Effect of the Uniaxial Compression on the GaAs Nanowire Solar Cell

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

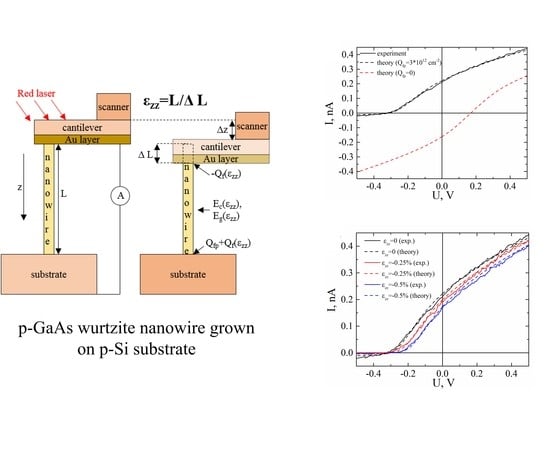

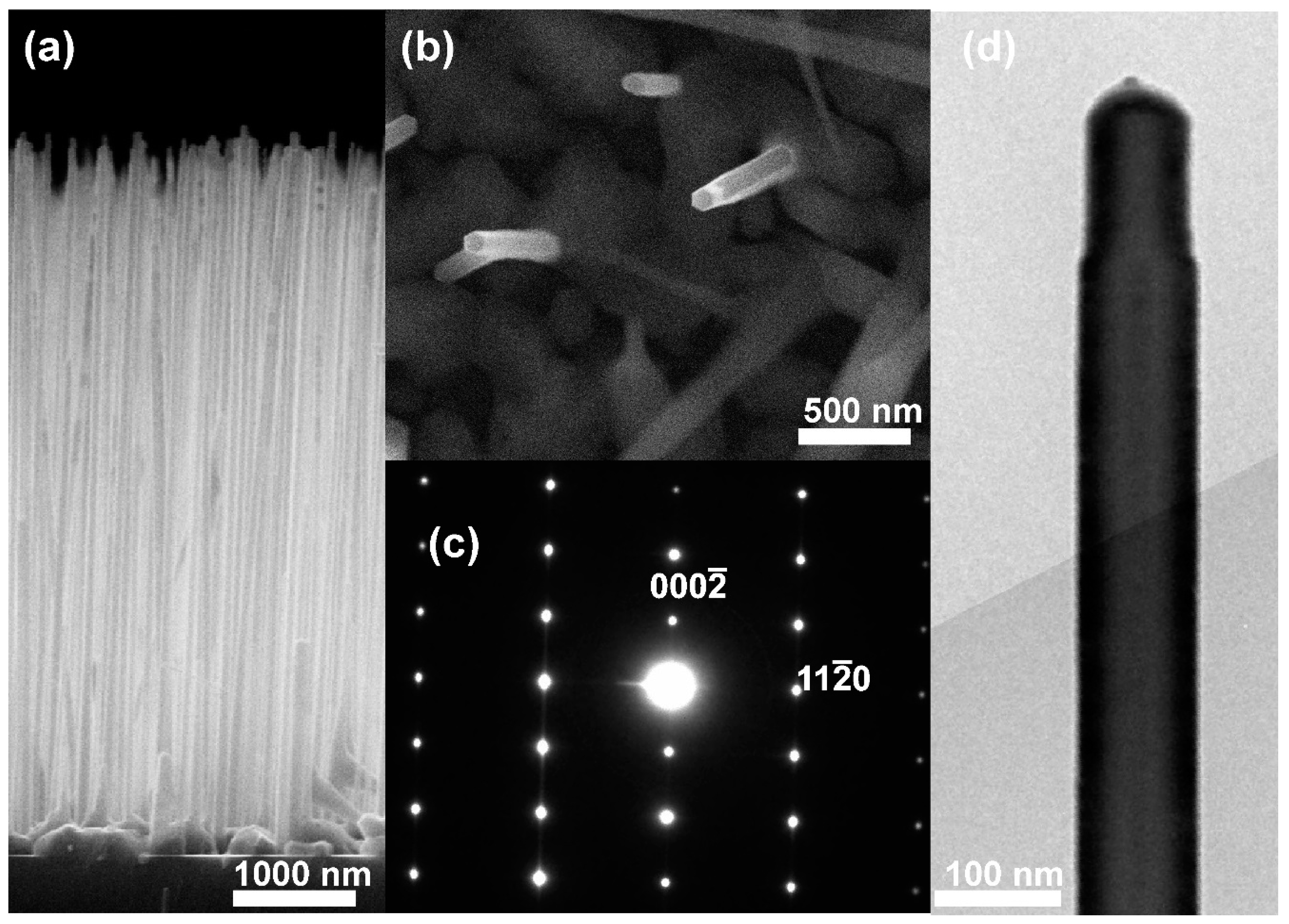

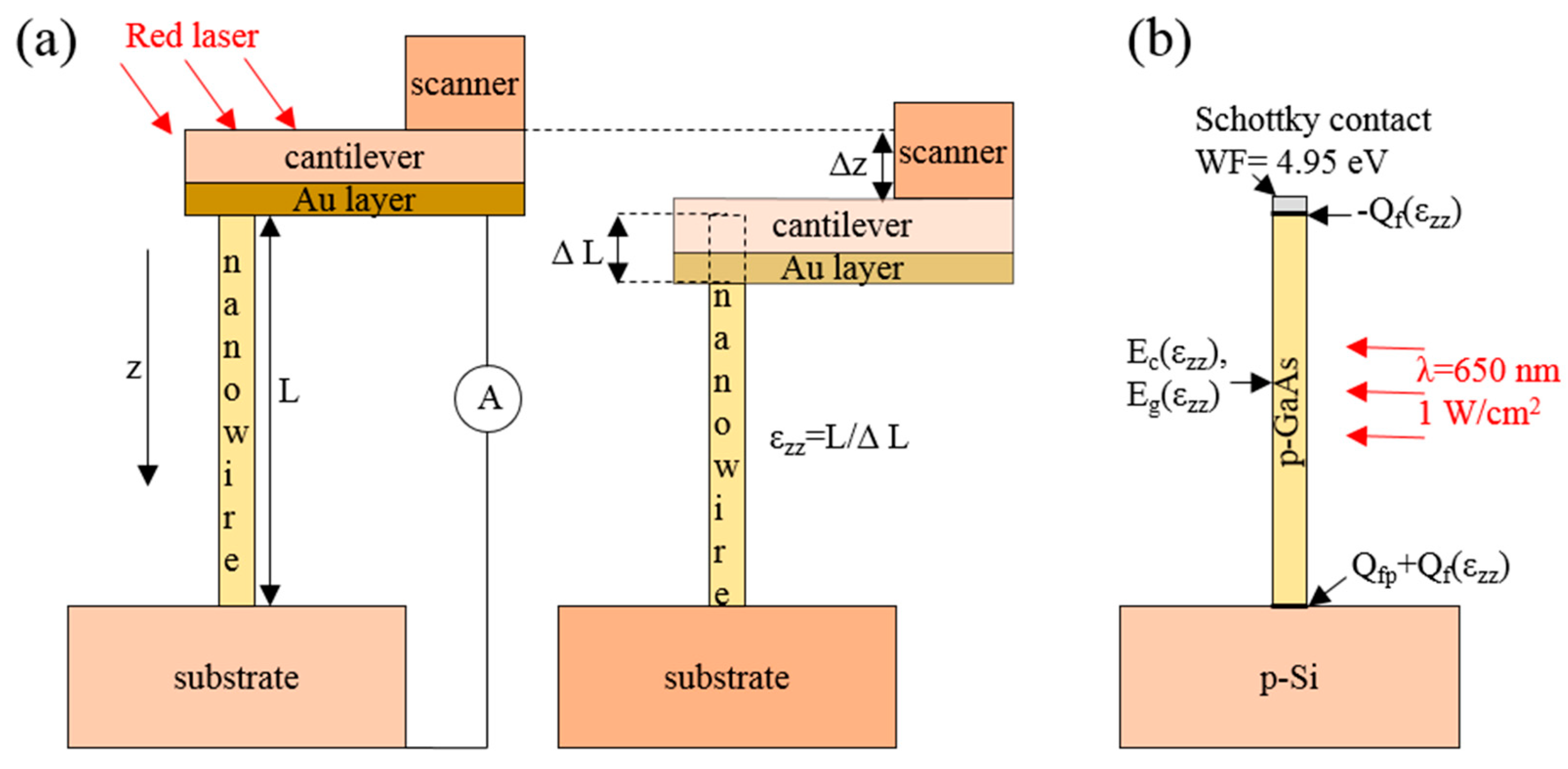

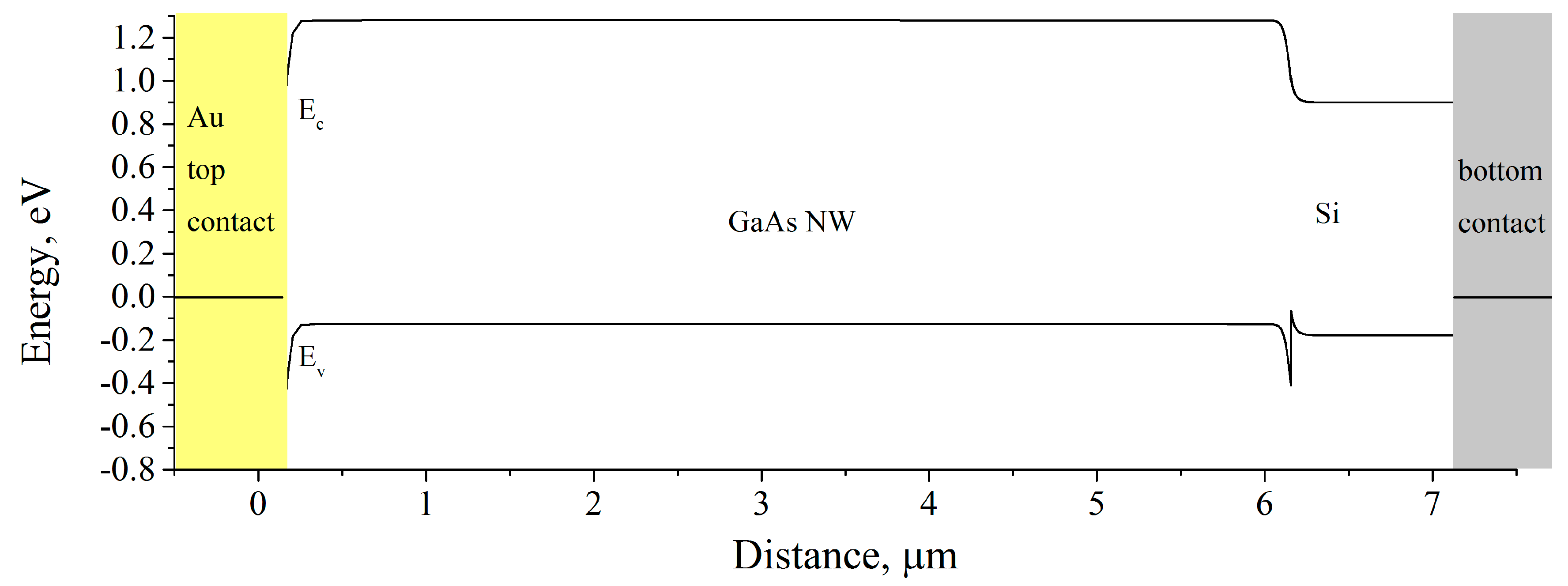

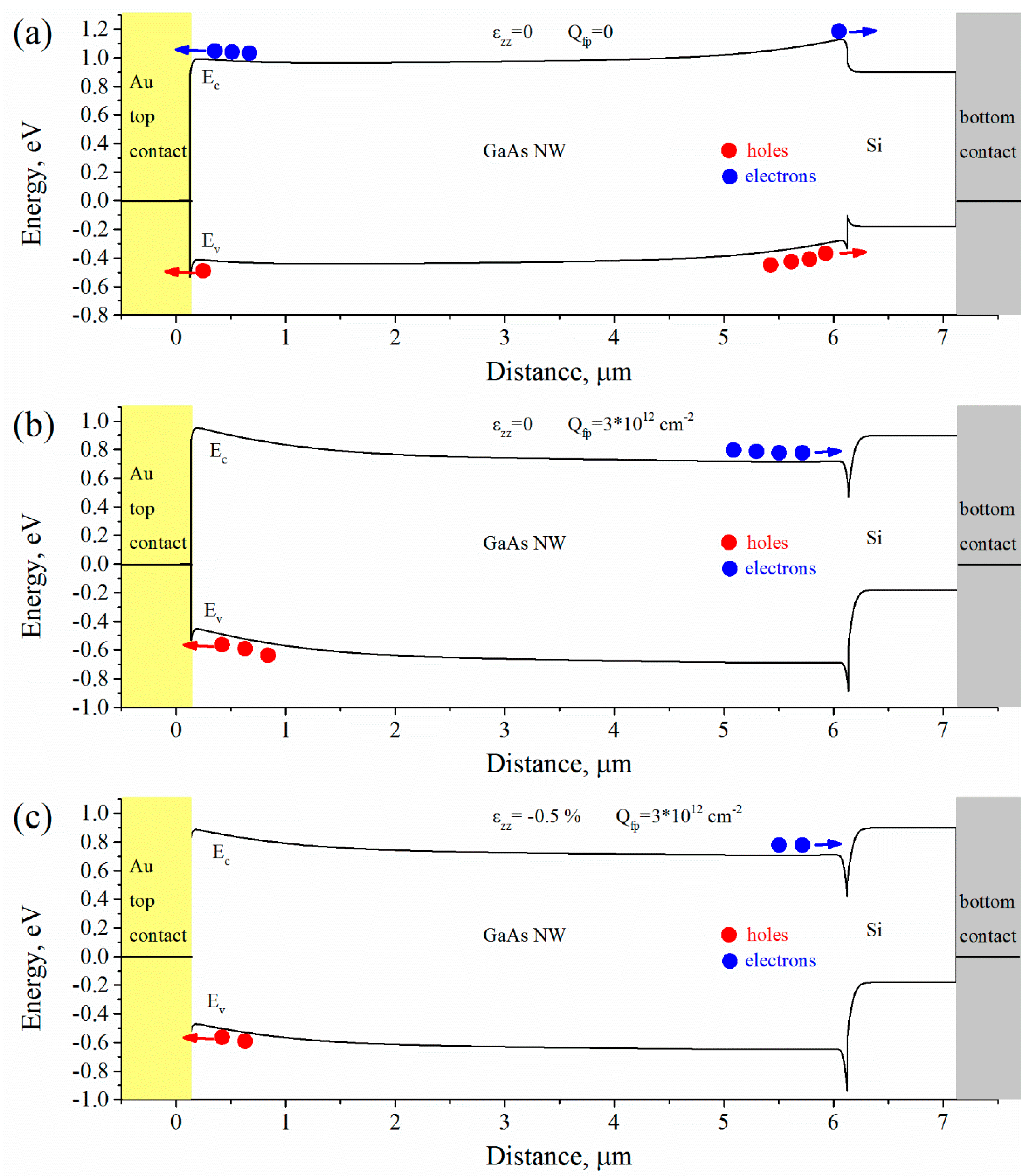

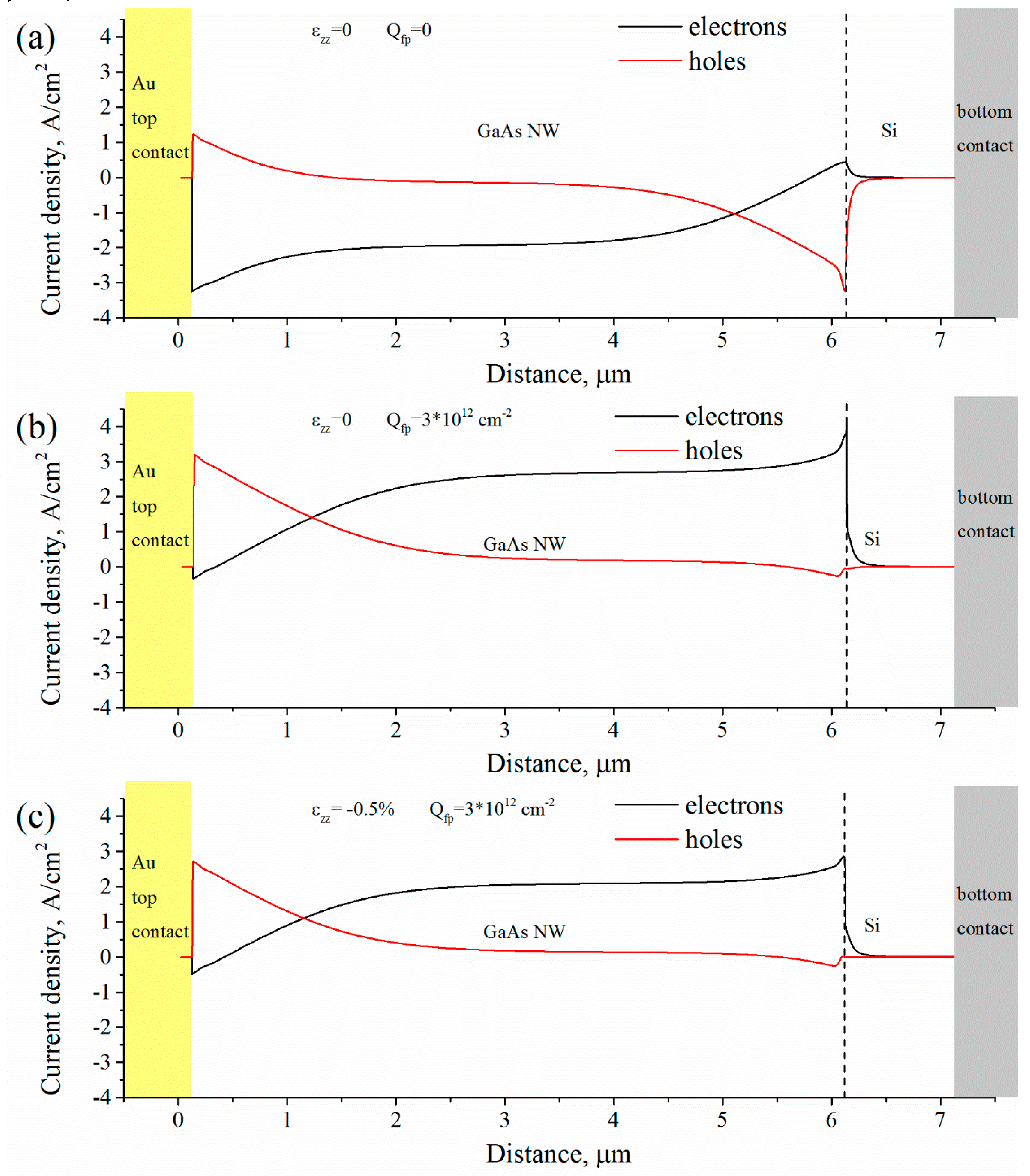

3.1. WZ p-GaAs NW Grown on p-Si Substrate

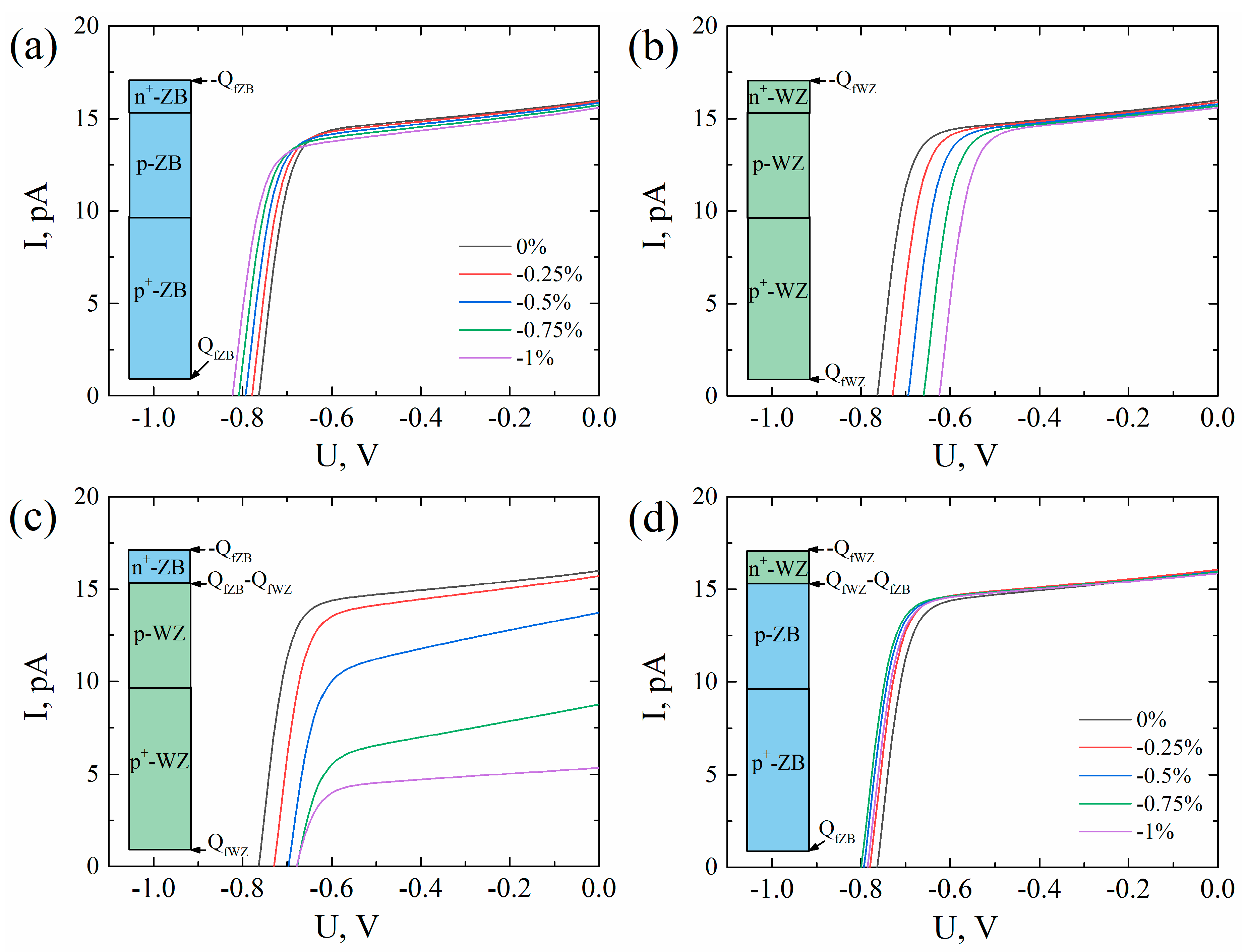

3.2. Axial p-n GaAs NW Solar Cell

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- LaPierre, R.; Chia, A.; Gibson, S.; Haapamaki, C.; Boulanger, J.; Yee, R.; Kuyanov, P.; Zhang, J.; Tajik, N.; Jewell, N.; et