High-Bandwidth Hysteresis Compensation of Piezoelectric Actuators via Multilayer Feedforward Neural Network Based Inverse Hysteresis Modeling

Abstract

:1. Introduction

2. The Hysteretic Nonlinearity of the Piezoelectric Actuator (PEA)

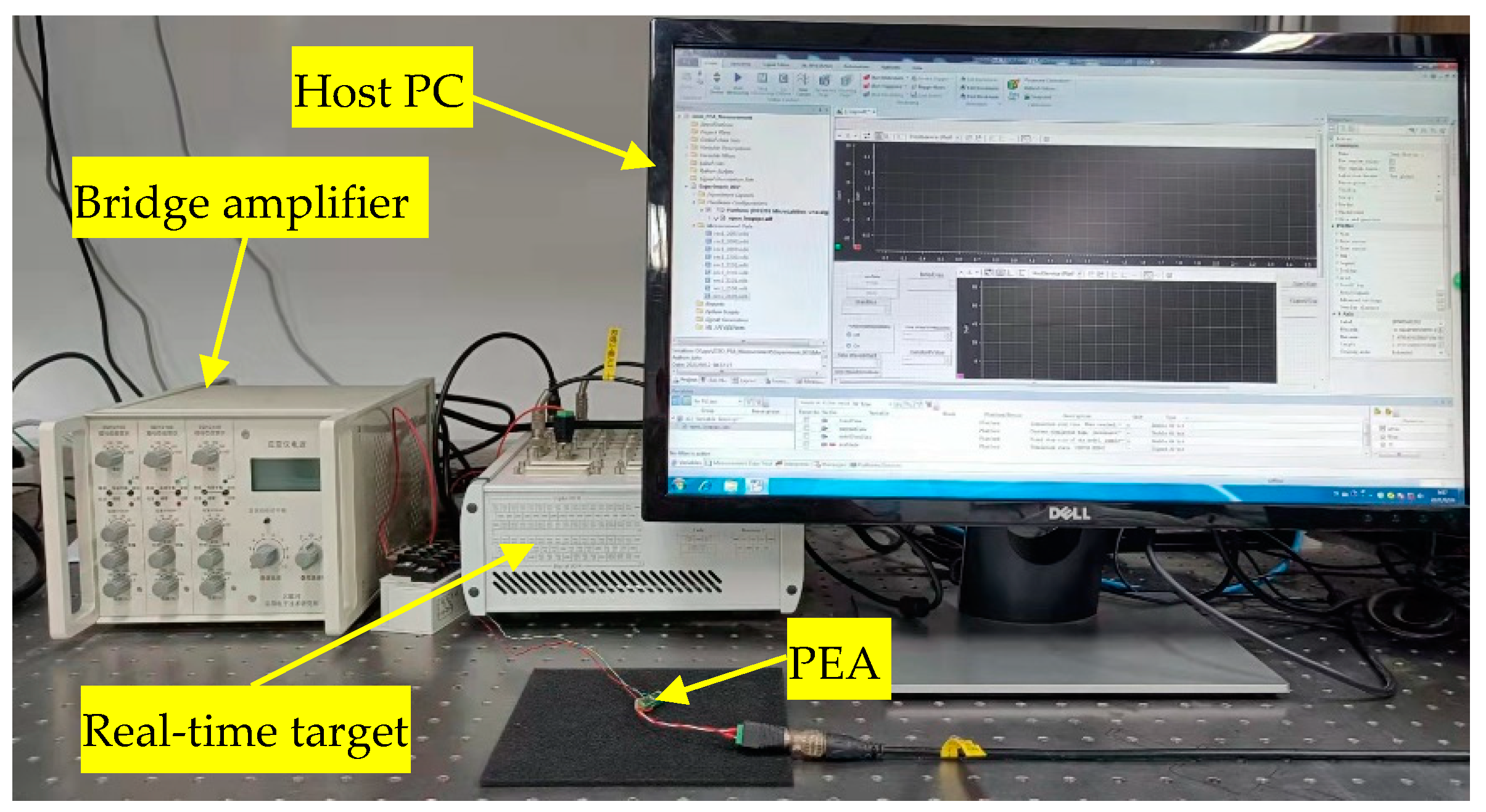

2.1. Experimental Setup

2.2. Characteristics of the PEA’s Hysteresis

3. Direct Inverse Hysteresis Modeling Based on Multi-Layer Feedforward Neural Network (MFNN)

3.1. The Structure of the Inverse Hysteresis Model

3.2. The Training Process

4. Feedforward and Feedback Combined Control

5. Experimental Verifications

- (1)

- Feedforward hysteresis compensation: the MFNN based inverse hysteresis model is utilized as the hysteresis compensator.

