Numerical Study of Nanoparticle Deposition in a Gaseous Microchannel under the Influence of Various Forces

Abstract

1. Introduction

2. Governing Equations

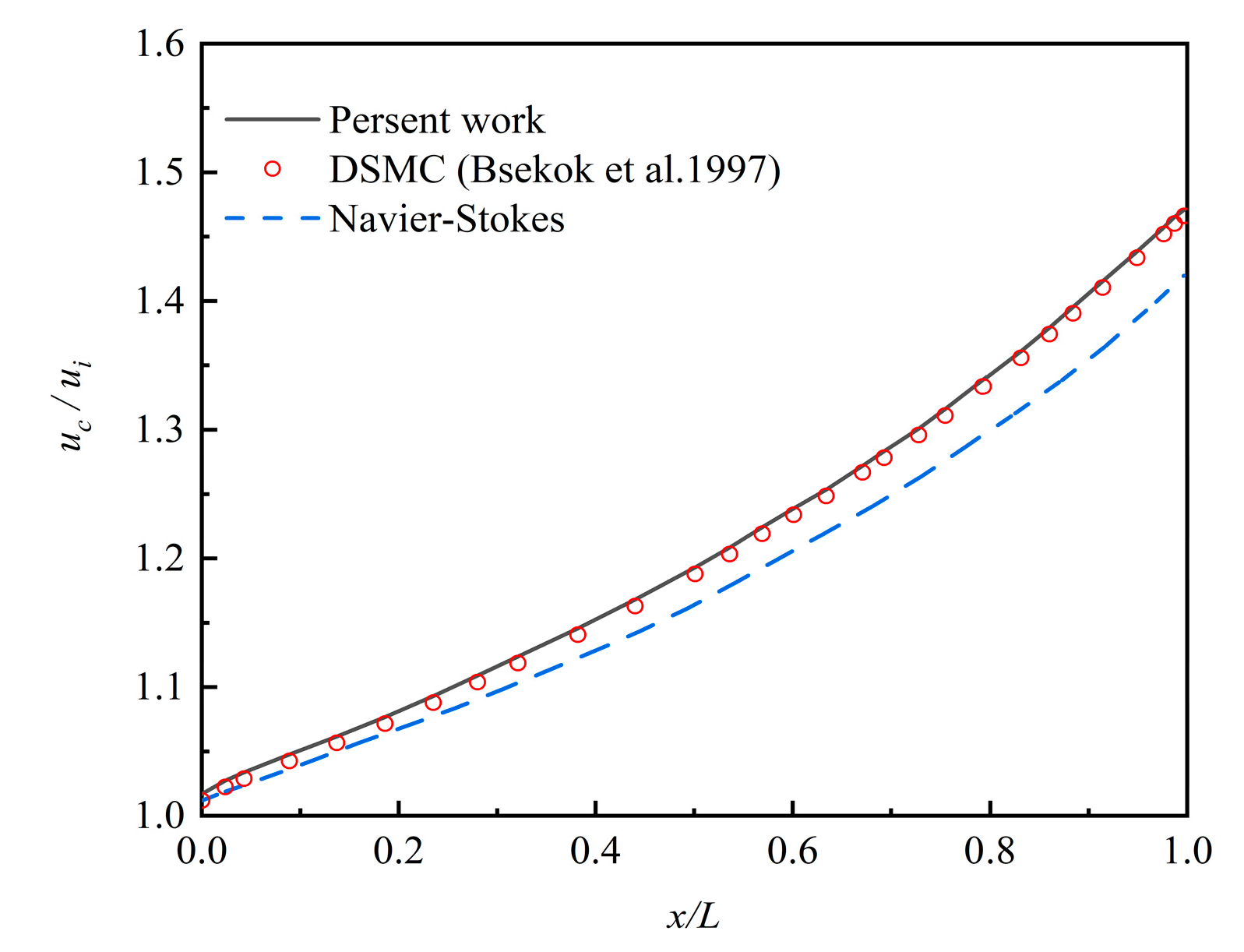

3. Simulation Parameters and Solution Verification

4. Results and Discussion

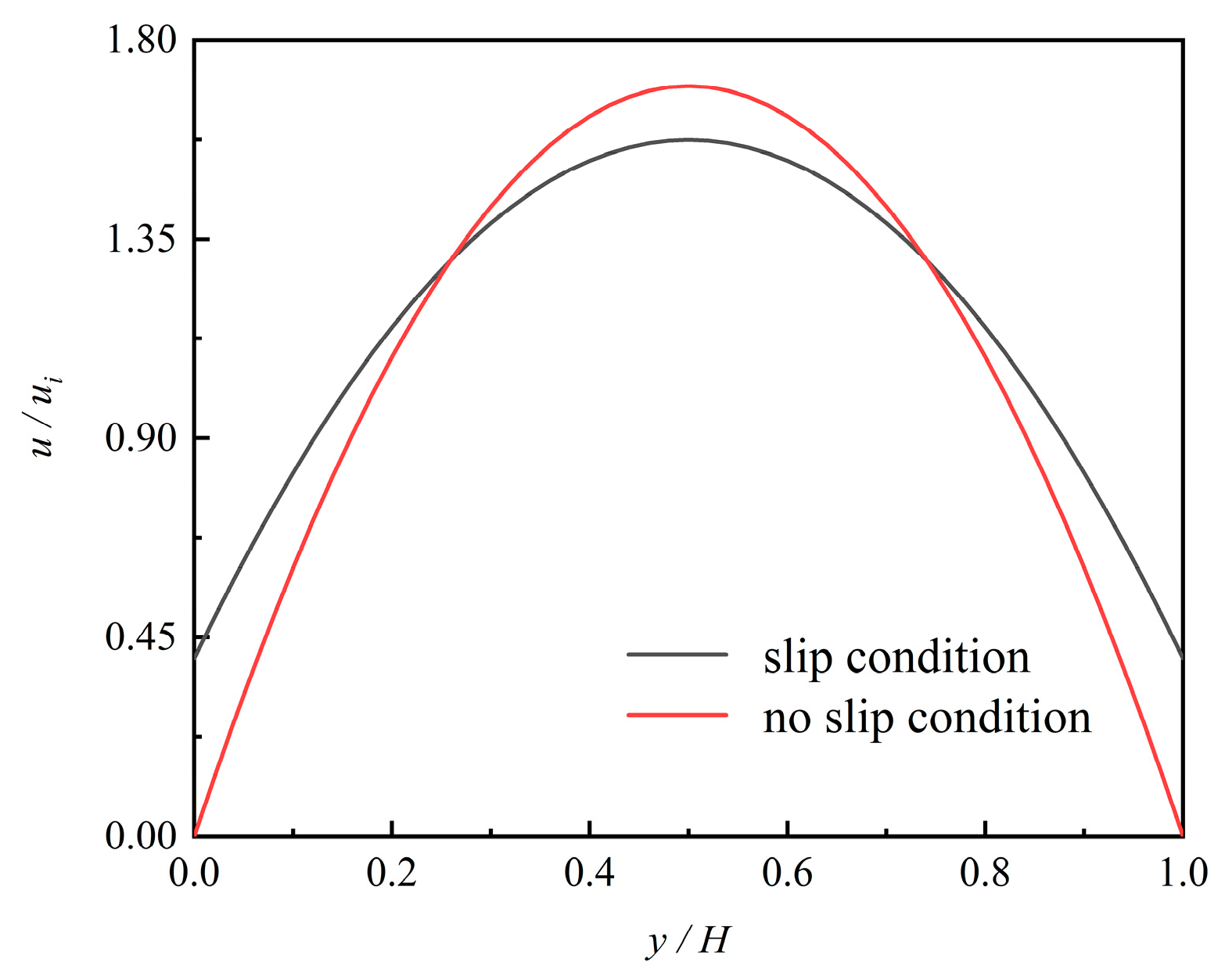

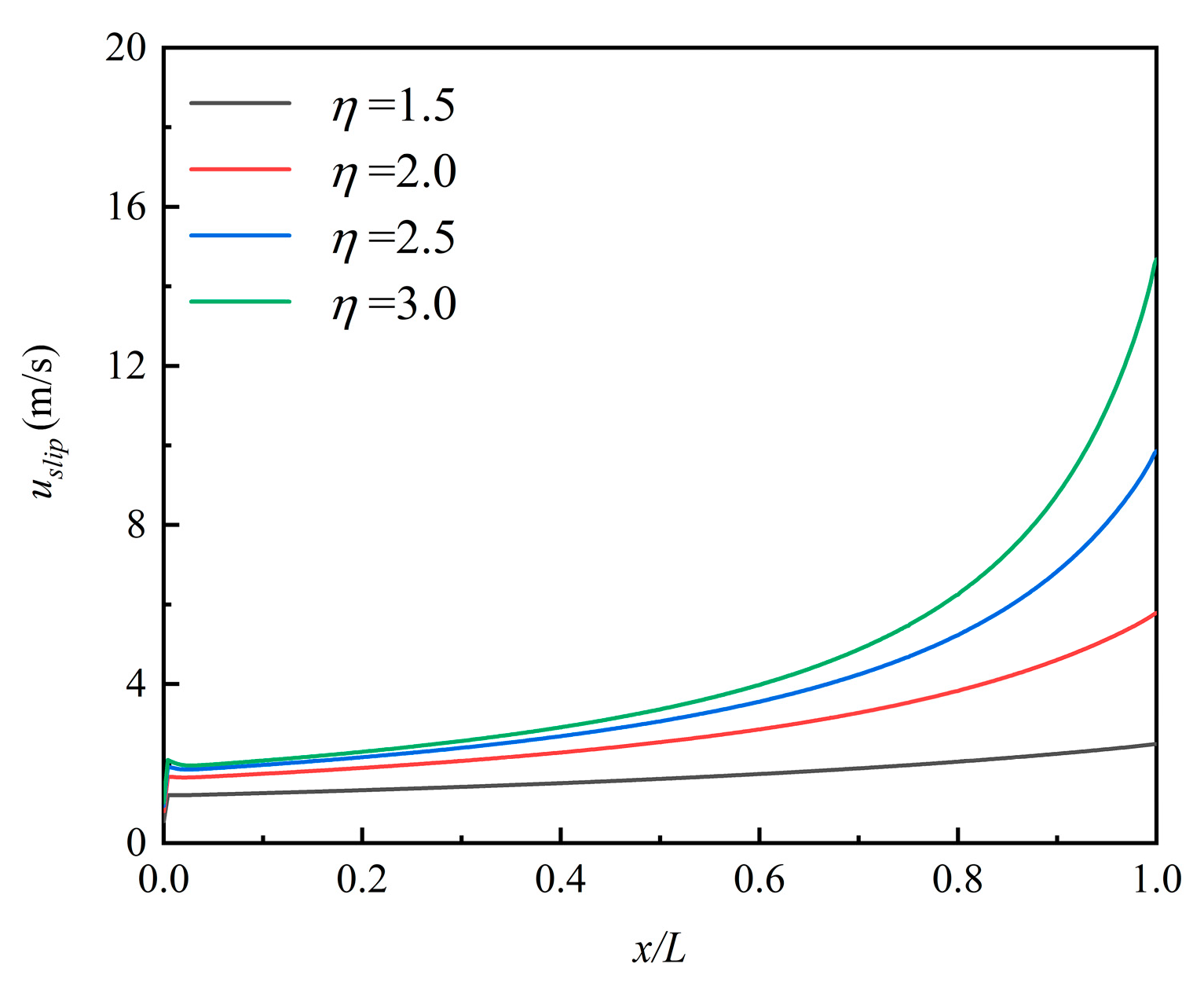

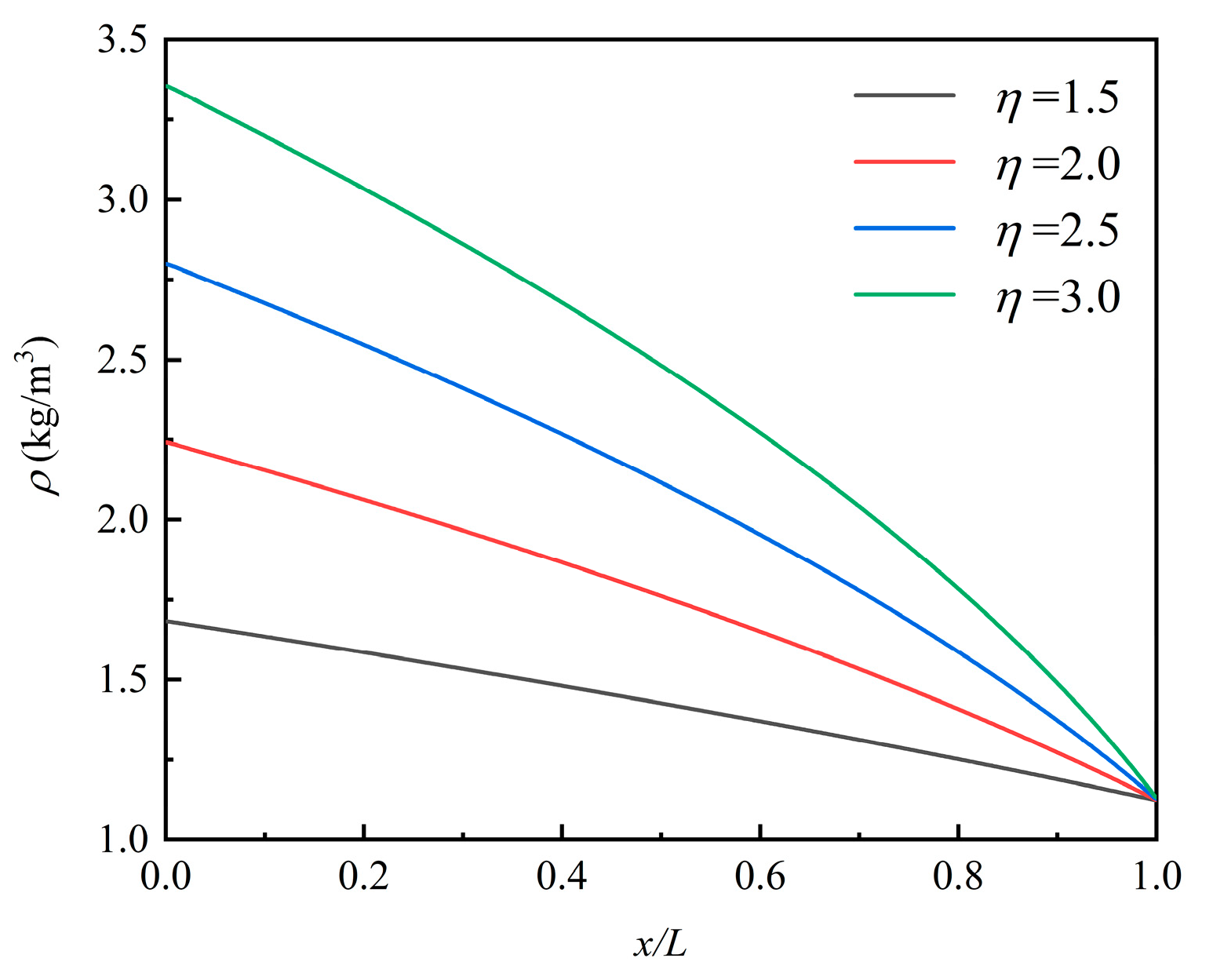

4.1. The Flow Field Characteristics and Influence on Particles Deposition

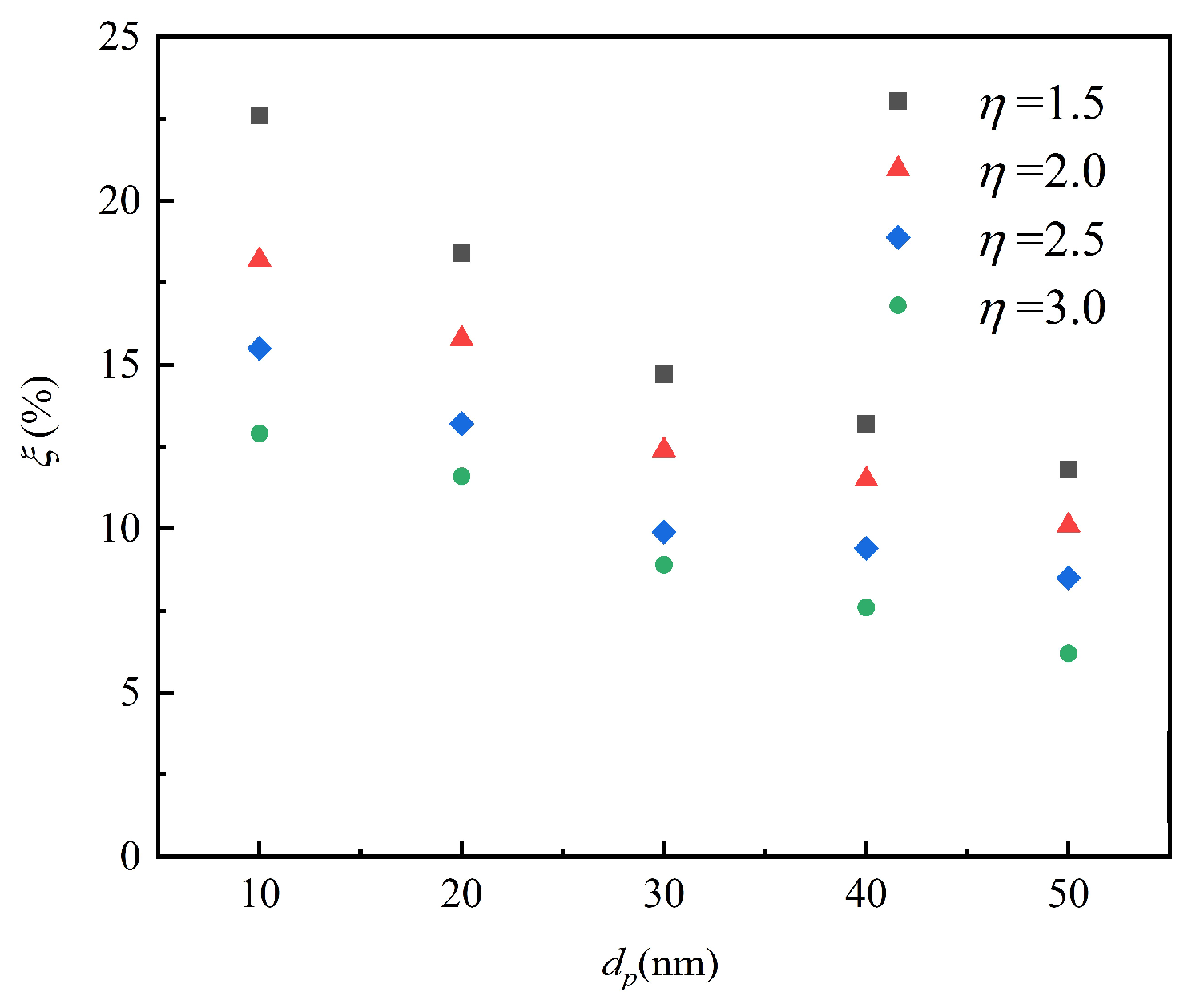

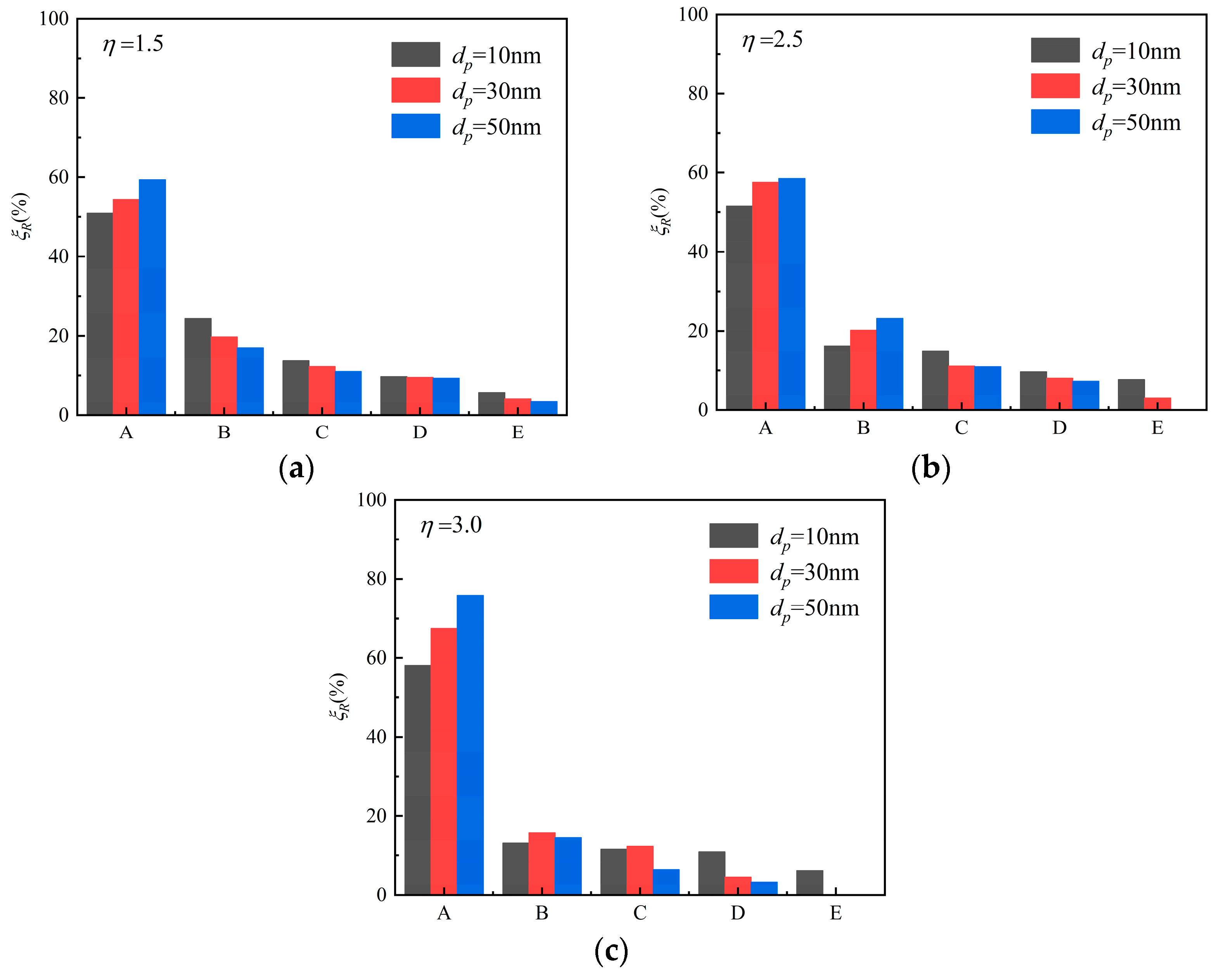

