Performance and Accuracy of the Shifted Laser Surface Texturing Method

Abstract

1. Introduction

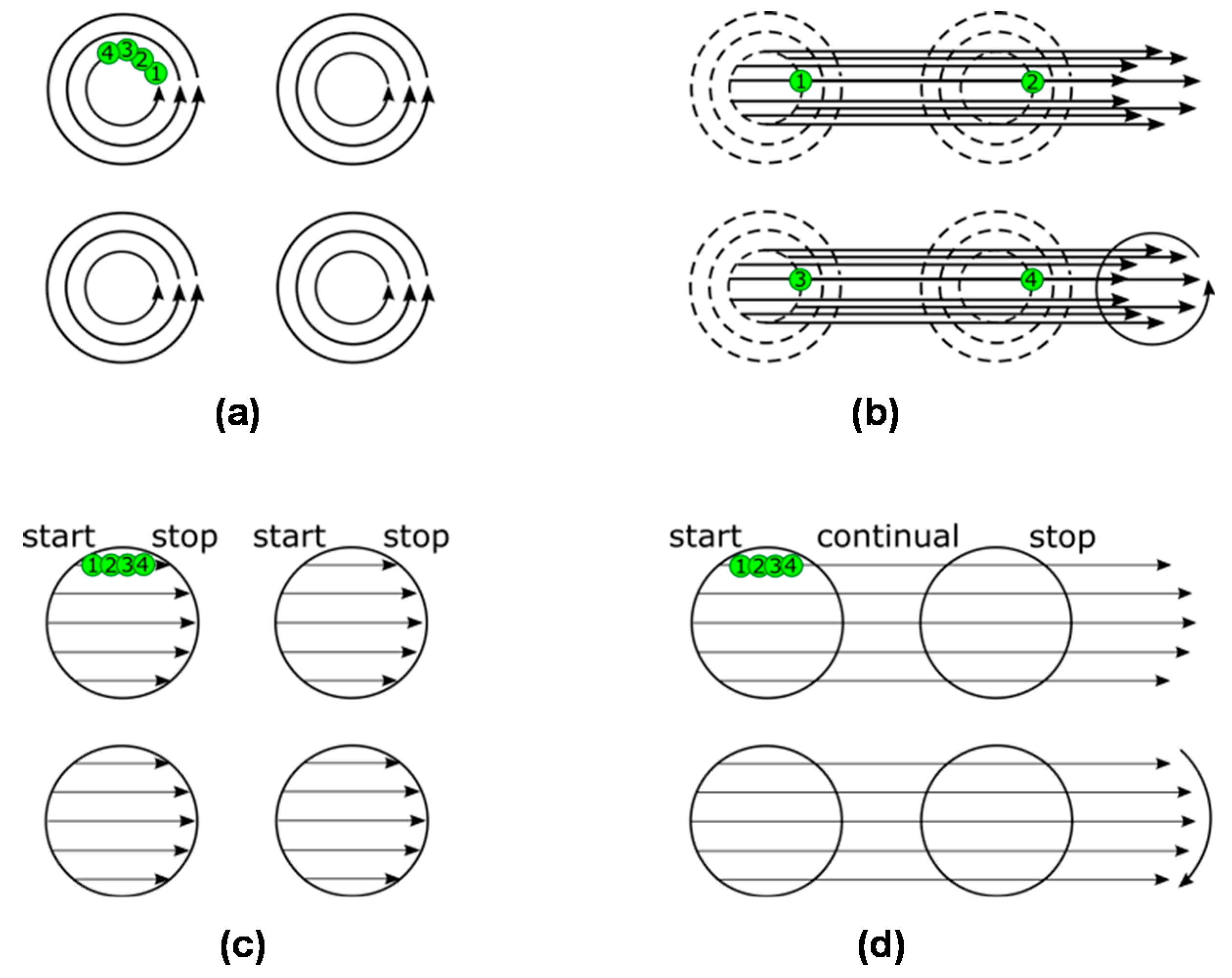

2. Laser Surface Texturing (LST) Methods

3. Experiment and Evaluation Methods

4. Results and Discussion

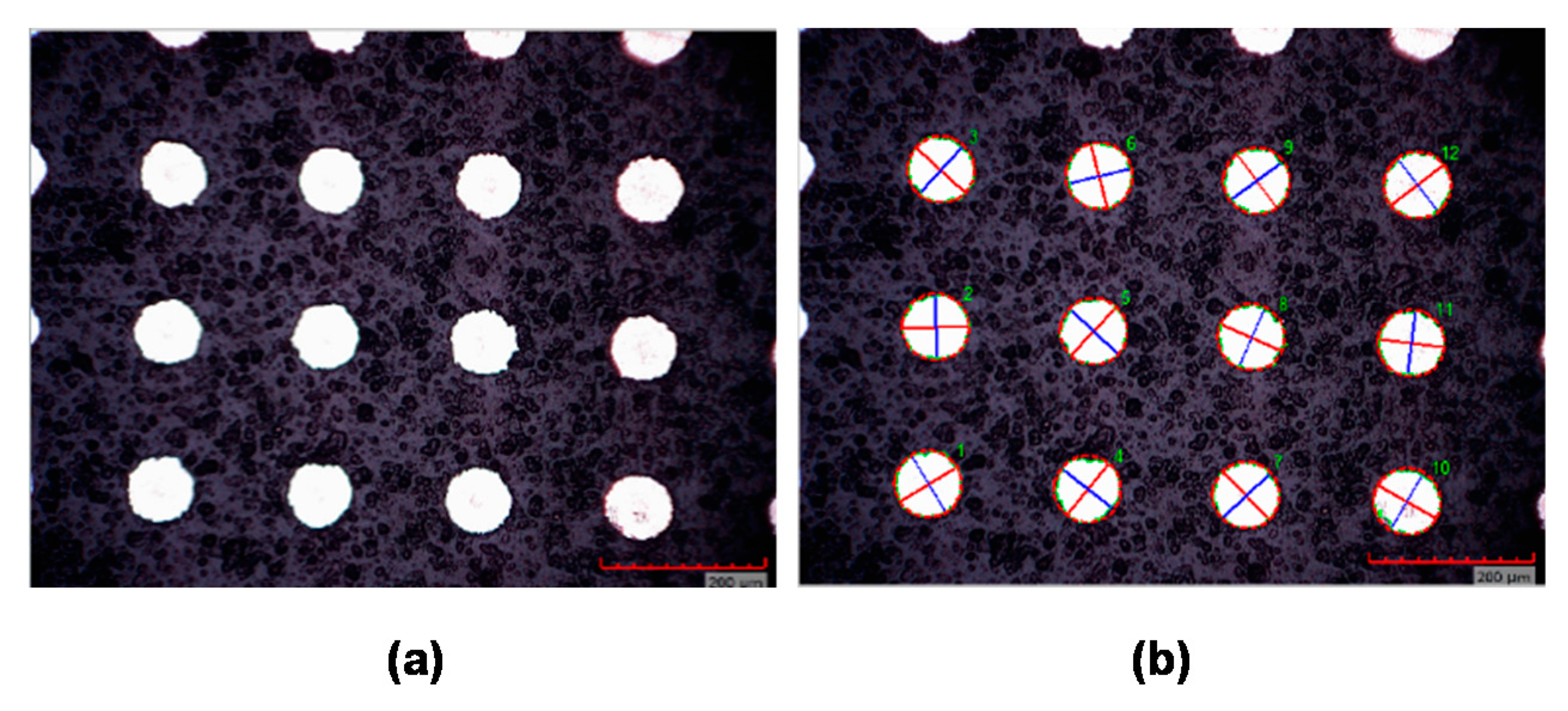

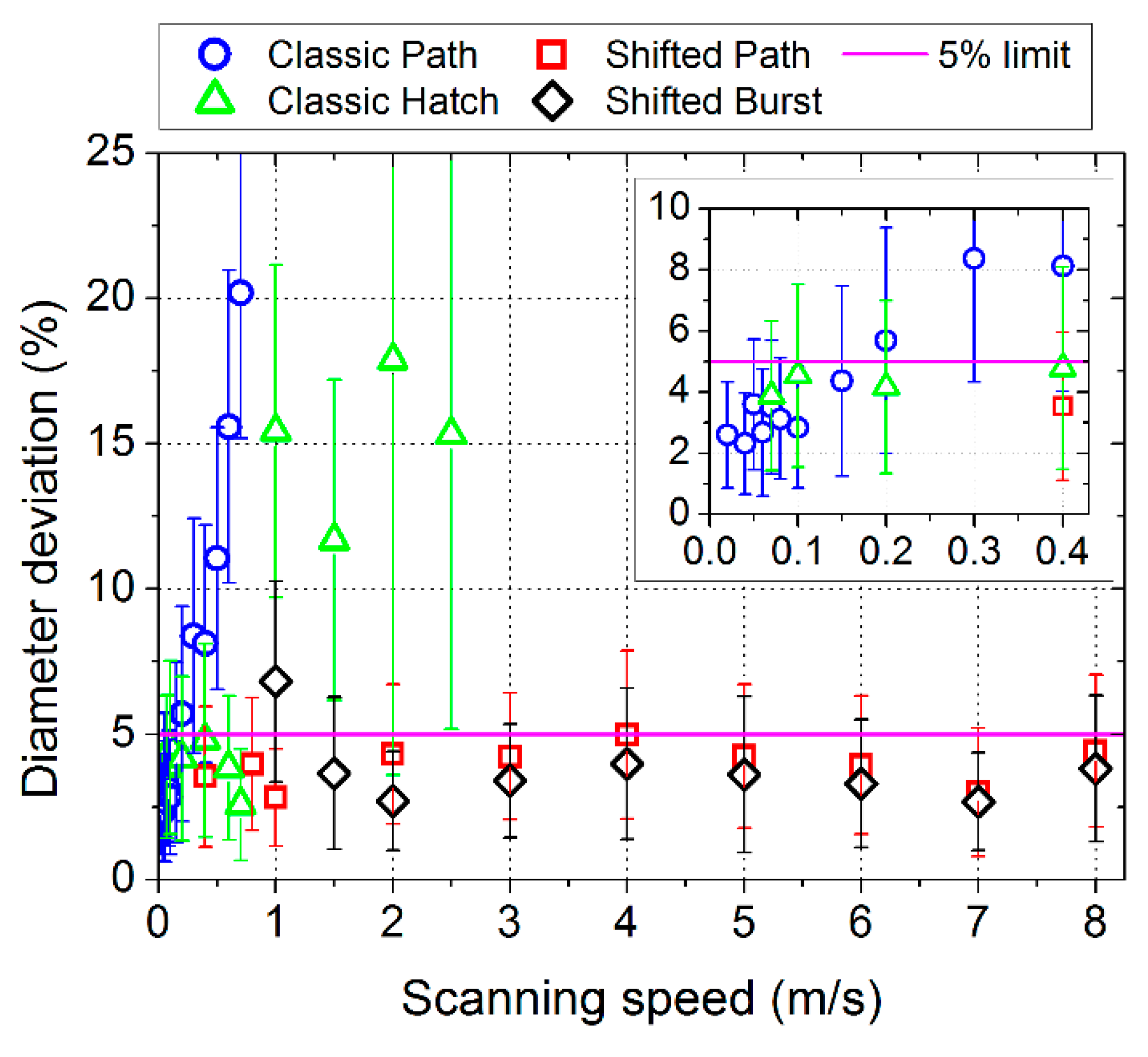

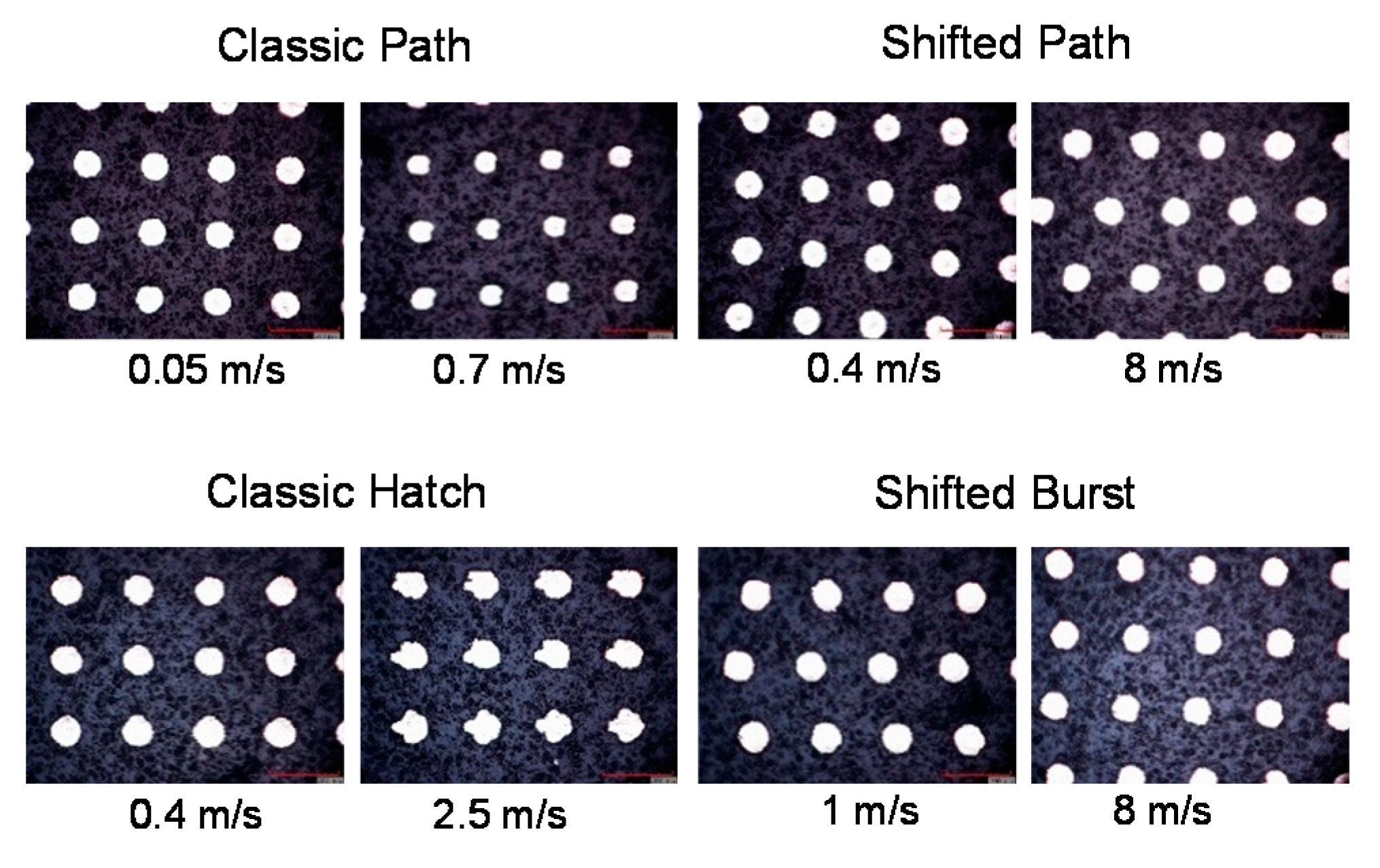

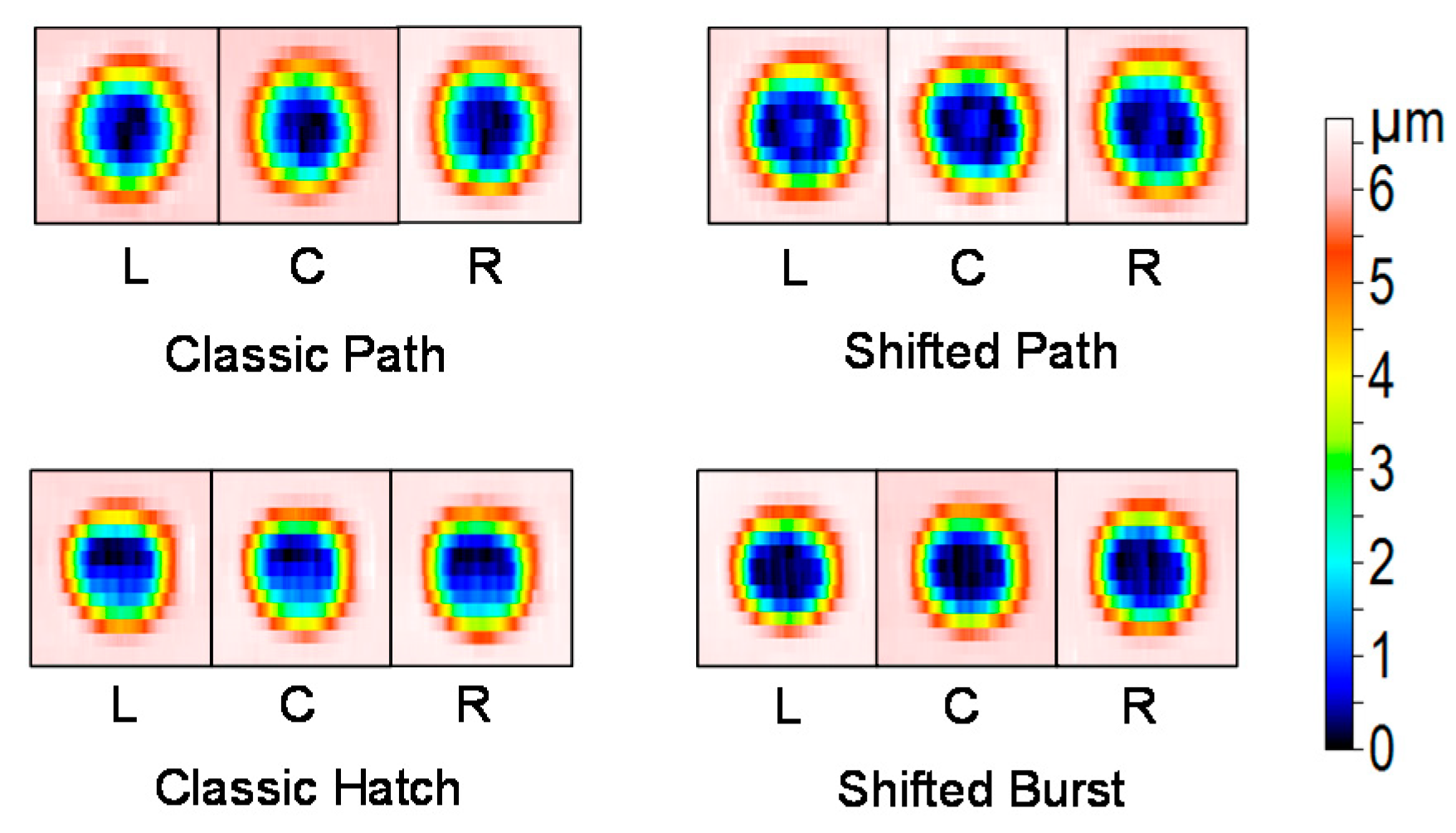

4.1. Size and Circularity of Dimples

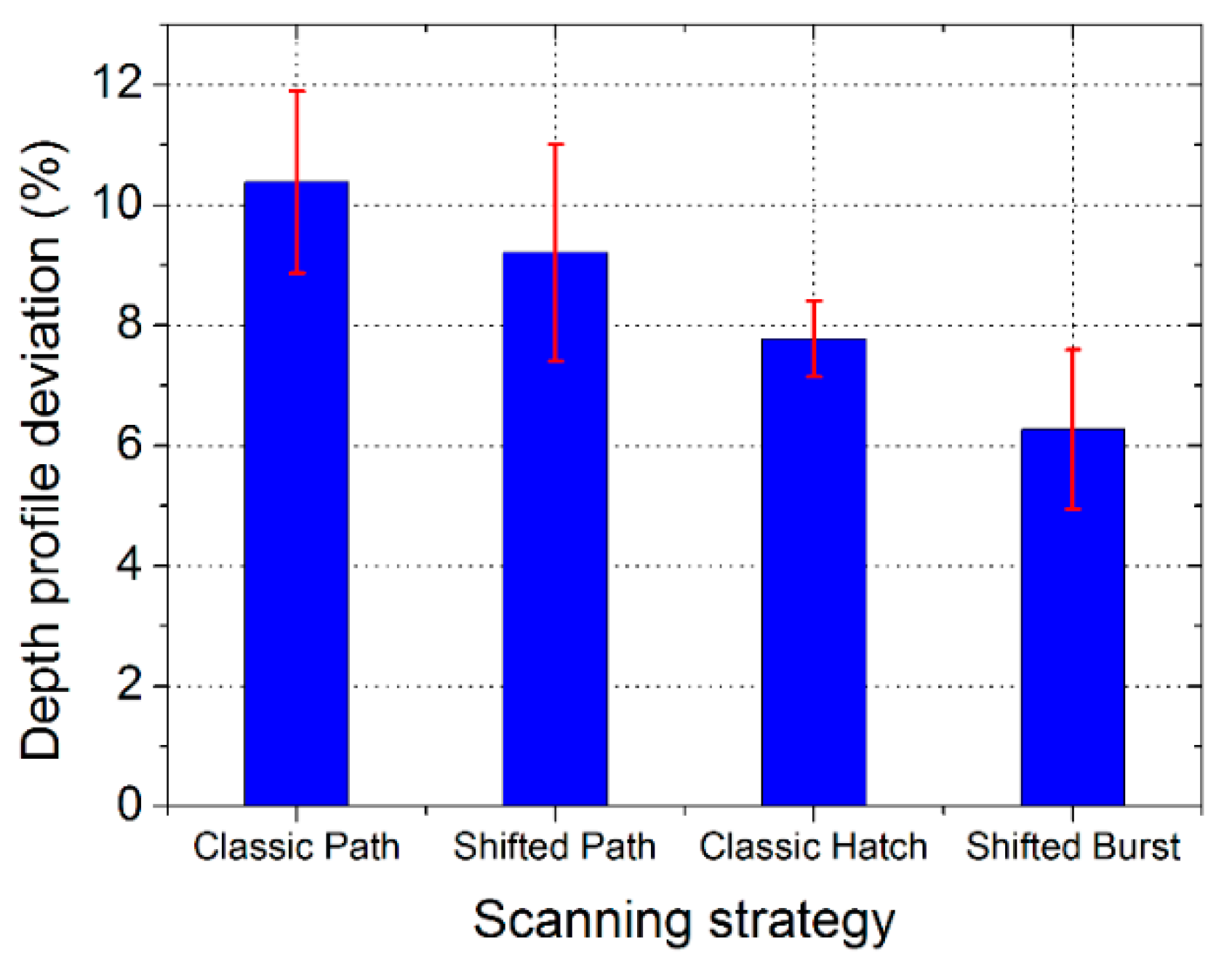

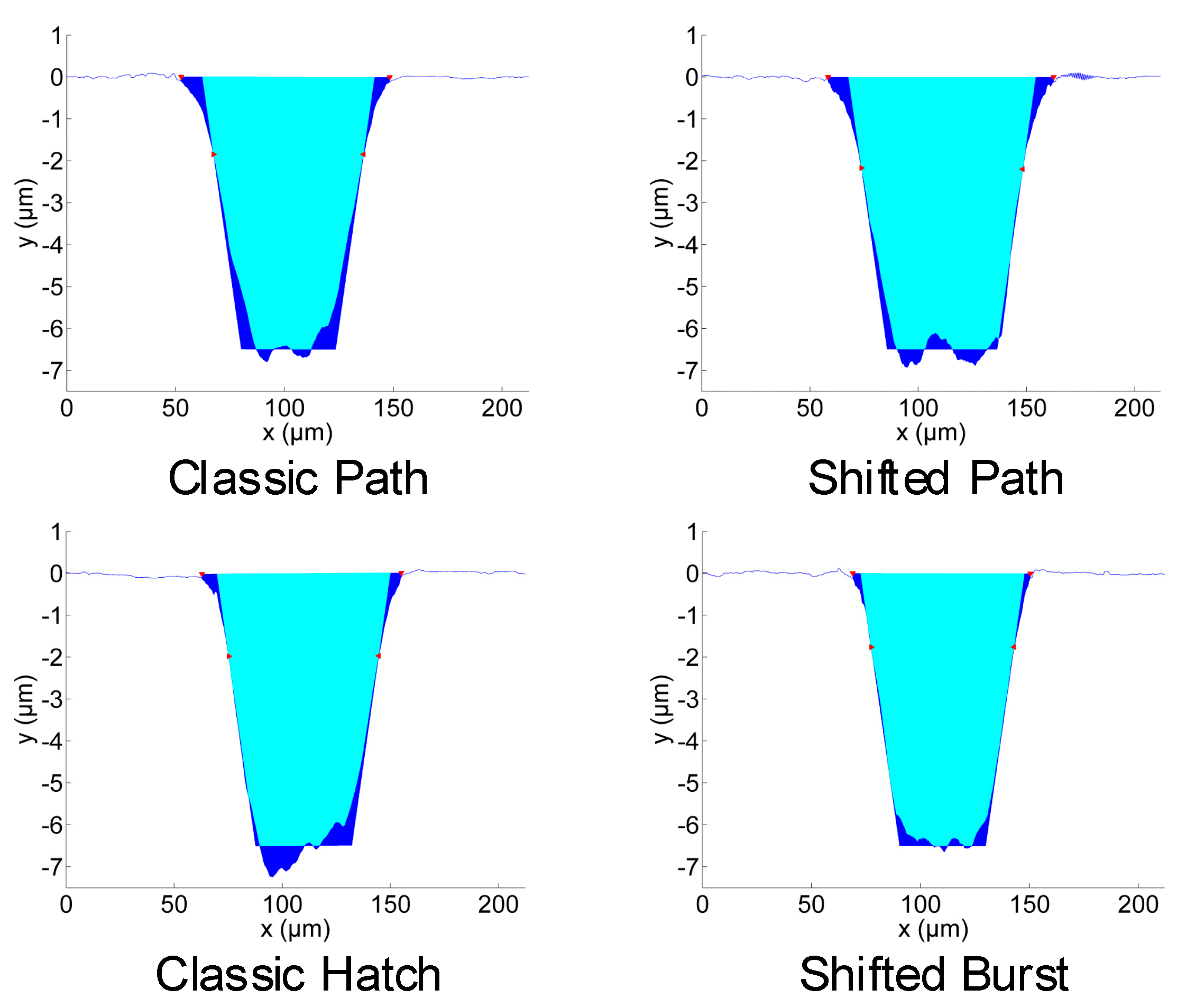

