Molecular Dynamic Investigation of the Anisotropic Response of Aluminum Surface by Ions Beam Sputtering

Abstract

:1. Introduction

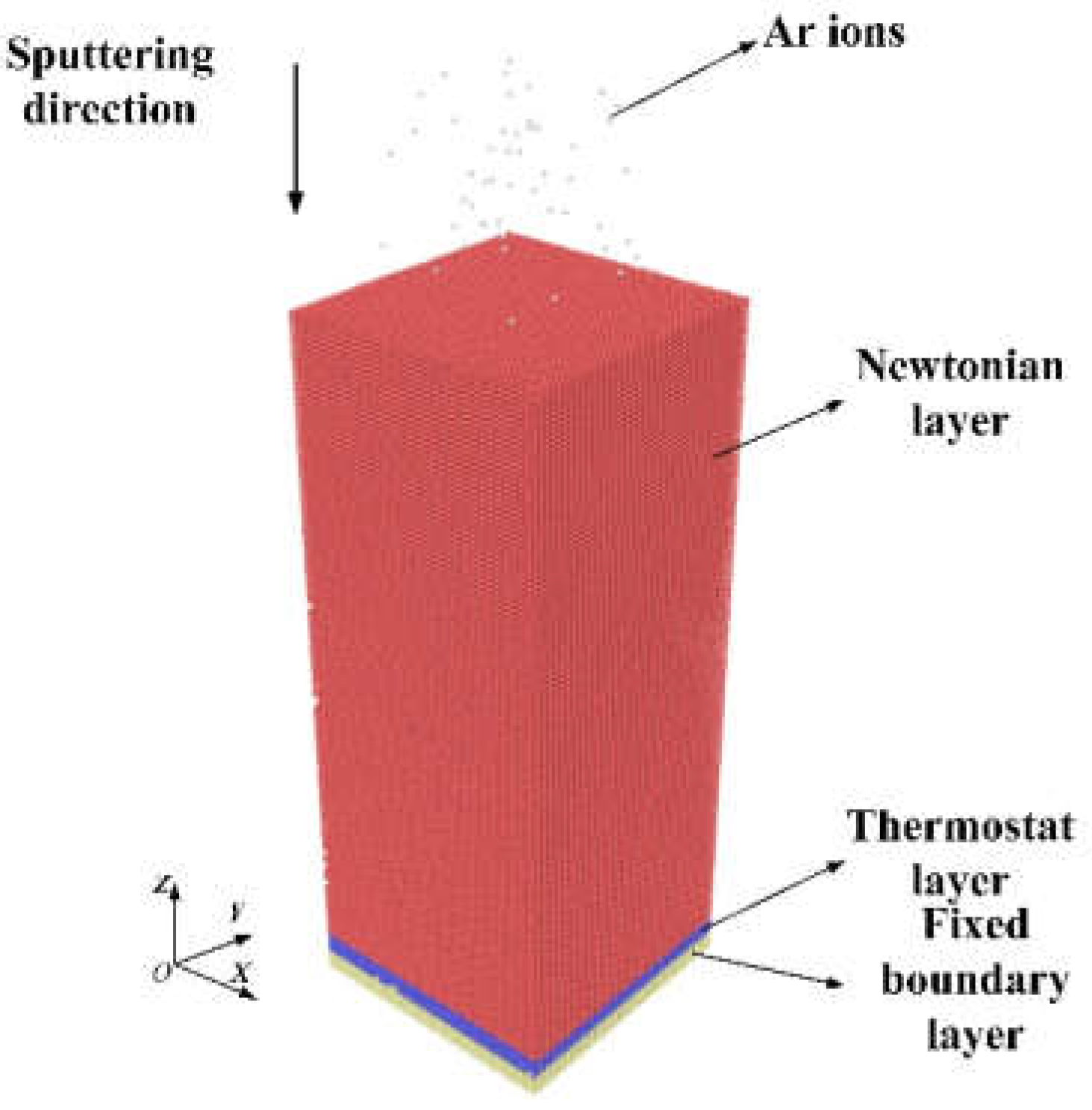

2. Simulation Method

