Large-Scale Flow in Micro Electrokinetic Turbulent Mixer

Abstract

1. Introduction

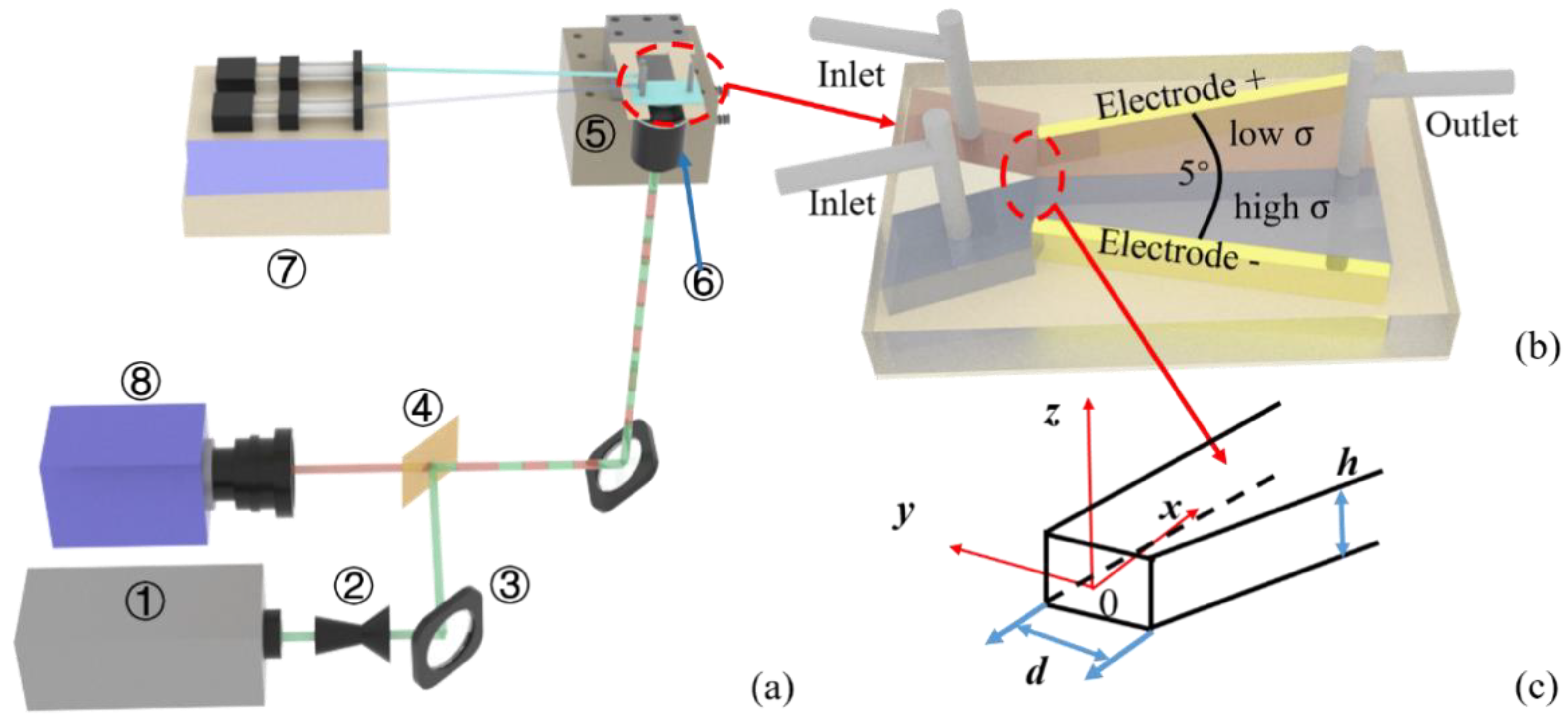

2. Experiments Setup

2.1. Experimental System

2.2. Microchannel Chip

2.3. Velocity Fields Measured by μPIV

3. Governing Equation of µEK Turbulence

4. Experiments Results and Discussion

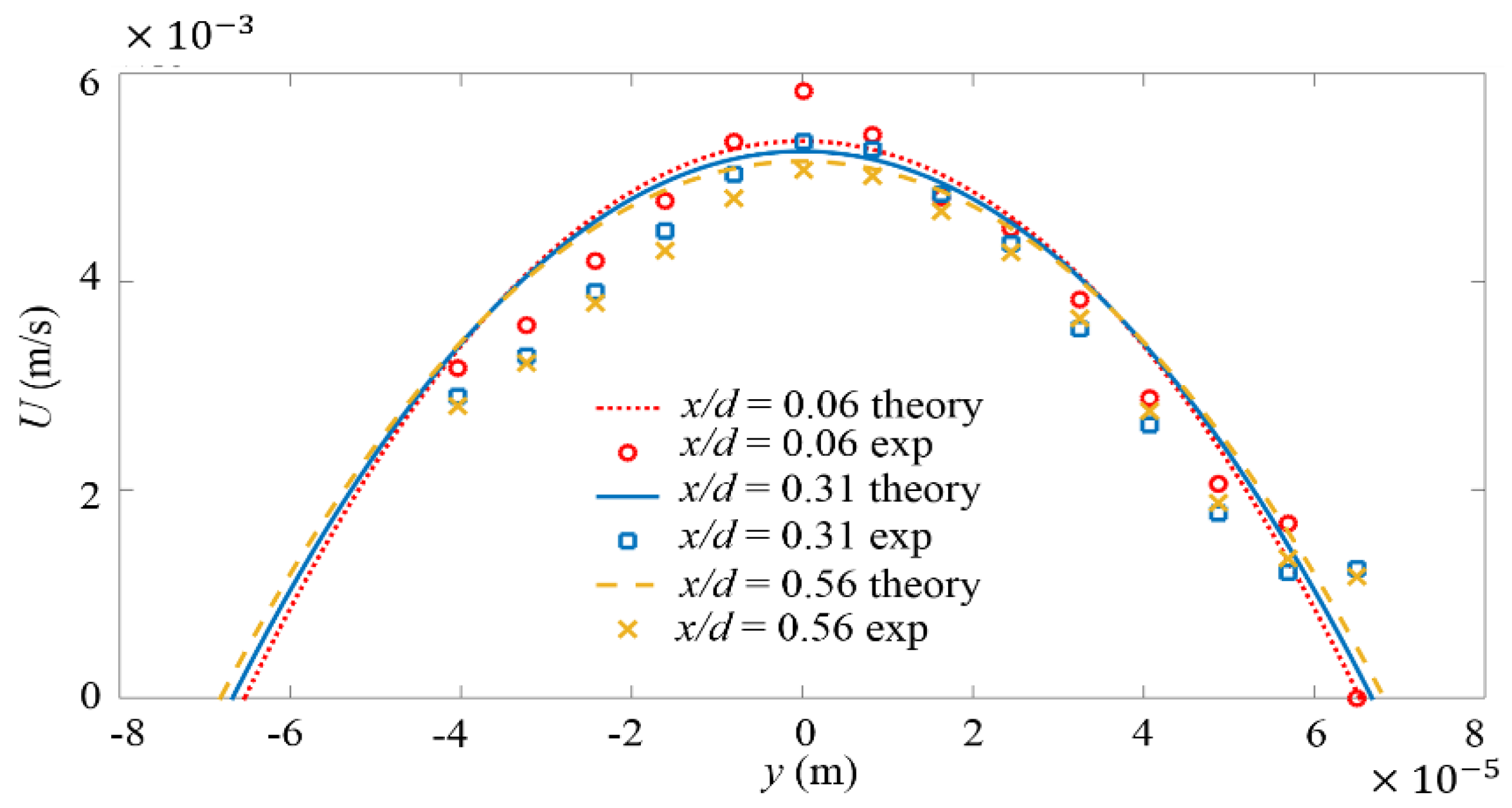

4.1. Distribution of Mean Velocity Field

