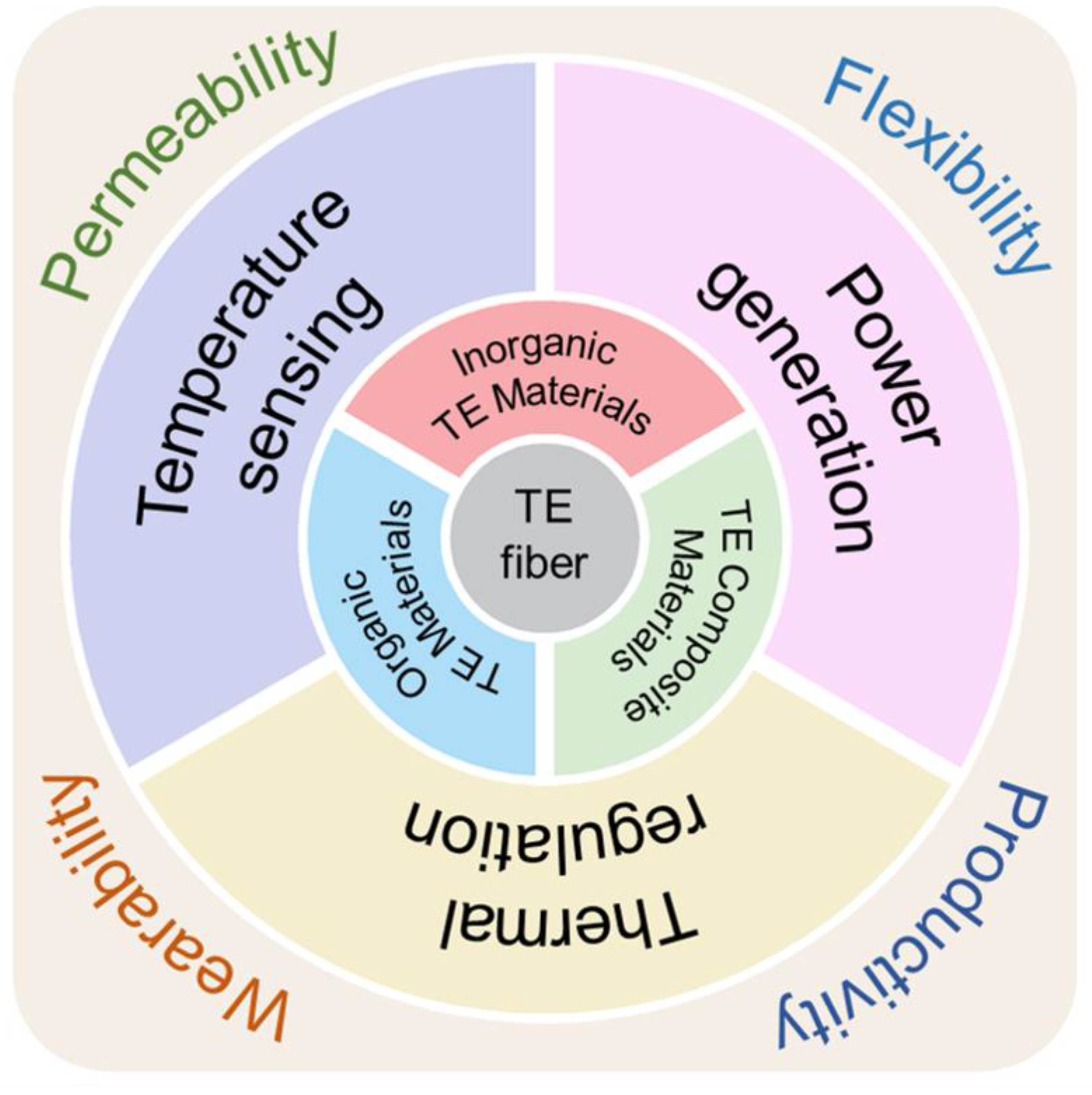

Fiber-Based Thermoelectric Materials and Devices for Wearable Electronics

Abstract

:1. Introduction

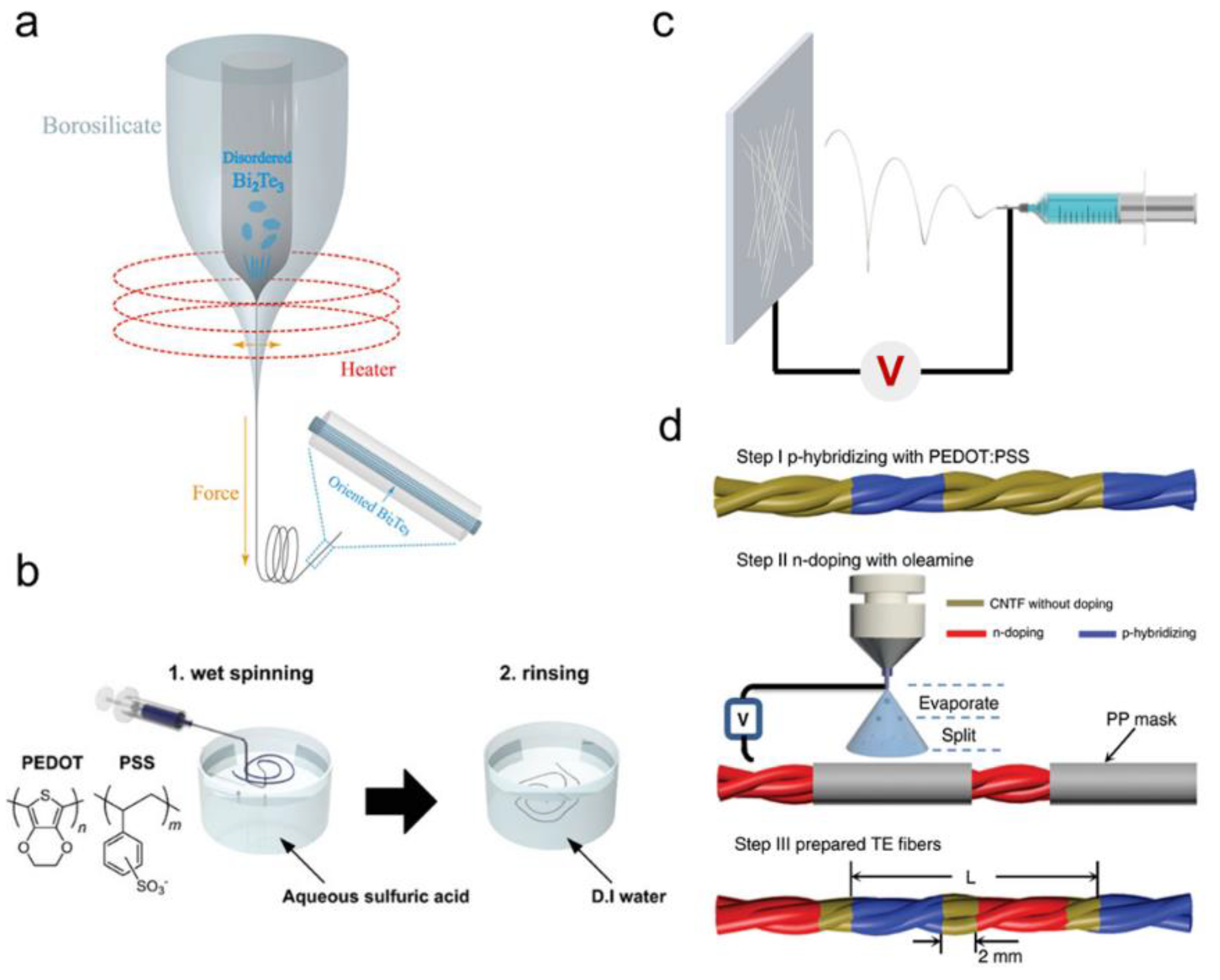

2. Fabrication Methods for TE Fiber

2.1. Thermal Co-Drawing

2.2. Electrospinning

2.3. Wet Spinning

2.4. Coating

3. Thermoelectric Fiber Materials

