Combination of Ceramic Laser Micromachining and Printed Technology as a Way for Rapid Prototyping Semiconductor Gas Sensors

Abstract

:1. Introduction

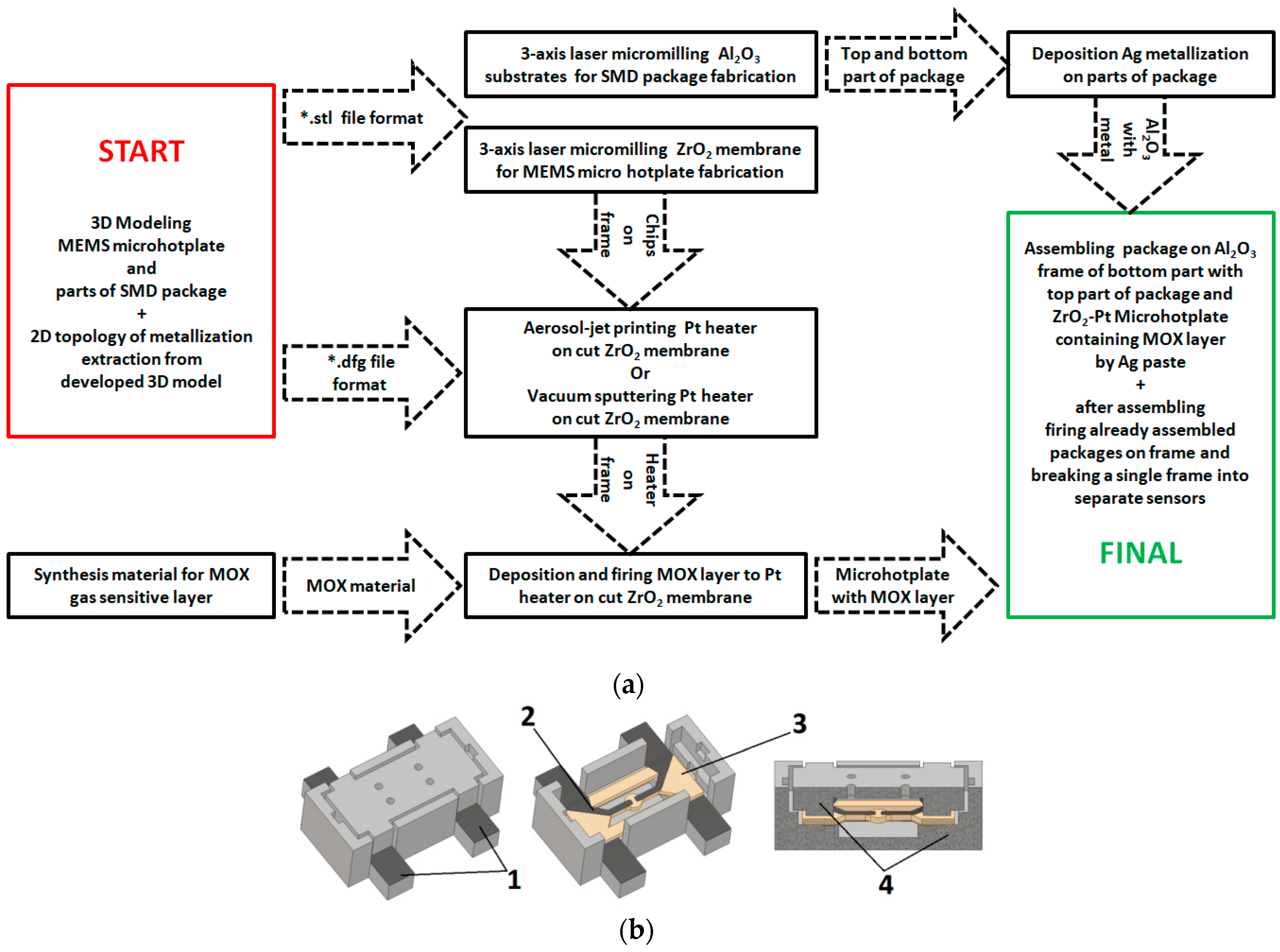

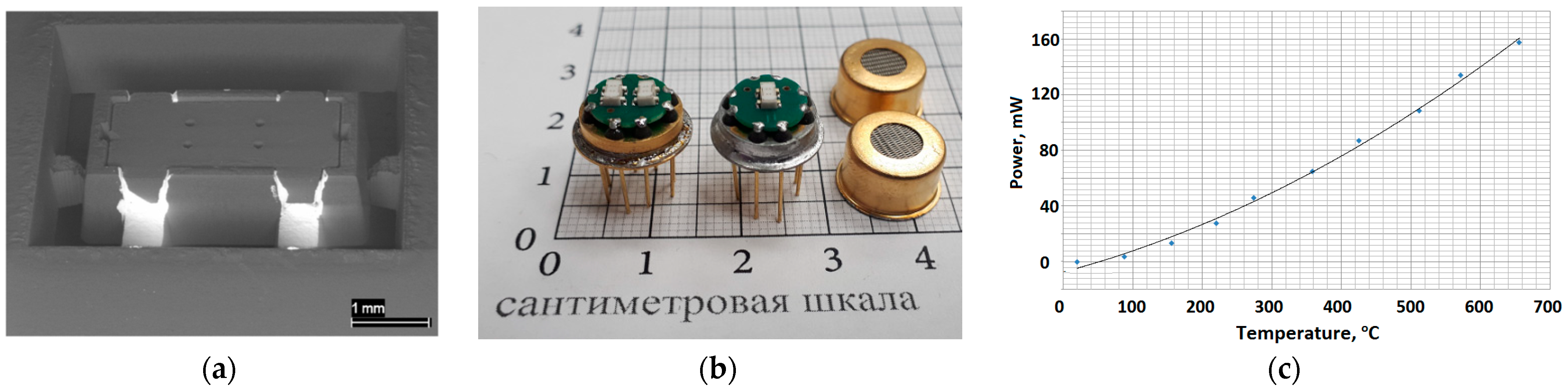

2. Materials and Methods

