Fabrication of Energetic Composites with 91% Solid Content by 3D Direct Writing

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

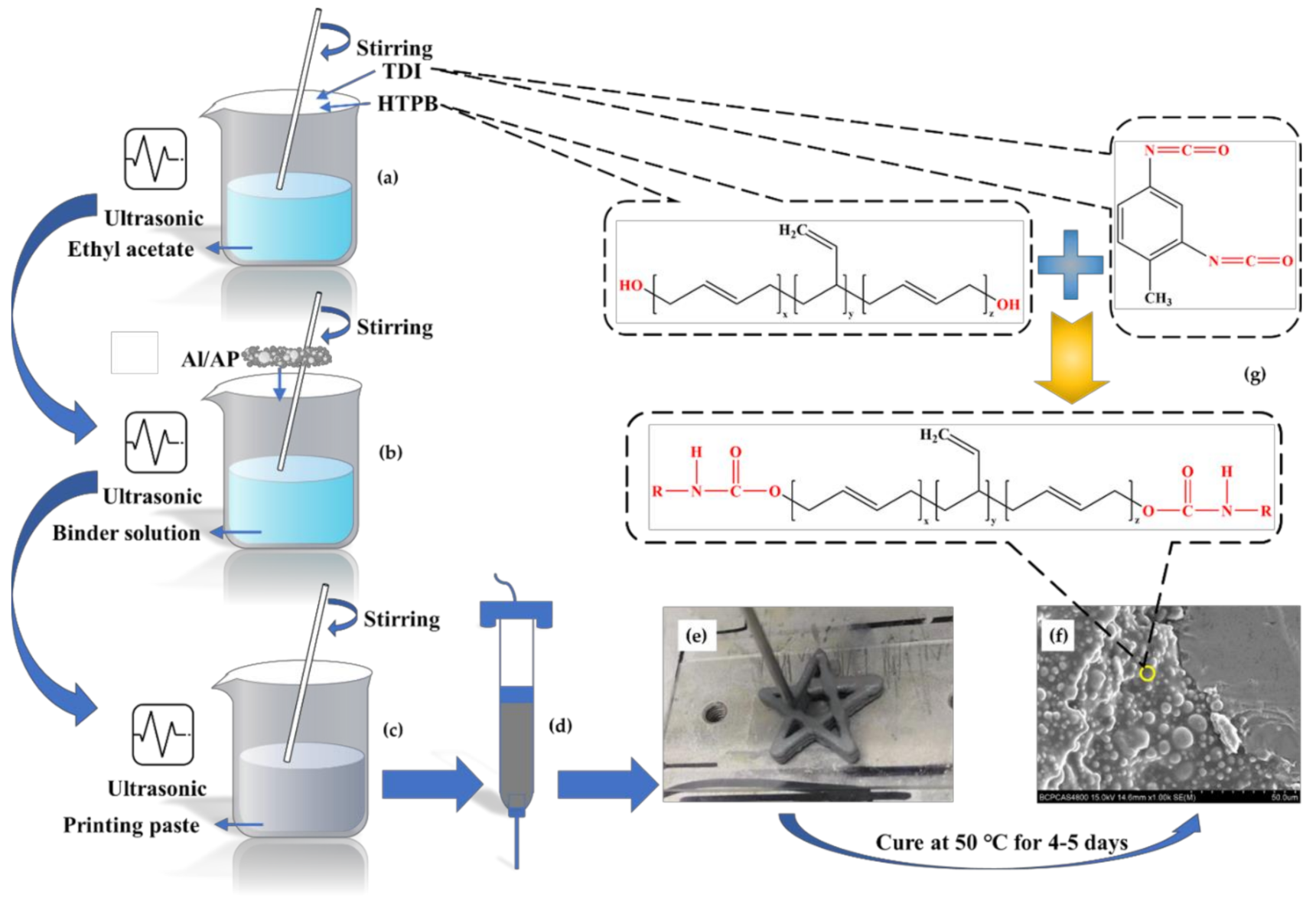

