Numerical Evaluation on Residual Thermal Stress-Induced Delamination at PDMS–Metal Interface of Neural Prostheses

Abstract

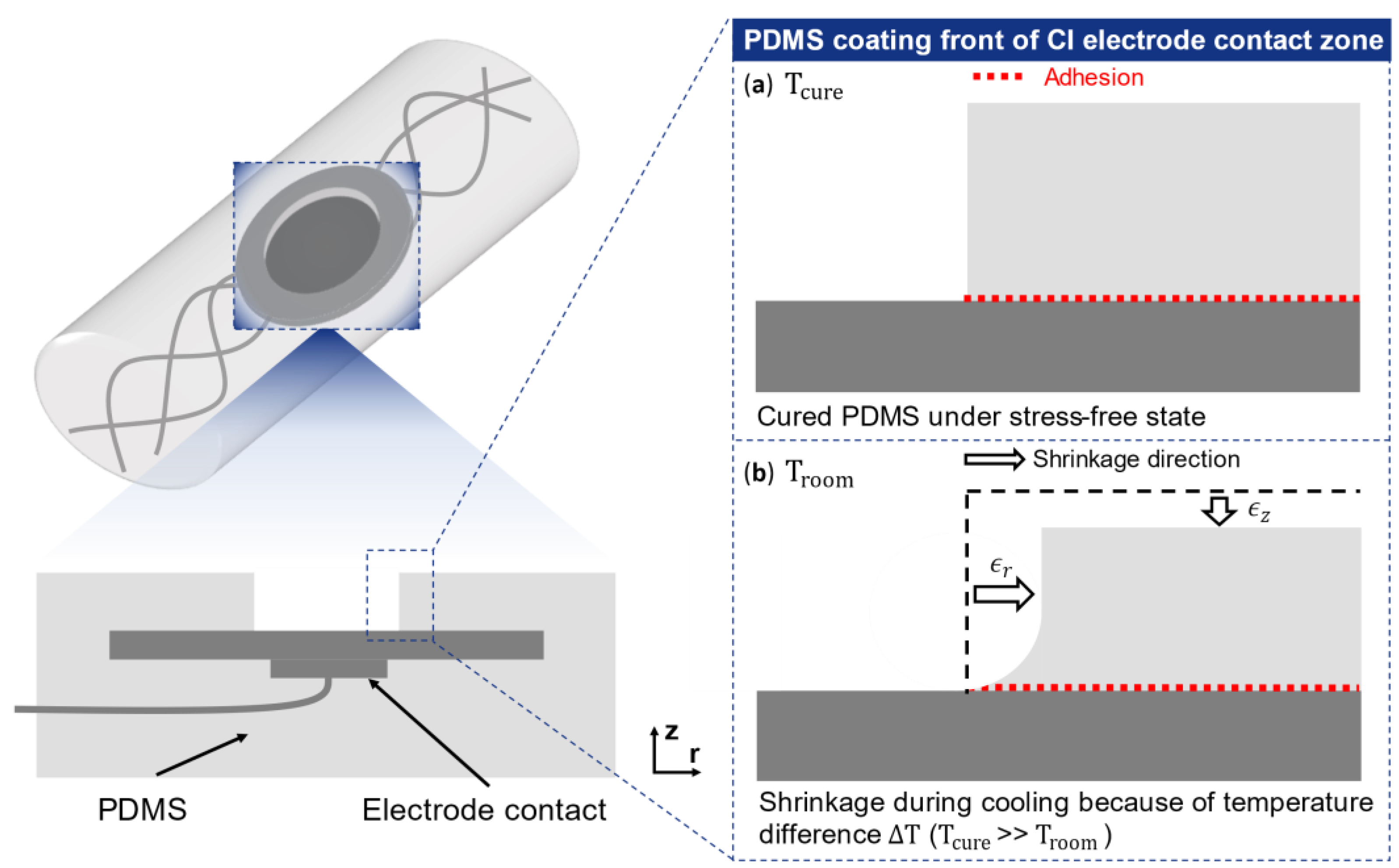

1. Introduction

2. Materials and Methods

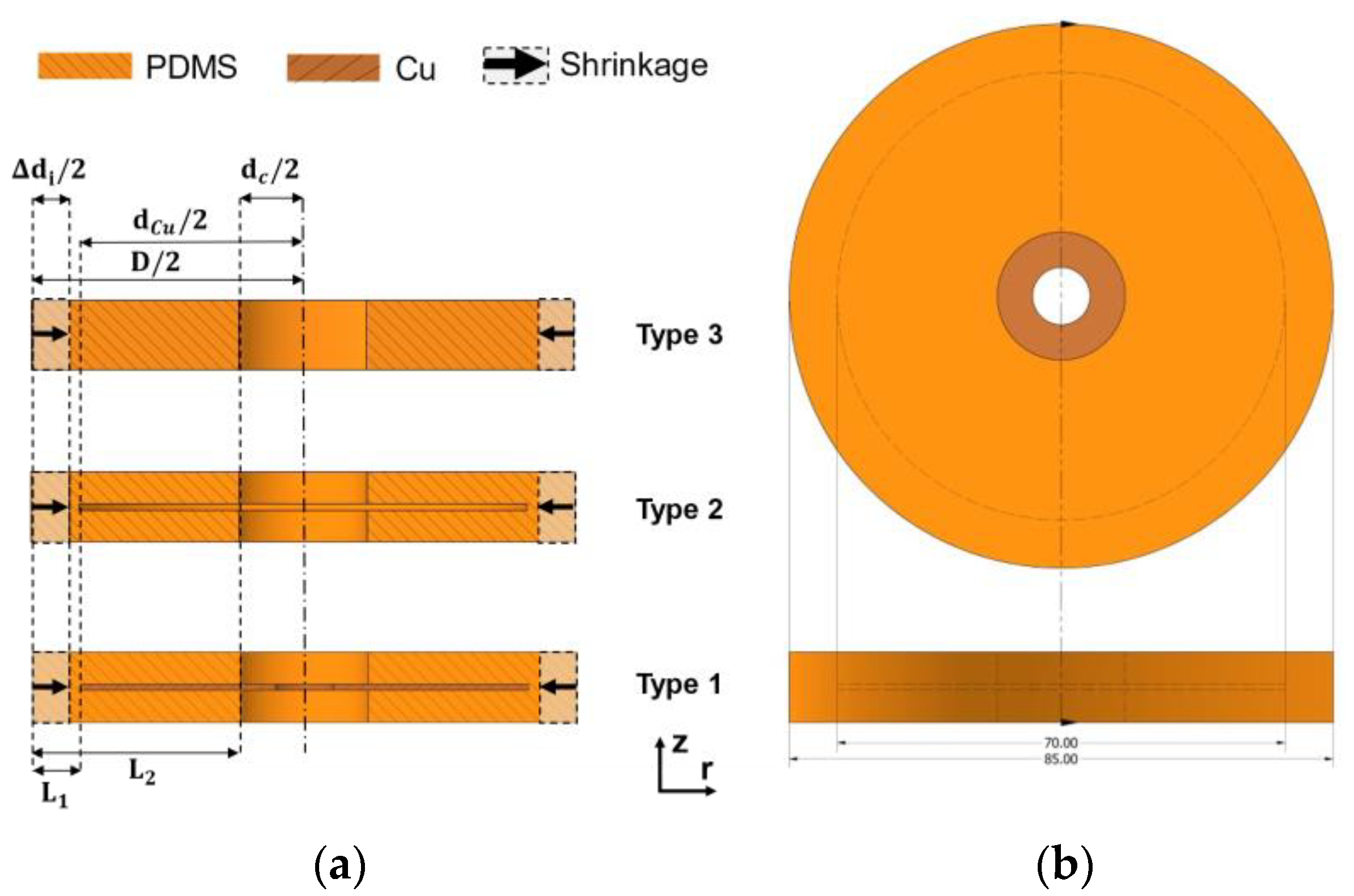

2.1. Test Specimen Fabrication

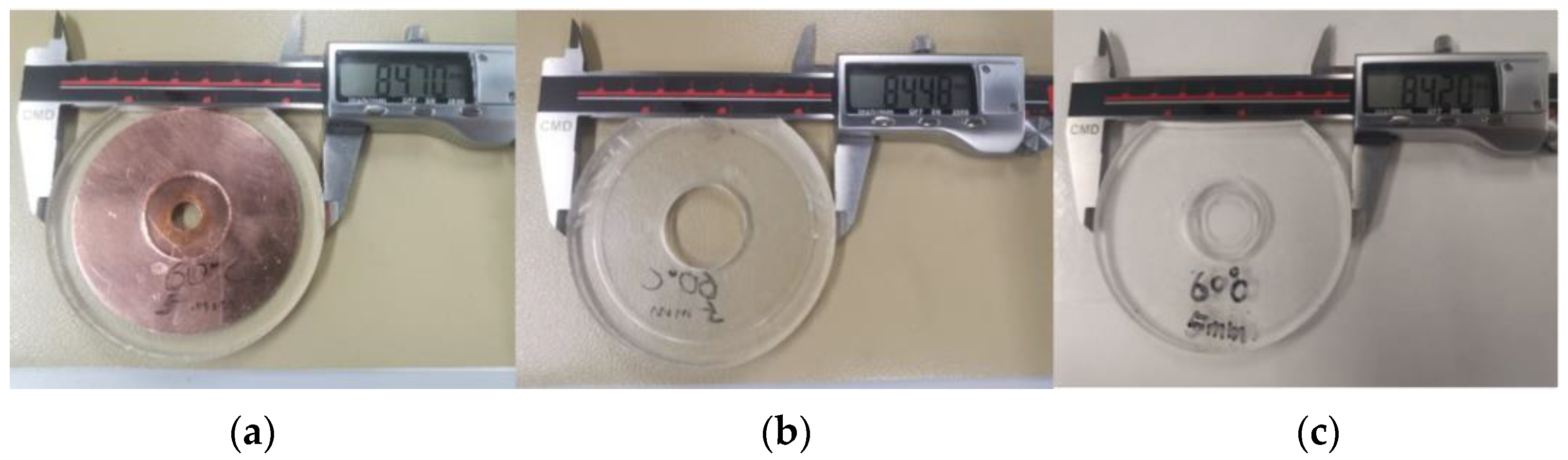

2.2. Shrinkage Measurement Experiment

