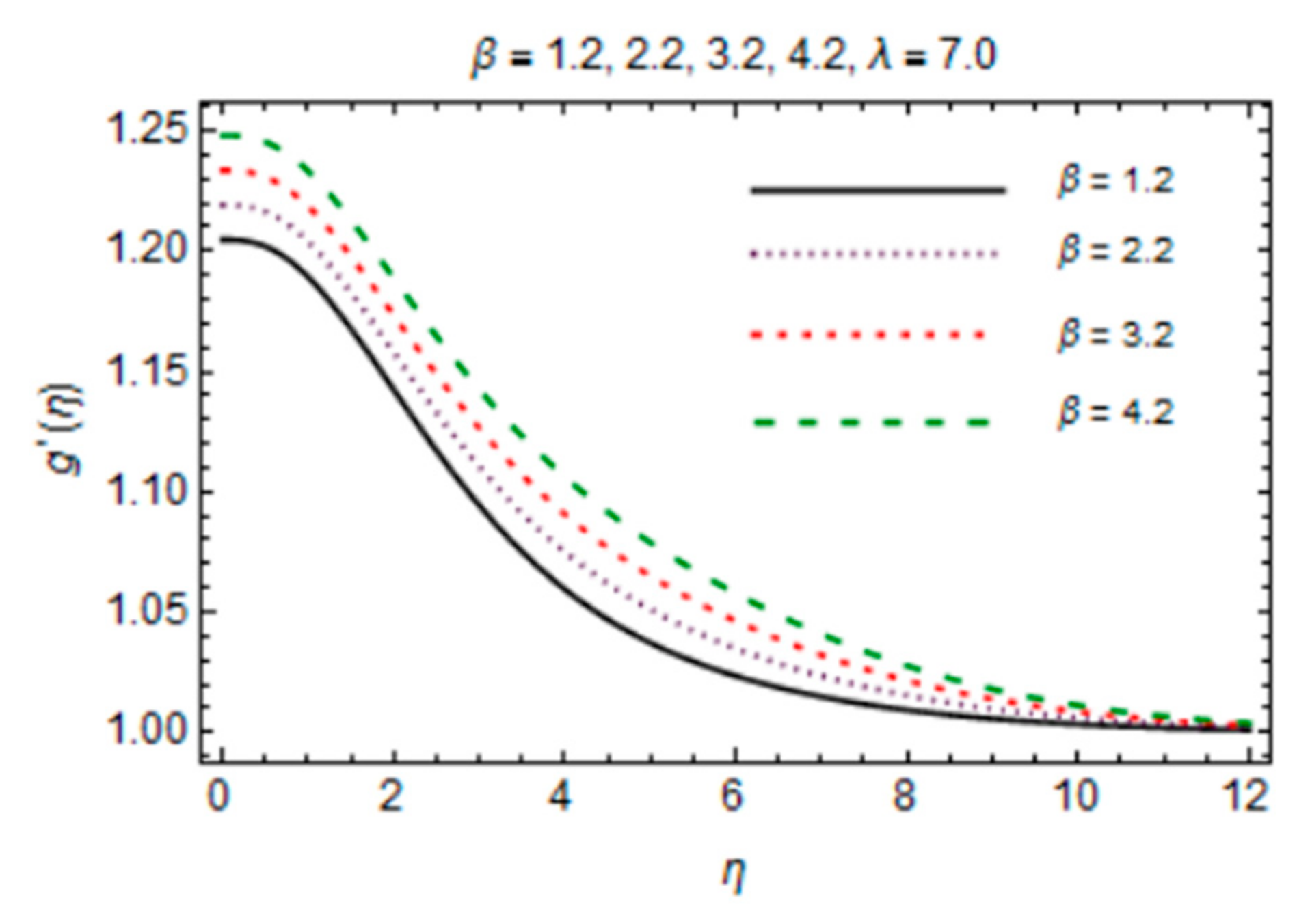

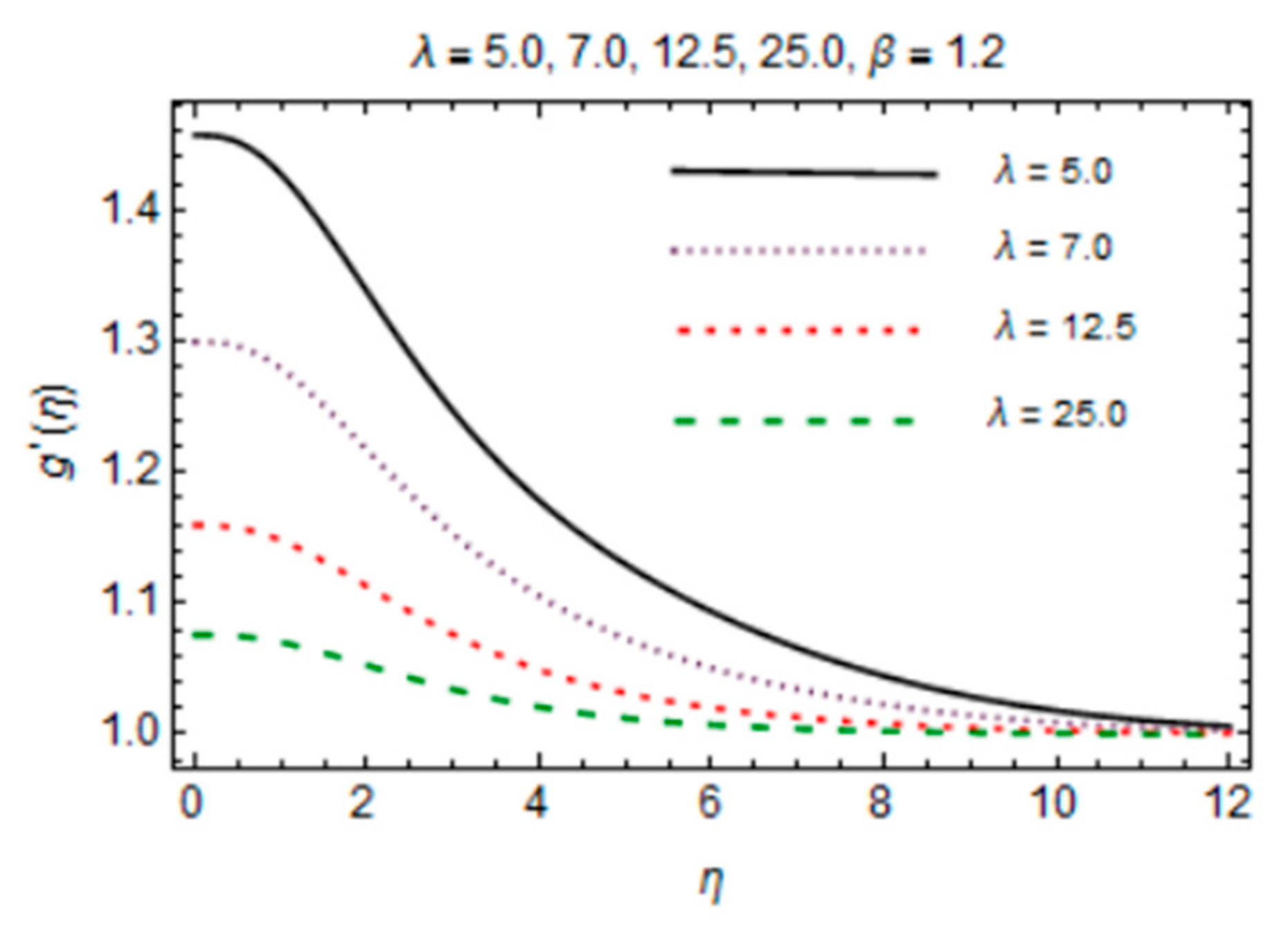

- and profiles are increasing functions of magnetic parameter while an opposite behavior is seen for enhancing values of λ.