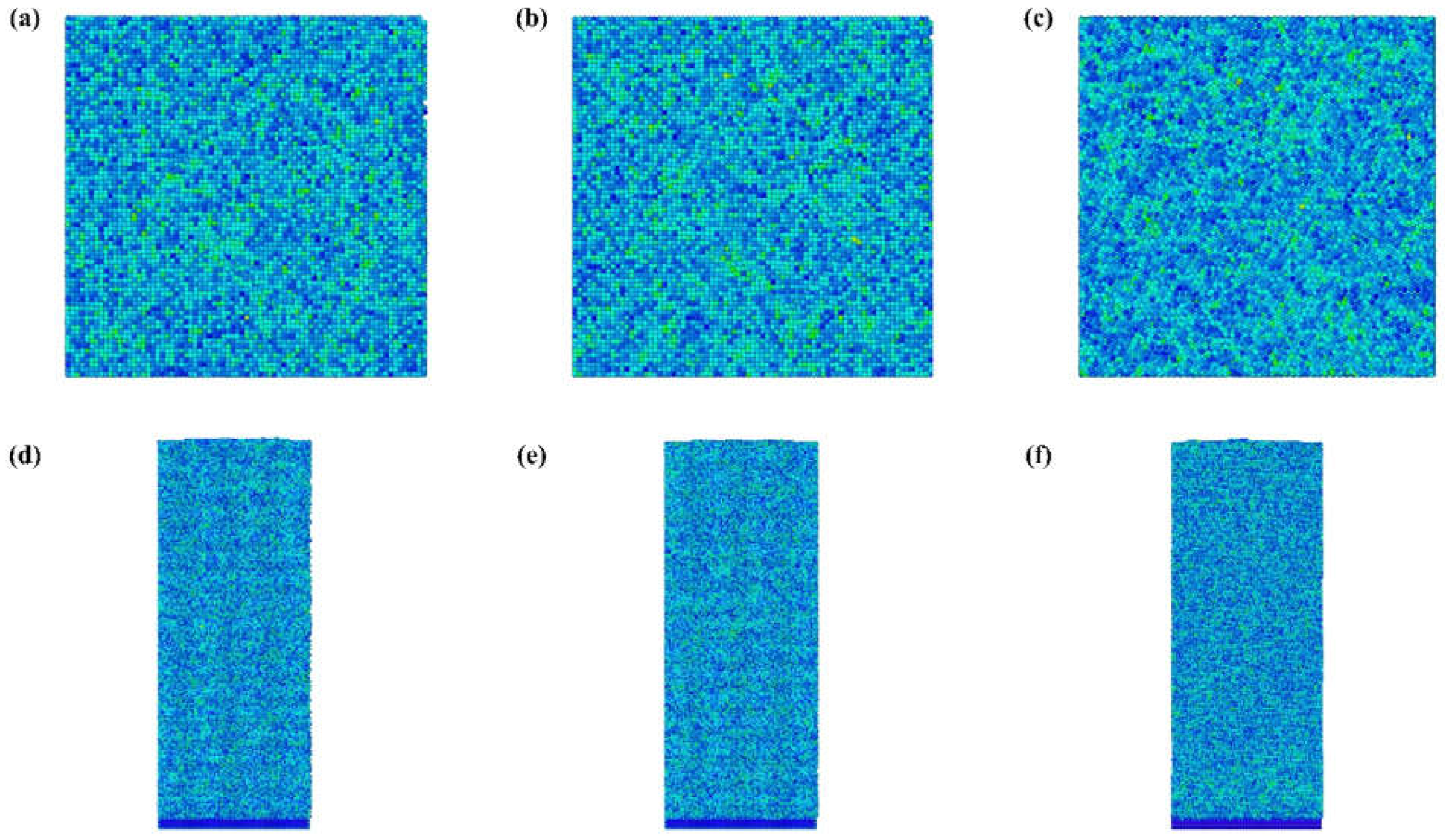

2.1. Simulation Description

2.2. Potential Description

3. Results and Discussion

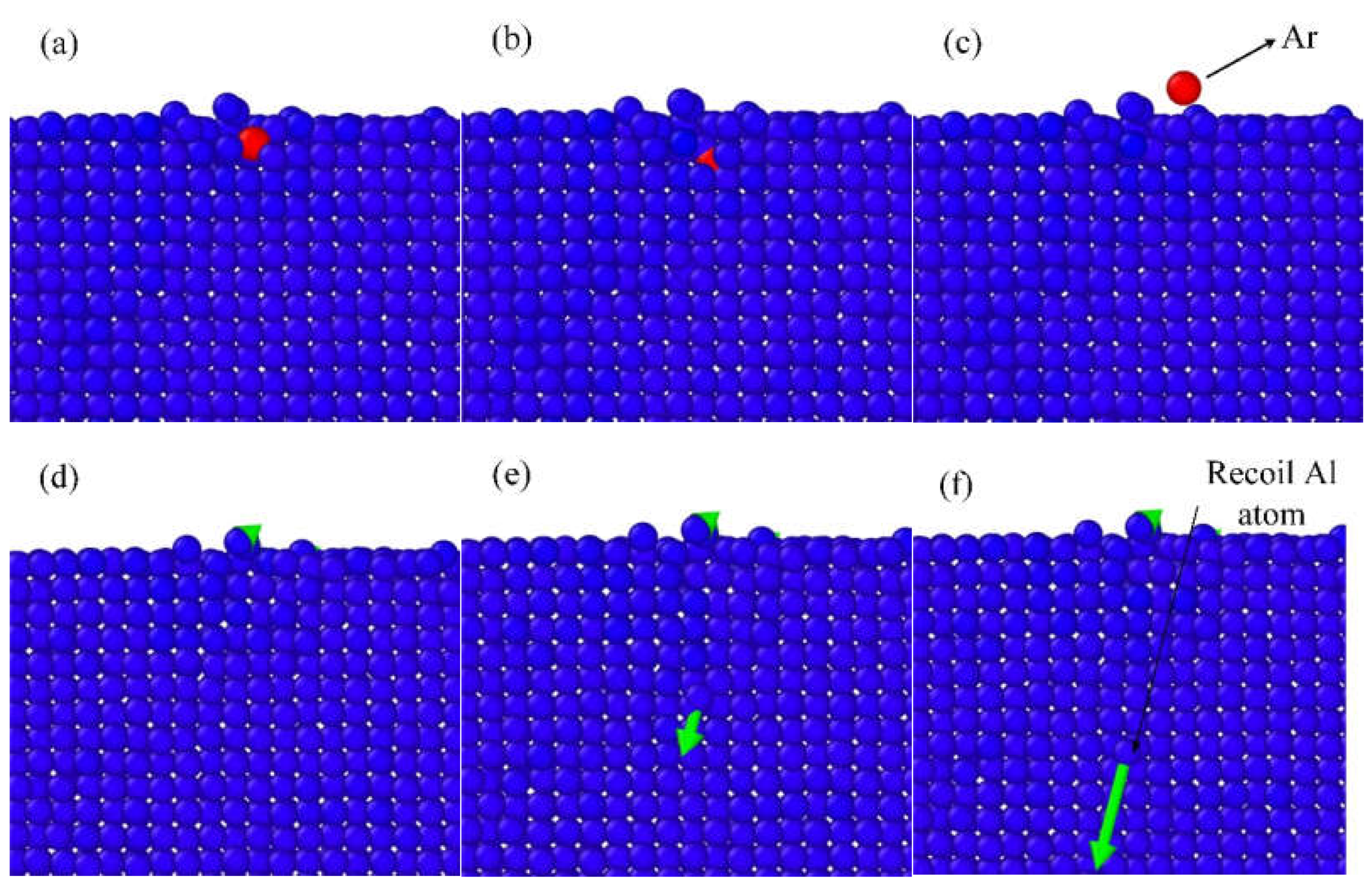

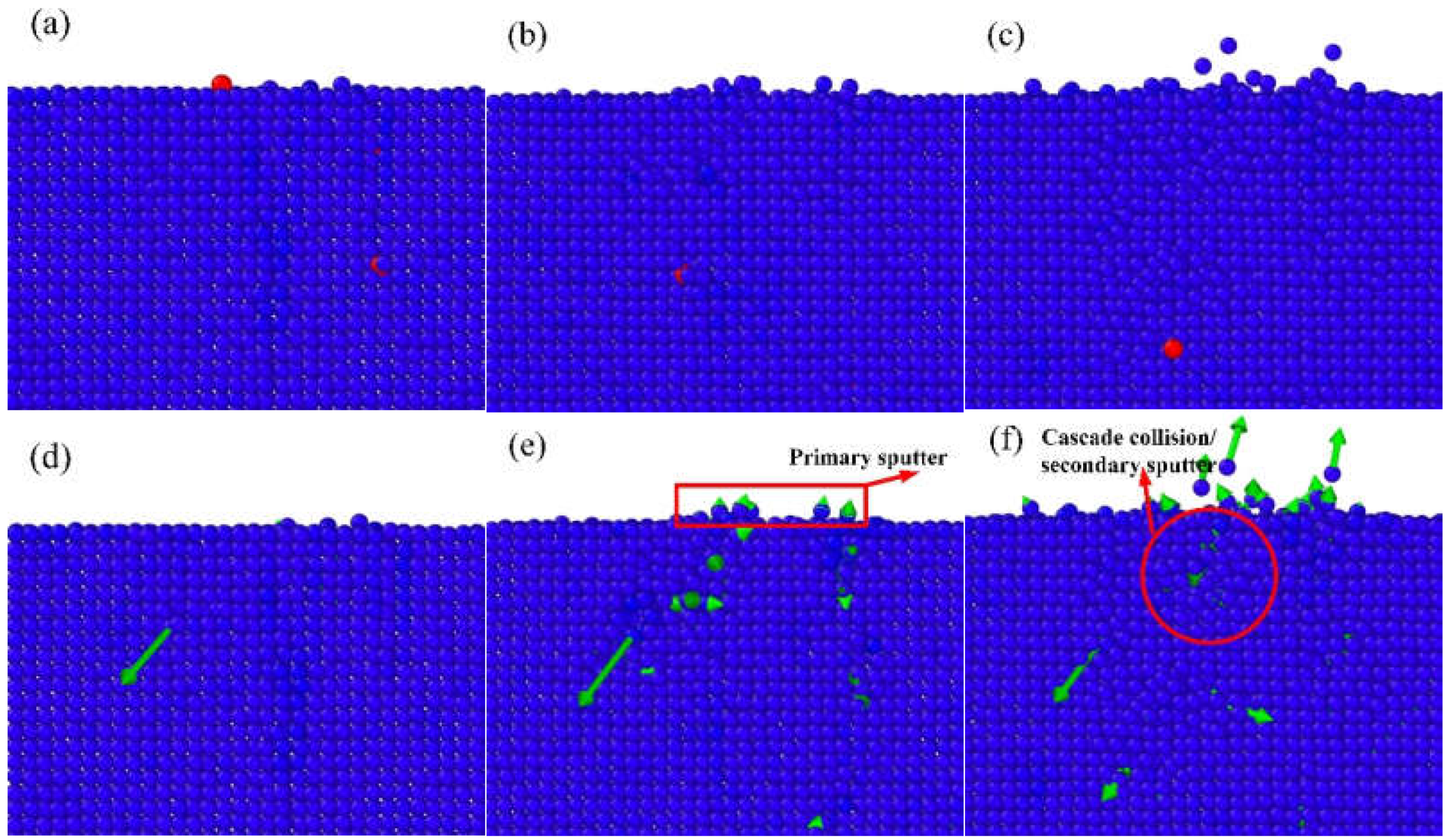

