The Design and Implementation of a High-Precision Positioner Fixture

Abstract

1. Introduction

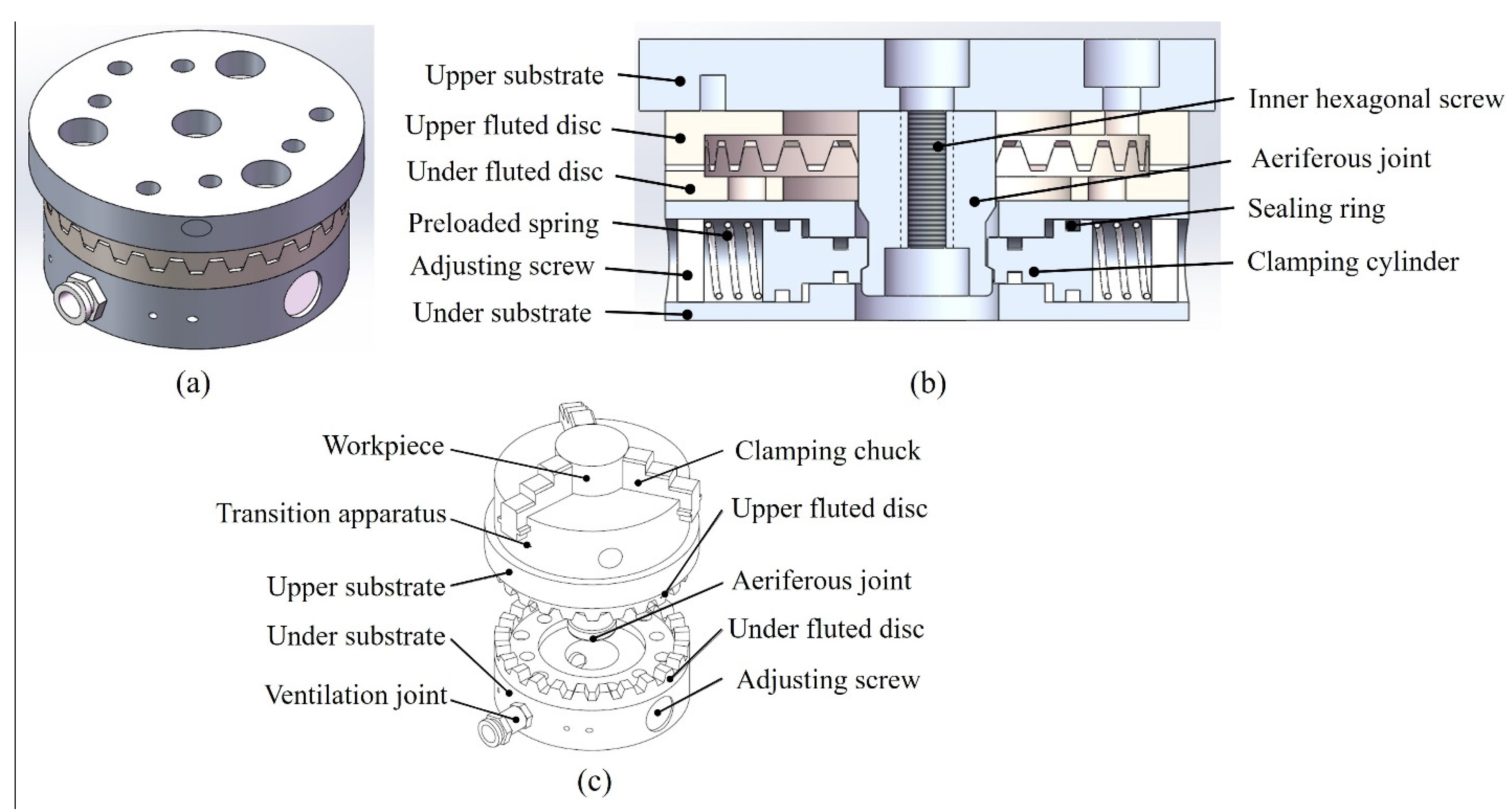

2. Design of the High-Precision Positioner Fixture

3. Analysis and Calculation of the Positioning Error

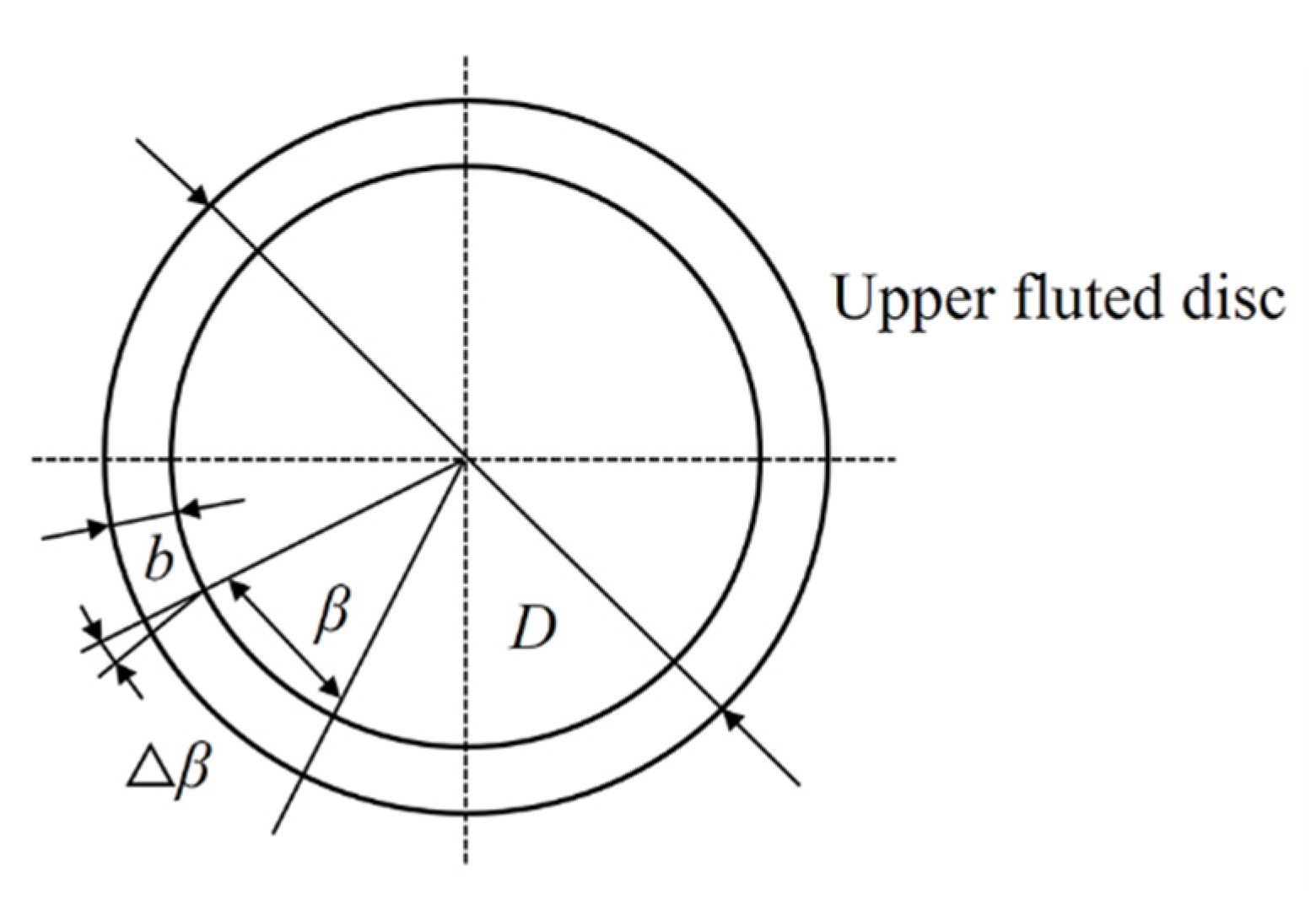

3.1. The Cumulative Error of the Tooth Pitch

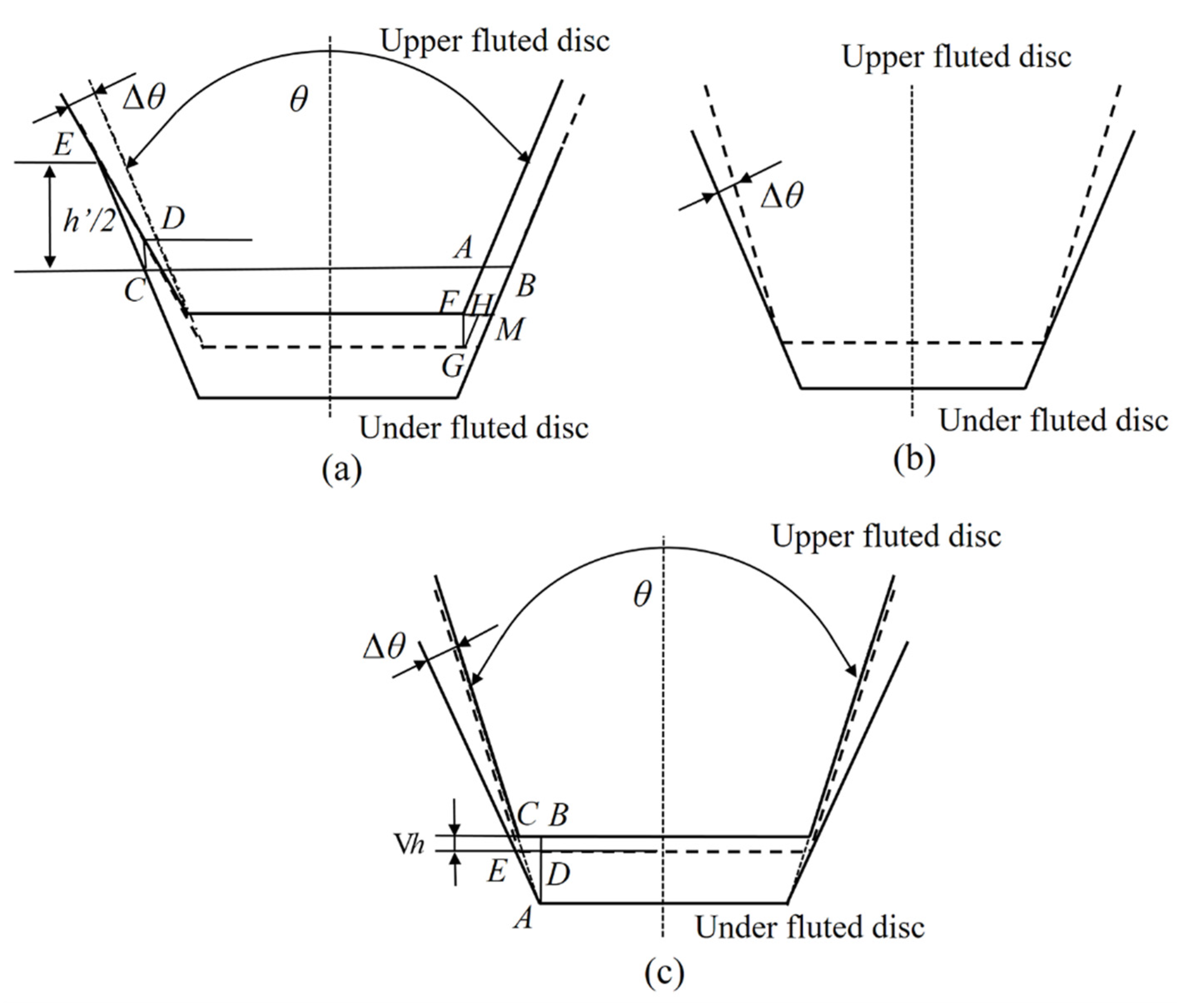

3.2. The Tooth Alignment Error

3.3. The Error of Tooth Profile Half-Angle

4. Results and Discussion

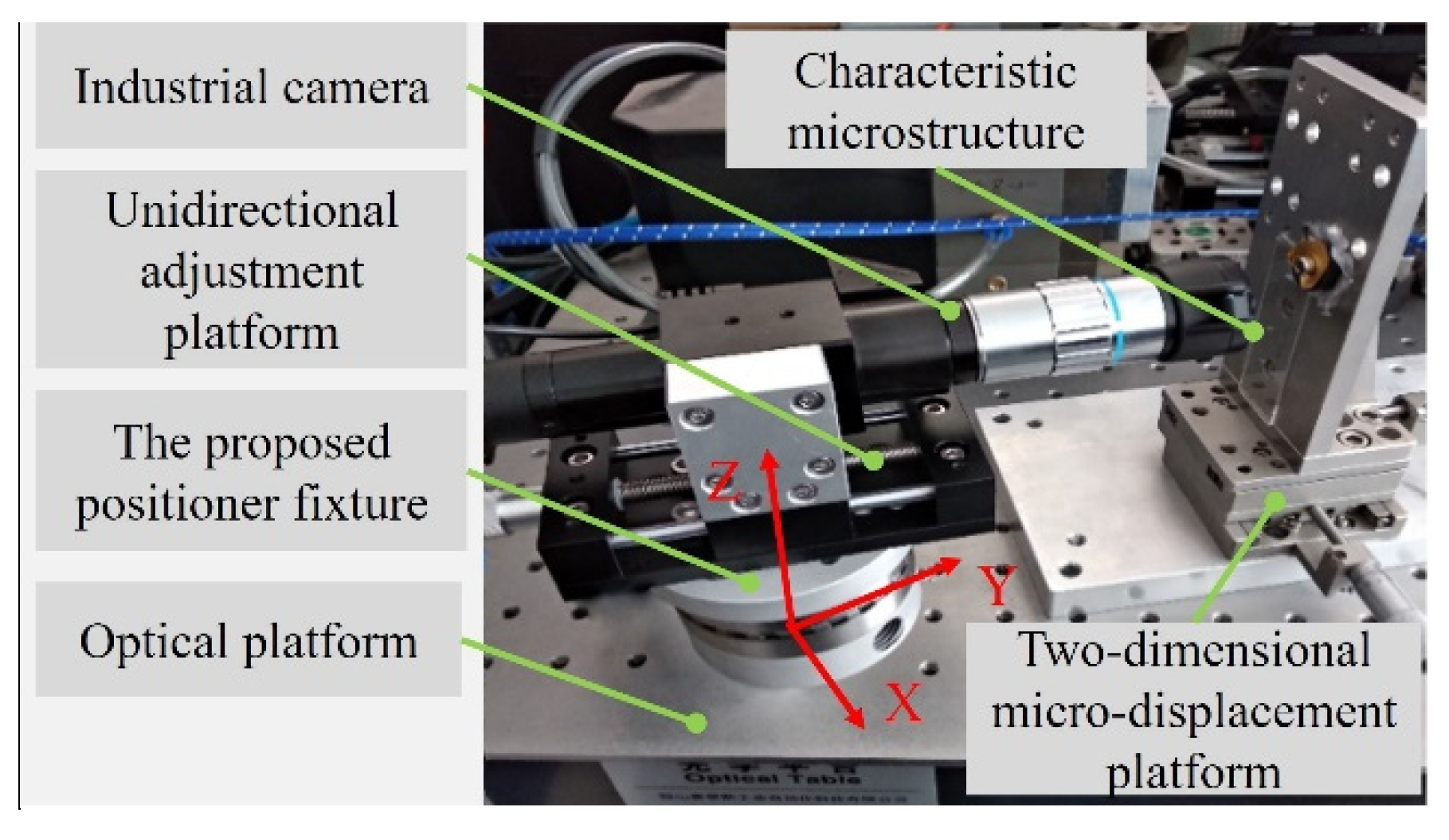

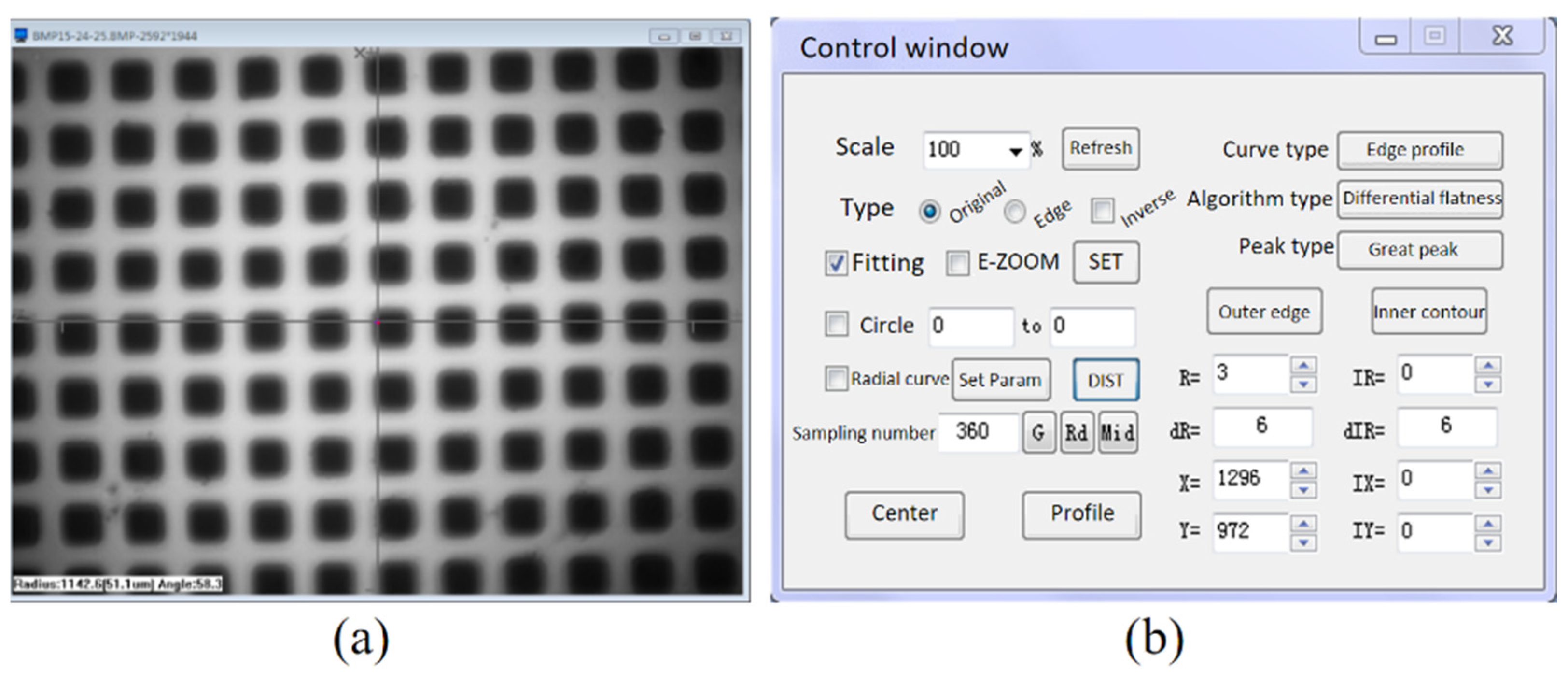

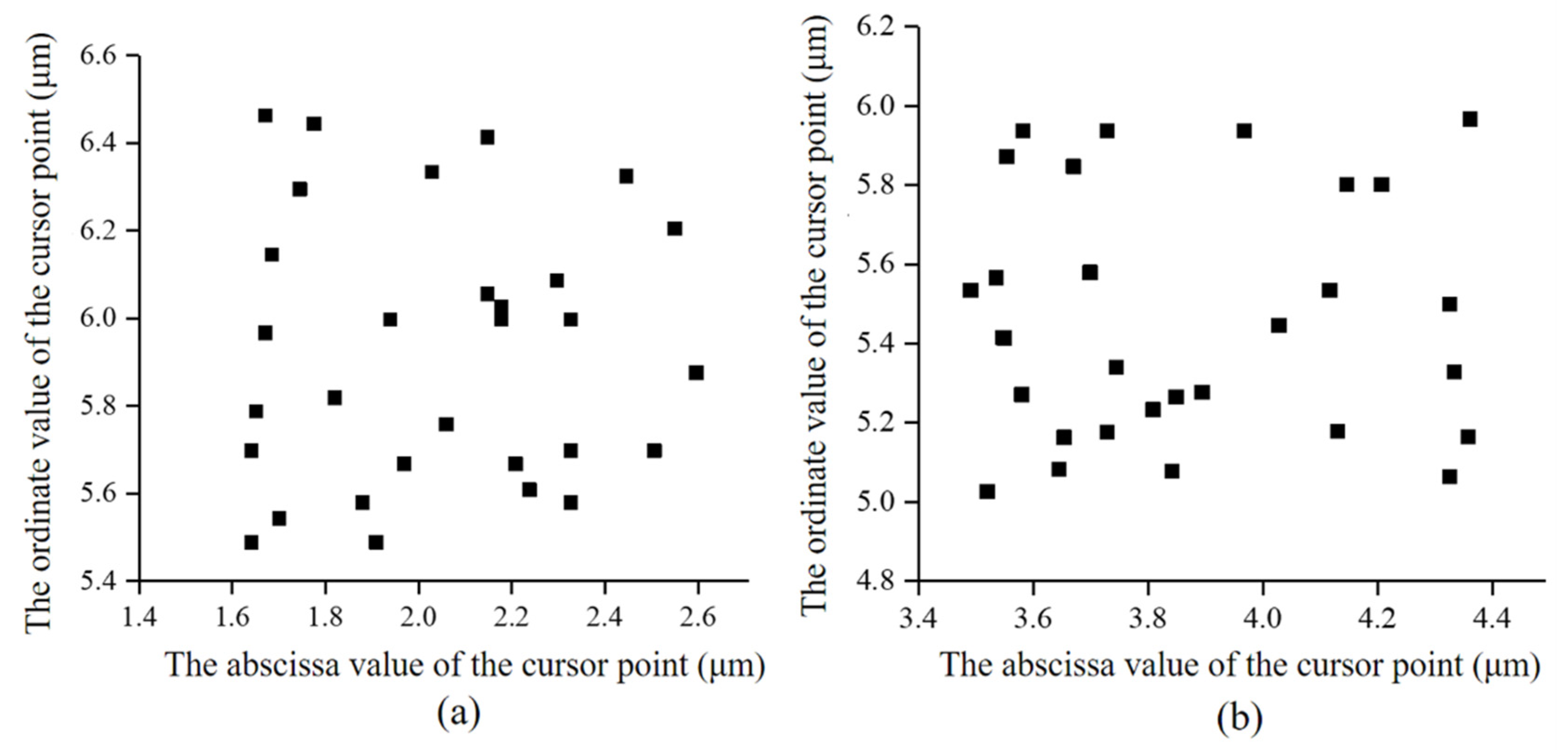