4.2. The Pressure Ratio Effect on the Particle Deposition Efficiency

4.3. The Temperature Effect on the Deposition Process

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ge, L.; Peng, Z.; Moreno-Atanasio, R.; Doroodchi, E.; Evans, G.M. Three-dimensional VOF-DEM Model for simulating particle dynamics in the liquid slugs of a vertical gas-liquid-solid taylor flow Microreactor. Ind. Eng. Chem. Res. 2020, 59, 7965–7981. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, M.; Chen, X.; Yu, Y.; Zhou, Q. Modeling of the filtered drag force in gas–solid flows via a deep learning approach. Chem. Eng. Sci. 2020, 225, 115835. [Google Scholar] [CrossRef]

- Jang, H.; Park, H. An experimental investigation of liquid slug—Gas bubble flow characteristics in a micromixer manufactured by 3D printing technique. Trans. Korean Soc. Mech. Eng. B 2020, 44, 325–330. [Google Scholar] [CrossRef]

- Hosseini, S.M.J.; Goharrizi, A.S.; Abolpour, B. Numerical study of aerosol particle deposition in simple and converging–diverging micro-channels with a slip boundary condition at the wall. Particuology 2014, 13, 100–105. [Google Scholar] [CrossRef]

- Sharipov, F.; Seleznev, V. Data on internal rarefied gas flows. J. Phys. Chem. Ref. Data 1998, 27, 657–706. [Google Scholar] [CrossRef]

- Taassob, A.; Kamali, R.; Bordbar, A. Investigation of rarefied gas flow through bended microchannels. Vacuum 2018, 151, 197–204. [Google Scholar] [CrossRef]

- Sharipov, F. Rarefied gas flow through a long tube at arbitrary pressure and temperature drops. J. Vac. Sci. Technol. A Vac. Surf. Film. 1997, 15, 2434–2436. [Google Scholar] [CrossRef]

- Sharipov, F. Non-isothermal gas flow through rectangular microchannels. J. Micromechanics Microeng. 1999, 9, 394. [Google Scholar] [CrossRef]