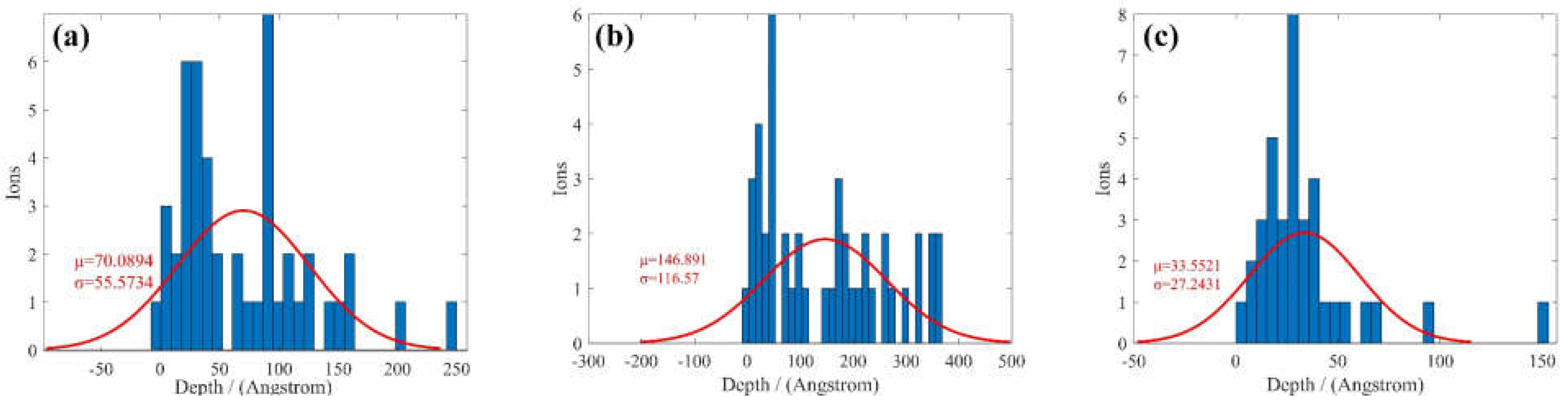

3.1. Ion Beam Sputtering Mechanism

3.2. Sputter Yield Analysis

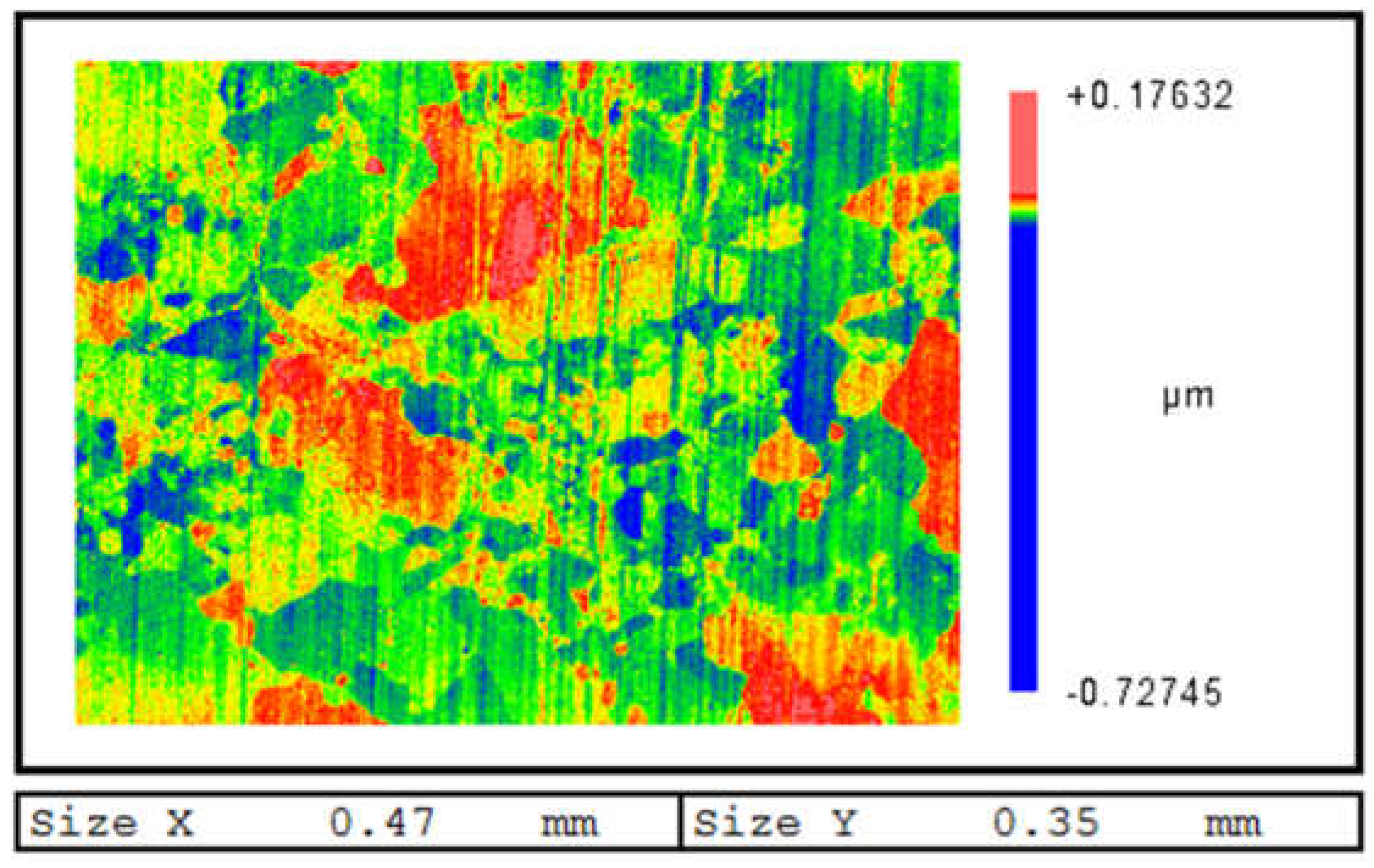

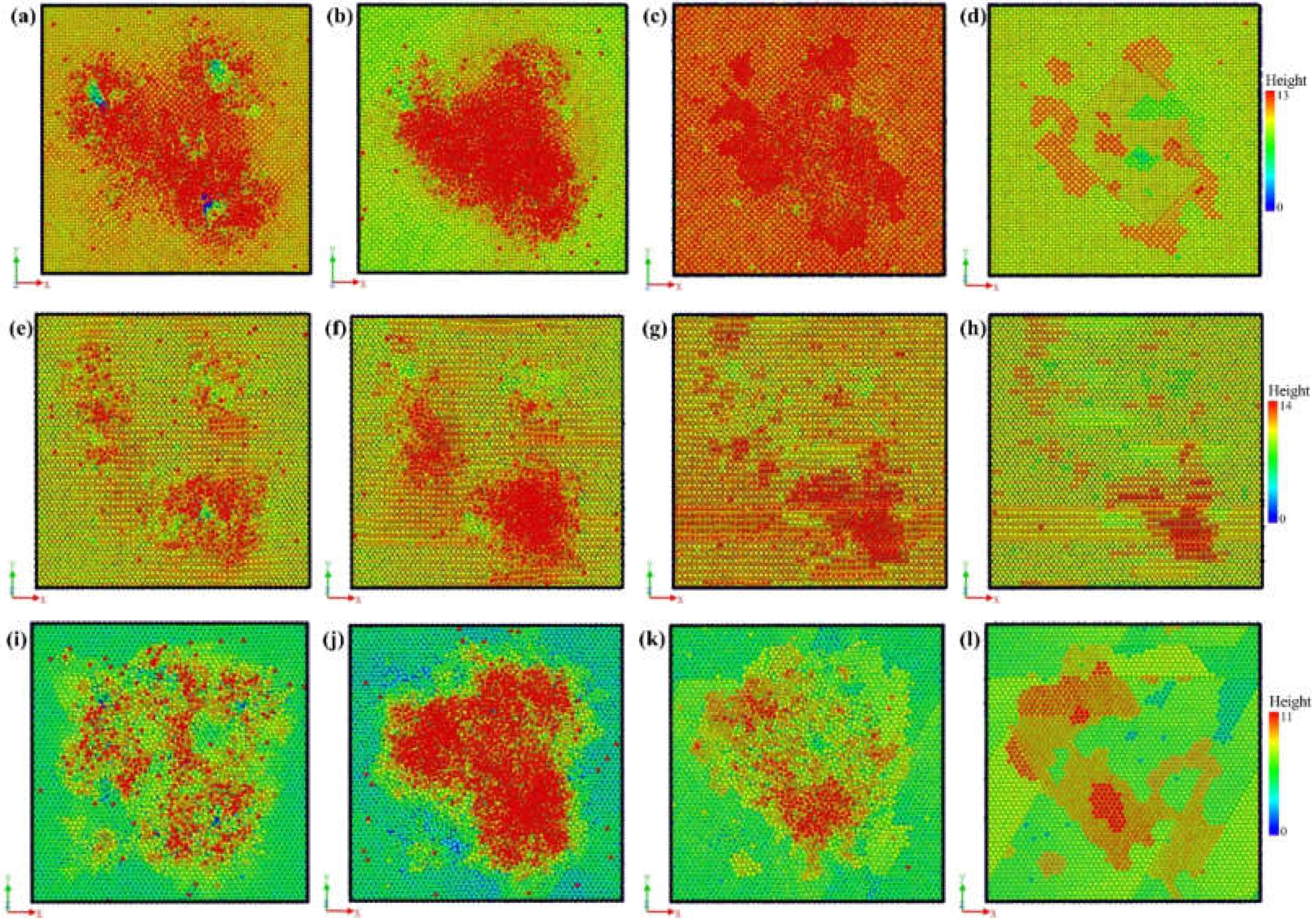

