Inconsistency Calibrating Algorithms for Large Scale Piezoresistive Electronic Skin

Abstract

1. Introduction

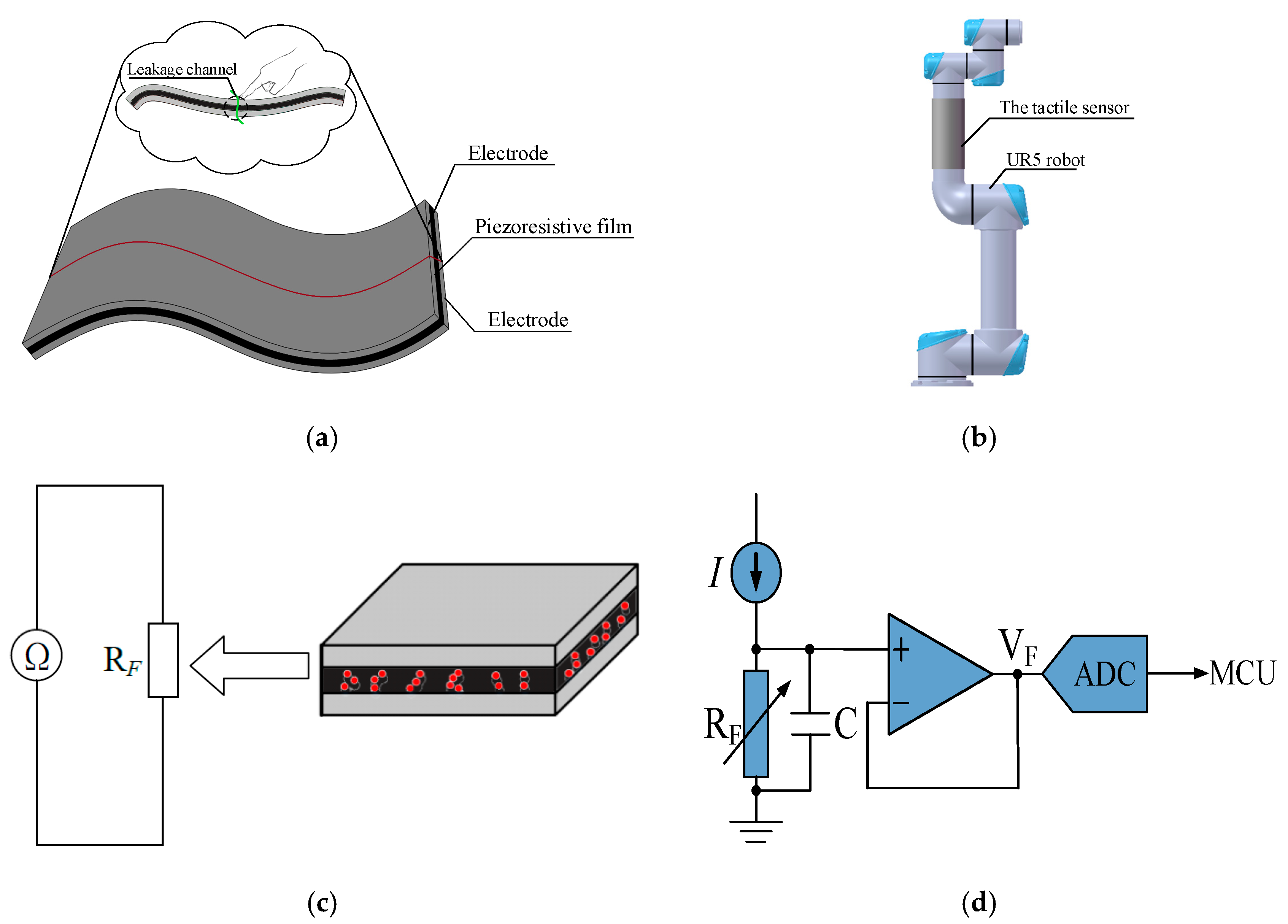

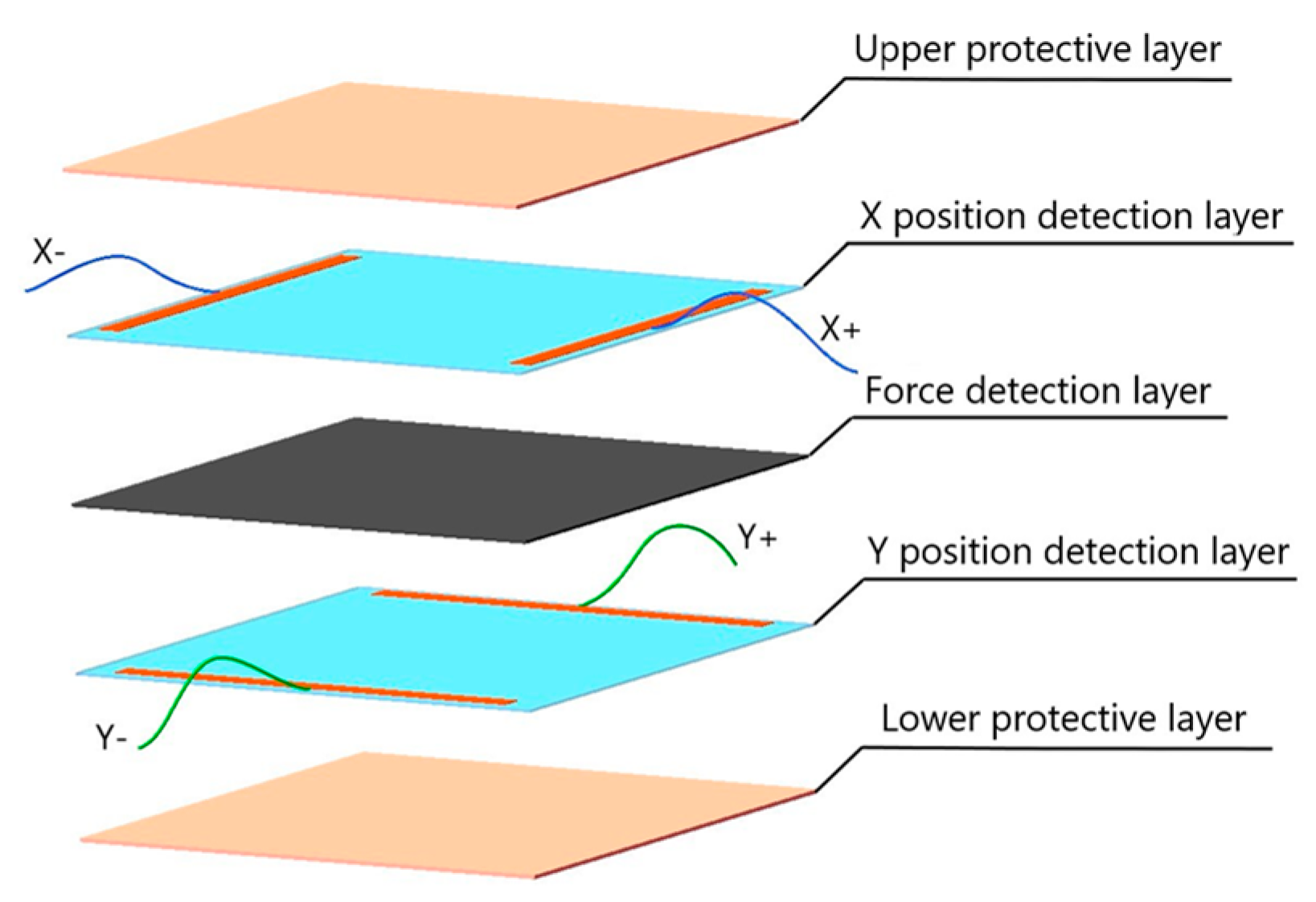

2. Principle of the Large Scale Piezoresistive Tactile Sensor

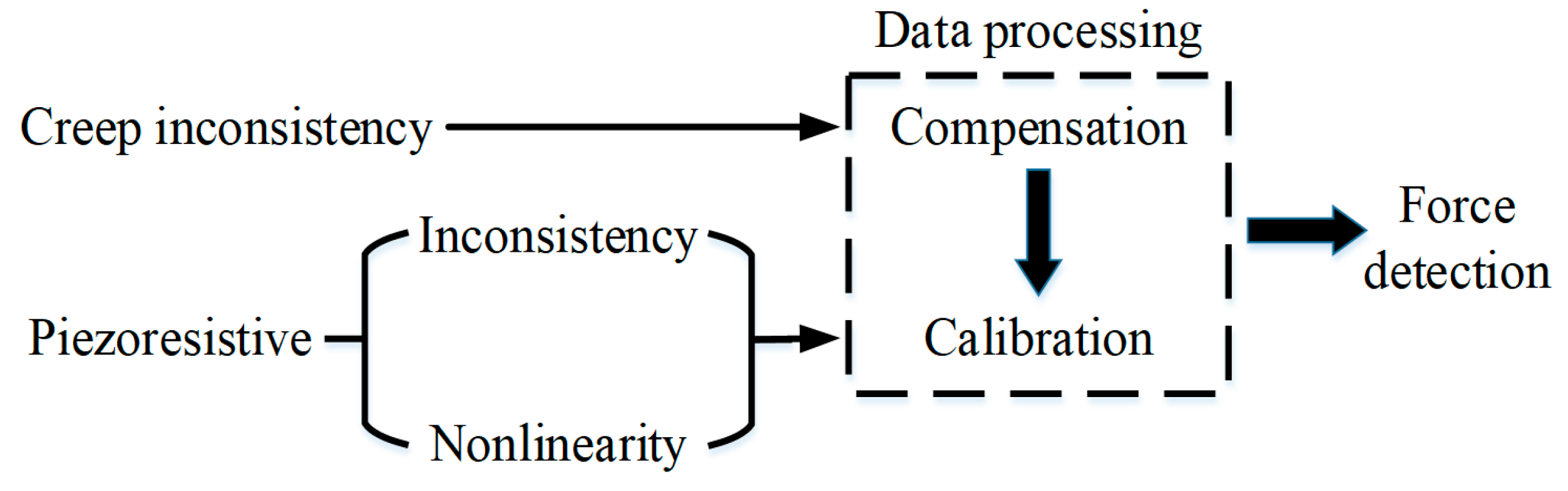

