Research on Decomposition of Offset in MEMS Capacitive Accelerometer

Abstract

:1. Introduction

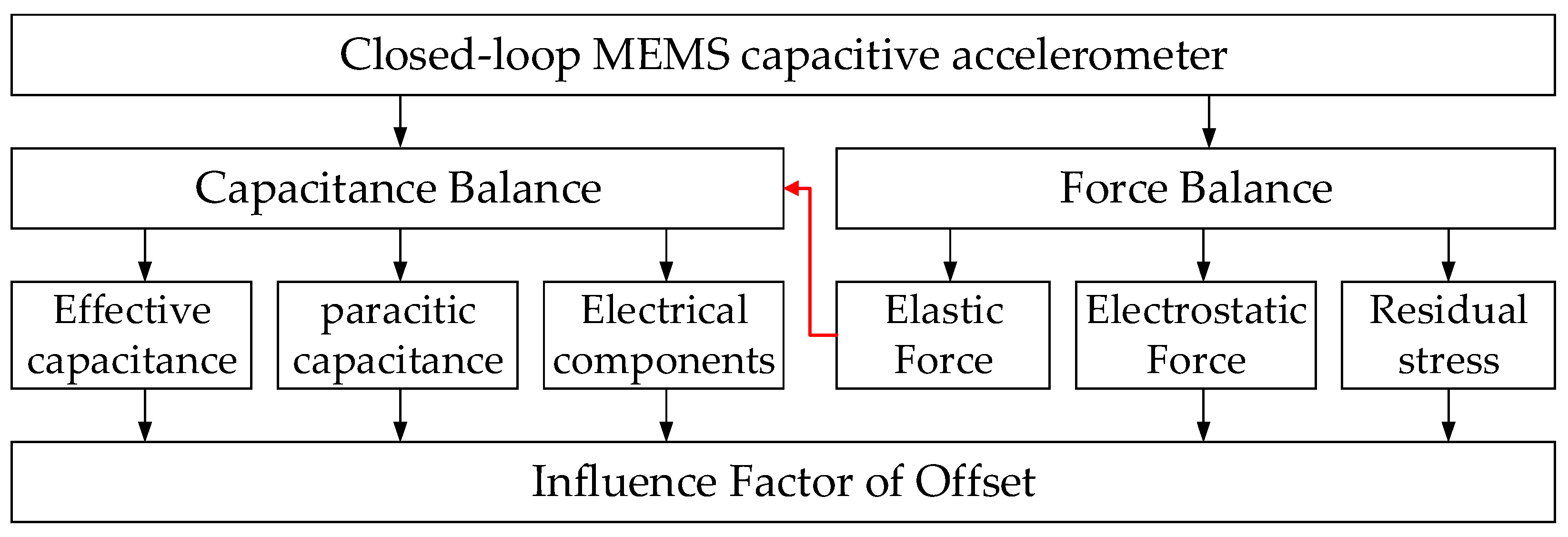

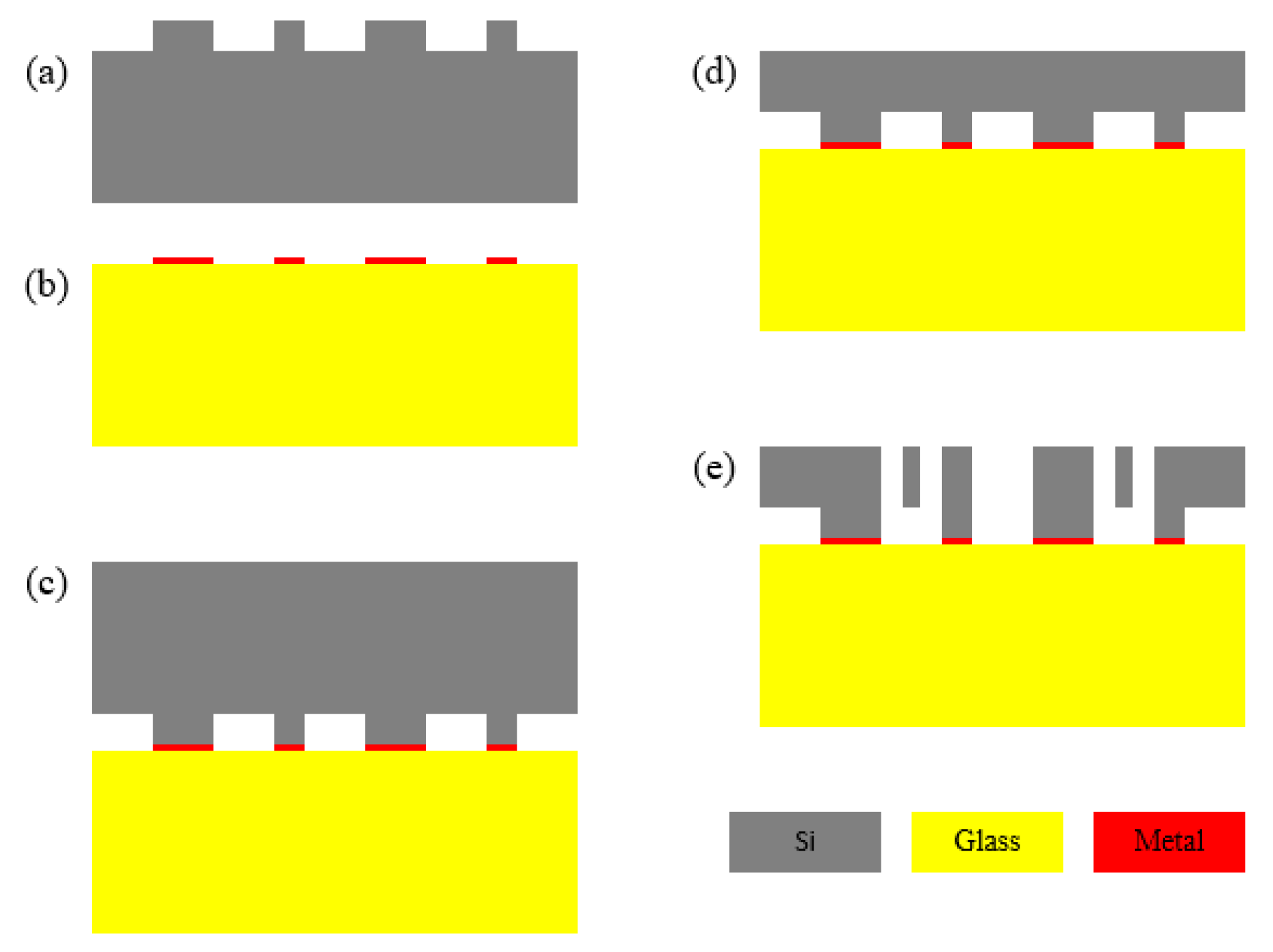

2. Decomposition of Offset

2.1. Composition of Offset

