Design and Implementation of Ultrasonic Impact Peening-Based Device for Stainless Steel Surface Texture Fabrication

Abstract

:1. Introduction

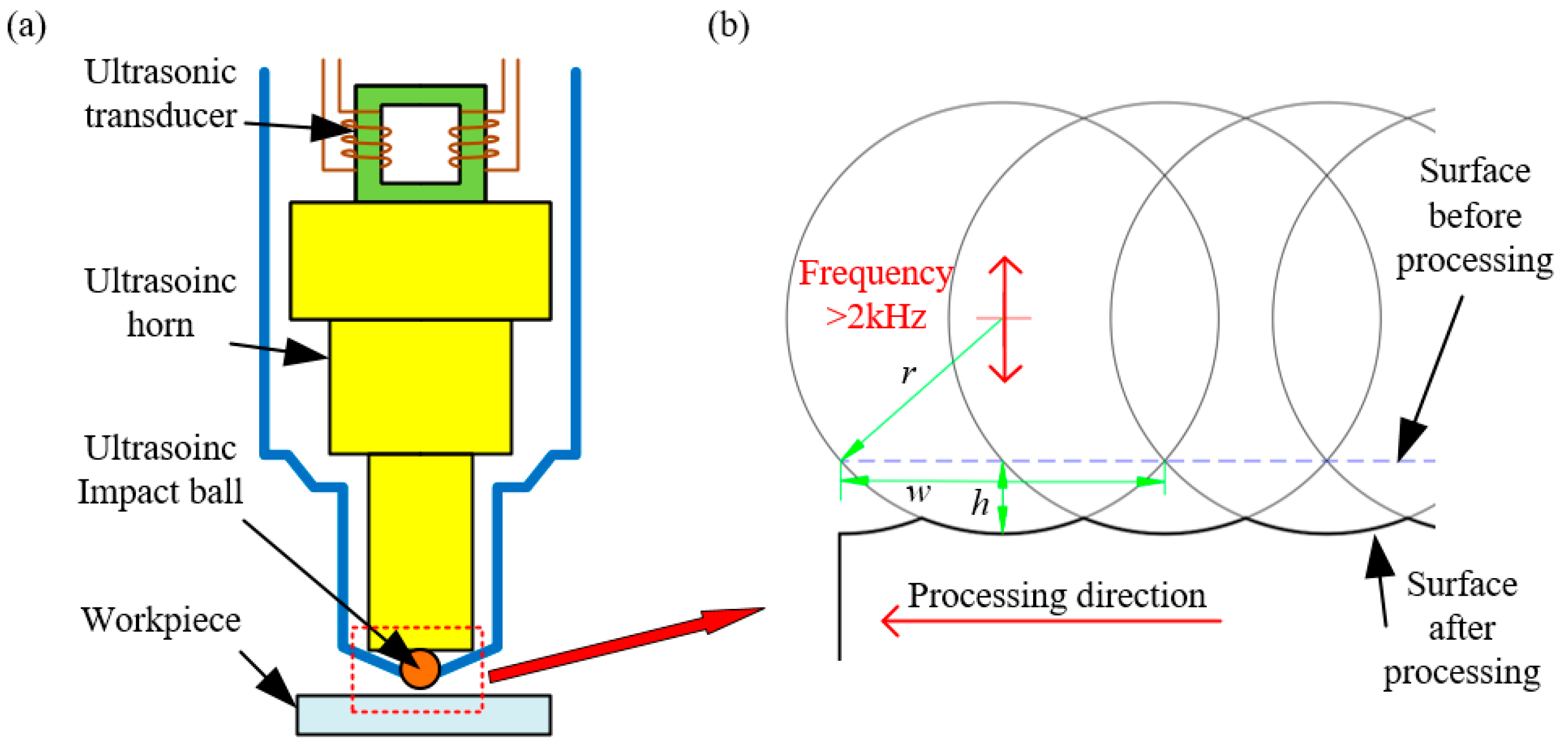

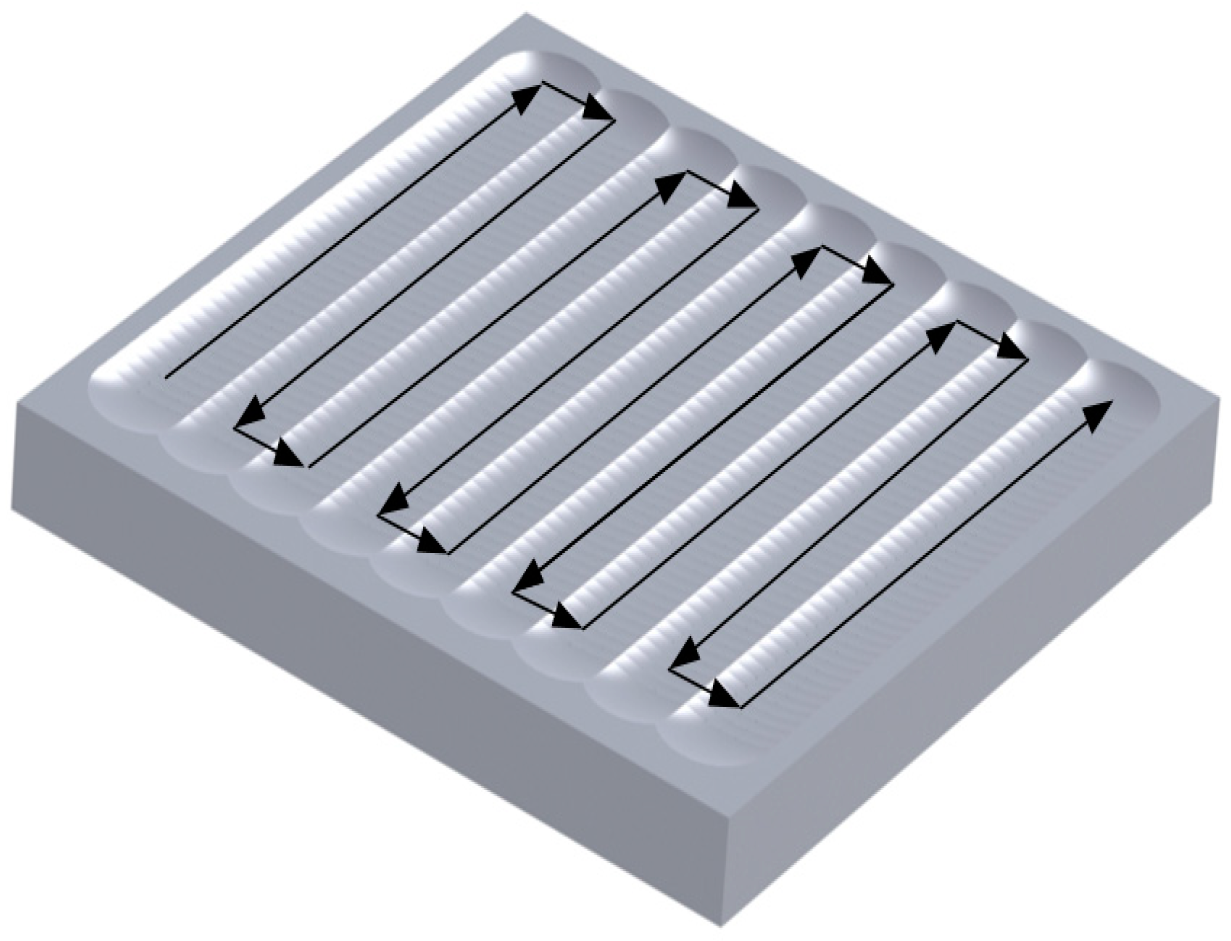

2. Principle of Surface Texture Fabrication Based on UIP

3. Design of UIP-Based Device for Surface Texture Fabrication

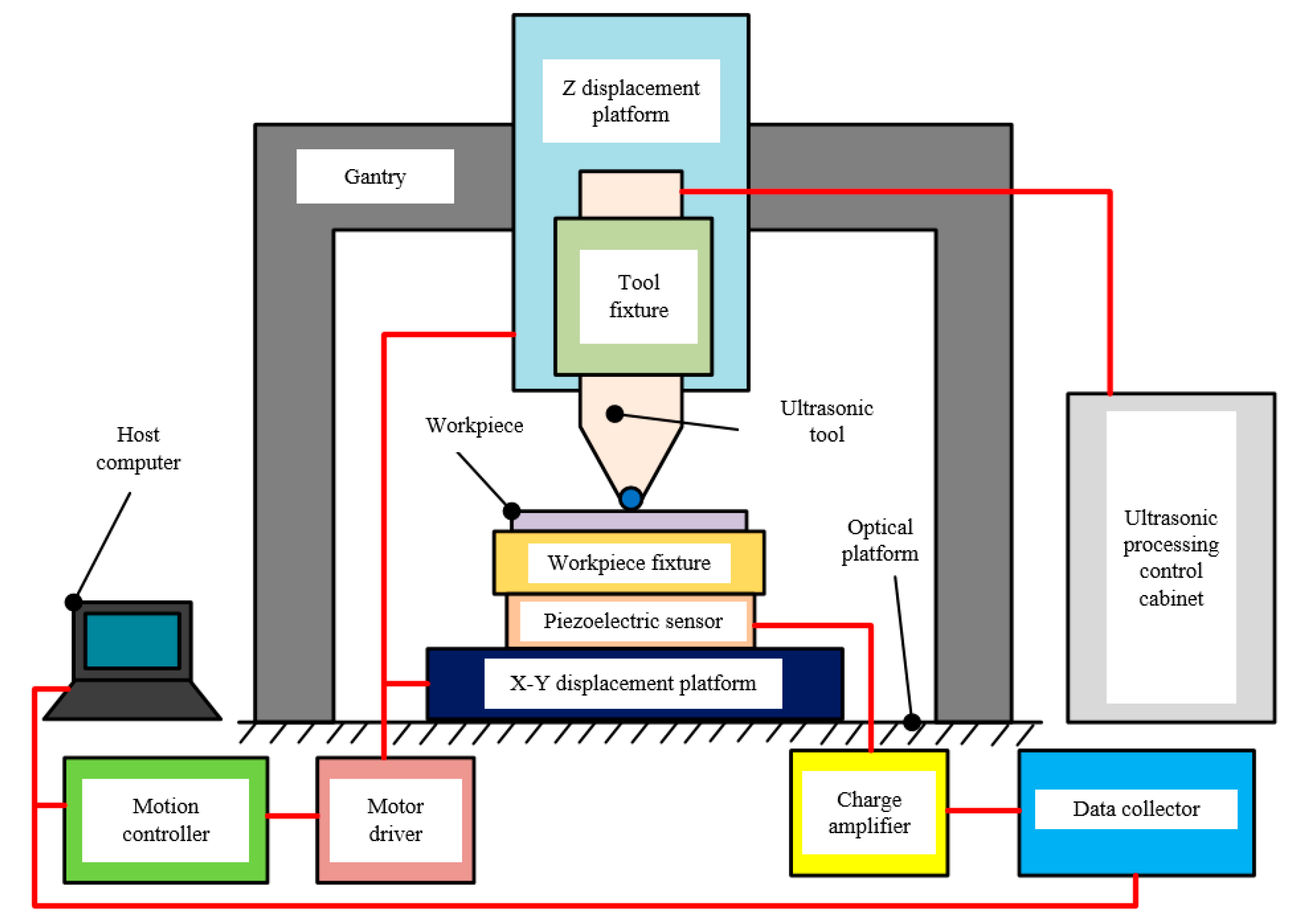

3.1. Configuration of the UIP-Based Device

3.2. Functional Systems of the UIP Device

3.2.1. Ultrasonic Impact Peening System

3.2.2. Motion Control System

3.2.3. Force Detection System

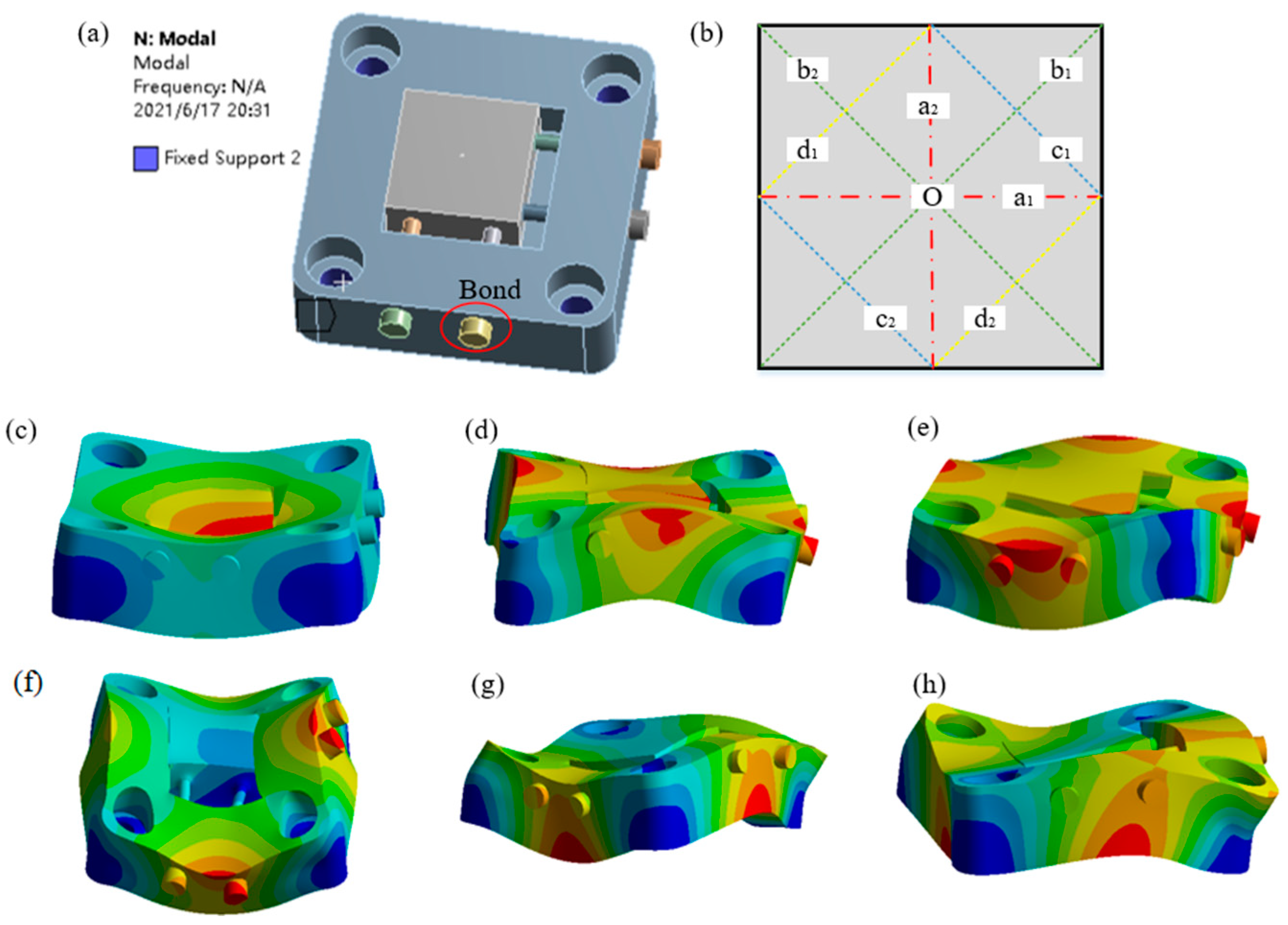

3.3. Mechanical Structures of UIP Device

3.3.1. Overall Layout of Mechanical Structures

3.3.2. Tool Fixture

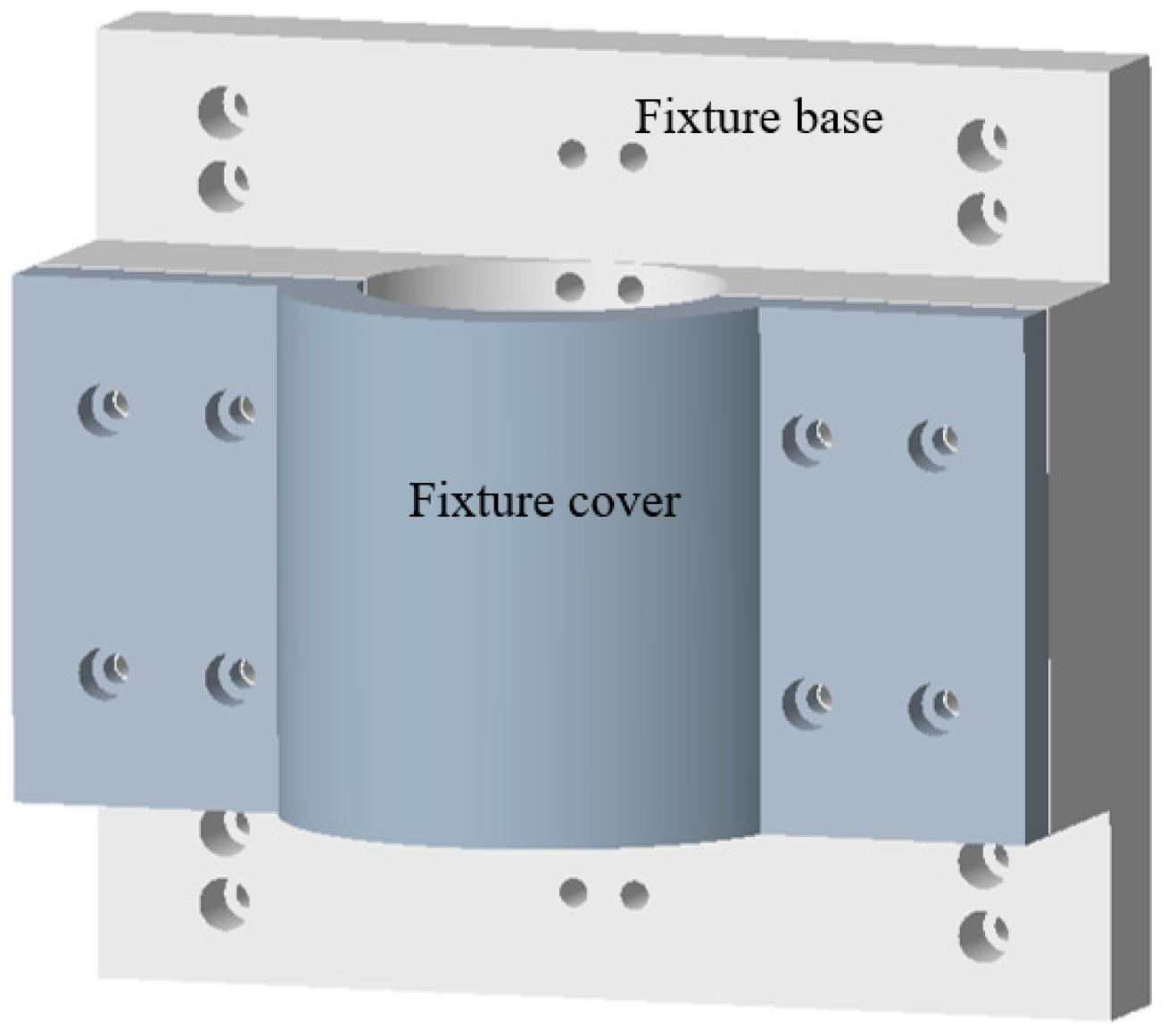

3.3.3. Workpiece Fixture