3. Creep Compensation before Sensor Calibration

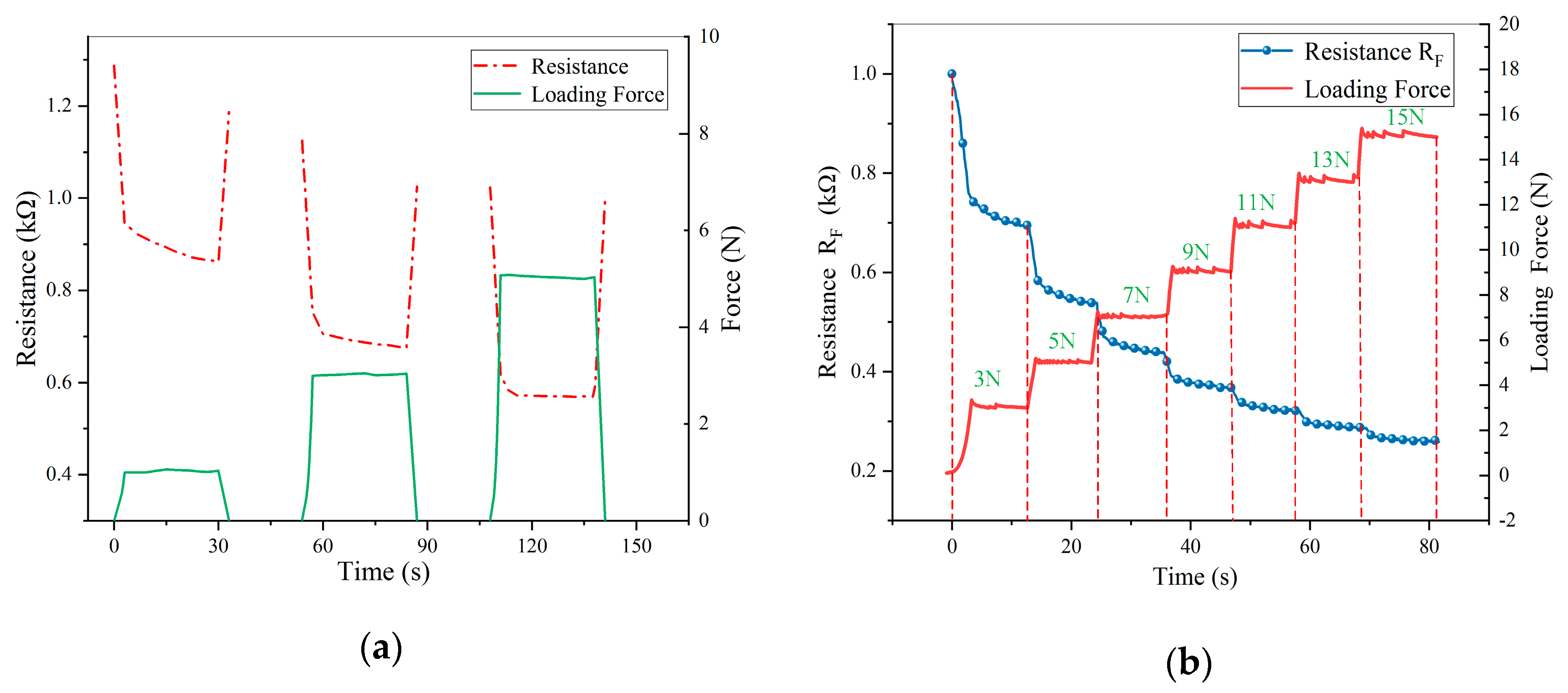

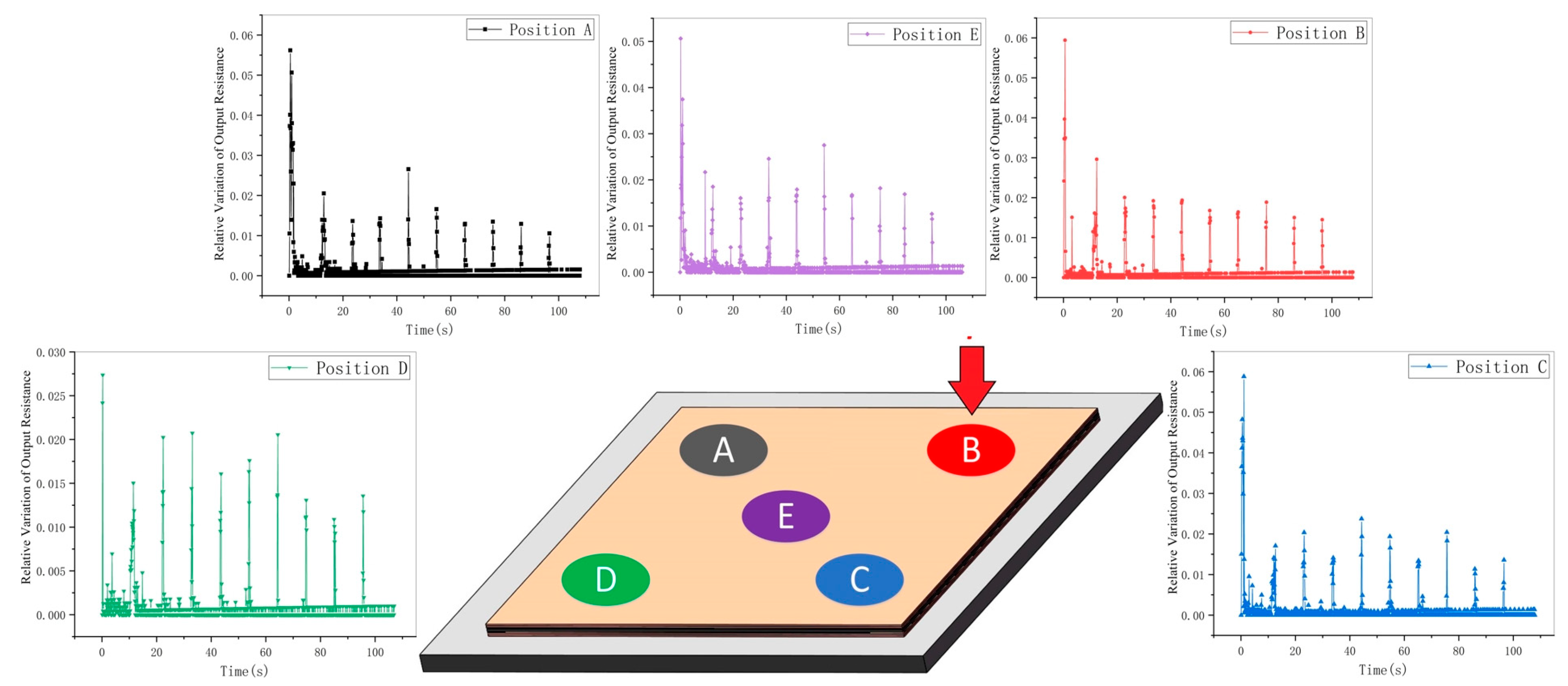

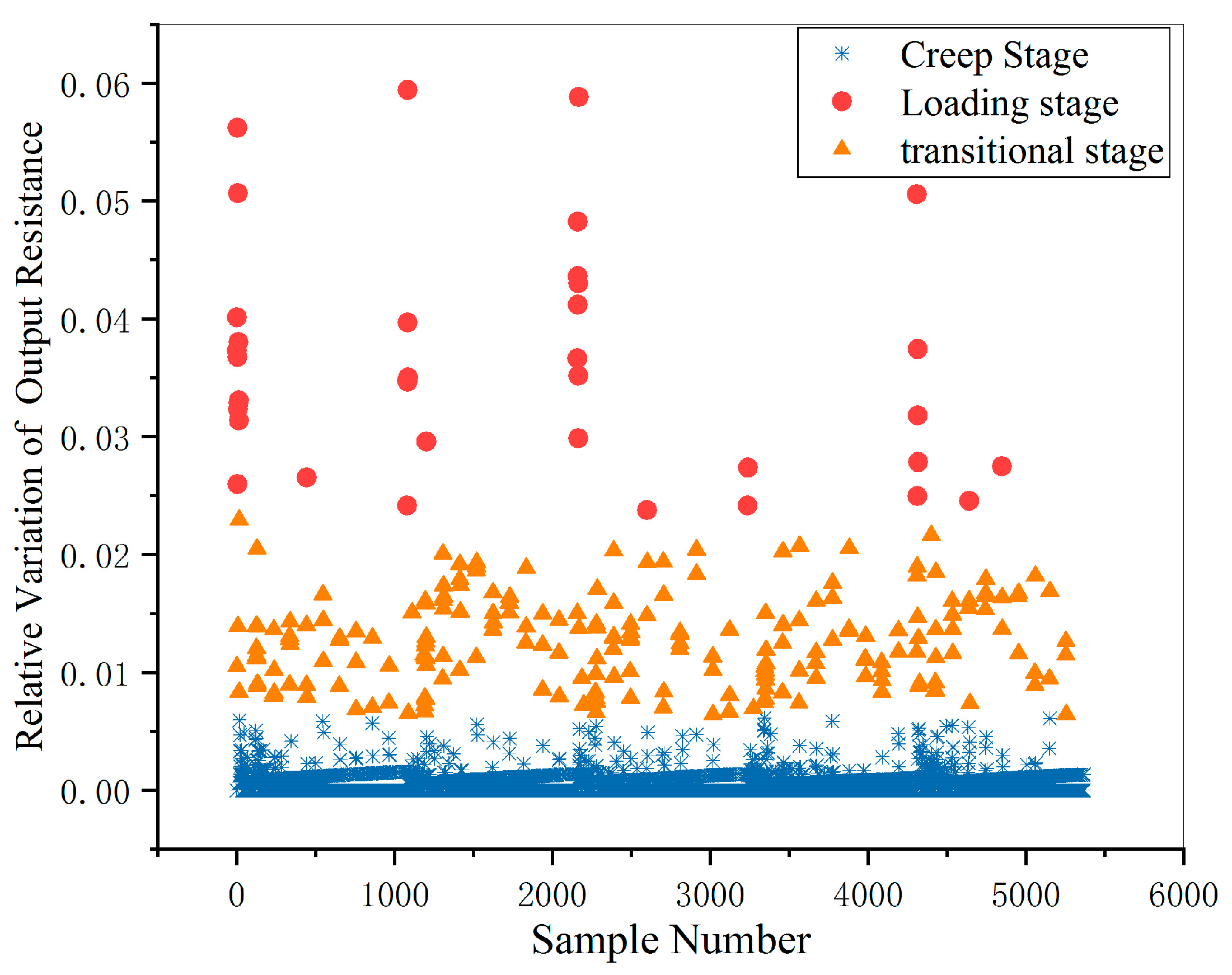

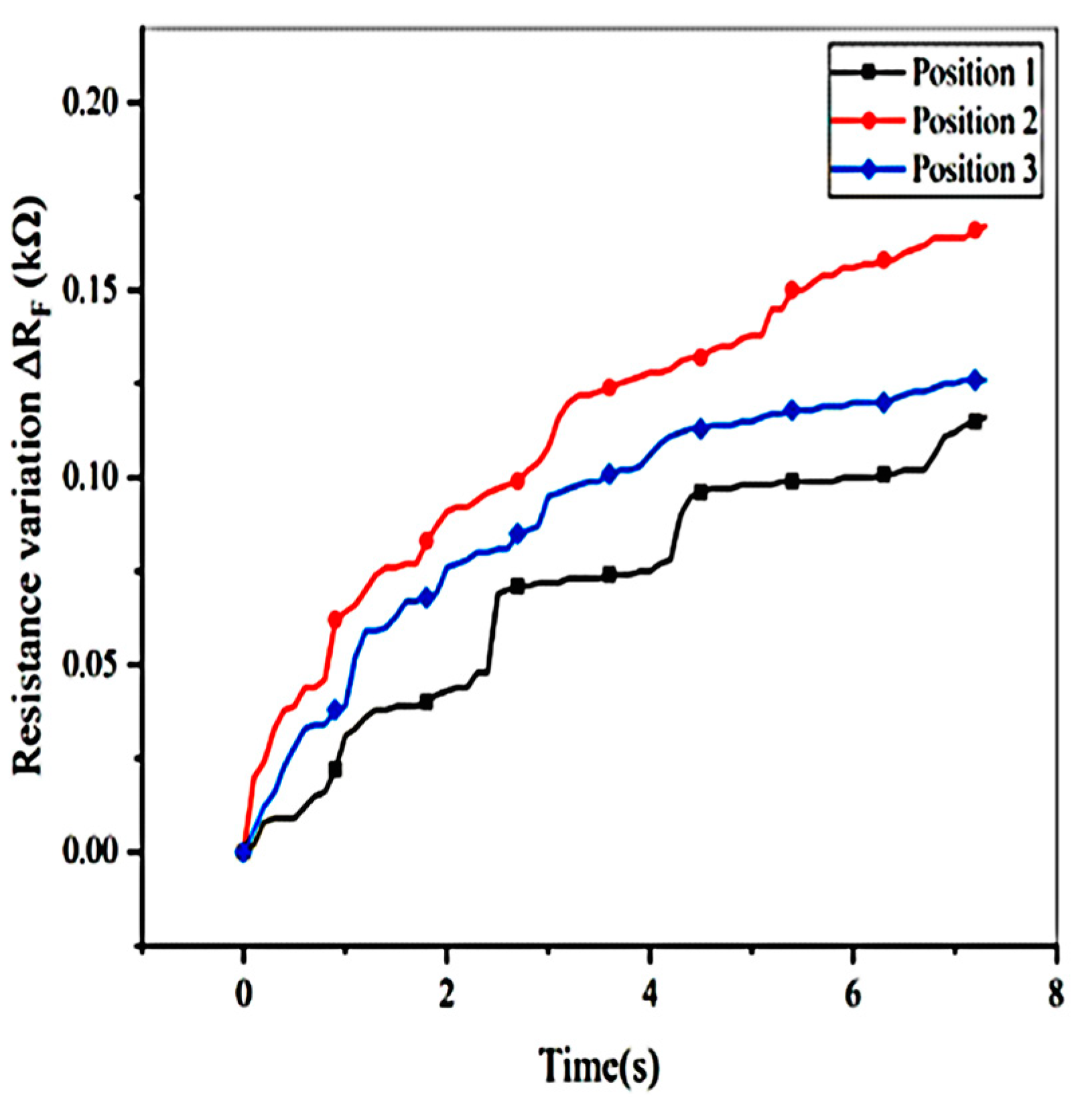

3.1. Creep Process Analysis

- (1)

- Loading/unloading stage: the resistance increases or decreases significantly.

- (2)

- Creep stage: when the loading force remains constant, the resistance decreases slowly.

- (3)

- Transitional stage: it closes to the junction of loading/unloading and creep stage, and represented by the circle in the following figure.

