3.1. Static Equilibrium Profile of the Liquid Surface Wrinkle

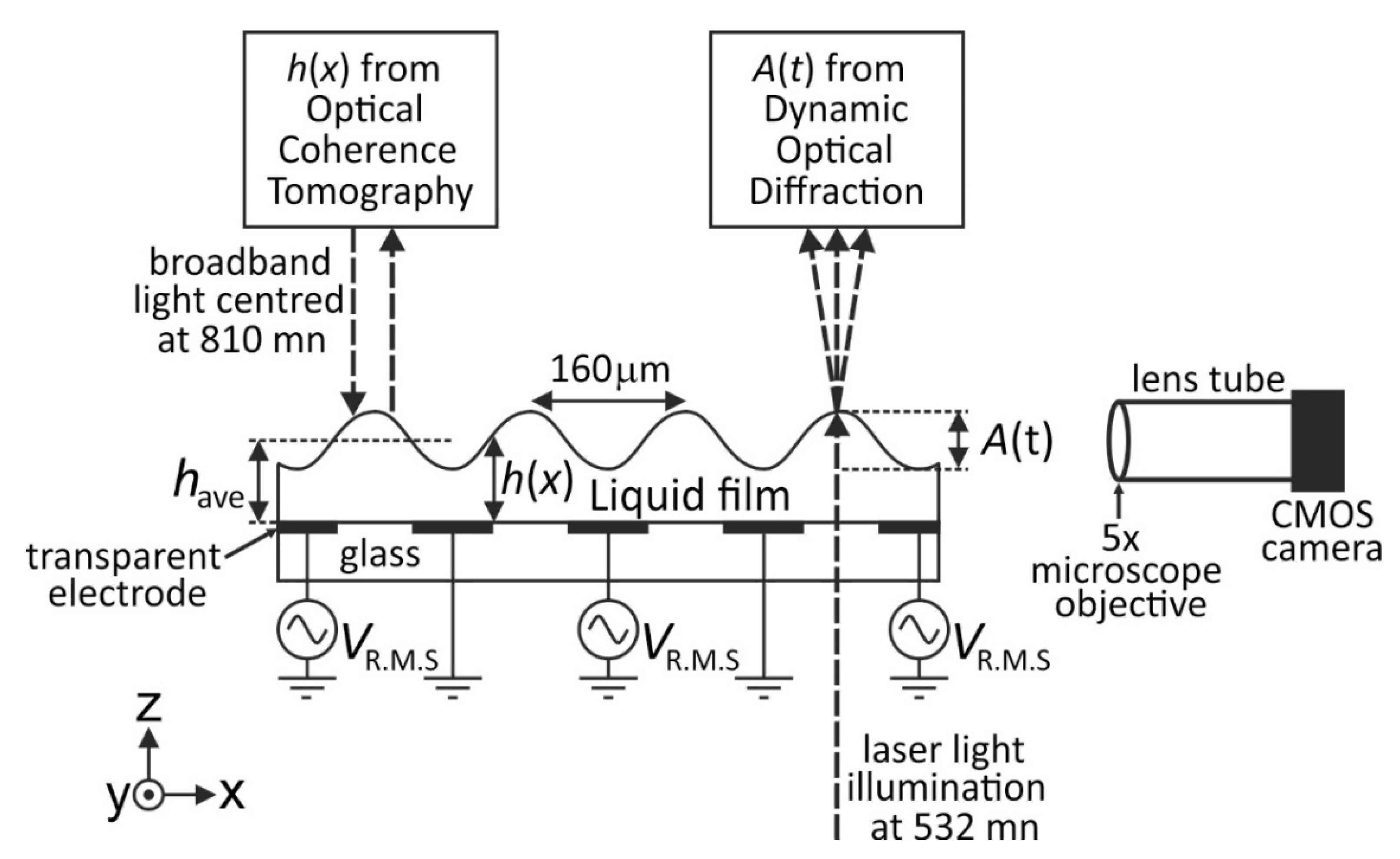

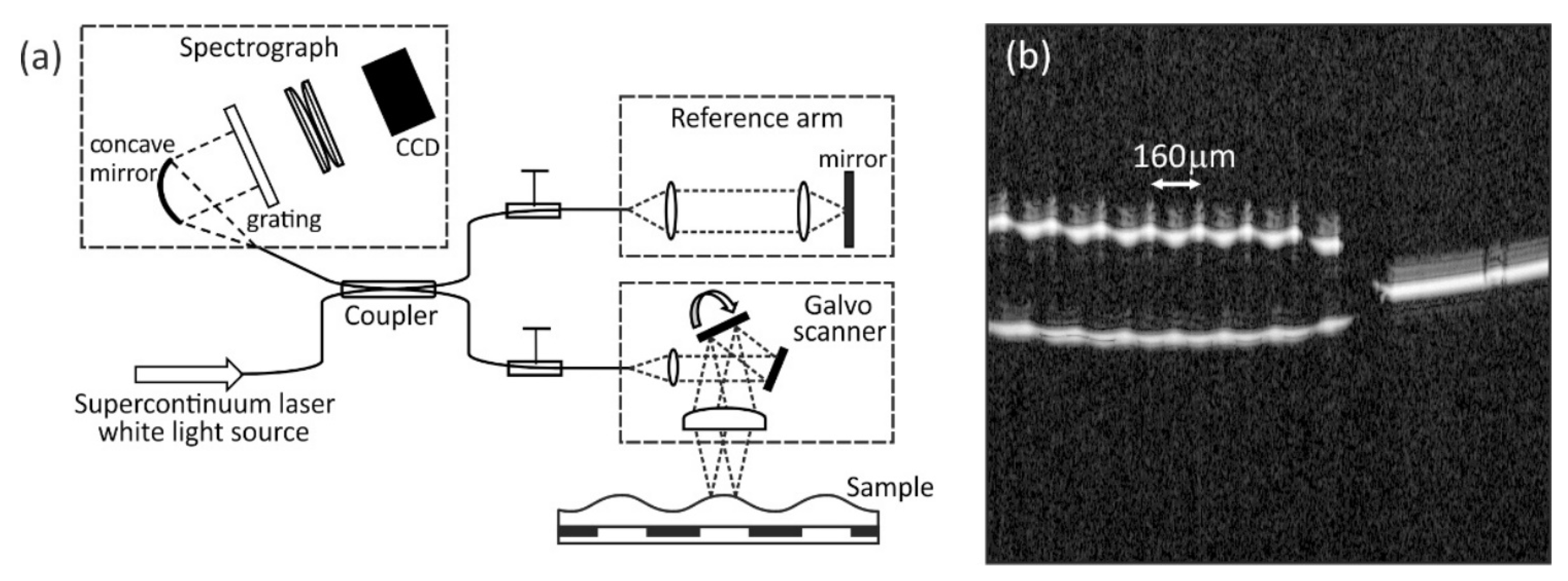

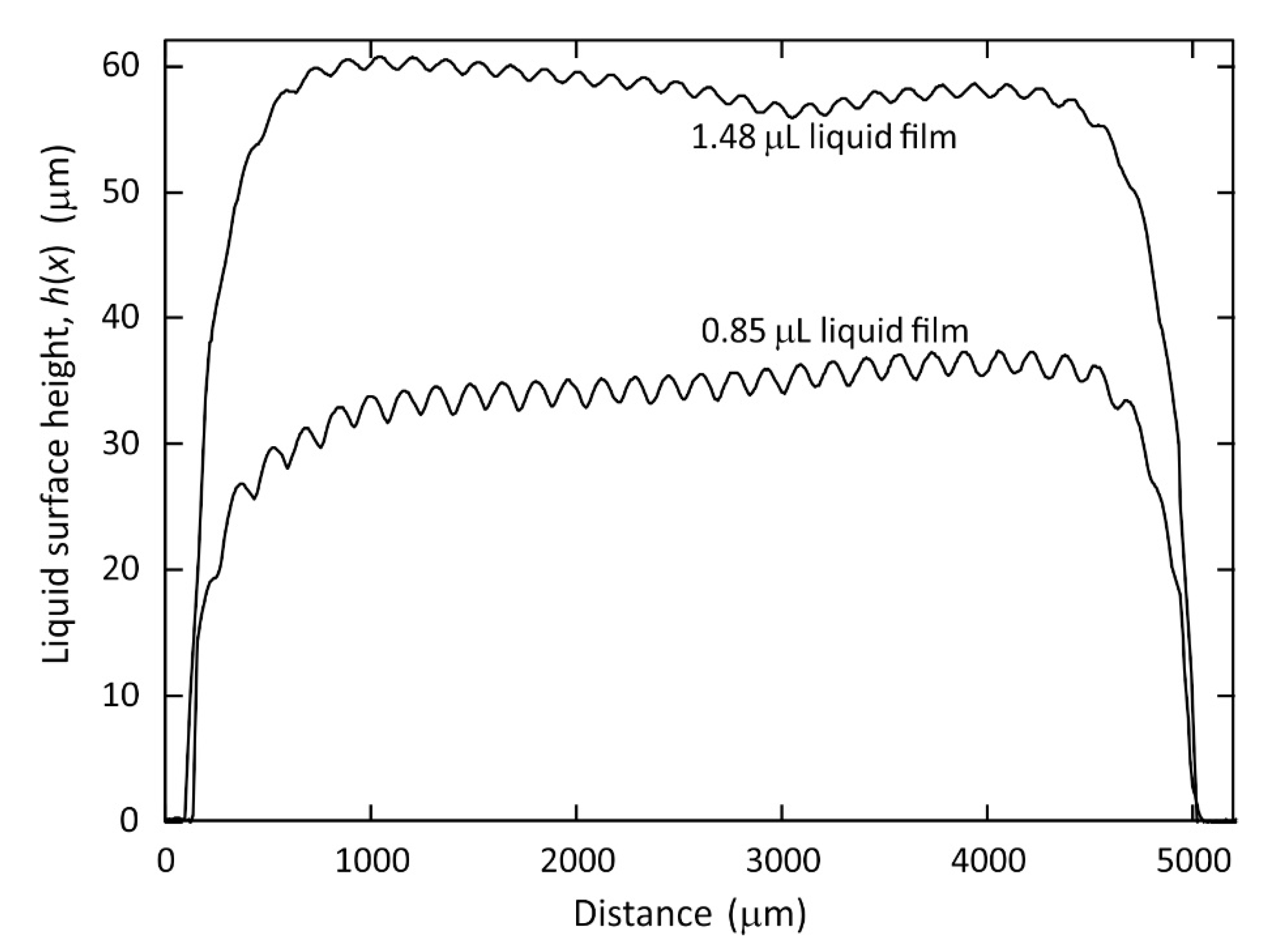

We first demonstrate the use of Optical Coherence Tomography imaging to measure the surface profile of a static periodic surface wrinkle deformation on the spread liquid film. We created and maintained the liquid film and the wrinkle using dielectrophoresis forces. We deposited a 1.48 ± 0.05 μL volume of the liquid TMP-TG-E on to our device substrate and applied an A.C. voltage

= 200 V (1 kHz) to the electrodes. The liquid rapidly spread, within 1 s of the voltage being applied, into a thin film and developed a static periodic surface wrinkle deformation, with the film surface attaining a static equilibrium shape under the influence of the constant applied voltage. We analysed the OCT cross-section