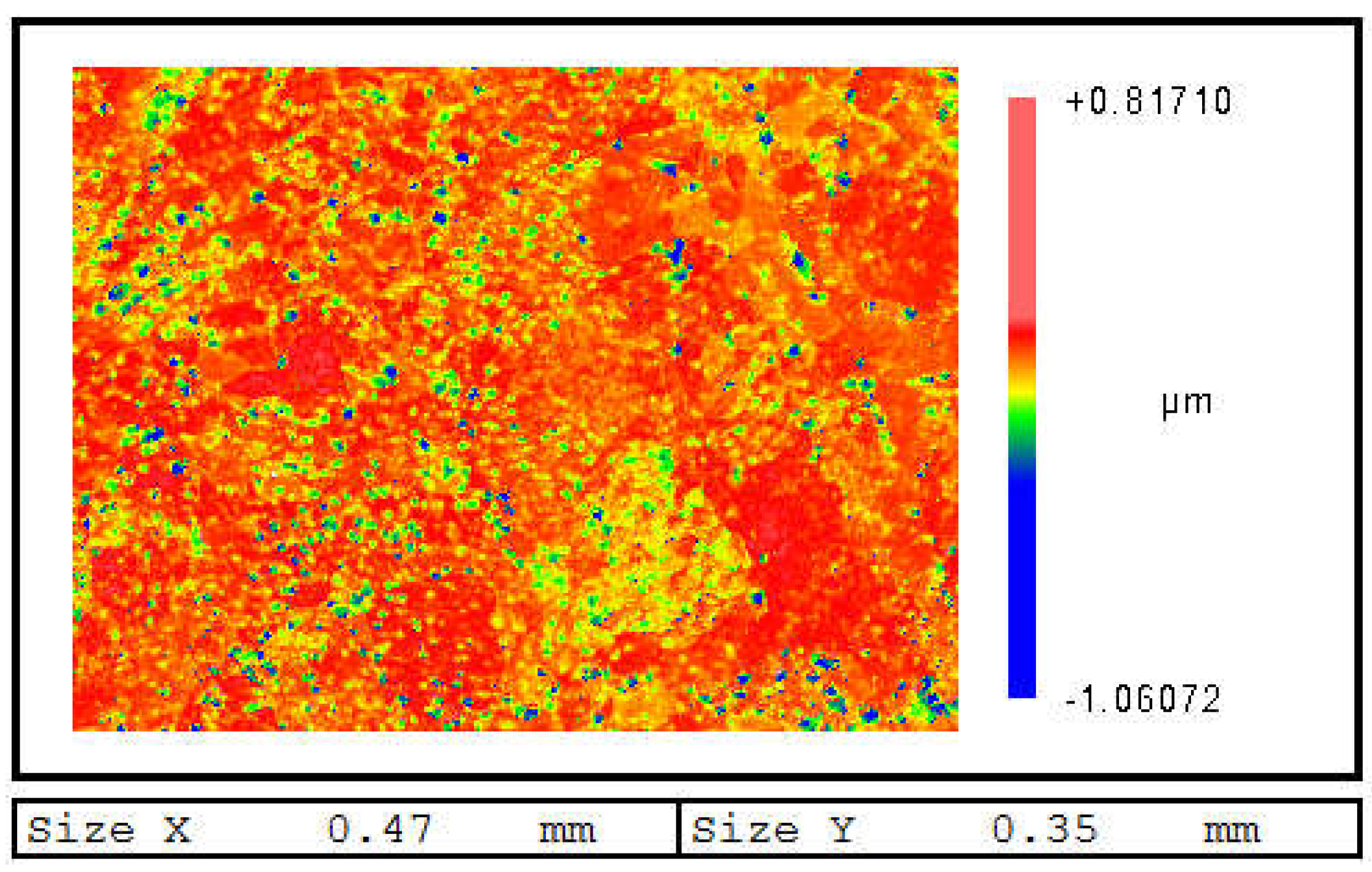

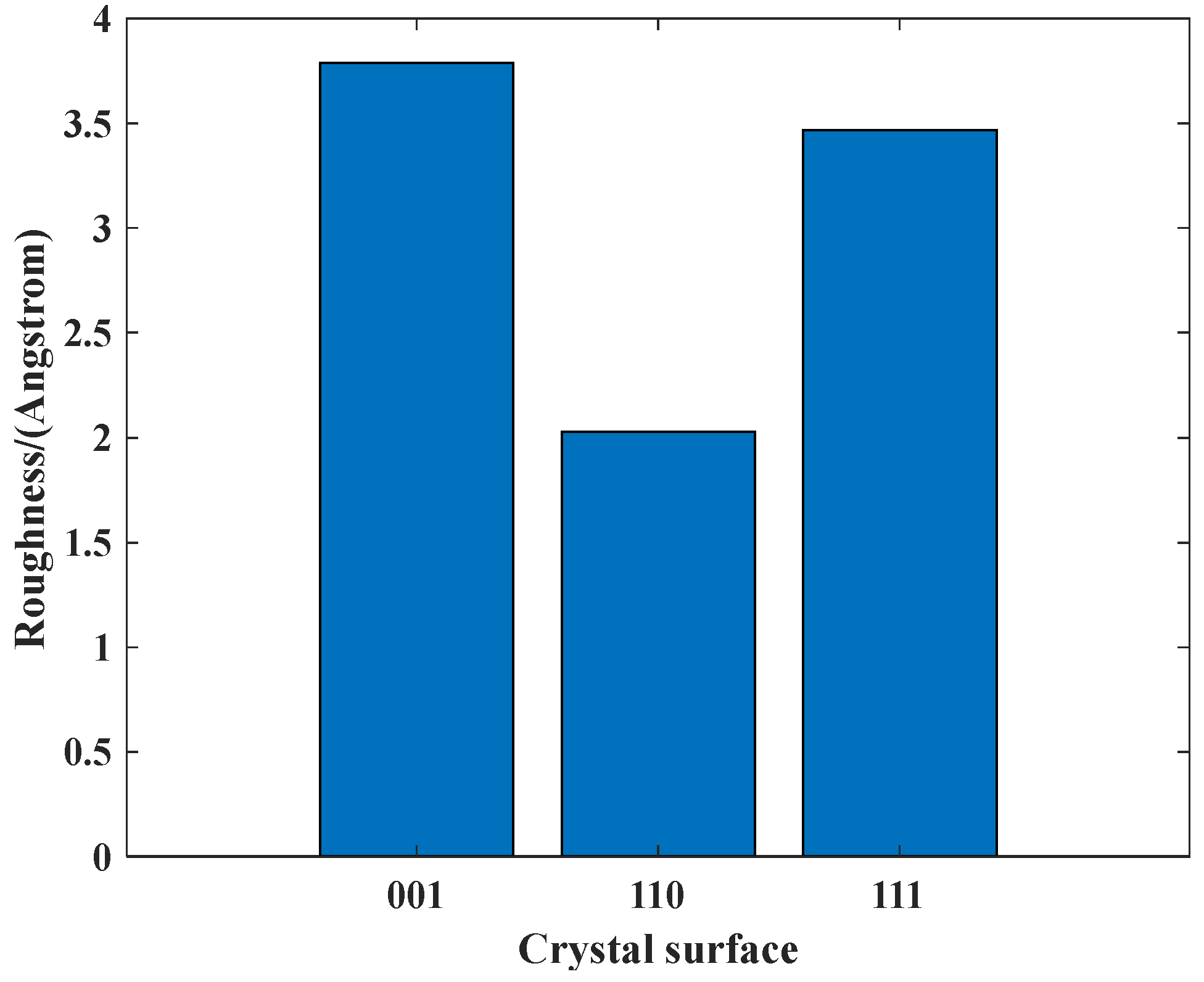

3.3. Surface Morphology and Roughness Evolution

3.4. Subsurface Damage and Machining Stress Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, Y.; Li, Z.; Liu, X.; Fang, F.Z. Freeform-objective Chernin multipass cell: Application of a freeform surface on assembly simplification. Appl. Opt. 2017, 56, 8541–8546. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Fang, F.; Zhang, X. Integrated manufacture of a freeform off-axis multi-reflective imaging system without optical alignment. Opt. Express 2018, 26, 7625–7637. [Google Scholar] [CrossRef]