- Graur, I.; Sharipov, F. Non-isothermal flow of rarefied gas through a long pipe with elliptic cross section. Microfluid. Nanofluidics 2009, 6, 267–275. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, W.; Agarwal, R.K. Formulation of a new set of simplified conventional Burnett equations for computation of rarefied hypersonic flows. Aerosp. Sci. Technol. 2014, 38, 64–75. [Google Scholar] [CrossRef]

- Torrilhon, M.; Struchtrup, H. Regularized 13-moment equations: Shock structure calculations and comparison to Burnett models. J. Fluid Mech. 2004, 513, 171. [Google Scholar] [CrossRef]

- Rath, A.; Singh, N.; Agrawal, A. A perturbation-based solution of Burnett equations for gaseous flow in a long microchannel. J. Fluid Mech. 2018, 844, 1038. [Google Scholar] [CrossRef]

- Agarwal, R.K.; Yun, K.-Y.; Balakrishnan, R. Beyond Navier–Stokes: Burnett equations for flows in the continuum–transition regime. Phys. Fluids 2001, 13, 3061–3085. [Google Scholar] [CrossRef]

- Zhong, X.; MacCormack, R.W.; Chapman, D.R. Stabilization of the Burnett equations and application to hypersonicflows. AIAA J. 1993, 31, 1036–1043. [Google Scholar] [CrossRef]