2.3. Modified Thermal Shrinkage Model for Correlation

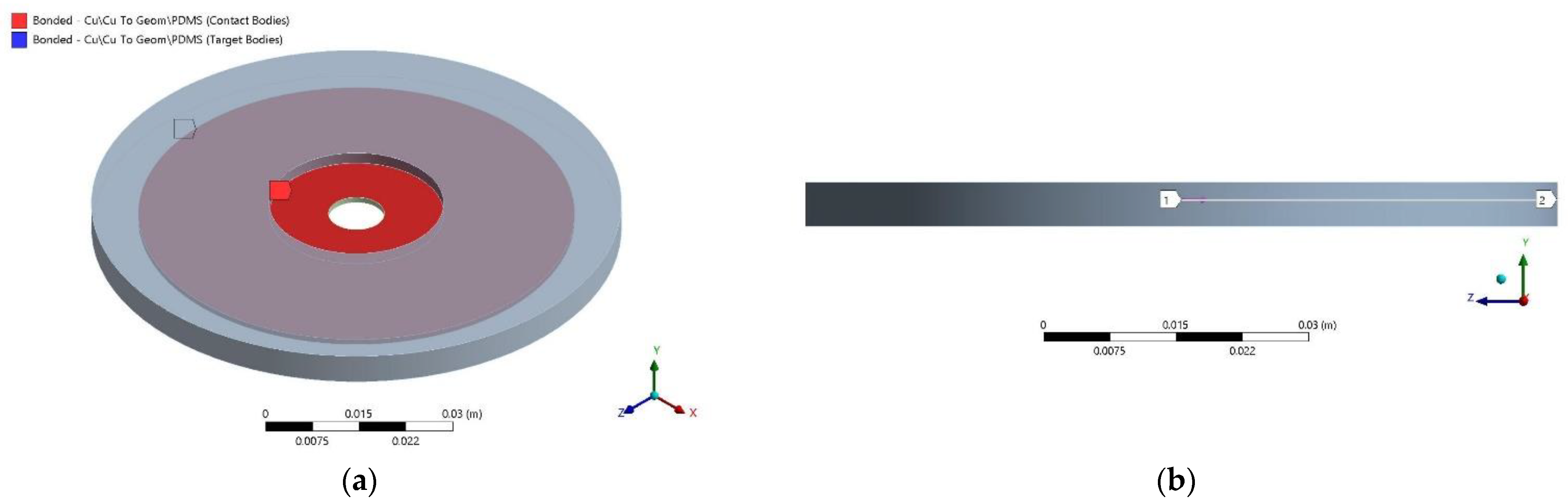

2.4. Finite Element Method (FEM) Simulations

- Creation of the finite element model and perform the thermal simulation.

- Definition of the boundary and contact constraints and thermal simulation results as inputs for mechanical simulation.

- Post-processing and evaluation of the simulation results.