al. III–V nanowire photovoltaics: Review of design for high efficiency. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2013, 7, 815–830. [Google Scholar] [CrossRef]

- Green, M.A. Third generation photovoltaics: Ultra-high conversion efficiency at low cost. Prog. Photovolt. Res. Appl. 2001, 9, 123–135. [Google Scholar] [CrossRef]

- LaPierre, R. Numerical model of current-voltage characteristics and efficiency of GaAs nanowire solar cells. J. Appl. Phys. 2011, 109, 034311. [Google Scholar] [CrossRef]

- Bauhuis, G.; Mulder, P.; Haverkamp, E.; Huijben, J.; Schermer, J. 26.1% thin-film GaAs solar cell using epitaxial lift-off. Sol. Energy Mater. Sol. Cells 2009, 93, 1488–1491. [Google Scholar] [CrossRef]

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; et al. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2017, 2, 17032. [Google Scholar] [CrossRef]

- Dhaka, V.; Haggren, T.; Jussila, H.; Jiang, H.; Kauppinen, E.; Huhtio, T.; Sopanen, M.; Lipsanen, H. High quality GaAs nanowires grown on glass substrates. Nano Lett. 2012, 12, 1912–1918. [Google Scholar] [CrossRef] [PubMed]

- Garnett, E.C.; Brongersma, M.L.; Cui, Y.; McGehee, M.D. Nanowire solar cells. Annu. Rev. Mater. Res. 2011, 41, 269–295. [Google Scholar] [CrossRef]

- Krogstrup, P.; Jørgensen, H.I.; Heiss, M.; Demichel, O.; Holm, J.V.; Aagesen, M.; Nygard, J.; i Morral, A.F. Single-nanowire solar cells beyond the Shockley–Queisser limit. Nat. Photonics 2013, 7, 306–310. [Google Scholar] [CrossRef]

- Holm, J.V.; Jørgensen, H.I.; Krogstrup, P.; Nygård, J.; Liu, H.; Aagesen, M. Surface-passivated GaAsP single-nanowire solar cells exceeding 10% efficiency grown on silicon. Nat. Commun. 2013, 4, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Cirlin, G.; Bouravleuv, A.; Soshnikov, I.; Samsonenko, Y.B.; Dubrovskii, V.; Arakcheeva, E.; Tanklevskaya, E.; Werner, P. Photovoltaic properties of p-doped GaAs nanowire arrays grown on n-type GaAs (111) B substrate. Nanoscale Res. Lett. 2010, 5, 360–363. [Google Scholar] [CrossRef] [PubMed]

- Tchernycheva, M.; Rigutti, L.; Jacopin, G.; de Luna Bugallo, A.; Lavenus, P.; Julien, F.; Timofeeva, M.; Bouravleuv, A.; Cirlin, G.; Dhaka, V.; et al. Photovoltaic properties of GaAsP core–shell nanowires on Si (001) substrate. Nanotechnology 2012, 23, 265402. [Google Scholar] [CrossRef] [PubMed]