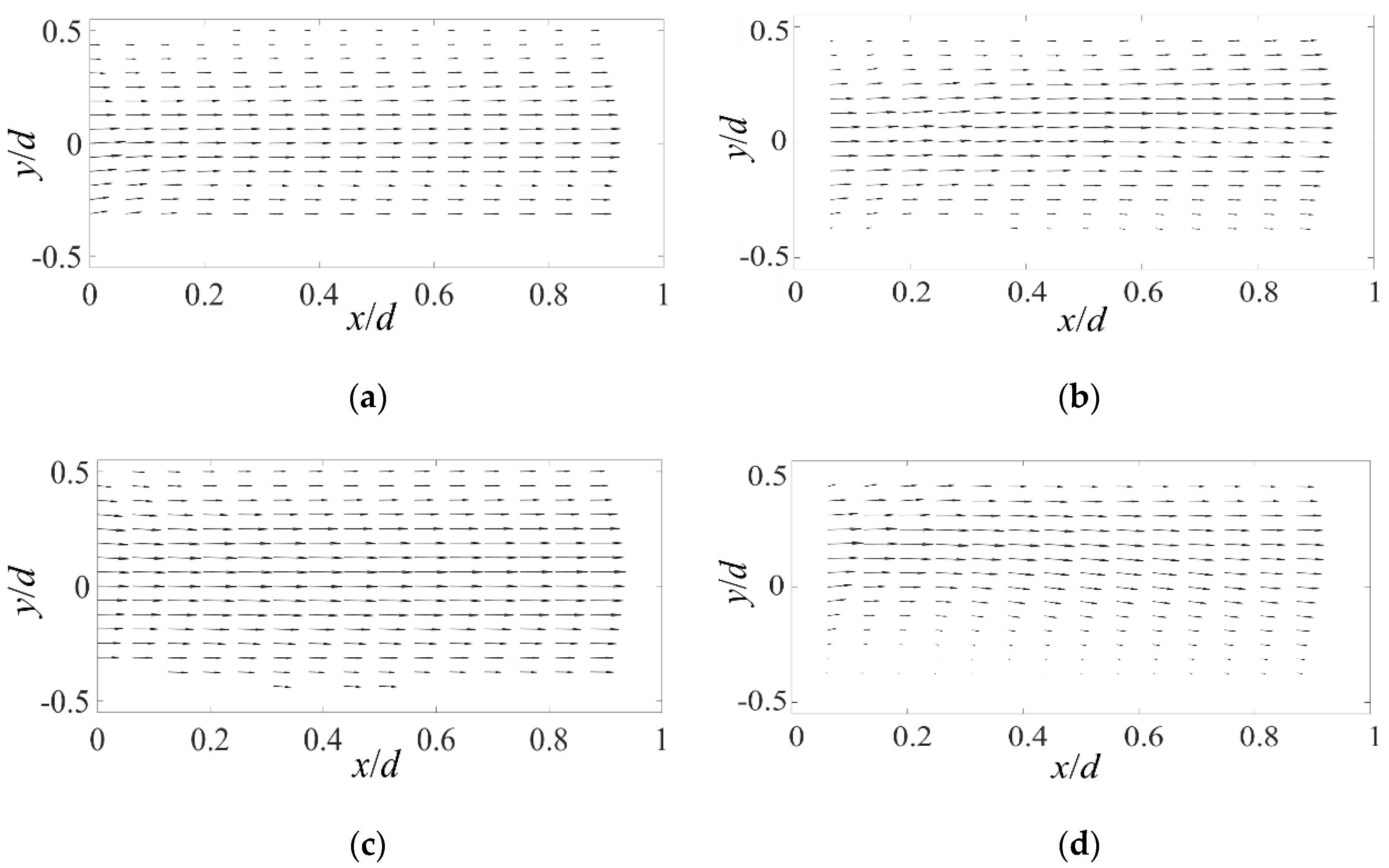

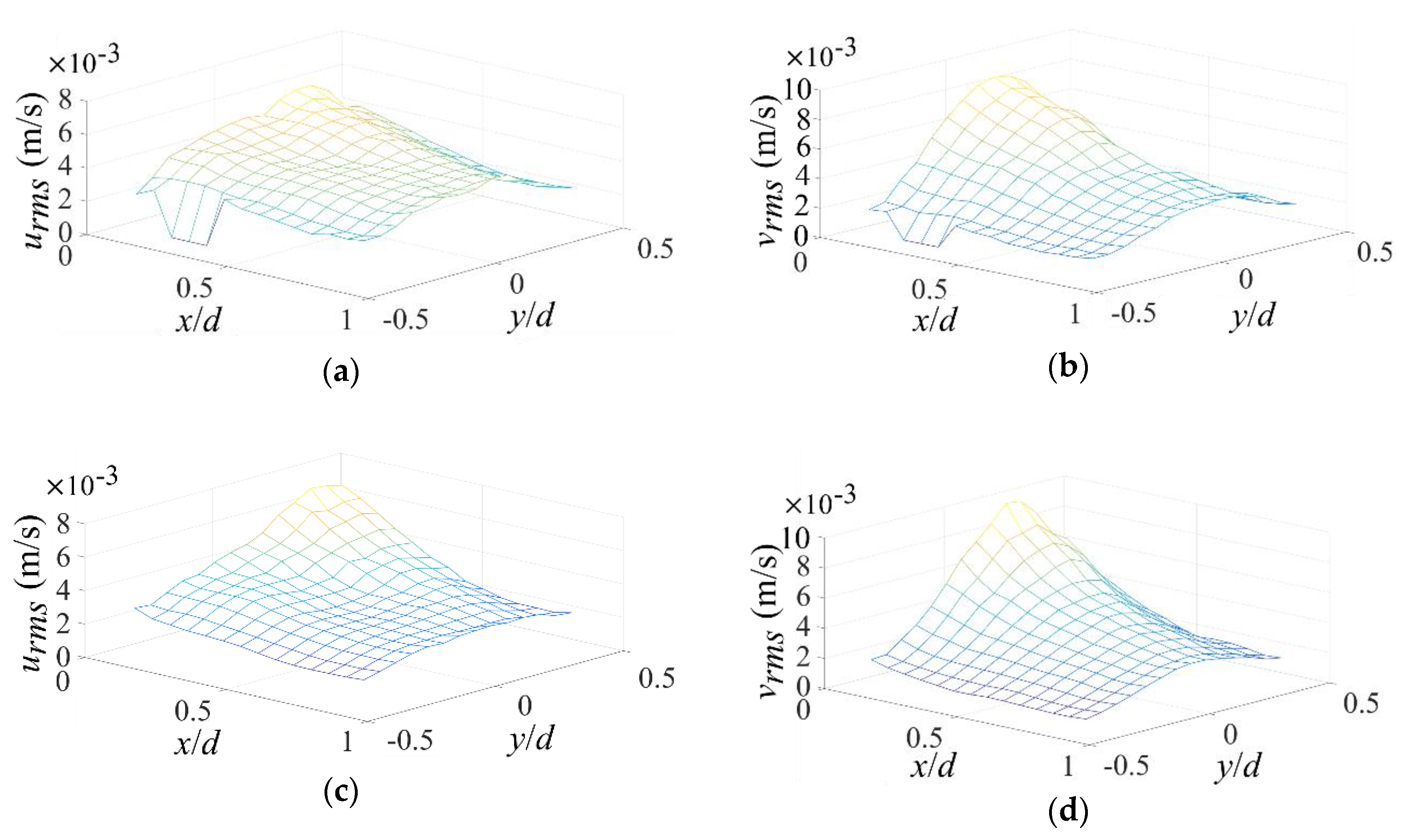

4.2. Velocity Fluctuation Fields

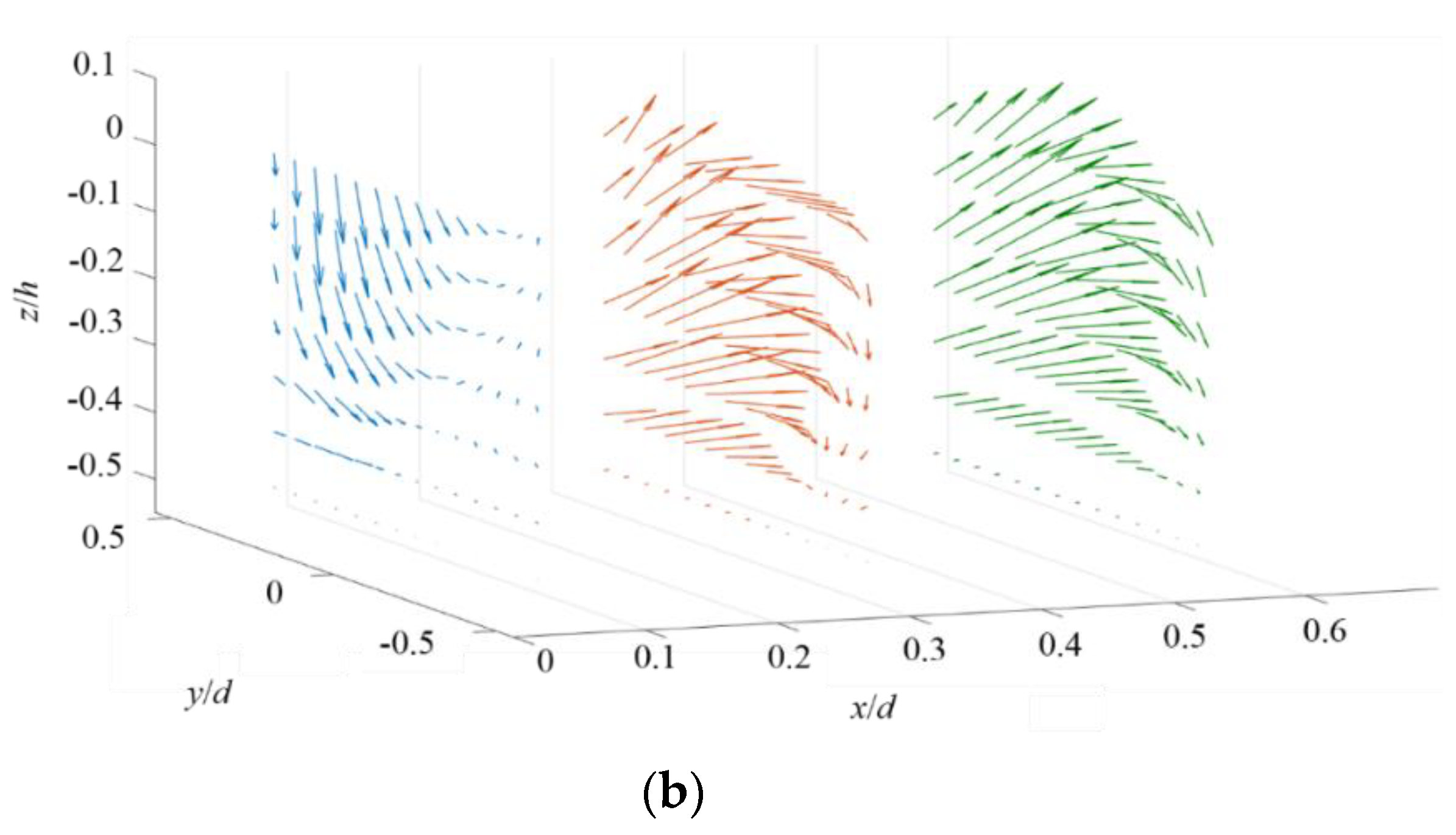

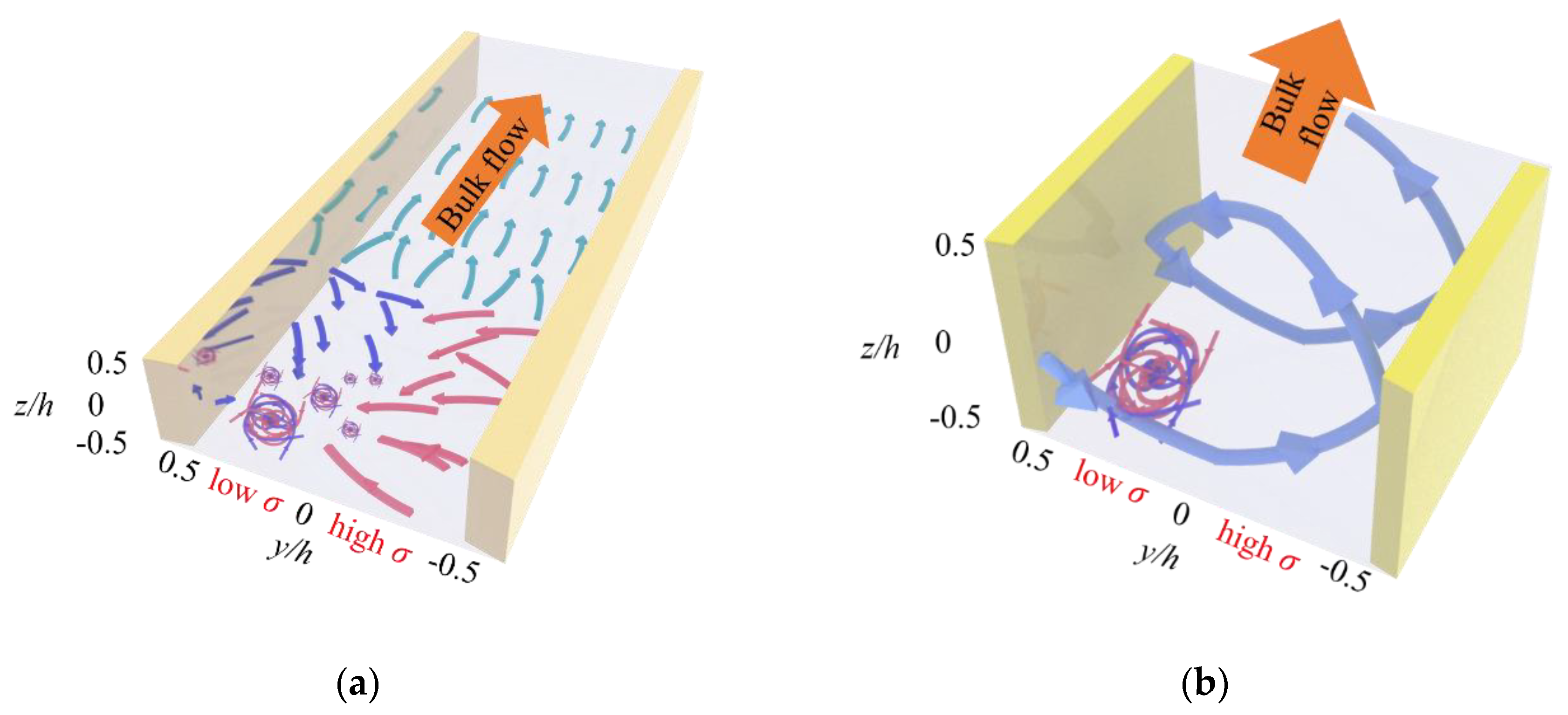

4.3. 3D Mean Velocity Field

4.4. -Directional Mean Vorticity

5. Discussions

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ma, J.; Wang, Y.; Liu, J. Biomaterials