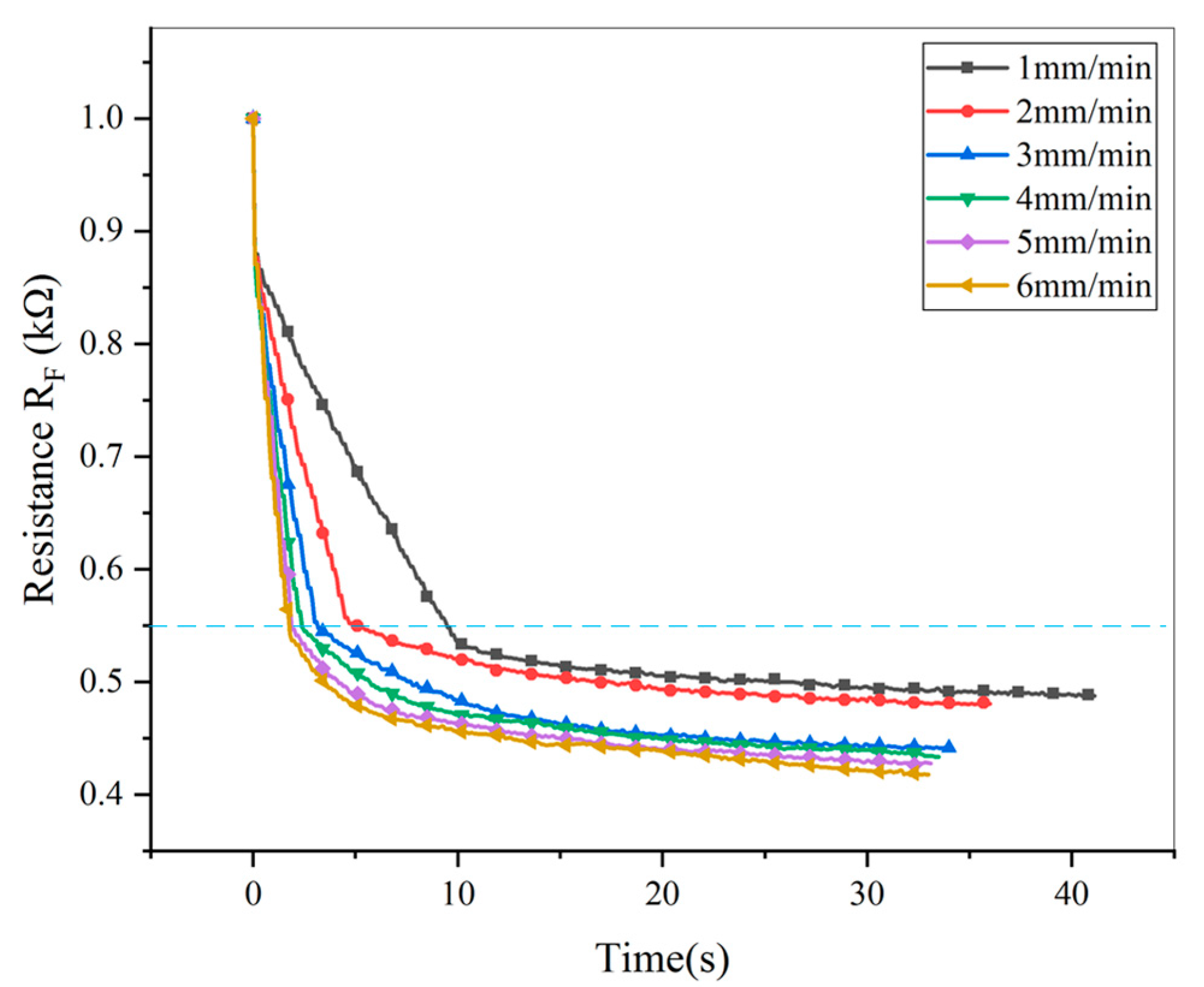

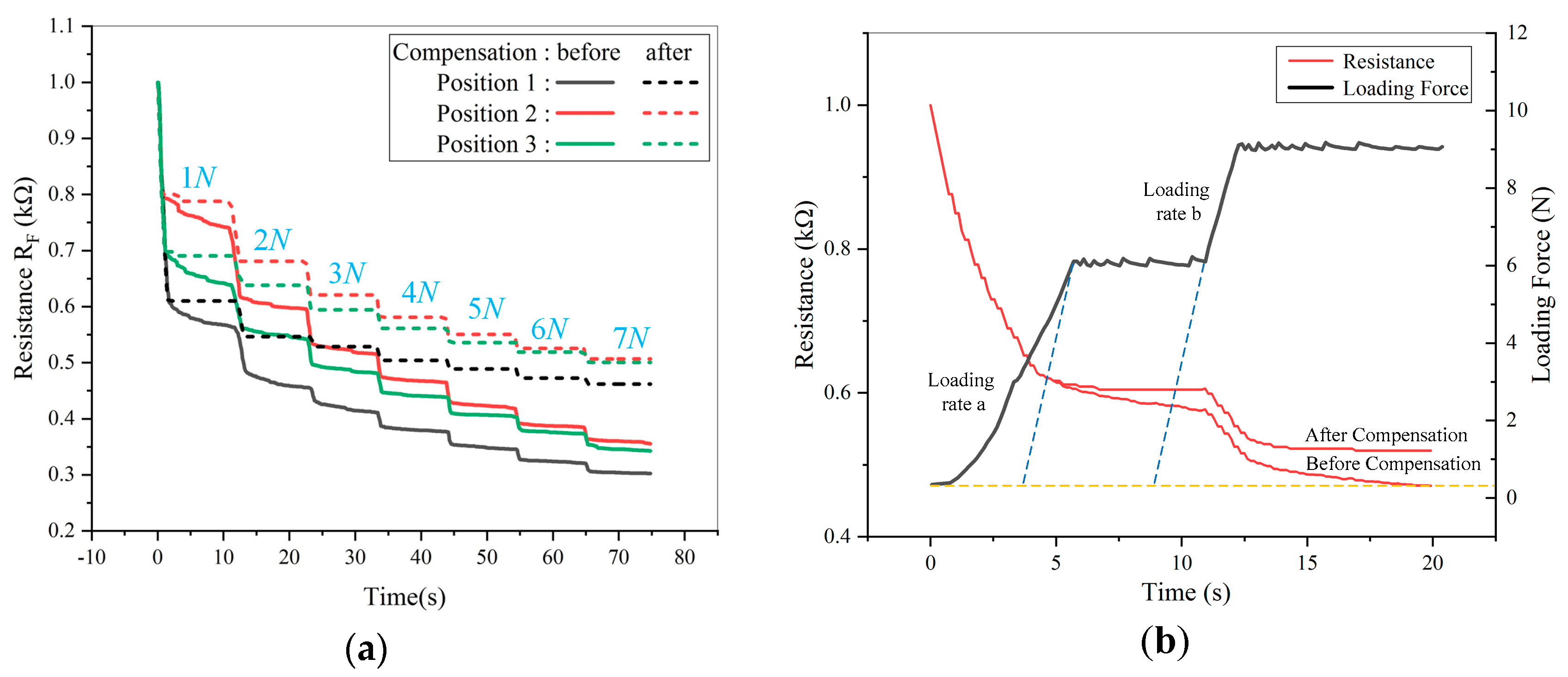

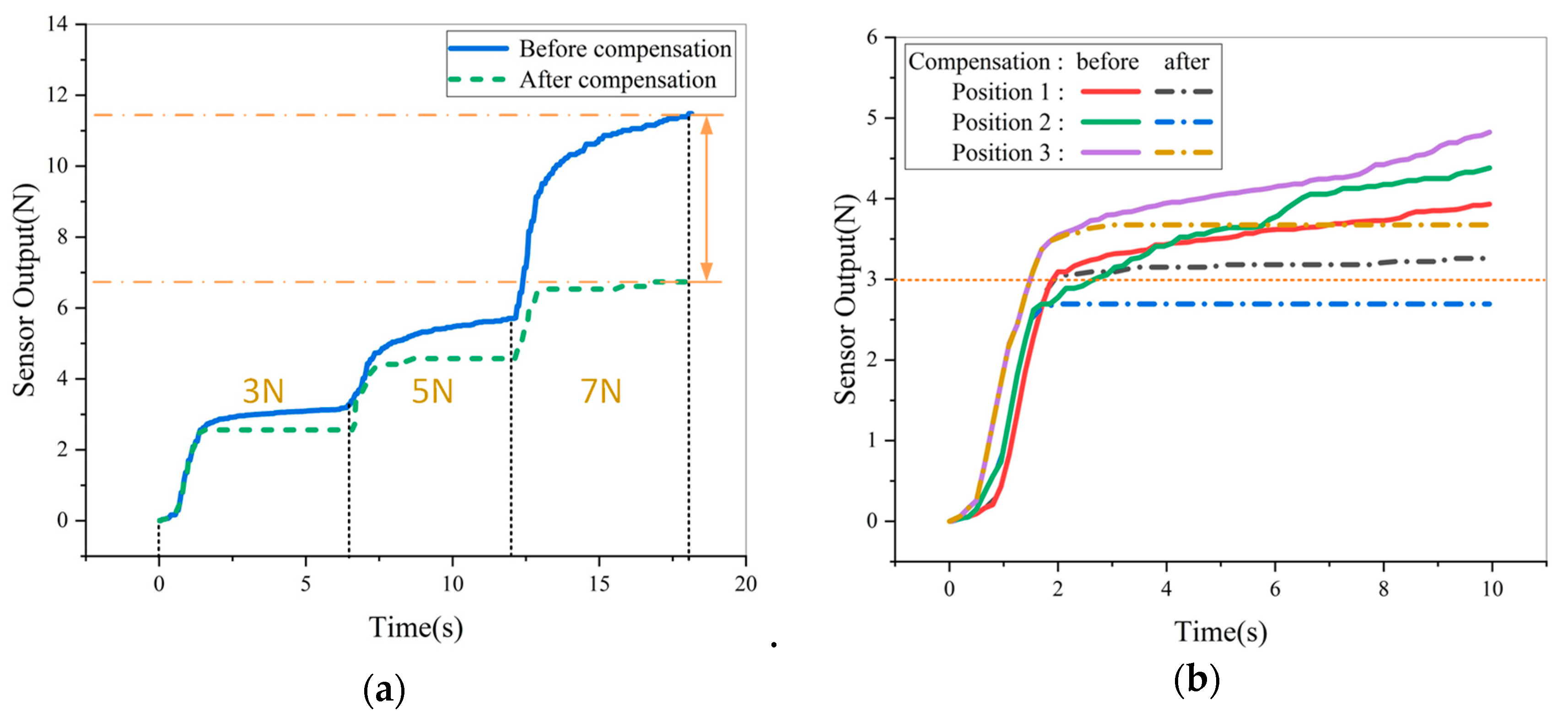

3.2. Creep Tracking Compensation

- (1)

- An incremental stepper force of 1 N to 7 N (at 1 N intervals) was applied to three random positions of the sensor. After each increase, the force was maintained for 10 s.