2.2. Ink Preparation and Curing

2.3. Characterization and Testing

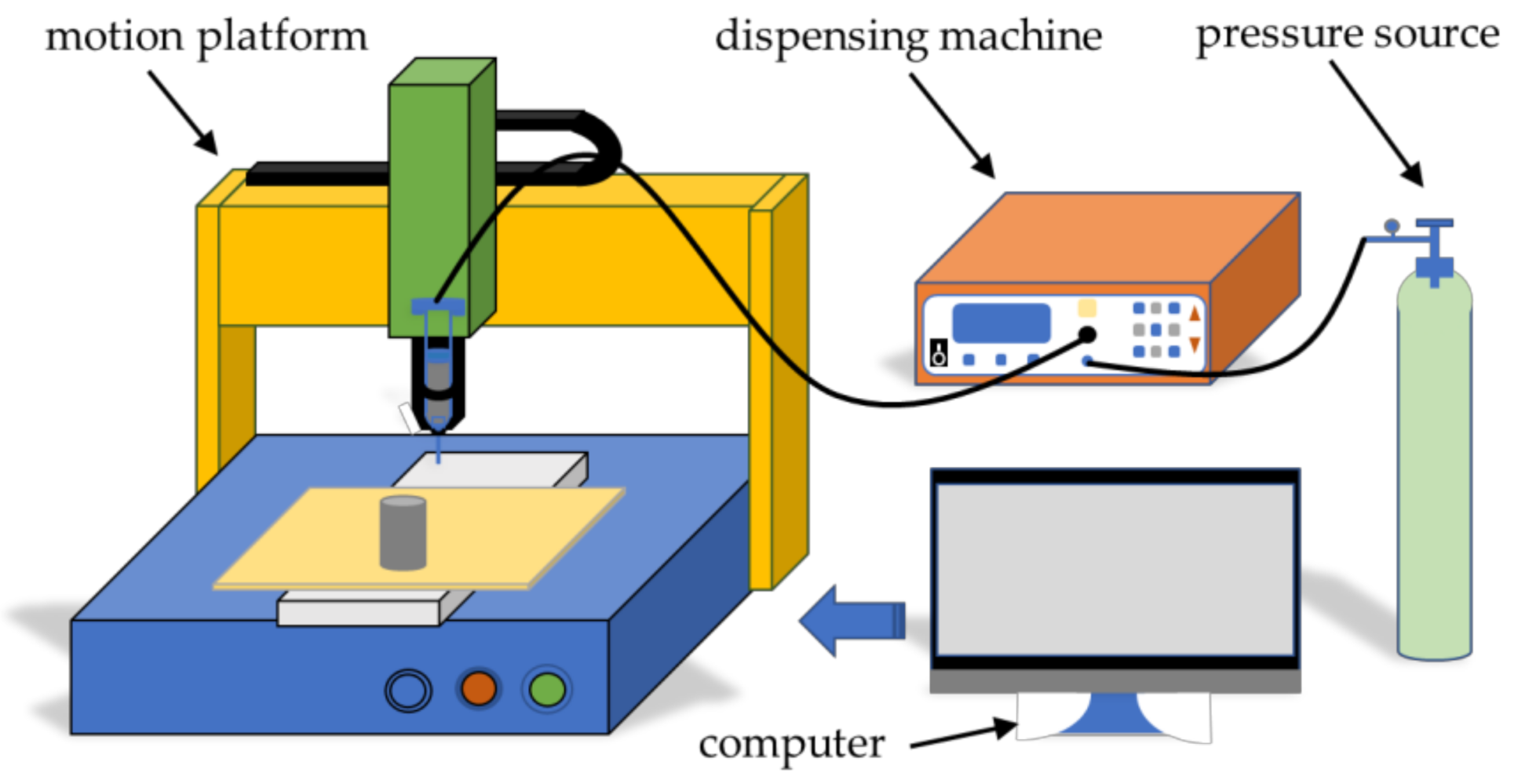

2.4. Equipment and Process Adjustment

3. Results