4.2. Depth Profile of Dimples

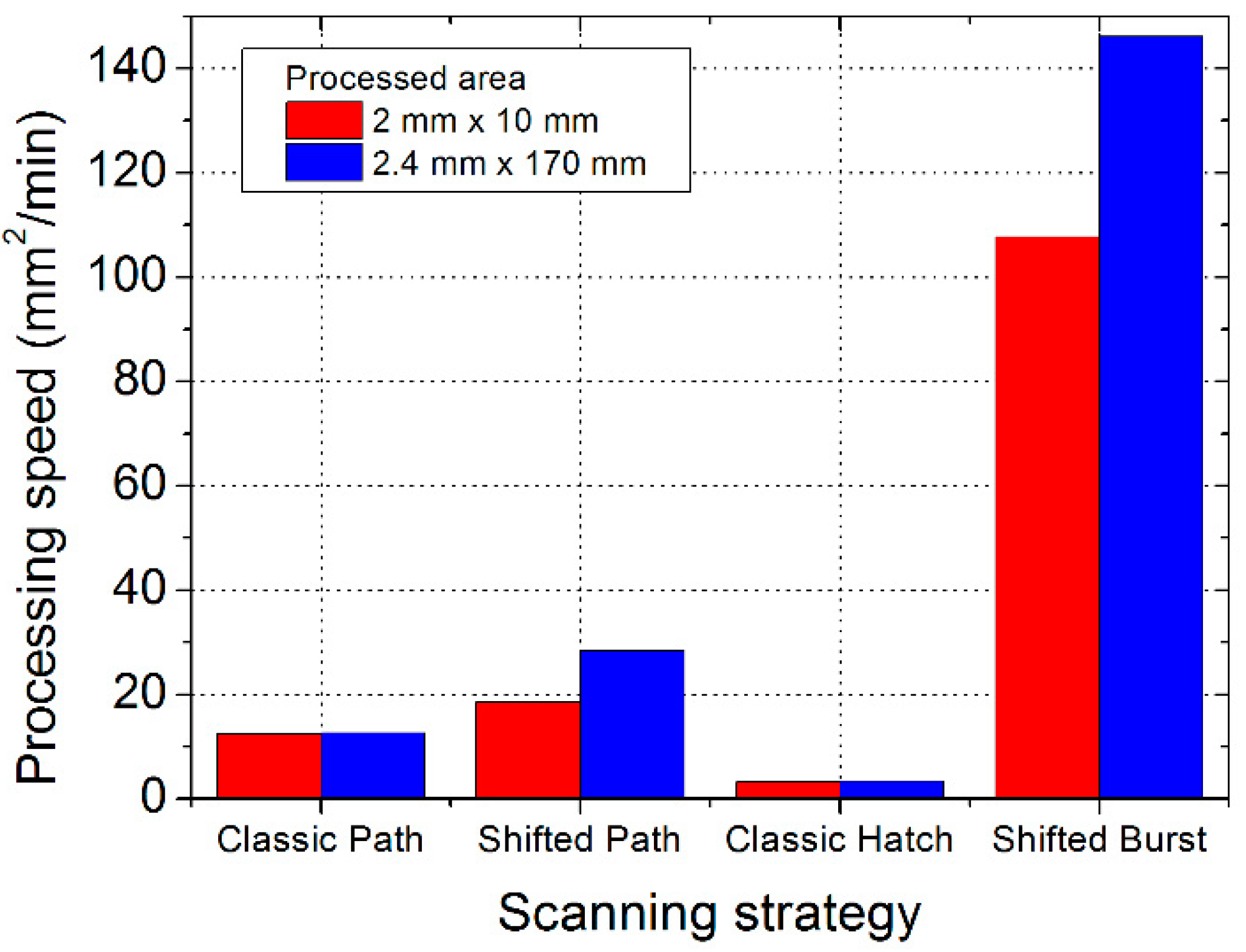

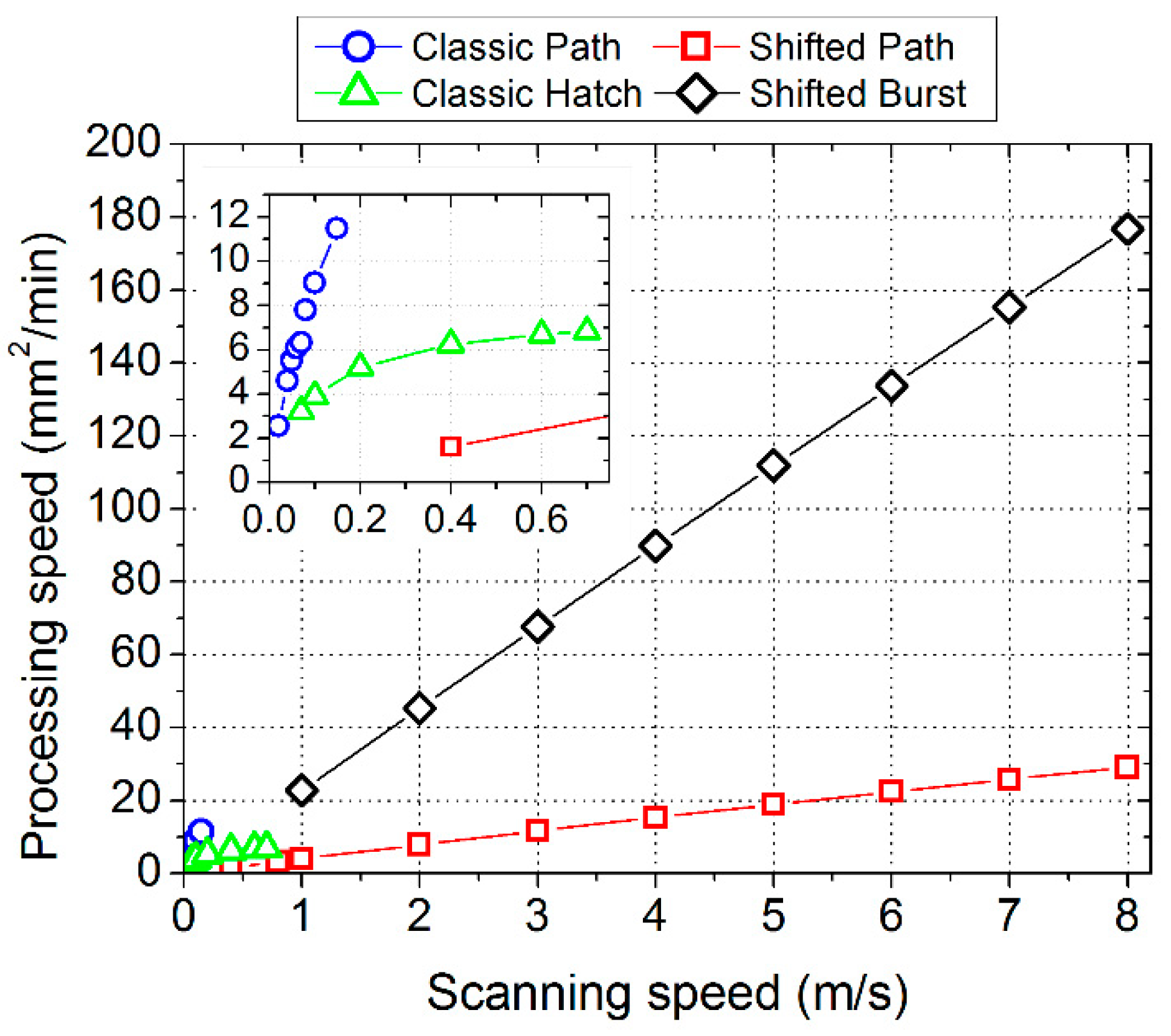

4.3. Processing Speed of the Laser Texturing Methods

5. Conclusions

6. Patents

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Mishra, S.; Yadava, V. Laser Beam MicroMachining (LBMM)—A review. Opt. Lasers Eng. 2015, 73, 89–122. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Profito, F.J.; Rosenkranz, A. Multi-scale surface texturing in tribology-current knowledge and future perspectives. Lubricants 2019, 7, 95. [Google Scholar] [CrossRef]