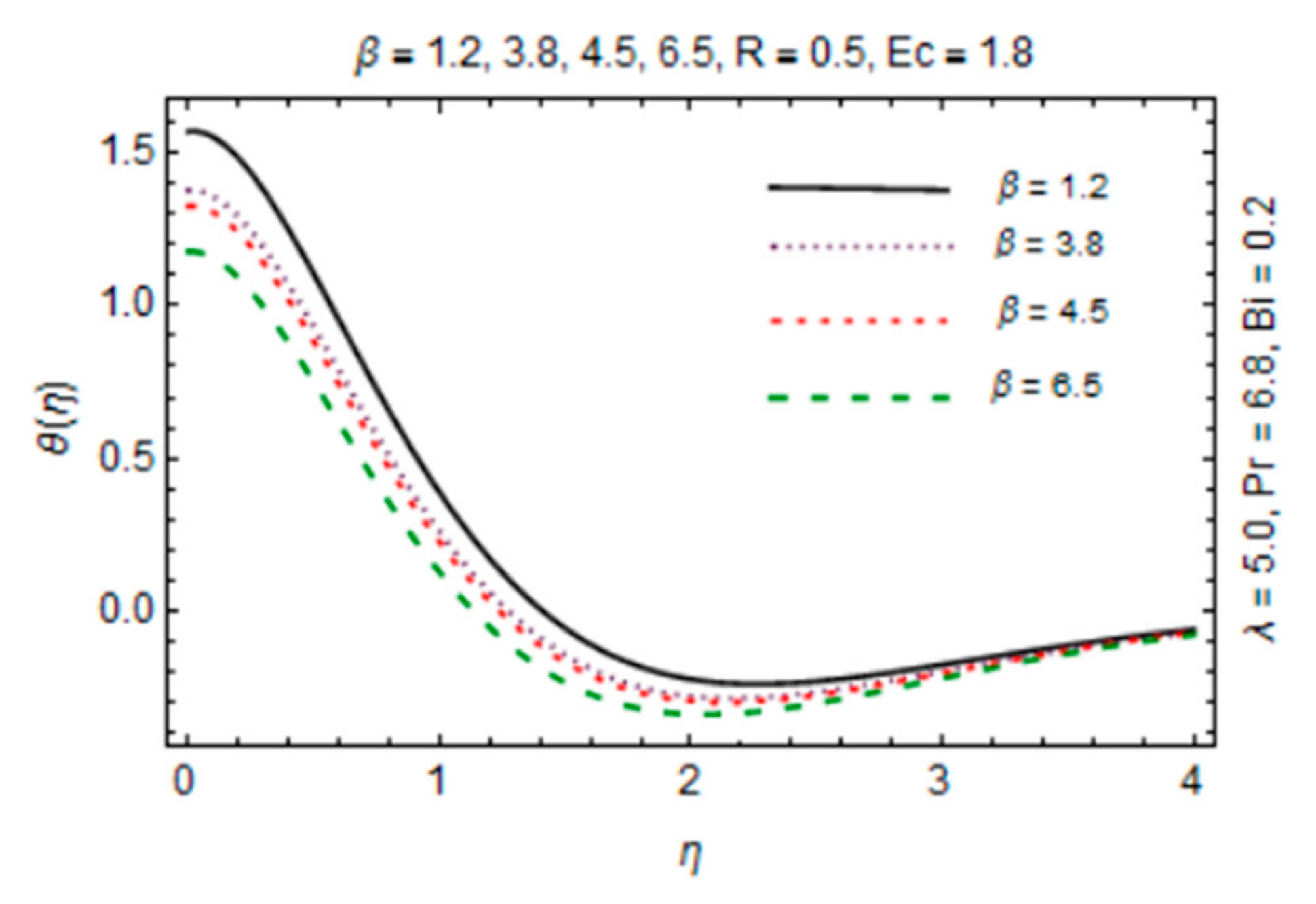

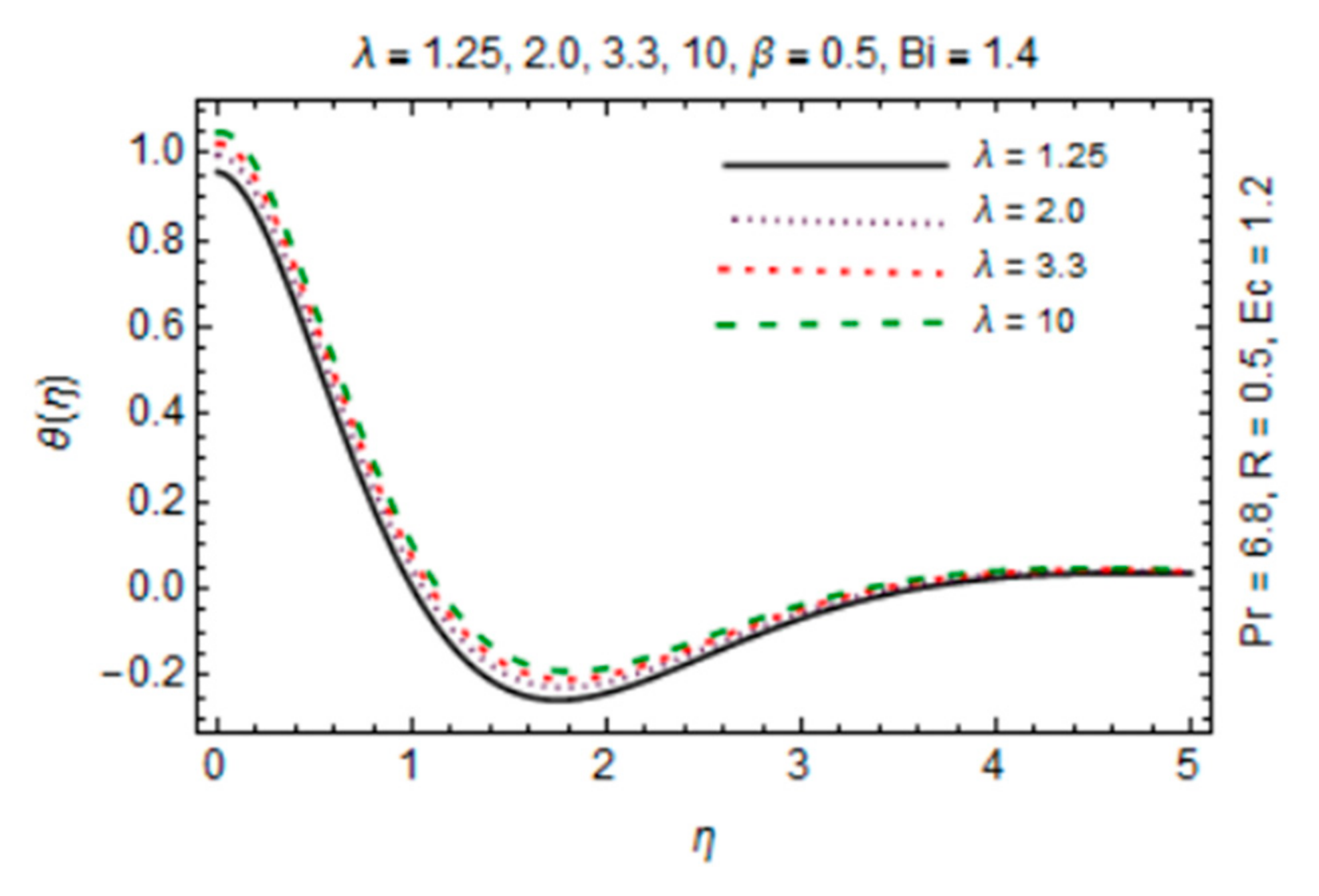

- Increment in β results in an enhancement in temperature, whereas it reduces against λ.