BScan image of the liquid film. Firstly, we corrected the curvature of the field as shown on the right hand side of the example BScan profile shown

Figure 2b. We then fitted the depth profile (AScan) for the peaks corresponding to the air-liquid and air-substrate interfaces at each

x position to subpixel accuracy. After accounting for the refractive index of the liquid TMP-TG-E this gave the film thickness at each

x position. Repeating this procedure for a range of

x positions yielded the equilibrium surface height profile of the film shown in the labelled plots on the graph of

h(

x) versus distance

x in

Figure 3. This height profile represents a cross-section through the centre of the film in the

x-direction. The 1.48 ± 0.05 μL volume of TMP-TG-E resulted in a spread liquid film having average thickness

in the range 57 μm to 60 μm across a significant proportion (

x = 0.5 mm to

x = 4.5 mm) of the span of the 5 mm wide region covered by the electrode in the

x-direction, shown in the upper labelled plot in

Figure 3. The device substrate was then cleaned using propan-2-ol before a smaller volume of TMP-TG-E was dispensed onto the electrode area, 0.85 ± 0.05 μL and subjected to the same applied A.C. voltage

= 200 V (1 kHz). The equilibrium surface profile for this film, also extracted from OCT measurements, is shown as the lower labelled plot in the

h(

x) versus

x graph in

Figure 3. This lower volume resulted in a spread liquid film with an average thickness

in the range 30 μm to 34 μm in the region between

x = 0.5 mm and

x = 4.5 mm. It is clear from

Figure 3 that the static equilibrium peak to trough amplitude of the wrinkles,

, is larger on the liquid film that has the lower average thickness that was produced from the lower dispensed volume.