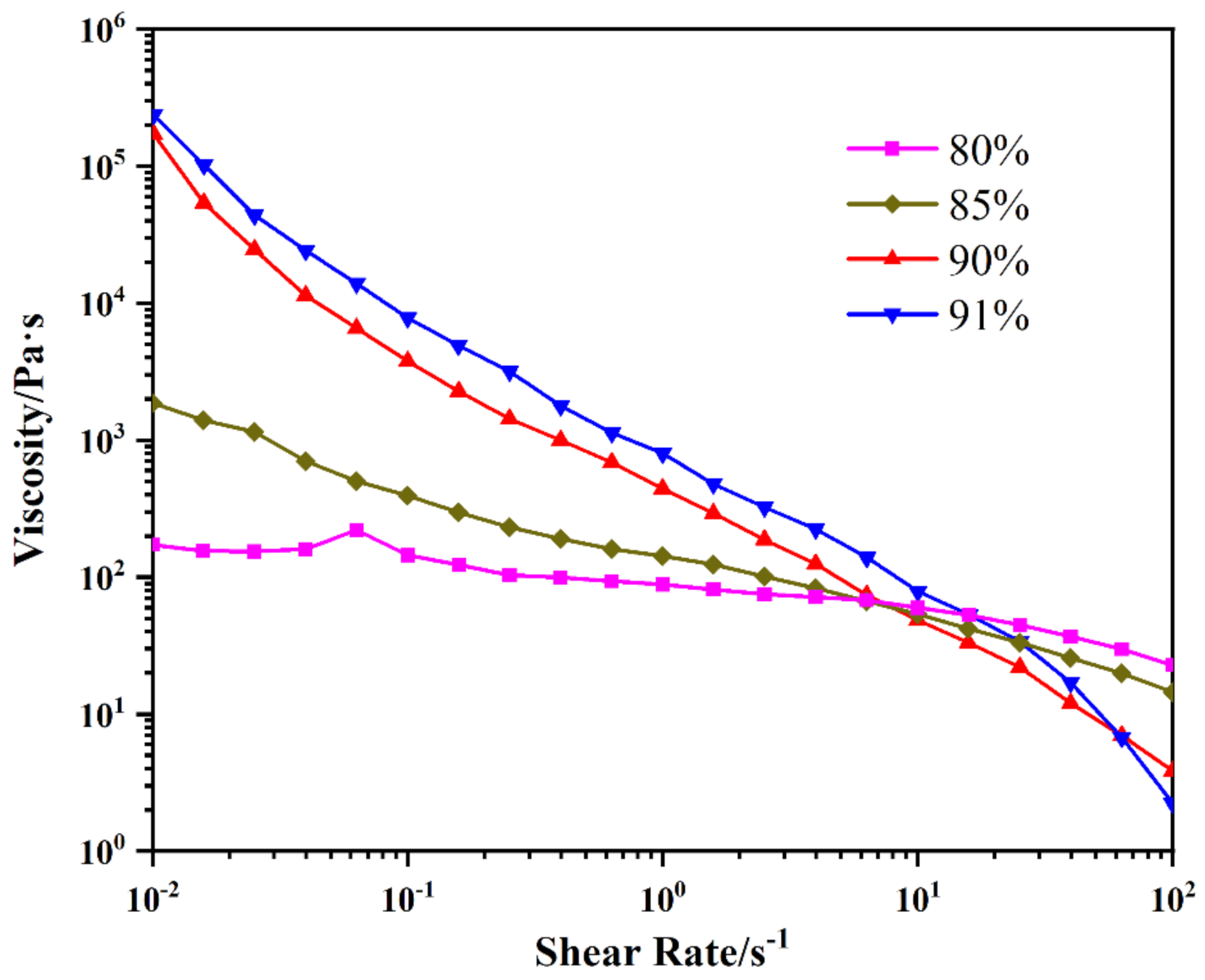

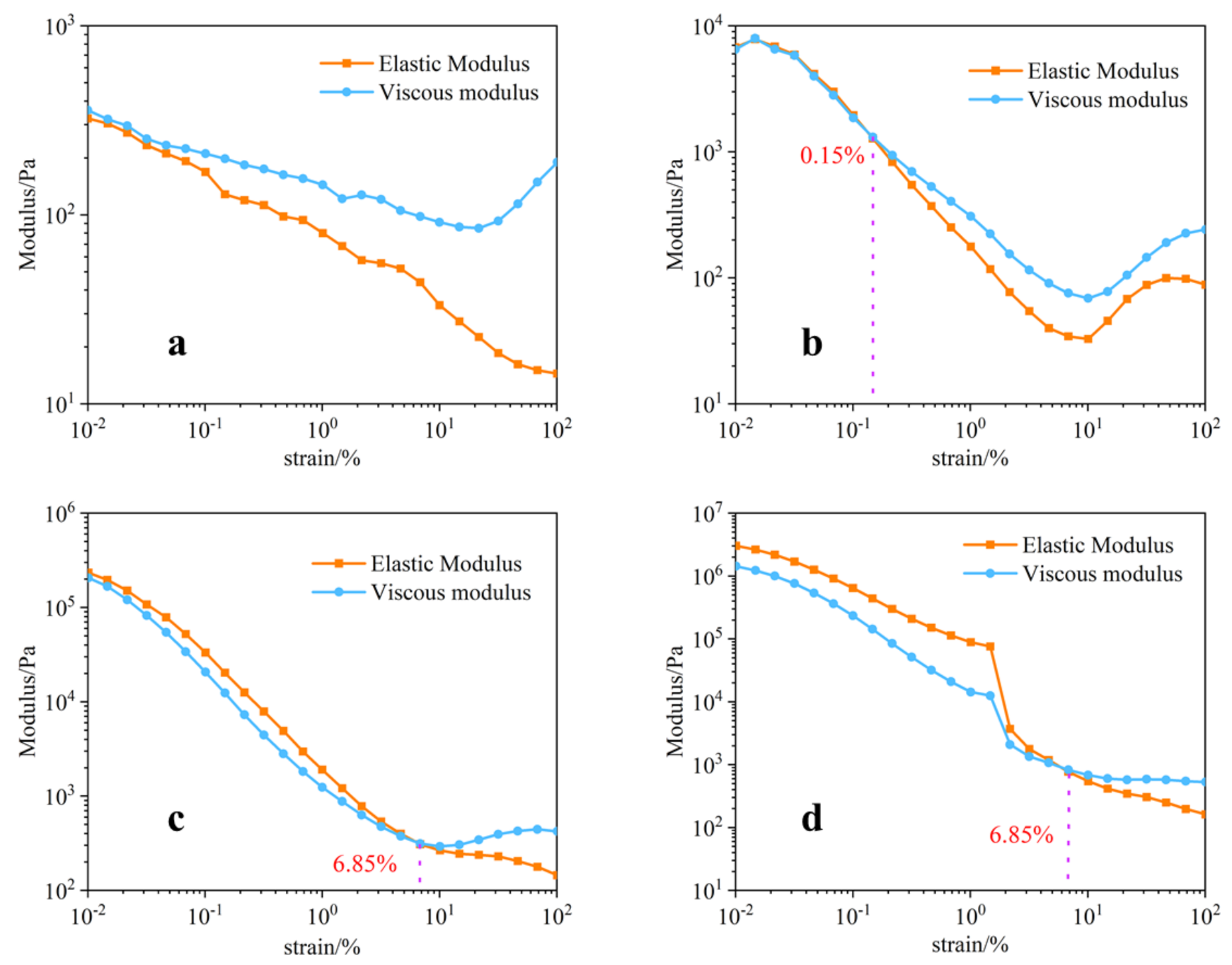

3.1. Rheology

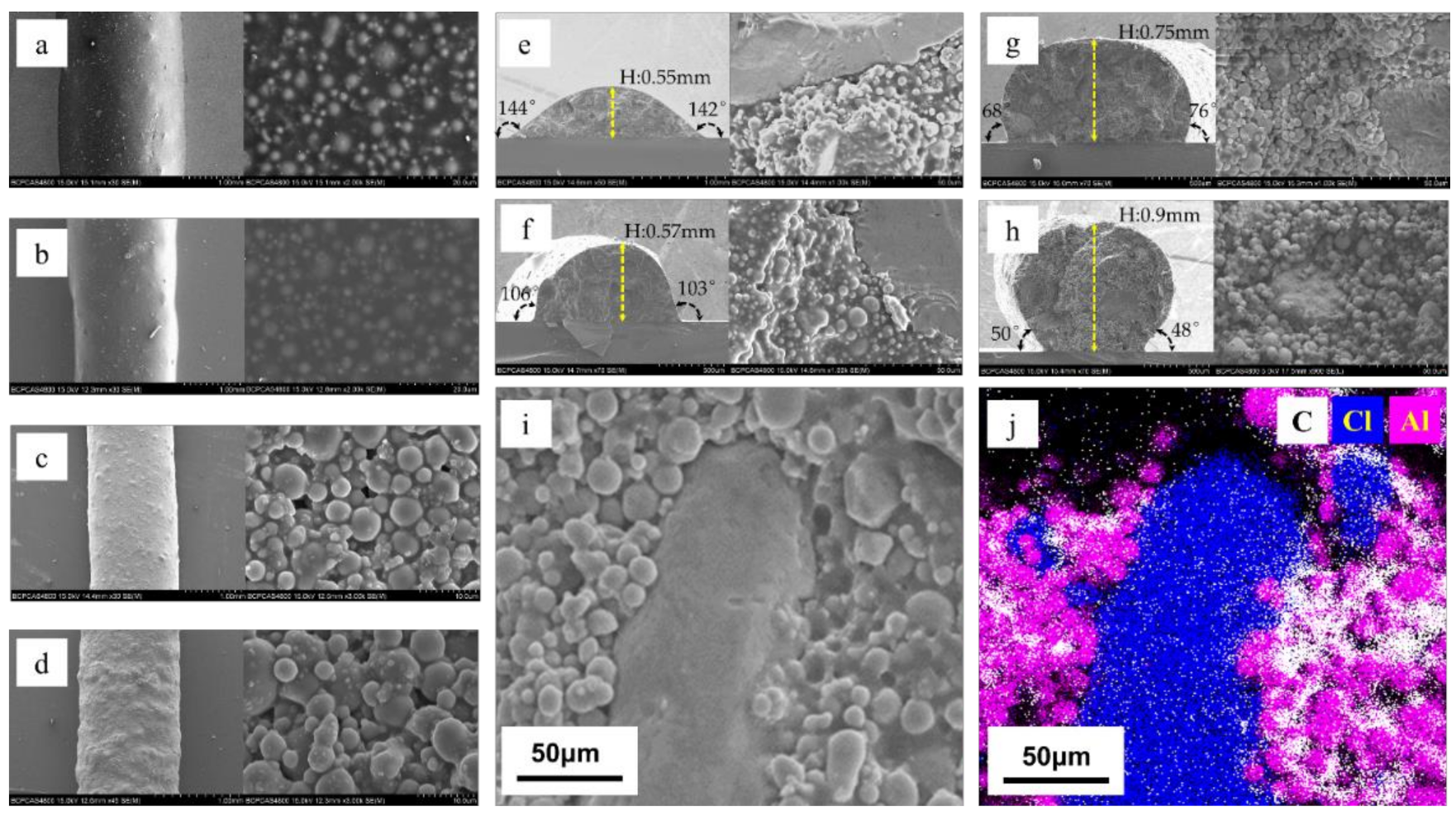

3.2. Micromorphology