3.1. Inorganic TE Fibers

3.2. Organic TE Fibers

3.3. TE Composite Fibers

4. Fiber-Based Thermoelectric Devices and Applications

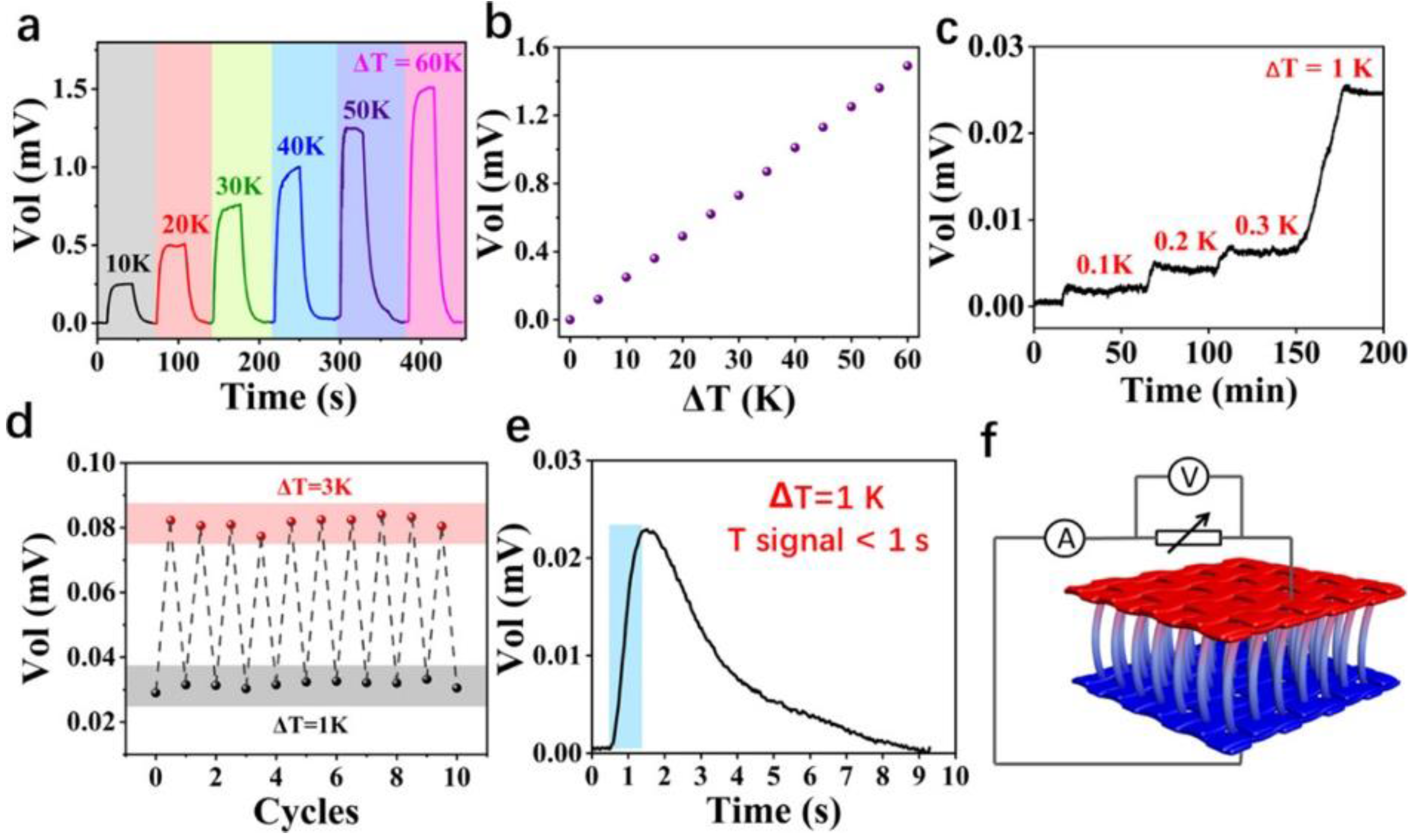

4.1. Temperature Sensing

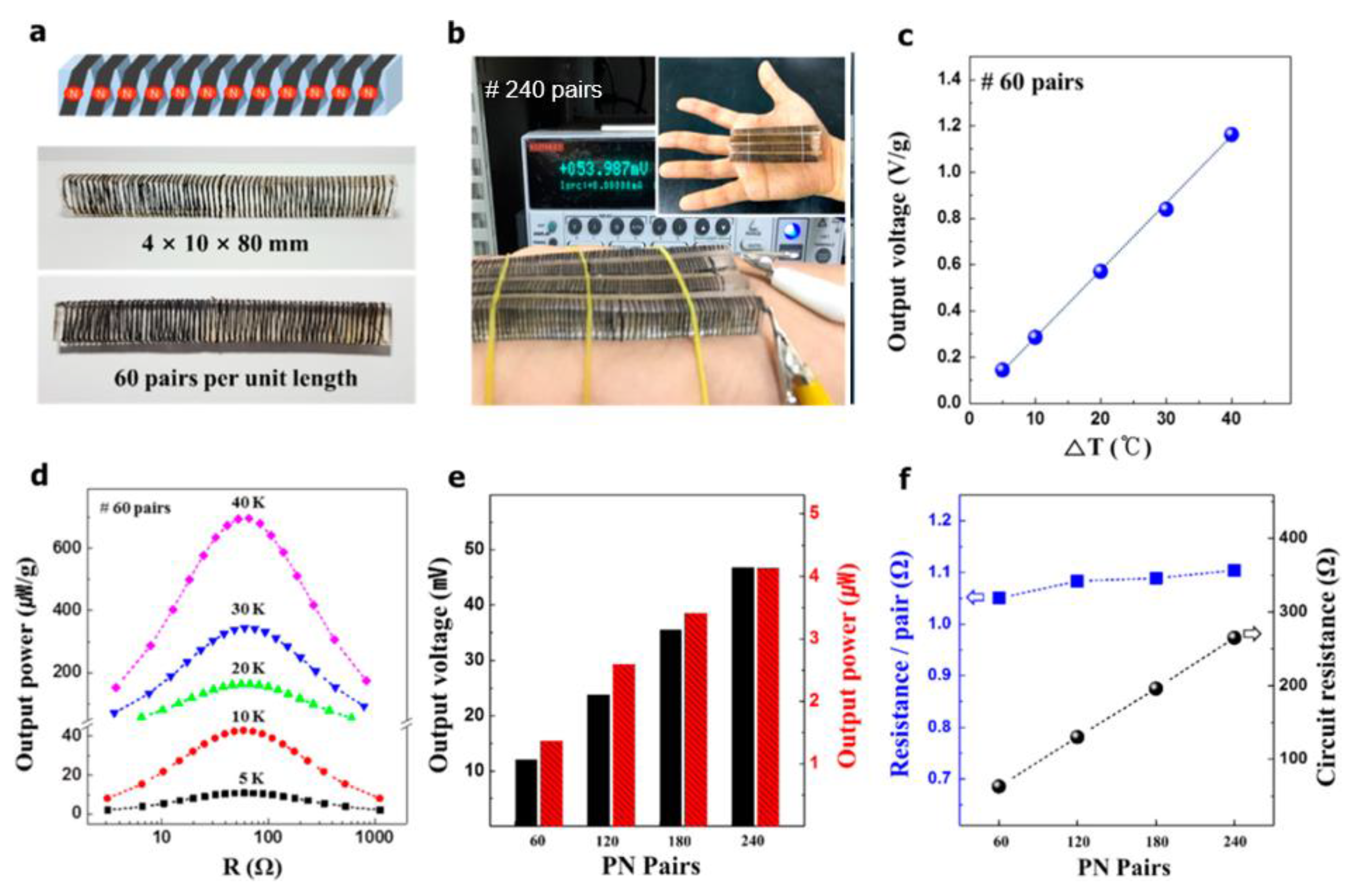

4.2. Power Generation

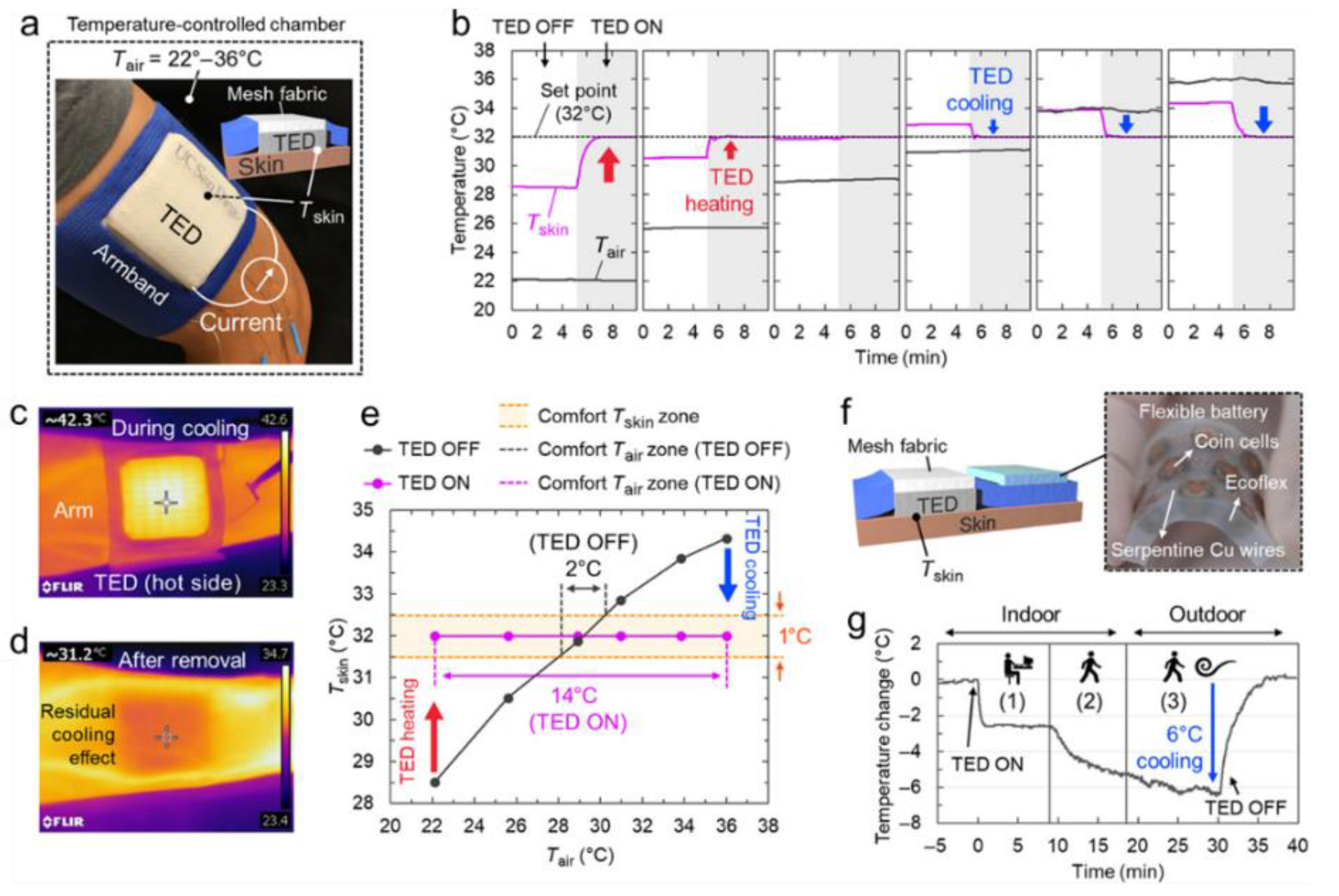

4.3. Thermal Regulation

5. Conclusions and Outlook

Funding

Acknowledgments

Conflicts of Interest

References

- Hu, H.W.; Shen, T.L.; Lin, T.Y.; Chen, Y.F. Interactive color-changing electronic skin based on flexible and piezoelectrically tunable quantum dots light-emitting diodes. Adv. Opt. Mater. 2020, 8, 1901715. [Google Scholar] [CrossRef]