4.1. Experiment to Test the Repeated Positioning Accuracy

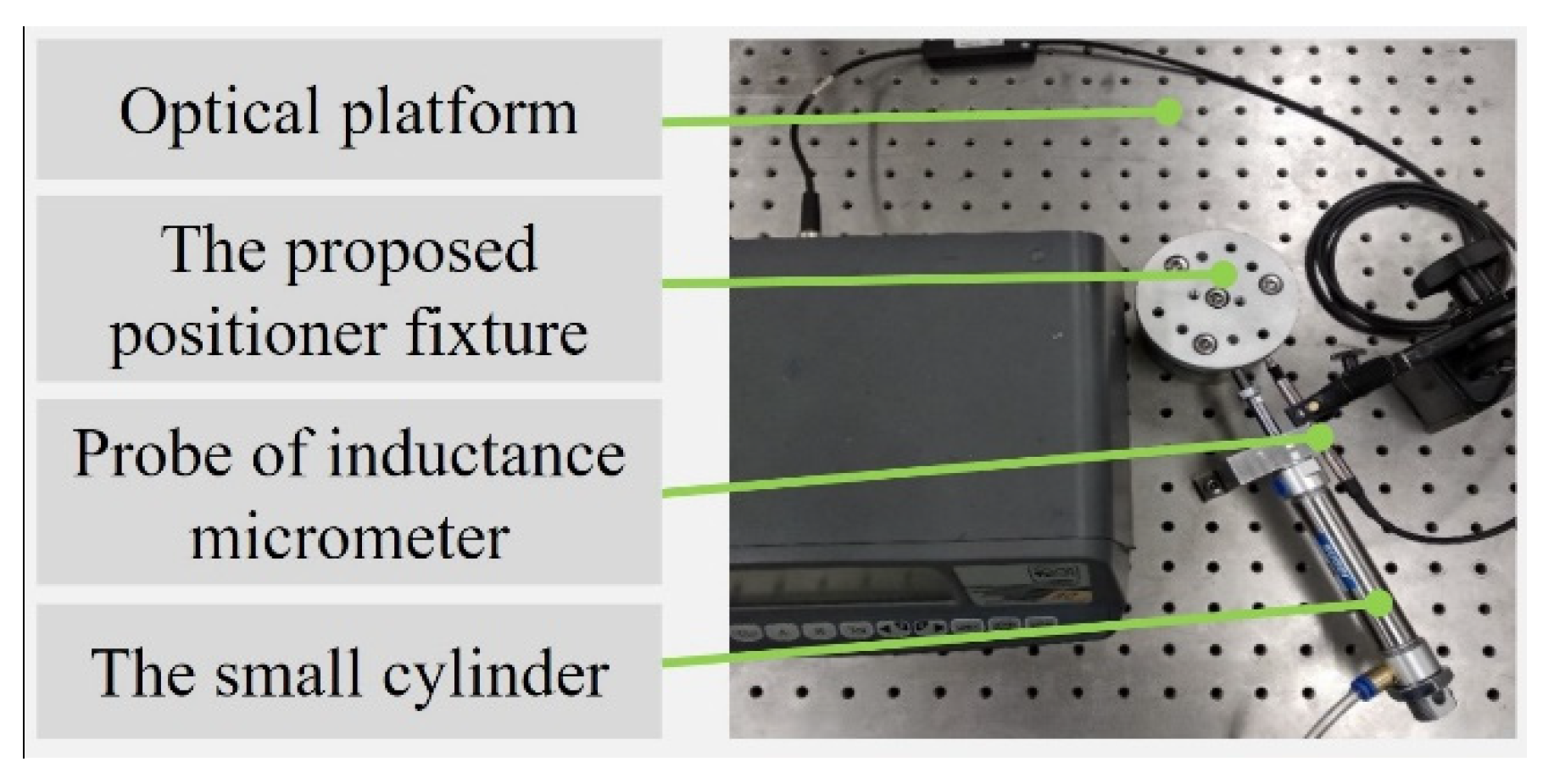

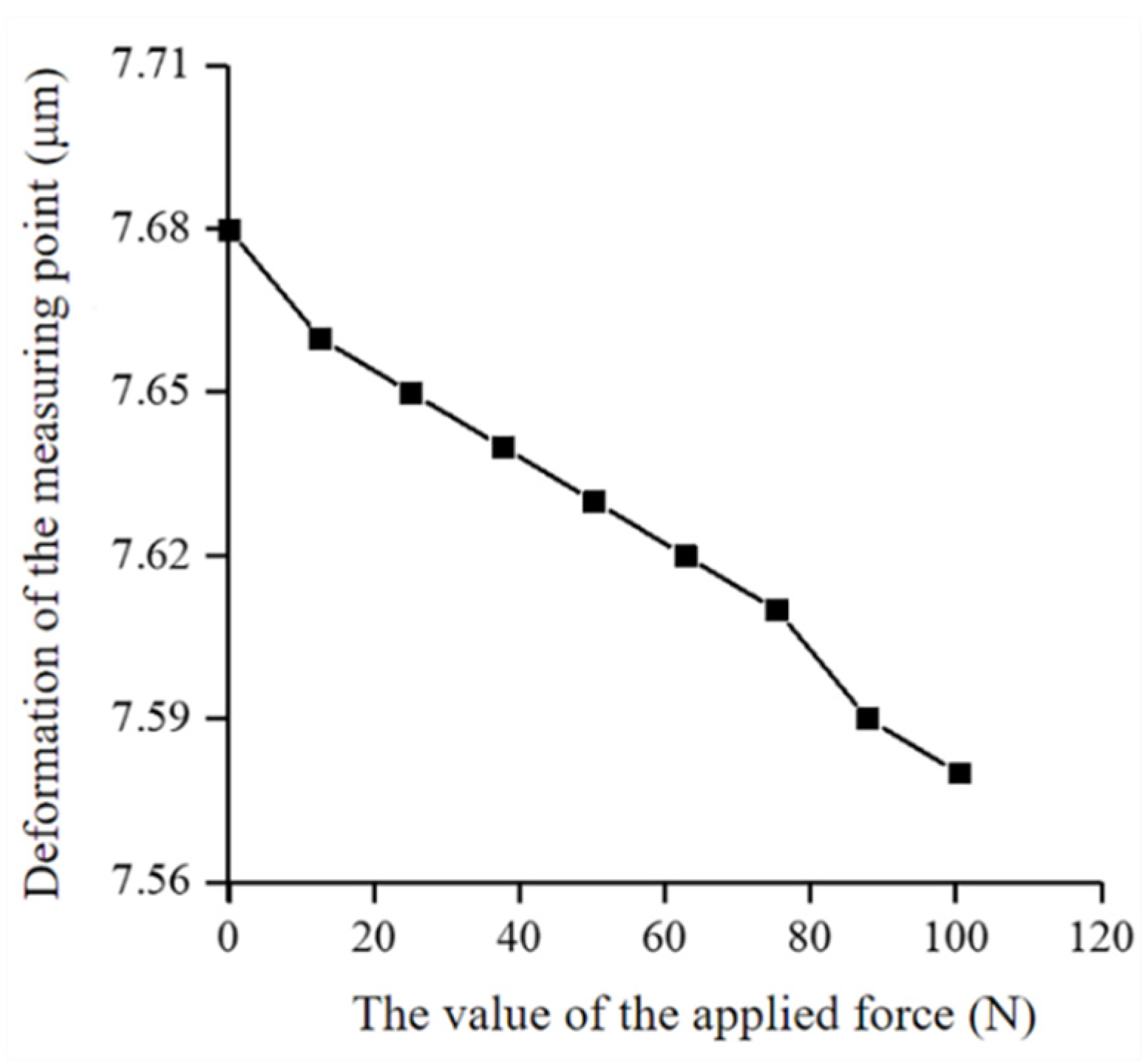

4.2. Stiffness Measurement of the Proposed Positioner Fixture

5. Conclusions

- An innovative high-precision positioner fixture was proposed and investigated in this paper. The proposed positioner fixture had the advantages of a short positioning time and simple operation. The high-precision end-toothed disc was the key point for achieving the high repeated positioning accuracy. The mathematical models of the cumulative error of the tooth