1. Introduction

The research field of metasurfaces represents a novel development within photonics where structured surfaces are used to manipulate light at an unprecedented level. Typically consisting of planar arrays of resonant structures which are small compared to the wavelength of the electromagnetic field, metasurfaces seem capable of almost arbitrary field control—the phase, polarization, amplitude and dispersion of the transmitted or reflected field interacting with the surface can almost be determined at will through clever design of the structure. Combined with the possibility of fabricating such structures using existing silicon processing techniques, these capabilities for unprecedented field control have made metasurfaces one of the most active research fields within photonics today.

In parallel with the drive towards demonstrating novel field control, the research field has recently intensified efforts towards bringing metasurface fabrication into the established silicon processing lines (e.g., of VECSEL lasers and optical detectors [

1,

2]). The goal of this direction is to offer a route towards dramatic miniaturization and integration of optical components (e.g., integrating flat lenses into optical detectors [

2] or on of top diode lasers [

1]). While optical systems have generally been big, heavy and expensive, metasurface fabrication in silicon fabs represents a new paradigm for optical systems whereby they can become small, lightweight and inexpensive. For this reason, metasurface research field was listed among the Top Ten Emerging Technologies 2019 by the World Economic Forum. It is currently generating significant industry interest with several emerging startups.

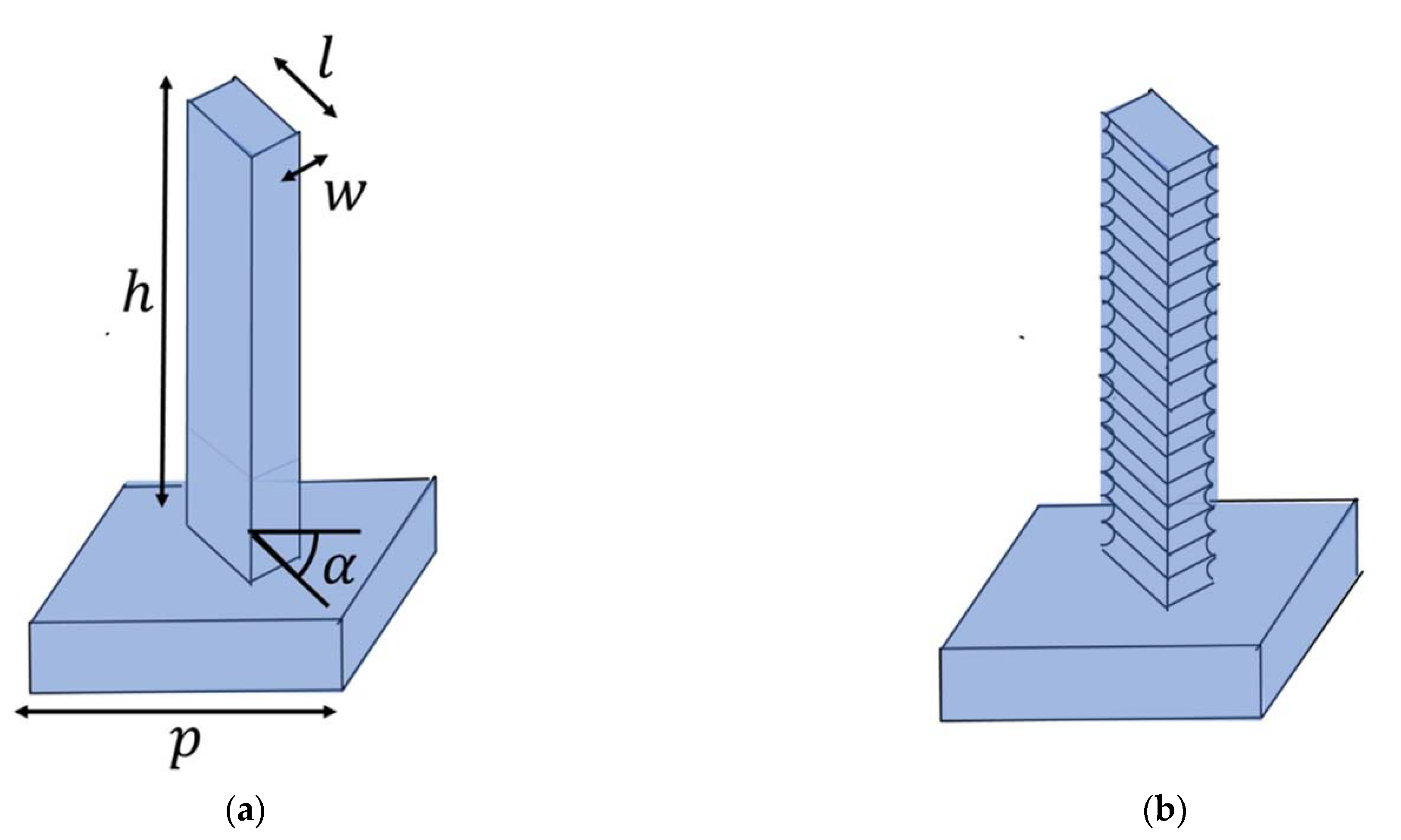

For high-performance dielectric metasurfaces, there is often a need for medium-to-high gap aspect ratios between dielectric pillars [

3,

4,

5,

6,

7]. For instance, some dispersion engineering applications are limited by the achievable aspect ratios [

5]. In the literature, some of the highest aspect ratios between metasurface dielectric pillars have been achieved by using a process relying on patterning of high aspect ratio resist holes and subsequent Atomic Layer Deposition (ALD) and lift-off [

4,

5,

6]. While this technique achieves gaps as small as ~20 nm between pillars of heights in the order of 600 nm [