- Wang, Z.W.; Cong, Y.; Fu, J. Stretchable and tough conductive hydrogels for flexible pressure and strain sensors. J. Mater. Chem. B 2020, 8, 3437–3459. [Google Scholar] [CrossRef]

- Xiong, Y.X.; Shen, Y.K.; Tian, L.; Hu, Y.G.; Zhu, P.L.; Sun, R.; Wong, C.P. A flexible, ultra-highly sensitive and stable capacitive pressure sensor with convex microarrays for motion and health monitoring. Nano Energy 2020, 70, 104436. [Google Scholar] [CrossRef]

- Zhu, M.M.; Lou, M.N.; Abdalla, I.; Yu, J.Y.; Li, Z.L.; Ding, B. Highly shape adaptive fiber based electronic skin for sensitive joint motion monitoring and tactile sensing. Nano Energy 2020, 69, 104429. [Google Scholar] [CrossRef]

- Wan, Y.B.; Wang, Y.; Guo, C.F. Recent progresses on flexible tactile sensors. Mater. Today Phys. 2017, 1, 61–73. [Google Scholar] [CrossRef]

- Park, S.; Heo, S.W.; Lee, W.; Inoue, D.; Jiang, Z.; Yu, K.; Jinno, H.; Hashizume, D.; Sekino, M.; Yokota, T.; et al. Self-powered ultra-flexible electronics via nano-grating-patterned organic photovoltaics. Nature 2018, 561, 516–521. [Google Scholar] [CrossRef] [PubMed]

- Suarez, F.; Parekh, D.P.; Ladd, C.; Vashaee, D.; Dickey, M.D.; Ozturk, M.C. Flexible thermoelectric generator using bulk legs and liquid metal interconnects for wearable electronics. Appl. Energy 2017, 202, 736–745. [Google Scholar] [CrossRef]

- Yu, Y.; Nassar, J.; Xu, C.H.; Min, J.H.; Yang, Y.R.; Dai, A.; Doshi, R.; Huang, A.; Song, Y.; Gehlhar, R.; et al. Biofuel-powered soft electronic skin with multiplexed and wireless sensing for human-machine interfaces. Sci. Robot. 2020, 5, eaaz7946. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, D.Z.; Xu, Z.Y.; Yang, Z.M.; Song, X.S. High-performance flexible self-powered tin disulfide nanoflowers/reduced graphene oxide nanohybrid-based humidity sensor driven by triboelectric nanogenerator. Nano Energy 2020, 67, 104251. [Google Scholar] [CrossRef]

- Huang, L.; Lin, S.Z.; Xu, Z.S.; Zhou, H.; Duan, J.J.; Hu, B.; Zhou, J. Fiber-based energy conversion devices for human-body energy harvesting. Adv. Mater. 2020, 32, 1902034. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, L.D. Thermoelectric materials: Energy conversion between heat and electricity. J. Mater. 2015, 1, 92–105. [Google Scholar] [CrossRef] [Green Version]

- Wan, C.L.; Gu, X.K.; Dang, F.; Itoh, T.; Wang, Y.F.; Sasaki, H.; Kondo, M.; Koga, K.; Yabuki, K.; Snyder, G.J.; et al. Flexible n-type thermoelectric materials by organic intercalation of layered transition metal dichalcogenide TiS2. Nat. Mater. 2015, 14, 622–627. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Zhao, L.D. Seeking new, highly effective thermoelectrics. Science 2020, 367, 1196–1197. [Google Scholar] [CrossRef] [PubMed]

- Shuai, J.; Mao, J.; Song, S.W.; Zhang, Q.Y.; Chen, G.; Ren, Z.F. Recent progress and future challenges on thermoelectric Zintl materials. Mater. Today Phys. 2017, 1, 74–95. [Google Scholar] [CrossRef]

- Acharyya, P.; Roychowdhury, S.; Samanta, M.; Biswas, K. Ultralow thermal conductivity, enhanced mechanical stability, and high thermoelectric performance in (GeTe)1–2x(SnSe)x(SnS)x. J. Am. Chem. Soc. 2020, 142, 20502–20508. [Google Scholar] [CrossRef]

- Shi, X.L.; Zou, J.; Chen, Z.G. Advanced thermoelectric design: From materials and structures to devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef]

- Lu, Z.S.; Zhang, H.H.; Mao, C.P.; Li, C.M. Silk fabric-based wearable thermoelectric generator for energy harvesting from the human body. Appl. Energy 2016, 164, 57–63. [Google Scholar] [CrossRef]

- Varghese, T.; Hollar, C.; Richardson, J.; Kempf, N.; Han, C.; Gamarachchi, P.; Estrada, D.; Mehta, R.J.; Zhang, Y.L. High-performance and flexible thermoelectric films by screen printing solution-processed nanoplate crystals. Sci. Rep. 2016, 6, 33135. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Qiu, Y.; Cai, K.F.; Ding, Y.F.; Wang, M.D.; Jiang, C.; Yao, Q.; Huang, C.J.; Chen, L.D.; He, J.Q. Ultrahigh power factor and flexible silver selenide-based composite film for thermoelectric devices. Energy Environ. Sci. 2020, 13, 1240–1249. [Google Scholar] [CrossRef]

- Sargolzaeiaval, Y.; Ramesh, V.P.; Neumann, T.V.; Misra, V.; Vashaee, D.; Dickey, M.D.; Ozturk, M.C. Flexible thermoelectric generators for body heat harvesting—Enhanced device performance using high thermal conductivity elastomer encapsulation on liquid metal interconnects. Appl. Energy 2020, 262, 114370. [Google Scholar] [CrossRef]

- Dargusch, M.; Liu, W.D.; Chen, Z.G. Thermoelectric generators: Alternative power supply for wearable electrocardiographic systems. Adv. Sci. 2020, 7, 2001362. [Google Scholar] [CrossRef] [PubMed]