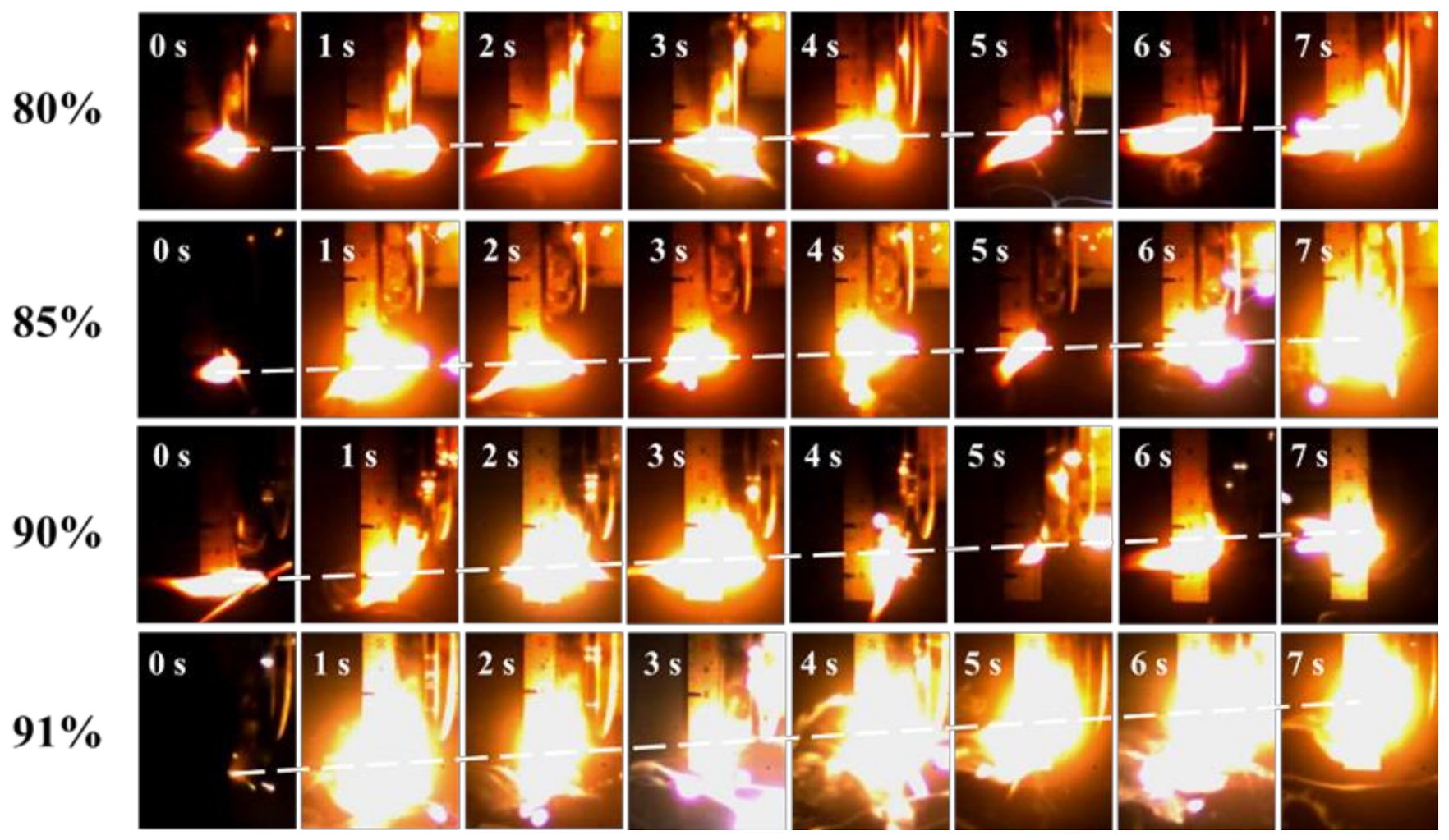

3.3. Density and Combustion Performance

3.4. Special Shaped Structure Printing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeman, S.; Jungová, M. Sensitivity and Performance of Energetic Materials. Propellants Explos. Pyrotech. 2016, 41, 426–451. [Google Scholar] [CrossRef] [Green Version]