- Tanvir Ahmmed, K.M.; Grambow, C.; Kietzig, A.M. Fabrication of micro/nano structures on metals by femtosecond laser micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Braun, D.; Greiner, C.; Schneider, J.; Gumbsch, P. Efficiency of laser surface texturing in the reduction of friction under mixed lubrication. Tribol. Int. 2014, 77, 142–147. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Multifunctional surfaces produced by femtosecond laser pulses. J. Appl. Phys. 2015, 033103, 6–11. [Google Scholar] [CrossRef]

- Dumas, V.; Guignandon, A.; Vico, L.; Mauclair, C.; Zapata, X.; Linossier, M.T.; Bouleftour, W.; Granier, J.; Peyroche, S.; Dumas, J.C.; et al. Femtosecond laser nano/micro patterning of titanium influences mesenchymal stem cell adhesion and commitment. Biomed. Mater. 2015, 10. [Google Scholar] [CrossRef]

- Pardal, G.; Meco, S.; Dunn, A.; Williams, S.; Ganguly, S.; Hand, D.P.; Wlodarczyk, K.L. Laser spot welding of laser textured steel to aluminium. J. Mater. Process. Technol. 2017, 241, 24–35. [Google Scholar] [CrossRef]

- Kromer, R.; Costil, S.; Cormier, J.; Courapied, D.; Berthe, L.; Peyre, P.; Boustie, M. Laser surface patterning to enhance adhesion of plasma sprayed coatings. Surf. Coat. Technol. 2015, 278, 171–182. [Google Scholar] [CrossRef]

- Kümmel, J.; Braun, D.; Gibmeier, J.; Schneider, J.; Greiner, C.; Schulze, V.; Wanner, A. Study on micro texturing of uncoated cemented carbide cutting tools for wear improvement and built-up edge stabilisation. J. Mater. Process. Technol. 2015, 215, 62–70. [Google Scholar] [CrossRef]

- Schonlau, T.; Hebel, R.; Pause, S.; Mayer, G. Machining strategies for versatile ultra-short pulse laser applications. In Proceedings of the 8th International Conference on Photonic Technologies LANE 2014, Furth, Germany, 8–11 September 2014; Bayerisches Laserzentrum GmbH: Erlangen, Germany, 2014; pp. 1–4. [Google Scholar]

- Bauer, F.; Michalowski, A.; Kiedrowski, T.; Nolte, S. Heat accumulation in ultra-short pulsed scanning laser ablation of metals. Opt. Express 2015, 23, 1035–1043. [Google Scholar] [CrossRef]