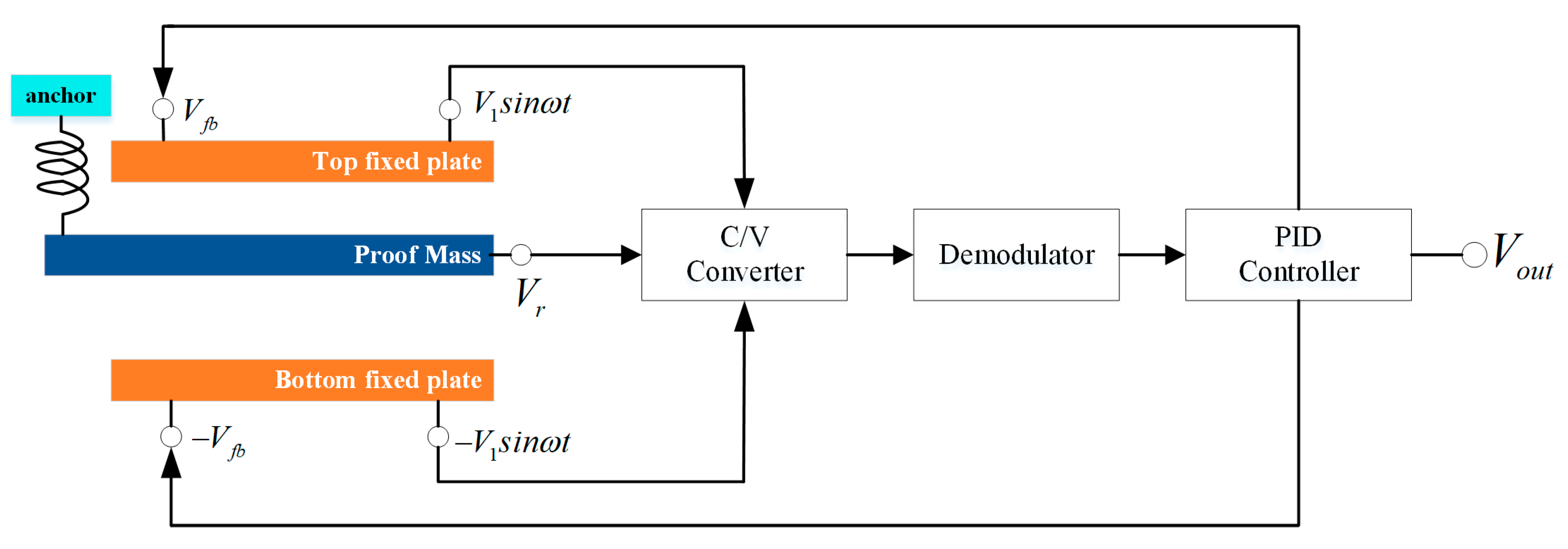

2.1.1. Offset from Electrical Part

2.1.2. Offset from Mechanical Part

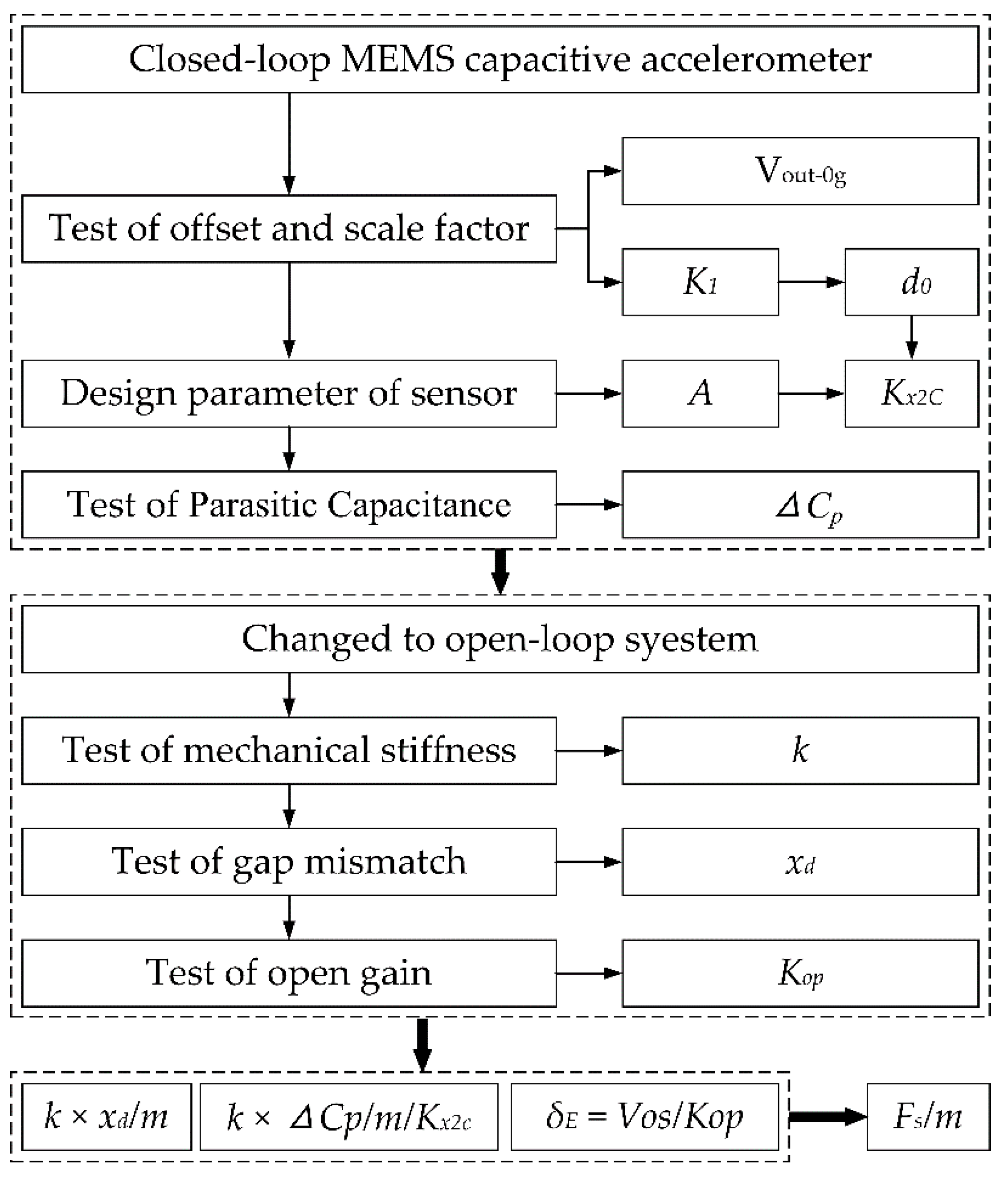

2.2. Parameters of MEMS Sensor

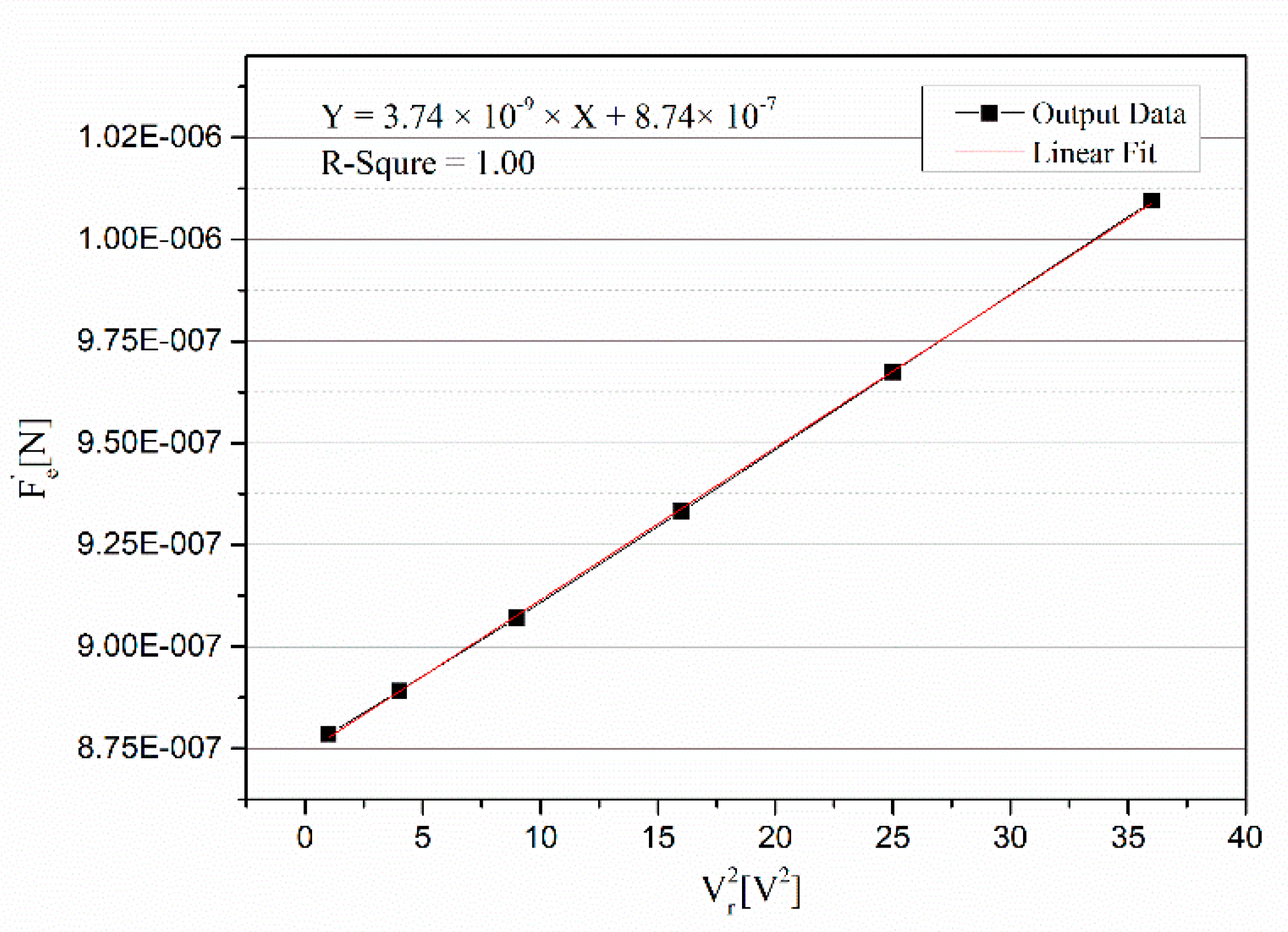