- Xu, K.; Li, Z. Microchannel flow in the slip regime: Gas-kinetic BGK–Burnett solutions. J. Fluid Mech. 2004, 513, 87–110. [Google Scholar] [CrossRef]

- Bao, F.; Lin, J. Burnett simulation of gas flow and heat transfer in micro Poiseuille flow. Int. J. Heat Mass Transf. 2008, 51, 4139–4144. [Google Scholar] [CrossRef]

- Singh, N.; Agrawal, A. The Burnett equations in cylindrical coordinates and their solution for flow in a microtube. J. Fluid Mech. 2014, 751, 121–141. [Google Scholar] [CrossRef]

- Sauret, A.; Barney, E.C.; Perro, A.; Villermaux, E.; Stone, H.A.; Dressaire, E. Clogging by sieving in microchannels: Application to the detection of contaminants in colloidal suspensions. Appl. Phys. Lett. 2014, 105, 074101. [Google Scholar] [CrossRef]

- Sauret, A.; Somszor, K.; Villermaux, E.; Dressaire, E. Growth of clogs in parallel microchannels. Phys. Rev. Fluids 2018, 3, 104301. [Google Scholar] [CrossRef]

- Dressaire, E.; Sauret, A. Clogging of microfluidic systems. Soft Matter 2017, 13, 37–48. [Google Scholar] [CrossRef]

- Mohajer, B.; Aliakbar, V.; Shams, M.; Moshfegh, A. Heat transfer analysis of a microspherical particle in the slip flow regime by considering variable properties. Heat Transf. Eng. 2015, 36, 596–610. [Google Scholar] [CrossRef]

- Kishore, N.; Ramteke, R.R. Forced convective heat transfer from spheres to Newtonian fluids in steady axisymmetric flow regime with velocity slip at fluid–solid interface. Int. J. Therm. Sci. 2016, 105, 206–217. [Google Scholar] [CrossRef]

- Mu, Z.; Liu, Z.; Wu, H. Lattice Boltzmann simulation of particle sedimentation considering micro-scale gas rarefaction effect. Chin. J. Comput. Phys. 2019, 34, 395–402. [Google Scholar]

- Islam, M.S.; Saha, S.C.; Sauret, E.; Gemci, T.; Yang, I.A.; Gu, Y.T. Ultrafine particle transport and deposition in a large scale 17-generation lung model. J. Biomech. 2017, 64, 16–25. [Google Scholar] [CrossRef][Green Version]

- Lu, H.; Zhang, L.Z.; Lu, L.; Pan, A. Numerical investigation on monodispersed particle deposition in turbulent duct flow with thermophoresis. Energy Procedia 2019, 158, 5711–5716. [Google Scholar] [CrossRef]

- Macgibbon, B.S. The Effect of Thermophoresis on Particle Deposition in a Tungsten Low Pressure Chemical Vapor Deposition Reactor. J. Electrochem. Soc. 1999, 146, 105–112. [Google Scholar] [CrossRef]

- Bao, F.; Wang, J.; Lin, J. Burnett Simulation of Gaseous Flow in Micro/Nano-Filter. Curr. Nanosci. 2012, 8, 12–16. [Google Scholar] [CrossRef]

- Rojas-Cárdenas, M.; Graur, I.; Perrier, P.; Méolans, J.G. A new method to measure the thermal slip coefficient. Int. J. Heat Mass Transf. 2015, 88, 766–774. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Perrier, P.; Ho, M.T.; Méolans, J.G.; Niimi, T.; Graur, I. Mass flow rate measurement of thermal creep flow from transitional to slip flow regime. J. Fluid Mech. 2016, 795, 690–707. [Google Scholar] [CrossRef]

- Sharipov, F. Data on the velocity slip and temperature jump on a gas-solid interface. J. Phys. Chem. Ref. Data 2011, 40, 023101. [Google Scholar] [CrossRef]

- Colin, S.; Lalonde, P.; Caen, R. Validation of a Second-Order Slip Flow Model in Rectangular Microchannels. Heat Transf. Eng. 2004, 25, 23–30. [Google Scholar] [CrossRef]

- Beskok, A.; Karniadakis, G.E.; Trimmer, W. Rarefaction and Compressibility Effects in Gas Microflows. J. Fluids Eng. 1996, 118, 448–456. [Google Scholar] [CrossRef]

- Andarwa, S.; Basirat Tabrizi, H.; Ahmadi, G. Effect of correcting near-wall forces on nanoparticle transport in a microchannel. Particuology 2014, 16, 84–90. [Google Scholar] [CrossRef]