- Wamboldt, L.; Roy, B.; Crifasi, J.; Stephens, S.; Hanninen, D.; Woodard, K.; Felock, R.; Polczwartek, S.; Parenteau, J. An ultra-low surface finish process for 6061-Al mirrors. Proc. SPIE 2015, 9451, 94511X1–94511X9. [Google Scholar]

- Ahn, Y.; Yoon, J.Y.; Baek, C.W.; Kim, Y.K. Chemical mechanical polishing by colloidal silica-based slurry for micro-scratch reduction. Wear 2004, 257, 785–789. [Google Scholar] [CrossRef]

- Harvey, J.E. Parametric analysis of the effect of scattered light upon the modulation transfer function. Opt. Eng. 2013, 52, 073110. [Google Scholar] [CrossRef]

- Dumas, P.; Golini, D.; Tricard, M. Improvement of figure and finish of diamond turned surfaces with magneto-rheological finishing. Proc. SPIE 2005, 5786, 296–304. [Google Scholar]

- Wang, Y.L.; Wu, J.; Liu, C.W.; Wang, T.C.; Dun, J.W. Material characteristics and chemical-mechanical polishing of aluminum alloy thin films. Thin Solid Film. 1998, 332, 397–403. [Google Scholar] [CrossRef]

- Drueding, T.W.; Bifano, T.G.; Fawcett, S.C. Contouring algorithm for ion figuring. Precis. Eng. 1995, 17, 10–21. [Google Scholar] [CrossRef]

- Weiser, M. Ion beam figuring for lithography optics. Nucl. Instrum. Methods Phys. Res. Sect. B 2009, 267, 1390–1393. [Google Scholar] [CrossRef]

- Yuan, Z.; Dai, Y.F.; Zhou, L.; Feng, S.R. Cleaning of iron powders embedded into the surface of KDP crystal by ion beam figuring. J. Synth. Cryst. 2013, 42, 582–586. [Google Scholar]

- Dai, Y.F.; Liao, W.L.; Zhou, L.; Chen, S.S.; Xie, X.X. Ion beam figuring of high-slope surfaces based on figure error compensation algorithm. Appl. Opt. 2010, 49, 6630–6636. [Google Scholar] [CrossRef]

- Bradley, R.M.; Harper, J.M.E. Theory of ripple topography induced by ion bombardment. J. Vac. Sci. Technol. A 1998, 6, 2390–2395. [Google Scholar] [CrossRef]

- Keller, A.; Facsko, S.; Moller, W. Evolution of ion-induced ripple patterns on SiO2 surfaces. Nucl. Instrum. Meth. B 2009, 267, 656–659. [Google Scholar] [CrossRef]

- Xu, M.J.; Dai, Y.F.; Zhou, L.; Peng, X.Q.; Chen, S.S.; Liao, W.L. Evolution mechanism of surface roughness during ion beam sputtering of fused silica. Appl. Opt. 2018, 57, 5566–5573. [Google Scholar] [CrossRef] [PubMed]

- Chkhalo, N.I.; Churin, S.A.; Mikhaylenko, M.S.; Pestov, A.E.; Polkovnikov, V.N.; Salashchenko, N.N.; Zorina, M.V. Ion-beam polishing of fused silica substrates for imaging soft x-ray and extreme ultraviolet optics. Appl. Opt. 2016, 55, 1249–1256. [Google Scholar] [CrossRef]

- Egert, C.M. Roughness evolution of optical materials induced by ion beam milling. Proc. SPIE 1992, 1752, 63–72. [Google Scholar]

- Du, C.Y.; Dai, Y.F.; Hu, H.; Guan, C.L. Surface Roughness Evolution Mechanism of Optical Aluminum 6061 Alloy during Low Energy Ar+ Ion Beam Sputtering. Opt. Express 2020, 28, 34054–34068. [Google Scholar] [CrossRef] [PubMed]

- Papanikolaou, M.; Salonitis, K. Fractal roughness effects on nanoscale grinding. Appl. Surf. Sci. 2019, 467, 309–319. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Xu, Z.; Wang, Y.; Gao, X.; Kong, R. Effect of ion implantation on material removal mechanism of 6H-SiC in nano-cutting: A molecular dynamics study. Comp. Mater. Sci. 2020, 174, 109476. [Google Scholar] [CrossRef]

- Chavoshi, S.Z.; Xu, S.; Luo, X. Dislocation-mediated plasticity in silicon during nanometric cutting: A molecular dynamics simulation study. Mat. Sci. Semicon. Proc. 2016, 519, 60–70. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.S.; Zhang, X.D.; Fang, F.Z.; Chen, R.T. Diamond cutting of micro-structure array on brittle material assisted by multi-ion implantation. Int. J. Mach. Tool. Manuf. 2019, 137, 58–66. [Google Scholar] [CrossRef]

- Xiao, Y.J.; Fang, F.Z.; Xu, Z.W.; Hu, X.T. Annealing recovery of nanoscale silicon surface damage caused by Ga focused ion beam. Appl. Surf. Sci. 2015, 343, 56–69. [Google Scholar] [CrossRef]

- Xiao, H.; Dai, Y.F.; Duan, J.; Tian, Y.; Li, J. Material removal and surface evolution of single crystal silicon during ion beam polishing. Appl. Surf. Sci. 2021, 544, 148954. [Google Scholar] [CrossRef]

- Turowski, M.; Jupé, M.; Melzig, T.; Pflug, A.; Ristau, D. Multiple scale modeling of Al2O3 thin film growth in an ion beam sputtering process. Proc. SPIE 2015, 27, 96271M. [Google Scholar]