- Trung, N.H.; Toan, N.V.; Ono, T. Fabrication of pi-type flexible thermoelectric generators using an electrochemical deposition method for thermal energy harvesting applications at room temperature. J. Micromech. Microeng. 2017, 27, 125006. [Google Scholar] [CrossRef]

- Ferhat, S.; Domains, C.; Vidal, J.; Noel, D.; Ratier, B.; Lucas, B. Flexible thermoelectric device based on TiS2(HA)(x) n-type nanocomposite printed on paper. Org. Electron. 2019, 68, 256–263. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhu, K.; Li, J.; Li, Q.; Deng, B.; Zhang, P.X.; Wang, Q.; Guo, C.F.; Wang, W.C.; Liu, W.S. Leaf-inspired flexible thermoelectric generators with high temperature difference utilization ratio and output power in ambient air. Adv. Sci. 2021, 8, 2004947. [Google Scholar] [CrossRef]

- Liu, W.D.; Yu, Y.; Dargusch, M.; Liu, Q.F.; Chen, Z.G. Carbon allotrope hybrids advance thermoelectric development and applications. Renew. Sustain. Energy Rev. 2021, 141, 110800. [Google Scholar] [CrossRef]

- Liu, W.D.; Yang, L.; Chen, Z.G. Cu2Se thermoelectrics: Property, methodology, and device. Nano Today 2020, 35, 100938. [Google Scholar] [CrossRef]

- Wu, R.; Ma, L.; Liu, S.; Patil, A.B.; Hou, C.; Zhang, Y.; Zhang, W.; Yu, R.; Yu, W.; Guo, W.; et al. Fibrous inductance strain sensors for passive inductance textile sensing. Mater. Today Phys. 2020, 15, 100243. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, Q.; Chang, J.; Chen, L.D. Enhanced thermoelectric properties of CNT/PANI composite nanofibers by highly orienting the arrangement of polymer chains. J. Mater. Chem. 2012, 22, 17612–17618. [Google Scholar] [CrossRef]

- Lee, J.A.; Aliev, A.E.; Bykova, J.S.; de Andrade, M.J.; Kim, D.; Sim, H.J.; Lepro, X.; Zakhidov, A.A.; Lee, J.B.; Spinks, G.M.; et al. Woven-yarn thermoelectric textiles. Adv. Mater. 2016, 28, 5038–5044. [Google Scholar] [CrossRef] [Green Version]

- Li, M.F.; Chen, J.X.; Zhong, W.B.; Luo, M.Y.; Wang, W.; Qing, X.; Lu, Y.; Liu, Q.Z.; Liu, K.; Wang, Y.D.; et al. Large-area, wearable, self-powered pressure-temperature sensor based on 3D thermoelectric spacer fabric. ACS Sens. 2020, 5, 2545–2554. [Google Scholar] [CrossRef]

- Lund, A.; Tian, Y.; Darabi, S.; Muller, C. A polymer-based textile thermoelectric generator for wearable energy harvesting. J. Power Sources 2020, 480, 228836. [Google Scholar] [CrossRef]

- Chen, W.Y.; Shi, X.L.; Zou, J.; Chen, Z.G. Wearable fiber-based thermoelectrics from materials to applications. Nano Energy 2021, 81, 105684. [Google Scholar] [CrossRef]

- Wang, L.M.; Zhang, K. Textile-based thermoelectric generators and their applications. Energy Environ. Mater. 2020, 3, 67–79. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.S.; Lin, S.P.; Hua, T.; Huang, B.L.; Liu, S.R.; Tao, X.M. Fiber-based thermoelectric generators: Materials, device structures, fabrication, characterization, and applications. Adv. Energy Mater. 2018, 8, 1700524. [Google Scholar] [CrossRef]

- Cherenack, K.; Zysset, C.; Kinkeldei, T.; Munzenrieder, N.; Troster, G. Woven electronic fibers with sensing and display functions for smart textiles. Adv. Mater. 2010, 22, 5178–5182. [Google Scholar] [CrossRef]

- Daoud, W.A.; Xin, J.H.; Szeto, Y.S. Polyethylenedioxythiophene coatings for humidity, temperature and strain sensing polyamide fibers. Sens. Actuators B Chem. 2005, 109, 329–333. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, Y.; Zhang, J.; Sun, X.M.; Peng, H.S. Energy harvesting and storage in 1D devices. Nat. Rev. Mater. 2017, 2, 1–12. [Google Scholar] [CrossRef]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.M. Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Hu, Y.; Wang, H.; Cheng, Y.; Thomas, T.; Ma, R.; Wang, J. Activating inverse spinel NiCo2O4 embedded in N-doped carbon nanofibers via Fe substitution for bifunctional oxygen electrocatalysis. Mater. Today Phys. 2021, 17, 100353. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Q.; Deng, Z.; Gong, M.; Lei, F.; Zhang, J.; Zhang, X.; Wang, Q.; Liu, Y.; Wu, Z.; et al. Ionic liquid-activated wearable electronics. Mater. Today Phys. 2019, 8, 78–85. [Google Scholar] [CrossRef]

- Sun, M.; Qian, Q.; Tang, G.W.; Liu, W.W.; Qian, G.Q.; Shi, Z.G.; Huang, K.M.; Chen, D.D.; Xu, S.H.; Yang, Z.M. Enhanced thermoelectric properties of polycrystalline Bi2Te3 core fibers with preferentially oriented nanosheets. Appl. Mater. 2018, 6, 036103. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Lund, A.; Noh, H.; Hofmann, A.I.; Craighero, M.; Darabi, S.; Zokaei, S.; Park, J.I.; Yoon, M.H.; Muller, C. Robust PEDOT:PSS wet-spun fibers for thermoelectric textiles. Macromol. Mater. Eng. 2020, 305, 1900749. [Google Scholar] [CrossRef]

- Sun, T.T.; Zhou, B.Y.; Zheng, Q.; Wang, L.J.; Jiang, W.; Snyder, G.J. Stretchable fabric generates electric power from woven thermoelectric fibers. Nat. Commun. 2020, 11, 572. [Google Scholar] [CrossRef]

- Sun, M.; Tang, G.W.; Qian, G.Q.; Liu, W.W.; Shi, Z.G.; Chen, D.D.; Qian, Q.; Yang, Z.M. In4Se3 alloy core thermoelectric fibers. Mater. Lett. 2018, 217, 13–15. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, M.; Tan, G.W.; Qian, G.Q.; Liu, W.W.; Shi, Z.G.; Zhu, W.M.; Qian, Q.; Xu, S.H.; Yang, Z.M. Multifunctional GeSe core fibers. Mater. Lett. 2019, 247, 193–196. [Google Scholar] [CrossRef]