Meet Microfluidics: From Synthesis Technologies to Biological Applications. Micromachines 2017, 8, 255. [Google Scholar] [CrossRef] [PubMed]

- Kang, K.K.; Lee, B.; Lee, C.S. Microfluidic approaches for the design of functional materials. Microelectron. Eng. 2018, 199, 1–15. [Google Scholar] [CrossRef]

- Javanmard, M.; Talasaz, A.H.; Nemat-Gorgani, M.; Pease, F.; Ronaghi, M.; Davis, R.W. Electrical detection of protein biomarkers using bioactivated microfluidic channels. Lab. Chip 2009, 9, 1429–1434. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Sun, B.; Jiang, J.; Shi, N.; Xu, W. Application of microfluidics technology in chemical engineering for enhanced safety. Process. Saf. Prog. 2016, 35, 365–373. [Google Scholar] [CrossRef]

- Wang, F. Research Progress of Microfluidic Chips Preparation and its Optical Element. Sens. Transducers 2014, 166, 29–38. [Google Scholar]

- Sharma, M.K.; Gostl, R.; Frijns, A.J.H.; Wieringa, F.P.; Kooman, J.P.; Sijbesma, R.P.; Smeulders, D.M. A Fluorescent Micro-Optofluidic Sensor for In-Line Ion Selective Electrolyte Monitoring. IEEE Sens. J. 2018, 18, 3946–3951. [Google Scholar] [CrossRef]