3. Results and Discussions

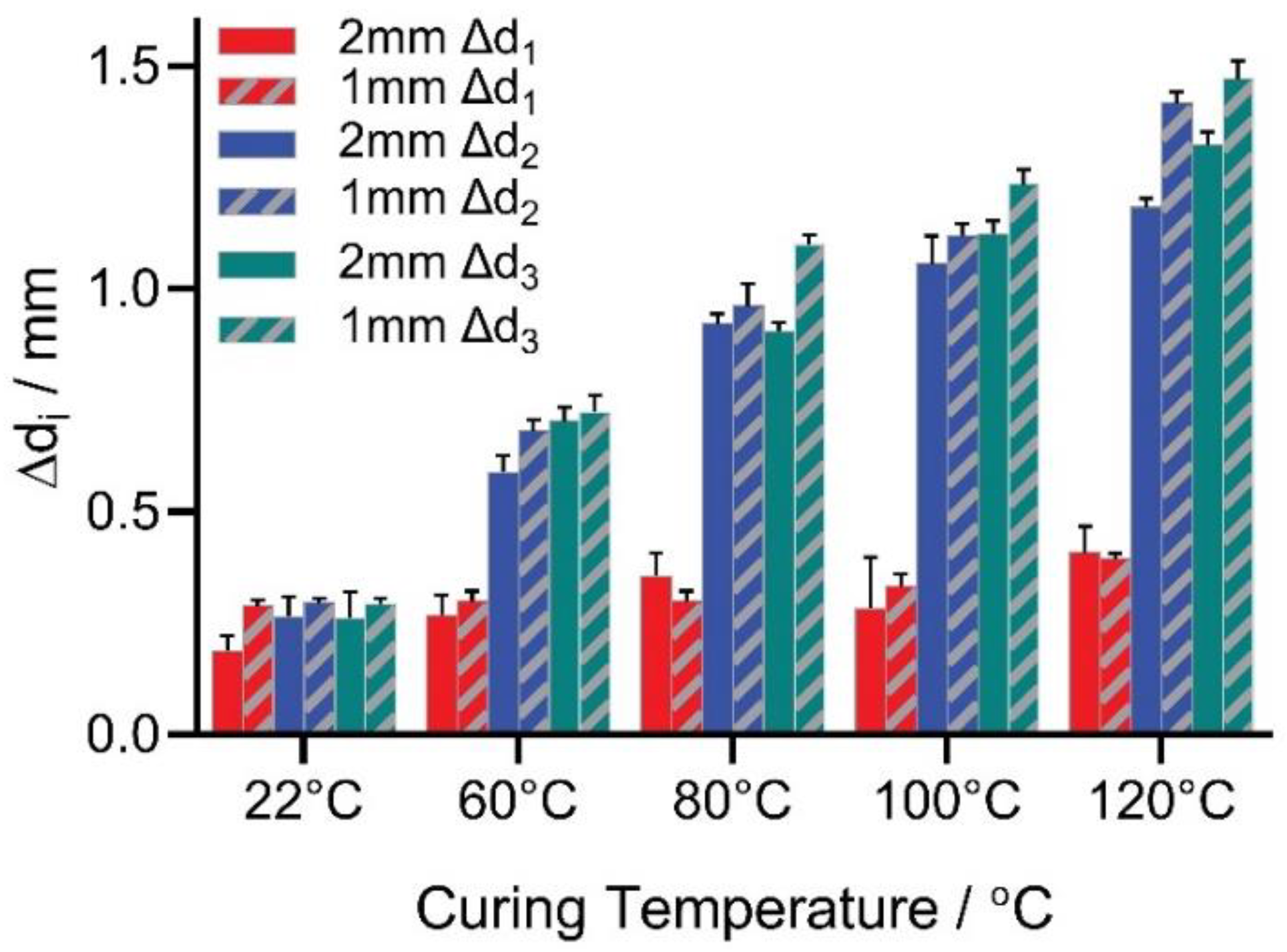

3.1. PDMS Lateral Shrinkage

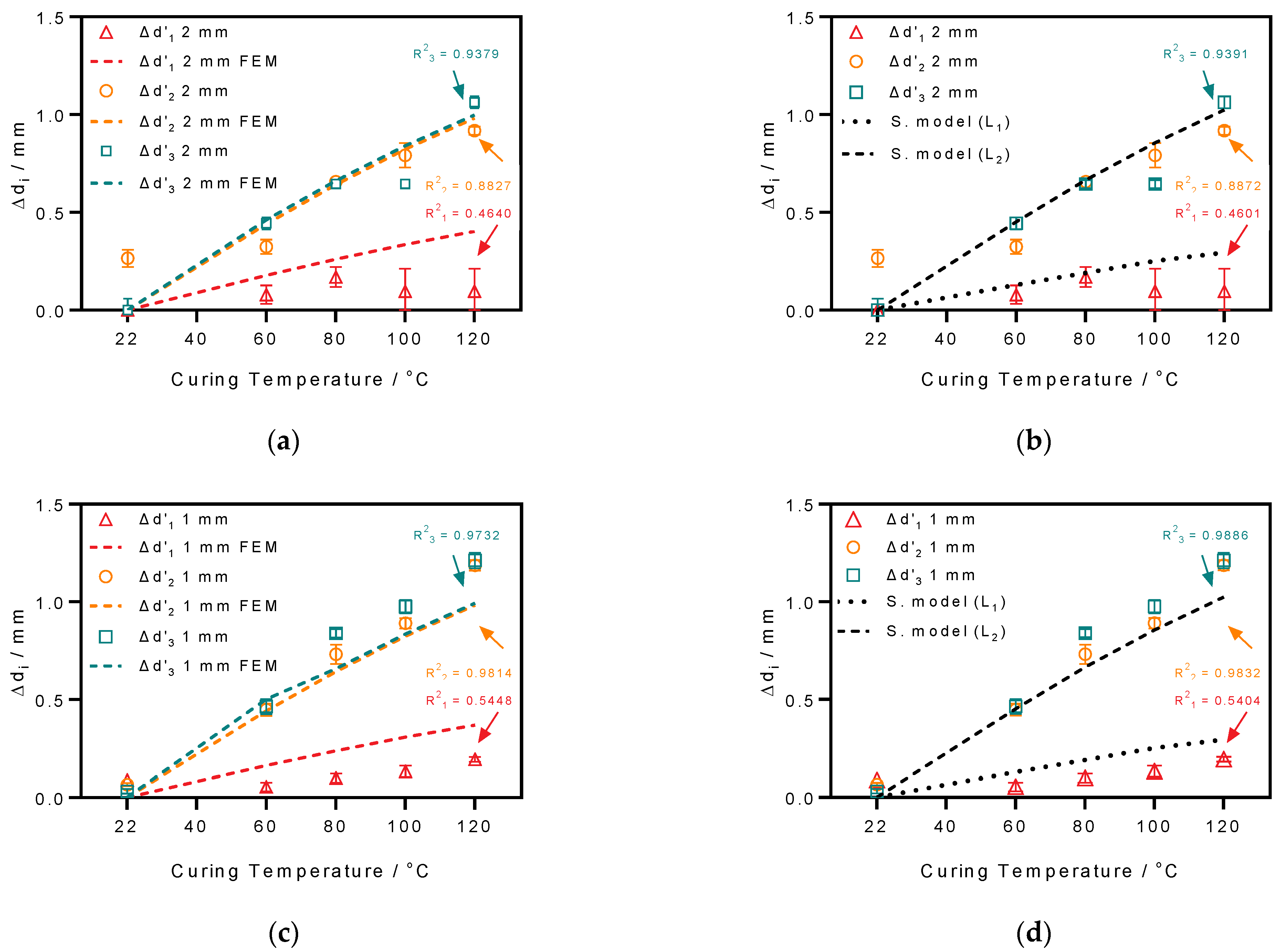

3.2. Validation of the Shrinkage Measurement Results

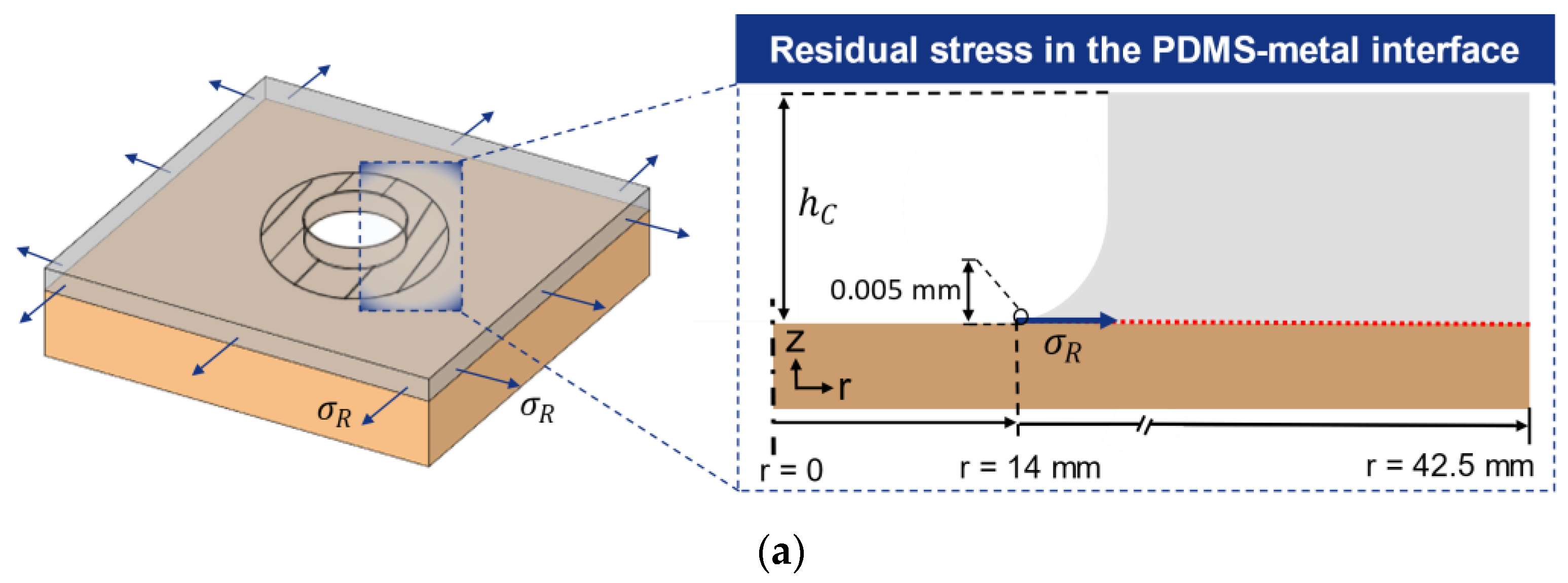

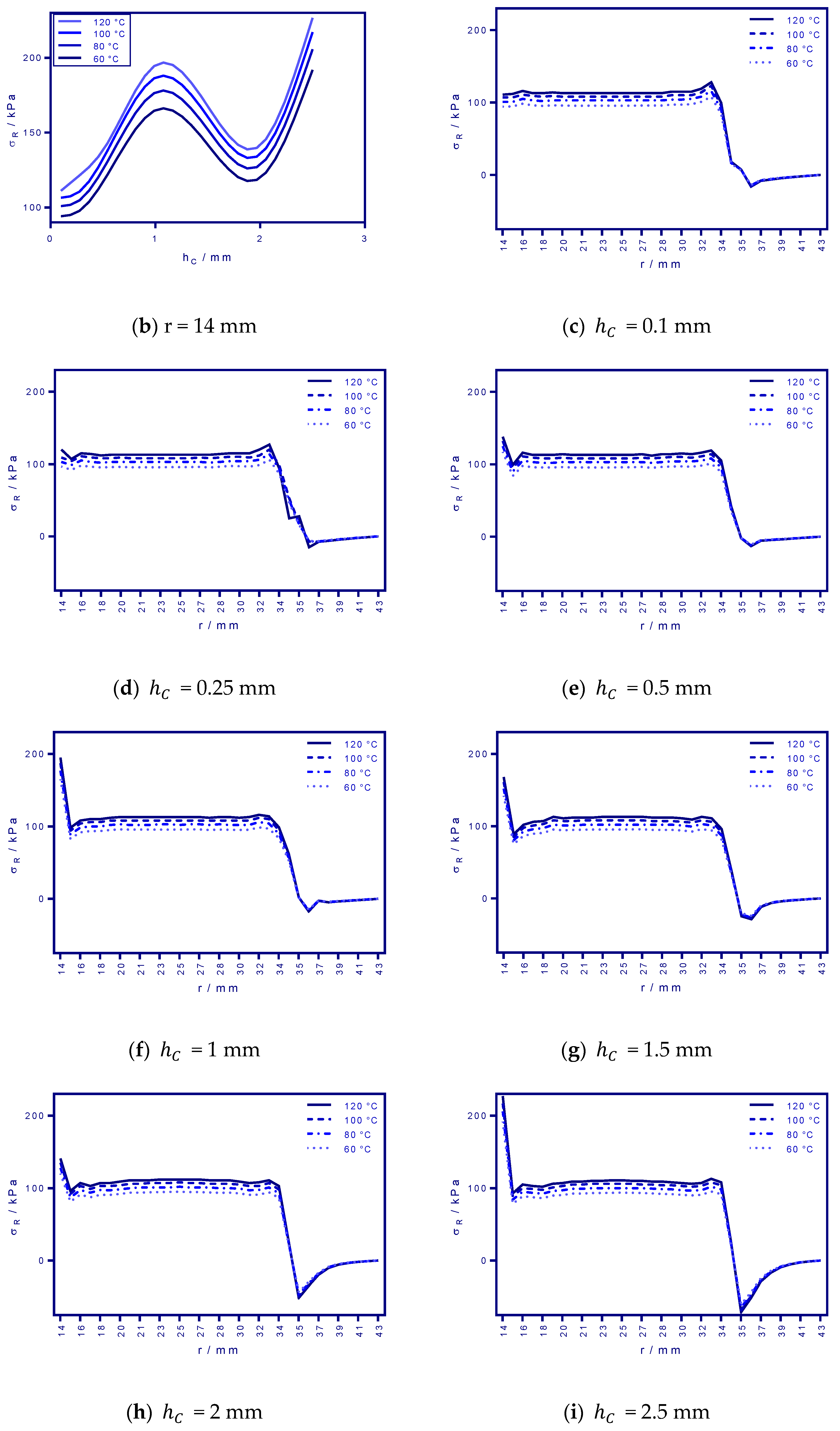

3.3. Simulated In-Plane Residual Stress Distribution in PDMS-Metal Interface

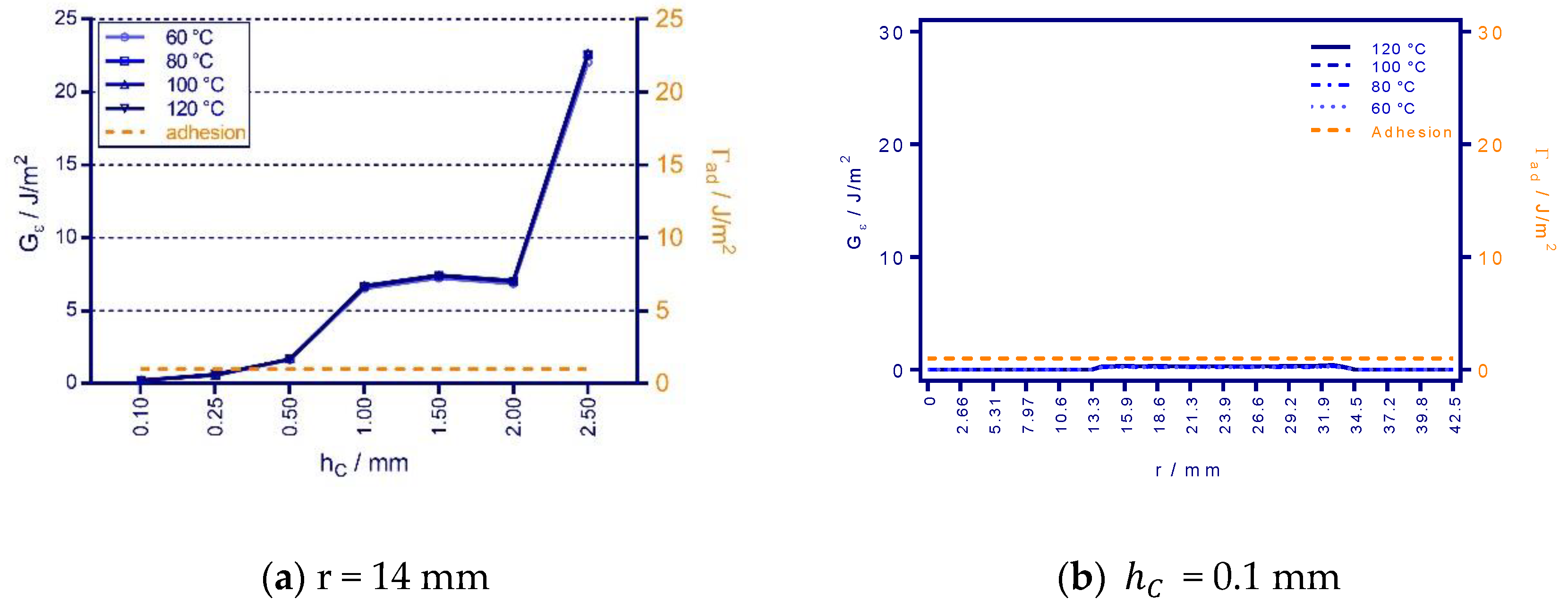

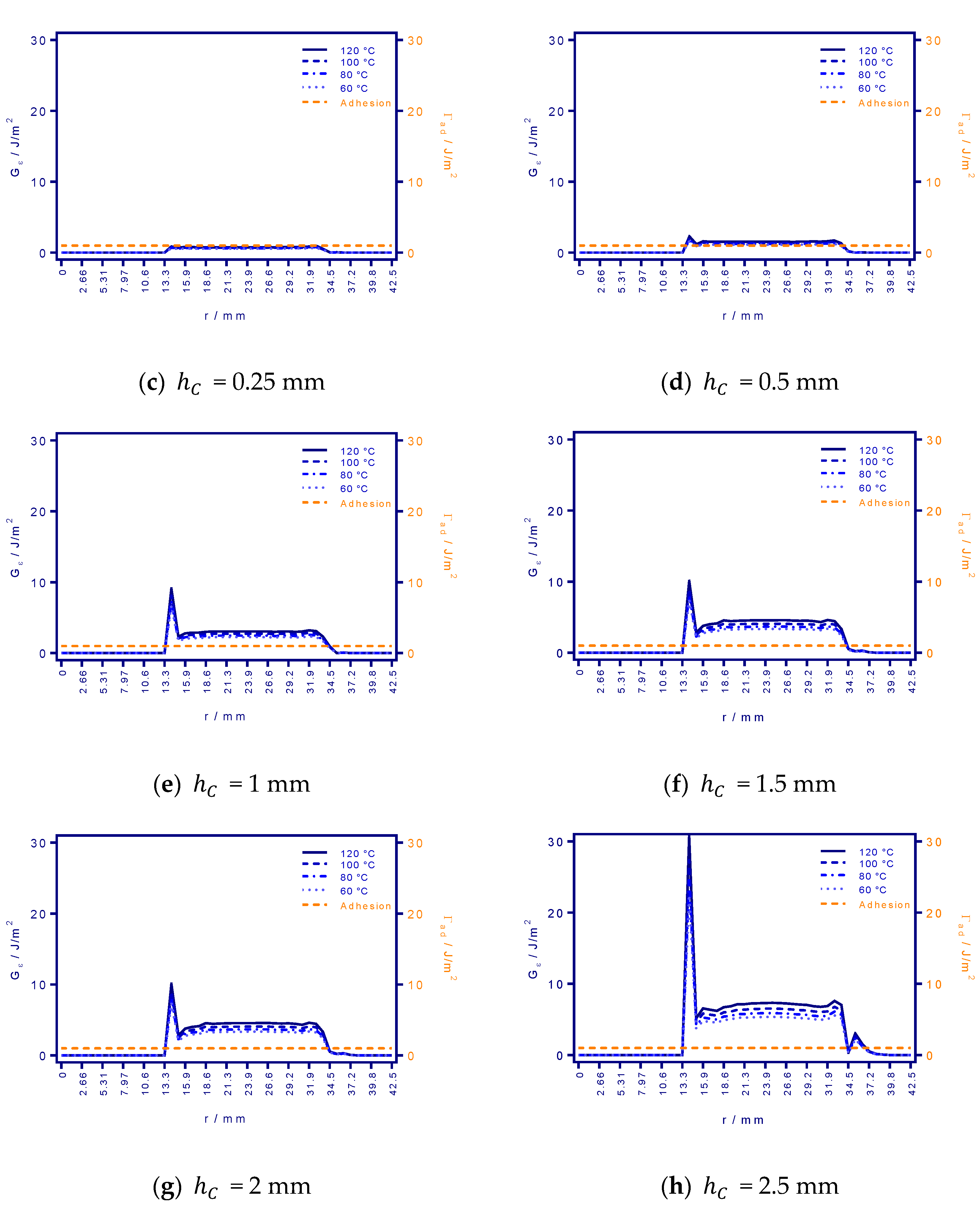

3.4. Estimation of Delamination Driven by Residual Stress

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AMID | Active Implantable Medical Devices |

| ECoG | electrocorticography |

| PDMS | polydimethylsiloxane |

| CI | cochlear implant |

| CTE | coefficients of thermal expansion |

| FEM | finite element method |

| APDL | ANSYS Parametric Design Language |

References