- Sikder, A.K.; Sikder, N. A review of advanced high performance, insensitive and thermally stable energetic materials emerging for military and space applications. J. Hazard. Mater. 2004, 112, 1–15. [Google Scholar] [CrossRef]

- Zhang, C. Origins of the Energy and Safety of Energetic Materials and of the Energy & Safety Contradiction. Propellants Explos. Pyrotech. 2018, 43, 855–856. [Google Scholar] [CrossRef]

- Hong, D.; Chou, D.T.; Velikokhatnyi, O.I.; Roy, A.; Lee, B.; Swink, I.; Issaev, I.; Kuhn, H.A.; Kumta, P.N. Binder-jetting 3D printing and alloy development of new biodegradable Fe-Mn-Ca/Mg alloys. Acta Biomater. 2016, 45, 375–386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cicala, G.; Giordano, D.; Tosto, C.; Filippone, G.; Recca, A.; Blanco, I. Polylactide (PLA) Filaments a Biobased Solution for Additive Manufacturing: Correlating Rheology and Thermomechanical Properties with Printing Quality. Materials 2018, 11, 1191. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2012, 67, 1191–1203. [Google Scholar] [CrossRef]

- Mpofu, T.P.; Mawere, C.; Mukosera, M. The Impact and Application of 3D Printing Technology. Int. J. Sci. Res. 2012, 3, 2148–2152. [Google Scholar]

- Lahr, C.A.; Landgraf, M.; Sanchez-Herrero, A.; Dang, H.P.; Wagner, F.; Bas, O.; Bray, L.J.; Tran, P.; Holzapfel, B.M.; Shafiee, A.; et al. A 3D-printed biomaterials-based platform to advance established therapy avenues against primary bone cancers. Acta Biomater. 2020, 118, 69–82. [Google Scholar] [CrossRef]

- Sangkert, S.; Kamolmatyakul, S.; Gelinsky, M.; Meesane, J. 3D printed scaffolds of alginate/polyvinylalcohol with silk fibroin based on mimicked extracellular matrix for bone tissue engineering in maxillofacial surgery. Mater. Today Commun. 2021, 26, 102140. [Google Scholar] [CrossRef]

- Su, X.; Wang, T.; Guo, S. Applications of 3D printed bone tissue engineering scaffolds in the stem cell field. Regen 2021, 16, 63–72. [Google Scholar] [CrossRef]

- Varghese, G.; Moral, M.; Castro-García, M.; López-López, J.J.; Marín-Rueda, J.R.; Yagüe-Alcaraz, V.; Hernández-Afonso, L.; Ruiz-Morales, J.C.; Canales-Vázquez, J. Fabrication and characterisation of ceramics via low-cost DLP 3D printing. Bol. Soc. Esp. Ceram. Vidr. 2018, 57, 9–18. [Google Scholar] [CrossRef]

- Rosental, T.; Magdassi, S. A New Approach to 3D Printing Dense Ceramics by Ceramic Precursor Binders. Adv. Eng. Mater. 2019, 21, 1900604. [Google Scholar] [CrossRef]

- Carloni, D.; Zhang, G.; Wu, Y. Transparent alumina ceramics fabricated by 3D printing and vacuum sintering. J. Eur. Ceram. Soc. 2021, 41, 781–791. [Google Scholar] [CrossRef]

- Troksa, A.L.; Eshelman, H.V.; Chandrasekaran, S.; Rodriguez, N.; Ruelas, S.; Duoss, E.B.; Kelly, J.P.; Cerón, M.R.; Campbell, P.G. 3D-printed nanoporous ceramics: Tunable feedstock for direct ink write and projection microstereolithography. Mater. Des. 2021, 198, 109337. [Google Scholar] [CrossRef]

- Lin, Y.-P.; Zhang, Y.; Yu, M.-F. Parallel Process 3D Metal Microprinting. Adv. Mater. Technol. 2019, 4, 1800393. [Google Scholar] [CrossRef] [Green Version]

- Lawson, S.; Alwakwak, A.A.; Rownaghi, A.A.; Rezaei, F. Gel-Print-Grow: A New Way of 3D Printing Metal-Organic Frameworks. ACS Appl. Mater. Interfaces 2020, 12, 56108–56117. [Google Scholar] [CrossRef]

- Kristombu Baduge, S.; Navaratnam, S.; Abu-Zidan, Y.; McCormack, T.; Nguyen, K.; Mendis, P.; Zhang, G.; Aye, L. Improving performance of additive manufactured (3D printed) concrete: A review on material mix design, processing, interlayer bonding, and reinforcing methods. Structures 2021, 29, 1597–1609. [Google Scholar] [CrossRef]