- Sun, M.; Tang, G.W.; Liu, W.W.; Qian, G.Q.; Huang, K.M.; Chen, D.D.; Qian, Q.; Yang, Z.M. Sn-Se alloy core fibers. J. Alloys Compd. 2017, 725, 242–247. [Google Scholar] [CrossRef]

- Qian, G.Q.; Sun, M.; Tang, G.W.; Liu, W.W.; Shi, Z.G.; Qian, Q.; Zhang, Q.Y.; Yang, Z.M. High-performance and high-stability bismuth selenide core thermoelectric fibers. Mater. Lett. 2018, 233, 63–66. [Google Scholar] [CrossRef]

- Carey, G.H.; Abdelhady, A.L.; Ning, Z.J.; Thon, S.M.; Bakr, O.M.; Sargent, E.H. Colloidal quantum dot solar cells. Chem. Rev. 2015, 115, 12732–12763. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, T.; Zhang, H.; Wang, Z.X.; Li, C.; Wang, Z.; Li, K.W.; Huang, X.M.; Chen, M.; Chen, Z.; et al. Single-crystal SnSe thermoelectric fibers via laser-induced directional crystallization: From 1D fibers to multidimensional fabrics. Adv. Mater. 2020, 32, 2002702. [Google Scholar] [CrossRef]

- Maensiri, S.; Nuansing, W. Thermoelectric oxide NaCo2O4 nanofibers fabricated by electrospinning. Mater. Chem. Phys. 2006, 99, 104–108. [Google Scholar] [CrossRef]

- Lee, D.; Cho, K.; Choi, J.; Kim, S. Effect of mesoscale grains on thermoelectric characteristics of aligned ZnO/INP composite nanofibers. Mater. Lett. 2015, 142, 250–252. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, W.; Kang, Y.H.; Cho, S.Y.; Jang, K.S. Wet-spinning and post-treatment of CNT/PEDOT:PSS composites for use in organic fiber-based thermoelectric generators. Carbon 2018, 133, 293–299. [Google Scholar] [CrossRef]

- Kim, J.Y.; Mo, J.H.; Kang, Y.H.; Cho, S.Y.; Jang, K.S. Thermoelectric fibers from well-dispersed carbon nanotube/poly(vinyliedene fluoride) pastes for fiber-based thermoelectric generators. Nanoscale 2018, 10, 19766–19773. [Google Scholar] [CrossRef]

- Allison, L.; Hoxie, S.; Andrew, T.L. Towards seamlessly-integrated textile electronics: Methods to coat fabrics and fibers with conducting polymers for electronic applications. Chem. Commun. 2017, 53, 7182–7193. [Google Scholar] [CrossRef]

- Lan, X.Q.; Wang, T.Z.; Liu, C.C.; Liu, P.P.; Xu, J.K.; Liu, X.F.; Du, Y.K.; Jiang, F.X. A high performance all-organic thermoelectric fiber generator towards promising wearable electron. Compos. Sci. Technol. 2019, 182, 107767. [Google Scholar] [CrossRef]

- Kim, G.H.; Shao, L.; Zhang, K.J.; Pipe, K.P. Engineered doping of organic semiconductors for enhanced thermoelectric efficiency. Nat. Mater. 2013, 12, 719–723. [Google Scholar] [CrossRef]

- Liu, J.; Jia, Y.H.; Jiang, Q.L.; Jiang, F.X.; Li, C.C.; Wang, X.D.; Liu, P.; Liu, P.P.; Hu, F.; Du, Y.K.; et al. Highly conductive hydrogel polymer fibers toward promising wearable thermoelectric energy harvesting. ACS Appl. Mater. Interfaces 2018, 10, 44033–44040. [Google Scholar] [CrossRef]

- Hiura, S.; Okada, N.; Wakui, J.; Narita, H.; Kanehashi, S.; Shimomura, T. Thermoelectric properties of poly (3-hexylthiophene) nanofiber mat with a large void fraction. Materials 2017, 10, 468. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jia, Y.H.; Li, X.J.; Jiang, F.X.; Li, C.C.; Wang, T.Z.; Jiang, Q.L.; Hou, J.; Xu, J.K. Effects of additives and post-treatment on the thermoelectric performance of vapor-phase polymerized PEDOT films. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1738–1744. [Google Scholar] [CrossRef]

- Wang, D.G.; Su, Y.Y.; Chen, D.Z.; Wang, L.; Xiang, X.Z.; Zhu, D.L. Preparation and characterization of poly (3-octylthiophene)/carbon fiber thermoelectric composite materials. Compos. Part B Eng. 2015, 69, 467–471. [Google Scholar] [CrossRef]

- Bae, E.J.; Kang, Y.H.; Jang, K.S.; Cho, S.Y. Enhancement of thermoelectric properties of PEDOT: PSS and tellurium-PEDOT: PSS hybrid composites by simple chemical treatment. Sci. Rep. 2016, 6, 18805. [Google Scholar]

- Zheng, Y.Y.; Zhang, Q.H.; Jin, W.L.; Jing, Y.Y.; Chen, X.Y.; Han, X.; Bao, Q.Y.; Liu, Y.P.; Wang, X.H.; Wang, S.R.; et al. Carbon nanotube yarn based thermoelectric textiles for harvesting thermal energy and powering electronics. J. Mater. Chem. A 2020, 8, 2984–2994. [Google Scholar] [CrossRef]

- Jin, Q.; Shi, W.B.; Zhao, Y.; Qiao, J.X.; Qiu, J.H.; Sun, C.; Lei, H.; Tai, K.P.; Jiang, X. Cellulose fiber-based hierarchical porous bismuth telluride for high-performance flexible and tailorable thermoelectrics. ACS Appl. Mater. Interfaces 2018, 10, 1743–1751. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Dresselhaus, M.S.; Dresselhaus, G.; Fleurial, J.P.; Caillat, T. Recent developments in thermoelectric materials. Int. Mater. Rev. 2003, 48, 45–66. [Google Scholar] [CrossRef]

- Tan, G.J.; Zhao, L.D.; Kanatzidis, M.G. Rationally designing high-performance bulk thermoelectric materials. Chem. Rev. 2016, 116, 12123–12149. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Tritt, T.M. Advances in thermoelectric materials research: Looking back and moving forward. Science 2017, 357, 1369. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.S.; Hu, J.Z.; Zhang, S.M.; Deng, M.J.; Han, C.G.; Liu, Y. New trends, strategies and opportunities in thermoelectric materials: A perspective. Mater. Today Phys. 2017, 1, 50–60. [Google Scholar] [CrossRef]