4. Surface Texture Fabrication Experiment by UIP

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- De las Herasa, E.; Egidi, D.A.; Corengia, P.; González-Santamaría, D.; García-Luis, A.; Brizuela, M.; López, G.A.; FloresMartinez, M. Duplex surface treatment of an AISI 316L stainless steel; microstructure and tribological behavior. Surf. Coat. Technol. 2008, 202, 2945–2954. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372, 21–41. [Google Scholar] [CrossRef]

- Meng, R.; Deng, J.X.; Duan, R.; Liu, Y.Y.; Zhang, G.L. Modifying tribological performances of AISI 316 stainless steel surfaces by laser surface texturing and various solid lubricants. Opt. Laser Technol. 2019, 109, 401–411. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Heib, T.; Gachot, C.; Mücklich, F. Oil film lifetime and wear particle analysis of laser-patterned stainless steel surfaces. Wear 2015, 334, 1–12. [Google Scholar] [CrossRef]

- Dunn, A.; Wlodarczyk, K.L.; Carstensen, J.V.; Hansen, E.B.; Gabzdyl, J.; Harrison, P.M.; Shephard, J.D.; Hand, D.P. Laser surface texturing for high friction contacts. Appl. Surf. Sci. 2015, 357, 2313–2319. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Verma, R.; Kango, S.; Sharma, V.S. Recent progresses and applications in Laser-based surface texturing systems. Mater. Today Commun. 2021, 26, 101736. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, D.; Mishra, S.K.; Tiwari, S.K. Laser cladding of Stellite 6 on stainless steel to enhance solid particle erosion and cavitation resistance. Surf. Coat. Technol. 2014, 251, 87–97. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.L.