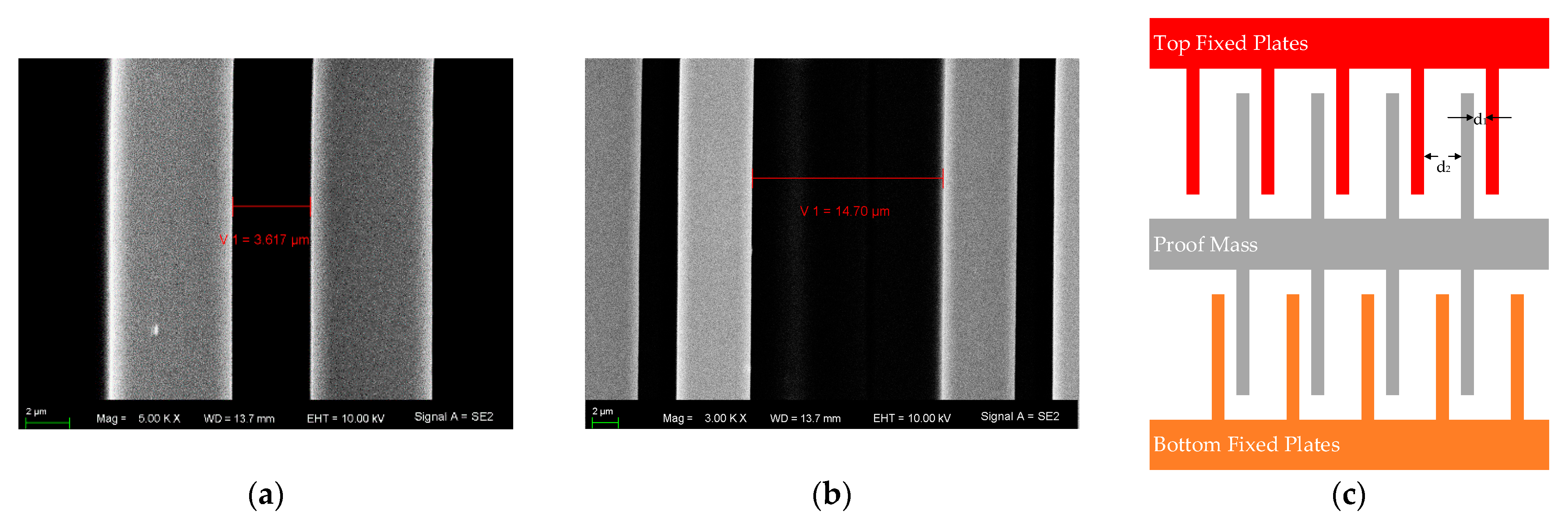

2.2.1. Gap of Sensor

2.2.2. Mismatch of Parasitic Capacitance

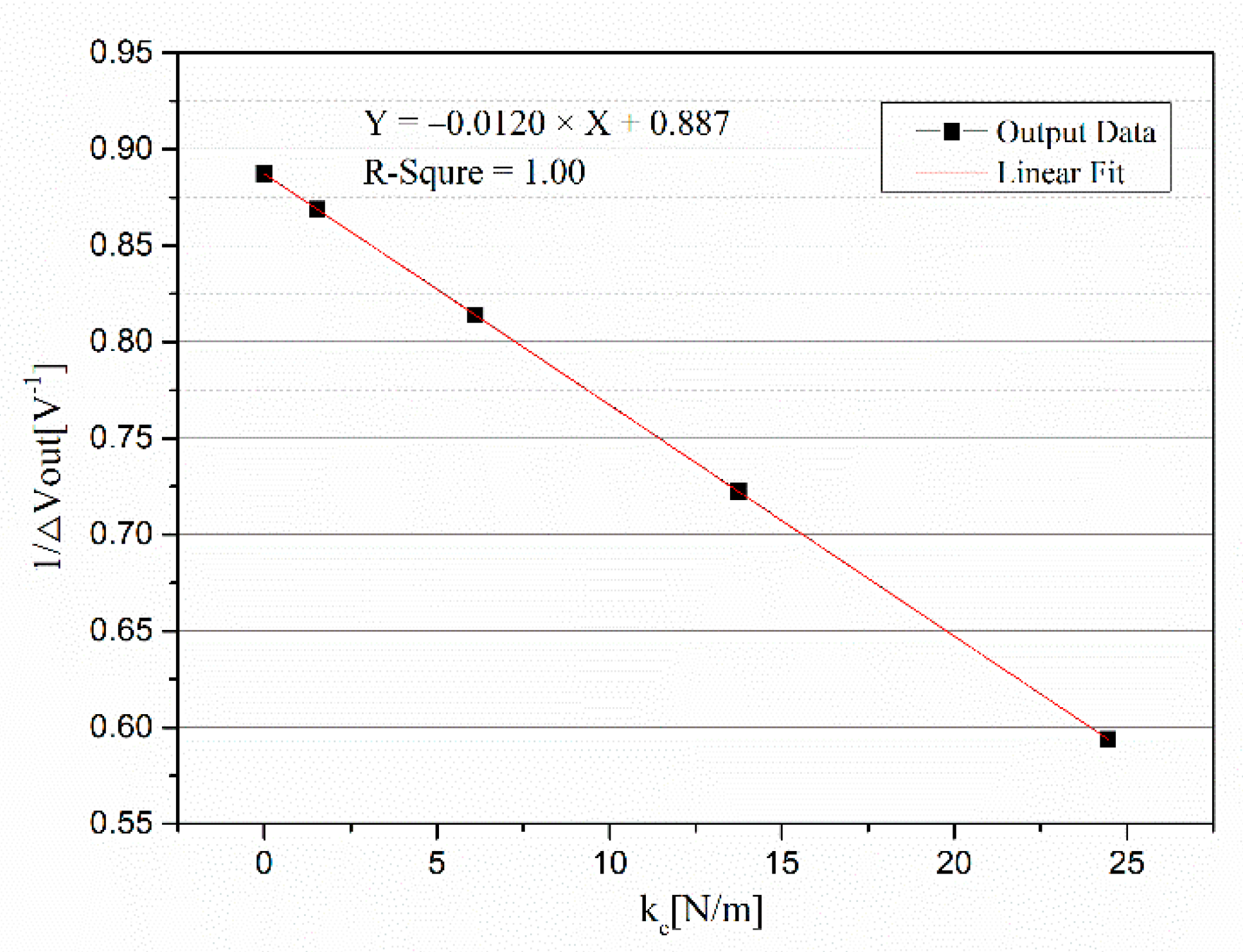

2.2.3. Mechanical Stiffness of Spring

2.2.4. Mismatch of Gap

2.3. Procedure of Decomposition Method

