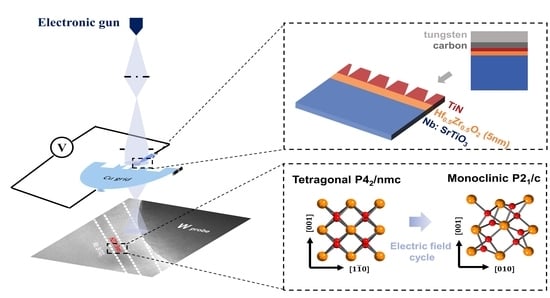

Optimization of the In Situ Biasing FIB Sample Preparation for Hafnia-Based Ferroelectric Capacitor

Abstract

:1. Introduction

2. Materials and Methods

3. Results

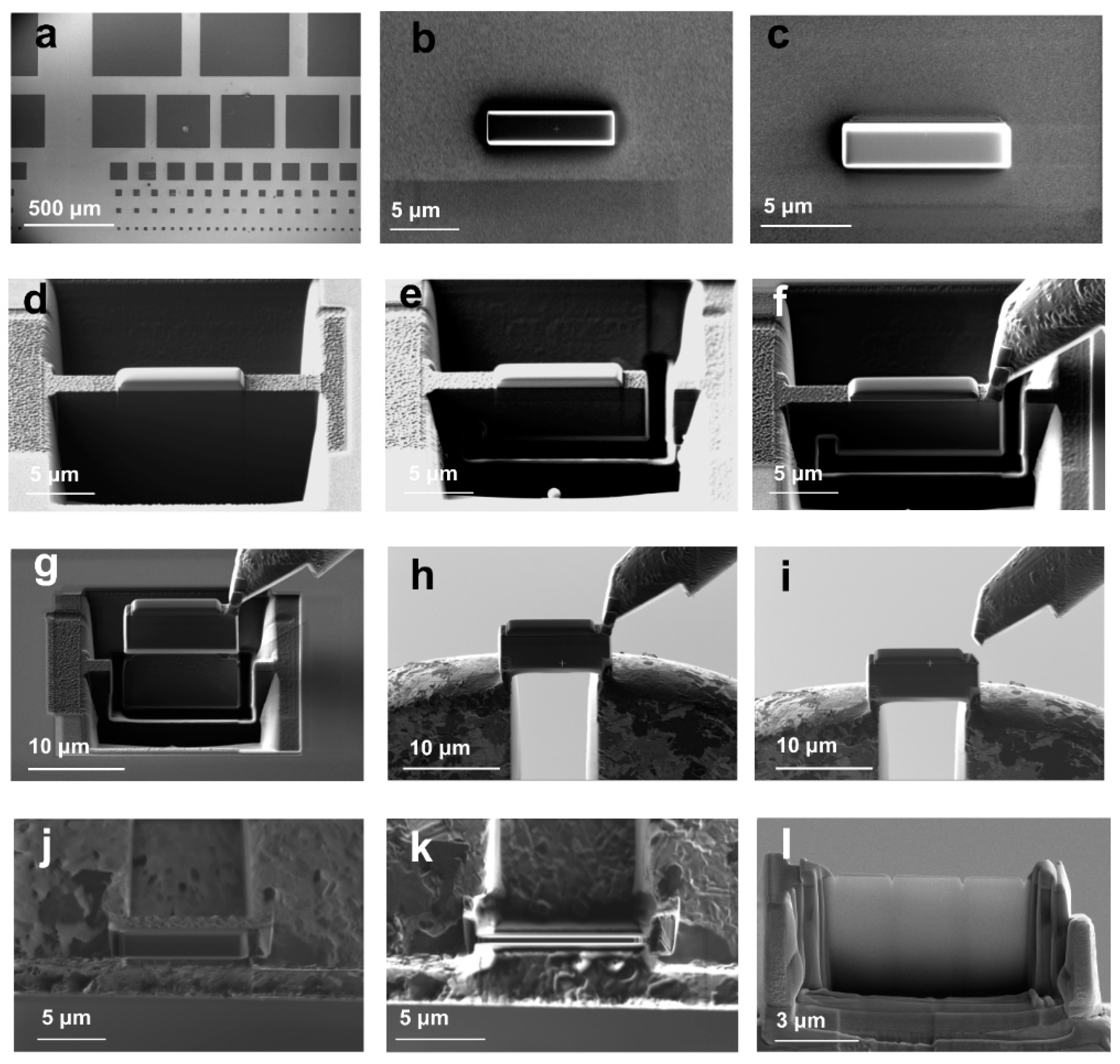

3.1. The Process of In Situ TEM Sample Preparation

3.2. Depositing a Carbon Protective Layer to Position the Interface

3.3. Welding the Sample on the Top of the Column of the Cu Grid

3.4. Cutting the Sample into “Comb” Shape When Thinning

3.5. In Situ Biasing Experiment of Structural Transformation in Hafnia-Based Ferroelectric Thin Film

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Müller, J.; Polakowski, P.; Müller, S.; Mikolajick, T. Ferroelectric Hafnium Oxide Based Materials and Devices: Assessment of Current Status and Future Prospects. ECS Meet. Abstr. 2014, 4, N30–N35. [Google Scholar] [CrossRef]

- Mikolajick, T.; Slesazeck, S.; Park, M.H.; Schroeder, U. Ferroelectric hafnium oxide for ferroelectric random-access memories and ferroelectric field-effect transistors. MRS Bull. 2018, 43, 340–346. [Google Scholar] [CrossRef]

- Ota, K.; Deguchi, J.; Fujii, S.; Saitoh, M.; Yamaguchi, M.; Berdan, R.; Marukame, T.; Nishi, Y.; Matsuo, K.; Takahashi, K.; et al. Performance Maximization of In-Memory Reinforcement Learning with Variability-Controlled Hf1-xZrxO2 Ferroelectric Tunnel Junctions. In Proceedings of the 2019 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 7–11 December 2019. [Google Scholar] [CrossRef]

- Zhao, B.; Jiang, J.; He, L.; Meng, J.; Geng, W.; Chen, Z.; Jiang, A. The effect of in situ annealing oxygen pressure on the ferro-electric resistive switching characteristic. Ceram. Int. 2015, 41, S835–S840. [Google Scholar] [CrossRef]

