Design and Dynamic Modeling of a 3-RPS Compliant Parallel Robot Driven by Voice Coil Actuators

Abstract

:1. Introduction

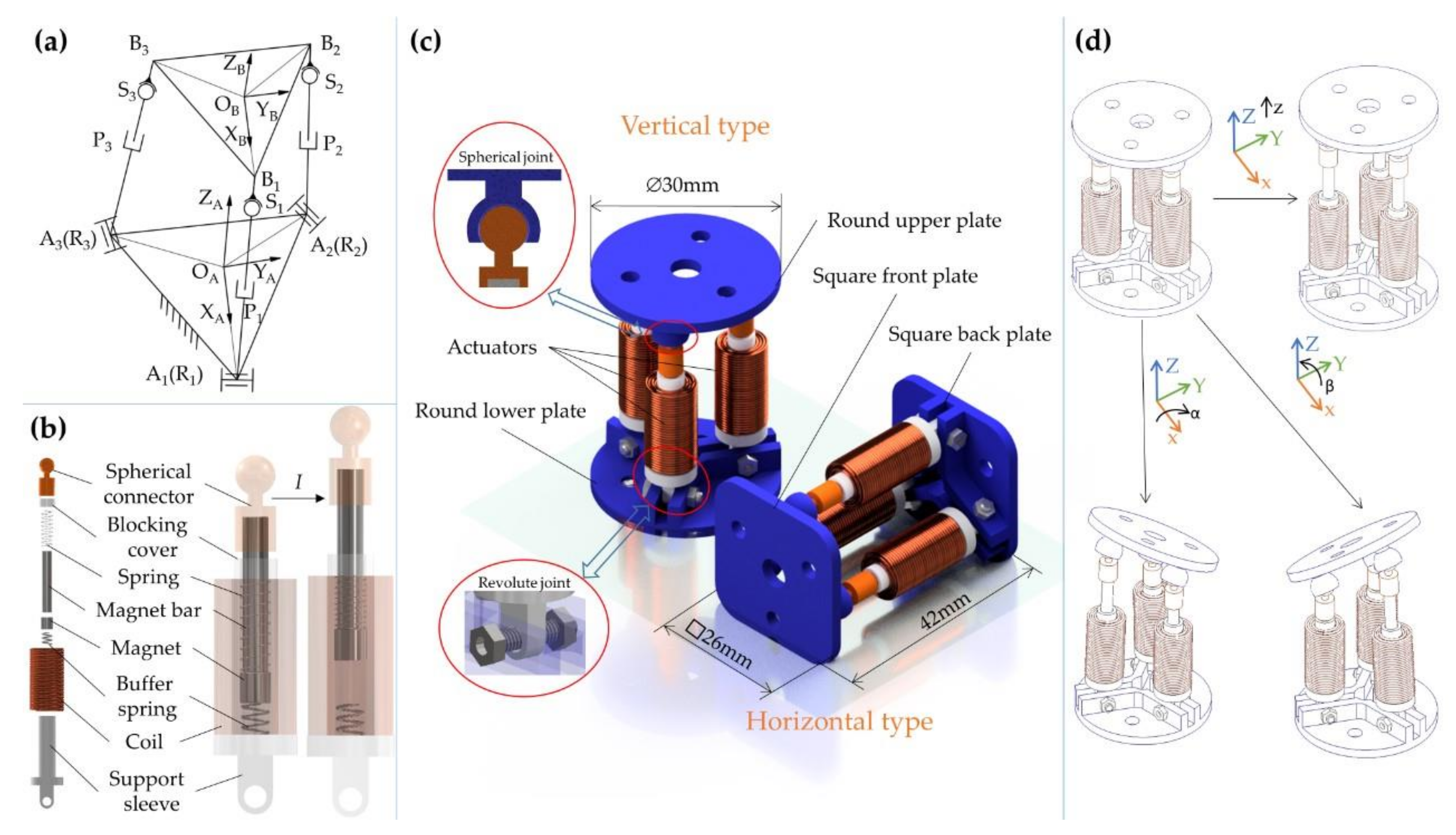

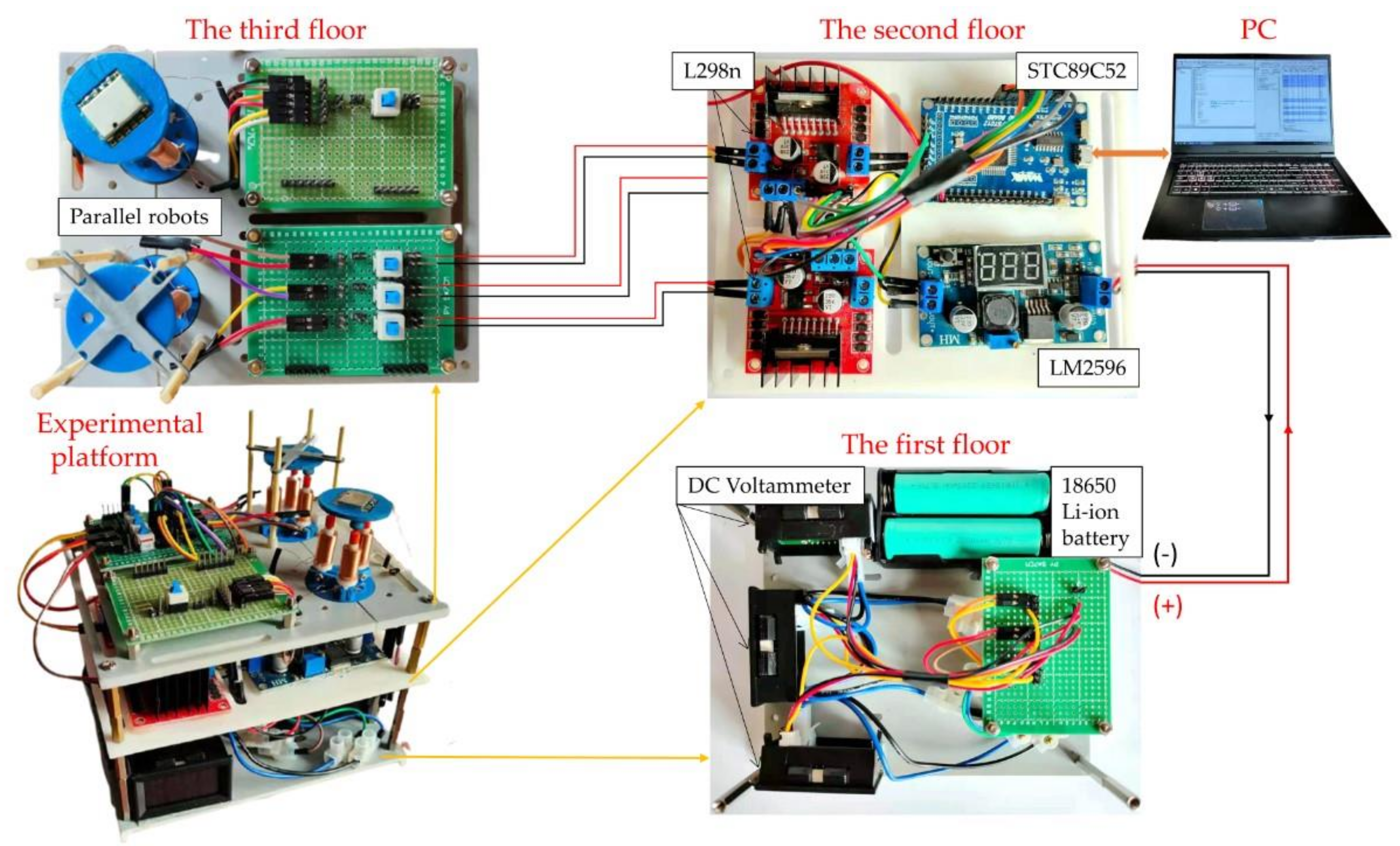

2. Design of the Parallel Robot

2.1. Mechanical Structure Design of the Robot

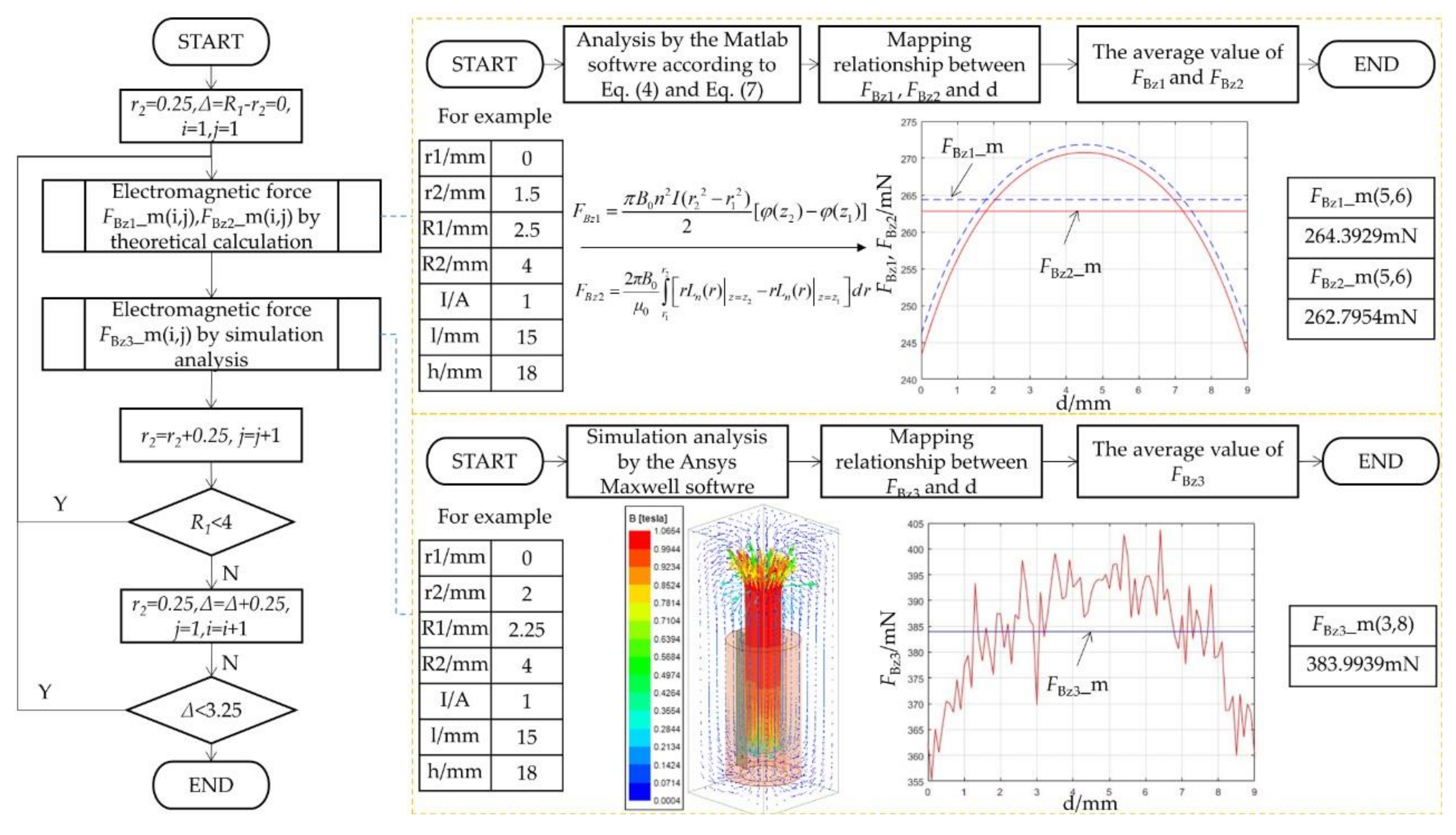

2.2. Theoretical Analysis of Electromagnetic Force

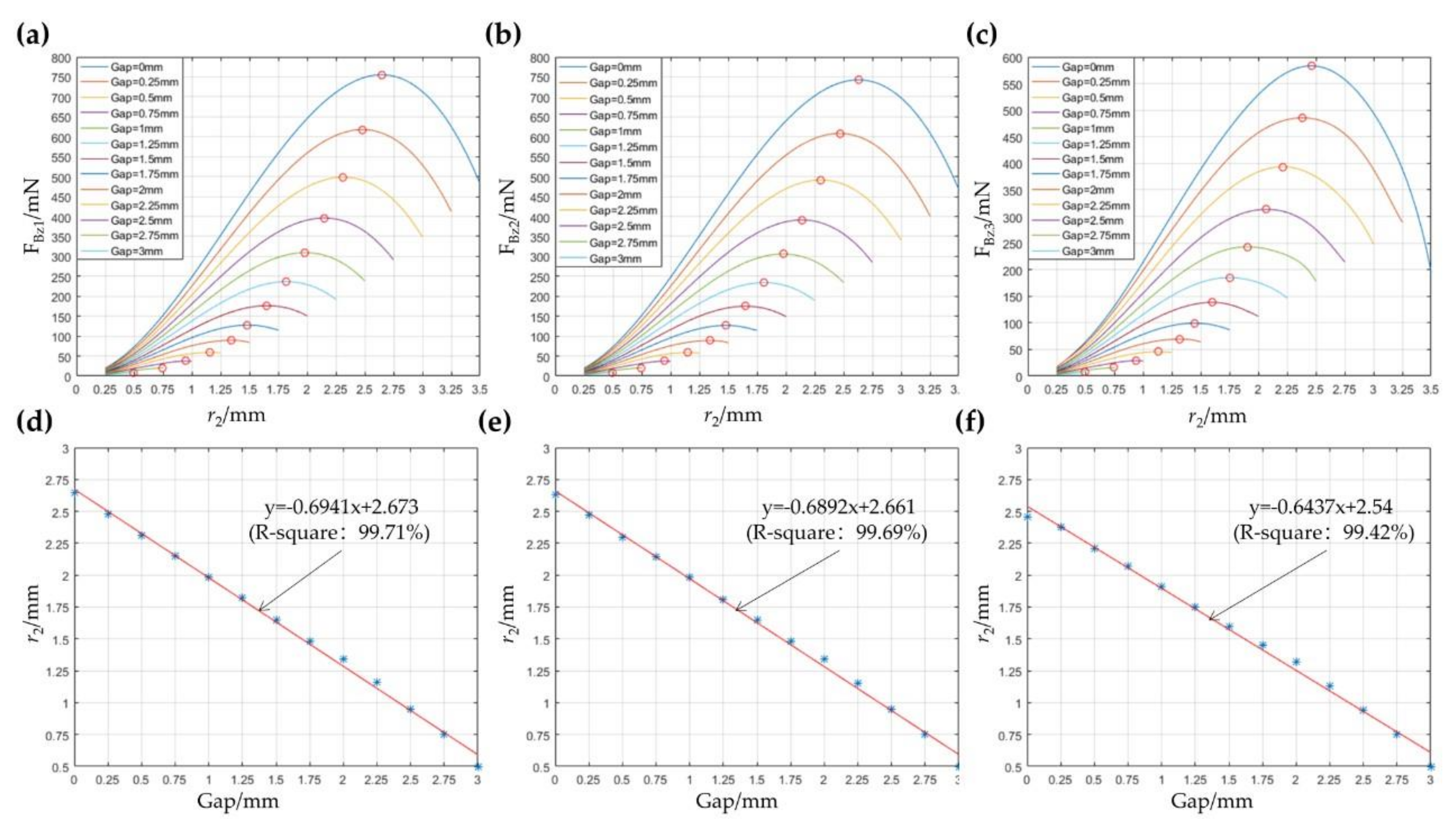

2.3. Parameter Selection of the Actuator