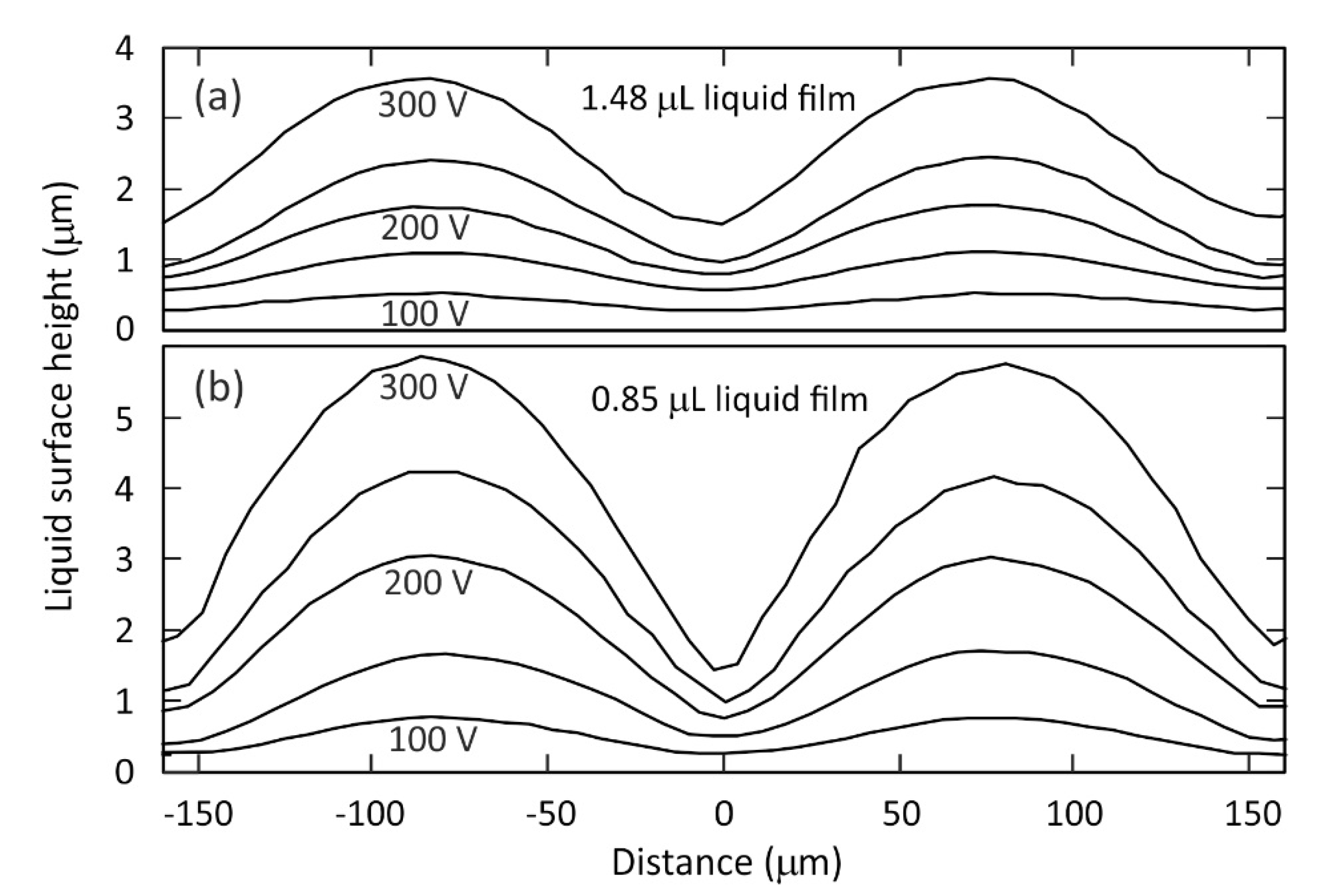

The liquid surfaces were then examined in finer detail (

Figure 4). Since OCT imaging depends on the amount of scattered light from a liquid surface, regions with steep features will scatter less light back and therefore be more challenging to image. To overcome this problem, it is necessary to perform averaging over scans, particularly for the higher wrinkle amplitudes shown in

Figure 4. Noise on the profiles shown was reduced by averaging over scans on 3 distinct neighbouring regions of the wrinkle after removal of the slow

x-variation of the average height baseline. The different vertical profiles in

Figure 4 were measured with a range of A.C. voltage values applied to the electrodes under the liquid,

= 100, 150, 200, 250, 300 V (1 kHz). The vertical positions of the profiles shown are offset for clarity to facilitate shape and amplitude comparisons between them.

Figure 4 shows that the liquid-air interface profiles have a peak to trough wrinkle amplitude

that has a monotonic dependence on the applied voltage, with higher amplitude at higher voltage. The plots also show that for a given applied voltage the wrinkle amplitude is higher for the liquid film of lower thickness shown in

Figure 4b than for the thicker liquid film in

Figure 4a. For example, with an applied voltage of

= 200 V the peak to trough wrinkle amplitude is

= 2.25 ± 0.05 μm on the film with thickness 30 μm to 34 μm in

Figure 4b, compared with

= 0.93 ± 0.05 μm on the film with thickness 57 μm to 60 μm in

Figure 4a. This effect is a consequence of the fact that the electric fields above the electrodes decay exponentially with distance in the

z direction. Hence for a thinner liquid film the air-liquid interface is closer to the electrodes compared to a thicker film, and so the former experiences a substantially stronger dielectrophoresis force to create the larger wrinkle deformation. The shapes of the periodic surface wrinkles show greater deviation from an idealized sinusoidal shape for the higher voltage values, particularly for the thinner liquid film.

In previous work in the literature, the shapes and amplitudes of dielectrophoresis induced liquid surface wrinkles, including derived from direct imaging and Mach–Zehnder based interferometric measurements, were analysed using a number of different theoretical approaches [

16,

20,

33,

35,

36]. An approximate analytical expression has previously been derived, Equation (8) in reference [

37], that relates the peak to trough wrinkle amplitude,

, to the square of the voltage,

(where

), via a coefficient that depends on the variables

,

,

, and

have that have been defined in the Experimental section and in

Figure 1 of this paper. This analytical expression was derived by assuming a spatially periodic potential at

z = 0 that is a sinusoidal function of

x and that

, with the condition that

. This expression predicts that the voltage scaled wrinkle peak to trough amplitude will be given by

= 0.86 × 10

−10 mV

−2 for the data shown in

Figure 4a, for which the experimentally measured amplitudes are in the range (0.91–1.06) × 10

−10 mV

−2, and by

= 1.87 × 10

−10 mV

−2 for the data shown in

Figure 4b, for which the experimentally measured amplitudes are in the range (1.85–2.17) × 10

−10 mV

−2. Whilst this analytical expression should not be expected to provide precise quantitative predictions, due to the simplified model of the non-uniform electric fields in the system, the sinusoidal profile approximation, and due to the presence of a thin solid dielectric protective film over-coating the electrodes, we do find very good correspondence between the predicted voltage-scaled wrinkle amplitude values and the values measured from our OCT results. The results from OCT imaging shown in

Figure 4 illustrate how OCT techniques can be used to obtain high axial resolution profiles of micrometer scale features on a liquid-air surface, across a range of liquid-air wrinkle amplitudes spanning from

= 0.24 μm (100 V, Ω = 1.48 ± 0.05 μL) up to

= 4.42 μm (300 V, Ω = 0.85 ± 0.05 μL).