4], its reliance on Electron Beam Lithography (EBL) for resist patterning and ALD for deposition of the pillars make it too slow for industrial metasurface fabrication. Two industrially relevant techniques which offer high aspect ratios are top-down etching processes by Bosch and Cryogenic Deep Reactive Ion Etching (DRIE). Bosch DRIE is readily available in most MEMS fabs and it relies on a three-step process to achieve high aspect ratio (HAR) structures—cyclical alternation between isotropic etching, passivation and de-passivation. The process leads to characteristic washboard-type surface roughness. In the literature it has sometimes been assumed that straight sidewalls are necessary [

6] for high optical quality, which at first glance may seem to put the Bosch process at a disadvantage. However, we have recently argued and shown by simulations that the surface roughness can be compensated for, as long as the scallops are small relative to the wavelength [

8]. Despite the availability of Bosch DRIE, the Cryogenic (Cryo) technique is also becoming more common in developing nanostructures for optical applications [

9,

10]. The cryogenic etching process is a single step continuous process using SF

6 and O

2 as process gases, performed at low temperatures, below −100 °C, which enable the formation and condensation of SiF

xO

y on cooled surfaces, and act as a passivation layer. The O

2 in the plasma is mainly responsible for the formation of the passivation layer by reacting with bare Si and SiF

4 byproducts. By controlling the O

2 concentration, the process can be adjusted to create vertical profiles, positive or negative slopes [

11]. These advantages can be tracked back to the cryogenic process being continuous, with the passivation of the sidewalls taking place simultaneously, in contrast to the Bosch process, which requires separate passivation and etching steps. Sidewall profile control can be much more easily obtained just by adjusting O

2 flow and the Inductively Coupled Plasma (ICP) generator power levels. Due to this fact, cryogenic etching processes can be employed for etching extremely small structures down to the resolution of electron beam lithography without undercutting the masking layer. In addition, the cryogenic SF

6/O

2 etching process is carbon-free and therefore extremely clean, without deposition of the polymer on the surfaces of the resulting nanopatterned structures and the chamber walls. However, Cryo etch has so far been less prevalent in industry than Bosch due to its dependence on very accurate temperature control of the wafer and etched structures towards achieving process controllability, uniformity and repeatability. There are nevertheless indications that Cryo is gaining interest also in industry [

9]. Taking on the advantages of cryogenic etching, Yao and Wu demonstrated the feasibility of manufacturing an all-dielectric metasurface with positive sloped sidewalls, showing more than 90% reflection in the 600 to 800 nm wavelength range [

12]. In this case, SiF

xO

y passivation was not only used to control the slope angle, but also to protect the softer materials like SiO

2 and Si

3N

4 deposited on the bottom a-Si layer.

Removing the scallops which form during the Bosch process can be beneficial when one has to achieve extremely narrow gaps or if the pillar dimensions are small compared to the scallop depths. Cryogenic silicon etching enabled Li et al. to successfully fabricate different types of metasurfaces ranging from nanopillars to hollow cylinders and honeycomb networks with extreme dimensions, standing up to 200 nm in height and having a sidewall thickness of only 10 nm [

9]. This approach allows exploration of new types of nano-scale features for manufacturing metasurfaces.

In this publication we present metastructures fabricated by cryogenic DRIE and compare them with earlier fabricated metastructures using Bosch DRIE [

8]. The resulting optical performance of the metasurfaces for the smooth (cryo) and washboard type (Bosch) sidewalls resulting from each technique are considered. As Bosch and increasingly Cryogenic process are etching techniques of industrial relevance towards the fabrication of HAR metasurfaces, we have chosen to also use the high-throughput UV-Nanoimprint lithography technique to pattern the wafers. Until recently, virtually all high-end HAR metasurfaces have been fabricated using Electron Beam Lithography (EBL) patterning, which is comparatively slow and challenging to use for cost-effective large area metasurface fabrication.