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Tran, N.G.; Chun, D.M. Simple and fast surface modification of nanosecond-pulse laser-textured stainless steel for robust superhydrophobic surfaces. CIRP Ann. 2020, 69, 525–528. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Gläbe, R.; Schönemann, L. Review on diamond-machining processes for the generation of functional surface structures. CIRP J. Manuf. Sci. Technol. 2012, 5, 1–7. [Google Scholar] [CrossRef]

- Sierra, D.R.; Edwardson, S.P.; Dearden, G. Laser surface texturing of titanium with thermal post-processing for improved wettability properties. Procedia CIRP 2018, 74, 362–366. [Google Scholar] [CrossRef]

- Kumaravelu, G.; Alkaisi, M.M.; Bittar, A.; Macdonald, D.; Zhao, J. Damage studies in dry etched textured silicon surfaces. Curr. Appl. Phys. 2004, 4, 108–110. [Google Scholar] [CrossRef]

- Cui, C.; Duan, X.L.; Collier, B.; Poduska, K.M. Fabrication and Wettability Analysis of Hydrophobic Stainless Steel Surfaces With Microscale Structures From Nanosecond Laser Machining. J. Micro Nano Manuf. 2018, 6, 031006. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.B.; Bai, F.; Wang, C.W.; Zhao, Q.Z. Angle-dependent lubricated tribological properties of stainless steel by femtosecond laser surface texturing. Opt. Laser Technol. 2016, 81, 60–66. [Google Scholar] [CrossRef]

- Jaeggi, B.; Neuenschwander, B.; Schmid, M.; Muralt, M.; Zuercher, J.; Hunziker, U. Influence of the Pulse Duration in the ps-Regime on the Ablation Efficiency of Metals. Phys. Procedia 2011, 12, 164–171. [Google Scholar] [CrossRef] [Green Version]