- Ordonez, J.; Schuettler, M.; Boehler, C.; Boretius, T.; Stieglitz, T. Thin films and microelectrode arrays for neuroprosthetics. MRS Bull. 2012, 37, 590–598. [Google Scholar] [CrossRef]

- Durisin, M.; Krause, C.; Arnoldner, C.; Kontorinis, G.; Buechner, A.; Lenarz, T.; Lesinki-Schiedat, A.; Profant, O.; Neuburger, J. Electron microscopy changes of cochlear implant electrodes with permanently high impedances. Cochlear Implants Int. 2011, 12, 228–233. [Google Scholar] [CrossRef] [PubMed]

- Wissel, K.; Brandes, G.; Pütz, N.; Angrisani, G.L.; Thieleke, J.; Lenarz, T.; Durisin, M. Platinum corrosion products from electrode contacts of human cochlear implants induce cell death in cell culture models. PLoS ONE 2018, 13, e0196649. [Google Scholar] [CrossRef] [PubMed]

- Čvančara, P.; Boretius, T.; López-Álvarez, V.M.; Maciejasz, P.; Andreu, D.; Raspopovic, S.; Petrini, F.; Micera, S.; Granata, G.; Fernandez, E.; et al. Stability of flexible thin-film metallization stimulation electrodes: Analysis of explants after first-in-human study and improvement of in vivo performance. J. Neural Eng. 2020, 17, 046006. [Google Scholar] [CrossRef] [PubMed]

- Schuettler, M.; Stieglitz, T. Assembly and Packaging. In Implantable Sensor Systems for Medical Applications; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1–510. ISBN 9781845699871. [Google Scholar]

- Ordonez, J.S.; Ieee, M.; Boehler, C.; Schuettler, M.; Ieee, M.; Stieglitz, T.; Ieee, S.M. Improved Polyimide Thin-Film Electrodes for Neural Implants. In Proceedings of the 2012 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, San Diego, CA, USA, 28 August–1 September 2012; pp. 5134–5137. [Google Scholar] [CrossRef] [PubMed]

- Li, C.Y.; Liao, Y.C. Adhesive Stretchable Printed Conductive Thin Film Patterns on PDMS Surface with an Atmospheric Plasma Treatment. ACS Appl. Mater. Interfaces 2016, 8, 11868–11874. [Google Scholar] [CrossRef] [PubMed]