3.2. Dynamic Growth and Decay of the Liquid Surface Wrinkle

We next demonstrate how dynamic optical diffraction techniques can be employed to quantify the time dependent amplitude

of a dielectrophoresis induced periodic wrinkle on a liquid surface during its growth towards equilibrium immediately after a voltage is abruptly applied, and also during its decay after a voltage is abruptly reduced. For a liquid with a relatively low viscosity, both wrinkle growth and wrinkle decay will take place on timescales well below 1 millisecond [

16]. We demonstrate here a facile indirect optical diffraction-based measurement technique that exploits the fact that a periodic wrinkle deformation on a liquid-air surface acts as a diffraction grating. If the wrinkle is approximated by a sinusoidal functional dependence,

, then the spatially periodic optical path variation,

, will be given by Equation (1).

Here

is the wavelength of the incident light, the refractive indices of the liquid and air are denoted by

and

, respectively, and we define

.

A collimated beam of coherent light that impinges normally (in the

z-direction) on the corrugated liquid-air interface

in the

x-

y plane will be diffracted into the

x-

z plane because of the spatially periodic optical path. The relative intensity of the

th diffracted order of monochromatic light transmitted through such a sinusoidal phase transmission grating has an analytical solution and is predicted by the Kirchoff integral to scale as the square of Bessel functions of first kind,

, where

is the phase delay excursion in radians [

38,

39], given from Equation (1) as

. This direct relationship between the argument

of the squares of the Bessel functions that predict the relative intensities of the diffracted orders, and the peak to trough amplitude

of the liquid surface corrugation, provides a facile means to extract the rapidly time varying value of

from optical diffraction measurements.