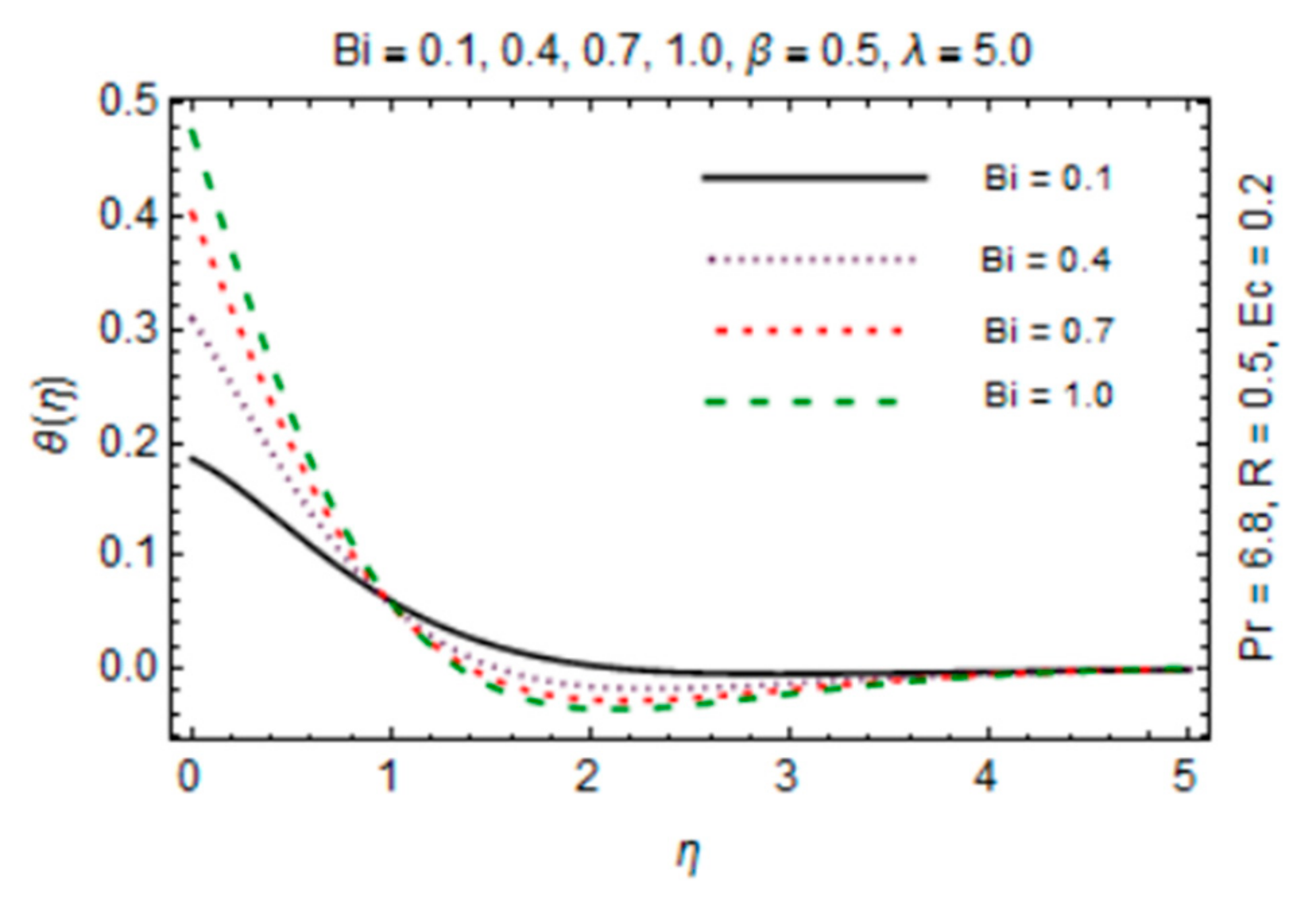

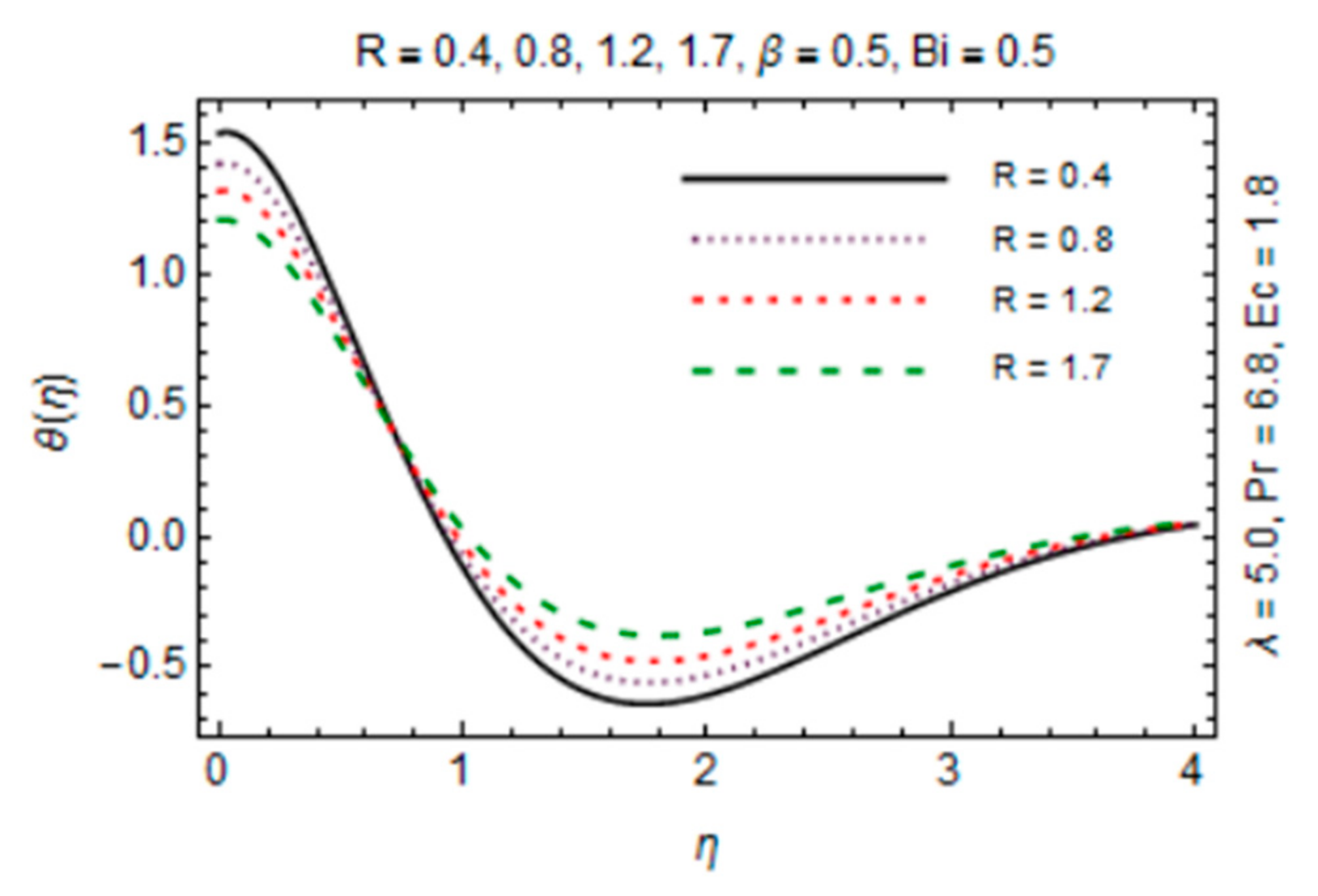

- An increasing behavior for the temperature of the fluid is observed against rising values of parameters Bi and R at the surface. An opposite trend is depicted in the ambient region with a point of inflection in the field.