- (2)

- The sensor central position was selected to be applied a force of 6 N firstly at a loading speed of a. When reaching to 6 N, the force remained constant for 5 s. Then, the force was increased continuously to 9 N at a loading speed of b, and remained it for a period of time.

- (3)

- 5 N single loading was applied to a random position of the sensor.

- (4)

- An incremental stepper force of 1 N to 10 N (at 1 N intervals) was applied to the position which is same as the position of experiment (3). After each increase, the force was maintained for 10 s.

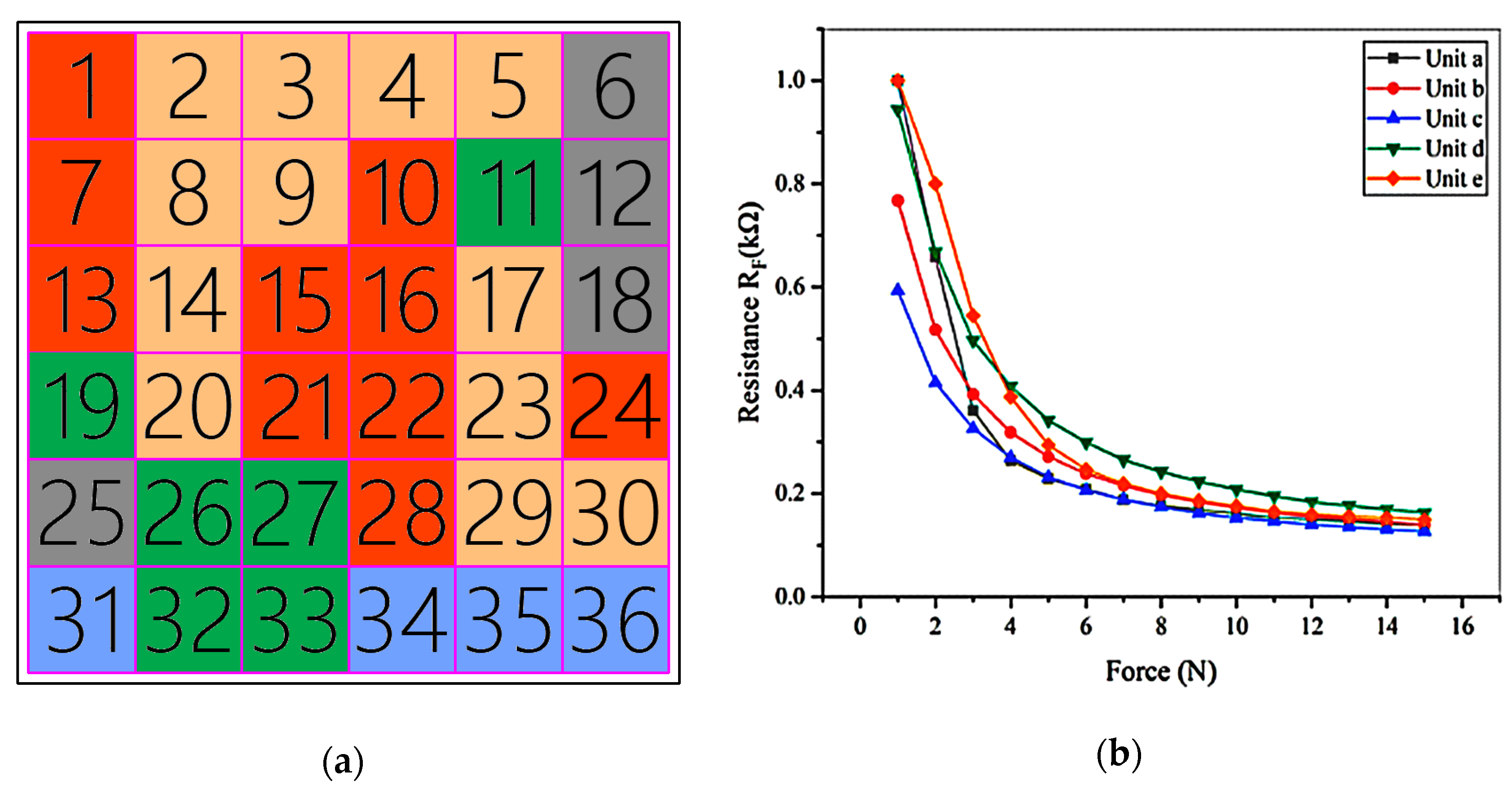

4. Fusion and Calibration for Piezoresistive Units

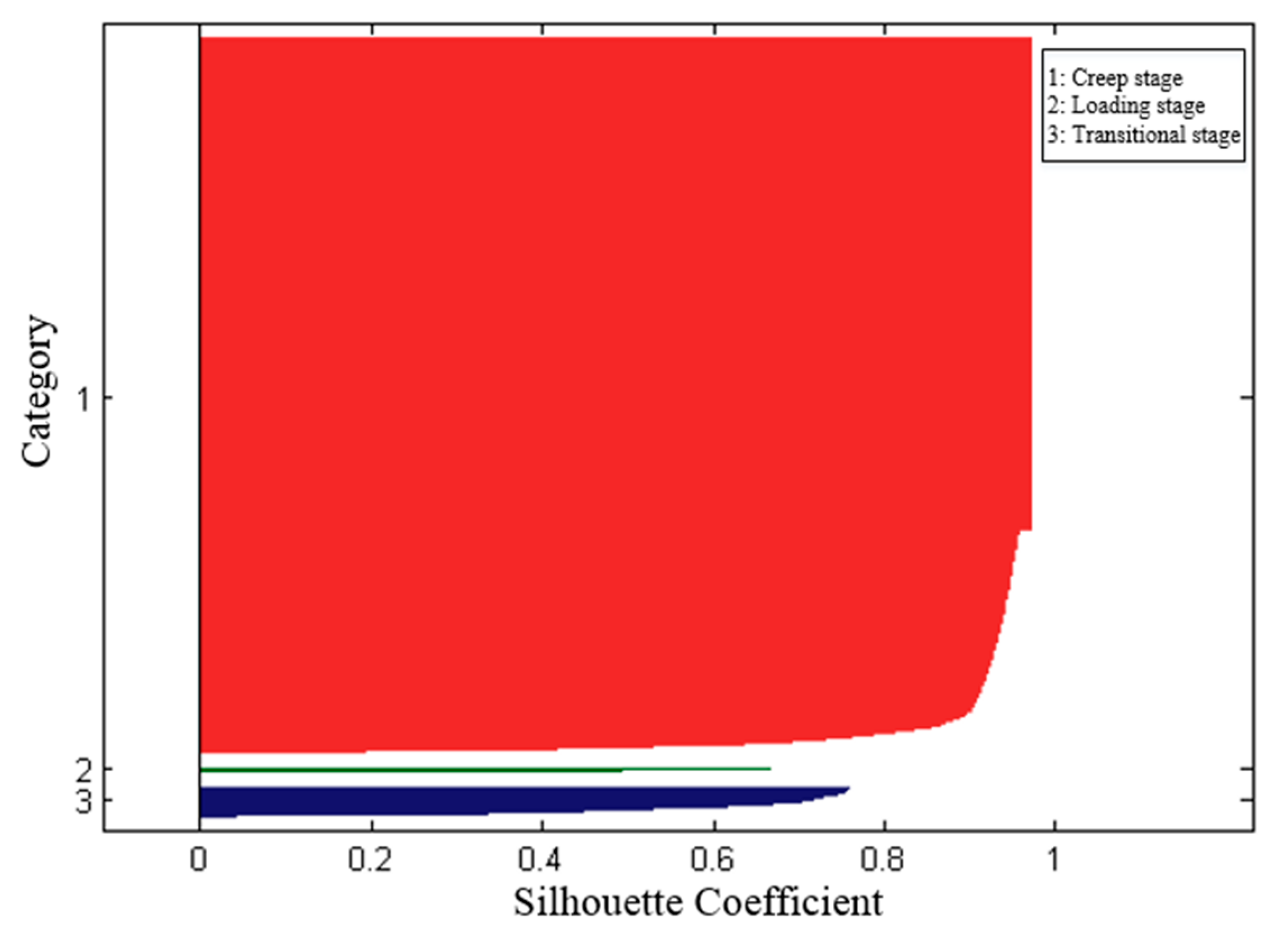

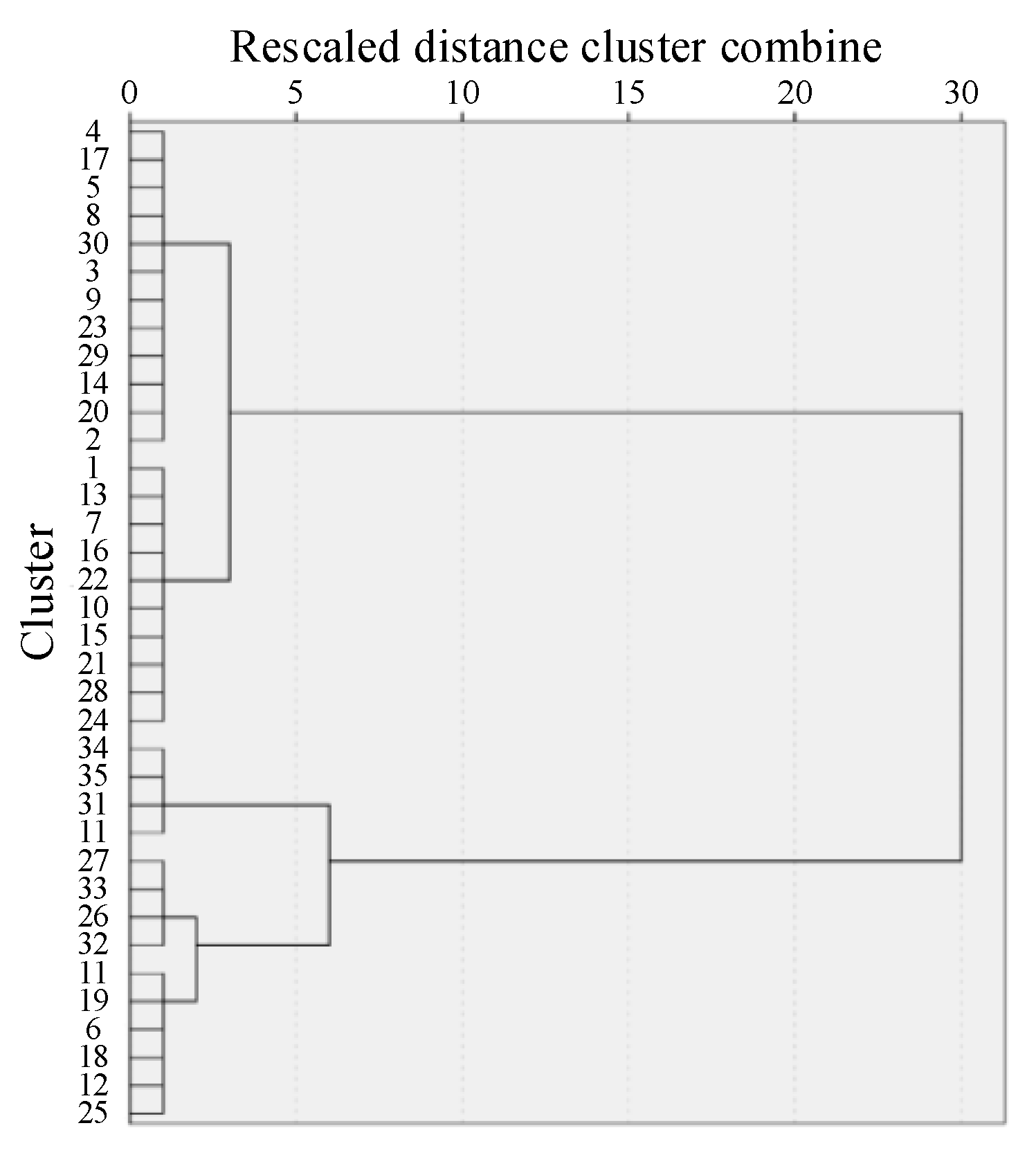

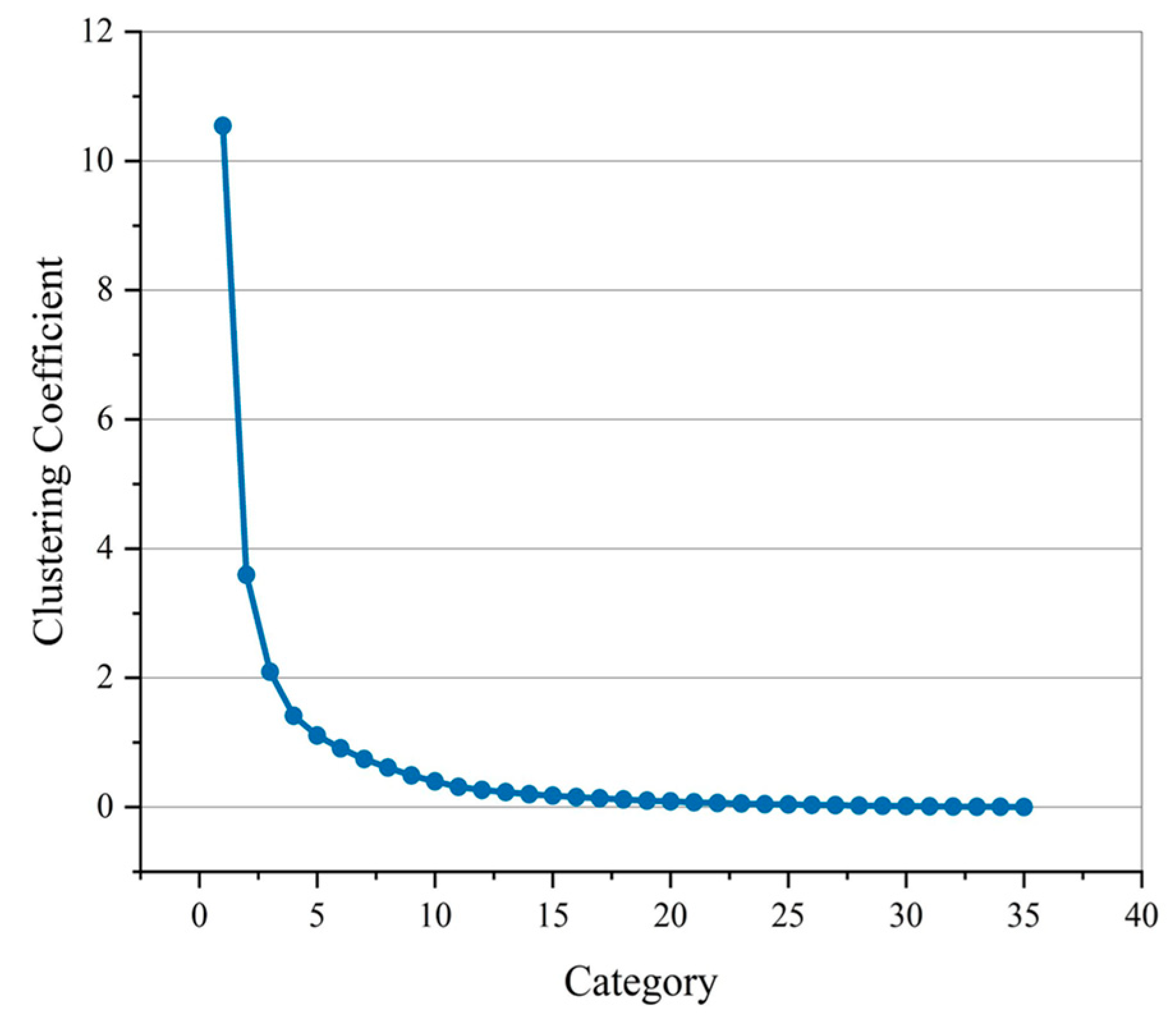

4.1. Clustering Analysis of Sensing Units

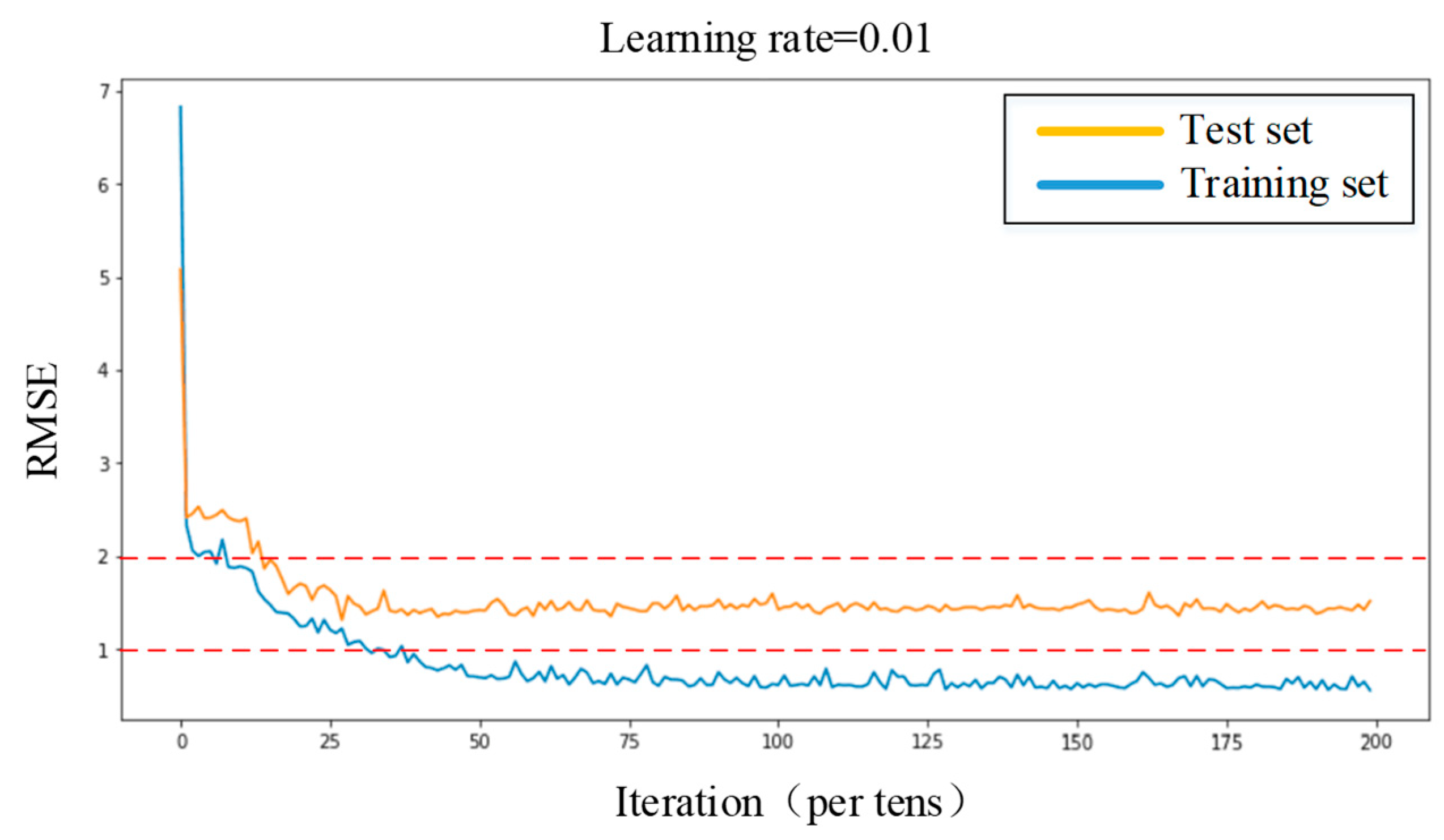

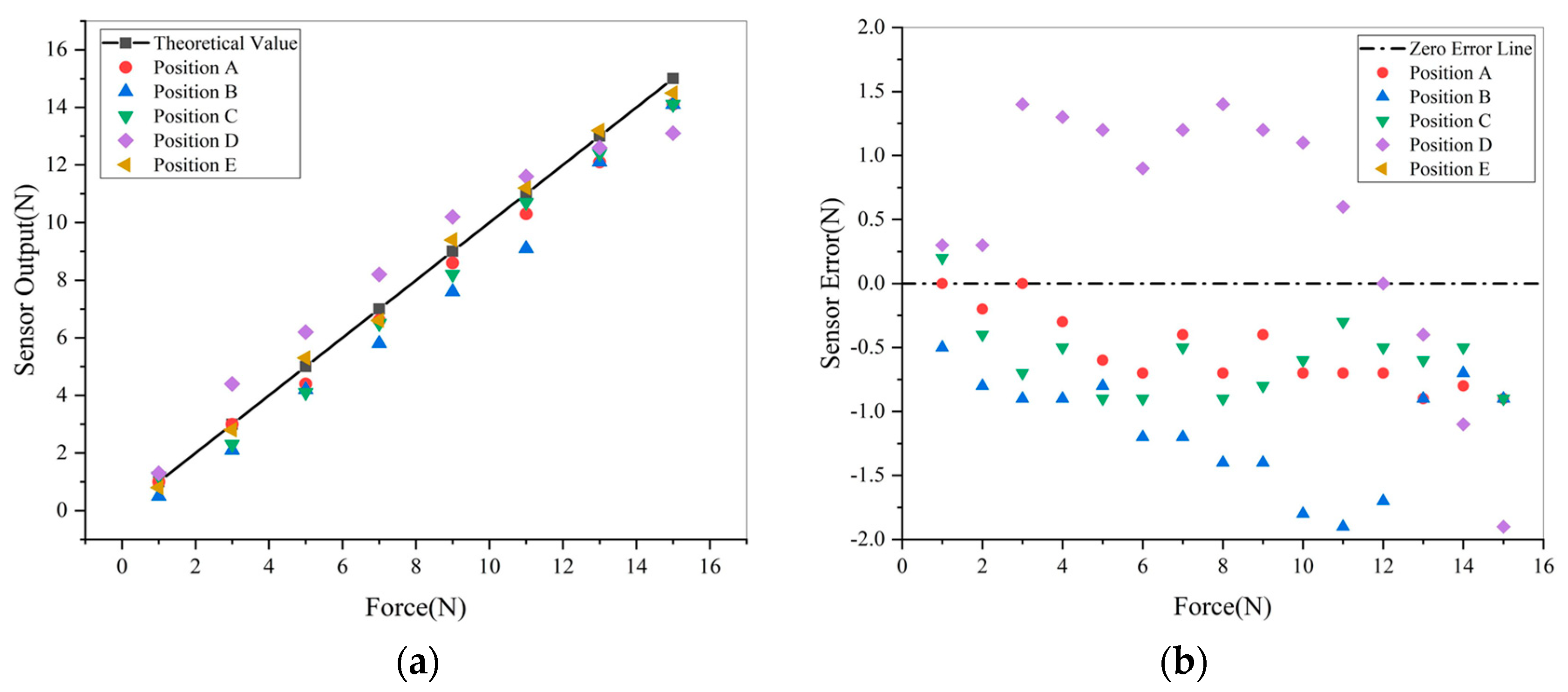

4.2. Force Calibration

5. Experiments

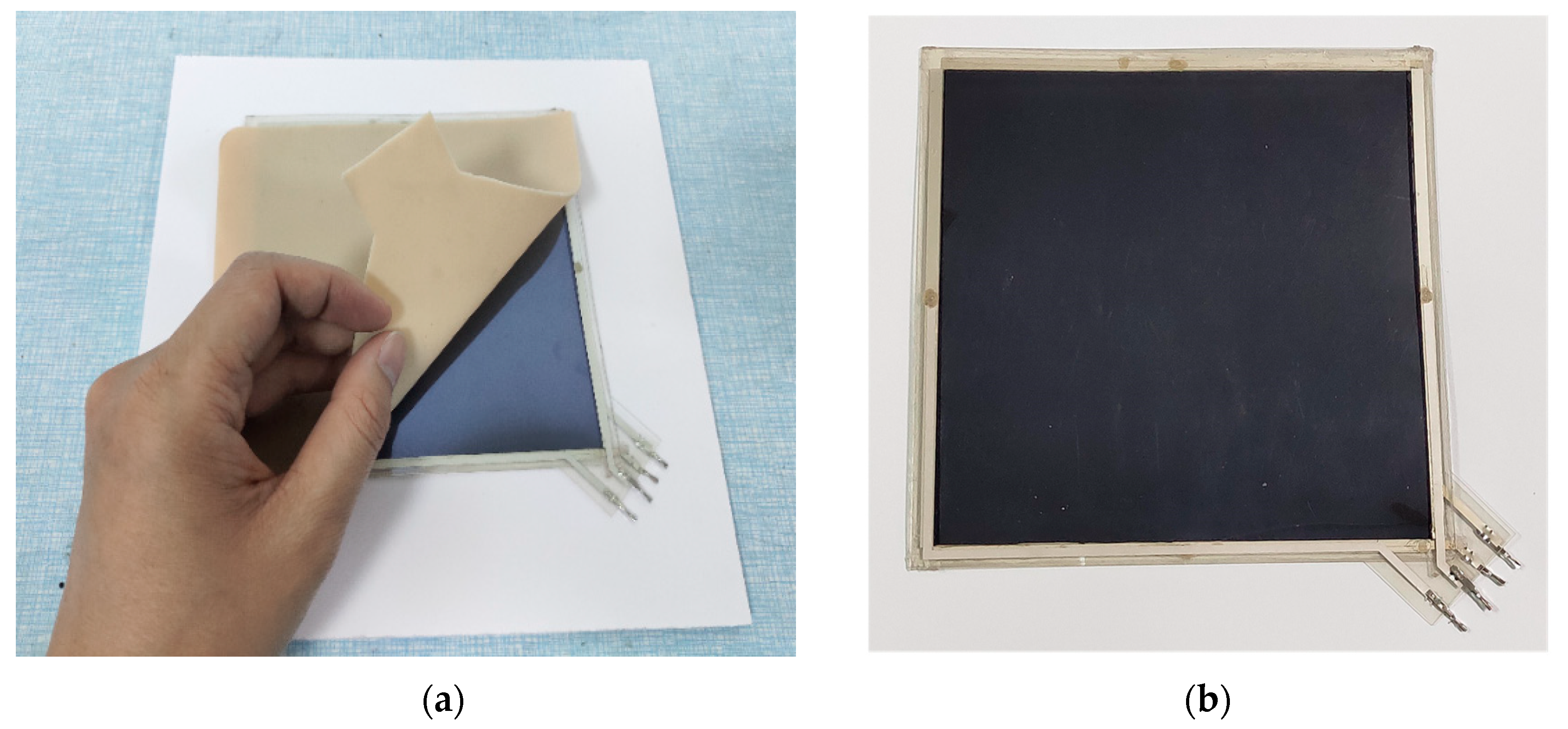

5.1. Design and Fabrication of Sensor

5.2. the Creep and Inconsistence Test for Piezoresistive Film

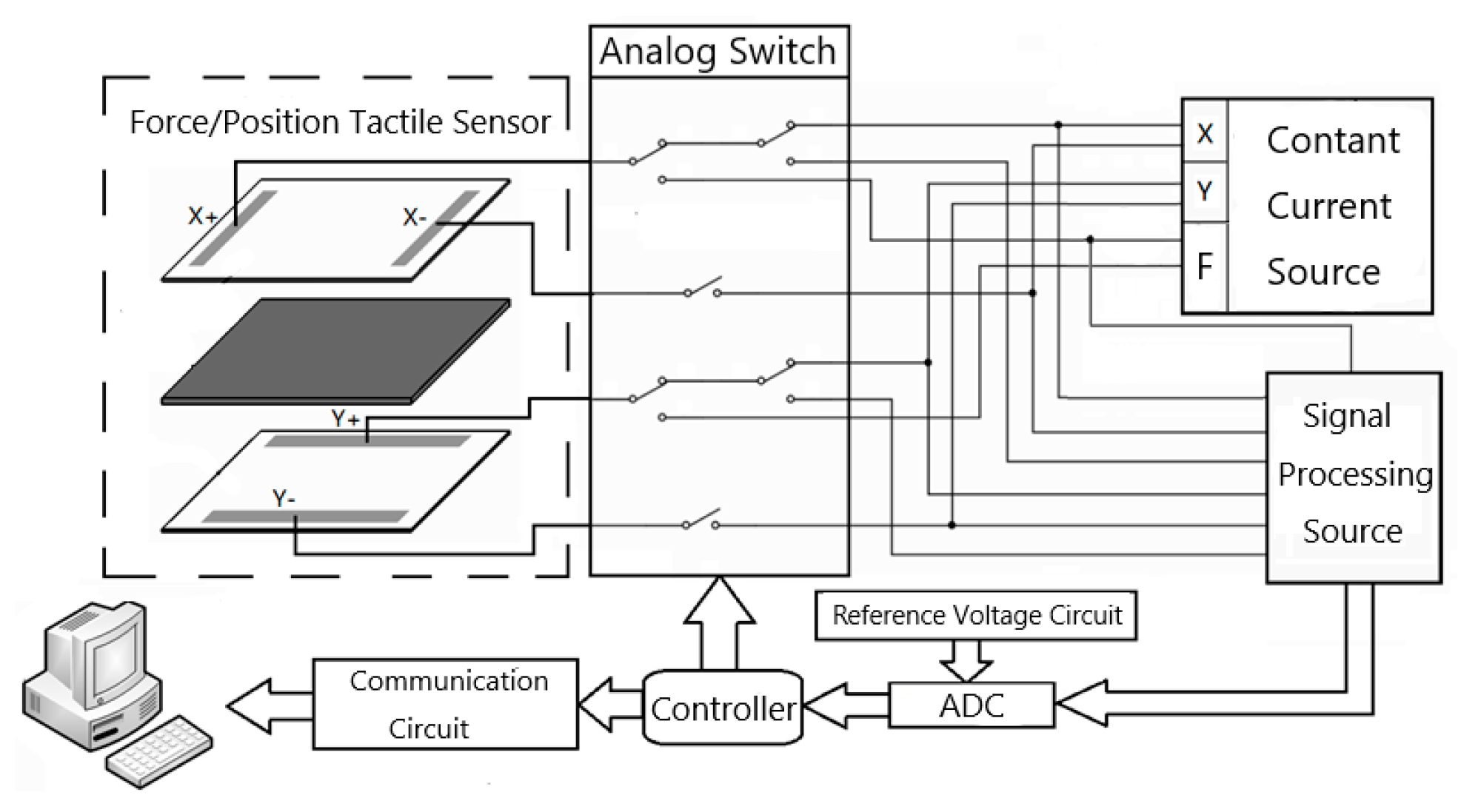

5.3. Detection Circuit

- (1)

- The sensor’s lead wires are connected with corresponding analog switch. The controller controls the analog switch to connect different detection channels and exciting sources cyclically.

- (2)

