Experimental Study on the Lubrication and Cooling Effect of Graphene in Base Oil for Si3N4/Si3N4 Sliding Pairs

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Tribological Test

2.3. Characterization

3. Results and Discussion

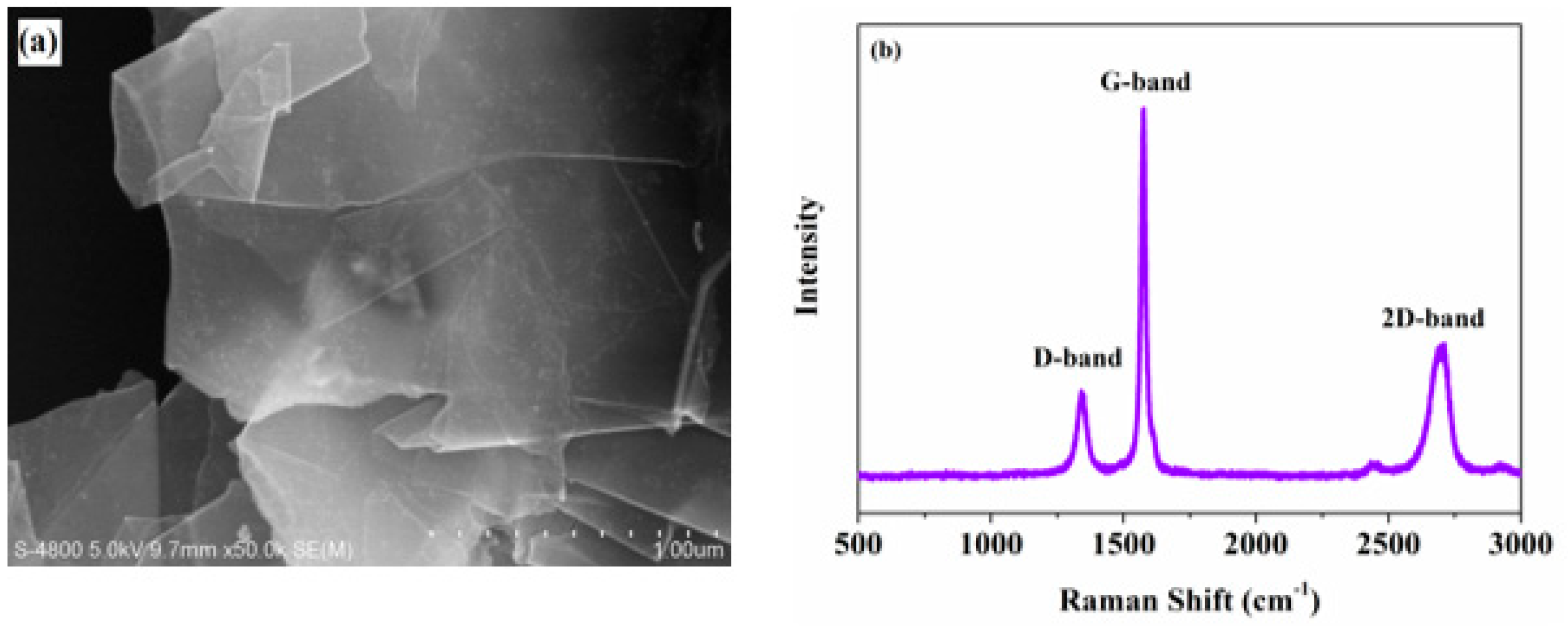

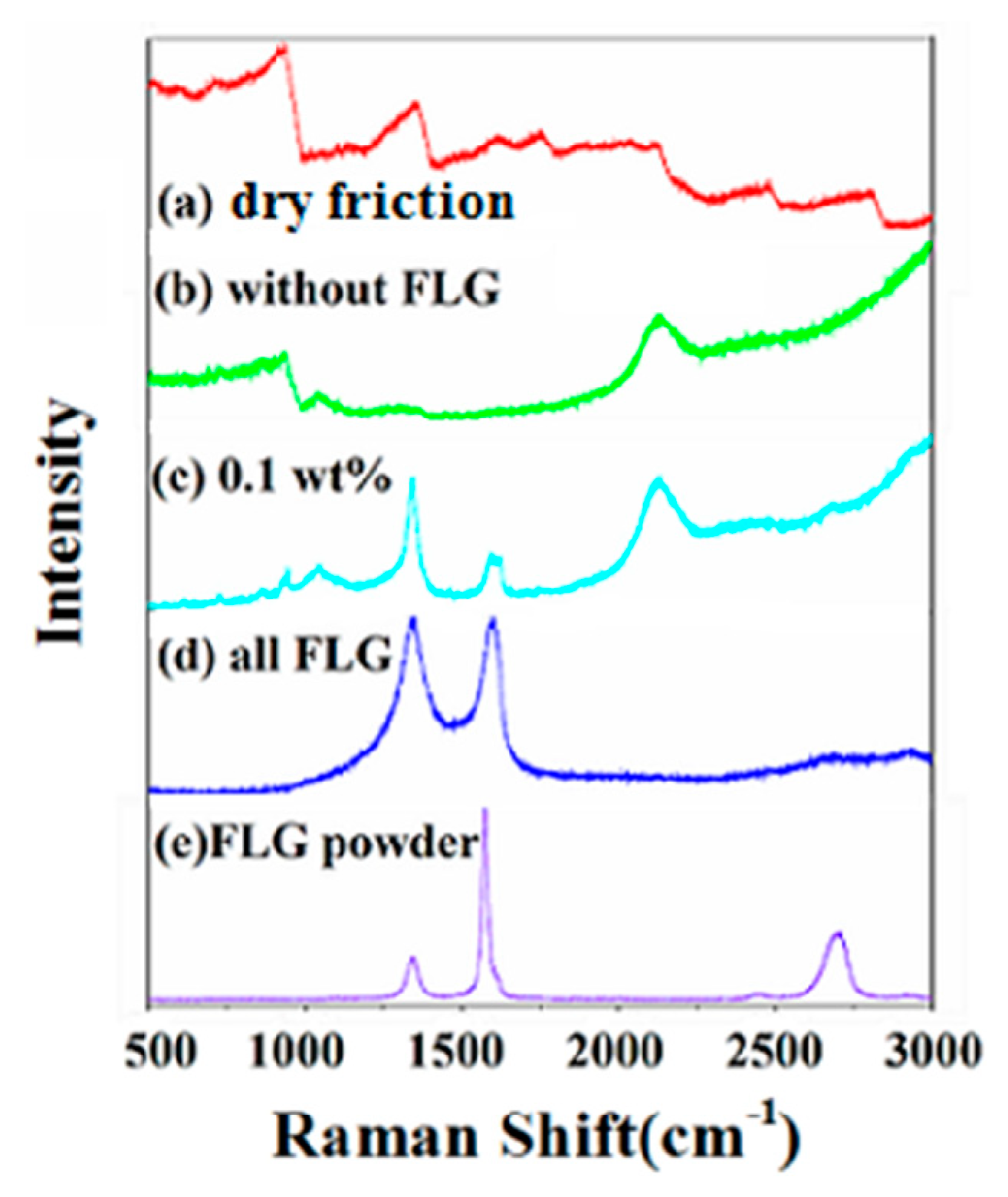

3.1. Materials Characterization