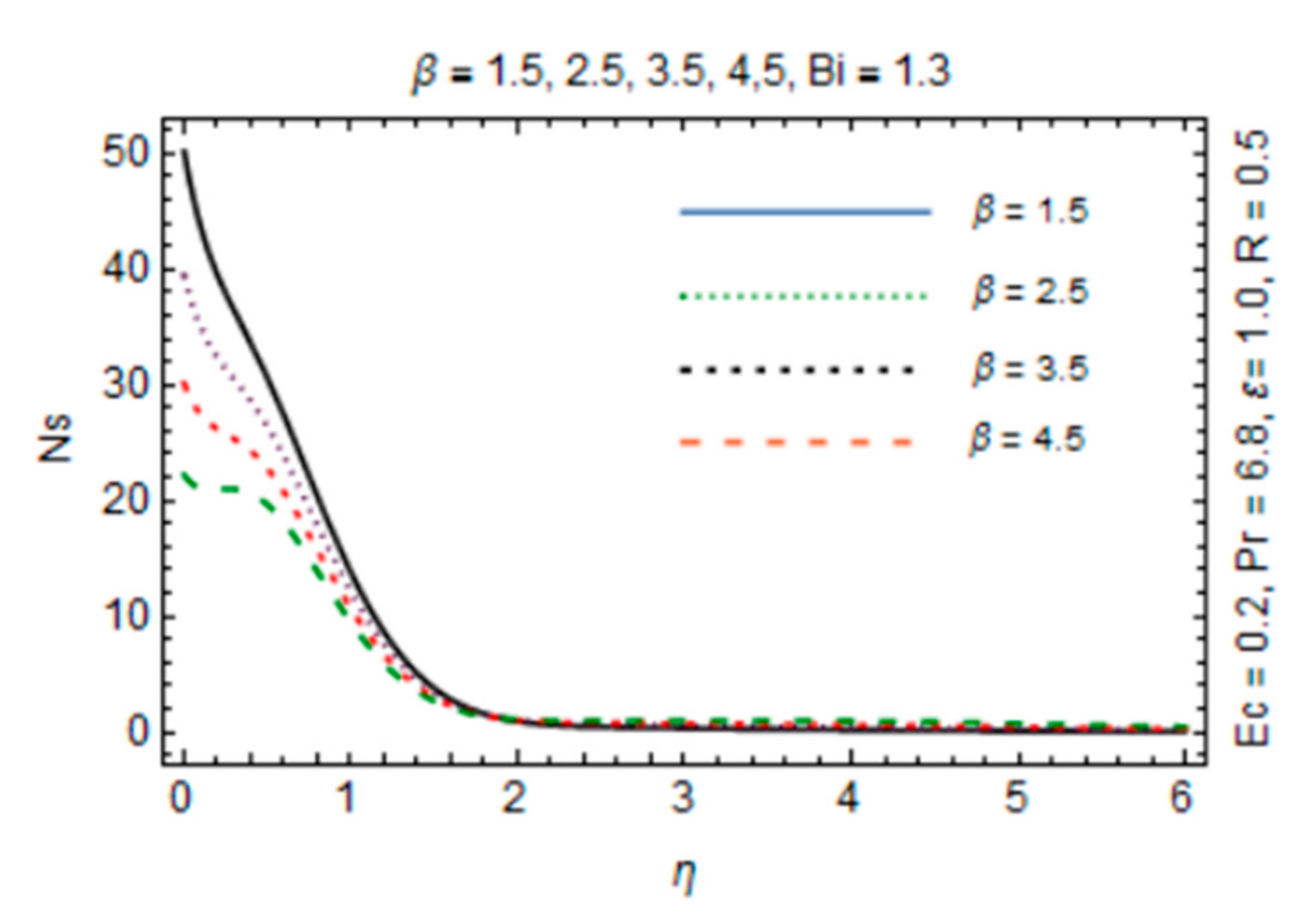

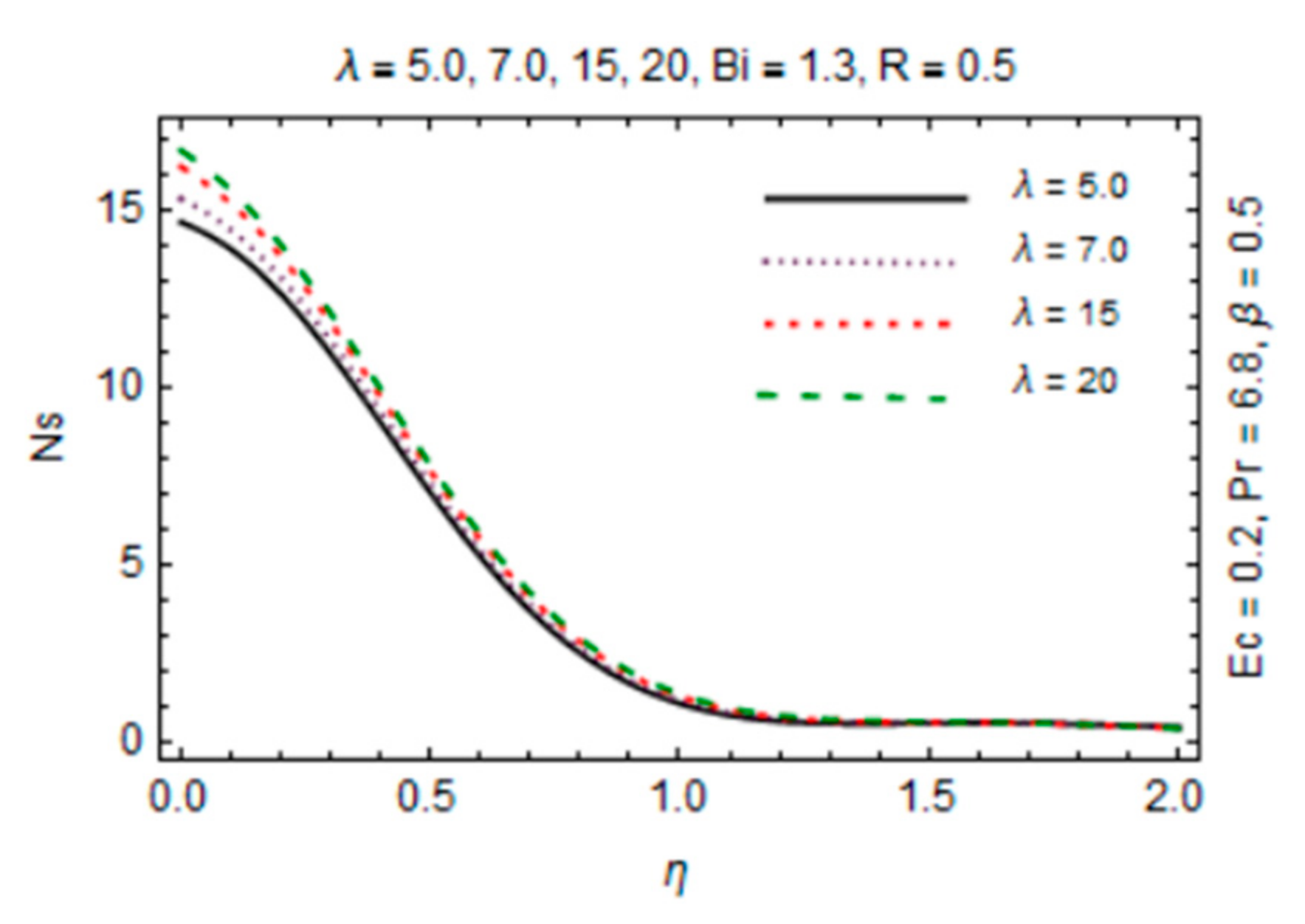

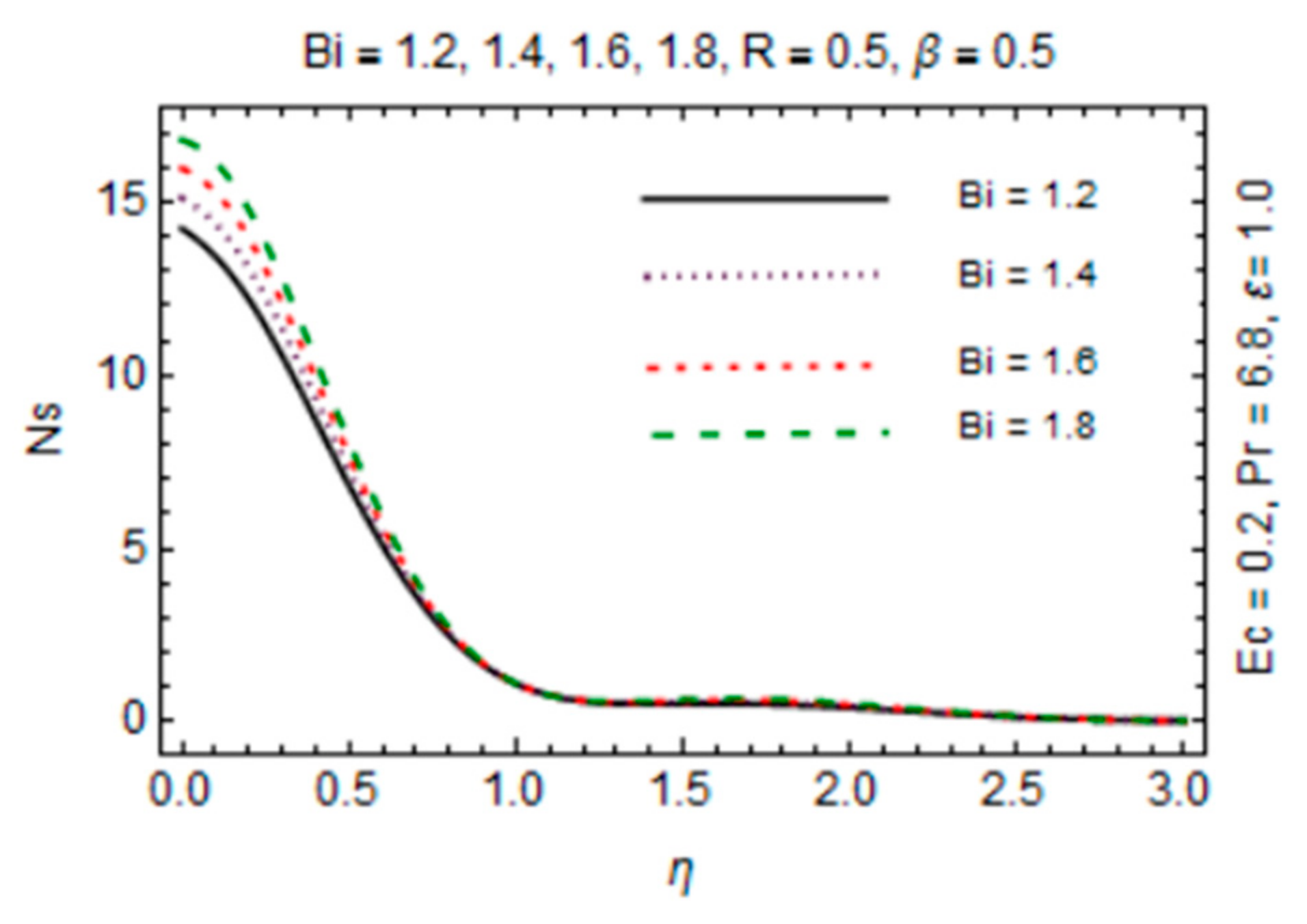

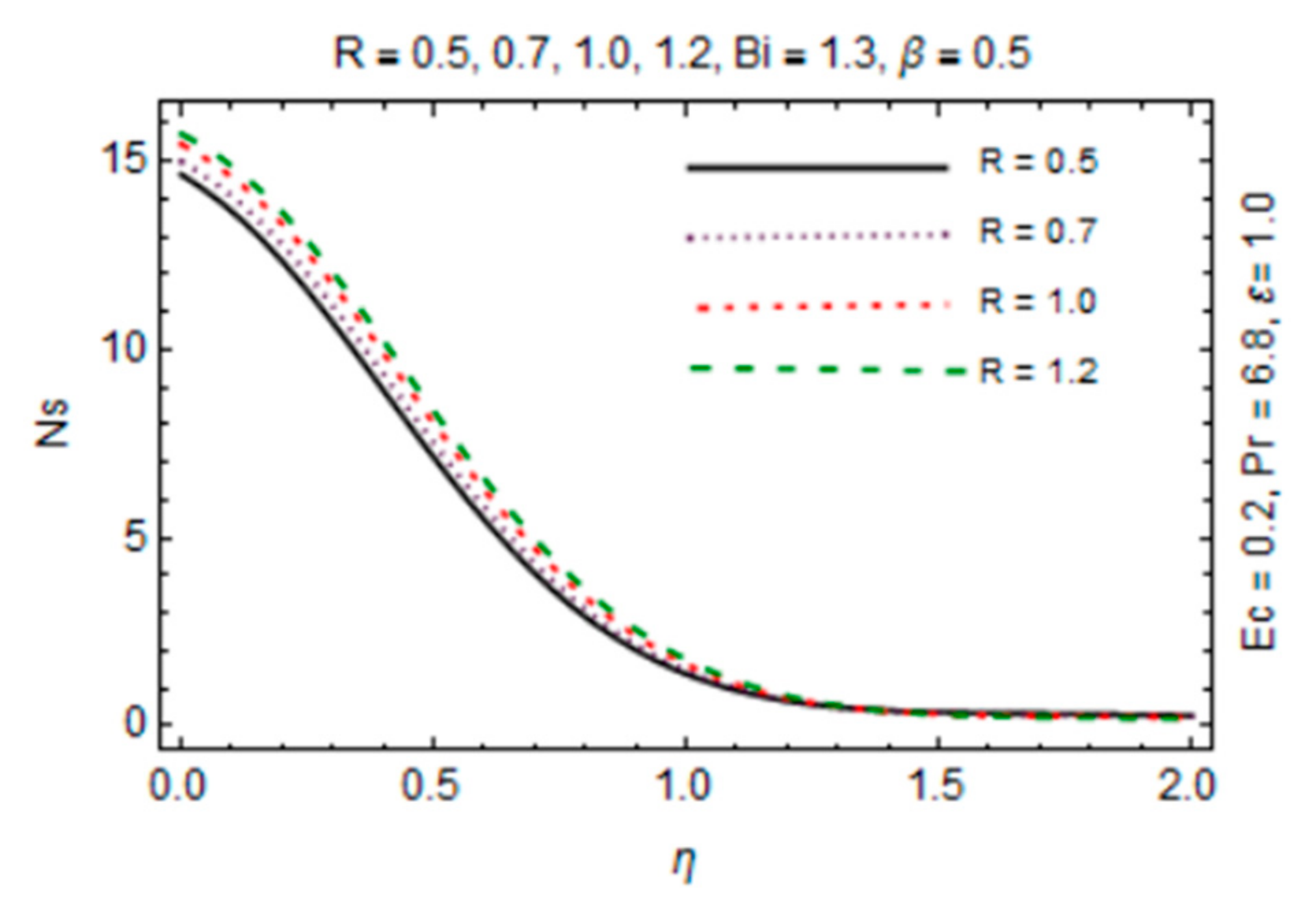

- Entropy generation number enhances for enhancement in values of parameters Bi, R and λ but diminishes against β.

- Flow profiles and entropy generation number are large near the surface of the disk and then decrease asymptotically far away from it. Also, these are more sensitive to fluctuate at the interface for several involved parameters.

- At the interface, fluid temperature is significantly different from ambient temperature. Thus, convection at the wall corresponding to high values of convective heat coefficient leads to increased rate of heat transfer at the interface.

- Values of skin friction and heat transfer coefficient can be optimized by choosing suitable values of involved parameters regarding different physical problems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Nomenclature | Greek Symbols | ||

| a | Constant | Magnetic parameter | |

| Bi | Biot number | Dimensionless similarity variable | |

| cf | Skin friction coefficient | Nanoparticles volume fraction | |

| Ec | Eckert number | Thermal conductivity | |

| H0 | Uniform magnetic field | Density | |

| h | Convective heat transfer coefficient | Heat capacity | |

| k | Mean absorption coefficient | Magnetic permeability | |

| Nu | Nusselt number | Magnetic diffusivity | |

| Pr | Prandtl number | μ | Dynamic viscosity |

| qr | Radiative heat flux | Kinematic viscosity | |

| qw | Heat transfer at wall | σ | Stefan-Boltzmann constant |

| R | Radiation parameter | θ | Dimensionless temperature |

| Re | Reynolds number | Wall shear stress | |

| s | Nanoparticles shape factor | ε | Temperature ratio parameter |

| T | Fluid temperature | Subscripts | |

| Tw | Surface temperature | hnf | Hybrid nanofluid |

| T∞ | Ambient temperature | f | Base fluid |

| u, w | Velocity components in r-, z- directions. | w | Surface condition |

| Uw | Stretching velocity | ∞ | Ambient condition |

| U∞ | Ambient velocity | s1,s2 | Shape factors of Copper and Alumina |

References

- Sakiadis, B.C. Boundary layer phenomenon. J. AIChE 1961, 7, 26–28. [Google Scholar] [CrossRef]

- Crane, L.J. Flow past a stretching plate. Z. Angew. Math. Phys. 1970, 21, 645–647. [Google Scholar] [CrossRef]

- Khan, A.S.; Nie, Y.; Shah, Z.; Dawar, A.; Khan, W.; Islam, S. Three-Dimensional Nanofluid Flow with Heat and Mass Transfer Analysis over a Linear Stretching Surface with Convective Boundary Conditions. Appl. Sci. 2018, 8, 2244. [Google Scholar] [CrossRef] [Green Version]