pitch, the tooth alignment error and the error of the tooth profile half-angle of the end-toothed were analyzed. The analysis results indicated that the tooth alignment error and the tooth profile half-angle error had a smaller effect on the total error whereas the cumulative error of the tooth pitch had a greater influence. The allowable tolerance values of the cumulative error of the tooth pitch, the tooth alignment error and the error of the tooth profile half-angle of the end-tooth were given.

- The repeated positioning accuracy test results showed that the proposed positioner fixture had a high repeated positioning accuracy and its repeated positioning accuracy in the x, y and z directions were ±0.48 μm, ±0.45 μm and ±0.49 μm, respectively, which was significantly higher than previous positioner fixtures. The stiffness test results showed that the stiffness of the proposed positioner fixture was 1050.5 N/μm, which was large enough for a fixture usually used in the field of precision machining. The above analysis results indicate that the designed positioner fixture had the advantages of a high repeated positioning accuracy, high stiffness, short positioning time and simple operation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hashemi, H.; Shaharoun, A.M.; Sudin, I. A case-based reasoning approach for design of machining fixture. Int. J. Adv. Manuf. Technol. 2014, 74, 113–124. [Google Scholar] [CrossRef]

- Guevara-Pantoja, P.E.; Chavez-Pineda, O.G.; Solis-Serrano, A.M.; Garcia-Cordero, J.L.; Caballero-Robledo, G.A. An affordable 3D-printed positioner fixture improves the resolution of conventional milling for easy prototyping of acrylic microfluidic devices. Lab Chip 2020, 20, 3179. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, F.; Wang, C. Integrating case-based with rule-based reasoning in body-in-white fixture design. Int. J. Adv. Manuf. Technol. 2016, 85, 1807–1824. [Google Scholar] [CrossRef]

- Wang, H.; Rong, Y.; Li, H.; Shaun, P. Computer aided fixture design: Recent research and trends. Comput.-Aided Des. 2010, 42, 1085–1094. [Google Scholar] [CrossRef]

- Boyle, I.; Rong, Y.; Brown, D.C. A review and analysis of current computer-aided fixture design approaches. Robot. Comput.-Integr. Manuf. 2011, 27, 1–12. [Google Scholar] [CrossRef]

- Ryll, M.; Papastathis, T.N.; Ratchev, S. Towards an intelligent fixturing system with rapid reconfiguration and part positioning. J. Mater. Process. Technol. 2008, 201, 198–203. [Google Scholar] [CrossRef]

- Xichun, L.; Kai, C.; Dave, W.; Frank, W. Design of ultraprecision machine tools with applications to manufacture of miniature and micro components. J. Mater. Process. Technol. 2005, 167, 515–528. [Google Scholar] [CrossRef]

- Li, Z.; Dai, Y.; Guan, C.; Yong, J.; Sun, Z.; Du, C. High-Precision Machining Method of Weak-Stiffness Mirror Based on Fast Tool Servo Error Compensation Strategy. Micromachines 2021, 12, 607. [Google Scholar] [CrossRef] [PubMed]