3. Results and Discussions

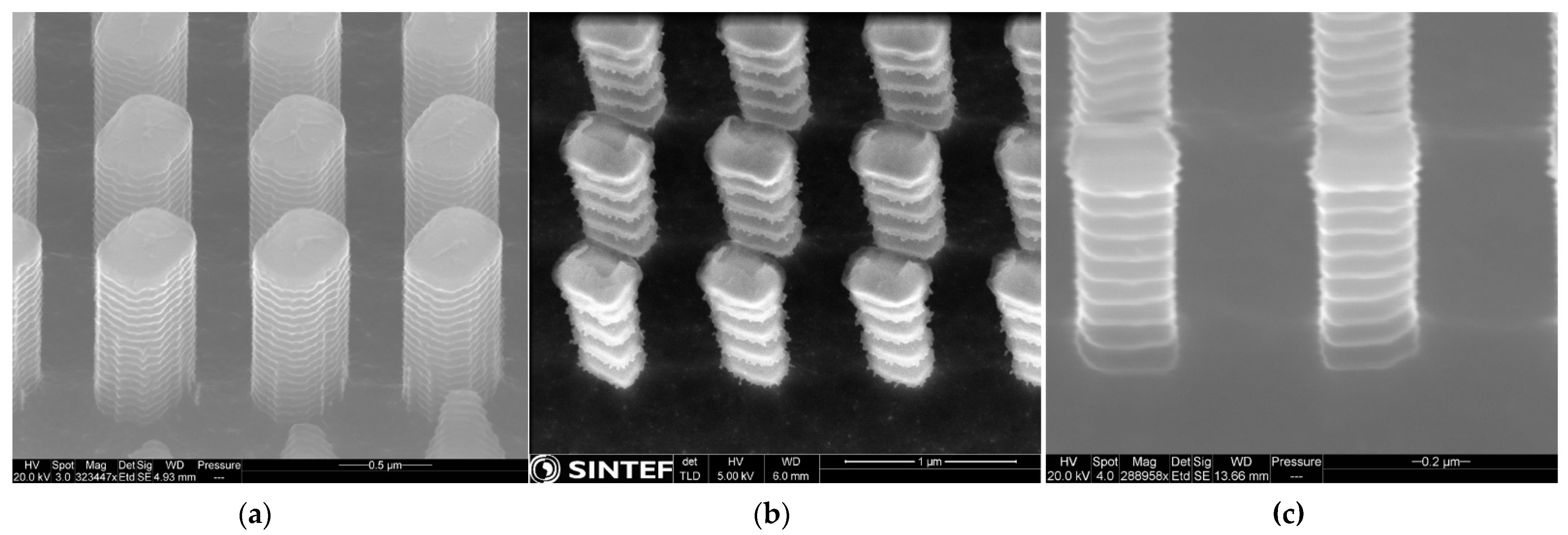

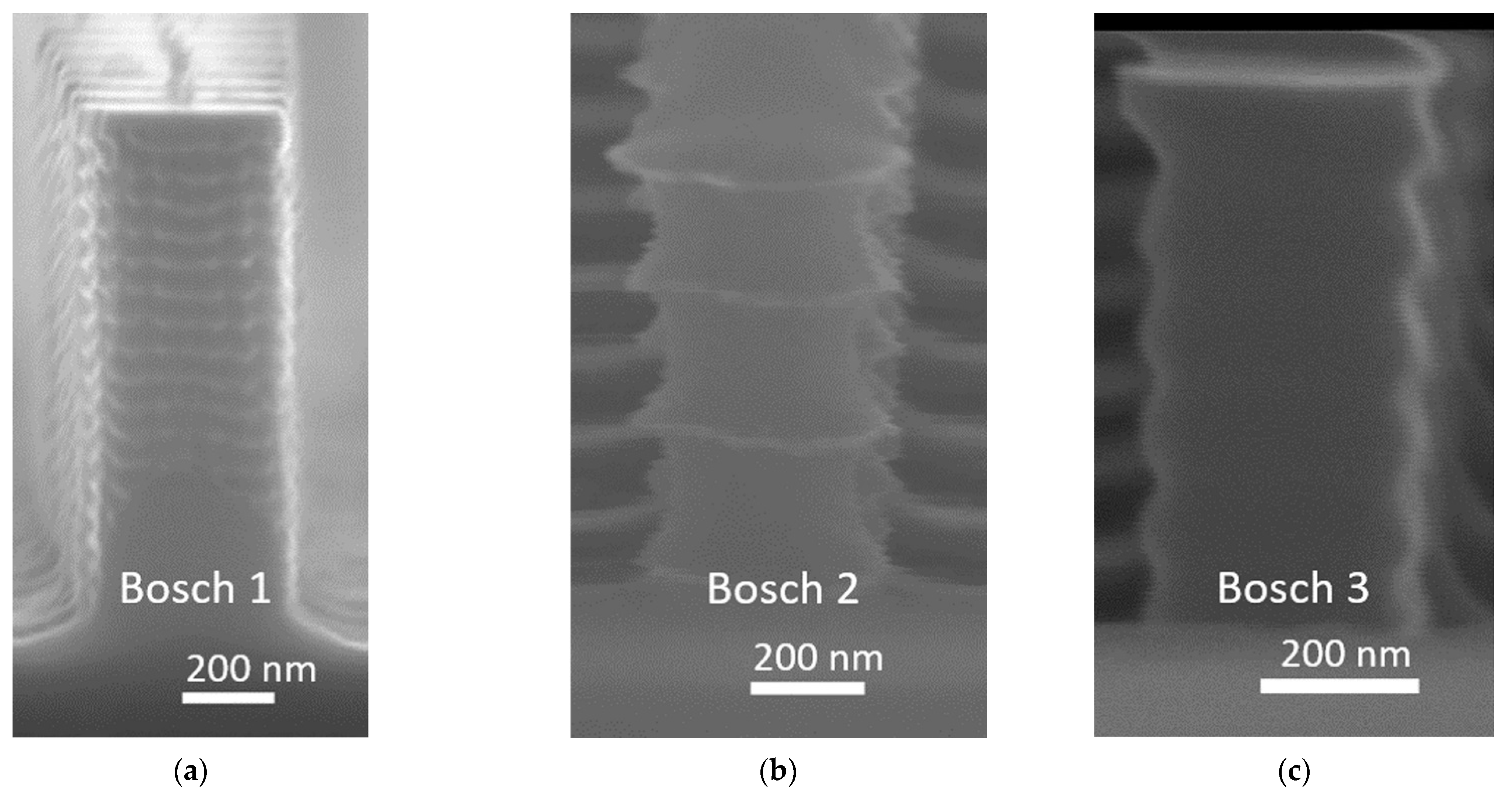

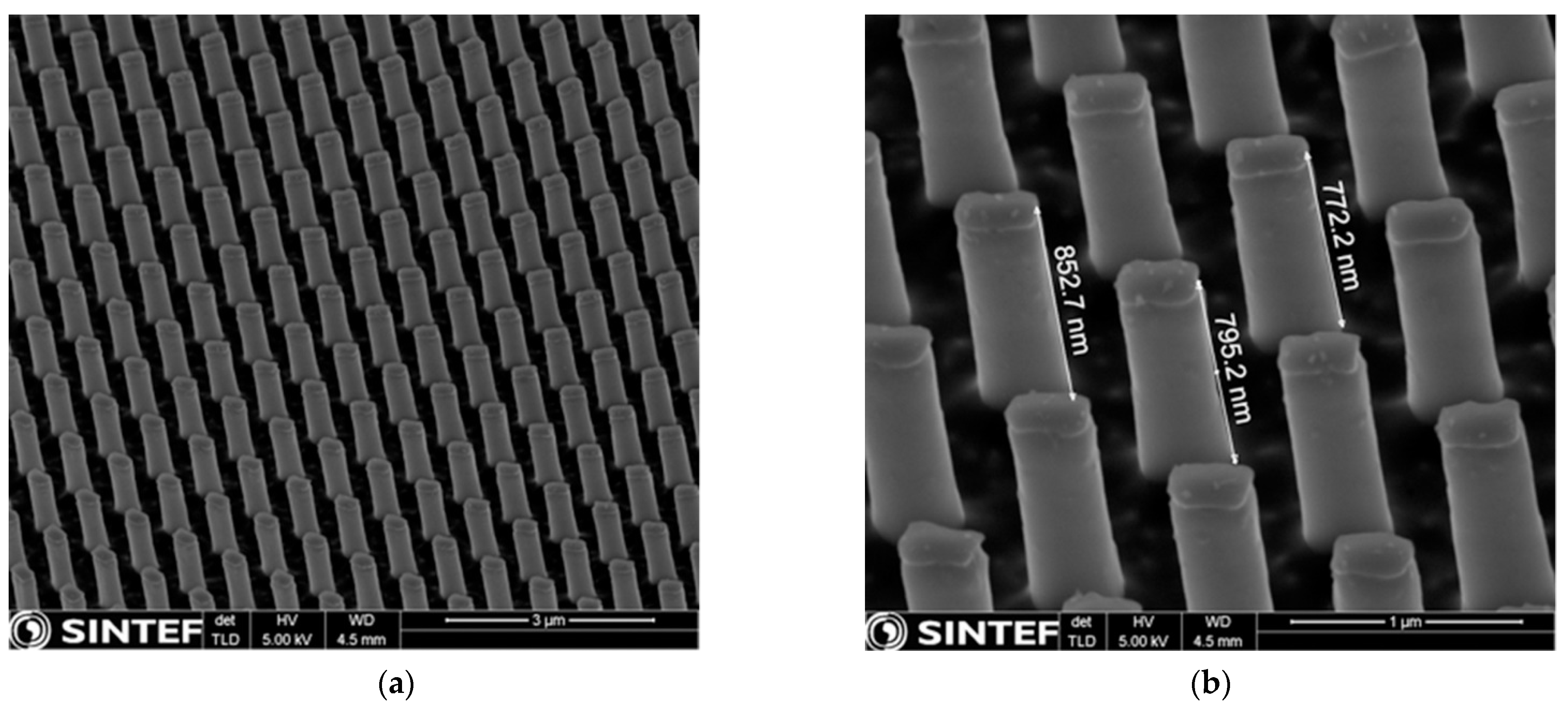

Table 1 lists and compares the lateral dimensions of the different metastructures achieved from the fabrication steps discussed above. For the Bosch processed structures, the lateral dimensions are measured from peak-to-peak on the washboard surface patterns. The cryo-processed structures match the target lateral dimensions of the metastructure well, being roughly 235 × 355 nm, however being slightly short of the desired height with around 800 nm.

For the Cryo-processed structures, the masking pattern shrunk in size by ~20% after O2 plasma ashing. This shrinkage, along with rounding of the corners of the patterned structures, was caused by using a pure O2 for the plasma ashing process, which is slightly isotropic, etching away not only the residual layer but the sidewalls of the masking patterns as well. These new slightly reduced dimensions were subsequent transferred to the silicon layer in the cryogenic etching process.

Regarding the obtained height of the silicon nanopillars, the performed cryogenic etching recipe should have provided a depth of 1200 nm. However, the obtained depth of only 800 nm was probably caused by the incomplete removal of the residual layer, resulting in a lower efficiency than expected. This issue can be overcome either by accurately measuring the residual layer or by performing a longer cryogenic etching process.