- Åberg, I.; Vescovi, G.; Asoli, D.; Naseem, U.; Gilboy, J.P.; Sundvall, C.; Dahlgren, A.; Svensson, K.E.; Anttu, N.; Björk, M.T.; et al. A GaAs nanowire array solar cell with 15.3% efficiency at 1 sun. IEEE J. Photovolt. 2015, 6, 185–190. [Google Scholar]

- Borgström, M.T.; Magnusson, M.H.; Dimroth, F.; Siefer, G.; Höhn, O.; Riel, H.; Schmid, H.; Wirths, S.; Björk, M.; Åberg, I.; et al. Towards nanowire tandem junction solar cells on silicon. IEEE J. Photovolt. 2018, 8, 733–740. [Google Scholar] [CrossRef]

- Yao, M.; Cong, S.; Arab, S.; Huang, N.; Povinelli, M.L.; Cronin, S.B.; Dapkus, P.D.; Zhou, C. Tandem solar cells using GaAs nanowires on Si: Design, fabrication, and observation of voltage addition. Nano Lett. 2015, 15, 7217–7224. [Google Scholar] [CrossRef] [PubMed]

- LaPierre, R. Theoretical conversion efficiency of a two-junction III-V nanowire on Si solar cell. J. Appl. Phys. 2011, 110, 014310. [Google Scholar] [CrossRef]

- Hu, Y.; Chang, Y.; Fei, P.; Snyder, R.L.; Wang, Z.L. Designing the electric transport characteristics of ZnO micro/nanowire devices by coupling piezoelectric and photoexcitation effects. ACS Nano 2010, 4, 1234–1240. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Guo, X.; Wang, W.; Zhang, Y.; Xu, S.; Lien, D.H.; Wang, Z.L. Enhancing sensitivity of a single ZnO micro-/nanowire photodetector by piezo-phototronic effect. ACS Nano 2010, 4, 6285–6291. [Google Scholar] [CrossRef] [PubMed]

- Arlt, G.; Quadflieg, P. Piezoelectricity in iii-v compounds with a phenomenological analysis of the piezoelectric effect. Phys. Status Solidi 1968, 25, 323–330. [Google Scholar] [CrossRef]

- Smith, D. Strain-generated electric fields in [111] growth axis strained-layer superlattices. Solid State Commun. 1986, 57, 919–921. [Google Scholar] [CrossRef]

- Boxberg, F.; Søndergaard, N.; Xu, H. Elastic and piezoelectric properties of zincblende and wurtzite crystalline nanowire heterostructures. Adv. Mater. 2012, 24, 4692–4706. [Google Scholar] [CrossRef] [PubMed]

- Boxberg, F.; Søndergaard, N.; Xu, H. Photovoltaics with piezoelectric core-shell nanowires. Nano Lett. 2010, 10, 1108–1112. [Google Scholar] [CrossRef] [PubMed]

- Chung, K.-W.; Wang, Z.; Costa, J.; Williamson, F.; Ruden, P.; Nathan, M. Barrier height change in GaAs Schottky diodes induced by piezoelectric effect. Appl. Phys. Lett. 1991, 59, 1191–1193. [Google Scholar] [CrossRef]

- Calahorra, Y.; Husmann, A.; Bourdelain, A.; Kim, W.; Vukajlovic-Plestina, J.; Boughey, C.; Jing, Q.; i Morral, A.F.; Kar-Narayan, S. Highly sensitive piezotronic pressure sensors based on undoped GaAs nanowire ensembles. J. Phys. D Appl. Phys. 2019, 52, 294002. [Google Scholar] [CrossRef]

- Zhang, X.; Dubrovskii, V.G.; Sibirev, N.V.; Ren, X. Analytical study of elastic relaxation and plastic deformation in nanostructures on lattice mismatched substrates. Cryst. Growth Des. 2011, 11, 5441–5448. [Google Scholar] [CrossRef]

- Hübner, K. Piezoelectricity in zincblende-and wurtzite-type crystals. Phys. Status Solidi 1973, 57, 627–634. [Google Scholar] [CrossRef]

- Qiao, S.; Liu, J.; Fu, G.; Ren, K.; Li, Z.; Wang, S.; Pan, C. ZnO nanowire based CIGS solar cell and its efficiency enhancement by the piezo-phototronic effect. Nano Energy 2018, 49, 508–514. [Google Scholar] [CrossRef]

- Pan, C.; Niu, S.; Ding, Y.; Dong, L.; Yu, R.; Liu, Y.; Zhu, G.; Wang, Z.L. Enhanced Cu2S/CdS coaxial nanowire solar cells by piezo-phototronic effect. Nano Lett. 2012, 12, 3302–3307. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Jing, L.; Huang, X.; Liu, M.; Du, C.; Liu, T.; Pu, X.; Hu, W.; Wang, Z.L. Enhanced solar cell conversion efficiency of InGaN/GaN multiple quantum wells by piezo-phototronic effect. ACS Nano 2017, 11, 9405–9412. [Google Scholar] [CrossRef] [PubMed]

- Signorello, G.; Lörtscher, E.; Khomyakov, P.; Karg, S.; Dheeraj, D.; Gotsmann, B.; Weman, H.; Riel, H. Inducing a direct-to-pseudodirect bandgap transition in wurtzite GaAs nanowires with uniaxial stress. Nat. Commun. 2014, 5, 3655. [Google Scholar] [CrossRef]