- Fong, J.; Xiao, Z.; Takahata, K. Wireless implantable chip with integrated nitinol-based pump for radio-controlled local drug delivery. Lab. Chip 2014, 15, 1050–1058. [Google Scholar] [CrossRef]

- Dutta, G.; Rainbow, J.; Zupancic, U.; Papamatthaiou, S.; Estrela, P.; Moschou, D. Microfluidic Devices for Label-Free DNA Detection. Chemosensors 2018, 6, 43. [Google Scholar] [CrossRef]

- Cortelezzi, L.; Ferrari, S.; Dubini, G. A scalable active micro-mixer for biomedical applications. Microfluid. Nanofluidics 2017, 21, 31. [Google Scholar] [CrossRef]

- Ko, Y.-J.; Maeng, J.-H.; Ahn, Y.; Hwang, S.Y. DNA ligation using a disposable microfluidic device combined with a micromixer and microchannel reactor. Sens. Actuators B Chem. 2011, 157, 735–741. [Google Scholar] [CrossRef]

- Wong, S.; Ward, M.; Wharton, C. Micro T-mixer as a rapid mixing micromixer. Sens. Actuators B Chem. 2004, 100, 359–379. [Google Scholar] [CrossRef]

- Lin, J.; Huang, L.; Chen, G. A three-dimensional vortex microsystem designed and fabricated for controllable mixing. Sci. China Ser. B Chem. 2009, 52, 1080–1084. [Google Scholar] [CrossRef]

- Kim, D.S.; Lee, S.H.; Ahn, C.H.; Lee, J.Y.; Kwon, T.H. Disposable integrated microfluidic biochip for blood typing by plastic microinjection moulding. Lab. Chip 2006, 6, 794–802. [Google Scholar] [CrossRef] [PubMed]

- Auroux, P.A.; Iossifidis, D.; Reyes, D.R.; Manz, A. Micro Total Analysis Systems. 2. Analytical Standard Operations and Applications. Anal. Chem. 2002, 74, 2637–2652. [Google Scholar] [CrossRef] [PubMed]

- Veldurthi, N.; Ghoderao, P.; Sahare, S.; Kumar, V.; Bodas, D.; Kulkarni, A.; Bhave, T. Magnetically active micromixer assisted synthesis of drug nanocomplexes exhibiting strong bactericidal potential. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 68, 455–464. [Google Scholar] [CrossRef]

- Karakurt, A.; Khandelwal, B.; Sethi, V.; Singh, R. Study of Novel Micromix Combustors to be Used in Gas Turbines; Using Hydrogen, Hydrogen-Methane, Methane and Kerosene as a Fuel. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Atlanta, Georgia, 30 July–1 August 2012. [Google Scholar]

- Coogan, S.; Brun, K.; Teraji, D. Micromix Combustor for High Temperature Hybrid Gas Turbine Concentrated Solar Power Systems. Energy Procedia 2014, 49, 1298–1307. [Google Scholar] [CrossRef]

- Stroock, A.D.; Dertinger, S.K.; Ajdari, A.; Mezic, I.; Stone, H.A.; Whitesides, G.M. Chaotic mixer for microchannels. Science 2002, 295, 647–651. [Google Scholar] [CrossRef]

- Brody, J.P.; Yager, P.; Goldstein, R.E.; Austin, R.H. Biotechnology at low Reynolds numbers. Biophys. J. 1996, 71, 3430–3441. [Google Scholar] [CrossRef]

- Paul, E.L.; Atiemo-Obeng, V.A.; Kresta, S.M. Handbook of Industrial Mixing: Science and Practice; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Elvira, K.S.; I Solvas, X.C.; Wootton, R.C.R.; Demello, A.J. The past, present and potential for microfluidic reactor technology in chemical synthesis. Nat. Chem. 2013, 5, 905–915. [Google Scholar] [CrossRef]

- Jiang, L.; Zeng, Y.; Sun, Q.; Sun, Y.; Guo, Z.; Qu, J.Y.; Yao, S. Microsecond protein folding events revealed by time-resolved fluorescence resonance energy transfer in a microfluidic mixer. Anal. Chem 2015, 87, 5589–5595. [Google Scholar] [CrossRef]

- Lien, K.Y.; Lee, G.B. Miniaturization of molecular biological techniques for gene assay. Analyst 2010, 135, 1499–1518. [Google Scholar] [CrossRef]

- Stedtfeld, R.D.; Tourlousse, D.M.; Seyrig, G.; Stedtfeld, T.M.; Kronlein, M.; Price, S.; Ahmad, F.; Gulari, E.; Tiedje, J.M.; Hashsham, S.A. Gene-Z: A device for point of care genetic testing using a smartphone. Lab. Chip 2012, 12, 1454–1462. [Google Scholar] [CrossRef] [PubMed]