- The sensor’s output signals are amplified and filtered by the signal processing circuit. Then, they are input into corresponding A/D conversion ports respectively.

- (3)

- The controller uploads the quantized data to the host computer for the algorithm calibration through the serial port. Ultimately, the contact position and force can be calculated and shown on PC.

5.4. Pressing Experiment after Calibration

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shan, L.; Bimbo, J.; Dahiya, R.; Liu, H. Robotic tactile perception of object properties: A review. Mechatronics 2017, 48, 54–67. [Google Scholar]

- Lederman, S.; Klatzky, R. Haptic perception: A tutorial. Atten. Percept. Psychophys. 2009, 71, 1439–1459. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.; Kwak, S. In Feel Me If You Can: The Effect of Robot Types and Robot’s Tactility Types on Users’ Perception toward a Robot. In Proceedings of the Companion of the 2017 ACM/IEEE International Conference on Human-Robot Interaction, Vienna, Austria, 3–4 March 2017. [Google Scholar]

- Shimojo, M.; Namiki, A.; Ishikawa, M.; Makino, R.; Mabuchi, K. A Tactile Sensor Sheet Using Pressure Conductive Rubber with Electrical-Wires Stitched Method. IEEE Sens. J. 2004, 4, 589–596. [Google Scholar] [CrossRef]

- Bugmann, G.; Pan, Z.; Zhu, Z. Flexible full-body tactile sensor of low cost and minimal output connections for service robot. Ind. Robot 2005, 32, 485–491. [Google Scholar]