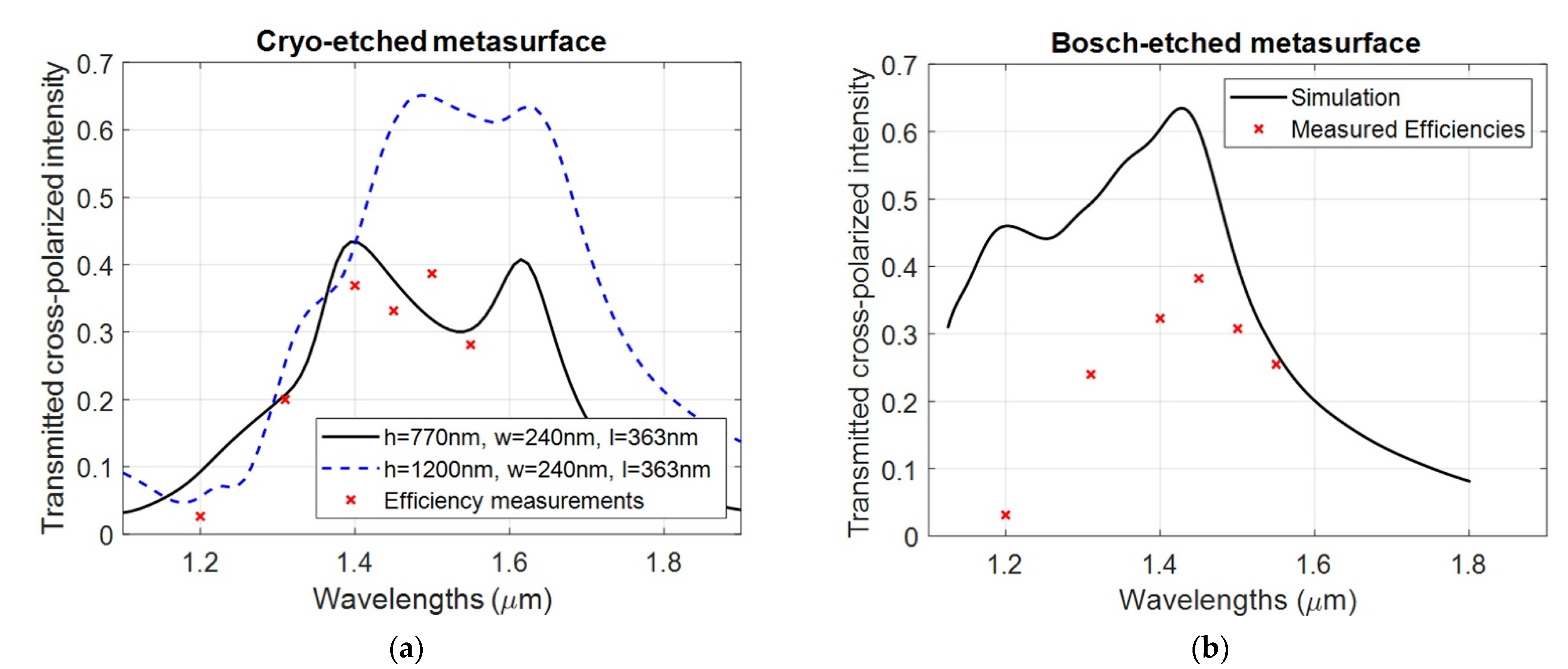

Figure 6a compares the optical efficiency of the Cryo-etched metalens with the corresponding simulations for two heights. The transmission curve (solid curve) fits qualitatively with the measured efficiency of the cryo-etched metasurface. The simulation curves indicate that the efficiency can be raised to the design efficiency by raising the heights to the target height of 1200 nm through a longer etch step. Hence, the process parameters for the UV-NIL and Cryo etch process have been close to achieving the target structures in this case.

It should be pointed out that during the RL removing process, we observed considerable differences of the residual layer thickness between wafers. A simple solution for improving process control could be the automated dispensing of resist in the UV-NIL process.

The optical efficiency measurements were done as described in [

8], except that the light source was a fiber-coupled thermal lamp (SLS 201 by Thorlabs, Newton, NJ, USA). After emerging from the multi-mode fiber, the light was collimated using an NIR antireflection-coated aspherical lens, before passing through an aperture with diameter 0.9 mm. After the aperture, the beam passed through the backside of the Si-substrate before being focused by the metalens. The focal point was imaged using a ×20 infinity corrected NIR microscope objective (Mitutoyo Plan Apo by Mitutoyo, Kanagawa, Japan), tube lens and NIR camera (NiT WiDy SenS 640 V-ST by New Imaging Technologies, Verrières le Buisson, France). To measure the efficiencies at several wavelengths between 1.2 and 1.55 um, narrowband filters with a full width half maximum of 12 nm were used to filter the thermal light prior to the light being coupled into the multi-mode fiber. To be able to compare efficiencies at different wavelengths, the output of the filtered thermal source was measured using a power meter for each of the wavelengths, and the camera efficiency was subsequently determined by imaging the source fiber tip directly for each wavelength. The absolute efficiency value was acquired by using results from [

8], where metalenses fabricated using the Bosch process were measured to have an efficiency of 26% at 1.55 um by comparing to an anti-reflection-coated aspherical lens.