- Mamur, H.; Bhuiyan, M.R.A.; Korkmaz, F.; Nil, M. A review on bismuth telluride (Bi2Te3) nanostructure for thermoelectric applications. Renew. Sustain. Energy Rev. 2018, 82, 4159–4169. [Google Scholar] [CrossRef]

- Fang, T.; Li, X.; Hu, C.L.; Zhang, Q.; Yang, J.; Zhang, W.Q.; Zhao, X.B.; Singh, D.J.; Zhu, T.J. Complex band structures and lattice dynamics of Bi2Te3-based compounds and solid solutions. Adv. Funct. Mater. 2019, 29, 1900677. [Google Scholar] [CrossRef]

- Vaney, J.B.; Yamini, S.A.; Takaki, H.; Kobayashi, K.; Kobayashi, N.; Mori, T. Magnetism-mediated thermoelectric performance of the Cr-doped bismuth telluride tetradymite. Mater. Today Phys. 2019, 9, 100090. [Google Scholar] [CrossRef]

- Prieto, A.L.; Sander, M.S.; Martin-Gonzalez, M.; Gronsky, R.; Sands, T.; Stacy, A.M. Electrodeposition of ordered Bi2Te3 nanowire arrays. J. Am. Chem. Soc. 2001, 123, 7160–7161. [Google Scholar] [CrossRef] [Green Version]

- Huang, B.L.; Kaviany, M. Ab initio and molecular dynamics predictions for electron and phonon transport in bismuth telluride. Phys. Rev. B 2008, 77, 125209. [Google Scholar] [CrossRef] [Green Version]

- Shu, R.; Zhou, Y.C.; Wang, Q.; Han, Z.J.; Zhu, Y.B.; Liu, Y.; Chen, Y.X.; Gu, M.; Xu, W.; Wang, Y.; et al. Mg3+δSbxBi2-x family: A promising substitute for the state-of-the-art n-type thermoelectric materials near room temperature. Adv. Funct. Mater. 2019, 29, 1807235. [Google Scholar] [CrossRef] [Green Version]

- Han, Z.J.; Gui, Z.G.; Zhu, Y.B.; Qin, P.; Zhang, B.P.; Zhang, W.Q.; Huang, L.; Liu, W.S. The electronic transport channel protection and tuning in real space to boost the thermoelectric performance of Mg3+ δSb2-yBiy near room temperature. Research 2020, 2020, 1672051. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, S.; Jia, F.; Zheng, S.Q.; Shi, X.L.; Jiang, D.Q.; Wang, S.Y.; Lu, G.W.; Wu, L.M.; Chen, Z.G. Point defect engineering and machinability in n-type Mg3Sb2-based materials. Mater. Today Phys. 2020, 15, 100269. [Google Scholar] [CrossRef]

- Mao, J.; Wu, Y.X.; Song, S.W.; Shuai, J.; Liu, Z.H.; Pei, Y.Z.; Ren, Z.F. Anomalous electrical conductivity of n-type Te-doped Mg3.2Sb1.5Bi0.5. Mater. Today Phys. 2017, 3, 1–6. [Google Scholar] [CrossRef]

- Xin, J.; Li, G.; Auffermann, G.; Borrmann, H.; Schnelle, W.; Gooth, J.; Zhao, X.; Zhu, T.; Felser, C.; Fu, C. Growth and transport properties of Mg3X2(X = Sb, Bi) single crystals. Mater. Today Phys. 2018, 7, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Sun, Y.M.; Xu, W.; Zhu, D.B. Organic thermoelectric materials: Emerging green energy materials converting heat to electricity directly and efficiently. Adv. Mater. 2014, 26, 6829–6851. [Google Scholar] [CrossRef]

- Zhang, Y.; Heo, Y.J.; Park, M.; Park, S.J. Recent advances in organic thermoelectric materials: Principle mechanisms and emerging carbon-based green energy materials. Polymers 2019, 11, 167. [Google Scholar] [CrossRef] [Green Version]

- Peng, S.J.; Wang, D.J.; Lu, J.D.; He, M.; Xu, C.; Li, Y.; Zhu, S.C. A review on organic polymer-based thermoelectric materials. J. Polym. Environ. 2017, 25, 1208–1218. [Google Scholar] [CrossRef]

- Fan, Z.; Ouyang, J.Y. Thermoelectric properties of PEDOT:PSS. Adv. Electron. Mater. 2019, 5, 1800769. [Google Scholar] [CrossRef]

- Shi, H.; Liu, C.C.; Jiang, Q.L.; Xu, J.K. Effective approaches to improve the electrical conductivity of PEDOT:PSS: A review. Adv. Electron. Mater. 2015, 1, 1500017. [Google Scholar] [CrossRef]

- Sarabia-Riquelme, R.; Shahi, M.; Brill, J.W.; Weisenberger, M.C. Effect of drawing on the electrical, thermoelectrical, and mechanical properties of wet-spun PEDOT:PSS fibers. ACS Appl. Polym. Mater. 2019, 1, 2157–2167. [Google Scholar] [CrossRef]

- Jin, H.L.; Li, J.; Iocozzia, J.; Zeng, X.; Wei, P.C.; Yang, C.; Li, N.; Liu, Z.P.; He, J.H.; Zhu, T.J.; et al. Hybrid organic-inorganic thermoelectric materials and devices. Angew. Chemie Int. Ed. 2019, 58, 15206–15226. [Google Scholar] [CrossRef] [PubMed]

- Dey, A.; Bajpai, O.P.; Sikder, A.K.; Chattopadhyay, S.; Khan, M.A.S. Recent advances in CNT/graphene based thermoelectric polymer nanocomposite: A proficient move towards waste energy harvesting. Renew. Sustain. Energy Rev. 2016, 53, 653–671. [Google Scholar] [CrossRef]

- Zheng, Y.; Luo, Y.B.; Du, C.F.; Zhu, B.B.; Liang, Q.H.; Hng, H.H.; Hippalgaonkar, K.; Xu, J.W.; Yan, Q.Y. Designing hybrid architectures for advanced thermoelectric materials. Mater. Chem. Front. 2017, 1, 2457–2473. [Google Scholar] [CrossRef]