- Yang, Y.J.; Cheng, M.Y.; Chang, W.Y.; Tsao, L.C.; Yang, S.A.; Shih, W.P.; Chang, F.Y.; Chang, S.H.; Fan, K.C. An integrated flexible temperature and tactile sensing array using PI-copper films. Sens. Actuators A Phys. 2008, 143, 143–153. [Google Scholar] [CrossRef]

- Engel, J.; Chen, N.; Tucker, C.; Liu, C.; Kim, S.H.; Jones, D. Flexible Multimodal Tactile Sensing System for Object Identification. In Proceedings of the 2016 IEEE Conference on Sensors, Daegu, Korea, 22–25 October 2016. [Google Scholar]

- Luo, Y.; Xiao, Q.; Li, B. A Stretchable Pressure-Sensitive Array Based on Polymer Matrix. Sensors 2017, 17, 1571. [Google Scholar]

- Wang, H.; Zhou, D.; Cao, J. Development of a Skin-Like Tactile Sensor Array for Curved Surface. IEEE Sens. J. 2013, 14, 55–61. [Google Scholar] [CrossRef]

- Cheng, M.; Tsao, C.; Yang, Y. An anthropomorphic robotic skin using highly twistable tactile sensing array. In Proceedings of the 2010 IEEE Conference on Industrial Electronics & Applications, Taichung, Taiwan, 15–17 June 2010. [Google Scholar]

- Yao, A.; Yang, C.; Seo, K.; Soleimani, M. EIT-based fabric pressure sensing. Comput. Math. Methods Med. 2013, 4, 405325. [Google Scholar] [CrossRef]