- Alekseev, P.A.; Sharov, V.A.; Geydt, P.; Dunaevskiy, M.S.; Lysak, V.V.; Cirlin, G.E.; Reznik, R.R.; Khrebtov, A.I.; Soshnikov, I.P.; Lähderanta, E. Piezoelectric current generation in wurtzite GaAs nanowires. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2018, 12, 1700358. [Google Scholar] [CrossRef]

- Bouravleuv, A.; Ilkiv, I.; Reznik, R.; Kotlyar, K.; Soshnikov, I.; Cirlin, G.; Brunkov, P.; Kirilenko, D.; Bondarenko, L.; Nepomnyaschiy, A.; et al. New method for MBE growth of GaAs nanowires on silicon using colloidal Au nanoparticles. Nanotechnology 2017, 29, 045602. [Google Scholar] [CrossRef] [PubMed]

- Harmand, J.-C.; Patriarche, G.; Glas, F.; Panciera, F.; Florea, I.; Maurice, J.-L.; Travers, L.; Ollivier, Y. Atomic step flow on a nanofacet. Phys. Rev. Lett. 2018, 121, 166101. [Google Scholar] [CrossRef] [PubMed]

- Biermanns, A.; Breuer, S.; Trampert, A.; Davydok, A.; Geelhaar, L.; Pietsch, U. Strain accommodation in Ga-assisted GaAs nanowires grown on silicon (111). Nanotechnology 2012, 23, 305703. [Google Scholar] [CrossRef] [PubMed]

- Mikulik, D.; Ricci, M.; Tutuncuoglu, G.; Matteini, F.; Vukajlovic, J.; Vulic, N.; Alarcon-Llado, E.; i Morral, A.F. Conductive-probe atomic force microscopy as a characterization tool for nanowire-based solar cells. Nano Energy 2017, 41, 566–572. [Google Scholar] [CrossRef]

- Alekseev, P.; Dunaevskiy, M.; Mikhailov, A.; Lebedev, S.; Lebedev, A.; Ilkiv, I.; Khrebtov, A.; Bouravleuv, A.; Cirlin, G. Electrical properties of GaAs nanowires grown on Graphene/SiC hybrid substrates. Semiconductors 2018, 52, 1611–1615. [Google Scholar] [CrossRef]

- Brantley, W. Calculated elastic constants for stress problems associated with semiconductor devices. J. Appl. Phys. 1973, 44, 534–535. [Google Scholar] [CrossRef]

- Hsin, C.-L.; Mai, W.; Gu, Y.; Gao, Y.; Huang, C.-T.; Liu, Y.; Chen, L.-J.; Wang, Z.-L. Elastic properties and buckling of silicon nanowires. Adv. Mater. 2008, 20, 3919–3923. [Google Scholar] [CrossRef]

- Wang, Y.-B.; Wang, L.-F.; Joyce, H.J.; Gao, Q.; Liao, X.-Z.; Mai, Y.-W.; Tan, H.H.; Zou, J.; Ringer, S.P.; Gao, H.-J.; et al. Super deformability and Young’s modulus of GaAs nanowires. Adv. Mater. 2011, 23, 1356–1360. [Google Scholar] [CrossRef] [PubMed]

- Silvaco Atlas. Available online: https://www.silvaco.com/products/tcad/device_simulation/atlas/atlas.html (accessed on 10 June 2020).

- Alekseev, P.; Geydt, P.; Dunaevskiy, M.; Lähderanta, E.; Haggrén, T.; Kakko, J.-P.; Lipsanen, H. I–V curve hysteresis induced by gate-free charging of GaAs nanowires’ surface oxide. Appl. Phys. Lett. 2017, 111, 132104. [Google Scholar] [CrossRef]

- Lin, A.; Shapiro, J.N.; Senanayake, P.N.; Scofield, A.C.; Wong, P.-S.; Liang, B.; Huffaker, D.L. Extracting transport parameters in GaAs nanopillars grown by selective-area epitaxy. Nanotechnology 2012, 23, 105701. [Google Scholar] [CrossRef] [PubMed]

- Signorello, G.; Karg, S.; Björk, M.T.; Gotsmann, B.; Riel, H. Tuning the light emission from GaAs nanowires over 290 meV with uniaxial strain. Nano Lett. 2013, 13, 917–924. [Google Scholar] [CrossRef] [PubMed]

- Spicer, W.; Lindau, I.; Skeath, P.; Su, C.; Chye, P. Unified mechanism for Schottky-barrier formation and III-V oxide interface states. Phys. Rev. Lett. 1980, 44, 420. [Google Scholar] [CrossRef]

- Freeouf, J.; Woodall, J. Schottky barriers: An effective work function model. Appl. Phys. Lett. 1981, 39, 727–729. [Google Scholar] [CrossRef]

- Alekseev, P.A.; Dunaevskiy, M.S.; Cirlin, G.E.; Reznik, R.R.; Smirnov, A.N.; Kirilenko, D.A.; Davydov, V.Y.; Berkovits, V.L. Unified mechanism of the surface Fermi level pinning in III-As nanowires. Nanotechnology 2018, 29, 314003. [Google Scholar] [CrossRef] [PubMed]

- Alekseev, P.A.; Sharov, V.A.; Dunaevskiy, M.S.; Kirilenko, D.A.; Ilkiv, I.V.; Reznik, R.R.; Cirlin, G.E.; Berkovits, V.L. Control of conductivity of in x Ga1–x as nanowires by applied tension and surface states. Nano Lett. 2019, 19, 4463–4469. [Google Scholar] [CrossRef] [PubMed]