- Yee, S.K.; Coates, N.E.; Majumdar, A.; Urban, J.J.; Segalman, R.A. Thermoelectric power factor optimization in PEDOT:PSS tellurium nanowire hybrid composites. Phys. Chem. Chem. Phys. 2013, 15, 4024–4032. [Google Scholar] [CrossRef]

- Finefrock, S.W.; Zhu, X.Q.; Sun, Y.M.; Wu, Y. Flexible prototype thermoelectric devices based on Ag2Te and PEDOT:PSS coated nylon fibre. Nanoscale 2015, 7, 5598–5602. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Z.; Srinivasan, B.; Wang, Z.X.; Zhang, J.; Li, K.W.; Boussard-Pledel, C.; Troles, J.; Bureau, B.; Wei, L. Ultraflexible glassy semiconductor fibers for thermal sensing and positioning. ACS Appl. Mater. Interfaces 2019, 11, 2441–2447. [Google Scholar] [CrossRef]

- Choi, J.; Jung, Y.; Yang, S.J.; Oh, J.Y.; Oh, J.; Jo, K.; Son, J.G.; Moon, S.E.; Park, C.R.; Kim, H. Flexible and robust thermoelectric generators based on all-carbon nanotube yarn without metal electrodes. ACS Nano 2017, 11, 7608–7614. [Google Scholar] [CrossRef]

- Yadav, A.; Pipe, K.P.; Shtein, M. Fiber-based flexible thermoelectric power generator. J. Power Sources 2008, 175, 909–913. [Google Scholar] [CrossRef]

- Wu, Q.; Hu, J. A novel design for a wearable thermoelectric generator based on 3D fabric structure. Smart Mater. Struct. 2017, 26, 45037. [Google Scholar] [CrossRef]

- Du, Y.; Cai, K.F.; Chen, S.; Wang, H.X.; Shen, S.Z.; Donelson, R.; Lin, T. Thermoelectric fabrics: Toward power generating clothing. Sci. Rep. 2015, 5, 6411. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.Q.; Zhu, W.B.; Yu, X.G.; Huang, P.; Fu, S.Y.; Hu, N.; Liao, K. Multifunctional wearable device based on flexible and conductive carbon sponge/polydimethylsiloxane composite. ACS Appl. Mater. Interfaces 2016, 8, 33189–33196. [Google Scholar] [CrossRef]

- Hsu, P.C.; Song, A.Y.; Catrysse, P.B.; Liu, C.; Peng, Y.C.; Xie, J.; Fan, S.H.; Cui, Y. Radiative human body cooling by nanoporous polyethylene textile. Science 2016, 353, 1019–1023. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cai, L.L.; Song, A.Y.; Li, W.; Hsu, P.C.; Lin, D.C.; Catrysse, P.B.; Liu, Y.Y.; Peng, Y.C.; Chen, J.; Wang, H.X. Spectrally selective nanocomposite textile for outdoor personal cooling. Adv. Mater. 2018, 30, 1802152. [Google Scholar] [CrossRef]

- Cui, Y.; Gong, H.X.; Wang, Y.J.; Li, D.W.; Bai, H. A thermally insulating textile inspired by polar bear hair. Adv. Mater. 2018, 30, 1706807. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.Z.; Zhao, Y.Y.; Liu, W.M. Electrospun polyethylene glycol/cellulose acetate phase change fibers with core–sheath structure for thermal energy storage. Renew. Energy 2013, 60, 222–225. [Google Scholar] [CrossRef]

- Tabor, J.; Chatterjee, K.; Ghosh, T.K. Smart textile-based personal thermal comfort systems: Current status and potential solutions. Adv. Mater. Technol. 2020, 5, 1901155. [Google Scholar] [CrossRef]

- Hong, S.; Gu, Y.; Seo, J.K.; Wang, J.; Liu, P.; Meng, Y.S.; Xu, S.; Chen, R.K. Wearable thermoelectrics for personalized thermoregulation. Sci. Adv. 2019, 5, eaaw0536. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.F.; Sekine, T.; Takeda, Y.; Yokosawa, K.; Matsui, H.; Kumaki, D.; Shiba, T.; Nishikawa, T.; Tokito, S. Fully printed PEDOT:PSS-based temperature sensor with high humidity stability for wireless healthcare monitoring. Sci. Rep. 2020, 10, 2467. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Inorganic fibers | ||||||

| Bi2Te3 | 130.5 | 744 | 0.52 | 0.73 | 300 | [41] |

| Bi2Se3 | −150.85 | 319 | 1.25 | 0.18 | 300 | [47] |

| SnSe | 306.9 | 56.4 | 0.25 | 2 | 862 | [49] |

| Sb2Te3 | −176 | 88 | 1.2 | 0.07 | - | [29] |

| Organic fibers | ||||||

| PEDOT:PSS | 72 | 950 | 0.42 | 0.42 | 297 | [56] |

| PEDOT:PSS | 14.8 | 172.5 | - | - | - | [57] |

| Poly (3-hexylthiophene) | 14.8 | 50 | 0.0708 | 0.016 | - | [58] |

| PEDOT | 23 | 869 | 0.37 | 0.036 | - | [59] |

| Composite fibers | ||||||

| Poly (3-octylthiophene)-CNT | 136 | 3.6 | - | - | - | [60] |

| PEDOT:PSS-Te | 115 | 215 | 0.2 | 0.39 | - | [61] |

| PEDOT:PSS-CNT | 70.1 | 1043.5 | 0.4–1.0 | - | - | [62] |

| Cellulose- Bi2Te3 | −134.2 | 209.6 | 0.47 | 0.38 | 437 | [63] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Deng, B.; Sun, W.; Zheng, Z.; Liu, W. Fiber-Based Thermoelectric Materials and Devices for Wearable Electronics. Micromachines 2021, 12, 869. https://doi.org/10.3390/mi12080869

Zhang P, Deng B, Sun W, Zheng Z, Liu W. Fiber-Based Thermoelectric Materials and Devices for Wearable Electronics. Micromachines. 2021; 12(8):869. https://doi.org/10.3390/mi12080869

Chicago/Turabian StyleZhang, Pengxiang, Biao Deng, Wenting Sun, Zijian Zheng, and Weishu Liu. 2021. "Fiber-Based Thermoelectric Materials and Devices for Wearable Electronics" Micromachines 12, no. 8: 869. https://doi.org/10.3390/mi12080869

APA StyleZhang, P., Deng, B., Sun, W., Zheng, Z., & Liu, W. (2021). Fiber-Based Thermoelectric Materials and Devices for Wearable Electronics. Micromachines, 12(8), 869. https://doi.org/10.3390/mi12080869