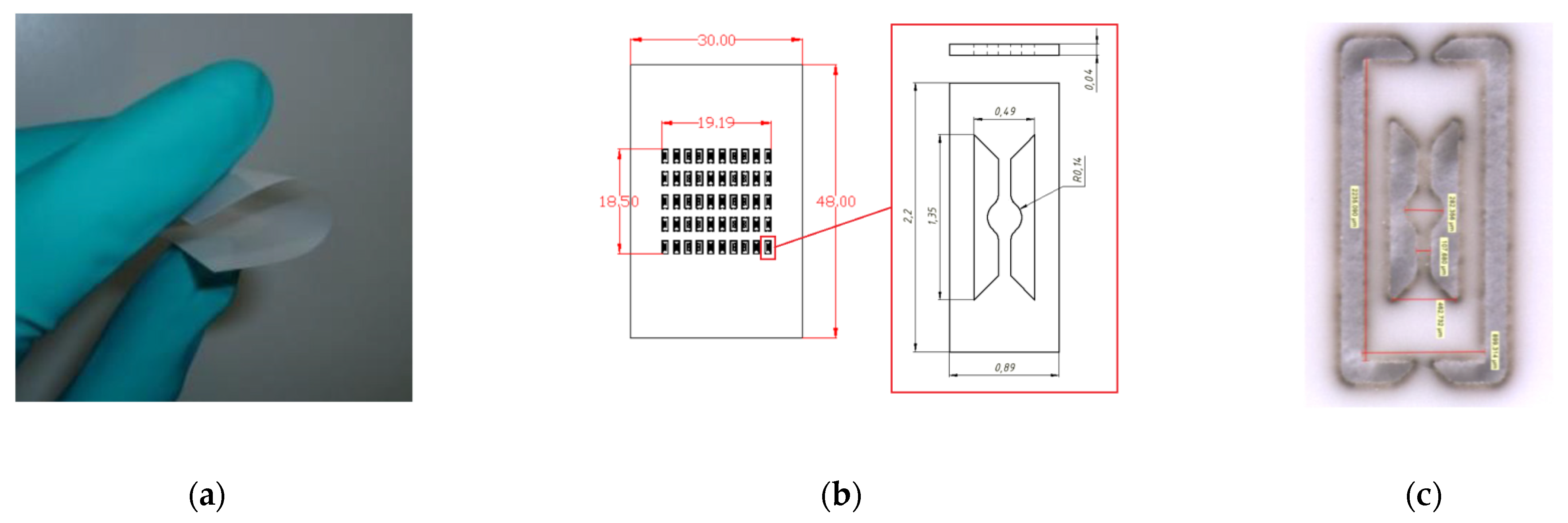

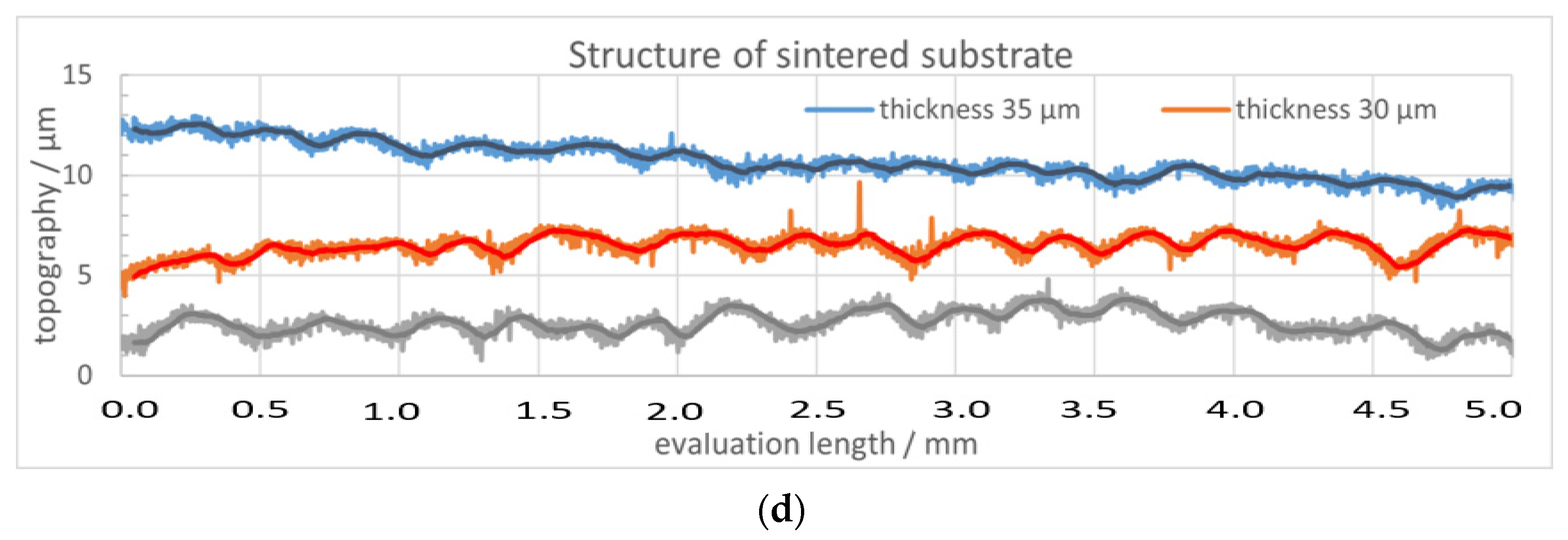

2.1. Fabrication Ultra Thin Zirconium Oxide Membrane

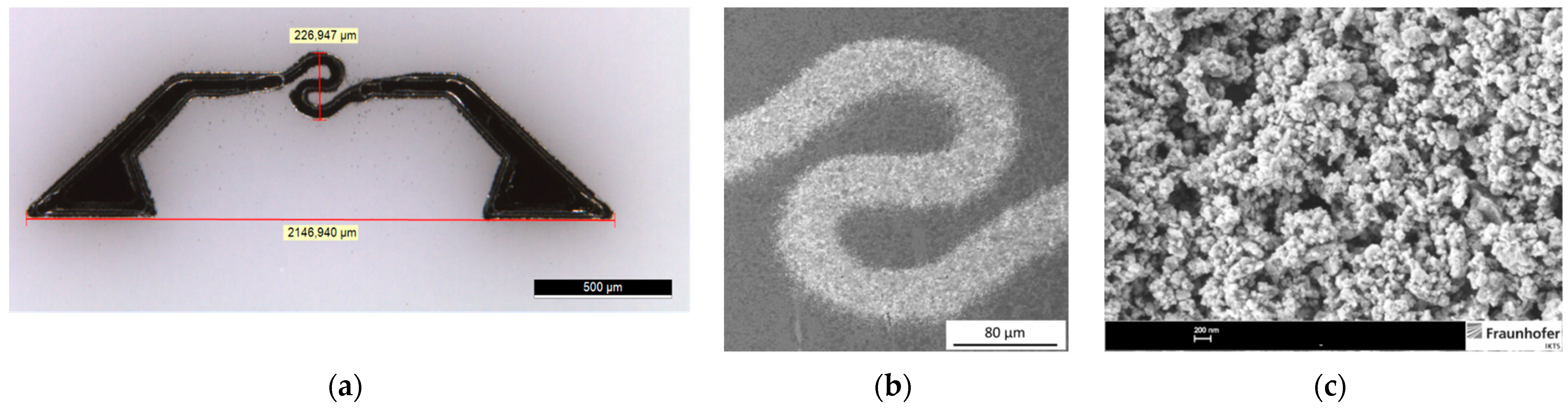

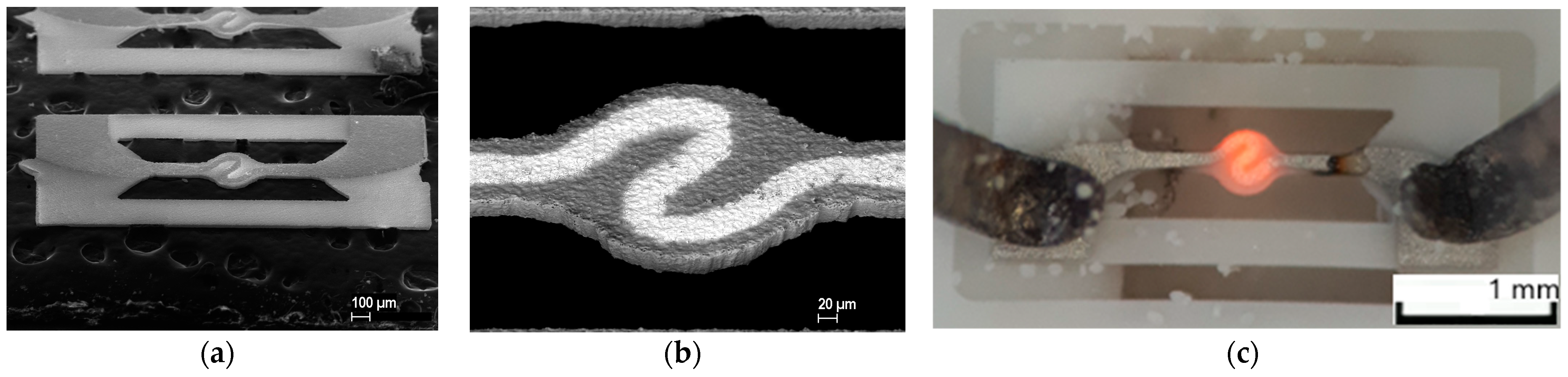

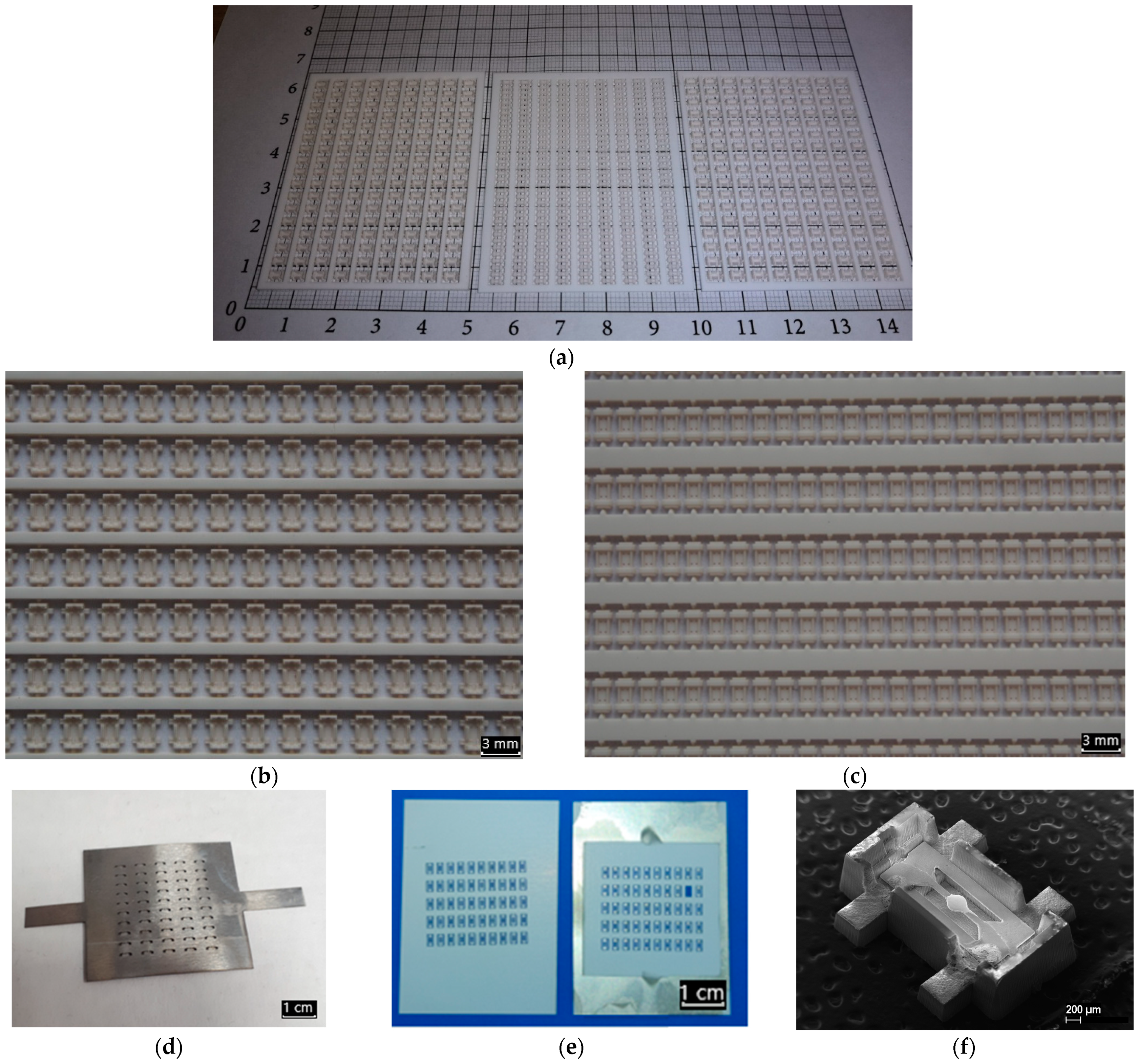

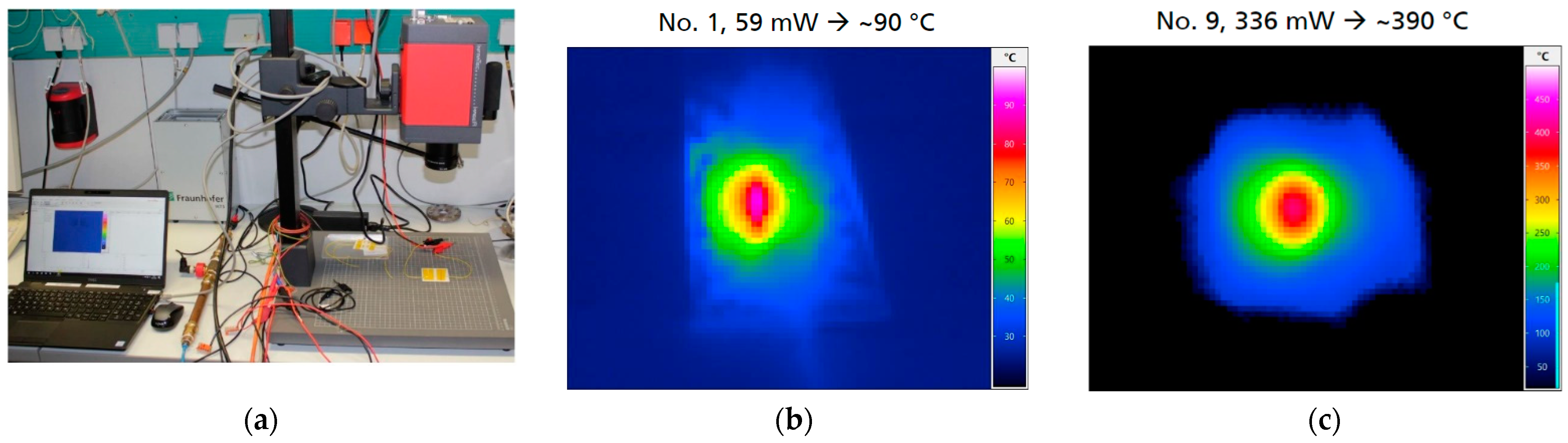