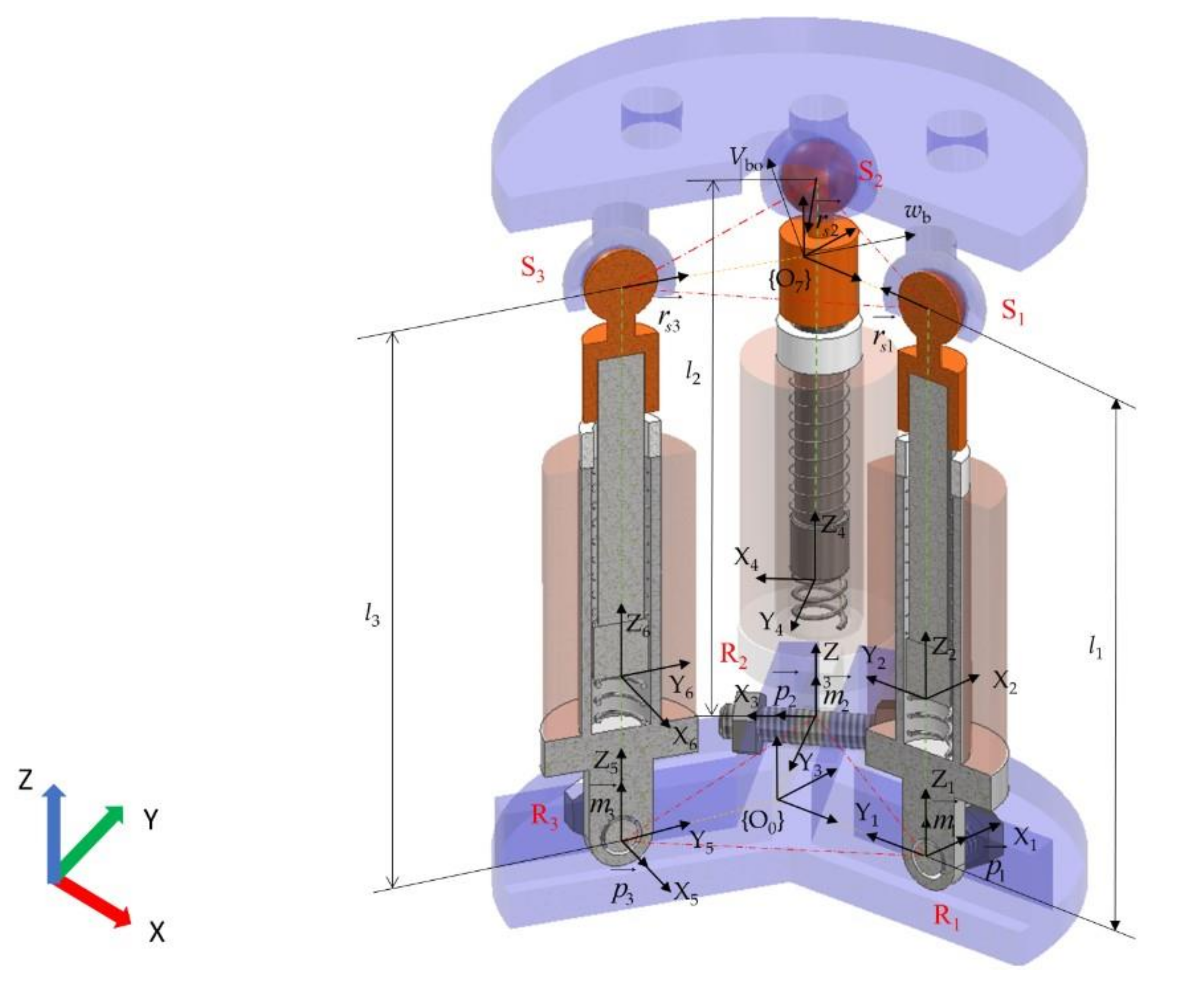

3. Dynamic Modeling of the Robot

3.1. Dynamic Modeling with the Euler–Lagrangian Approach

3.2. Dynamic Simulation Analysis

4. Experiments of the Robots

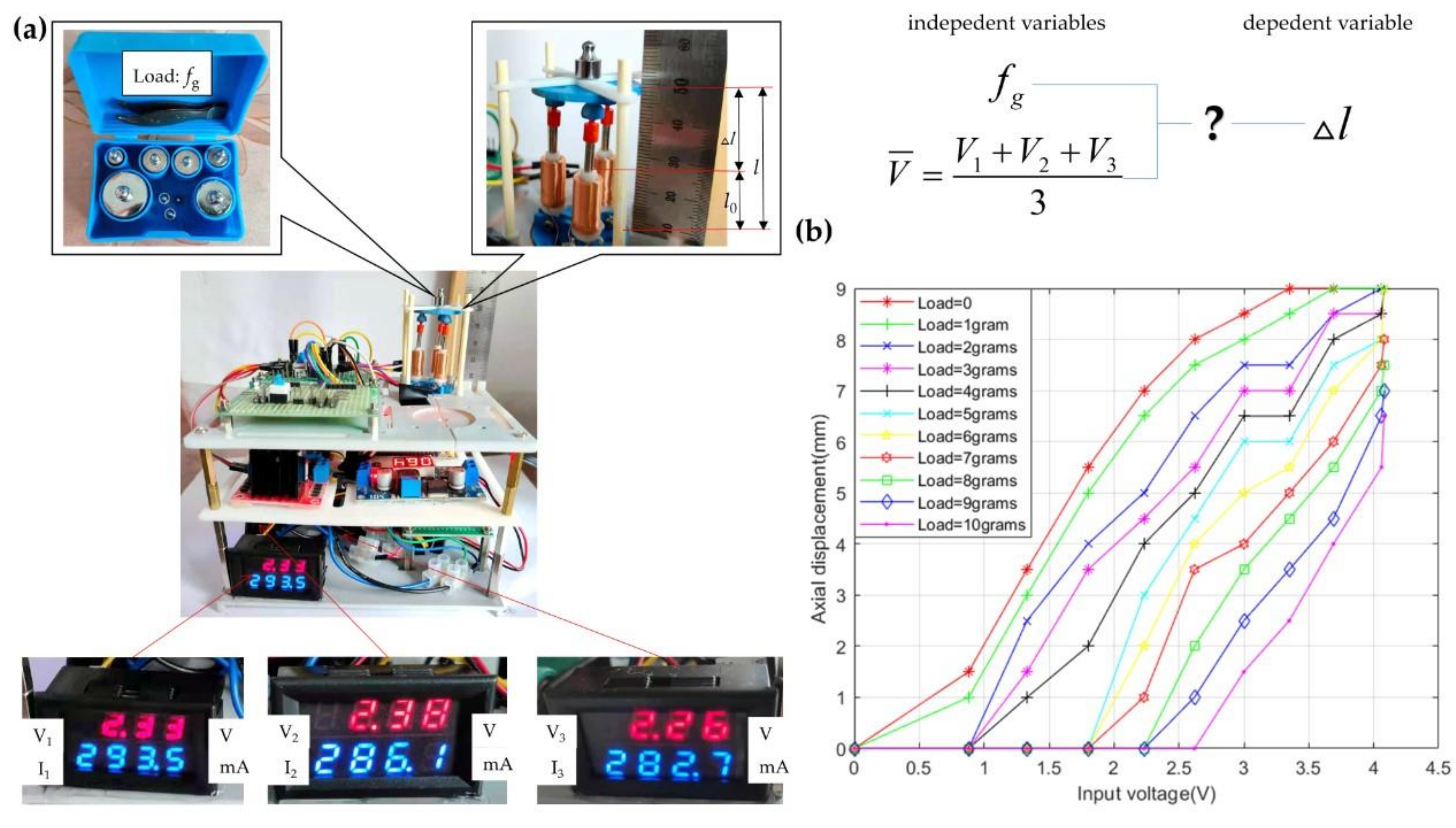

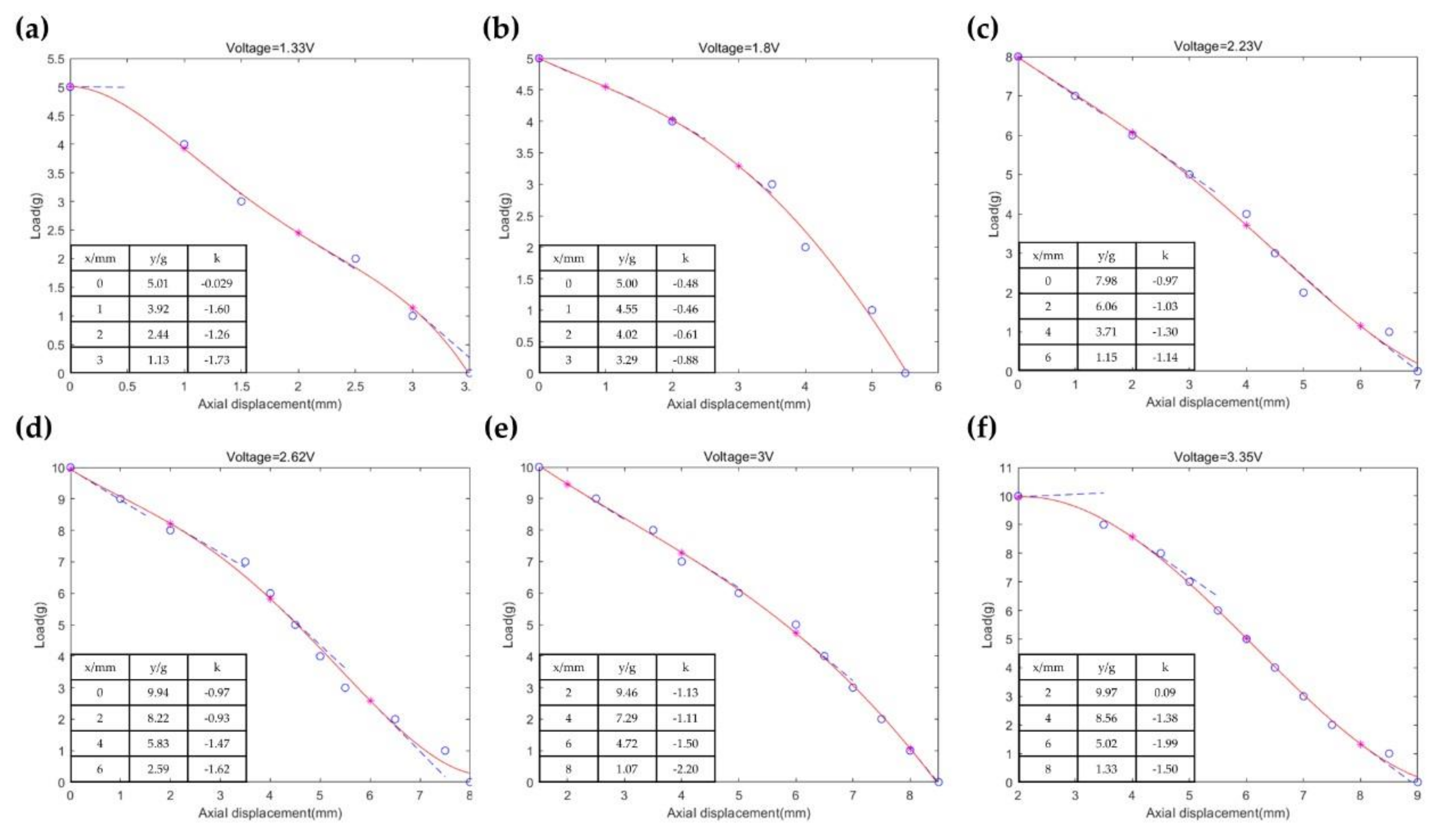

4.1. The Static Performance Test of the Robot

4.1.1. The Load Resistance Test of the Robot

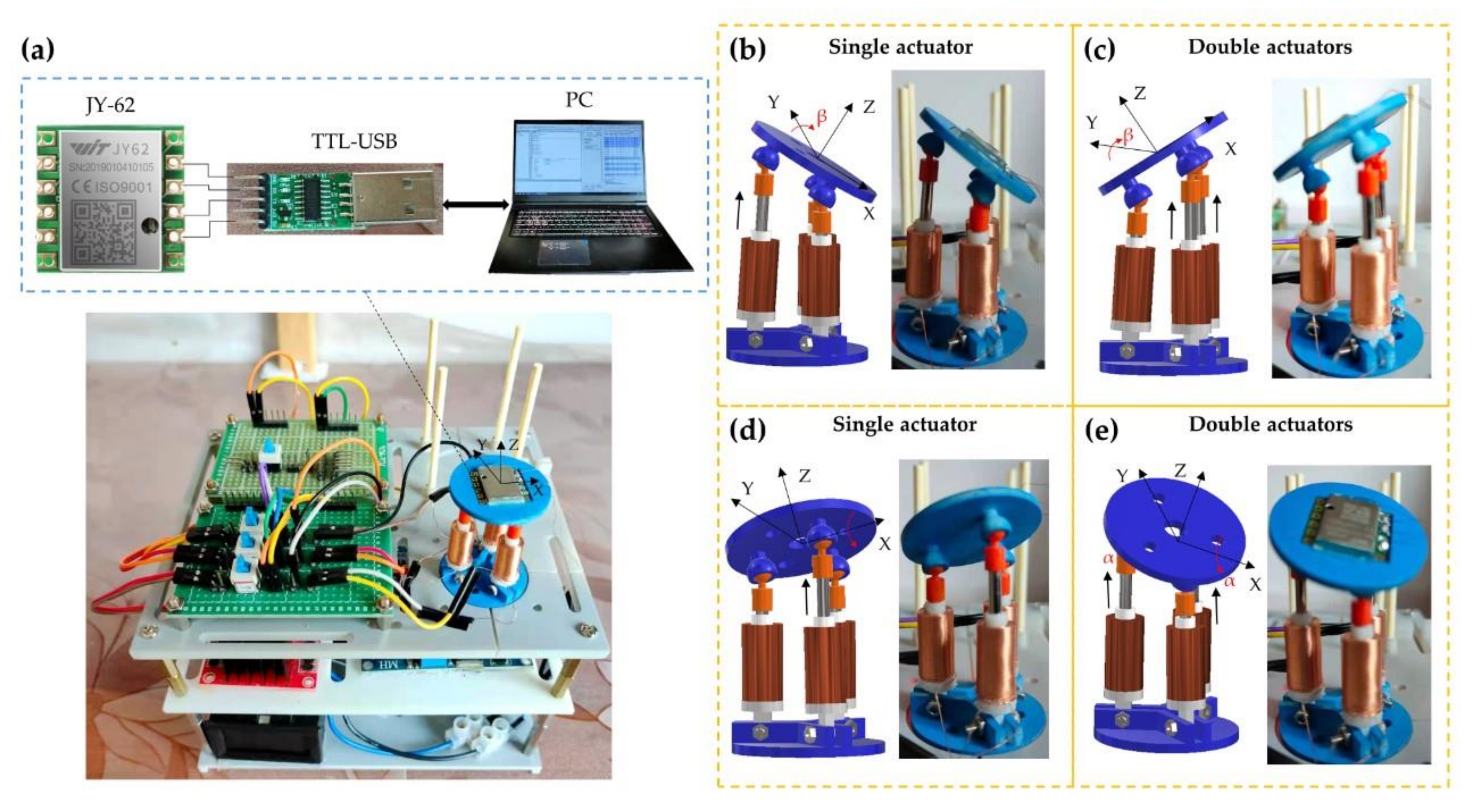

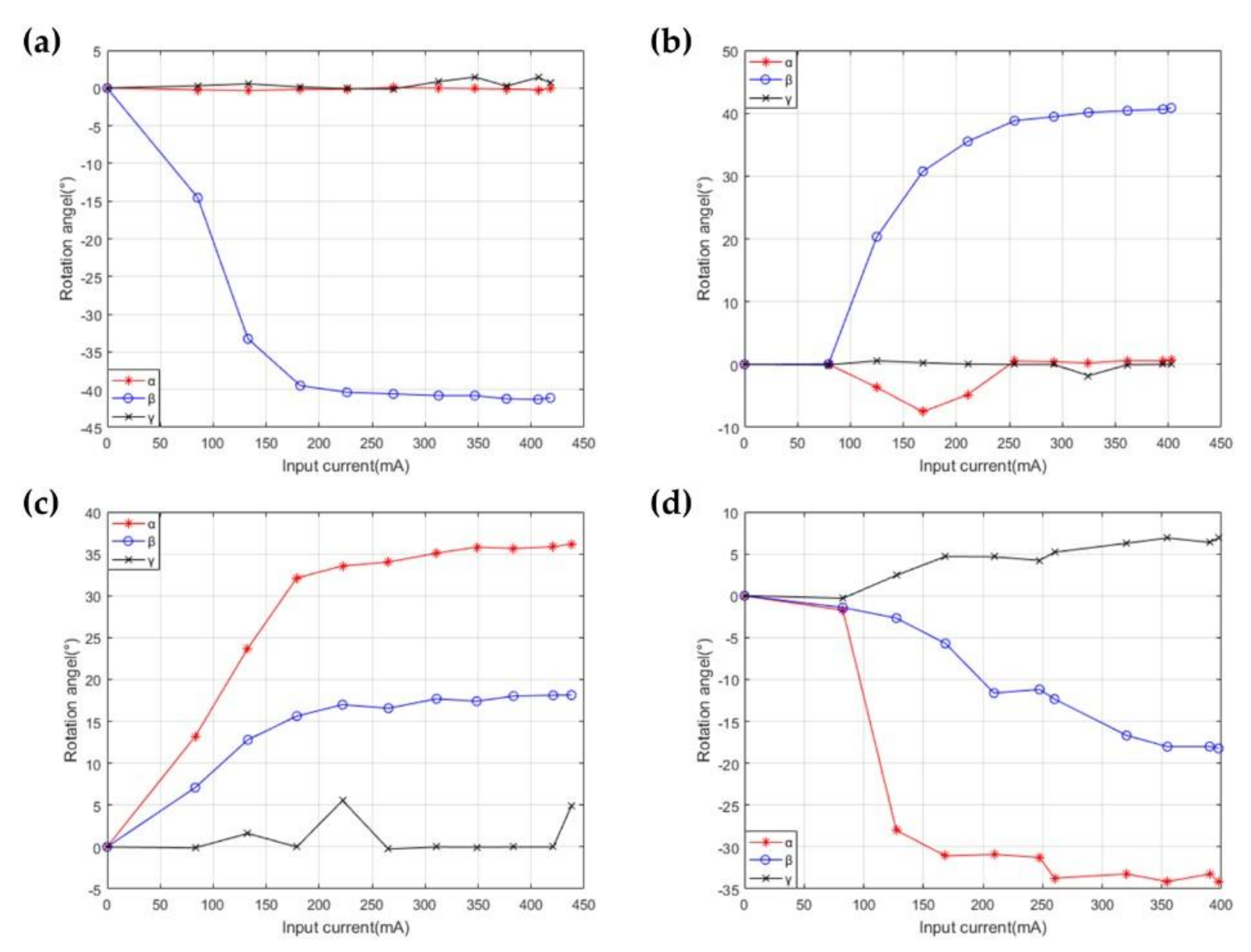

4.1.2. The Rotation Ability Test of the Robot