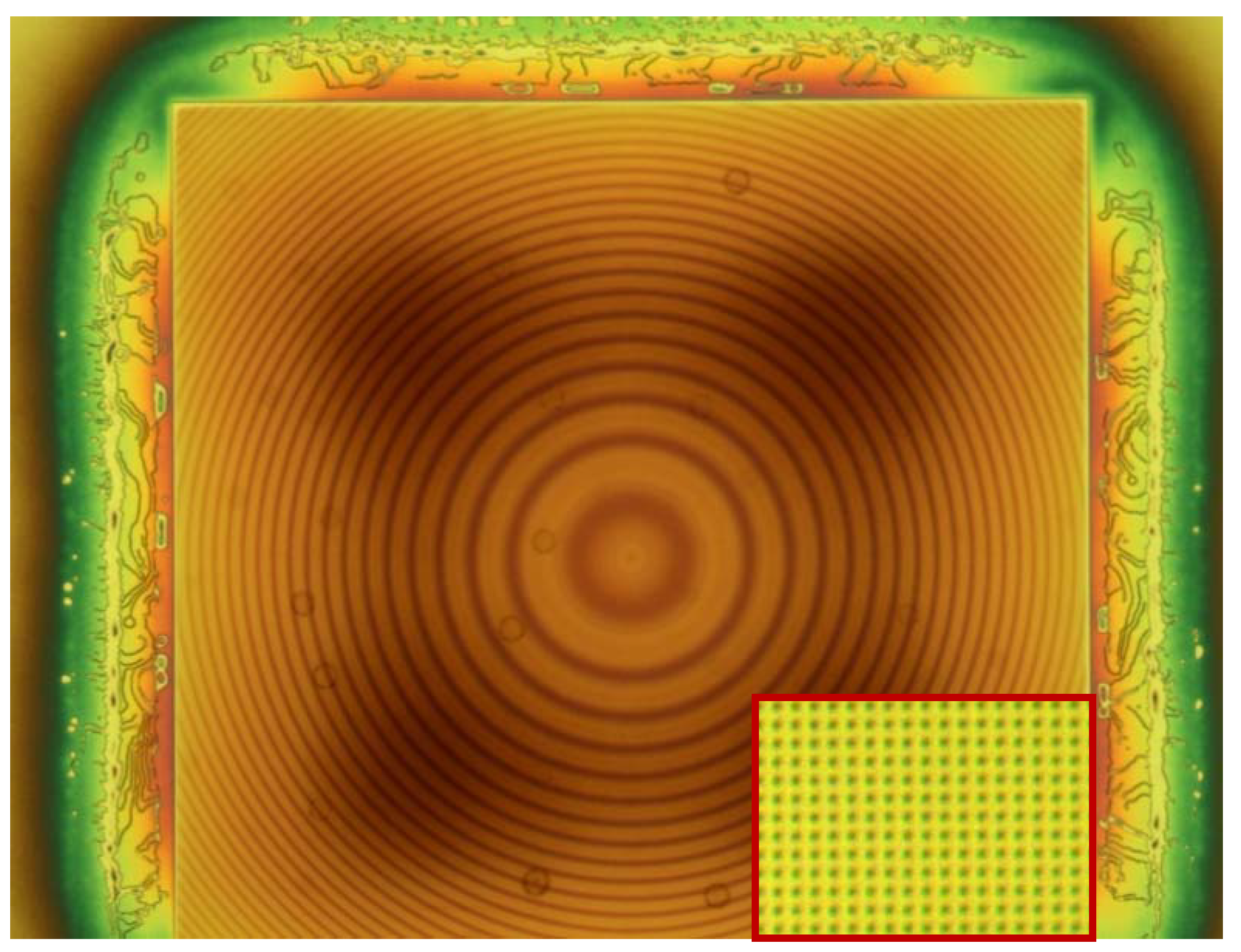

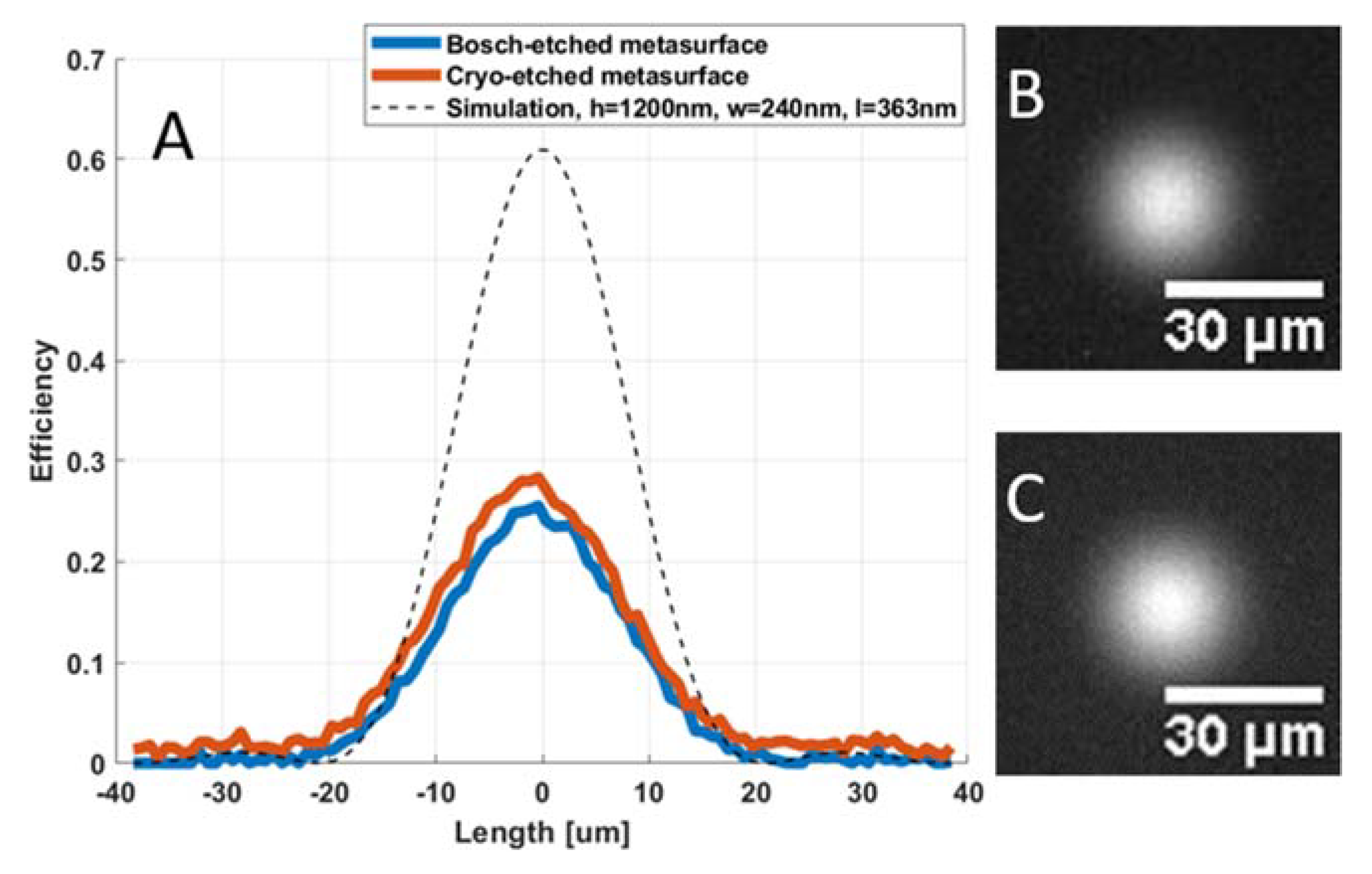

The measured focal spots of the metalenses are shown in

Figure 7. As expected, the use of the geometric phase principle leads to close-to-diffraction limited focusing despite certain deviations in the fabricated structures from the target. High aspect rectangular dielectric pillar metalenses of the kind we have fabricated are known to typically exhibit strong chromatic aberrations [