3. Measurement Results and Discussion

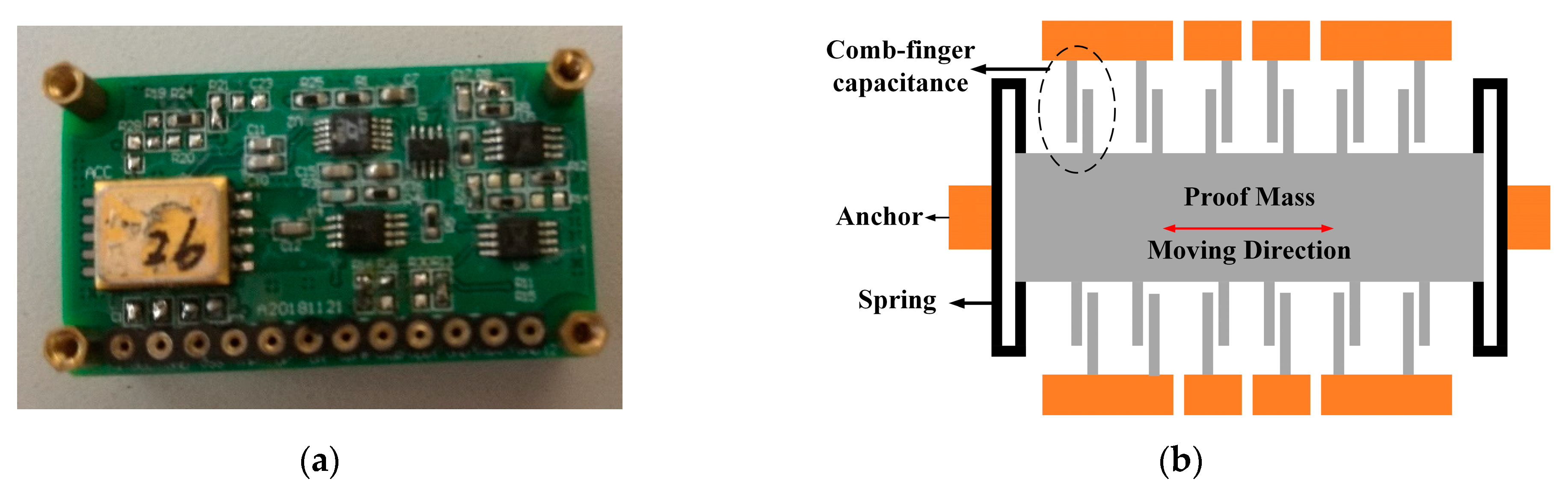

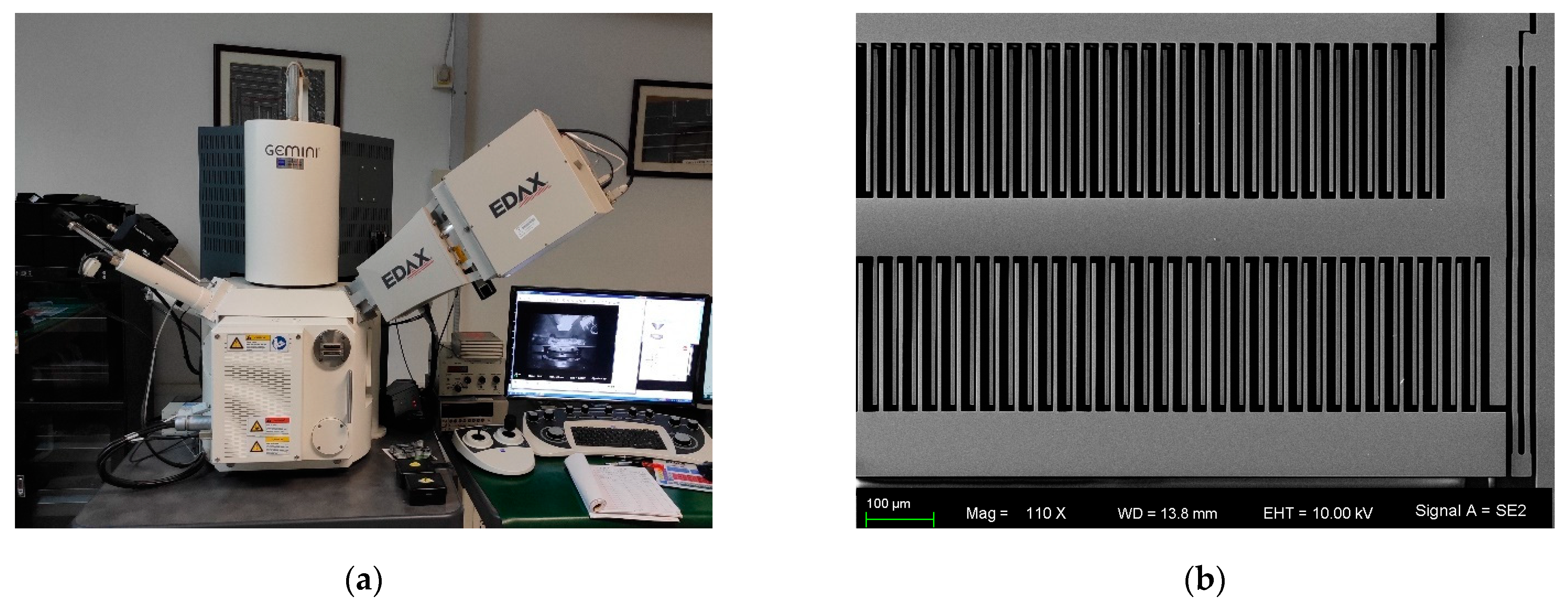

3.1. MEMS Capacitive Accelerometer

3.2. Measurement Results

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rao, K.; Wei, X.; Zhang, S.; Zhang, M.; Hu, C.; Liu, H.; Tu, L.-C. A MEMS Micro-g Capacitive Accelerometer Based on Through-Silicon-Wafer-Etching Process. Micromachines 2019, 10, 380. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ullah, P.; Ragot, V.; Zwahlen, P.; Rudolf, F. A new high performance sigma-delta MEMS accelerometer for inertial navigation. In Proceedings of the 2015 Dgon Inertial Sensors and Systems Symposium, Karlsruhe, Germany, 22–23 September 2015. [Google Scholar]