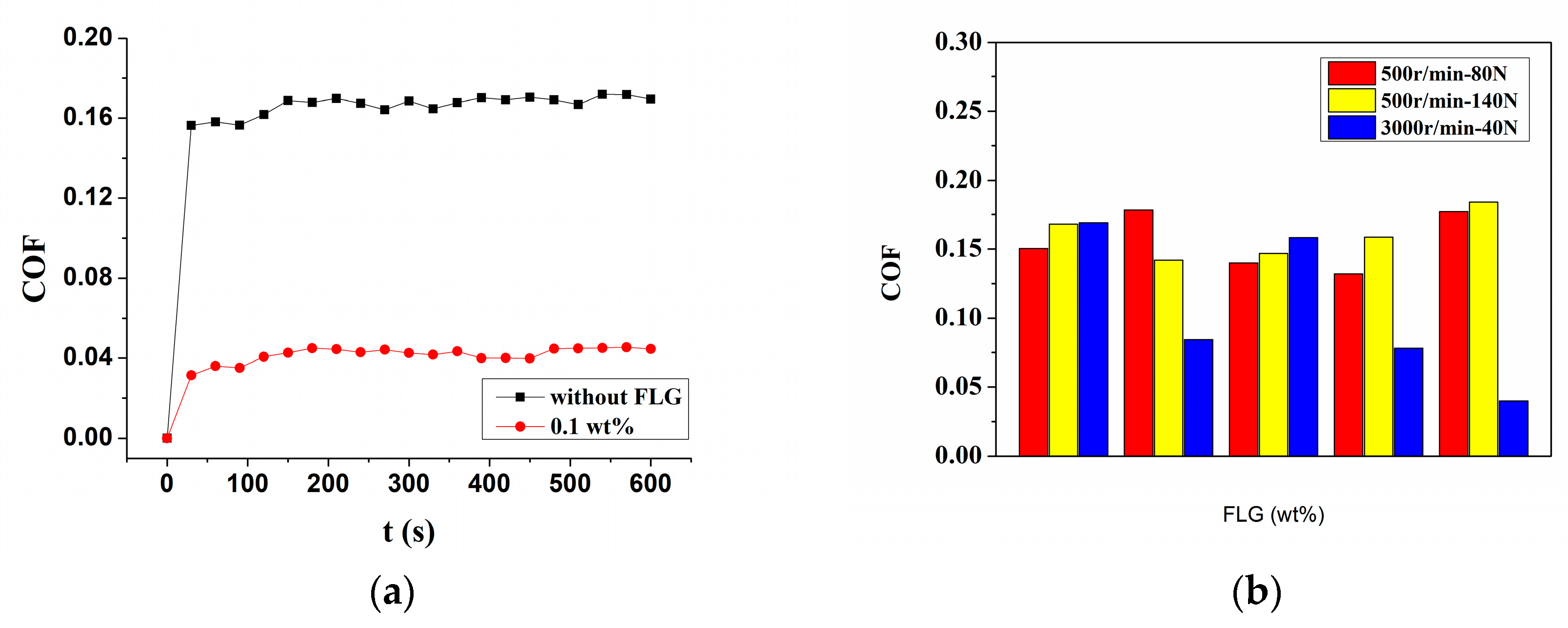

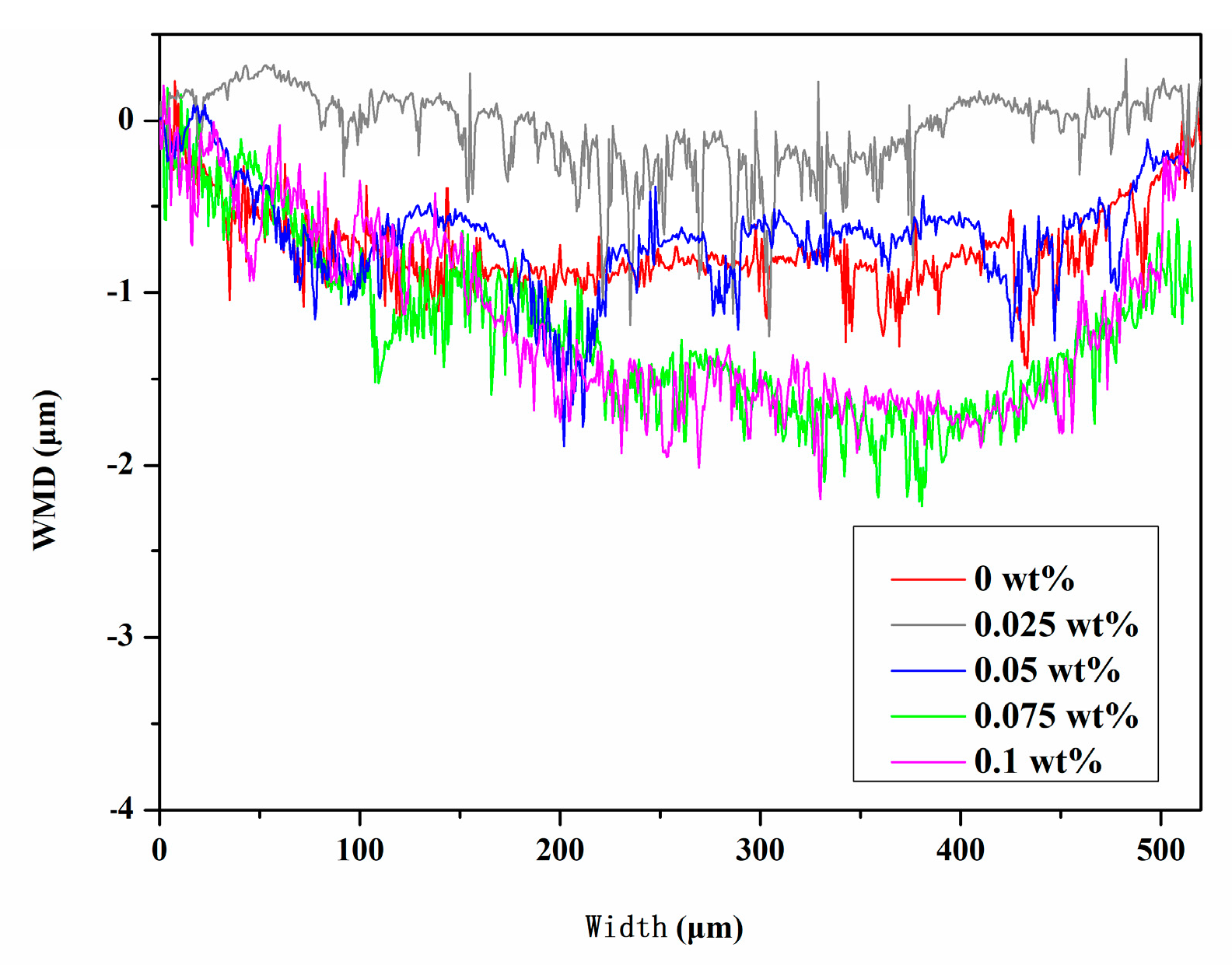

3.2. Tribological Properties

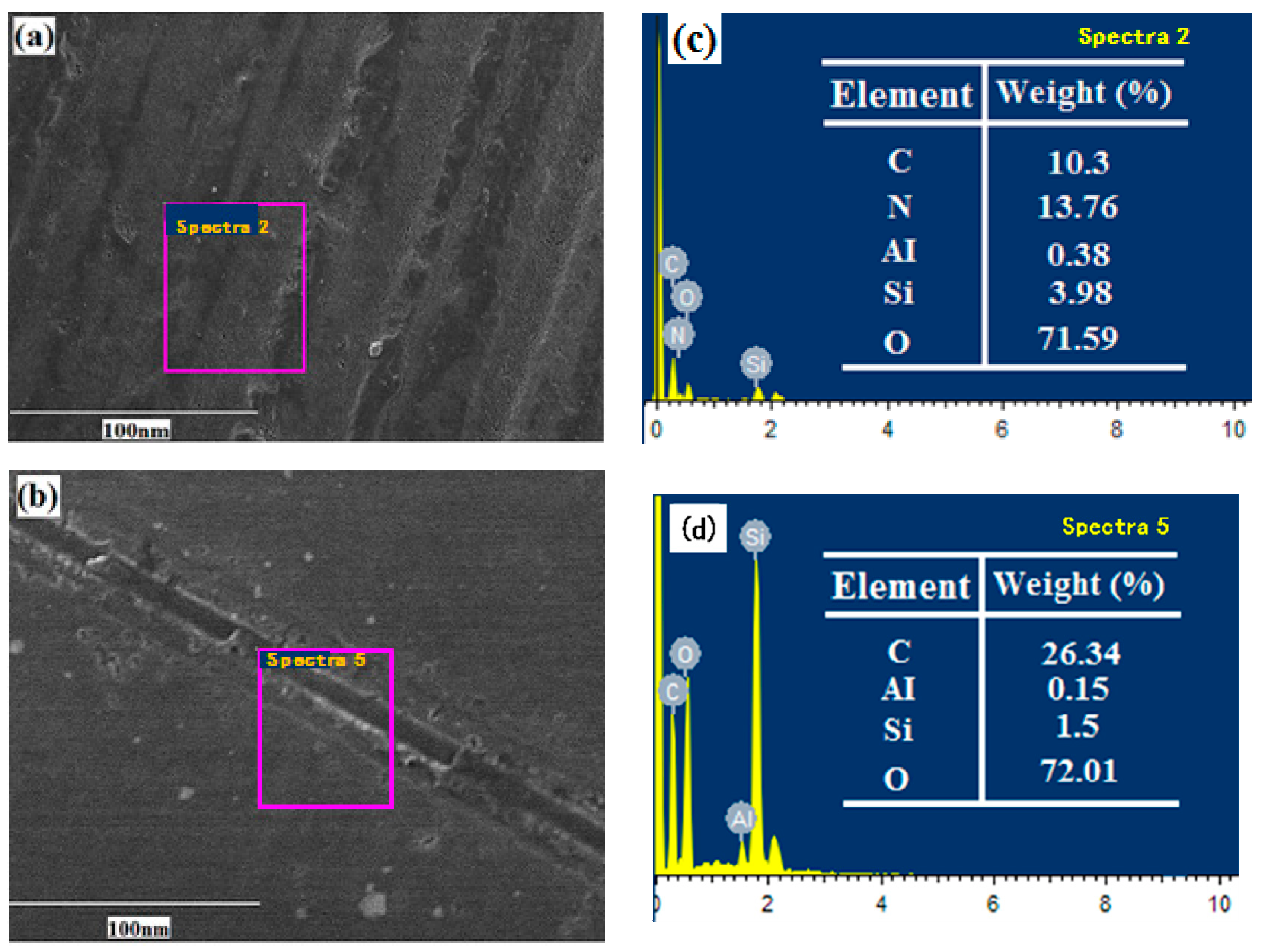

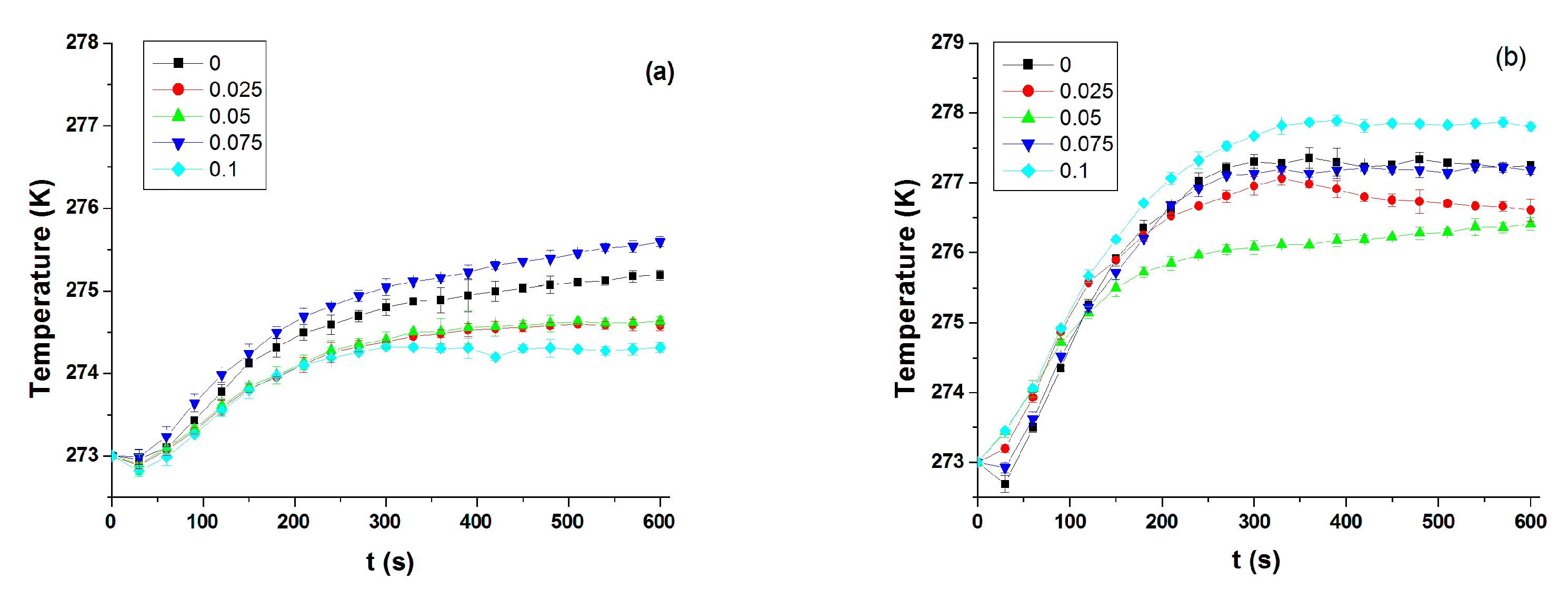

3.3. Cooling Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, W.; Hadfield, M.; Wereszczak, A.A. Surface strength of silicon nitride in relation to rolling