- Gireesha, B.J.; Umeshaiah, M.; Prasannakumara, B.C.; Shashikumar, N.S.; Archana, N. Impact of nonlinear thermal radiation on magnetohydrodynamic three dimensional boundary layer flow of Jeffrey nanofluid over a nonlinearly permeable stretching sheet. Phys. A Stat. Mech. Appl. 2020, 549, 124051. [Google Scholar]

- Hayat, T.; Khan, W.A.; Abbas, S.Z.; Nadeem, S.; Ahmad, S. Impact of induced magnetic field on second-grade nanofluid flow past a convectively heated stretching sheet. Appl. Nanosci. 2020, 10, 3001–3009. [Google Scholar] [CrossRef]

- Rafiq, M.; Siddiqa, S.; Begum, N.; Al-Mdallal, Q.; Hossain, M.; Gorla, R.S.R. Non-linear radiation effect on dusty fluid flow near a rotating blunt-nosed body. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2021. [Google Scholar] [CrossRef]

- Khan, W.; Awais, M.; Parveen, N.; Ali, A.; Awan, S.; Malik, M.; He, Y. Analytical Assessment of (Al2O3–Ag/H2O) Hybrid Nanofluid Influenced by Induced Magnetic Field for Second Law Analysis with Mixed Convection, Viscous Dissipation and Heat Generation. Coatings 2021, 11, 498. [Google Scholar] [CrossRef]

- Adeniyan, A.; Mabood, F.; Okoya, S. Effect of heat radiating and generating second-grade mixed convection flow over a vertical slender cylinder with variable physical properties. Int. Commun. Heat Mass Transf. 2021, 121, 105110. [Google Scholar] [CrossRef]

- Iyyappan, G.; Singh, A.K. MHD flows on irregular boundary over a diverging channel with viscous dissipation effect. Int. J. Numer. Methods Heat Fluid Flow 2021, 31, 2112–2127. [Google Scholar] [CrossRef]

- Amjad, M.; Zehra, I.; Nadeem, S.; Abbas, N.; Saleem, A.; Issakhov, A. Influence of Lorentz force and induced magnetic field effects on Casson micropolar nanofluid flow over a permeable curved stretching/shrinking surface under the stagnation region. Surf. Interfaces 2020, 21, 100766. [Google Scholar] [CrossRef]

- Xenos, M.A.; Petropoulou, E.N.; Siokis, A.; Mahabaleshwar, U.S. Solving the Nonlinear Boundary Layer Flow Equations with Pressure Gradient and Radiation. Symmetry 2020, 12, 710. [Google Scholar] [CrossRef]

- Singh, A.K.; Roy, S. Analysis of mixed convection in water boundary layer flows over a moving vertical plate with variable viscosity and Prandtl number. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 602–616. [Google Scholar] [CrossRef]

- Bilal, M.; Nazeer, M. Numerical analysis for the non-Newtonian flow over stratified stretching/shrinking inclined sheet with the aligned magnetic field and nonlinear convection. Arch. Appl. Mech. 2021, 91, 949–964. [Google Scholar] [CrossRef]

- Agrawal, P.; Dadheech, P.K.; Jat, R.; Bohra, M.; Nisar, K.S.; Khan, I. Lie similarity analysis of MHD flow past a stretching surface embedded in porous medium along with imposed heat source/sink and variable viscosity. J. Mater. Res. Technol. 2020, 9, 10045–10053. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nano Particles; Argonne National Laboratory: Lemont, IL, USA, 1995; Volume 66, pp. 99–105.

- Puneeth, V.; Manjunatha, S.; Gireesha, B.J.; Gorla, R.S.R. Magneto convective flow of Casson nanofluid due to Stefan blowing in the presence of bio-active mixers. Proc. Inst. Mech. Eng. Part N J. Nanomater. Nanoeng. Nanosyst. 2021, 48, 1137–1149. [Google Scholar] [CrossRef]

- Awais, M.; Kumam, P.; Parveen, N.; Ali, A.; Shah, Z.; Thounthong, P. Slip and Hall Effects on Peristaltic Rheology of Copper-Water Nanomaterial through Generalized Complaint Walls With Variable Viscosity. Front. Phys. 2020, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Mohammed, H.I.; Ashkezari, A.Z.; Shahsavar, A.; Hussein, A.K.; Rostami, S. An experimental investigation on the rheological behavior of nanofluids made by suspending multi-walled carbon nanotubes in liquid paraffin. J. Mol. Liq. 2020, 300, 112269. [Google Scholar] [CrossRef]

- Hu, Y.; He, Y.; Zhang, Z.; Wen, D. Enhanced heat capacity of binary nitrate eutectic salt-silica nanofluid for solar energy storage. Sol. Energy Mater. Sol. Cells 2019, 192, 94–102. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Muhammad, N.; Abohamzeh, E.; Hakeem, A.A.; Hajizadeh, M.R.; Li, Z.; Bach, Q.-V. Finned unit solidification with use of nanoparticles improved PCM. J. Mol. Liq. 2020, 314, 113659. [Google Scholar] [CrossRef]

- Bazdar, H.; Toghraie, D.; Pourfattah, F.; Akbari, O.A.; Nguyen, H.; Asadi, A. Numerical investigation of turbulent flow and heat transfer of nanofluid inside a wavy microchannel with different wavelengths. J. Therm. Anal. Calorim. 2020, 139, 2365–2380. [Google Scholar] [CrossRef]

- Tarakaramu, N.; Narayana, P.S.; Venkateswarlu, B. Numerical simulation of variable thermal conductivity on 3D flow of nanofluid over a stretching sheet. Nonlinear Eng. 2020, 9, 233–243. [Google Scholar] [CrossRef]

- Waini, I.; Ishak, A.; Pop, I. MHD flow and heat transfer of a hybrid nanofluid past a permeable stretching/shrinking wedge. Appl. Math. Mech. 2020, 41, 507–520. [Google Scholar] [CrossRef]

- Parveen, N.; Awais, M.; Mumraz, S.; Ali, A.; Malik, M.Y. An estimation of pressure rise and heat transfer rate for hybrid nanofluid with endoscopic effects and induced magnetic field: Computational intelligence application. Eur. Phys. J. Plus 2020, 135, 1–41. [Google Scholar] [CrossRef]

- Radhika, M.; Gowda, R.J.P.; Naveenkumar, R.; Siddabasappa; Prasannakumara, B.C. Heat transfer in dusty fluid with suspended hybrid nanoparticles over a melting surface. Heat Transfer 2021, 50, 2150–2167. [Google Scholar] [CrossRef]

- Reddy, M.G.; Rani, M.V.V.N.L.S.; Kumar, K.G.; Prasannakumar, B.C.; Lokesh, H.J. Hybrid dusty fluid flow through a Cattaneo–Christov heat flux model. Phys. A Stat. Mech. Its Appl. 2020, 551, 123975. [Google Scholar]

- Khan, A.M.; Jamil, M.; Mia, M.; He, N.; Zhao, W.; Gong, L. Sustainability-based performance evaluation of hybrid nanofluid assisted machining. J. Clean. Prod. 2020, 257, 120541. [Google Scholar] [CrossRef]

- LLund, A.; Omar, Z.; Khan, I.; Sherif, E.S.M. Dual solutions and stability analysis of a hybrid nanofluid over a stretching/shrinking sheet executing MHD flow. Symmetry 2020, 12, 276. [Google Scholar] [CrossRef] [Green Version]

- Qureshi, I.H.; Awais, M.; Awan, S.E.; Abrar, M.N.; Raja, M.A.Z.; Alharbi, S.O.; Khan, I. Influence of radially magnetic field properties in a peristaltic flow with internal heat generation: Numerical treatment. Case Stud. Therm. Eng. 2021, 26, 101019. [Google Scholar] [CrossRef]

- Ellahi, R.; Hussain, F.; Abbas, S.A.; Sarafraz, M.M.; Goodarzi, M.; Shadloo, M.S. Study of Two-Phase Newtonian Nanofluid Flow Hybrid with Hafnium Particles under the Effects of Slip. Inventions 2020, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- Venkateswarlu, B.; Narayana, P.V.S. Cu-Al2O3/H2O hybrid nanofluid flow past a porous stretching sheet due to temperatue-dependent viscosity and viscous dissipation. Heat Transf. 2021, 50, 432–449. [Google Scholar] [CrossRef]

- Dogonchi, A.; Tayebi, T.; Karimi, N.; Chamkha, A.J.; Alhumade, H. Thermal-natural convection and entropy production behavior of hybrid nanoliquid flow under the effects of magnetic field through a porous wavy cavity embodies three circular cylinders. J. Taiwan Inst. Chem. Eng. 2021, 124, 162–173. [Google Scholar] [CrossRef]

- Sahoo, A.; Nandkeolyar, R. Entropy generation and dissipative heat transfer analysis of mixed convective hydromagnetic flow of a Casson nanofluid with thermal radiation and Hall current. Sci. Rep. 2021, 11, 1–31. [Google Scholar] [CrossRef]

- Shoaib, M.; Raja, M.A.Z.; Khan, M.A.R.; Farhat, I.; Awan, S.E. Neuro-Computing Networks for Entropy Generation under the Influence of MHD and Thermal Radiation. Surf. Interfaces 2021, 25, 101243. [Google Scholar]

- Abrar, M.N.; Sagheer, M.; Hussain, S. Entropy analysis of Hall current and thermal radiation influenced by cilia with single- and multi-walled carbon nanotubes. Bull. Mater. Sci. 2019, 42, 250. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Muhammad, R.; Khan, M.I.; Khan, W.A.; Abbas, S.Z. Entropy optimized MHD nanomaterial flow subject to variable thicked surface. Comput. Methods Programs Biomed. 2020, 189, 105311. [Google Scholar] [CrossRef] [PubMed]

- Dehghan, M.; Shirilord, A. The use of homotopy analysis method for solving generalized Sylvester matrix equation with applications. Eng. Comput. 2021, 1–18. [Google Scholar] [CrossRef]

- Odibat, Z. An improved optimal homotopy analysis algorithm for nonlinear differential equations. J. Math. Anal. Appl. 2020, 488, 124089. [Google Scholar] [CrossRef]