- Garoosi, F.; Talebi, F. Numerical simulation of conjugate conduction and natural convection heat transfer of nanofluid inside a square enclosure containing a conductive partition and several disconnected conducting solid blocks using the Buongiorno’s two phase model. Powder Technol. 2017, 317, 48–71. [Google Scholar] [CrossRef]

- Kim, M.M.; Zydney, A.L. Effect of electrostatic, hydrodynamic, and Brownian forces on particle trajectories and sieving in normal flow filtration. J. Colloid Interface 2004, 269, 425–431. [Google Scholar] [CrossRef]

- Talbot, L.; Cheng, R.K.; Schefer, R.W.; Willis, D.R. Thermophoresis of particles in a heated boundary layer. J. Fluid Mech. 2006, 101, 737–758. [Google Scholar] [CrossRef]

- Garoosi, F.; Hoseininejad, F.; Rashidi, M.M. Numerical study of heat transfer performance of nanofluids in a heat exchanger. Appl. Therm. Eng. 2016, 105, 436–455. [Google Scholar] [CrossRef]

- Zhang, H.; Li, G.; An, X.; Ye, X.; Wei, G.; Yu, A. Numerical study on the erosion process of the low temperature economizer using computational fluid dynamics-discrete particle method. Wear 2020, 450–451, 203269. [Google Scholar] [CrossRef]

- Sommerfeld, M. Validation of a stochastic Lagrangian modelling approach for inter-particle collisions in homogeneous isotropic turbulence. Int. J. Multiph. Flow 2001, 27, 1829–1858. [Google Scholar] [CrossRef]

- Andarwa, S.; Tabrizi, H.B. Nanoparticle deposition in transient gaseous microchannel flow considering hindered motion and rarefaction effect. Korean J. Chem. Eng. 2017, 34, 1319–1327. [Google Scholar] [CrossRef]

- Beskok, A. Simulations an Models for Gas Flows in Microgeometries. Ph.D. Thesis, Prineeton University, Princeton, NJ, USA, 1996. [Google Scholar]

- Dongari, N.; Agrawal, A.; Agrawal, A. Analytical solution of gaseous slip flow in long microchannels. Int. J. Heat Mass Transf. 2007, 50, 3411–3421. [Google Scholar] [CrossRef]

| Coefficients | Maxwell Molecules | Hard-Sphere Molecules |

|---|---|---|

| ω1 | 10/3 | 4.056 |

| ω2 | 2 | 2.028 |

| ω3 | 3 | 2.418 |

| ω4 | 0 | 0.681 |

| ω5 | 3 | 0.219 |

| ω6 | 8 | 7.424 |

| θ1 | 75/8 | 11.644 |

| θ2 | −45/8 | −5.822 |

| θ3 | −3 | −0.393 |

| θ4 | 3 | 2.418 |

| θ5 | 117/4 | 25.157 |

| Case | Total Cell Number | Velocity | Relative Error from DSMC [41] (%) |

|---|---|---|---|

| Case 1 | 200 × 20 | 14.6839 | 1.47 |

| Case 2 | 300 × 30 | 14.8025 | 0.67 |

| Case 3 | 400 × 40 | 14.8582 | 0.30 |

| Case 4 | 500 × 50 | 14.8913 | 0.08 |

| Case 5 | 600 × 60 | 14.8956 | 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, F.; Hao, H.; Yin, Z.; Tu, C. Numerical Study of Nanoparticle Deposition in a Gaseous Microchannel under the Influence of Various Forces. Micromachines 2021, 12, 47. https://doi.org/10.3390/mi12010047

Bao F, Hao H, Yin Z, Tu C. Numerical Study of Nanoparticle Deposition in a Gaseous Microchannel under the Influence of Various Forces. Micromachines. 2021; 12(1):47. https://doi.org/10.3390/mi12010047

Chicago/Turabian StyleBao, Fubing, Hanbo Hao, Zhaoqin Yin, and Chengxu Tu. 2021. "Numerical Study of Nanoparticle Deposition in a Gaseous Microchannel under the Influence of Various Forces" Micromachines 12, no. 1: 47. https://doi.org/10.3390/mi12010047

APA StyleBao, F., Hao, H., Yin, Z., & Tu, C. (2021). Numerical Study of Nanoparticle Deposition in a Gaseous Microchannel under the Influence of Various Forces. Micromachines, 12(1), 47. https://doi.org/10.3390/mi12010047