- Weber, R.; Graf, T.; Berger, P.; Onuseit, V.; Wiedenmann, M.; Freitag, C.; Feuer, A. Heat accumulation during pulsed laser materials processing. Opt. Express 2014, 22, 11312–11324. [Google Scholar] [CrossRef] [PubMed]

- Mao, X.L.; Chan, W.T.; Shannon, M.A.; Russoa, R.E. Plasma shielding during picosecond laser sampling of solid materials by ablation in He versus Ar atmosphere. J. Appl. Phys. 1993, 74, 4915–4922. [Google Scholar] [CrossRef]

- König, J.; Nolte, S.; Tünnermann, A. Plasma evolution during metal ablation with ultrashort laser pulses. Opt. Express 2005, 13, 10597. [Google Scholar] [CrossRef] [PubMed]

- Bulgakova, N.M.; Panchenko, A.N.; Zhukov, V.P.; Kudryashov, S.I.; Pereira, A.; Marine, W.; Mocek, T.; Bulgakov, A.V. Impacts of ambient and ablation plasmas on short- and ultrashort-pulse laser processing of surfaces. Micromachines 2014, 5, 1344–1372. [Google Scholar] [CrossRef]

- Moskal, D.; Kučera, M.; Smazalová, E.; Houdková, Š.; Kromer, R. Application of Shifted Laser Surface Texturing. In Proceedings of the METAL 2015—24th International Conference on Metallurgy and Materials, Brno, Czech Republic, 3–5 June 2015; Tanger Ltd.: Ostrava, Czech Republic, 2015; pp. 1016–1021. [Google Scholar]

- Schille, J.; Schneider, L.; Streek, A.; Kloetzer, S.; Loeschner, U. High-throughput machining using high average power ultrashort pulse lasers and ultrafast polygon scanner. In Proceedings of the Laser-based Micro- and Nanoprocessing X, San Francisco, CA, USA, 4 March 2016; p. 97360R. [Google Scholar]

- Romer, G.R.B.E.; Bechtold, P. Electro-optic and acousto-optic laser beam scanners. Phys. Procedia 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Li, L.; Guo, W.; Wang, Z.B.; Liu, Z.; Whitehead, D.; Luk’yanchuk, B. Large-area laser nano-texturing with user-defined patterns. J. Micromechanics Microengineering 2009, 19, 054002. [Google Scholar] [CrossRef]

- Burrow, G.M.; Gaylord, T.K. Multi-beam interference advances and applications: Nano-electronics, photonic crystals, metamaterials, subwavelength structures, optical trapping, and biomedical structures. Micromachines 2011, 2, 221–257. [Google Scholar] [CrossRef]

- Aguilar-Morales, A.I.; Alamri, S.; Lasagni, A.F. Micro-fabrication of high aspect ratio periodic structures on stainless steel by picosecond direct laser interference patterning. J. Mater. Process. Technol. 2018, 252, 313–321. [Google Scholar] [CrossRef]

- Amako, J.; Fujii, E. Beam delivery system with a non-digitized diffractive beam splitter for laser-drilling of silicon. Opt. Lasers Eng. 2016, 77, 1–7. [Google Scholar] [CrossRef]

- Silvennoinen, M.; Kaakkunen, J.; Paivasaari, K.; Vahimaa, P. Parallel microstructuring using femtosecond laser and spatial light modulator. Phys. Procedia 2013, 41, 693–697. [Google Scholar] [CrossRef]

- Neuenschwander, B.; Jaeggi, B.; Zimmermann, M.; Markovic, V.; Resan, B.; Weingarten, K.; de Loor, R.; Penning, L. Laser Surface Structuring with 100W of Average Power and Sub-ps Pulses. J. Laser Appl. 2016, 28, 022506. [Google Scholar] [CrossRef]

- Žemaitis, A.; Gaidys, M.; Gečys, P.; Račiukaitis, G.; Gedvilas, M. Rapid high-quality 3D micro-machining by optimised efficient ultrashort laser ablation. Opt. Lasers Eng. 2019, 114, 83–89. [Google Scholar] [CrossRef]

- Houdková; Šperka, P.; Repka, M.; Martan, J.; Moskal, D. Shifted laser surface texturing for bearings applications. J. Phys. Conf. Ser. 2017, 843. [Google Scholar] [CrossRef]

- Martan, J.; Moskal, D.; Kučera, M. Laser surface texturing with shifted method—Functional surfaces at high speed. J. Laser Appl. 2019, 31, 022507. [Google Scholar] [CrossRef]

- Moskal, D.; Martan, J.; Kucera, M. Shifted laser surface texturing (sLST) in burst regime. J. Laser Micro Nanoeng. 2019, 14, 179–185. [Google Scholar] [CrossRef]

- Matějíček, J.; Vilémová, M.; Moskal, D.; Mušálek, R.; Krofta, J.; Janata, M.; Kutílek, Z.; Klečka, J.; Heuer, S.; Martan, J.; et al. The Role of Laser Texturing in Improving the Adhesion of Plasma Sprayed Tungsten Coatings. J. Therm. Spray Technol. 2019, 28, 1346–1362. [Google Scholar] [CrossRef]

- Kucera, M.; Moskal, D.; Martan, J. Method of Laser Beam Writing with Shifted Laser Surface Texturing. Patent Application Number PCT/IB2015/000807 WO2016189344, 28 May 2015. [Google Scholar]

- Cheng, C.W. Ablation of copper by a scanning Gaussian beam of a femtosecond laser pulse. Int. J. Adv. Manuf. Technol. 2017, 92, 151–156. [Google Scholar] [CrossRef]

- Lorbeer, R.-A.; Scharring, S.; Karg, S.; Pastow, J.; Pastuschka, L.; Förster, D.J.; Eckel, H.-A. Thrust noise minimization in long-term laser ablation of propellant material in the nanosecond and picosecond regime. Opt. Eng. 2016, 56, 011010. [Google Scholar] [CrossRef]

- Neuenschwander, B.; Jaeggi, B.; Schmid, M.; Hennig, G. Surface structuring with ultra-short laser pulses: Basics, limitations and needs for high throughput. Phys. Procedia 2014, 56, 1047–1058. [Google Scholar] [CrossRef]

- Raciukaitis, G.; Brikas, M.; Gecys, P.; Gedvilas, M. Accumulation effects in laser ablation of metals with high-repetition- rate lasers Gediminas. SPIE 2008, 7005, 70052L. [Google Scholar] [CrossRef]