- Aguirre, G.R.; Efremov, V.; Kitsara, M.; Ducrée, J. Integrated micromixer for incubation and separation of cancer cells on a centrifugal platform using inertial and dean forces. Microfluid. Nanofluidics 2014, 18, 513–526. [Google Scholar] [CrossRef]

- Branebjerg, J.; Gravesen, P.; Krog, J.P.; Nielsen, C.R. (Eds.) Fast mixing by lamination. In IEEE International Workshop on Micro Electro Mechanical Systems; IEEE: San Diego, CA, USA, 1996. [Google Scholar]

- Martinez-Lopez, J.I.; Mojica, M.; Rodriguez, C.A.; Siller, H.R. Xurography as a Rapid Fabrication Alternative for Point-of-Care Devices: Assessment of Passive Micromixers. Sensors 2016, 16, 705. [Google Scholar] [CrossRef] [PubMed]

- Sakurai, R.; Yamamoto, K.; Motosuke, M. Concentration-adjustable micromixer using droplet injection into a microchannel. Analyst 2019, 144, 2780–2787. [Google Scholar] [CrossRef] [PubMed]

- Ruijin, W.; Beiqi, L.; Dongdong, S.; Zefei, Z. Investigation on the splitting-merging passive micromixer based on Baker’s transformation. Sens. Actuators B Chem. 2017, 249, 395–404. [Google Scholar] [CrossRef]

- Paik, P.; Pamula, V.K.; Fair, R.B. Rapid droplet mixers for digital microfluidic systems. Lab. Chip 2003, 3, 253–259. [Google Scholar] [CrossRef]

- Long, M.; Sprague, M.A.; Grimes, A.A.; Rich, B.D.; Khine, M. A simple three-dimensional vortex micromixer. Appl. Phys. Lett. 2009, 94, 133501. [Google Scholar] [CrossRef]

- Zhang, W.P.; Wang, X.; Feng, X.; Yang, C.; Mao, Z.S. Investigation of Mixing Performance in Passive Micromixers. Ind. Eng. Chem. Res. 2016, 55, 10036–10043. [Google Scholar] [CrossRef]

- Hong, C.C.; Choi, J.W.; Ahn, C.H. A novel in-plane passive microfluidic mixer with modified Tesla structures. Lab. Chip 2004, 4, 109–113. [Google Scholar] [CrossRef]

- Li, P.; Cogswell, J.; Faghri, M. Design and test of a passive planar labyrinth micromixer for rapid fluid mixing. Sens. Actuators B Chem. 2012, 174, 126–132. [Google Scholar] [CrossRef]

- Hossain, S.; Lee, I.; Kim, S.M.; Kim, K.Y. A micromixer with two-layer serpentine crossing channels having excellent mixing performance at low Reynolds numbers. Chem. Eng. J. 2017, 327, 268–277. [Google Scholar] [CrossRef]

- Izadi, D.; Nguyen, T.; Lapidus, L. Complete Procedure for Fabrication of a Fused Silica Ultrarapid Microfluidic Mixer Used in Biophysical Measurements. Micromachines 2017, 8, 16. [Google Scholar] [CrossRef]

- Ahmed, D.; Mao, X.; Shi, J.; Juluri, B.K.; Huang, T.J. A millisecond micromixer via single-bubble-based acoustic streaming. Lab. Chip 2009, 9, 2738–2741. [Google Scholar] [CrossRef]

- Deval, J.; Tabeling, P.; Ho, C.M. (Eds.) A dielectrophoretic chaotic mixer. In Technical Digest Mems IEEE International Conference Fifteenth IEEE International Conference on Micro Electro Mechanical Systems; IEEE: Las Vegas, NV, USA, 2002. [Google Scholar]

- Wu, H.Y.; Liu, C.H. A novel electrokinetic micromixer. Sens. Actuators A Phys. 2005, 118, 107–115. [Google Scholar]

- Park, J.; Shin, S.M.; Huh, K.Y.; Kang, I.S. Application of electrokinetic instability for enhanced mixing in various micro–T-channel geometries. Phys. Fluids 2005, 17, 118101. [Google Scholar] [CrossRef]

- Posner, J.D.; Santiago, J.G. Convective instability of electrokinetic flows in a cross-shaped microchannel. J. Fluid Mech. 2006, 555, 1–42. [Google Scholar] [CrossRef]

- Ghosal, S. Electrokinetic flow and dispersion in capillary electrophoresis. Annu. Rev. Fluid Mech. 2016, 38, 309–338. [Google Scholar] [CrossRef]

- Nguyen, T.; van der Meer, D.; van den Berg, A.; Eijkel, J.C.T. Investigation of the effects of time periodic pressure and potential gradients on viscoelastic fluid flow in circular narrow confinements. Microfluid. Nanofluidics 2017, 21, 37. [Google Scholar] [CrossRef]

- Ramos, A.; Morgan, H.; Green, N.G.; Castellanos, A. Ac electrokinetics: A review of forces in microelectrode structures. J. Phys. D Appl. Phys. 1998, 31, 2338–2353. [Google Scholar] [CrossRef]