- Park, M.H.; Chung, C.C.; Schenk, T.; Richter, C.; Opsomer, K.; Detavernier, C.; Adelmann, C.; Jones, J.L.; Mikolajick, T.; Schroeder, U. Effect of Annealing Ferroelectric HfO2 Thin Films: In Situ, High Temperature X-ray Diffraction. Adv. Electron. Mater. 2018, 4, 1800091. [Google Scholar] [CrossRef]

- Park, M.H.; Lee, Y.H.; Kim, H.J.; Schenk, T.; Lee, W.; Kim, K.D.; Fengler, F.P.G.; Mikolajick, T.; Schroeder, U.; Hwang, C.S. Surface and grain boundary energy as the key enabler of ferroelectricity in nanoscale hafnia-zirconia: A comparison of model and experiment. Nanoscale 2017, 9, 9973–9986. [Google Scholar] [CrossRef] [Green Version]

- Sang, X.; Grimley, E.D.; Schenk, T.; Schroeder, U.; Lebeau, J.M. On the structural origins of ferroelectricity in HfO2 thin films. Appl. Phys. Lett. 2015, 106, 162905. [Google Scholar] [CrossRef]

- Park, M.H.; Lee, Y.H.; Kim, H.J.; Kim, Y.J.; Moon, T.; Kim, K.D.; Hyun, S.D.; Mikolajick, T.; Schroeder, U.; Hwang, C.S. Understanding the formation of the metastable ferroelectric phase in hafnia–zirconia solid solution thin films. Nanoscale 2017, 10, 716–725. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qi, Y.B.; Singh, S.; Lau, C.; Huang, F.T.; Xu, X.H.; Walker, F.J.; Ahn, C.H.; Cheong, S.W.; Rabe, K.M. Stabilization of Com-peting Ferroelectric Phases of HfO2 under Epitaxial Strain. Phys. Rev. Lett. 2020, 125, 257603. [Google Scholar] [CrossRef]

- Dogan, M.; Gong, N.; Ma, T.-P.; Ismail-Beigi, S. Causes of ferroelectricity in HfO2-based thin films: An ab initio perspective. Phys. Chem. Chem. Phys. 2019, 21, 12150–12162. [Google Scholar] [CrossRef] [Green Version]