- Hirayama, Y.; Obara, M. Heat-affected zone and ablation rate of copper ablated with femtosecond laser. J. Appl. Phys. 2005, 97, 064903. [Google Scholar] [CrossRef]

- Shang, Q.; Yu, A.B.; Wu, J.Z.; Shi, C.C.; Niu, W.Y. Influence of heat affected zone on tribological properties of CuSn6 bronze laser dimple textured surface. Tribol. Int. 2017, 105, 158–165. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Liu, L.L.; Deng, J.X.; Meng, R.; Zou, X.Q.; Wu, F.F. Fabrication of micro-scale textured grooves on green ZrO2 ceramics by pulsed laser ablation. Ceram. Int. 2017, 43, 6519–6531. [Google Scholar] [CrossRef]

- Jarosz, K.; Löschner, P.; Niesłony, P. Effect of Cutting Speed on Surface Quality and Heat-affected Zone in Laser Cutting of 316L Stainless Steel. Procedia Eng. 2016, 149, 155–162. [Google Scholar] [CrossRef] [Green Version]

- Brinksmeier, E.; Schönemann, L. Generation of discontinuous microstructures by Diamond Micro Chiseling. CIRP Ann. 2014, 63, 49–52. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Riemer, O.; Gläbe, R.; Lünemann, B.; Kopylow, C.V.; Dankwart, C.; Meier, A. Submicron functional surfaces generated by diamond machining. CIRP Ann. 2010, 59, 535–538. [Google Scholar] [CrossRef]

- Zhang, J.J.; Zhang, J.G.; Rosenkranz, A.; Zhao, X.L.; Song, Y.L. Surface Textures Fabricated by Laser Surface Texturing and Diamond Cutting—Influence of Texture Depth on Friction and Wear. Adv. Eng. Mater. 2018, 20, 1700995. [Google Scholar] [CrossRef]

- Zhang, S.J.; Zhou, Y.P.; Zhang, H.J.; Xiong, Z.W.; To, S. Advances in ultra-precision machining of micro-structured functional surfaces and their typical applications. Int. J. Mach. Tools Manuf. 2019, 142, 16–41. [Google Scholar] [CrossRef]

- Zhu, Z.W.; To, S.; Tong, Z.; Zhuang, Z.X.; Jiang, X.Q. Modulated diamond cutting for the generation of complicated micro/nanofluidic channels. Precis. Eng. 2019, 56, 136–142. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.G.; Zhang, J.J.; Rosenkranz, A.; Suzuki, N.; Shamoto, E. Frictional properties of surface textures fabricated on hardened steel by elliptical vibration diamond cutting. Precis. Eng. 2019, 59, 66–72. [Google Scholar] [CrossRef]

- Kinoshita, K.; Imamura, A.; Watanabe, Y.; Handa, M. Effects of ultrasonic peening on fatigue strength of out-of-plane gusset joints. Int. J. Steel Struct. 2014, 14, 769–776. [Google Scholar] [CrossRef]

- Zhao, X.H.; Wang, M.Y.; Zhang, Z.Q.; Liu, Y. The effect of ultrasonic peening treatment on fatigue performance of welded joints. Materials 2016, 9, 471. [Google Scholar] [CrossRef] [Green Version]

- Roy, S.; Fisher, J.W.; Yen, B.T. Fatigue resistance of welded details enhanced by ultrasonic impact treatment (UIT). Int. J. Fatigue 2003, 25, 1239–1247. [Google Scholar] [CrossRef]

- Galtier, A.; Statnikov, E.S. The Influence of Ultrasonic Impact Treatment on Fatigue Behaviour of Welded Joints in High-Strength Steel. Weld. World 2004, 48, 61–66. [Google Scholar] [CrossRef]

- Statnikov, E.S.; Muktepavel, V.O.; Blomqvist, A. Comparison of Ultrasonic Impact Treatment (UIT) and Other Fatigue Life Improvement Methods. Weld. World 2002, 46, 20–32. [Google Scholar] [CrossRef]

- Malaki, M.; Ding, H.T. A review of ultrasonic peening treatment. Mater. Des. 2015, 87, 1072–1086. [Google Scholar] [CrossRef]

- Ye, C.; Telang, A.; Gill, A.S.; Suslov, S.; Idell, Y.; Zweiacker, K.; Wiezorek, J.M.K.; Zhou, Z.; Qian, D.; Mannava, S.R.; et al. Gradient nanostructure and residual stresses induced by Ultrasonic Nano-crystal Surface Modification in 304 austenitic stainless steel for high strength and high ductility. Mater. Sci. Eng. A 2014, 613, 274–288. [Google Scholar] [CrossRef] [Green Version]