- Kruger, J.; du Plessis, A.; van Zijl, G. An investigation into the porosity of extrusion-based 3D printed concrete. Addit. Manuf. 2021, 37. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, H.; Ding, T. Finite element analysis on the anisotropic behavior of 3D printed concrete under compression and flexure. Addit. Manuf. 2021, 39, 101712. [Google Scholar] [CrossRef]

- Blanco, I. The Use of Composite Materials in 3D Printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef] [Green Version]

- ASTM F2792-12. Standard Terminology for Additive Manufacturing Technologies; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mulhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [Green Version]

- Ihnen, A.C.; Petrock, A.M.; Chou, T.; Samuels, P.J.; Fuchs, B.E.; Lee, W.Y. Crystal morphology variation in inkjet-printed organic materials. Appl. Surf. Sci. 2011, 258, 827–833. [Google Scholar] [CrossRef]

- Xu, C.; An, C.; Li, Q.; Xu, S.; Wang, S.; Guo, H.; Wang, J. Preparation and Performance of Pentaerythrite Tetranitrate-Based Composites by Direct Ink Writing. Propellants Explos. Pyrotech. 2018, 43, 1149–1156. [Google Scholar] [CrossRef]

- Kong, S.; An, C.-W.; Li, C.-Y.; Liao, D.-J.; Jia, Y.-M.; Ye, B.-Y.; Wu, B.-D.; Wang, J.-Y.; Guo, H. Performances and direct writing of CL-20 based ultraviolet curing explosive ink. Def. Technol. 2020. [Google Scholar] [CrossRef]

- Fleck, T.J.; Murray, A.K.; Gunduz, I.E.; Son, S.F.; Chiu, G.T.C.; Rhoads, J.F. Additive manufacturing of multifunctional reactive materials. Addit. Manuf. 2017, 17, 176–182. [Google Scholar] [CrossRef]

- Murray, A.K.; Novotny, W.A.; Fleck, T.J.; Gunduz, I.E.; Son, S.F.; Chiu, G.T.C.; Rhoads, J.F. Selectively-deposited energetic materials: A feasibility study of the piezoelectric inkjet printing of nanothermites. Addit. Manuf. 2018, 22, 69–74. [Google Scholar] [CrossRef]

- Wang, H.; Shen, J.; Kline, D.J.; Eckman, N.; Agrawal, N.R.; Wu, T.; Wang, P.; Zachariah, M.R. Direct Writing of a 90 wt% Particle Loading Nanothermite. Adv. Mater. 2019, 31, e1806575. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.Y.; Rehwoldt, M.; Kline, D.J.; Wu, T.; Wang, P.; Zachariah, M.R. Comparison study of the ignition and combustion characteristics of directly-written Al/PVDF, Al/Viton and Al/THV composites. Combust. Flame 2019, 201, 181–186. [Google Scholar] [CrossRef]

- Li, Q.B.; An, C.W.; Han, X.; Xu, C.H.; Song, C.K.; Ye, B.Y.; Wu, B.D.; Wang, J.Y. CL-20 based Explosive Ink of Emulsion Binder System for Direct Ink Writing. Propellants Explos. Pyrotech. 2018, 43, 533–537. [Google Scholar] [CrossRef]

- Dunju, W.; Changping, G.; Ruihao, W.; Baohui, Z.; Bing, G.; Fude, N. Additive manufacturing and combustion performance of CL-20 composites. J. Mater. Sci. 2019, 55, 2836–2845. [Google Scholar] [CrossRef]

- Ye, B.Y.; Song, C.K.; Huang, H.; Li, Q.B.; An, C.W.; Wang, J.Y. Direct ink writing of 3D-Honeycombed CL-20 structures with low critical size. Def. Technol. 2020, 16, 588–595. [Google Scholar] [CrossRef]

- Gu, Y.; Park, D.; Bowen, D.; Das, S.; Hines, D.R. Direct-Write Printed, Solid-Core Solenoid Inductors with Commercially Relevant Inductances. Adv. Mater. Technol. 2019, 4, 1800312. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Wang, K.; Hu, Q.; Zhang, C.; Wang, B. Direct-write and sacrifice-based techniques for vasculatures. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 104, 109936. [Google Scholar] [CrossRef] [PubMed]

- Noh, S.; Kim, K.; Kim, J.-I.; Shin, J.H.; Kang, H.-W. Direct-write printing for producing biomimetic patterns with self-aligned neurites. Addit. Manuf. 2020, 32, 101072. [Google Scholar] [CrossRef]