- Fan, P.; Zhang, Y.K.; Yang, Q.; Jiang, J.; Jiang, L.M.; Liao, M.; Zhou, Y.C. Origin of the Intrinsic Ferroelectricity of HfO2 from ab Initio Molecular Dynamics. J. Phys. Chem. C 2019, 123, 21743–21750. [Google Scholar] [CrossRef]

- Nukala, P.; Ahmadi, M.; Antoja-Lleonart, J.; de Graaf, S.; Wei, Y.; Zandbergen, H.W.; Kooi, B.J.; Noheda, B. In situ heating studies on temperature-induced phase transitions in epitaxial Hf0.5Zr0.5O2/La0.67Sr0.33MnO3 heterostructures. Appl. Phys. Lett. 2021, 118, 062901. [Google Scholar] [CrossRef]

- Nukala, P.; Ahmadi, M.; Wei, Y.; de Graaf, S.; Stylianidis, E.; Chakrabortty, T.; Matzen, S.; Zandbergen, H.W.; Björling, A.; Mannix, D.; et al. Reversible oxygen migration and phase transitions in hafnia-based ferroelectric devices. Science 2021, 372, 630–635. [Google Scholar] [CrossRef] [PubMed]

- Kwon, D.-H.; Kim, K.M.; Jang, J.H.; Jeon, J.M.; Lee, M.H.; Kim, G.H.; Li, X.-S.; Park, G.-S.; Lee, B.; Han, S.; et al. Atomic structure of conducting nanofilaments in TiO2 resistive switching memory. Nat. Nanotechnol. 2010, 5, 148–153. [Google Scholar] [CrossRef] [PubMed]

- Liao, H.G.; Zherebetskyy, D.; Xin, H.L.; Czarnik, C.; Ercius, P.; Elmlund, H.; Pan, M.; Wang, L.W.; Zheng, H.M. Facet de-velopment during platinum nanocube growth. Science 2014, 345, 916–919. [Google Scholar] [CrossRef] [PubMed]

- Jia, C.L.; Lentzen, M.; Urban, K. Atomic-Resolution Imaging of Oxygen in Perovskite Ceramics. Science 2003, 299, 870–873. [Google Scholar] [CrossRef] [Green Version]

- Huang, R.; Ikuhara, Y. STEM characterization for lithium-ion battery cathode materials. Curr. Opin. Solid State Mater. Sci. 2012, 16, 31–38. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, R.; Pekin, T.C.; Gammer, C.; Ciston, J.; Ercius, P.; Ophus, C.; Bustillo, K.; Song, C.; Zhao, S.; et al. Functional Materials Under Stress: In Situ TEM Observations of Structural Evolution. Adv. Mater. 2019, 32, e1906105. [Google Scholar] [CrossRef] [Green Version]

- Narasimhan, V.K.; McBriarty, M.E.; Passarello, D.; Adinolfi, V.; Toney, M.F.; Mehta, A.; Littau, K.A. In Situ Characterization of Ferroelectric HfO2 During Rapid Thermal Annealing. Phys. Status Solidi (RRL) Rapid Res. Lett. 2021, 15, 2000598. [Google Scholar] [CrossRef]

- Yu, Q.; Mao, M.-M.; Li, Q.-J.; Fu, X.-Q.; Tian, H.; Li, J.-X.; Mao, S.X.; Zhang, Z. In Situ Observation on Dislocation-Controlled Sublimation of Mg Nanoparticles. Nano Lett. 2016, 16, 1156–1160. [Google Scholar] [CrossRef]

- Zhang, D.; Jin, C.; Tian, H.; Xiong, Y.; Zhang, H.; Qiao, P.; Fan, J.; Zhang, Z.; Li, Z.Y.; Li, J. An In situ TEM study of the surface oxidation of palladium nanocrystals assisted by electron irradiation. Nanoscale 2017, 9, 6327–6333. [Google Scholar] [CrossRef] [Green Version]