contact performance. Ceram. Int. 2009, 35, 3339–3346. [Google Scholar] [CrossRef]

- Gates, R.S.; Hsu, S.M. Silicon Nitride Boundary Lubrication: Lubrication Mechanism of Alcohols. Tribol. Trans. 1995, 38, 645–653. [Google Scholar] [CrossRef]

- Kalin, M.; Vizintin, J.; Novak, S.; Dražić, G. Wear mechanisms in oil-lubricated and dry fretting of silicon nitride against bearing steel contacts. Wear 1997, 210, 27–38. [Google Scholar] [CrossRef]

- Kasar, A.K.; Menezes, P.L. Synthesis and recent advances in tribological applications of graphene. Int. J. Adv. Manuf. Technol. 2018, 97, 3999–4019. [Google Scholar] [CrossRef]

- Peng, B.; Locascio, M.; Zapol, P.; Li, S.; Mielke, S.L. Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat. Nanotech. 2008, 3, 626–631. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, U.D.; Zwörner, O.; Köster, P.; Wiesendanger, R. Quantitative analysis of the frictional properties of solid materials at low loads. I. Carbon compounds. Phys. Rev. B 1997, 56, 6987–6996. [Google Scholar] [CrossRef]

- Liu, X.; Pu, J.; Xue, Q.; Wang, L. Novel DLC/ionic liquid/graphene nanocomposite coatings towards high-vacuum related space applications. J. Mater. Chem. A 2013, 1, 3797. [Google Scholar] [CrossRef]

- Huang, H.; Tu, J.; Gan, L.; Li, C. An investigation on tribological properties of graphite nanosheets as oil additive. Wear 2006, 261, 140–144. [Google Scholar] [CrossRef]