5] and the hyperbolic lens function utilized is known to lead to significant coma [

17], however the current metalenses have not been thoroughly characterized for aberrations. The metalenses were designed to have a focal length of 10 mm for

λ = 1.55 µm, but the actual focal length is wavelength-dependent, increasing to around 12 mm as the wavelength is reduced to

λ = 1.31 µm, as expected from the lens phase function, which predicts that the focal length scales inversely with the wavelength. The uncertainty of the efficiency measurements is largely determined by the absolute efficiency comparison with the aspherical lens, but is also affected by the wavelength dependency measurements described above. Based on the repeatability of our measurements, we estimate the accuracy of the results to be in the order of 5%.

The Rigorously Coupled Wave Analysis (RCWA) method was used in the GD-Calc implementation to simulate a unit cell consisting of an individual pillar and 10 diffraction orders that were used.

Due to the aforementioned resist broadening at the base of the UV-NIL-imprinted resist pillars, the intended Bosch process (Bosch 1) ended up with dimensions significantly larger than the target dimensions. As a result, it has a poor optical response within the wavelength bandwidth of interest

. Nonetheless, had the lateral dimensions been scaled correctly (by fine-tuning the resist opening step, or reducing the lateral dimensions in the master) simulations indicate that the structure would have given a high-quality optical performance. It is worth noting that the resist broadening likely can be dealt with by using a suitable residual layer removal process, as seems to have been achieved in the case of the cryogenic metasurface fabrication. Also, the authors of [

15] present an optimized process which removes such resist broadening. Another possible route towards avoiding resist broadening may be the fabrications of an Si-master consisting of holes instead of protrusions (and thereby fabricate a stamp from, e.g., resist imprinted by the master) whereby the rounding effect may then occur at the top of the pillars rather than at the base.

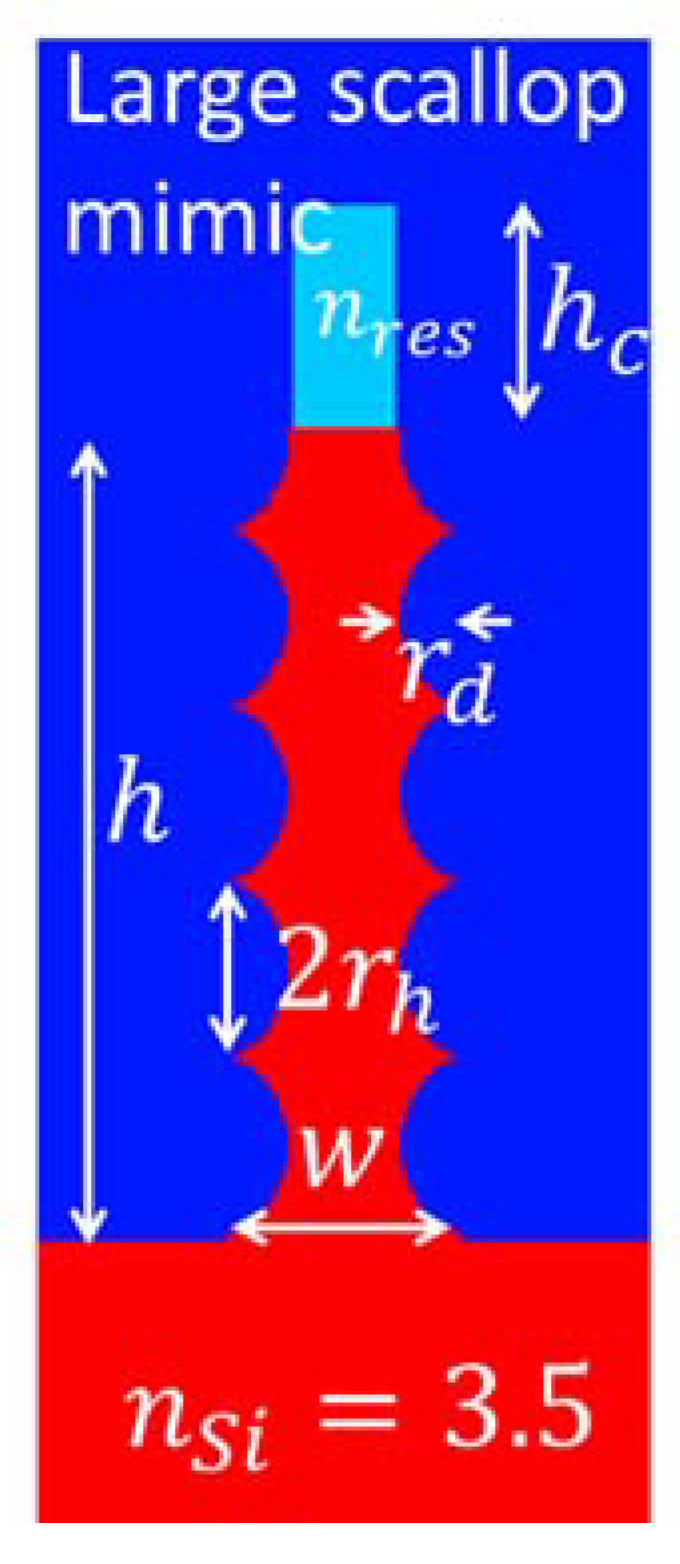

In this paper, the strategies employed to reduce the lateral dimensions in Bosch 2 and Bosch 3 gave dimensions closer to the target, although also for Bosch 3 the resulting dimensions place the peak optical performance outside the wavelength bandwidth of interest. Although the peak-to-peak values of the washboard patterns (