2.2. Fabrication Platinum Printing Microhotplate

2.3. Fabrication Platinum Sputtering Microhotplate

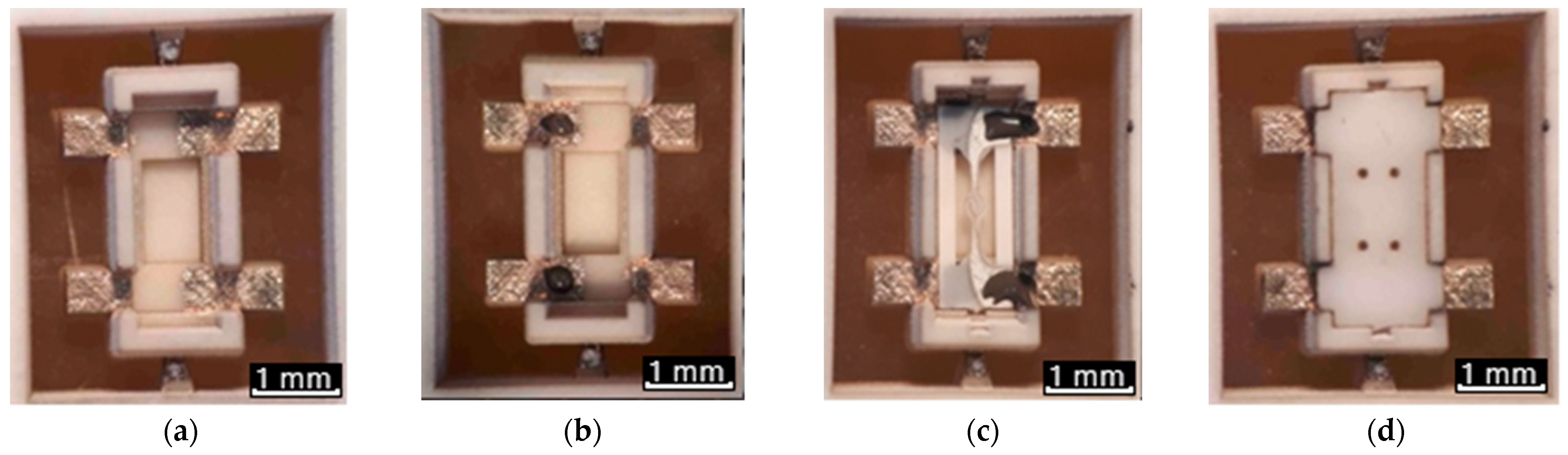

2.4. Fabrication Ceramic Package for MOX Sensor

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Barsan, N.; Koziej, D.; Weimar, U. Metal oxide-based gas sensor research: How to? Sens. Actuators B 2007, 121, 18–35. [Google Scholar] [CrossRef]

- Figaro Engineering Inc. Available online: https://www.figaro.co.jp/en/product/sensor/ (accessed on 21 October 2021).

- Sensirion’s MOXSens® Technology. Available online: https://www.sensirion.com/en/environmental-sensors/gas-sensors/ (accessed on 21 October 2021).

- SGX Sensortech. Available online: https://www.sgxsensortech.com/products-services/industrial-safety/metal-oxide-sensors/ (accessed on 21 October 2021).