- Grinberg, B.; Feingold, A.; Koenigsberg, L.; Furman, L. Closed-loop MEMS accelerometer: From design to production. In Proceedings of the 2016 Dgon Inertial Sensors and Systems Symposium, New York, NY, USA, 20–21 September 2016. [Google Scholar]

- Yeh, C.Y.; Huang, J.T.; Tseng, S.H.; Wu, P.-C.; Tsai, H.-H.; Juang, Y.-Z. A low-power monolithic three-axis accelerometer with automatically sensor offset compensated and interface circuit. Microelectron. J. 2019, 86, 150–160. [Google Scholar] [CrossRef]

- Tie, J.; Cao, J.; Chang, L.; Cai, S.; Wu, M.; Lian, J. A Model of Gravity Vector Measurement Noise for Estimating Accelerometer Bias in Gravity Disturbance Compensation. Sensors 2018, 18, 883. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, Y.; Ying, G.; Su, S.W. An Efficient Autocalibration Method for Triaxial Accelerometer. In IEEE Transactions on Instrumentation and Measurement; IEEE: Piscataway, NJ, USA, 2017; Volume 66. [Google Scholar]

- Hao, R.; Yu, H.J.; Zhou, W.; Peng, B.; Guo, J. Effect of Slice Error of Glass on Zero Offset of Capacitive Accelerometer. In Proceedings of the 19th Annual Conference and 8th International Conference of Chinese Society of Micro/Nano Technology, Dalian, China, 26–29 October 2017. [Google Scholar]

- Huang, J.; Zhao, M.; Zhang, T.; Chen, Z.; Hong, L.; Wu, F.; Zhang, Y.; Lu, W.; Gao, C.; Hao, Y. Linearity analysis of closed-loop capacitive accelerometer due to distance mismatch between plates and the influence of compensation capacitor array. Sci. China Inf. Sci. 2013, 57, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Gupta, N.; Shaveta; Dutta, S.; Pal, R.; Jain, K.K. Effect of Residual Stress on Cantilever Type Push–Pull Capacitive Accelerometer Structure. In Proceedings of the Physics of Semiconductor Devices; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Tavakoli, M.; Sarpeshkar, R. An offset-canceling low-noise lock-in architecture for capacitive sensing. IEEE J. Solid State Circuits 2003, 38, 244–253. [Google Scholar] [CrossRef]

- Zhou, W.; Li, F.; Yu, H.; Qu, H.; Hao, R.; Wang, N.; Sun, S.; Peng, B. Influence of adhesive non-uniformity on zero offset of micro accelerometer. Int. J. Mod. Phys. B 2017, 31, 1750242. [Google Scholar] [CrossRef]

- Guo, C.; Sun, Y.B.; Luo, Y.; Wang, X. Study on effect of adhesive layer on zero error of accelerometer. Transducer Microsyst. Technol. 2018, 37, 19–22. [Google Scholar] [CrossRef]

- Liu, M.J.; Dong, J.X. Compensation for bias in capacitive micro accelerometer. J. Chin. Inert. Technol. 2008, 16, 86–89. [Google Scholar] [CrossRef]

- Chang, C.-C.; Yang, H.-T.; Su, Y.-F.; Hong, Y.-T.; Chiang, K.-N. A method to compensate packaging effects on three-axis MEMS accelerometer. In Proceedings of the 15th IEEE InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Las Vegas, NV, USA, 31 May–3 June 2016. [Google Scholar]

- Wu, W.; Liu, D.; Qiu, W.; Liu, H.; Hu, F.; Fan, J.; Hu, C.; Tu, L. A precise spacing-control method in MEMS packaging for capacitive accelerometer applications. J. Micromech. Microeng. 2018, 28, 125016. [Google Scholar] [CrossRef]

- Lajevardi, P.; Petkov, V.; Murmann, B. A ΔΣ interface for MEMS accelerometers using electrostatic spring-constant modulation for cancellation of bondwire capacitance drift. In Proceedings of the IEEE International Solid-State Circuits Conference, San Francisco, CA, USA, 19–23 February 2012. [Google Scholar]

- Liu, Y.-S.; Wen, K.-A. Monolithic Low Noise and Low Zero-g Offset CMOS/MEMS Accelerometer Readout Scheme. Micromachines 2018, 9, 637. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jeong, Y.; Ayazi, F. A novel offset calibration method to suppress capacitive mismatch in MEMS accelerometer. In Proceedings of the Samsung Electro-Mechanics Best Paper Award, Seoul, Korea, 13 November 2013. [Google Scholar]