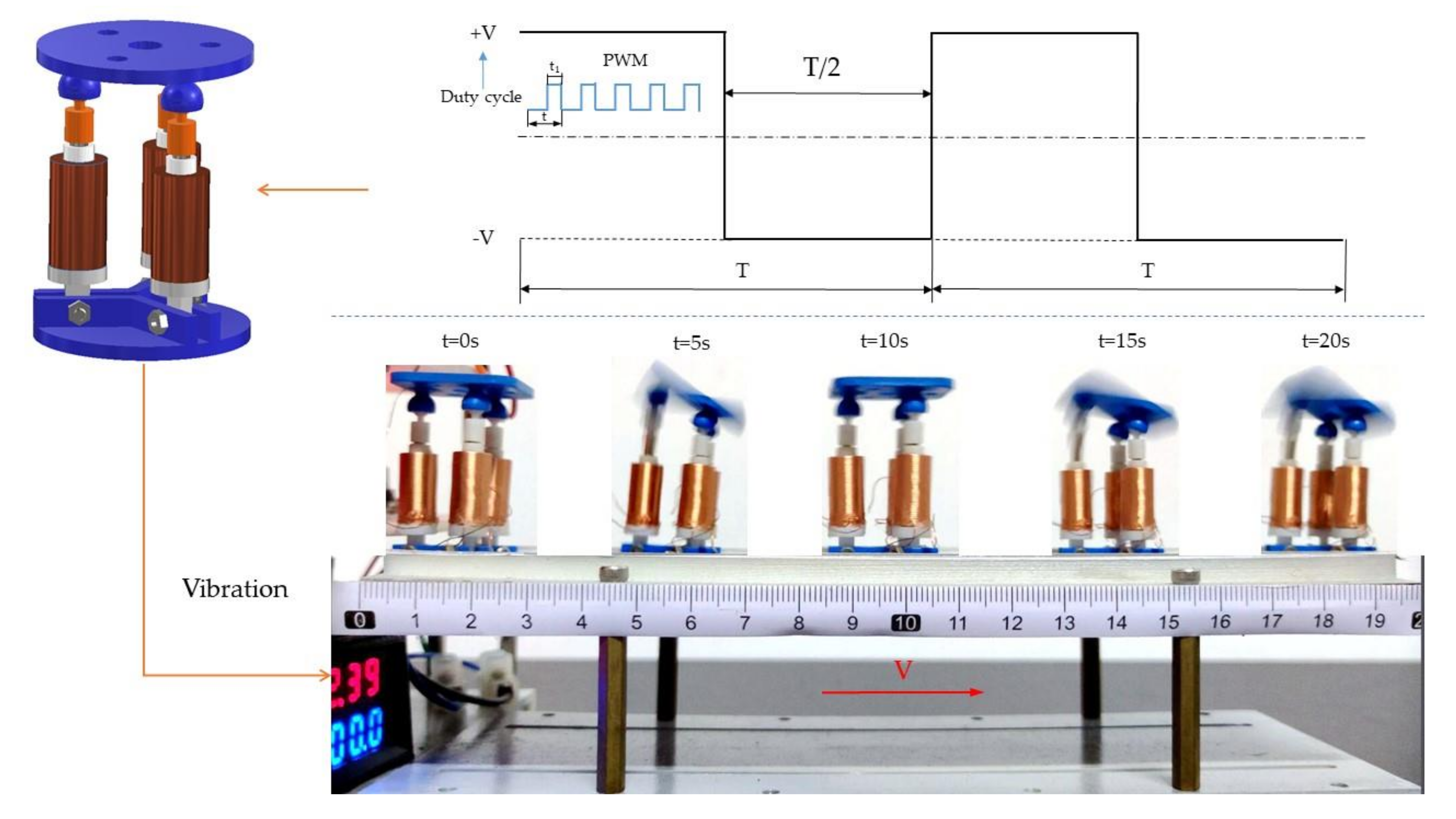

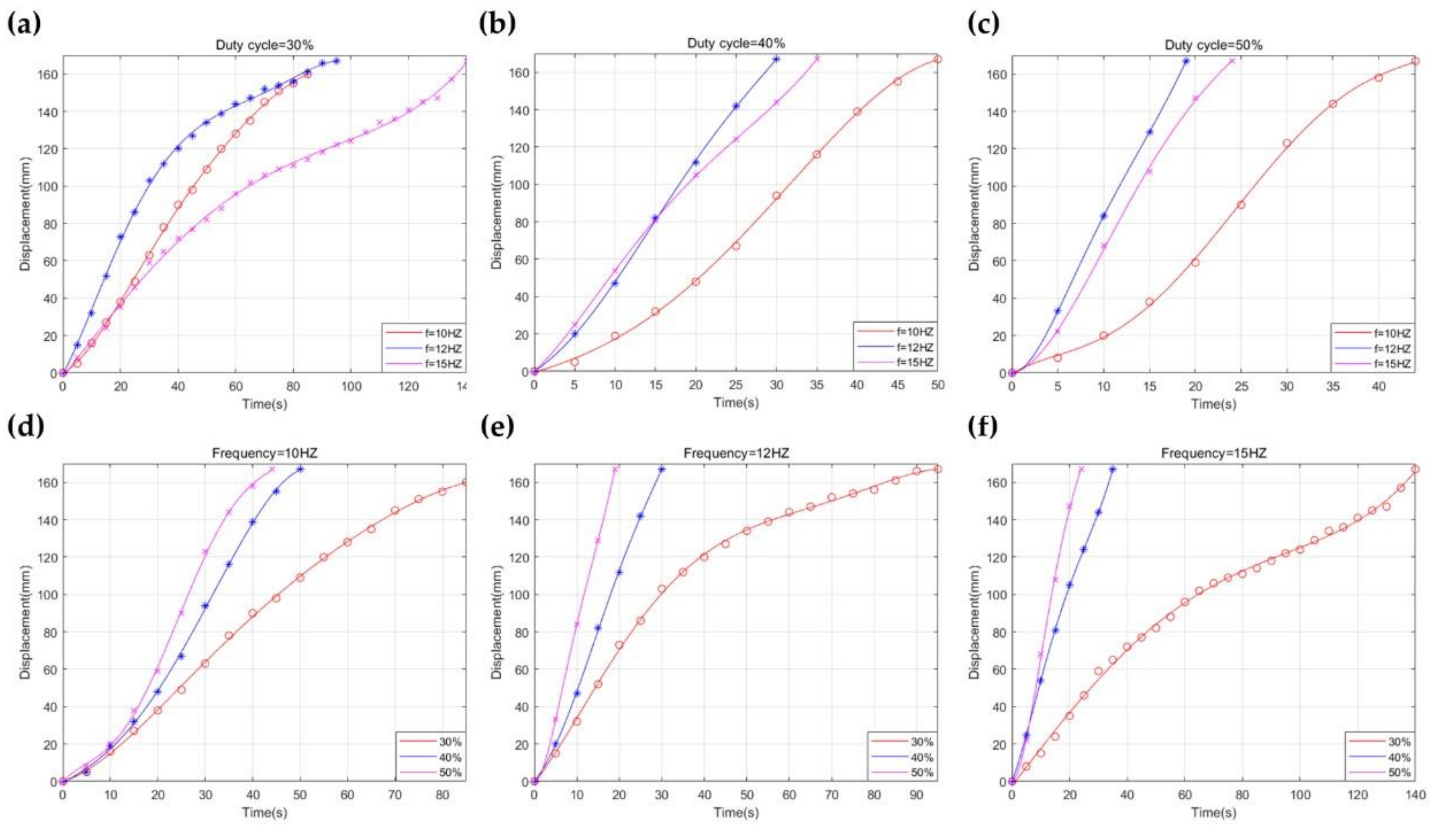

4.2. The Dynamic Performance Test of the Robot

5. Conclusions

- (1)

- The electromagnetic force calculated by Biot–Savart law combined with Lagrangian interpolation takes into account the magnetic field at the boundary point of the magnet, and the values are closer to simulation results. When the electromagnetic force reaches the maximum, the outer diameter of the magnet changes linearly with the gap within the 95% confidence interval, which is used as the regulation for the selection of structural parameters.

- (2)

- The input current and the pose of the motion platform are regarded as the input and output, respectively. The current can be further transformed into the motion parameters of the robot through dynamic analysis by taking the driving force as the intermediate variable. The end pose of the motion platform can be adjusted by regulating the input current through the mapping relationship between them.

- (3)

- The robot can accomplish basic movements such as axial translation and the rotation of the motion platform. The output stiffness can be regulated by varying the input voltage and the displacement of the robot. In addition, the robot can move forward relying on the vibration. With the increase in the input frequency, the speed of the joint firstly increases and then decreases when the input voltage is kept constant. With the rise of the input voltage amplitude, the speed of the robot increases when the input voltage keeps constant.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Displacment (mm) | Velocity (mm/s) | Bandwith (Hz) | Load (g) | Power (mW) |

|---|---|---|---|---|

| 9 | 36 | 25 | 5 | 0.22 |

| F (g) | d (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| v = 0.87 V | v = 1.33 V | v = 1.8 V | v = 2.23 V | v = 2.62 V | v = 3 V | v = 3.35 V | v = 3.69 V | v = 4.06 V | v = 4.08 V | |