- Shen, J.; Wang, H.; Kline, D.J.; Yang, Y.; Wang, X.; Rehwoldt, M.; Wu, T.; Holdren, S.; Zachariah, M.R. Combustion of 3D printed 90 wt% loading reinforced nanothermite. Combust. Flame 2020, 215, 86–92. [Google Scholar] [CrossRef]

- Li, M.; Pang, A.; Li, W.; Zhang, Y.; Lv, X.; Ma, Z. Combustion Performances of Spherical Al/AP Nanoenergetic Composites Produced by Solvent Evaporation and Crystallization. Combust. Sci. Technol. 2020, 1–14. [Google Scholar] [CrossRef]

- Ge, Y.-H.; Kang, J.-Y.; Zhou, J.-H.; Shi, L.-W. Theoretical investigation on thermal aging mechanism and the aging effect on mechanical properties of HTPB–IPDI polyurethane. Comput. Mater. Sci. 2016, 115, 92–98. [Google Scholar] [CrossRef]

- Wu, X.-Y.; Cui, Q.-Z.; Xu, J. Curing reaction kinetics of HTPB/TDI bonding system. Chin. J. Energetic Mater. 2016, 24, 1097–1101. [Google Scholar]

- Wilson, S.A.; Cross, L.M.; Peak, C.W.; Gaharwar, A.K. Shear-Thinning and Thermo-Reversible Nanoengineered Inks for 3D Bioprinting. ACS Appl. Mater. Interfaces 2017, 9, 43449–43458. [Google Scholar] [CrossRef] [PubMed]

- Amorim, P.A.; d’Ávila, M.A.; Anand, R.; Moldenaers, P.; Van Puyvelde, P.; Bloemen, V. Insights on shear rheology of inks for extrusion-based 3D bioprinting. Bioprinting 2021, 22, e00129. [Google Scholar] [CrossRef]

- Sullivan, K.T.; Zhu, C.; Duoss, E.B.; Gash, A.E.; Kolesky, D.B.; Kuntz, J.D.; Lewis, J.A.; Spadaccini, C.M. Controlling Material Reactivity Using Architecture. Adv. Mater. 2016, 28, 1934–1939. [Google Scholar] [CrossRef] [PubMed]

| Solid Content/% | Solid Content/% | Binder Content/% | ||

|---|---|---|---|---|

| Al/g | AP/g | HTPB/g | TDI/g | |

| 80 | 7.5 | 2.5 | 2.36 | 0.14 |

| 85 | 7.5 | 2.5 | 1.66 | 0.10 |

| 90 | 7.5 | 2.5 | 1.05 | 0.06 |

| 91 | 7.5 | 2.5 | 0.93 | 0.05 |

| 95 | 7.5 | 2.5 | 0.50 | 0.03 |

| Solid Content/% | Needle Diameter/mm | Syringe Pressure/psi | Printing Speed/mm·s−1 |

|---|---|---|---|

| 80 | 1.3 | 30 | 2 |

| 85 | 36 | 1.5 | |

| 90 | 43 | 1 | |

| 91 | 45 | 1 |

| Solid Content/% | Density/g·cm−3 | Burning Rate /mm·s−1 | Heat of Combustion/kJ·cm−3 |

|---|---|---|---|

| 80 | 1.587 ± 0.04 | 1.34 ± 0.03 | 39.761 ± 0.09 |

| 85 | 1.636 ± 0.03 | 1.55 ± 0.01 | 40.099 ± 0.11 |

| 90 | 1.689 ± 0.02 | 2.22 ± 0.02 | 40.424 ± 0.13 |

| 91 | 1.700 ± 0.05 | 3.65 ± 0.03 | 40.636 ± 0.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Y.; Wu, X.; Deng, P.; Guan, F.; Ren, H. Fabrication of Energetic Composites with 91% Solid Content by 3D Direct Writing. Micromachines 2021, 12, 1160. https://doi.org/10.3390/mi12101160

Deng Y, Wu X, Deng P, Guan F, Ren H. Fabrication of Energetic Composites with 91% Solid Content by 3D Direct Writing. Micromachines. 2021; 12(10):1160. https://doi.org/10.3390/mi12101160

Chicago/Turabian StyleDeng, Yucheng, Xinzhou Wu, Peng Deng, Fayang Guan, and Hui Ren. 2021. "Fabrication of Energetic Composites with 91% Solid Content by 3D Direct Writing" Micromachines 12, no. 10: 1160. https://doi.org/10.3390/mi12101160

APA StyleDeng, Y., Wu, X., Deng, P., Guan, F., & Ren, H. (2021). Fabrication of Energetic Composites with 91% Solid Content by 3D Direct Writing. Micromachines, 12(10), 1160. https://doi.org/10.3390/mi12101160