- Maspero, F.; Lopez-Rey, V.F.; Joet, L.; Hentz, S.; Langfelder, G. Combined electronics and algorithm development for offset drift characterization in MEMS accelerometers. In Proceedings of the IEEE International Symposium on Inertial Sensors and Systems, Moltrasio, Italy, 26–29 March 2018. [Google Scholar]

- Grigorie, T.L. The matlab/simulink modeling and numerical simulation of an analogue capacitive micro-accelerometer. In Proceedings of the MEMSTECH’2008, Polyana, Ukraine, 21–24 May 2008. [Google Scholar]

- Dong, X.; Yang, S.; Zhu, J.; En, Y.; Huang, Q. Method of Measuring the Mismatch of Parasitic Capacitance in MEMS Accelerometer Based on Regulating Electrostatic Stiffness. Micromachines 2018, 9, 128. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, H.; Li, S.; Deng, K.; Gao, S.; Feng, L. Analysis and Design of Closed-loop Detection Technique for Micro-grating Accelerometer. J. Lightwave Technol. 2018, 36, 1. [Google Scholar] [CrossRef]

- Zhou, W.; He, J.B.; Yu, H.J.; He, X.P.; Peng, P. Analytical study of temperature coefficients of bulk MEMS capacitive accelerometers op-erating in closed-loop mode. Sens. Actuators A Phys. 2019, 290, 239–247. [Google Scholar] [CrossRef]

- Li, J.; Dong, J.X.; Liu, Y.F.; Wu, T.Z. Effects of preload voltage on performance of force-rebalance micro silicon accelerometer. J. Transducer Technol. 2004, 23, 35–40. [Google Scholar] [CrossRef]

- Li, J.; Gao, Z.; Dong, J.; Liu, Y.; Wang, S. Electrometric method for measuring the mechanical parameters of a comb-finger micro-mechanical accelerometer. J. Tsinghua Univ. 2003, 43, 651–654. [Google Scholar]

| Vout(+1g) [mV] | Vout(−1g) [mV] | SF [mV/g] | Offset [mV] | Offset [mg] |

|---|---|---|---|---|

| −694.96 | 462.95 | 578.955 | −116.005 | −200.4 |

| 1.000 | 1.000 | 8.79 × 10−7 |

| 2.000 | 4.000 | 8.89 × 10−7 |

| 3.000 | 9.000 | 9.07 × 10−7 |

| 4.000 | 16.000 | 9.33 × 10−7 |

| 5.000 | 25.000 | 9.67 × 10−7 |

| 6.000 | 36.000 | 1.009 × 10−6 |

| Vr [V] | ke [V] | Vout1 [V] | Vout2 [V] | ΔVout [V] |

|---|---|---|---|---|

| 0.000 | 0.0000 | −0.6627 | 0.4644 | 1.1271 |

| 1.000 | 1.529 | −0.6769 | 0.4740 | 1.1509 |

| 2.000 | 6.114 | −0.7240 | 0.5045 | 1.2285 |

| 3.000 | 13.757 | −0.8182 | 0.5661 | 1.3843 |

| 4.000 | 24.458 | −1.0006 | 0.6836 | 1.6842 |

| VB [V] | VT [V] | Vout [mV] |

|---|---|---|

| 0.000 | 0.000 | −116.0 |

| 1.000 | 0.000 | −282.2 |

| 1.000 | 1.000 | −118.1 |

| 1.000 | 1.008 | −116.0 |

| Composition of Offset | Value | |

|---|---|---|

| mechanical part | gap mismatch | −222.8 mg ± 6.9 mg |

| residual stress | −17.7 mg ± 1.4 mg | |

| electrical part | parasitic capacitance | +39.5 mg ± 1.8 mg |

| electrical components | +0.6 mg | |

| total | −200.4 mg | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Huang, Y.; Lai, P.; Huang, Q.; Su, W.; Li, S.; Xu, W. Research on Decomposition of Offset in MEMS Capacitive Accelerometer. Micromachines 2021, 12, 1000. https://doi.org/10.3390/mi12081000

Dong X, Huang Y, Lai P, Huang Q, Su W, Li S, Xu W. Research on Decomposition of Offset in MEMS Capacitive Accelerometer. Micromachines. 2021; 12(8):1000. https://doi.org/10.3390/mi12081000

Chicago/Turabian StyleDong, Xianshan, Yun Huang, Ping Lai, Qinwen Huang, Wei Su, Shiyuan Li, and Wei Xu. 2021. "Research on Decomposition of Offset in MEMS Capacitive Accelerometer" Micromachines 12, no. 8: 1000. https://doi.org/10.3390/mi12081000

APA StyleDong, X., Huang, Y., Lai, P., Huang, Q., Su, W., Li, S., & Xu, W. (2021). Research on Decomposition of Offset in MEMS Capacitive Accelerometer. Micromachines, 12(8), 1000. https://doi.org/10.3390/mi12081000