- Ancona, A.; Röser, F.; Rademaker, K.; Limpert, J.; Nolte, S.; Tünnermann, A. High speed laser drilling of metals using a high repetition rate, high average power ultrafast fiber CPA system. Opt. Express 2008, 16, 8958–8968. [Google Scholar] [CrossRef] [PubMed]

- Raciukaitis, G. Use of High Repetition Rate and High Power Lasers in Microfabrication: How to Keep the Efficiency High? J. Laser Micro/Nanoeng. 2009, 4, 186–191. [Google Scholar] [CrossRef]

- Schille, J.; Schneider, L.; Loeschner, U. Process optimization in high-average-power ultrashort pulse laser microfabrication: How laser process parameters influence efficiency, throughput and quality. Appl. Phys. A Mater. Sci. Process. 2015, 120, 847–855. [Google Scholar] [CrossRef]

- Villerius, V.; Kooiker, H.; Post, J.; Pei, Y.T. Ultrashort pulsed laser ablation of stainless steels. Int. J. Mach. Tools Manuf. 2019, 138, 27–35. [Google Scholar] [CrossRef]

- Mauersberger, S.; Schille, J.; Kujawa, K.; Schneider, L.; Million, C.; Hartung, K.; Oehlert, K.; Loeschner, U. High-precision surface profiling using multi-hundred watts ultrashort pulse lasers and ultrafast polygon-mirror based scanner. J. Laser Micro/Nanoeng. 2020, 15, 23. [Google Scholar] [CrossRef]

- Lasagni, A.F.; Alamri, S.; Aguilar-Morales, A.I.; Rößler, F.; Voisiat, B.; Kunze, T. Biomimetic surface structuring using laser based interferometric methods. Appl. Sci. 2018, 8, 1260. [Google Scholar] [CrossRef]

- Müller, D.W.; Fox, T.; Grützmacher, P.G.; Suarez, S.; Mücklich, F. Applying Ultrashort Pulsed Direct Laser Interference Patterning for Functional Surfaces. Sci. Rep. 2020, 10, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Lang, V.; Roch, T.; Lasagni, A.F. High-Speed Surface Structuring of Polycarbonate Using Direct Laser Interference Patterning: Toward 1 m 2 min −1 Fabrication Speed Barrier. Adv. Eng. Mater. 2016, 18, 1342–1348. [Google Scholar] [CrossRef]

- Kerse, C.; Kalaycıoğlu, H.; Elahi, P.; Çetin, B.; Kesim, D.K.; Akçaalan, Ö.; Yavaş, S.; Aşık, M.D.; Öktem, B.; Hoogland, H.; et al. Ablation-cooled material removal with ultrafast bursts of pulses. Nature 2016, 537, 84–88. [Google Scholar] [CrossRef]

- Bonamis, G.; Mishchick, K.; Audouard, E.; Hönninger, C.; Mottay, E.; Lopez, J.; Manek-Hönninger, I. High efficiency femtosecond laser ablation with gigahertz level bursts. J. Laser Appl. 2019, 31, 022205. [Google Scholar] [CrossRef]

- Povarnitsyn, M.E.; Levashov, P.R.; Knyazev, D.V. Simulation of ultrafast bursts of subpicosecond pulses: In pursuit of efficiency. Appl. Phys. Lett. 2018, 112. [Google Scholar] [CrossRef]

- Lumos Laser, DURO GHz. Available online: https://lumoslaser.com/specsheet/Lumos-Laser-Specheet.pdf (accessed on 14 April 2020).

- Next Scan Technology Polygon Scanner Systems. Available online: https://nextscantechnology.com/wp-content/uploads/2017/01/NST_Leaflet-Polygon-Scanner-Systems_2017.pdf (accessed on 27 June 2018).

| Texturing Method | Scanning Speed (m/s) | Repetition Frequency (kHz) | Number of Layers | Pulses Per Layer | Ablation Rate (μm3/pulse) (μm3/μJ) | Heat Accumulation ΔT (K) | |

|---|---|---|---|---|---|---|---|

| Classic Path | 0.15 | 21 | 45 | 56 | 7.7 | 0.70 | 45 |

| Shifted Path | 8 | 40 | 60 | 54 | 7.6 | 0.69 | 3 |

| Classic Hatch | 0.7 | 100 | 85 | 42–50 | 5.6–4.7 | 0.51–0.43 | 96 |

| Shifted Burst | 8 | 1143 | 90 | 39–47 | 4.8–4.0 | 0.44–0.36 | 320 |

| Texturing Method | Jump Delay Time (s) | Processing Time (s) | Jump Time Efficiency | Geometrical Efficiency | Laser Usage Efficiency | Average Laser Power (W) | Processing Speed (mm2/min) | Processing Efficiency (mm2/min/W) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Needed | Effective | Needed | Effective | |||||||

| Classic Path | 413 | 1943 | 79% | 99% | 78% | 0.24 | 0.18 | 12.6 | 53.5 | 68.6 |

| Shifted Path | 10 | 874 | 99% | 100% | 99% | 0.44 | 0.43 | 28.0 | 63.6 | 64.4 |

| Classic Hatch | 1821 | 3600 | 49% | 25% | 12% | 1.10 | 0.14 | 6.8 | 6.2 | 50.3 |

| Shifted Burst | 2 | 138 | 99% | 24% | 23% | 12.57 | 2.91 | 177.0 | 14.1 | 60.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martan, J.; Moskal, D.; Smeták, L.; Honner, M. Performance and Accuracy of the Shifted Laser Surface Texturing Method. Micromachines 2020, 11, 520. https://doi.org/10.3390/mi11050520

Martan J, Moskal D, Smeták L, Honner M. Performance and Accuracy of the Shifted Laser Surface Texturing Method. Micromachines. 2020; 11(5):520. https://doi.org/10.3390/mi11050520

Chicago/Turabian StyleMartan, Jiří, Denys Moskal, Ladislav Smeták, and Milan Honner. 2020. "Performance and Accuracy of the Shifted Laser Surface Texturing Method" Micromachines 11, no. 5: 520. https://doi.org/10.3390/mi11050520

APA StyleMartan, J., Moskal, D., Smeták, L., & Honner, M. (2020). Performance and Accuracy of the Shifted Laser Surface Texturing Method. Micromachines, 11(5), 520. https://doi.org/10.3390/mi11050520