- Winsen-Sensor. Available online: https://www.winsen-sensor.com/sensors/mems-gas-sensor/ (accessed on 21 October 2021).

- Van Den Broek, J.; Güntner, A.T.; Pratsinis, S.E. Highly selective and rapid breath isoprene sensing enabled by activated alumina filter. ACS Sens. 2018, 3, 677–683. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Samotaev, N.; Litvinov, A.; Etrekova, M.; Oblov, K.; Filipchuk, D.; Mikhailov, A. Prototype of nitro compound vapor and trace detector based on a capacitive MIS sensor. Sensors 2020, 20, 1514. [Google Scholar] [CrossRef] [Green Version]

- Van Den Broek, J.; Abegg, S.; Pratsinis, S.E.; Güntner, A.T. Highly selective detection of methanol over ethanol by a handheld gas sensor. Nat. Commun. 2019, 10, 4220. [Google Scholar] [CrossRef]

- Leidinger, M.; Rieger, M.; Sauerwald, T.; Alépée, C.; Schütze, A. Integrated pre-concentrator gas sensor microsystem for ppb level benzene detection. Sens. Actuators B 2016, 236, 988–996. [Google Scholar] [CrossRef]

- Kock, A.; Wimmer-Teubenbacher, R.; Sosada-Ludwikovska, F.; Rohracher, K.; Wachmann, E.; Herold, M.; Welden, T.V.; Min Kim, J.; Ali, Z.; Poenninger, A.; et al. 3D-Integrated Multi-Sensor Demonstrator System for Environmental Monitoring. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems and Eurosensors XXXIII, TRANSDUCERS 2019 and EUROSENSORS XXXIII, Berlin, Germany, 23 June 2019; pp. 1136–1139. [Google Scholar]

- Renesas. Gas Sensor Module. Available online: https://www.idt.com/us/en/document/dst/zmod4410-datasheet (accessed on 21 October 2021).

- Bosch BME 680 Sensor. Available online: https://www.bosch-sensortec.com/media/boschsensortec/downloads/datasheets/bst-bme680-ds001.pdf (accessed on 21 October 2021).

- Dietrich, S.; Kusnezoff, M.; Trofimenko, N.; Beckert, W.; Henze, J. Thick-film sensor for the detection of hydrogen in chlorine gas. In Proceedings of the Dresdner Sensor-Symposium, Dresden, Germany, 9 December 2013; pp. 219–223. [Google Scholar]

- Vasiliev, A.A.; Pisliakov, A.V.; Sokolov, A.V.; Samotaev, N.N.; Soloviev, S.A.; Oblov, K.; Guarnieri, V.; Lorenzelli, L.; Brunelli, J.; Maglione, A.; et al. Non-silicon MEMS platforms for gas sensors. Sens. Actuators B 2016, 224, 700–713. [Google Scholar] [CrossRef]

- Kerafol3YSZ—Sensor. Available online: https://www.kerafol.com/_wpframe_custom/downloads/files/KERAFOL_Datenblatt_3YSZ_01-20___081212-20022020.pdf (accessed on 21 October 2021).

- Kerafol Keral 96. Available online: https://www.kerafol.com/_wpframe_custom/downloads/files/KERAFOL_Datenblatt_Keral96_01-20___081306-20022020.pdf (accessed on 21 October 2021).

- Fraunhofer IKTS. Functional Inks for Inkjet-, Aerosol- and Screen-Printing Technologies—Printed Electronics and Sensor Applications. Available online: https://www.ikts.fraunhofer.de/en/departments/energy_systems/materials_and_components/HT_ElectrochemistryCatalysis/material_inks.html (accessed on 21 October 2021).

- PVNanoCell Ltd. Available online: https://www.pvnanocell.com/silver-inks.html (accessed on 21 October 2021).

- Samotaev, N.N.; Vasiliev, A.A.; Podlepetsky, B.I.; Sokolov, A.V.; Pisliakov, A.V. The mechanism of the formation of selective response of semiconductor gas sensor in mixture of CH4/H2/CO with air. Sens. Actuators B 2007, 127, 242–247. [Google Scholar] [CrossRef]

- NSamotaev, N.; Oblov, K.; Etrekova, M.; Veselov, D.; Gorshkova, A. Parameter Studies of Ceramic MEMS Microhotplates Fabricated by Laser Micromilling Technology. Mater. Sci. Forum 2020, 977, 238–243. [Google Scholar] [CrossRef]

- RichtekSOT23 FCOL Package Thermal Considerations. Available online: https://www.richtek.com/m/~/media/AN%20PDF/AN004_EN.pdf (accessed on 21 October 2021).