| 0 | 1.5 | 3.5 | 5.5 | 7 | 8 | 8.5 | 9 | 9 | 9 | 9 |

| 1 | 1 | 3 | 5 | 6.5 | 7.5 | 8 | 8.5 | 9 | 9 | 9 |

| 2 | 0 | 2.5 | 4 | 5 | 6.5 | 7.5 | 7.5 | 8.5 | 9 | 9 |

| 3 | 0 | 1.5 | 3.5 | 4.5 | 5.5 | 7 | 7 | 8.5 | 8.5 | 9 |

| 4 | 0 | 1 | 2 | 4 | 5 | 6.5 | 6.5 | 8 | 8.5 | 8.5 |

| 5 | 0 | 0 | 0 | 3 | 4.5 | 6 | 6 | 7.5 | 8 | 9 |

| 6 | 0 | 0 | 0 | 2 | 4 | 5 | 5.5 | 7 | 8 | 9 |

| 7 | 0 | 0 | 0 | 1 | 3.5 | 4 | 5 | 6 | 7.5 | 8 |

| 8 | 0 | 0 | 0 | 0 | 2 | 3.5 | 4.5 | 5.5 | 7 | 7.5 |

| 9 | 0 | 0 | 0 | 0 | 1 | 2.5 | 3.5 | 4.5 | 6.5 | 7 |

| 10 | 0 | 0 | 0 | 0 | 0 | 1.5 | 2.5 | 4 | 5.5 | 6.5 |

| Figure 12a | Figure 12b | Figure 12c | Figure 12d | ||||||

|---|---|---|---|---|---|---|---|---|---|

| I/mA | β/° | I/mA | β/° | I/mA | α/° | β/° | I/mA | α/° | β/° |

| 0 | 0.01 | 0 | 0.02 | 0 | 0.03 | 0.02 | 0 | 0.02 | 0.01 |

| 85.4 | 14.55 | 79.3 | 0.08 | 83 | 13.19 | 7.09 | 82.5 | 1.73 | 1.41 |

| 132.8 | 33.26 | 124.9 | 20.33 | 132.7 | 23.73 | 12.8 | 127.4 | 28 | 2.68 |

| 182.1 | 39.47 | 168.3 | 30.74 | 178.9 | 32.12 | 15.63 | 168.5 | 31.06 | 5.7 |

| 226.2 | 40.35 | 210.7 | 35.5 | 222 | 33.56 | 16.99 | 209.3 | 30.89 | 11.62 |

| 270 | 40.57 | 254.8 | 38.8 | 265.3 | 34.01 | 16.56 | 247.5 | 31.25 | 11.19 |

| 312.6 | 40.79 | 291.9 | 39.44 | 310.7 | 35.08 | 17.69 | 260 | 33.72 | 12.34 |

| 346.8 | 40.79 | 324.5 | 40.11 | 348.6 | 35.8 | 17.4 | 320.4 | 33.22 | 16.68 |

| 376.7 | 41.22 | 361.4 | 40.4 | 383.3 | 35.64 | 18.02 | 354.7 | 34.12 | 18.02 |

| 406.6 | 41.3 | 394.8 | 40.62 | 420.8 | 35.84 | 18.11 | 390.1 | 33.23 | 18 |

| 418.1 | 41.1 | 402.6 | 40.84 | 438 | 36.17 | 18.14 | 397.6 | 34.12 | 18.23 |

| Duty Cycle | Average Velocity (mm/s) | ||

|---|---|---|---|

| f = 10 Hz | f = 12 Hz | f = 15 Hz | |

| 30% | 1.03 | 1.2 | 0.68 |

| 40% | 1.51 | 2.7 | 2.51 |

| 50% | 1.79 | 4.1 | 3.43 |

References

- Garduño-Aparicio, M.; Rodríguez-Reséndiz, J.; Macias-Bobadilla, G.; Thenozhi, S. A multidisciplinary industrial robot approach for teaching mechatronics-related courses. IEEE Trans. Educ. 2017, 61, 55–62. [Google Scholar] [CrossRef]

- Padilla-Garcia, E.A.; Rodriguez-Angeles, A.; Reséndiz, J.R.; Cruz-Villar, C.A. Concurrent optimization for selection and control of AC servomotors on the powertrain of industrial robots. IEEE Access 2018, 6, 27923–27938. [Google Scholar] [CrossRef]

- Martínez-Prado, M.A.; Rodríguez-Reséndiz, J.; Gómez-Loenzo, R.-A.; Herrera-Ruiz, G.; Franco-Gasca, L.-A. An FPGA-Based Open Architecture Industrial Robot Controller. IEEE Access 2018, 6, 13407–13417. [Google Scholar] [CrossRef]

- García-Martínez, J.R.; Cruz-Miguel, E.E.; Carrillo-Serrano, R.V.; Mendoza-Mondragón, F.; Toledano-Ayala, M.; Rodríguez-Reséndiz, J. A PID-Type Fuzzy Logic Controller-Based Approach for Motion Control Applications. Sensors 2020, 20, 5323. [Google Scholar] [CrossRef]

- Amici, C.; Pellegrini, N.; Tiboni, M. The Robot Selection Problem for Mini-Parallel Kinematic Machines: A Task-Driven Approach to the Selection Attributes Identification. Micromachines 2020, 11, 711. [Google Scholar] [CrossRef]

- Luces, M.; Mills, J.K.; Benhabib, B. A Review of Redundant Parallel Kinematic Mechanisms. J. Intell. Robot. Syst. 2016, 86, 175–198. [Google Scholar] [CrossRef]

- Jamwal, P.K.; Hussain, S.; Ghayesh, M.H.; Rogozina, S.V. Impedance control of an intrinsically compliant parallel ankle rehabilitation robot. IEEE Trans. Ind. Electron. 2016, 63, 3638–3647. [Google Scholar] [CrossRef]

- Yujun, C.; Jianzhong, S.; Keshan, L.; Dapeng, F.; Dongxi, M.; Li, T. Review of soft-bodied robots. Chin. J. Mech. Eng. 2012, 48, 25–33. [Google Scholar]

- Rodriguez-Barroso, A.; Saltaren, R.; Portilla, G.A.; Cely, J.S.; Carpio, M. Cable-Driven Parallel Robot with Reconfigurable End Effector Controlled with a Compliant Actuator. Sensors 2018, 18, 2765. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tianmiao, W.; Yufei, H.; Xingbang, Y.; Li, W. Soft robotics structure actuation sensing and control. Chin. J. Mech. Eng. 2017, 53, 1–13. [Google Scholar]

- Huang, X.; Zhang, C.; Chen, J.; Yang, G. Modeling of a Halbach Array Voice Coil Actuator via Fourier Analysis Based on Equivalent Structure. IEEE Trans. Magn. 2019, 55, 1–6. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Ahn, D. Analysis of High Force Voice Coil Motors for Magnetic Levitation. Actuators 2020, 9, 133. [Google Scholar] [CrossRef]

- Cigarini, F.; Ito, S.; Troppmair, S.; Schitter, G. Comparative finite element analysis of a voice coil actuator and a hybrid reluctance actuator. IEEJ J. Ind. Appl. 2019, 8, 192–199. [Google Scholar] [CrossRef] [Green Version]

- Shinno, H.; Yoshioka, H.; Sawano, H. A newly developed long range positioning table system with a sub-nanometer resolution. CIRP annals. 2011, 60, 403–406. [Google Scholar] [CrossRef]

- Zheng, J.; Guo, G.; Wang, Y.; Wong, W. Optimal Narrow-Band Disturbance Filter for PZT-Actuated Head Positioning Control on a Spinstand. IEEE Trans. Magn. 2006, 42, 3745–3751. [Google Scholar] [CrossRef]

- Leang, K.K.; Devasia, S. Hysteresis, Creep, and Vibration Compensation for Piezoactuators: Feedback and Feedforward Control 1. IFAC Proc. Vol. 2002, 35, 263–269. [Google Scholar] [CrossRef] [Green Version]

- Feng, X.M.; Duan, Z.J.; Fu, Y.; Sun, A.L.; Zhang, D.W. The technology and application of voice coil actuator. In Proceedings of the Second International Conference on Mechanic Automation and Control Engineering, Inner Mongolia, China, 15–17 July 2011; pp. 892–895. [Google Scholar]

- Kibria, M.G.; Rashid, F.; Shahadat, M. Design, fabrication and performance analysis of a voice coil motor using different input signal. In Proceedings of the IEEE International Conference on Signal Processing Information Communication & Systems (SPICSCON), Dhaka, Bangladesh, 28–30 November 2019; pp. 118–121. [Google Scholar]

- Shewale, M.S.; Razban, A.; Deshmukh, S.P.; Mulik, S.; Zambare, H.B. Design and experimental validation of voice coil motor for high precision applications. In Proceedings of the 3rd International Conference for Convergence in Technology (I2CT), Pune, India, 6–8 April 2018; pp. 1–6. [Google Scholar]