- Naik, P.A.; Zu, J.; Ghoreishi, M. Estimating the approximate analytical solution of HIV viral dynamic model by using homotopy analysis method. Chaos Solitons Fractals 2020, 131, 109500. [Google Scholar] [CrossRef]

- Iqbal, Z.; Azhar, E.; Maraj, E.N. Utilization of the computational technique to improve the thermophysical performance in the transportation of an electrically conducting Al2O3-Ag/H2O hybrid nanofluid. Eur. Phys. J. Plus 2017, 132, 544. [Google Scholar] [CrossRef]

| Properties\Constituents | H2O | Al2O3 | Cu |

| Density, ρ (Kg/m3) | 997 | 3970 | 8933 |

| Specific heat, Cp (J/kg K) | 4179 | 765 | 385 |

| Thermal conductivity, κ (W/m K) | 0.613 | 40 | 401 |

| Properties | Nanofluid | Hybrid Nanofluid |

| Density | ||

| Heat Capacity | ||

| Viscosity | ||

| Thermal Conductivity |

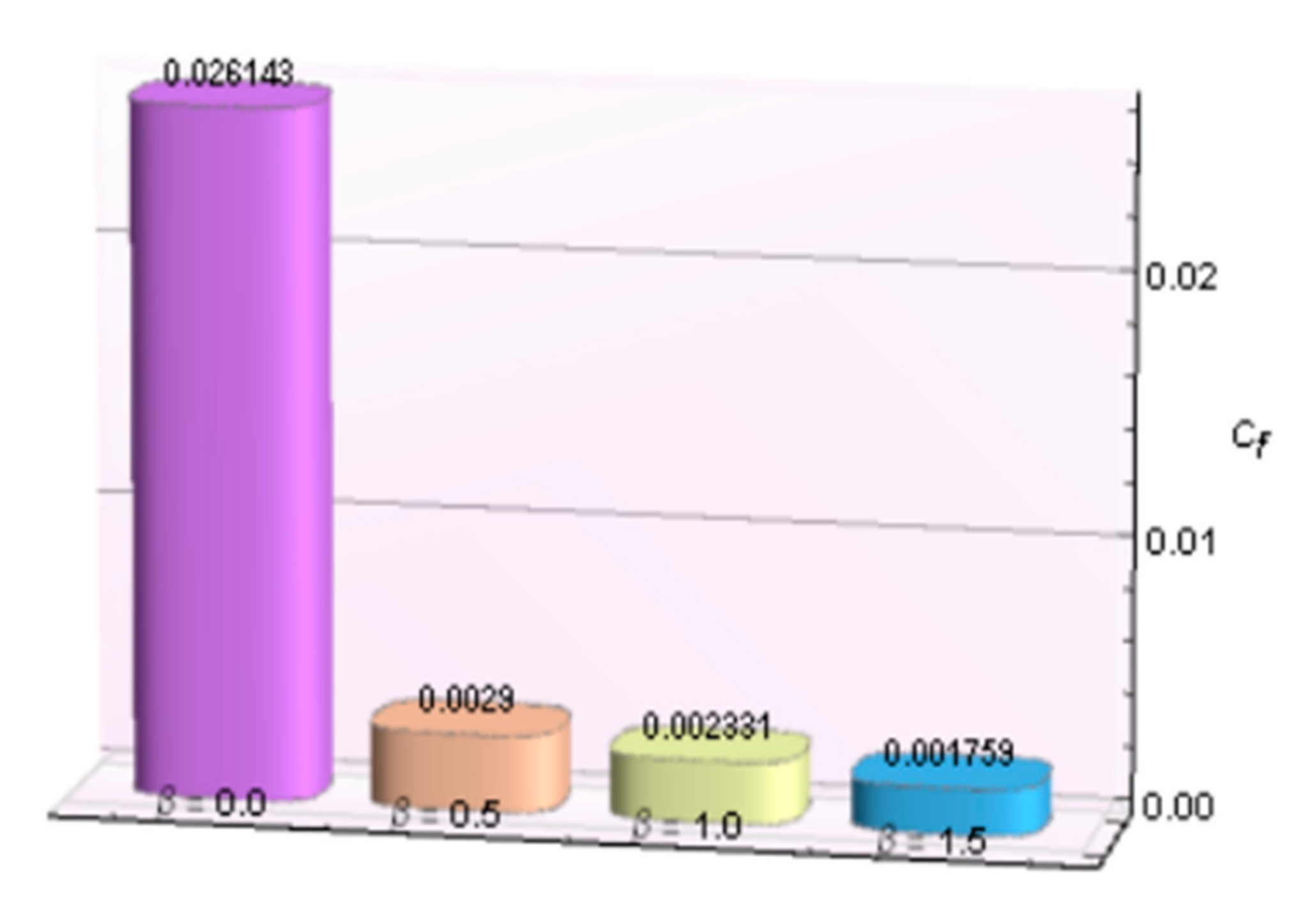

| β | λ | −Cf |

|---|---|---|

| 0.0 | 5.0 | 0.003467 |

| 0.5 | 0.002900 | |

| 1.0 | 0.002331 | |

| 1.5 | 0.001759 | |