- Green, N.G.; Ramos, A.; Gonza’lez, A.; Morgan, H.; Castellanos, A. Fluid flow induced by nonuniform ac electric fields in electrolytes on microelectrodes. I. Experimental measurements. Phys. Rev. E 2000, 61, 4011–4018. [Google Scholar] [CrossRef] [PubMed]

- González, A.; Ramos, A.; Green, N.G.; Castellanos, A.; Morgan, H. Fluid flow induced by nonuniform ac electric fields in electrolytes on microelectrodes. II. A linear double-layer analysis. Phys. Rev. E 2000, 61, 4019–4028. [Google Scholar] [CrossRef] [PubMed]

- Green, N.G.; Ramos, A.; Gonzalez, A.; Morgan, H.; Castellanos, A. Fluid flow induced by nonuniform ac electric fields in electrolytes on microelectrodes. III. Observation of streamlines and numerical simulation. Phys. Rev. E 2002, 66, 026305. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-H.; Lin, H.; Lele, S.K.; Santiago, J.G. Convective and absolute electrokinetic instability with conductivity gradients. J. Fluid Mech. 2005, 524, 263–303. [Google Scholar] [CrossRef]

- Posner, J.D.; Pérez, C.L.; Santiago, J.G. Electric fields yield chaos in microflows. Proc. Natl. Acad. Sci. USA 2012, 109, 14353–14356. [Google Scholar] [CrossRef]

- Wang, G.R.; Yang, F.; Zhao, W. There can be turbulence in microfluidics at low Reynolds number. Lab. A Chip 2014, 14, 1452–1458. [Google Scholar] [CrossRef]

- Wang, G.R.; Yang, F.; Zhao, W.; Chen, C.P. On micro-electrokinetic scalar turbulence in microfluidics at a low Reynolds number. Lab. Chip 2016, 16, 1030–1038. [Google Scholar] [CrossRef]

- Wang, G.R.; Yang, F.; Zhao, W. Microelectrokinetic turbulence in microfluidics at low Reynolds number. Phys. Rev. E 2016, 93, 013106. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, F.; Wang, K.G.; Bai, J.T.; Wang, G.R. Rapid mixing by turbulent-like electrokinetic microflow. Chem. Eng. Sci. 2017, 165, 113–121. [Google Scholar] [CrossRef]

- Wieneke, B. Stereo-PIV using self-calibration on particle images. Exp. Fluids 2005, 39, 267–280. [Google Scholar] [CrossRef]

- Prasad, A.K. Stereoscopic particle image velocimetry. Exp. Fluids 2000, 29, 103–116. [Google Scholar] [CrossRef]

- Yang, F.; Yang, X.; Jiang, H.; Wood, P.; Wang, G.R. (Eds.) Dielectrophoresis separation of colon cancer cell. In Proceedings of the ASME 2009 Second International Conference on Micro/Nanoscale Heat and Mass Transfer; ASME: Shanghai, China, 2009. [Google Scholar]

- Mortensen, N.A.; Okkels, F.; Bruus, H. Reexamination of Hagen-Poiseuille flow: Shape dependence of the hydraulic resistance in microchannels. Phys. Rev. E 2005, 71, 057301. [Google Scholar] [CrossRef] [PubMed]

- Bruus, H. Theoretical Microfluidics; Oxford University Press: New York, NY, USA, 2008. [Google Scholar]

- Goli, S.; Saha, S.K.; Agrawal, A. Three-dimensional numerical study of flow physics of single-phase laminar flow through diamond (diverging–converging) microchannel. SN Appl. Sci. 2019, 1, 1353. [Google Scholar] [CrossRef]

- Yin, Z.; Jian, Y.J.; Chang, L.; Na, R.; Liu, Q.S. Transient AC Electro-Osmotic Flow of Generalized Maxwell Fluids through Microchannels. Appl. Mech. Mater. 2014, 548, 216–223. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nan, K.; Hu, Z.; Zhao, W.; Wang, K.; Bai, J.; Wang, G. Large-Scale Flow in Micro Electrokinetic Turbulent Mixer. Micromachines 2020, 11, 813. https://doi.org/10.3390/mi11090813

Nan K, Hu Z, Zhao W, Wang K, Bai J, Wang G. Large-Scale Flow in Micro Electrokinetic Turbulent Mixer. Micromachines. 2020; 11(9):813. https://doi.org/10.3390/mi11090813

Chicago/Turabian StyleNan, Keyi, Zhongyan Hu, Wei Zhao, Kaige Wang, Jintao Bai, and Guiren Wang. 2020. "Large-Scale Flow in Micro Electrokinetic Turbulent Mixer" Micromachines 11, no. 9: 813. https://doi.org/10.3390/mi11090813

APA StyleNan, K., Hu, Z., Zhao, W., Wang, K., Bai, J., & Wang, G. (2020). Large-Scale Flow in Micro Electrokinetic Turbulent Mixer. Micromachines, 11(9), 813. https://doi.org/10.3390/mi11090813