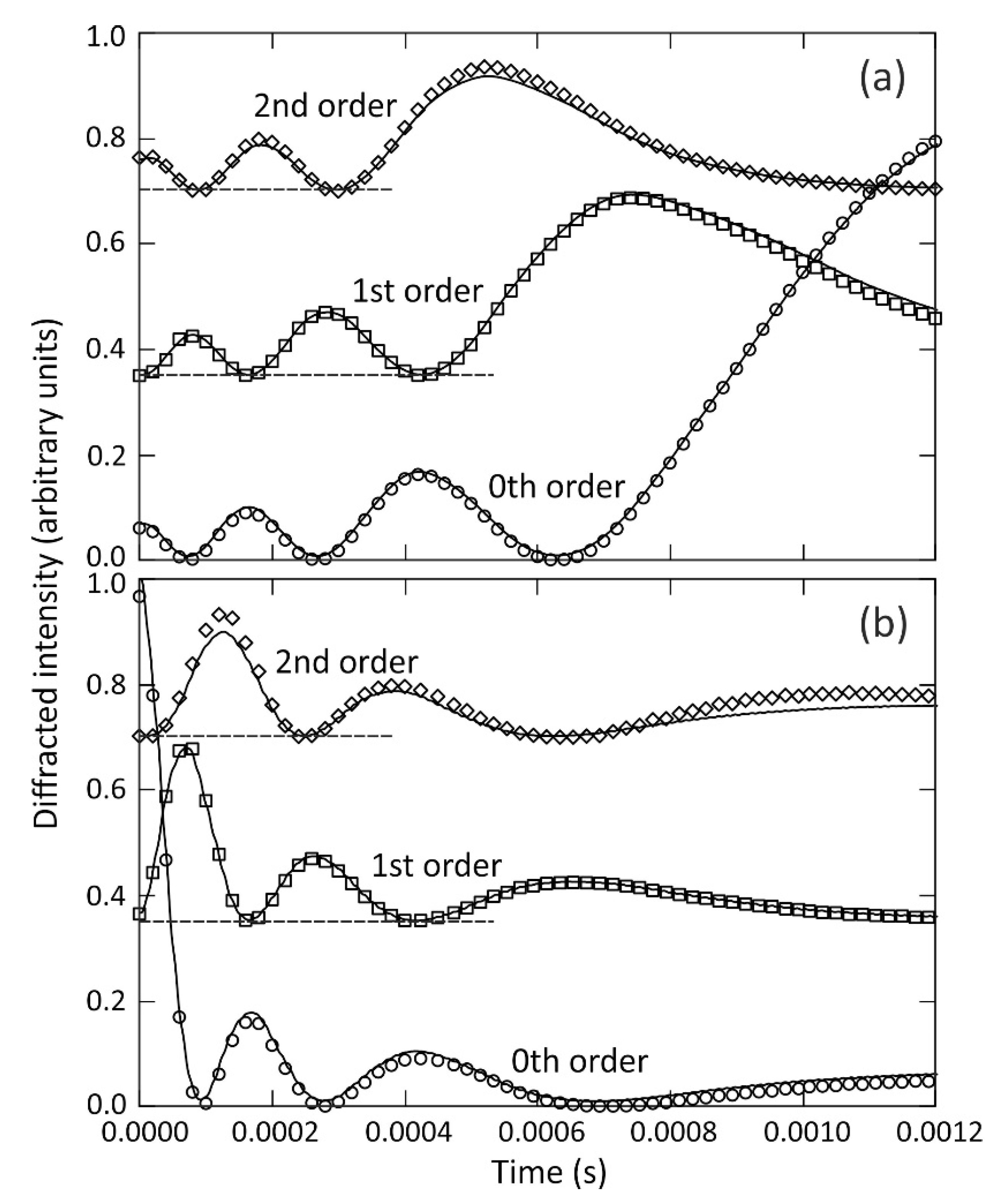

To explore the dynamics of wrinkle formation and decay we applied an A.C. sinewave voltage with frequency 2.5 kHz to the electrodes to form a film of the liquid TMP-TG-E (volume 0.99 ± 0.05 μL) of thickness

40 ± 1 μm in the region of the surface that we studied. The voltage was amplitude modulated, using a slower 100 Hz squarewave, alternating between a minimum value

= 46 V (±1 V) and a maximum value of

= 293 V (±1 V). Collimated monochromatic incident light of wavelength

= 532 nm from a green 10 mW laser diode was transmitted through the liquid and diffracted by the surface wrinkle. With the transitions of the modulation waveforms acting as timing triggers, we used a digital storage oscilloscope to capture the time dependent intensities of the zeroth, 1st and 2nd diffracted orders (

,

, and

, respectively) recorded by three separate photodiodes. The solid line plots in

Figure 5a show how the intensities of these three diffracted orders varied with time immediately after the voltage value had increased abruptly from 46 V to 293 V, which corresponds to the dielectrophoresis induced growth of the wrinkle peak to trough amplitude

. The solid line plots in

Figure 5b show how the intensities of these same three diffracted orders varied with time immediately after the voltage value had decreased abruptly from 293 V to 46 V, corresponding to the decay of the wrinkle peak to trough amplitude

during capillary driven levelling of the surface of the liquid film.

The selected electrical device addressing parameters, including the minimum voltage value at 46 V, the 2.5 kHz A.C. driving voltage that applied the dielectrophoresis forces to the liquid, and the 100 Hz low frequency modulation waveform that provided cycling between alternate 5 ms time periods of growth (293 V) or decay (46 V) of the wrinkle amplitude, were found in combination to deliver on the requirement to maintain constancy of the film thickness

have during the measurements. In addition, the selected parameters allow sufficient time for the measurement of growth to saturation and decay to negligible peak to trough amplitude of the surface corrugation during each 5 ms time period. At the 46 V minimum voltage, the equilibrium value of the wrinkle amplitude was sufficiently negligible to enable study of levelling, whilst this value also acted effectively to prevent the liquid film from beginning to de-wet and hence avoided any significant changes in the overall shape of the liquid film during the measurements. The efficacy of this approach was confirmed during the measurements using a CMOS camera (DCC1545M, Thorlabs, Ely, UK) fitted with a 5× objective lens and a 150 mm tube to image the edge of liquid film in the

y-direction to monitor the overall liquid film shape and the value of

at the position on the liquid film at which the collimated incident laser light was transmitted and diffracted. This imaging set-up is shown in

Figure 1.