- Schuettler, M.; Henle, C.; Ordonez, J.; Suaning, G.J.; Lovell, N.H.; Stieglitz, T. Patterning of silicone rubber for micro-electrode array fabrication. In Proceedings of the 2007 3rd International IEEE/EMBS Conference on Neural Engineering, Kohala Coast, HI, USA, 2–5 May 2007; pp. 53–56. [Google Scholar] [CrossRef]

- Hsu, Y.Y.; Gonzalez, M.; Bossuyt, F.; Axisa, F.; Vanfleteren, J.; De Wolf, I. In situ observations on deformation behavior and stretching induced failure of fine pitch stretchable interconnect. J. Mater. Res. 2009, 24, 3573–3582. [Google Scholar] [CrossRef]

- Rebscher, S.J.; Hetherington, A.M.; Snyder, R.L.; Leake, P.A.; Bonham, B.H. Design and fabrication of multichannel cochlear implants for animal research. J. Neurosci. Methods 2007, 166, 1–12. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Lee, S.W.; Lee, S.S. Shrinkage ratio of PDMS and its alignment method for the wafer level process. Microsyst. Technol. 2008, 14, 205–208. [Google Scholar] [CrossRef]

- Müller, A.; Wapler, M.C.; Wallrabe, U. A quick and accurate method to determine the Poisson’s ratio and the coefficient of thermal expansion of PDMS. Soft Matter 2019, 15, 779–784. [Google Scholar] [CrossRef] [PubMed]

- Johnston, I.D.; McCluskey, D.K.; Tan, C.K.L.; Tracey, M.C. Mechanical characterization of bulk Sylgard 184 for microfluidics and microengineering. J. Micromech. Microeng. 2014, 24, 7. [Google Scholar] [CrossRef]

- Dow Chemical Technical Data Sheet SYLGARDTM 184 Silicone Elastomer. Available online: https://www.dow.com/content/dam/dcc/documents/en-us/productdatasheet/11/11-31/11-3184-sylgard-184-elastomer.pdf?iframe=true (accessed on 15 March 2021).