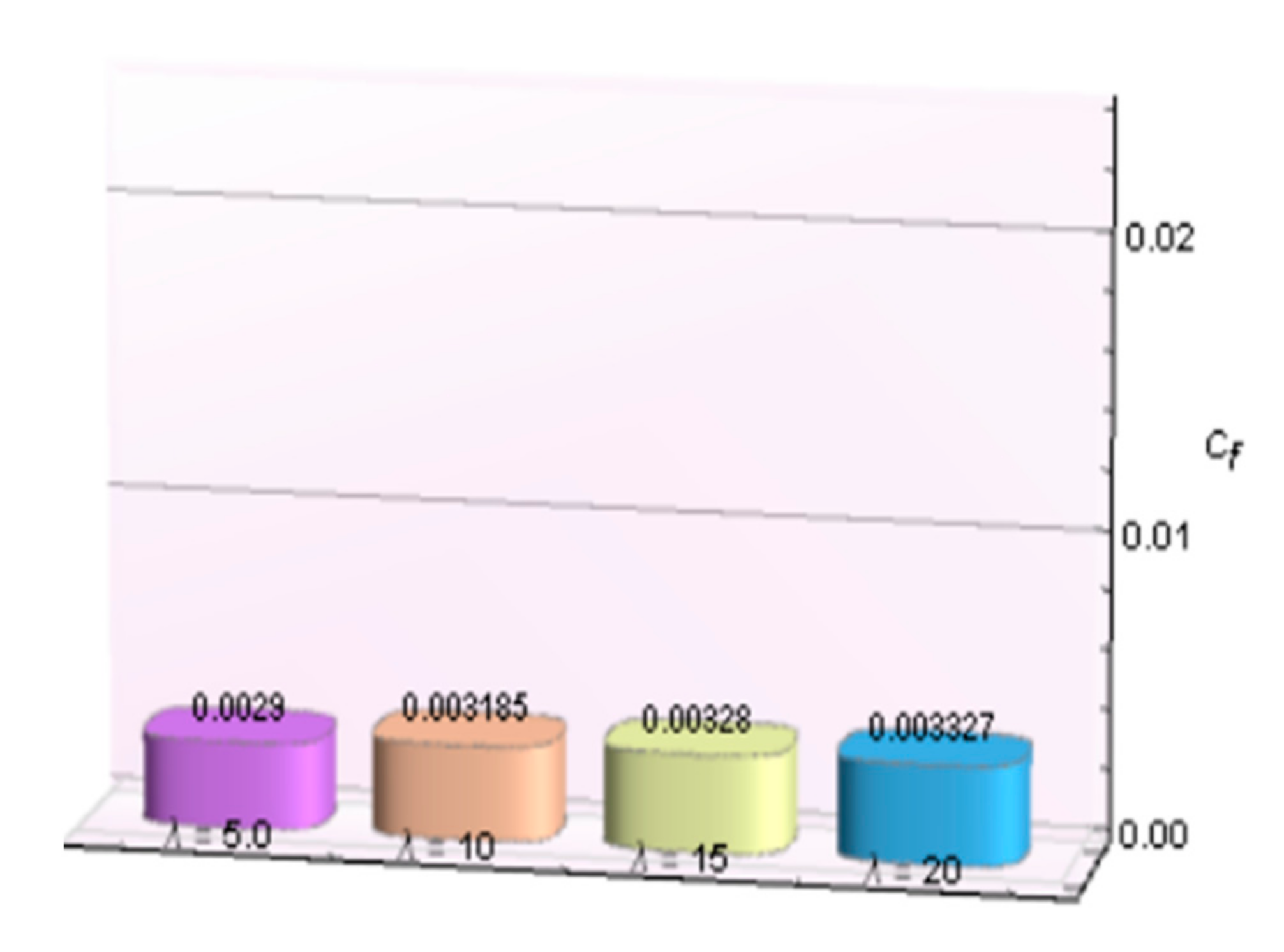

| 0.5 | 5.0 | 0.002900 |

| 10 | 0.003185 | |

| 15 | 0.003280 | |

| 20 | 0.003327 |

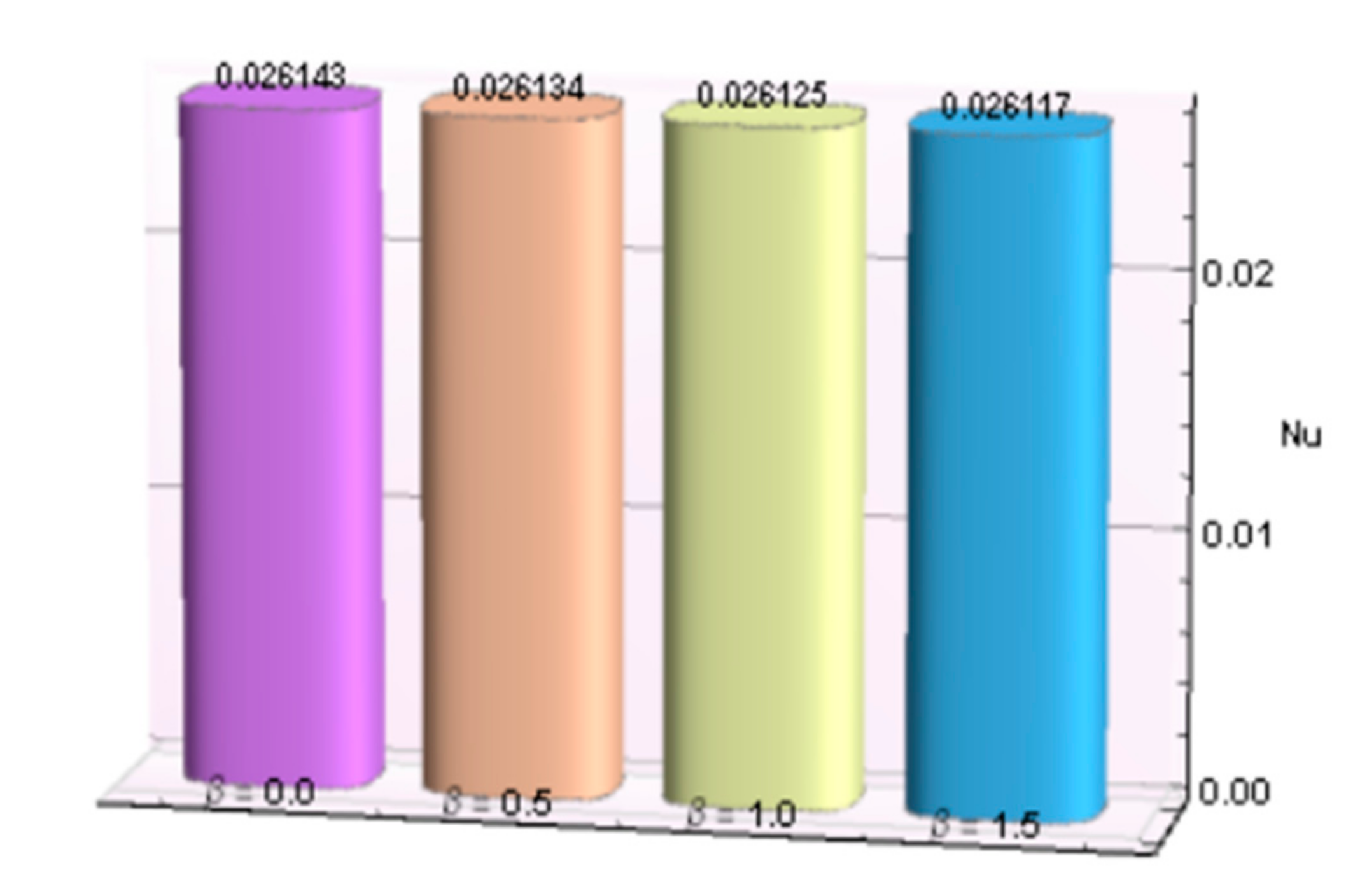

| β | λ | Bi | R | Ec | −Nu |

|---|---|---|---|---|---|

| 0.0 | 5.0 | 1.5 | 2.5 | 0.2 | 0.026143 |

| 0.5 | 0.026134 | ||||

| 1.0 | 0.026125 | ||||

| 1.5 | 0.026117 | ||||

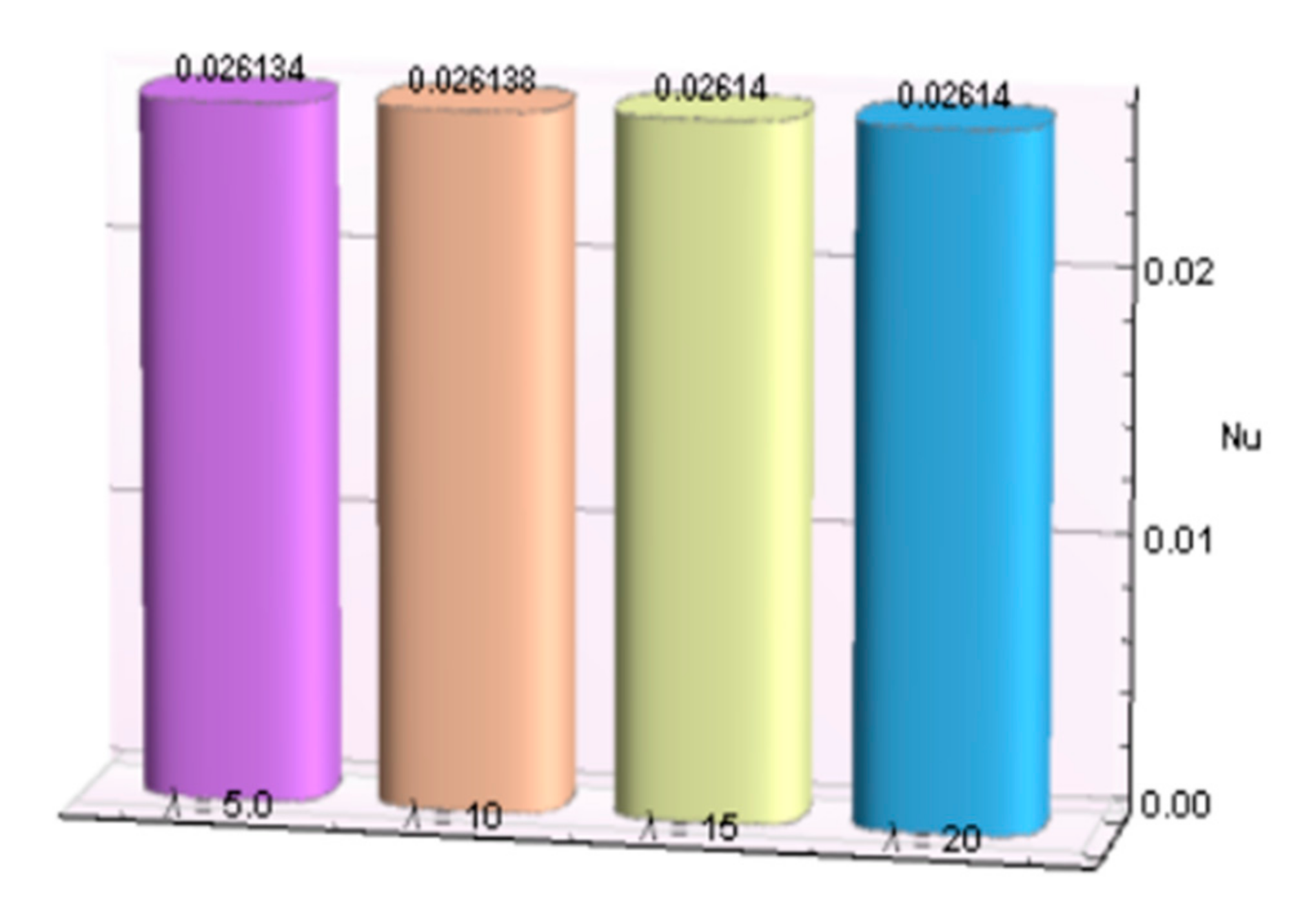

| 0.5 | 5.0 | 0.026134 | |||

| 10 | 0.026138 | ||||

| 15 | 0.026140 | ||||

| 20 | 0.026140 | ||||

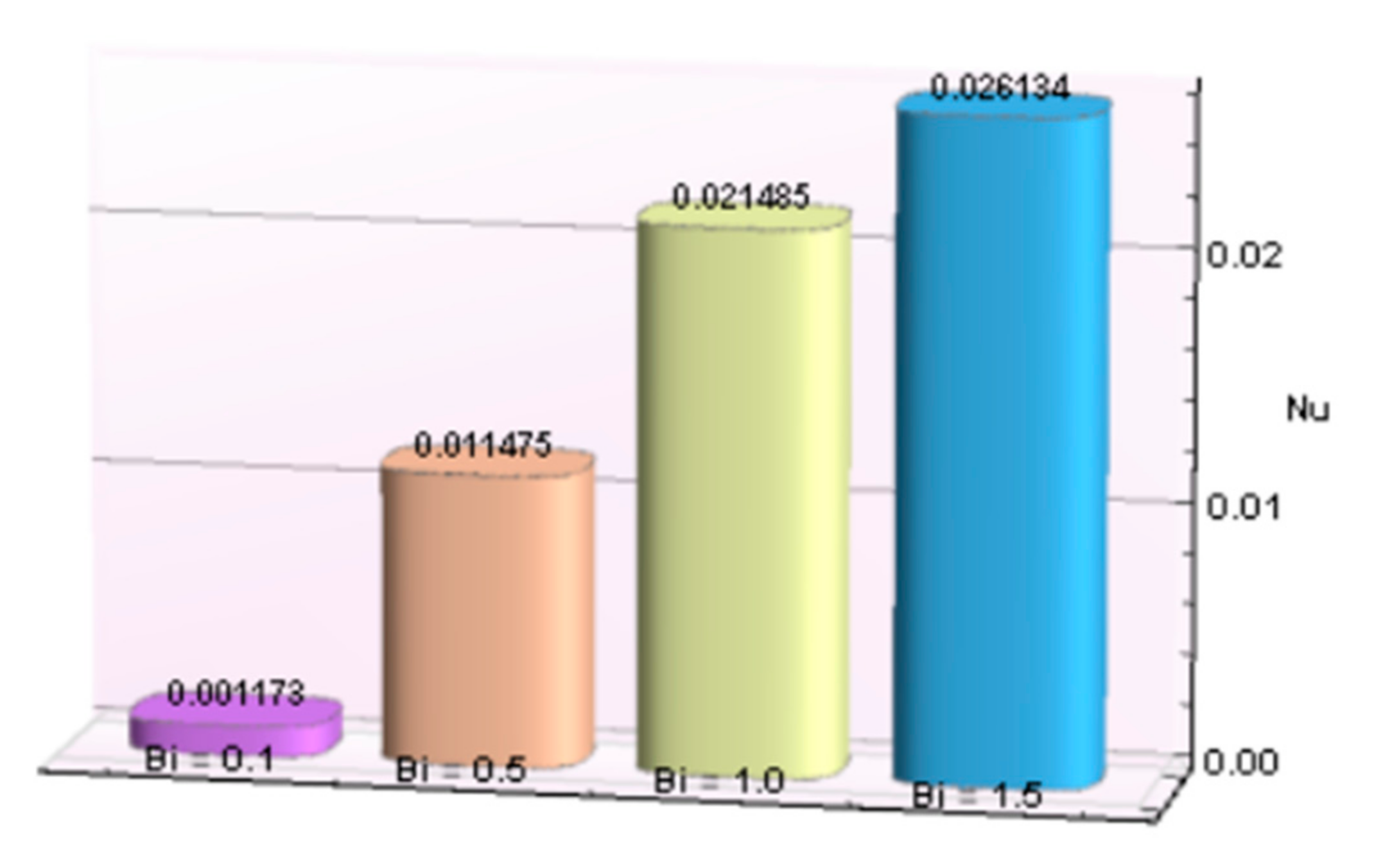

| 5.0 | 0.1 | 0.001173 | |||

| 0.5 | 0.011475 | ||||

| 1.0 | 0.021485 | ||||

| 1.5 | 0.026134 | ||||

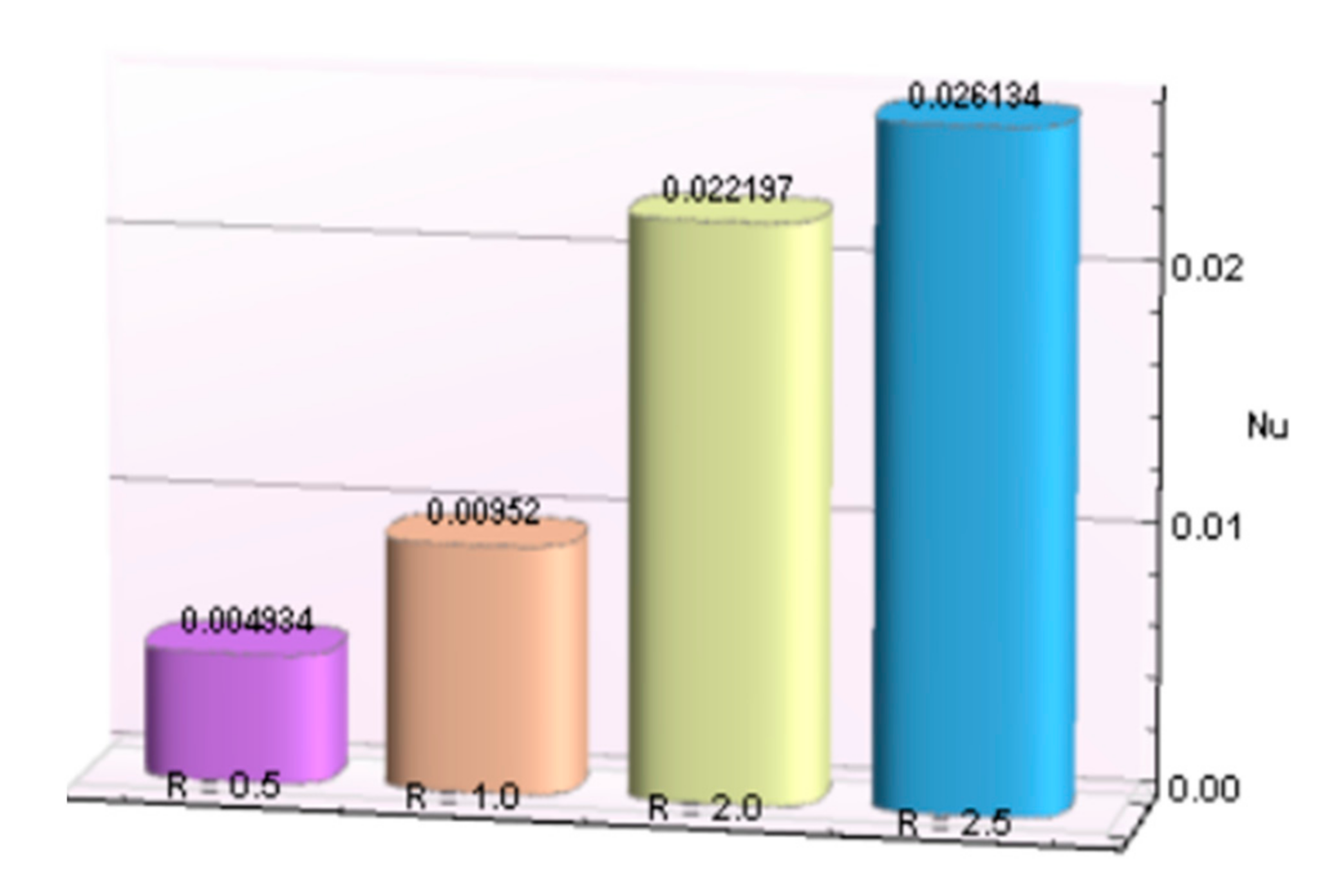

| 1.5 | 0.5 | 0.004934 | |||

| 1.0 | 0.00952 | ||||

| 2.0 | 0.022197 | ||||

| 2.5 | 0.026134 | ||||

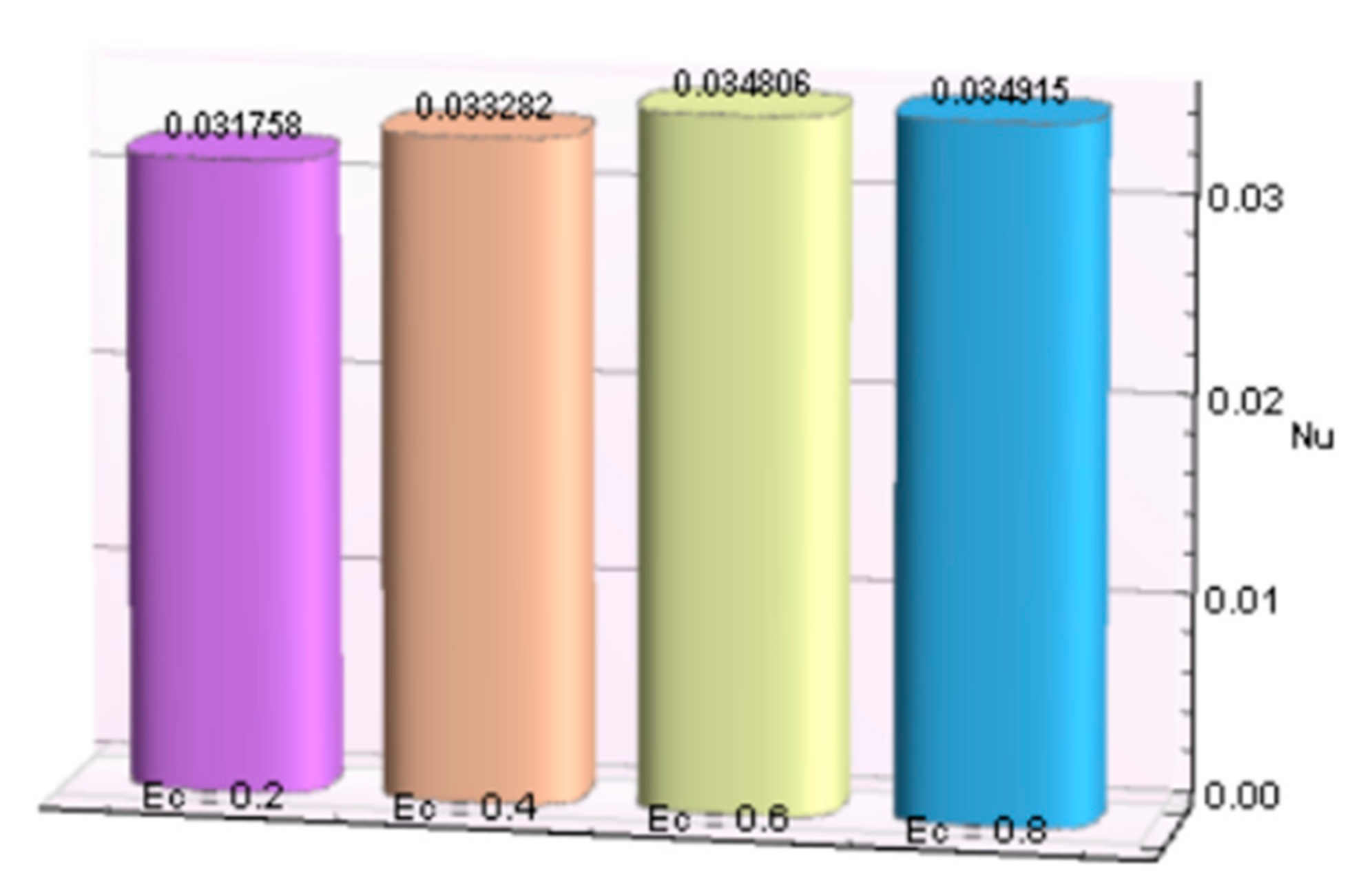

| 2.5 | 0.2 | 0.031758 | |||

| 0.4 | 0.033282 | ||||

| 0.6 | 0.034806 | ||||