- Samotaev, N.; Oblov, K.; Ivanova, A.; Gorshkova, A.; Podlepetsky, B. Rapid Prototyping of MOX Gas Sensors in Form-Factor of SMD Packages. In Proceedings of the 2019 IEEE 31st International Conference on Microelectronics (MIEL), Nis, Serbia, 16–18 September 2019; pp. 157–160. [Google Scholar]

- Samotaev, N.N.; Podlepetsky, B.I.; Vasiliev, A.A.; Pisliakov, A.V.; Sokolov, A.V. Metal-oxide gas sensor high-selective to ammonia. Autom. Remote Control 2013, 74, 308–312. [Google Scholar] [CrossRef]

- Samotaev, N.N.; Oblov, K.Y.; Gorshkova, A.V.; Ivanova, A.V.; Philipchuk, D.V. Ceramic packages prototyping for electronic components by using laser micromilling technology. J. Phys. Conf. Ser. 2020, 1686, 012010. [Google Scholar] [CrossRef]

- Biró, F.; Dücso, C.; Hajnal, Z.; Riesz, F.; Pap, A.E.; Bársony, I. Thermo-mechanical design and characterization of low dissipation micro-hotplates operated above 500 °C. Microelectron. J. 2015, 45, 1822–1828. [Google Scholar] [CrossRef]

- EOS. PA2200 Material Data Sheet. Available online: http://www.shapeways.com/topics/udesign/materials/white_strong_flexible/pa2200_material_data_sheet_12_08_en__.pdf (accessed on 21 October 2021).

- JSC MARS Factory. Leaded Hermetic Packages for Pressure Sensors. Available online: http://www.z-mars.ru/docum/57.pdf (accessed on 18 October 2021).

- Bíró, F.; Hajnal, Z.; Dücső, C.; Bársony, I. The critical impact of temperature gradients on Pt filament failure. Microelectron. Reliab. 2017, 78, 118–125. [Google Scholar] [CrossRef]

- Huotari, J.; Bjorklund, R.; Lappalainen, J.; Lloyd Spetz, A. Pulsed Laser Deposited Nanostructured Vanadium Oxide Thin Films Characterized as Ammonia Sensors. Sens. Actuators B 2015, 217, 22–29. [Google Scholar] [CrossRef]

- Huotari, J.; Kekkonen, V.; Haapalainen, T.; Leidinger, M.; Sauerwald, T.; Puustinen, J.; Liimatainen, J.; Lappalainen, J. Pulsed laser deposition of metal oxide nanostructures for highly sensitive gas sensor applications. Sens. Actuators B 2016, 236, 978–987. [Google Scholar] [CrossRef]

- Oros, C.; Horprathum, M.; Wisitsoraat, A.; Srichaiyaperk, T.; Samransuksamer, B.; Limwichean, S.; Eiamchai, P.; Phokharatkul, D.; Nuntawong, N.; Chananonnawathorn, C.; et al. Ultra-sensitive NO2 sensor based on vertically aligned SnO2 nanorods deposited by DC reactive magnetron sputtering with glancing angle deposition technique. Sens. Actuators B 2016, 223, 936–945. [Google Scholar] [CrossRef]

- Girija, K.G.; Somasundaram, K.; Topkar, A.; Vatsa, R.K. Highly selective H2S gas sensor based on Cu-doped ZnO nanocrystalline films deposited by RF magnetron sputtering of powder target. J. Alloy. Compd. 2016, 684, 15–20. [Google Scholar] [CrossRef]

- Takács, M.; Dücső, C.; Pap, A.E. Nano-structured WO3 layers sensitized with ALD Pt for quick detection of H2S. J. Mater. Sci. Mater. Electron. 2017, 28, 17148–17155. [Google Scholar] [CrossRef]

- Semancik, S.; Cavicchi, R.E.; Wheeler, M.C.; Tiffany, J.E.; Poirier, G.E.; Walton, R.M.; Suehle, J.S.; Panchapakesan, B.; DeVoe, D.L. Microhotplate platforms for chemical sensor research. Sens. Actuators B 2001, 77, 579–591. [Google Scholar] [CrossRef]

- Bhati, V.S.; Ranwa, S.; Fanetti, M.; Valant, M.; Kumar, M. Efficient hydrogen sensor based on Ni-doped ZnO nanostructures by RF sputtering. Sens. Actuators B 2018, 255, 558–597. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Li, K.H.H.; Tan, O.K. Microhotplates for Metal Oxide Semiconductor Gas Sensor Applications—Towards the CMOS-MEMS Monolithic Approach. Micromachines 2018, 9, 557. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.H.; Sung, J.S.; Son, Y.M.; Vasiliev, A.A.; Malyshev, V.V.; Koltypin, E.A.; Eryshkin, A.V.; Godovski, D.Y.; Pisyakov, A.V.; Yakimov, S.S. Propane/butane semiconductor gas sensor with low power consumption. Sens. Actuators B 1997, 44, 452–457. [Google Scholar] [CrossRef]

- Krainer, J.; Deluca, M.; Lackner, E.; Wimmer-Teubenbacher, R.; Sosada, F.; Gspan, C.; Rohracher, K.; Wachmann, E.; Köck, A. Hydrogen sulphide detection by CMOS integrated tungsten oxide nanowire networks. Mater. Today Proc. 2017, 4, 7132–7136. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Basu, P.K.; Mondal, B.; Saha, H.A. A low power MEMS gas sensor based on nanocrystalline ZnO thin films for sensing methane. Microelectron. Reliab. 2008, 48, 1772–1779. [Google Scholar] [CrossRef]