- Si, J.; Liu, Y.; He, Z.; Du, H.; Du, K.; Chen, D.; Li, J.; Xu, M.; Tian, H.; He, H.; et al. Efficient and High-Color-Purity Light-Emitting Diodes Based on In Situ Grown Films of CsPbX3 (X = Br, I) Nanoplates with Controlled Thicknesses. ACS Nano 2017, 11, 11100–11107. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Luo, C.; Tian, X.; Liang, F.; Xia, Y.; Chen, X.; Wang, C.; Liang, S.X.; Wu, X.; Chu, J. A revew of in situ transmission electron microscopy study on the switching mechanism and packaging reliability in non-volatile memory. J. Semicond. 2021, 42. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, W.; Yao, Y.; Sun, J.; Gu, C.; Gu, L.; Wang, Y.; Duan, X.; Yu, R. In situ TEM Observation of Resistance Switching in Titanate Based Device. Sci. Rep. 2014, 4, 3890. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, P.; Wang, Z.; Fu, W.; Liao, Z.; Liu, K.; Wang, W.; Bai, X.; Wang, E. In situ TEM studies of oxygen vacancy migration for electrically induced resistance change effect in cerium oxides. Micron 2010, 41, 301–305. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Lee, W.; Moon, T.; Hwang, C.S. Evolution of phases and ferroelectric properties of thin Hf0.5Zr0.5O2 films according to the thickness and annealing temperature. Appl. Phys. Lett. 2013, 102, 242905. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Lee, W.; Moon, T.; Kim, K.D.; Hwang, C.S. Study on the degradation mechanism of the ferroelectric properties of thin Hf0.5Zr0.5O2 films on TiN and Ir electrodes. Appl. Phys. Lett. 2014, 105, 072902. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Lee, Y.H.; Moon, T.; Kim, K.D.; Hyun, S.D.; Hwang, C.S. Study on the size effect in Hf0.5Zr0.5O2 films thinner than 8 nm before and after wake-up field cycling. Appl. Phys. Lett. 2015, 107, 192907. [Google Scholar] [CrossRef]

- Fields, S.S.; Smith, S.W.; Ryan, P.J.; Jaszewski, S.; Brummel, I.A.; Salanova, A.; Esteves, G.; Wolfley, S.L.; Henry, M.D.; Davids, P.S.; et al. Phase-Exchange-Driven Wake-Up and Fatigue in Ferroelectric Hafnium Zirconium Oxide Films. ACS Appl. Mater. Interfaces 2020, 12, 26577–26585. [Google Scholar] [CrossRef]

- Liu, S.; Hanrahan, B.M. Effects of growth orientations and epitaxial strains on phase stability of HfO2 thin films. Phys. Rev. Mater. 2019, 3, 054404. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.; Zhong, C.; Zheng, Y.; Gao, Z.; Cheng, Y.; Zhong, Q.; Liu, C.; Wang, Y.; Qi, R.; Huang, R.; et al. In-situ atomic visualization of structural transformation in Hf0.5Zr0.5O2 ferroelectric thin film: From nonpolar tetragonal phase to polar orthorhombic phase. In Proceedings of the 2021 Symposium on VLSI Technology, Kyoto, Japan, 13–19 June 2021; pp. 1–2. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, Q.; Wang, Y.; Cheng, Y.; Gao, Z.; Zheng, Y.; Xin, T.; Zheng, Y.; Huang, R.; Lyu, H. Optimization of the In Situ Biasing FIB Sample Preparation for Hafnia-Based Ferroelectric Capacitor. Micromachines 2021, 12, 1436. https://doi.org/10.3390/mi12121436

Zhong Q, Wang Y, Cheng Y, Gao Z, Zheng Y, Xin T, Zheng Y, Huang R, Lyu H. Optimization of the In Situ Biasing FIB Sample Preparation for Hafnia-Based Ferroelectric Capacitor. Micromachines. 2021; 12(12):1436. https://doi.org/10.3390/mi12121436

Chicago/Turabian StyleZhong, Qilan, Yiwei Wang, Yan Cheng, Zhaomeng Gao, Yunzhe Zheng, Tianjiao Xin, Yonghui Zheng, Rong Huang, and Hangbing Lyu. 2021. "Optimization of the In Situ Biasing FIB Sample Preparation for Hafnia-Based Ferroelectric Capacitor" Micromachines 12, no. 12: 1436. https://doi.org/10.3390/mi12121436

APA StyleZhong, Q., Wang, Y., Cheng, Y., Gao, Z., Zheng, Y., Xin, T., Zheng, Y., Huang, R., & Lyu, H. (2021). Optimization of the In Situ Biasing FIB Sample Preparation for Hafnia-Based Ferroelectric Capacitor. Micromachines, 12(12), 1436. https://doi.org/10.3390/mi12121436