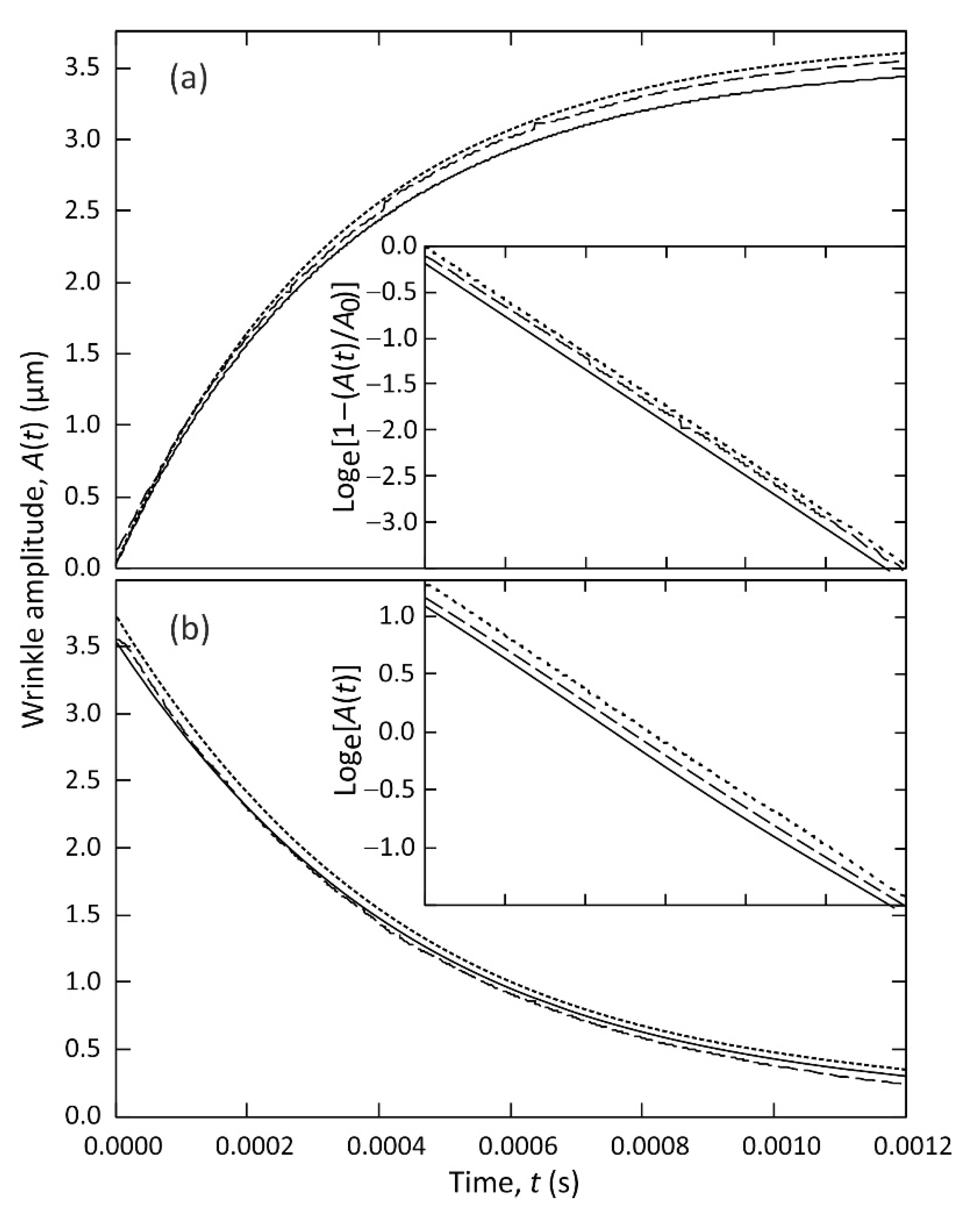

Figure 6 shows plots of the time dependent amplitude of the periodic wrinkle deformation

, during growth towards equilibrium amplitude in

Figure 6a, and during decay towards zero in

Figure 6b. These curves were obtained by extracting time dependent functions

from the fits shown in

Figure 5 of the squares of the Bessel functions

(shown by open circle symbols),

(open square symbols), and

(open diamond symbols), to the separately measured intensities of the diffracted orders,

,

, and

(shown by solid lines), respectively. As discussed above, the peak to trough wrinkle amplitude

on a film of liquid TMP-TG-E is related to the phase delay excursion

m(

t) by the expression

3.55 × 10

−7 m(

t) metres, for transmitted laser light of wavelength

= 532 nm, with

0.477, and assuming a spatially periodic wrinkle profile and commensurate optical path variation as given in Equation (1). Taking the measured 0th order diffraction data

shown by the open circles in

Figure 5a as an example, the solid line through the data shows the fit to the square of the Bessel function of first kind,

, to the normalised data,

, which yielded the time-dependent function

, and hence the plot of

against time

shown by the solid line in

Figure 6a. Extracting

from fitting

to the experimental data is an inverse problem, and the fitting function has an oscillatory dependence on its argument,

. We obtained the fit in a straightforward manner by considering each time interval between adjacent maxima and minima in turn.

In

Figure 6a the peak to trough amplitude

of a growing wrinkle deformation shows a steep rise from close to zero,

0.1 μm, at

0 s, when the voltage was abruptly increased from 46 V to 293 V, with the subsequent rate of increase slowing approaching an equilibrium asymptote of

3.6 μm. This growth in amplitude is the result of dielectrophoresis forces dynamically creating the wrinkle deformation, under the electrostatic action of the spatially periodic potential applied to the underside of the liquid film, whilst opposed by the Laplace pressure associated with surface tension forces and resisted by the liquid viscosity. Very similar shapes are found, as should be expected, for all three curves,

in

Figure 6a that were derived from separate fits to the 0th order diffracted order (

, solid line), the 1st order (

, dashed line), and the 2nd order (

, dotted line). The inset graph in

Figure 6a compares each of these three curves with the exponential rise to equilibrium function,

. The linear dependence demonstrates that the exponential rise provides an excellent description of the time dependence of the wrinkle growth. Linear regression analysis gave

= 3.55 μm, 3.61 μm, and 3.62 μm (±0.02 μm) and

= 3.469 × 10

−4 s, 3.496 × 10

−4 s, and 3.456 × 10

−4 s (±0.002 × 10

−4 s) for the curves

,

and

, respectively. The voltage was then abruptly decreased from 293 V to 46 V, and

Figure 6b shows the wrinkle amplitude

responding by decaying steeply from initial equilibrium amplitude

3.6 μm, at

0 s towards the equilibrium asymptote of

0.1 μm. Here capillary driven levelling of the surface of the liquid film, driven by the Laplace pressure associated with surface tension forces, is resisted by the liquid viscosity.