- Fan, Z.; Xu, H.; Li, D.; Zhang, L.; Liao, L.B. Surface Nanocrystallization of 35# Type Carbon Steel Induced by Ultrasonic Impact Treatment (UIT). Procedia Eng. 2012, 27, 1718–1722. [Google Scholar]

- Yang, X.J.; Wang, X.Y.; Ling, X.; Wang, D.X. Enhanced mechanical behaviors of gradient nano-grained austenite stainless steel by means of ultrasonic impact treatment. Results Phys. 2017, 7, 1412–1421. [Google Scholar] [CrossRef]

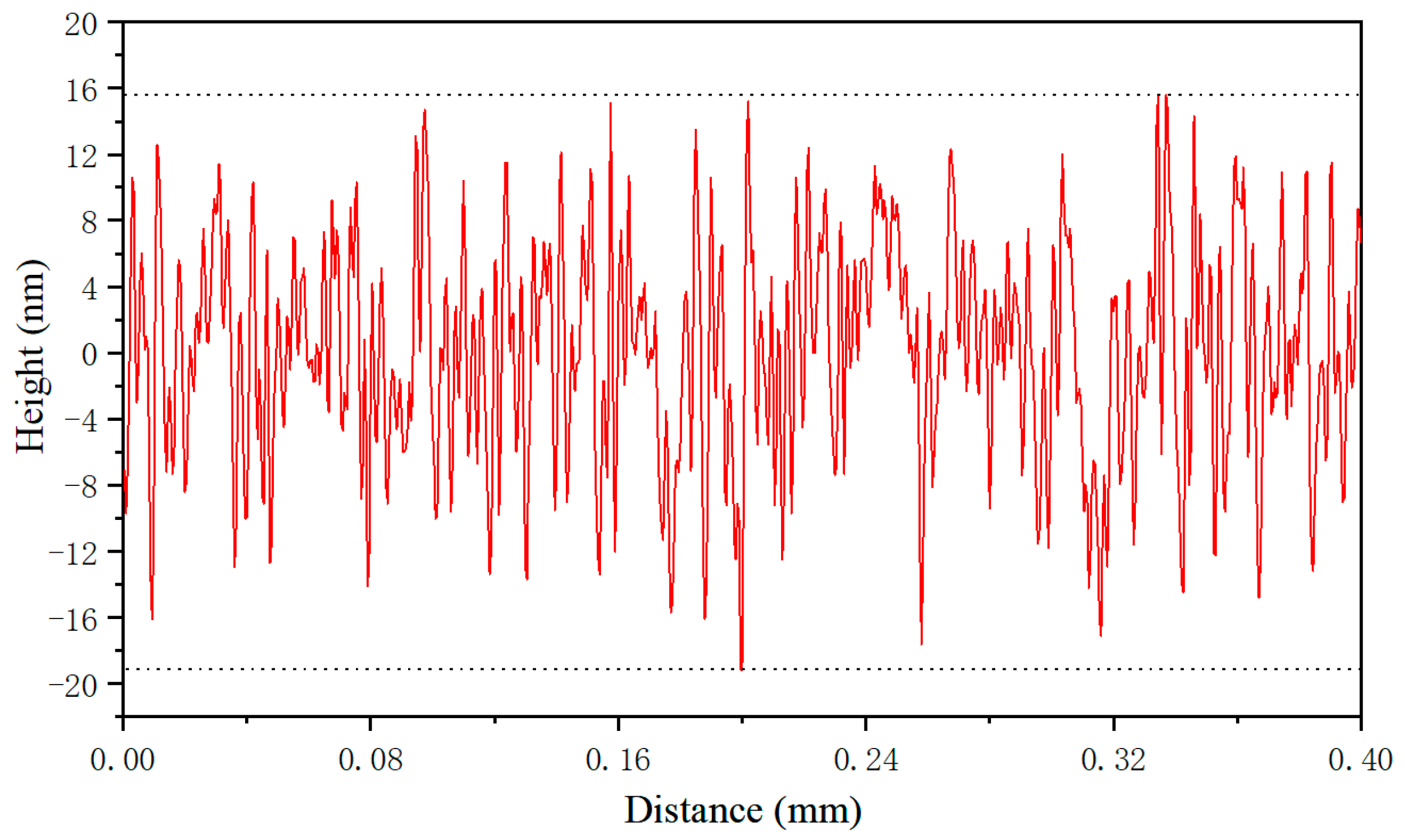

- Zhao, X.S.; Zhao, D.X.; Hu, W.J.; Zhang, J.J.; Wang, X.H.; Zhang, J.G.; Sun, T. Manufacturing of high-precision surface micro-structures on stainless steel by ultrasonic impact peening. Int. J. Adv. Manuf. Technol. 2021, Accepted. [Google Scholar]