- Filipovic, L.; Selberherr, S.; Mutinati, G.C.; Brunet, E.; Steinhauer, S.; Köck, A.; Teva, J.; Kraft, J.; Siegert, J.; Schrank, F. Modeling spray pyrolysis deposition. Lect. Notes Eng. Comput. Sci. 2013, 2, 987–992. [Google Scholar]

- Moon, S.E.; Lee, H.K.; Choi, N.J.; Kang, H.T.; Lee, J.; Ahn, S.D.; Kang, S.Y. Low power consumption micro C2H5OH gas sensor based on micro-heater and ink jetting technique. Sens. Actuators B 2015, 217, 146–150. [Google Scholar] [CrossRef]

- Krivetskiy, V.; Zamanskiy, K.; Beltyukov, A.; Asachenko, A.; Topchiy, M.; Nechaev, M.; Garshev, A.; Krotova, A.; Filatova, D.; Maslakov, K.; et al. Effect of AuPd Bimetal Sensitization on Gas Sensing Performance of Nanocrystalline SnO2 Obtained by Single Step Flame Spray Pyrolysis. Nanomaterials 2019, 9, 728. [Google Scholar] [CrossRef] [Green Version]

- Vasiliev, A.A.; Pavelko, R.G.; Gogish-Klushin, S.Y.; Kharitonov, D.Y.; Gogish-Klushina, O.S.; Sokolov, A.V.; Samotaev, N.N. Alumina MEMS platform for impulse semiconductor and IR optic gas sensors. In Proceedings of the TRANSDUCERS and EUROSENSORS 07—4th International Conference on Solid-State Sensors, Actuators and Microsystems, Lyon, France, 10–14 June 2007; pp. 2035–2037. [Google Scholar]

- You, R.; Liu, Y.Q.; Hao, Y.L.; Han, D.D.; Zhang, Y.L.; You, Z. Flexible Electronics: Laser Fabrication of Graphene-Based Flexible Electronics. Adv. Mater. 2020, 32, 1901981. [Google Scholar] [CrossRef] [PubMed]

- You, R.; Han, D.D.; Liu, F.; Zhang, Y.L.; Lu, G. Fabrication of flexible room-temperature NO2 sensors by direct laser writing of In2O3 and graphene oxide composites. Sens. Actuators B 2018, 277, 114–120. [Google Scholar] [CrossRef]

- Lin, Q.; Cheng, C.; Zou, J.; Kane, N.; Jin, H.; Zhang, X.; Gao, W.; Jin, Q.; Jian, J. Study of response and recovery rate of YSZ-based electrochemical sensor by laser ablation method. Ionics 2020, 26, 4163–4169. [Google Scholar] [CrossRef]

- Ueda, T.; Defferriere, T.; Hyodo, T.; Shimizu, Y.; Tuller, H.L. Nanostructured Pr-doped Ceria (PCO) thin films as sensing electrodes in solid-electrolyte type gas sensors with enhanced toluene sensitivity. Sens. Actuators B 2020, 317, 128037. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samotaev, N.; Oblov, K.; Dzhumaev, P.; Fritsch, M.; Mosch, S.; Vinnichenko, M.; Trofimenko, N.; Baumgärtner, C.; Fuchs, F.-M.; Wissmeier, L. Combination of Ceramic Laser Micromachining and Printed Technology as a Way for Rapid Prototyping Semiconductor Gas Sensors. Micromachines 2021, 12, 1440. https://doi.org/10.3390/mi12121440

Samotaev N, Oblov K, Dzhumaev P, Fritsch M, Mosch S, Vinnichenko M, Trofimenko N, Baumgärtner C, Fuchs F-M, Wissmeier L. Combination of Ceramic Laser Micromachining and Printed Technology as a Way for Rapid Prototyping Semiconductor Gas Sensors. Micromachines. 2021; 12(12):1440. https://doi.org/10.3390/mi12121440

Chicago/Turabian StyleSamotaev, Nikolay, Konstantin Oblov, Pavel Dzhumaev, Marco Fritsch, Sindy Mosch, Mykola Vinnichenko, Nikolai Trofimenko, Christoph Baumgärtner, Franz-Martin Fuchs, and Lena Wissmeier. 2021. "Combination of Ceramic Laser Micromachining and Printed Technology as a Way for Rapid Prototyping Semiconductor Gas Sensors" Micromachines 12, no. 12: 1440. https://doi.org/10.3390/mi12121440

APA StyleSamotaev, N., Oblov, K., Dzhumaev, P., Fritsch, M., Mosch, S., Vinnichenko, M., Trofimenko, N., Baumgärtner, C., Fuchs, F.-M., & Wissmeier, L. (2021). Combination of Ceramic Laser Micromachining and Printed Technology as a Way for Rapid Prototyping Semiconductor Gas Sensors. Micromachines, 12(12), 1440. https://doi.org/10.3390/mi12121440