- Łagowski, J.; Baltov, I.; Gatos, H.C. Surface photovoltage spectroscopy and surface piezoelectric effect in GaAs. Surf. Sci. 1973, 40, 216–226. [Google Scholar] [CrossRef]

- Ibbetson, J.P.; Fini, P.; Ness, K.; DenBaars, S.; Speck, J.; Mishra, U. Polarization effects, surface states, and the source of electrons in AlGaN/GaN heterostructure field effect transistors. Appl. Phys. Lett. 2000, 77, 250–252. [Google Scholar] [CrossRef]

- Li, S.; Ware, M.; Wu, J.; Minor, P.; Wang, Z.; Wu, Z.; Jiang, Y.; Salamo, G.J. Polarization induced pn-junction without dopant in graded AlGaN coherently strained on GaN. Appl. Phys. Lett. 2012, 101, 122103. [Google Scholar] [CrossRef]

- Zhang, Z.; Yao, K.; Liu, Y.; Jin, C.; Liang, X.; Chen, Q.; Peng, L.-M. Quantitative analysis of current–voltage characteristics of semiconducting nanowires: Decoupling of contact effects. Adv. Funct. Mater. 2007, 17, 2478–2489. [Google Scholar] [CrossRef]

- Geydt, P.; Alekseev, P.; Dunaevskiy, M.; Lähderanta, E.; Haggren, T.; Kakko, J.-P.; Lipsanen, H. Observation of linear IV curves on vertical GaAs nanowires with atomic force microscope. J. Phys. Conf. Ser. 2015, 661, 012031. [Google Scholar] [CrossRef]

- Suyatin, D.B.; Jain, V.; Nebol’sin, V.A.; Trägårdh, J.; Messing, M.E.; Wagner, J.B.; Persson, O.; Timm, R.; Mikkelsen, A.; Maximov, I.; et al. Strong Schottky barrier reduction at Au-catalyst/GaAs-nanowire interfaces by electric dipole formation and Fermi-level unpinning. Nat. Commun. 2014, 5, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Zamani, M.; Tütüncüoglu, G.; Martí-Sánchez, S.; Francaviglia, L.; Güniat, L.; Ghisalberti, L.; Potts, H.; Friedl, M.; Markov, E.; Kim, W.; et al. Optimizing the yield of A-polar GaAs nanowires to achieve defect-free zinc blende structure and enhanced optical functionality. Nanoscale 2018, 10, 17080–17091. [Google Scholar] [CrossRef] [PubMed]

- Balaghi, L.; Bussone, G.; Grifone, R.; Hübner, R.; Grenzer, J.; Ghorbani-Asl, M.; Krasheninnikov, A.V.; Schneider, H.; Helm, M.; Dimakis, E. Widely tunable GaAs bandgap via strain engineering in core/shell nanowires with large lattice mismatch. Nat. Commun. 2019, 10, 1–10. [Google Scholar] [CrossRef] [PubMed]

| Structure | Qf (εzz = 0) | Ec (εzz = 0) | Eg (εzz = 0) | Qf (εzz = −1%) | Ec (εzz = −1%) | Eg (εzz = −1%) |

|---|---|---|---|---|---|---|

| ZB | 0 | 4.07 eV | 1.42 eV | 1 × 1012 cm−2 | 4.01 eV | 1.52 eV |

| WZ | 0 | 4.07 eV | 1.42 eV | 1.8 × 1012 cm−2 | 4.22 eV | 1.32 eV |

| εzz,% | Pure p-n ZB, % | Pure p-n WZ, % | n-WZ/p-ZB, % | p-WZ/n-ZB, % |

|---|---|---|---|---|

| −0.25 | 1.2 | −5.4 | 3.7 | −9.2 |

| −0.5 | 1.8 | −10.8 | 5.2 | −32.6 |

| −0.75 | 2.1 | −16.3 | 6.3 | −61.9 |

| −1 | 2.3 | −21.3 | 4.0 | −73.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alekseev, P.A.; Sharov, V.A.; Borodin, B.R.; Dunaevskiy, M.S.; Reznik, R.R.; Cirlin, G.E. Effect of the Uniaxial Compression on the GaAs Nanowire Solar Cell. Micromachines 2020, 11, 581. https://doi.org/10.3390/mi11060581

Alekseev PA, Sharov VA, Borodin BR, Dunaevskiy MS, Reznik RR, Cirlin GE. Effect of the Uniaxial Compression on the GaAs Nanowire Solar Cell. Micromachines. 2020; 11(6):581. https://doi.org/10.3390/mi11060581

Chicago/Turabian StyleAlekseev, Prokhor A., Vladislav A. Sharov, Bogdan R. Borodin, Mikhail S. Dunaevskiy, Rodion R. Reznik, and George E. Cirlin. 2020. "Effect of the Uniaxial Compression on the GaAs Nanowire Solar Cell" Micromachines 11, no. 6: 581. https://doi.org/10.3390/mi11060581

APA StyleAlekseev, P. A., Sharov, V. A., Borodin, B. R., Dunaevskiy, M. S., Reznik, R. R., & Cirlin, G. E. (2020). Effect of the Uniaxial Compression on the GaAs Nanowire Solar Cell. Micromachines, 11(6), 581. https://doi.org/10.3390/mi11060581