- Wong, E.J. Modeling and Control of Rapid Cure in Polydimethylsiloxane (PDMS) for Microfluidic Device Applications. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2010. [Google Scholar]

- Schneider, F.; Fellner, T.; Wilde, J.; Wallrabe, U. Mechanical properties of silicones for MEMS. J. Micromech. Microeng. 2008, 18, 65008. [Google Scholar] [CrossRef]

- Wu, H.; Odom, T.W.; Chiu, D.T.; Whitesides, G.M. Fabrication of complex three-dimensional microchannel systems in PDMS. J. Am. Chem. Soc. 2003, 125, 554–559. [Google Scholar] [CrossRef] [PubMed]

- Jeong, O.C.; Konishi, S. Controlling the size of replicable polydimethylsiloxane (PDMS) molds/stamps using a stepwise thermal shrinkage process. In Proceedings of the Microelectronic Engineering; Elsevier: Amsterdam, The Netherlands, 2011; Volume 88, pp. 2286–2289. [Google Scholar]

- Freund, L.B.; Suresh, S. Thin Film Materials Stress, Defect Formation and Surface Evolution; Cambridge University Press: Cambridge, UK, 2004; ISBN 9780511165658. [Google Scholar]

- Creton, C.; Kramer, E.J.; Hui, C.Y.; Brown, H.R. Failure Mechanisms of Polymer Interfaces Reinforced with Block Copolymers. Macromolecules 1992, 25, 3075–3088. [Google Scholar] [CrossRef]

- Creton, C.; Hooker, J.; Shull, K.R. Bulk and interfacial contributions to the debonding mechanisms of soft adhesives: Extension to large strains. Langmuir 2001, 17, 4948–4954. [Google Scholar] [CrossRef]

| Curing Temperature (°C) | 25 | 40 | 60 | 80 | 100 | 120 |

|---|---|---|---|---|---|---|

| Curing protocol by FEM simulation (min) | 833 | 510 | 180 | 150 | 120 | 105 |

| Sylgard 184 data sheet (min) | 2880 | - | - | - | 35 | 25 |

| Mueller et al. [12] | - | 360 | - | - | - | 18 |

| Property | Copper | PDMS Sylgard 184 | ||||

|---|---|---|---|---|---|---|

| 22 °C | 60 °C | 80 °C | 100 °C | 120 °C | ||

| ) | 8942 | 982 * | ||||

| ) | 385 | 1100 * | ||||

| ) | 401 | 0.27 * | ||||

| Poisson’s ratio | 0.345 | 0.495 * | ||||

| 16.74 | 337.50 | 312.70 | 298.53 | 284.36 | 270.19 | |

| ) | 1.320 | 1.577 | 1.770 | 1.962 | 2.155 | |

| Shrinkage Types | 22 °C (mm) | 60 °C (mm) | 80 °C (mm) | 100 °C (mm) | 120 °C (mm) |

|---|---|---|---|---|---|

| 0.187 ± 0.034 | 0.267 ± 0.047 | 0.356 ± 0.051 | 0.284 ± 0.115 | 0.408 ± 0.059 | |

| 0.289 ± 0.012 | 0.299 ± 0.023 | 0.299 ± 0.023 | 0.333 ± 0.028 | 0.394 ± 0.013 | |

| 0.265 ± 0.045 | 0.589 ± 0.036 | 0.922 ± 0.022 | 1.057 ± 0.063 | 1.183 ± 0.021 | |

| 0.296 ± 0.008 | 0.682 ± 0.026 | 0.962 ± 0.049 | 1.120 ± 0.027 | 1.417 ± 0.027 | |

| 0.261 ± 0.058 | 0.704 ± 0.030 | 0.905 ± 0.020 | 1.123 ± 0.030 | 1.323 ± 0.030 | |

| 0.293 ± 0.012 | 0.724 ± 0.038 | 1.099 ± 0.021 | 1.235 ± 0.034 | 1.472 ± 0.040 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Y.; Pechenizkiy, I.; Stieglitz, T.; Doll, T. Numerical Evaluation on Residual Thermal Stress-Induced Delamination at PDMS–Metal Interface of Neural Prostheses. Micromachines 2021, 12, 669. https://doi.org/10.3390/mi12060669

Mao Y, Pechenizkiy I, Stieglitz T, Doll T. Numerical Evaluation on Residual Thermal Stress-Induced Delamination at PDMS–Metal Interface of Neural Prostheses. Micromachines. 2021; 12(6):669. https://doi.org/10.3390/mi12060669

Chicago/Turabian StyleMao, Yuyang, Ivan Pechenizkiy, Thomas Stieglitz, and Theodor Doll. 2021. "Numerical Evaluation on Residual Thermal Stress-Induced Delamination at PDMS–Metal Interface of Neural Prostheses" Micromachines 12, no. 6: 669. https://doi.org/10.3390/mi12060669

APA StyleMao, Y., Pechenizkiy, I., Stieglitz, T., & Doll, T. (2021). Numerical Evaluation on Residual Thermal Stress-Induced Delamination at PDMS–Metal Interface of Neural Prostheses. Micromachines, 12(6), 669. https://doi.org/10.3390/mi12060669