- (2)

- Feedback hysteresis compensation: the PID controller is utilized as the feedback controller.

- (3)

- Feedforward and feedback combined hysteresis compensation: the proposed method is applied to test the hysteresis compensation performance and the bandwidth of the overall system. In the feedback loop, both the PID and SNA controllers are utilized, and their performances are comparatively analyzed.

5.1. MFNN Based Feedforward Hysteresis Compensation

5.2. Protional-Integral-Differential (PID) Based Feedback Hysteresis Compensation

5.3. Feedforward and Feedback Combined Hysteresis Compensation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, H.; Zhu, B.; Zhang, X.; Wei, J.; Fatikow, S. Pose sensing and servo control of the compliant nanopositioners based on microscopic vision. IEEE Trans. Ind. Electron. 2020, 68, 3324–3335. [Google Scholar] [CrossRef]

- Qin, Y.; Soundararajan, R.; Jia, R.; Huang, S.-L. Direct inverse linearization of piezoelectric actuator’s initial loading curve and its applications in Full-Field Optical Coherence Tomography (FF-OCT). Mech. Syst. Signal Process. 2020, 148, 107147. [Google Scholar] [CrossRef]

- Tian, Y.; Lu, K.; Wang, F.; Zhou, C.; Ma, Y.; Jing, X.; Yang, C.; Zhang, D. A spatial deployable three-DOF compliant nano-positioner with a three-stage motion amplification mechanism. IEEE/ASME Trans. Mechatron. 2020, 25, 1322–1334. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, Q. Design and development of a novel two-directional energy harvester with single piezoelectric stack. IEEE Trans. Ind. Electron. 2020, 68, 1290–1298. [Google Scholar] [CrossRef]

- Tao, Y.-D.; Li, H.-X.; Zhu, L.-M. Rate-dependent hysteresis modeling and compensation of piezoelectric actuators using Gaussian process. Sens. Actuators A Phys. 2019, 295, 357–365. [Google Scholar] [CrossRef]

- Krasnosel’skiI, M.A.; PokrovskiI, A.V. Systems with Hysteresis; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Li, Z.; Shan, J.; Gabbert, U. Inverse compensation of hysteresis using Krasnoselskii-Pokrovskii model. IEEE/ASME Trans. Mechatron. 2018, 23, 966–971. [Google Scholar] [CrossRef]

- Qin, Y.; Zhao, X.; Zhou, L. Modeling and identification of the rate-dependent hysteresis of piezoelectric actuator using a modified Prandtl-Ishlinskii model. Micromachines 2017, 8, 114. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Chen, G. Identification of piezoelectric hysteresis by a novel Duhem model based neural network. Sensors Actuators A Phys. 2017, 264, 282–288. [Google Scholar] [CrossRef]

- Qin, Y.; Tian, Y.; Zhang, D.; Shirinzadeh, B.; Fatikow, S. A novel direct inverse modeling approach for hysteresis compensation of piezoelectric actuator in feedforward applications. IEEE/ASME Trans. Mechatronics 2012, 18, 981–989. [Google Scholar] [CrossRef]

- Li, Z.; Shan, J.; Gabbert, U. A direct inverse model for hysteresis compensation. IEEE Trans. Ind. Electron. 2021, 68, 4173–4181. [Google Scholar] [CrossRef]

- Yan, G. Inverse neural networks modelling of a piezoelectric stage with dominant variable. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–15. [Google Scholar] [CrossRef]

- Qin, Y.; Duan, H. Single-neuron adaptive hysteresis compensation of piezoelectric actuator based on Hebb learning rules. Micromachines 2020, 11, 84. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tai, N.T.; Ahn, K.K. A RBF neural network sliding mode controller for SMA actuator. Int. J. Control. Autom. Syst. 2010, 8, 1296–1305. [Google Scholar] [CrossRef]

- Xu, Q.; Wong, P.-K. Hysteresis modeling and compensation of a piezostage using least squares support vector machines. Mechatronics 2011, 21, 1239–1251. [Google Scholar] [CrossRef]

- Cheng, L.; Liu, W.; Hou, Z.-G.; Yu, J.; Tan, M. Neural-network-based nonlinear model predictive control for piezoelectric actuators. IEEE Trans. Ind. Electron. 2015, 62, 7717–7727. [Google Scholar] [CrossRef]

- Zou, J.; Gu, G. Feedforward control of the rate-dependent viscoelastic hysteresis nonlinearity in dielectric elastomer actuators. IEEE Robot. Autom. Lett. 2019, 4, 2340–2347. [Google Scholar] [CrossRef]

- Qin, Y.; Duan, H.; Han, J. Direct inverse hysteresis compensation of piezoelectric actuators using adaptive Kalman filter. IEEE Trans. Ind. Electron. 2021, 1. [Google Scholar] [CrossRef]