Figure 6b shows very similar shapes, as should be expected, for the three curves

derived from the separate fits to the 0th order diffracted order (

, solid line), the 1st order (

, dashed line), and the 2nd order (

, dotted line). The inset graph in

Figure 6b compares these three curves with the exponential decay function,

. The linear dependence demonstrates that the exponential decay provides an excellent description of the time dependence of the wrinkle levelling. Linear regression analysis gave

= 4.410 × 10

−4 s, 4.438 × 10

−4 s, and 4.394 × 10

−4 s (±0.003 × 10

−4 s) for

,

and

, respectively.

Figure 7 plots the values of the time constants for the dielectrophoresis induced formation and growth in the amplitude of the wrinkle deformation,

(filled diamonds), and the values of the time constants for the capillary force driven decay in the wrinkle amplitude,

(closed diamonds), for a periodic wrinkle deformation of pitch

= 160 μm on different TMP-TG-E liquid films having thicknesses in the range from

= 32 ± 1 µm up to

= 70 ± 1 µm. These time constant values were obtained from exponential rise to equilibrium or exponential decay function fits to time dependent peak to trough wrinkle amplitude

curves obtained from the 0th order diffraction data, using the experimental parameters and the data analysis and fitting processes as described above and as depicted in

Figure 5 and

Figure 6.

We first consider the time constant,

, for the exponential decay of the amplitude of the liquid surface wrinkle. The capillary force driven levelling of a sinusoidal distortion on a clean surface of a thin liquid layer was predicted by Orchard [

11] to be described by an exponential decay with characteristic decay time,

, given by the analytical expression in Equation (2).

The function tends to the limit

when

, so that when the pitch of the wrinkle is much greater than the thickness of the liquid film,

(where

), it simplifies to the familiar approximate expression

. The solid line on

Figure 7 shows a plot of the full Equation (2) using the physical parameters for our experimental system (see experimental section) as a function of the film thickness,

. There is close agreement between the solid line plot of Equation (2), and the experimental decay time constant data, shown by the open diamonds, across the range of film thicknesses explored. This agreement also extends to the lowest film thickness values where the initial shape of the wrinkle on the film deviates more significantly from being sinusoidal, as illustrated by the results of the OCT study of equilibrium surface profile shapes on a thin film as depicted earlier in

Figure 4b. The levelling that we have studied was initiated starting from wrinkle amplitudes and profiles that had been created using dielectrophoresis forces. The close agreement between the established theory for levelling with the experimental results gives confidence that potential sources of systematic error have been avoided in our experiments. For example, there is negligible ohmic heating by the electrodes since this would have been evident by a reduction in the liquid viscosity and hence the time constant

.

We now consider the time constant,

, for the dielectrophoresis driven increase in the amplitude of the liquid surface wrinkle. We use the theoretical approach to the formation of a wrinkle profile at the interface of two dielectric fluids by dielectrophoresis forces is described by Chappell and O’Dea [

33]. This approach uses Nyström based boundary integral methods to solve the equations of Stokes flow coupled with an approximate electrostatic potential model to obtain the potential on the fluid-air interface. This permits numerical solutions to the time dependent formation and decay of wrinkle profiles when supplemented with a kinematic boundary condition to model the interface motion resulting from the fluid velocity field. This approach uses a sinusoidal spatially periodic potential and sinusoidal wrinkle profile [

37]. We first checked that the numerical model gave the same results as predicted by Equation (2) for the exponential decay of the amplitude of a liquid surface wrinkle,

, and this gave an exact match to the solid line in

Figure 7. We then performed numerical modelling to find the timescales for the increase in a sinusoidal wrinkle amplitude,

, resulting in the dashed line in

Figure 7. Both the experimental data and the model follow the same trend of decreasing time constant for increasing film thickness, with the growth time constant being quicker than the decay time constant for all film thickness studied, i.e.,

. The difference between these time constants can be understood by consideration of the strength of the forces which drive the formation and decay of the wrinkle. Prior to switching the applied voltage to the “on” state the liquid-air interface is predominantly flattened by surface tension. Once the device is switched to the “on” state a Maxwell stress [

40] is induced at the interface which is resisted by the Laplace pressure. For the interface to distort, the Maxwell stress must overcome the Laplace pressure, therefore the force which forms the film is stronger than the force which drives the decay of the film. As the thickness of the liquid film decreases, the liquid-air interface becomes closer to the decaying electric field and this increases the strength of the Maxwell stress at the interface, as well as increasing the amplitude of the wrinkle formed since the maximum voltage was kept constant at 293 V for the full range of film thicknesses. Therefore, the difference between

and

is expected to increase with decreasing film thickness, as observed in the experiments. However, as the thickness of the film decreases, viscous dissipation within the film increases resulting in a retarding of both the formation and decay time.

As well as the numerical model of dielectrophoresis driven wrinkling correctly predicting that , we find excellent agreement between the experimental data and the numerical modelling prediction for the value of the growth time constant for film thicknesses above 50 μm. For liquid films with thickness below 50 μm we find that the model predicts a higher growth time constant compared to the experimentally measured switch on time. We found that the inclusion of higher harmonics in the potential and surface shape profile in the numerical simulation model led to a still further increase in the value of the predicted growth time constant, and hence did not account for this difference.