- Anderson, E.H.; Cash, M.F.; Hall, J.L.; Pettit, G.W. Hexapods for precision motion and vibration control, American Society for Precision Engineering. Control. Precis. Syst. 2004, 2004, 1–5. [Google Scholar]

- Chi, W.; Cao, D.; Wang, D.; Tang, J.; Nie, Y.; Huang, W. Design and Experimental Study of a VCM-Based Stewart Parallel Mechanism Used for Active Vibration Isolation. Energies 2015, 8, 8001–8019. [Google Scholar] [CrossRef] [Green Version]

- Fujii, Y.; Hashimoto, S. Evaluation of the dynamic properties of a Voice Coil Motor (VCM). In Proceedings of the 14th International Conference on Mechatronics and Machine Vision in Practice, Xiamen, China, 4–6 December 2007; pp. 57–61. [Google Scholar]

- Zhang, L.; Long, Z.; Cai, J.; Luo, F.; Fang, J.; Wang, M.Y. Multi-objective optimization design of a connection frame in macro–micro motion platform. Appl. Soft Comput. 2015, 32, 369–382. [Google Scholar] [CrossRef]

- Lei, G.; Shao, K.R.; Guo, Y.; Zhu, J.; Lavers, J.D. Improved sequential optimization method for high dimensional electromagnetic device optimization. IEEE Trans. Magn. 2009, 45, 3993–3996. [Google Scholar]

- Lei, G.; Guo, Y.G.; Zhu, J.G.; Chen, X.M.; Xu, W.; Shao, K.R. Sequential Subspace Optimization Method for Electromagnetic Devices Design With Orthogonal Design Technique. IEEE Trans. Magn. 2012, 48, 479–482. [Google Scholar] [CrossRef]

- Kang, D.; Kim, K.; Kim, D.; Shim, J.; Gweon, D.-G.; Jeong, J. Optimal design of high precision XY-scanner with nanometer-level resolution and millimeter-level working range. Mechatronics 2009, 19, 562–570. [Google Scholar] [CrossRef]

- Roemer, D.B.; Bech, M.M.; Johansen, P.; Pedersen, H.C. Optimum Design of a Moving Coil Actuator for Fast-Switching Valves in Digital Hydraulic Pumps and Motors. IEEE/ASME Trans. Mechatron. 2015, 20, 2761–2770. [Google Scholar] [CrossRef]

- Okyay, A.; Khamesee, M.B.; Erkorkmaz, K. Design and optimization of a voice coil actuator for precision motion applications. IEEE Trans. Magn. 2014, 51, 1–10. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, M.; Zhu, Y.; Yang, J.; Chen, B. Optimization of Voice Coil Motor to Enhance Dynamic Response Based on an Improved Magnetic Equivalent Circuit Model. IEEE Trans. Magn. 2011, 47, 2247–2251. [Google Scholar] [CrossRef]

- Echeverrıa, D.; Lahaye, D.; Encica, L.; Hemker, P.W. Optimisation in electromagnetics with the space-mapping. COMPEL 2005, 24, 952–966. [Google Scholar] [CrossRef]

- Echeverria, D.; Lahaye, D.; Encica, L.; Lomonova, E.A.; Hemker, P.W.; Vandenput, A.J.A. Manifold-mapping optimization applied to linear actuator design. IEEE Trans. Magn. 2006, 42, 1183–1186. [Google Scholar] [CrossRef] [Green Version]

- Gao, H.; Zhang, F.; Wang, E.; Liu, B.; Zeng, W.; Wang, Z. Optimization and simulation of a voice coil motor for fuel injectors of two-stroke aviation piston engine. Adv. Mech. Eng. 2019, 11. [Google Scholar] [CrossRef]

- Lee, J.; Wang, S. Topological Shape Optimization of Permanent Magnet in Voice Coil Motor Using Level Set Method. IEEE Trans. Magn. 2012, 48, 931–934. [Google Scholar] [CrossRef]

- Ebrahimi, N.; Schimpf, P.; Jafari, A. Design optimization of a solenoid-based electromagnetic soft actuator with permanent magnet core. Sens. Actuators A Phys. 2018, 284, 276–285. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, J.; Wang, H.; Chen, G.; Lai, X. Design of an electromagnetic prismatic joint with variable stiffness. Ind. Robot. Int. J. 2017, 44, 222–230. [Google Scholar] [CrossRef]

- Rogóż, M.; Dradrach, K.; Xuan, C.; Wasylczyk, P.A. Millimeter-Scale Snail Robot Based on A Light-Powered Liquid Crystal Elastomer Continuous Actuator. Macromol. Rapid Commun. 2019, 40, 1900279. [Google Scholar] [CrossRef] [PubMed]

- Xin, W.; Pan, F.T.; Li, Y.; Chiu, P.W.Y.; Li, Z. A Novel Biomimic Soft Snail Robot Aiming for Gastrointestinal (GI) Tract Inspection. In Proceedings of the 8th IEEE RAS/EMBS International Conference for Biomedical Robotics and Biomechatronics (BioRob), New York, NY, USA, 29 November–1 December 2020; pp. 1049–1054. [Google Scholar]

| Component | Parameter/mm | Value | Material |

|---|---|---|---|

| Coil | Inner diameter | 4.5 | Copper |

| Outer diameter | 8 | ||

| Height Wire diameter | 15 0.2 | ||

| Magnet bar | Outer diameter | 2.5 | NdFeB (N53) |

| Height | 12 | ||

| Soft spring | Outer diameter | 3 | SUS304 |

| Height Wire diameter | 9 0.1 | ||

| Magnet | Outer diameter | 3 | NdFeB (N53) |

| Height | 3 | ||

| Buffer spring | Outer diameter | 2.8 | SUS304 |

| Height Wire diameter | 3 0.3 |

| a | b | c | d | e | f | R-Square | |

|---|---|---|---|---|---|---|---|

| F1 | 46.04 | 0.006 | 1.553 | 30.29 | 1 | 4.912 | 100% |

| F2 | 49.39 | 0.002 | 1.560 | 33.72 | 1 | 4.912 | 100% |

| F3 | 42.73 | 0.022 | 1.505 | 26.81 | 1.001 | 4.910 | 100% |

| I1 | 158.6 | 0.171 | 1.099 | 74.70 | 1.058 | 4.752 | 99.98% |

| I2 | 180.1 | 0.234 | 0.906 | 74.87 | 1.108 | 4.598 | 99.98% |

| I3 | 158.8 | 0.005 | 2.102 | 73.76 | 1 | 4.951 | 99.98% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Lu, S.; Zhang, C.; Gao, J.; Zhang, B.; Wang, S. Design and Dynamic Modeling of a 3-RPS Compliant Parallel Robot Driven by Voice Coil Actuators. Micromachines 2021, 12, 1442. https://doi.org/10.3390/mi12121442

Wang C, Lu S, Zhang C, Gao J, Zhang B, Wang S. Design and Dynamic Modeling of a 3-RPS Compliant Parallel Robot Driven by Voice Coil Actuators. Micromachines. 2021; 12(12):1442. https://doi.org/10.3390/mi12121442

Chicago/Turabian StyleWang, Chuchao, Shizhou Lu, Caiyi Zhang, Jun Gao, Bin Zhang, and Shu Wang. 2021. "Design and Dynamic Modeling of a 3-RPS Compliant Parallel Robot Driven by Voice Coil Actuators" Micromachines 12, no. 12: 1442. https://doi.org/10.3390/mi12121442

APA StyleWang, C., Lu, S., Zhang, C., Gao, J., Zhang, B., & Wang, S. (2021). Design and Dynamic Modeling of a 3-RPS Compliant Parallel Robot Driven by Voice Coil Actuators. Micromachines, 12(12), 1442. https://doi.org/10.3390/mi12121442