- Zhao, X.; Su, Q.; Chen, S.; Tan, Y. Neural network adaptive control of nonlinear systems preceded by hysteresis. J. Intell. Mater. Syst. Struct. 2020, 32, 104–112. [Google Scholar] [CrossRef]

- Salah, M.; Saleem, A. Hysteresis compensation-based robust output feedback control for long-stroke piezoelectric actuators at high frequency. Sens. Actuators A Phys. 2021, 319, 112542. [Google Scholar] [CrossRef]

- Qin, S.; Cheng, L. A real-time tracking controller for piezoelectric actuators based on reinforcement learning and inverse compensation. Sustain. Cities Soc. 2021, 69, 102822. [Google Scholar] [CrossRef]

- Napole, C.; Barambones, O.; Calvo, I.; Velasco, J. Feedforward compensation analysis of piezoelectric actuators using artificial neural networks with conventional PID controller and single-neuron PID based on Hebb learning rules. Energies 2020, 13, 3929. [Google Scholar] [CrossRef]

- Yang, C.; Wang, Y.; Youcef-Toumi, K. Feedback-assisted feedforward hysteresis compensation: A unified approach and applications to piezoactuated nanopositioners. IEEE Trans. Ind. Electron. 2020, 68, 11245–11254. [Google Scholar] [CrossRef]

- Qin, Y.; Jia, R. Adaptive hysteresis compensation of piezoelectric actuator using direct inverse modelling approach. Micro Nano Lett. 2018, 13, 180–183. [Google Scholar] [CrossRef]

- Mao, X.; Wang, Y.; Liu, X.; Guo, Y. A hybrid feedforward-feedback hysteresis compensator in piezoelectric actuators based on least-squares support vector machine. IEEE Trans. Ind. Electron. 2017, 65, 5704–5711. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Cheng, L.; Hou, Z.-G.; Yu, J.; Tan, M. An inversion-free predictive controller for piezoelectric actuators based on a dynamic linearized neural network model. IEEE/ASME Trans. Mechatron. 2015, 21, 214–226. [Google Scholar] [CrossRef]

- Ma, L.; Shen, Y.; Li, J. A neural-network-based hysteresis model for piezoelectric actuators. Rev. Sci. Instrum. 2020, 91, 015002. [Google Scholar] [CrossRef] [PubMed]

- Visintin, A. Differential Models of Hysteresis; Springer: Berlin, Germany, 1994. [Google Scholar]

- Qin, Y.; Xu, Y.; Han, J. Hysteresis compensation of pneumatic artificial muscle actuated assistive robot for the elbow joint. Robot 2021, 43, 453–462. (In Chinese) [Google Scholar]

| Sampling Rate (Hz) | Training Time (s) | MS Error (V2) | Regression R Values |

|---|---|---|---|

| 100 | 8 | 0.68 | 0.957 |

| 1 k | 114 | 0.001 | 0.999 |

| 10 k | 917 | 0.015 | 0.999 |

| n | MS Error (V2) | MAX Errors (V) | Regression R Values |

|---|---|---|---|

| 0 | 0.5075 | 1.465 | 0.980 |

| 1 | 0.0013 | 0.7206 | 0.999 |

| 2 | 0.0010 | 0.6191 | 0.999 |

| 3 | 0.0008 | 0.5132 | 0.999 |

| 4 | 0.0007 | 0.4453 | 0.999 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Zhang, Y.; Duan, H.; Han, J. High-Bandwidth Hysteresis Compensation of Piezoelectric Actuators via Multilayer Feedforward Neural Network Based Inverse Hysteresis Modeling. Micromachines 2021, 12, 1325. https://doi.org/10.3390/mi12111325

Qin Y, Zhang Y, Duan H, Han J. High-Bandwidth Hysteresis Compensation of Piezoelectric Actuators via Multilayer Feedforward Neural Network Based Inverse Hysteresis Modeling. Micromachines. 2021; 12(11):1325. https://doi.org/10.3390/mi12111325

Chicago/Turabian StyleQin, Yanding, Yunpeng Zhang, Heng Duan, and Jianda Han. 2021. "High-Bandwidth Hysteresis Compensation of Piezoelectric Actuators via Multilayer Feedforward Neural Network Based Inverse Hysteresis Modeling" Micromachines 12, no. 11: 1325. https://doi.org/10.3390/mi12111325

APA StyleQin, Y., Zhang, Y., Duan, H., & Han, J. (2021). High-Bandwidth Hysteresis Compensation of Piezoelectric Actuators via Multilayer Feedforward Neural Network Based Inverse Hysteresis Modeling. Micromachines, 12(11), 1325. https://doi.org/10.3390/mi12111325