- Tetsuya, O.; Kiyoshi, M.; Kenya, O. Molecular dynamics simulation of non-equilibrium low energy (1–100 eV) ion beam deposition processes. Nucl. Instrum. Meth. B 1994, 91, 593–596. [Google Scholar] [CrossRef]

- Mäkinen, J.; Vehanen, A.; Hautojärvi, P.; Huomo, H.; Nieminen, R.M.; Valkealahti, S. Vacancy-type defect distributions near argon sputtered Al(110) surface studied by variable-energy positrons and molecular dynamics simulations. Surf. Sci. 1986, 175, 385–414. [Google Scholar] [CrossRef]

- Pogorelko, V.V.; Krasnikov, V.S.; Mayer, A.E. High-speed collision of copper nanoparticles with aluminum surface: Inclined impact, interaction with roughness and multiple impact. Comp. Mater. Sci. 2018, 142, 108–121. [Google Scholar] [CrossRef]

- Pogorelko, V.V.; Mayer, A.E.; Krasnikov, V.S. High-speed collision of copper nanoparticle with aluminum surface: Molecular dynamics simulation. Appl. Surf. Sci. 2016, 390, 289–302. [Google Scholar] [CrossRef]

- Gen, I.; Rei, K.; Kimiya, K.; Hiroyuki, K. Incident angle dependence of reflected particles in low-energy xenon-ion impacts on metal surfaces. Comp. Mater. Sci. 2021, 186, 109989. [Google Scholar]

- Zhu, P.; Li, R. Study of nanoscale friction behaviors of graphene on gold substrates using molecular dynamics. Nano Res. Lett. 2018, 13, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Xu, Z.; Tian, D.; Hartmaier, A.; Luo, X.; Zhang, J.; Fang, F. MD simulation of stress-assisted nanometric cutting mechanism of 3C silicon carbide. Ind. Lubr. Tribol. 2019, 71, 686–691. [Google Scholar] [CrossRef]

- Li, B.; Li, J.; Zhu, P.; Xu, J.; Li, R.; Yu, J. Influence of crystal anisotropy on deformation behaviors in nanoscratching of AlN. Appl. Surf. Sci. 2019, 487, 1068–1076. [Google Scholar] [CrossRef]

- Tian, Y.Y.; Fang, Q.H.; Li, J. Molecular dynamics simulations for nanoindentation response of nanotwinned FeNiCrCoCu high entropy alloy. Nanotechnology 2020, 31, 465701. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.; Agrawal, A.; Reuben, R.L. Diamond machining of silicon: A review of advances in molecular dynamics simulation. Int. J. Mach. Tools Manuf. 2015, 88, 131–164. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Xu, Z.W.; Li, R.R.; Zhu, R.; Xu, J.; Zhao, J.L.; Wang, C.; Nordlund, K.; Fu, X.; Fang, F.Z. Molecular dynamics simulation of helium ion implantation into silicon and its migration. Nucl. Instrum. Methods Phys. Res. Sect. B. 2019, 456, 53–59. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.Y.; Feng, H.; Li, J.; Fang, Q.H.; Zhang, L.C. Nanoscale sliding friction behavior on Cu/Ag bilayers influenced by water film. Appl. Surf. Sci. 2021, 545, 148957. [Google Scholar] [CrossRef]

- Korsunsky, A.M.; Guenole, J.; Salvati, E.; Sui, T.; Mousavi, M.; Prakash, A. Quantifying eigenstrain distributions induced by focused ion beam damage in silicon. Mater. Lett. 2016, 185, 47–49. [Google Scholar] [CrossRef]

- Sheng, H.W.; Kramer, M.J.; Cadien, A.; Fujita, T.; Chen, M.W. Highly optimized embedded-atom-method potentials for fourteen fcc metals. Phys. Rev. B 2011, 83, 134118. [Google Scholar] [CrossRef] [Green Version]

- Wu, H.; Zhang, N.; He, M.; Shih, C.Y.; Zhu, X.N. Calculation of Argon-Aluminum Interatomic Potential and its application in molecular dynamics simulation of femtosecond laser ablation. Chin. J. Las. 2016, 43, 0802004. [Google Scholar]

| Material | Aluminum |

|---|---|

| Dimension | 15 × 15 × 38 nm3 |

| Number of atoms | 554,040 |

| Time step | 1 fs |

| Initial temperature | 293 k |

| Incident angle | 90° |

| Ion energy (Ion velocity) | 500 eV (491 Å/fs) |

| Lattice plane | (110) (111) (001) |

| Ion dose | 2.2 × 1013 ion/cm2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, C.; Dai, Y.; Guan, C.; Hu, H. Molecular Dynamic Investigation of the Anisotropic Response of Aluminum Surface by Ions Beam Sputtering. Micromachines 2021, 12, 848. https://doi.org/10.3390/mi12070848

Du C, Dai Y, Guan C, Hu H. Molecular Dynamic Investigation of the Anisotropic Response of Aluminum Surface by Ions Beam Sputtering. Micromachines. 2021; 12(7):848. https://doi.org/10.3390/mi12070848

Chicago/Turabian StyleDu, Chunyang, Yifan Dai, Chaoliang Guan, and Hao Hu. 2021. "Molecular Dynamic Investigation of the Anisotropic Response of Aluminum Surface by Ions Beam Sputtering" Micromachines 12, no. 7: 848. https://doi.org/10.3390/mi12070848

APA StyleDu, C., Dai, Y., Guan, C., & Hu, H. (2021). Molecular Dynamic Investigation of the Anisotropic Response of Aluminum Surface by Ions Beam Sputtering. Micromachines, 12(7), 848. https://doi.org/10.3390/mi12070848