| 0.8 | 0.034915 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parveen, N.; Awais, M.; Awan, S.E.; Khan, W.U.; He, Y.; Malik, M.Y. Entropy Generation Analysis and Radiated Heat Transfer in MHD (Al2O3-Cu/Water) Hybrid Nanofluid Flow. Micromachines 2021, 12, 887. https://doi.org/10.3390/mi12080887

Parveen N, Awais M, Awan SE, Khan WU, He Y, Malik MY. Entropy Generation Analysis and Radiated Heat Transfer in MHD (Al2O3-Cu/Water) Hybrid Nanofluid Flow. Micromachines. 2021; 12(8):887. https://doi.org/10.3390/mi12080887

Chicago/Turabian StyleParveen, Nabeela, Muhammad Awais, Saeed Ehsan Awan, Wasim Ullah Khan, Yigang He, and Muhammad Yousaf Malik. 2021. "Entropy Generation Analysis and Radiated Heat Transfer in MHD (Al2O3-Cu/Water) Hybrid Nanofluid Flow" Micromachines 12, no. 8: 887. https://doi.org/10.3390/mi12080887

APA StyleParveen, N., Awais, M., Awan, S. E., Khan, W. U., He, Y., & Malik, M. Y. (2021). Entropy Generation Analysis and Radiated Heat Transfer in MHD (Al2O3-Cu/Water) Hybrid Nanofluid Flow. Micromachines, 12(8), 887. https://doi.org/10.3390/mi12080887