| Mode Order | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Frequency (Hz) | 16,779 | 23,367 | 23,631 | 24,942 | 25,907 | 25,929 |

| Parameter | Value |

|---|---|

| Frequency (kHz) | 25 |

| Amplitude (μm) | 6 |

| Feed speed of workpiece (m/min) | 2 |

| Feed depth of tool (μm) | 6 |

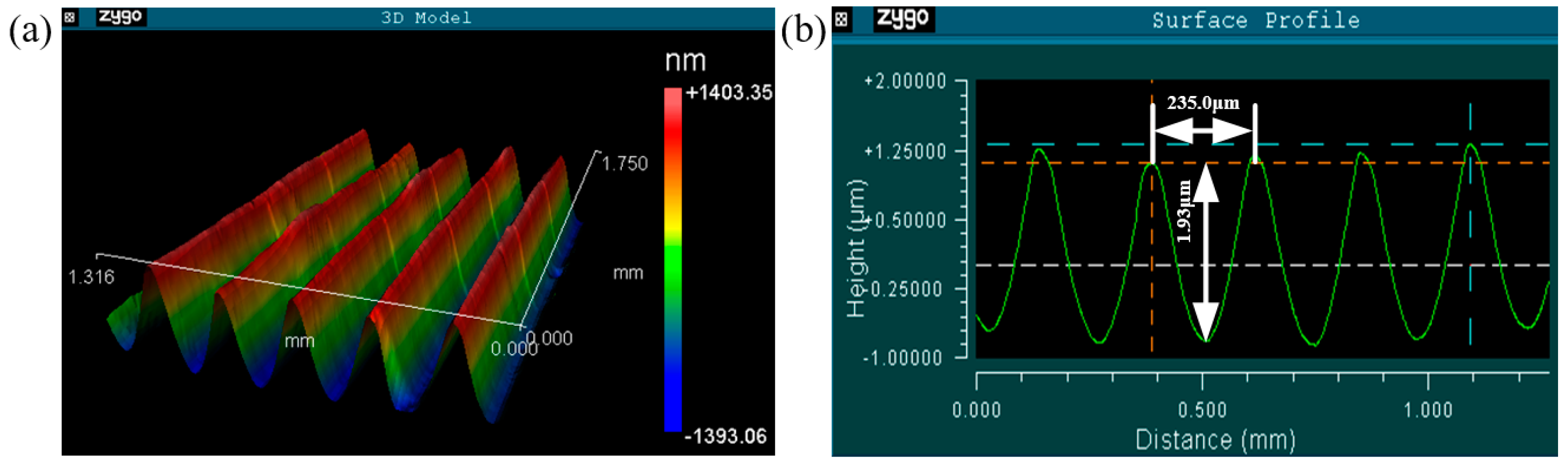

| Width periodicity of array microgroove (μm) | 240 |

| Diameter of impact ball (mm) | 6 |

| Sampling Area NO. | Width Periodicity (μm) | Depth (μm) |

|---|---|---|

| 1 | 240.7 | 2.10 |

| 2 | 235.0 | 1.93 |

| 3 | 240.8 | 1.80 |

| 4 | 240.0 | 2.12 |

| 5 | 239.7 | 2.14 |

| 6 | 236.8 | 2.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, W.; Zhang, Q.; Wang, X.; Zhao, D.; Hu, Z.; Zhao, X.; Shao, H.; Men, X.; Sun, T. Design and Implementation of Ultrasonic Impact Peening-Based Device for Stainless Steel Surface Texture Fabrication. Micromachines 2021, 12, 787. https://doi.org/10.3390/mi12070787

Hu W, Zhang Q, Wang X, Zhao D, Hu Z, Zhao X, Shao H, Men X, Sun T. Design and Implementation of Ultrasonic Impact Peening-Based Device for Stainless Steel Surface Texture Fabrication. Micromachines. 2021; 12(7):787. https://doi.org/10.3390/mi12070787

Chicago/Turabian StyleHu, Wangjie, Qiang Zhang, Xiaohui Wang, Dongxu Zhao, Zhenjiang Hu, Xuesen Zhao, Haiyan Shao, Xiuhua Men, and Tao Sun. 2021. "Design and Implementation of Ultrasonic Impact Peening-Based Device for Stainless Steel Surface Texture Fabrication" Micromachines 12, no. 7: 787. https://doi.org/10.3390/mi12070787

APA StyleHu, W., Zhang, Q., Wang, X., Zhao, D., Hu, Z., Zhao, X., Shao, H., Men, X., & Sun, T. (2021). Design and Implementation of Ultrasonic Impact Peening-Based Device for Stainless Steel Surface Texture Fabrication. Micromachines, 12(7), 787. https://doi.org/10.3390/mi12070787