- Lin, J.; Wang, L.; Chen, G. Modification of Graphene Platelets and their Tribological Properties as a Lubricant Additive. Tribol. Lett. 2011, 41, 209–215. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, X.; Wu, Y.; Wang, J.; Xi, D. Study on the effects of graphene oxide for tribological properties and cooling in lubricating oil. Mater. Res. Express 2018, 5, 126509. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cançado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1290. [Google Scholar] [CrossRef]

- Graf, D.; Molitor, F.; Ensslin, K.; Stampfer, C.; Jungen, A.; Hierold, C.; Wirtz, L. Spatially Resolved Raman Spectroscopy of Single- and Few-Layer Graphene. Nano Lett. 2007, 7, 238–242. [Google Scholar] [CrossRef] [PubMed]

- Thomsen, C.; Reich, S. Double Resonant Raman Scattering in Graphite. Phys. Rev. Lett. 2000, 85, 5214–5217. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Basko, D.M. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat. Nanotechnol. 2013, 8, 235–246. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Xie, Z.; Gu, L.; Song, B.; Wang, L. Investigation of the tribological behavior of graphene oxide nanoplates as lubricant additives for ceramic/steel contact. Tribol. Int. 2018, 128, 113–120. [Google Scholar] [CrossRef]

- Zheng, Q.; Kim, J.-K. (Eds.) Synthesis, structure, and properties of graphene and graphene oxide. In Graphene for Transparent Conductors: Synthesis, Properties and Applications; Springer: New York, NY, USA, 2015; pp. 29–94. [Google Scholar]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Rutkowski, P.; Stobierski, L.; Górny, G. Thermal stability and conductivity of hot-pressed Si3N4–graphene composites. J. Therm. Anal. Calorim. 2014, 116, 321–328. [Google Scholar] [CrossRef][Green Version]

- Song, H.; Wang, Z.; Yang, J. Tribological properties of graphene oxide and carbon spheres as lubricating additives. Appl. Phys. A 2016, 122, 933. [Google Scholar] [CrossRef]

- Wang, Y.; Pu, J.; Xia, L.; Ding, J.; Yuan, N.; Zhu, Y.; Cheng, G. Fabrication and Tribological Study of Graphene Oxide/Multiply-Alkylated Cyclopentanes Multilayer Lubrication Films on Si Substrates. Tribol. Lett. 2014, 53, 207–214. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 2013, 59, 167–175. [Google Scholar] [CrossRef]

- Wu, L.; Gu, L.; Xie, Z.; Zhang, C.; Song, B. Improved tribological properties of Si3N4/GCr15 sliding pairs with few layer graphene as oil additives. Ceram. Int. 2017, 43, 14218–14224. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Wei, X.; Wang, J.; Wu, Y.; An, D.; Xi, D. Experimental Study on the Lubrication and Cooling Effect of Graphene in Base Oil for Si3N4/Si3N4 Sliding Pairs. Micromachines 2020, 11, 160. https://doi.org/10.3390/mi11020160

Zhang L, Wei X, Wang J, Wu Y, An D, Xi D. Experimental Study on the Lubrication and Cooling Effect of Graphene in Base Oil for Si3N4/Si3N4 Sliding Pairs. Micromachines. 2020; 11(2):160. https://doi.org/10.3390/mi11020160

Chicago/Turabian StyleZhang, Lixiu, Xiaoyi Wei, Junhai Wang, Yuhou Wu, Dong An, and Dongyang Xi. 2020. "Experimental Study on the Lubrication and Cooling Effect of Graphene in Base Oil for Si3N4/Si3N4 Sliding Pairs" Micromachines 11, no. 2: 160. https://doi.org/10.3390/mi11020160

APA StyleZhang, L., Wei, X., Wang, J., Wu, Y., An, D., & Xi, D. (2020). Experimental Study on the Lubrication and Cooling Effect of Graphene in Base Oil for Si3N4/Si3N4 Sliding Pairs. Micromachines, 11(2), 160. https://doi.org/10.3390/mi11020160