- Kang, Y.; Rong, Y.; Yang, J.C. Computer-aided fixture design verification. Part 1. The framework and modelling. Int. J. Adv. Manuf. Technol. 2003, 21, 827–835. [Google Scholar] [CrossRef]

- Zhang, X.T.; Peng, G.L.; Hou, X.; Zhuang, T. A knowledge reuse-based computer-aided fixture design framework. Assem. Autom. 2014, 34, 169–181. [Google Scholar] [CrossRef]

- Vasundara, M.; Padmanaban, K.P. Recent developments on machining fixture layout design, analysis, and optimization using finite element method and evolutionary techniques. Int. J. Adv. Manuf. Technol. 2014, 70, 79–96. [Google Scholar] [CrossRef]

- Wan, N.; Wang, Z.; Mo, R. An intelligent fixture design method based on smart modular fixture unit. Int. J. Adv. Manuf. Technol. 2013, 69, 2629–2649. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Y.; Wei, W. A feature-based fixture design methodology for the manufacturing of aircraft structural parts. Robot. Comput.-Integr. Manuf. 2011, 27, 986–993. [Google Scholar] [CrossRef]

- Yu, K. Robust fixture design of compliant assembly process based on a support vector regression model. Int. J. Adv. Manuf. Technol. 2019, 103, 111–126. [Google Scholar] [CrossRef]

- Peng, G.; Chen, G.; Wu, C.; Xin, H.; Jiang, Y. Applying RBR and CBR to develop a VR based integrated system for machining fixture design. Expert Syst. Appl. 2011, 38, 26–38. [Google Scholar] [CrossRef]

- Varadarajan, K.M.; Culpepper, M.L. A dual-purpose positioner fixture for precision six-axis positioning and precision fixturing Part I. Modeling and design. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2007, 31, 276–286. [Google Scholar] [CrossRef]

- Varadarajan, K.M.; Culpepper, M.L. A dual-purpose positioner fixture for precision six-axis positioning and precision fixturing Part II. Characterization and calibration. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2007, 31, 287–292. [Google Scholar] [CrossRef]

- Li, Y.; Liu, C.; Hao, X.; Gao, J.X.; Maropoulos, P.G. Responsive fixture design using dynamic product inspection and monitoring technologies for the precision machining of large-scale aerospace parts. CIRP Ann.-Manuf. Technol. 2015, 64, 173–176. [Google Scholar] [CrossRef]

- Gonzalo, O.; Seara, J.M.; Guruceta, E.; Izpizua, A.; Esparta, M.; Zamakona, I.; Uterga, N.; Aranburu, A.; Thoelen, J. A method to minimize the workpiece deformation using a concept of intelligent fixture. Robot. Comput.-Integr. Manuf. 2017, 48, 209–218. [Google Scholar] [CrossRef]

- Pellegrinelli, S.; Terkaj, W.; Urgo, M. A Concept for a Pallet Configuration Approach Using Zero-point Clamping Systems. Procedia CIRP 2016, 41, 123–128. [Google Scholar] [CrossRef][Green Version]

- Urgo, M.; Terkaj, W.; Giannini, F.; Pellegrinelli, S.; Borgo, S. Exploiting Modular Pallet Flexibility for Product And Process Co-Evolution Through ZeroPoint Clamping Systems. In Factories of the Future, the Italian Flagship Initiative; Tolio, T., Copani, G., Terkaj, W., Eds.; Springer: Cham, Switzerland, 2019; pp. 57–82. [Google Scholar]

- Christiand; Wang, G.-N.; Kim, E.-W. Validating and verifying fixture kinematics for virtual manufacturing. Int. J. Comput. Integr. Manuf. 2014, 27, 1136–1143. [Google Scholar] [CrossRef]

- Chen, L. Study on Indexing Precision of Frontal Teeth Rings of a Servo/Dynamic Turret. Master’s Thesis, Southeast University, Nanjing, China, 2015. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Tan, R.; Wang, Z.; Zou, X.; Hu, Z.; Sun, T. The Design and Implementation of a High-Precision Positioner Fixture. Micromachines 2021, 12, 1227. https://doi.org/10.3390/mi12101227

Zhao X, Tan R, Wang Z, Zou X, Hu Z, Sun T. The Design and Implementation of a High-Precision Positioner Fixture. Micromachines. 2021; 12(10):1227. https://doi.org/10.3390/mi12101227

Chicago/Turabian StyleZhao, Xuesen, Rongkai Tan, Zhe Wang, Xicong Zou, Zhenjiang Hu, and Tao Sun. 2021. "The Design and Implementation of a High-Precision Positioner Fixture" Micromachines 12, no. 10: 1227. https://doi.org/10.3390/mi12101227

APA StyleZhao, X., Tan, R., Wang, Z., Zou, X., Hu, Z., & Sun, T. (2021). The Design and Implementation of a High-Precision Positioner Fixture. Micromachines, 12(10), 1227. https://doi.org/10.3390/mi12101227