Figure 3c) are only slightly smaller than the target value, the effective optical dimensions are smaller due to the pillar volume lost to the scallops in between. The measured lens efficiencies of resulting dimensions of Bosch 2 are shown in

Figure 6b. A simulation curve is added for a rectangular structure with elliptical washboard surface patterns intended to mimic the structures as seen in SEM images. The simulation geometry is shown in

Figure 8, for which the parameter values are

,

,

,

,

,

and

, i.e., a pillar with rectangular cross section of varying size along the pillar. A resist cap is included due to the fact that the attempted post-dicing piranha removal of the resist was unsuccessful, but simulations with and without this cap indicate that it has little influence on the optical performance. The Finite Difference Time Domain method (FDTD) in the OptiFDTD implementation was used for the relative ease at which complex geometries can be drawn. A single pillar was simulated with periodic boundary conditions laterally surrounding the unit cell, and perfectly matched layers above and below. A source pulse width FWHM of

for the target wavelength of

was used and a simulation time of 25,000 timesteps, each being

long. A non-uniform mesh grid was used to allow for a fine mesh nearby to the Si pillars (to properly resolve the scallops). For the directions orthogonal to the pillar heights (i.e., orthogonal to the optical axis) the FDTD mesh grid interspacing varied between

, while along the optical axis the mesh grid interspacing varied between

.

While the wavelength for peak optical efficiency coincides well with the measurements, the measured efficiency is somewhat lower than predicted. The geometry of the pillar is, however, not easily simulated accurately. Also, these pillars were not properly stripped for resist and etch polymer prior to optical testing, although this is at least partially accounted for in the simulation. Despite there potentially being several sources of error with the simulations, a part of the discrepancy is possibly explained by rounding effects within the groves of the washboard patterns, where it seems possible that the pillar cross-section ceases to be rectangular and rather begins to become more circular (see

Figure 3b). Circular cross-sections are incapable of converting between circular polarization states, hence reducing the efficiency of the metasurface. A reduction in the cross-polarization efficiency may, for instance, be observed by simulating a pillar consisting of a stack of alternating circular disks and rectangular bricks—an extreme version of what we see in

Figure 3b which has a simpler shape, which is easy to draw for simulation purposes. Despite the drawbacks of the resulting structures in the Bosch 2 fabrication, it is worth noting that the optical performance is comparable to that achieved by the Cryo process (

Figure 6a), indicating that even scallops as large as those seen in

Figure 3b allow for a metalens with reasonable efficiency. Indeed, the simulation curve indicates that a scallop pillar with rectangular cross-section should be able to achieve more than 60% efficiency, i.e., that the scallops do not present a problem in themselves.

These metalenses have been made to operate for NIR, while many optical imaging applications exist for metalenses in VIS. Although the use of Si metastructures is often avoided in VIS due to absorption, absorption can be significantly reduced by switching to a quartz substrate. Transitioning from NIR (1.55 µm) to VIS (~500 nm) will, however, generally involve reducing the structural dimensions (roughly by a factor of three) for which fabrication is potentially more challenging and in need of further process development.

4. Conclusions

We demonstrated the fabrication of metalenses using a combination of UV-NIL and Cryogenic-DRIE processes, and compared the results to metalenses fabricated by UV-NIL and Bosch DRIE. UV-Nanoimprint lithography was chosen as a patterning technique for its potential to achieve large-area nanopatterning at affordable operating costs. Hence, this publication has aimed to develop processes that are relevant for industrial metasurface fabrication. The Cryo-DRIE process enabled the fabrication of silicon nanopillars with smooth vertical profiles. Optical measurements of the Cryo metalenses were performed at discrete wavelengths in the interval λ ∈ (1.31 µm, 1.55 µm), achieving a peak efficiency of around 39%. Simulation results indicated that the efficiency can be raised to the target efficiency of around 65% by increasing the height of the silicon nanopillars from 800 to 1200 nm.

The efficiency of the Bosch-fabricated metalenses was found to be similar to that of the Cryo-etched lenses. The Bosch-fabricated metalenses ended up with dimensions larger than the target values due to resist broadening occurring at the base of the UV-NIL-imprinted resist nanopillars. To circumvent the issue, the scallop sizes were increased dramatically to reduce the effective optical dimensions of the Bosch pillars, i.e., although the peak-to-peak values of the resulting washboard patterns are larger than the target value, the effective optical dimensions are smaller due to the pillar volume lost to the scallops in between. The measured efficiency of the Bosch metalenses was lower than simulated. While there are several possible sources of error for the simulated curves in the case of the Bosch-processed structure, a part of the explanation may be pillar rounding within the groves of the washboard patterns. Indeed, simulations indicate that scallops in themselves are not a problem, and that a pillar with large scallops and rectangular cross-sections should be able to achieve more than 60% efficiency (i.e., the theoretical efficiency for a smooth structure with an Si substrate).

Process optimization strategies were discussed for both deep reactive ion etching techniques to improve metalens efficiency. Importantly, the resist broadening effect, occurring during the nanoimprint process, could potentially have been avoided by using a residual layer removing process similar to that used in the case of the cryogenic metasurface fabrication. Other possible routes could be to account for the broadening in the design of the master, or to avoid it by fabricating the Si-master consisting of holes instead of pillars.