- Lee, H.; Kwon, D.; Cho, H.; Park, I.; Kim, J. Soft Nanocomposite Based Multi-point, Multi-directional Strain Mapping Sensor Using Anisotropic Electrical Impedance Tomography. Sci. Rep. 2017, 7, 39837. [Google Scholar] [CrossRef] [PubMed]

- Vidhate, S.; Chung, J.; Vaidyanathan, V.; Souza, N. Time dependent piezoresistive behavior of polyvinylidene fluoride/carbon nanotube conductive composite. Mater. Lett. 2009, 63, 1771–1773. [Google Scholar] [CrossRef]

- Ying, H.; Xiulan, F.; Min, W.; Panfeng, H.; Yunjian, G. Research on Nano-SiO2/Carbon Black Composite for Flexible Tactile Sensing. In Proceedings of the 2007 IEEE International Conference on Information Acquisition (ICIA’07), Seogwipo-si, Korea, 8–11 July 2007; pp. 260–264. [Google Scholar]

- Wang, P.; Ding, T. Creep of electrical resistance under uniaxial pressures for carbon black–silicone rubber composite. J. Mater. Sci. 2010, 45, 3595–3601. [Google Scholar] [CrossRef]

- Almassr, A.; Wan, Z.; Hasan, W.; Ahmad, S. Self-Calibration Algorithm for a Pressure Sensor with a Real-Time Approach Based on an Artificial Neural Network. Sensors 2018, 18, 2561. [Google Scholar] [CrossRef] [PubMed]

- Ding, T.; Wang, L.; Peng, W. Changes in electrical resistance of carbon-black-filled silicone rubber composite during compression. J. Polym. Sci. Part B Polym. Phys. 2010, 45, 2700–2706. [Google Scholar] [CrossRef]

- Phan, K.L. Methods to correct for creep in elastomer-based sensors. In Proceedings of the 2008 IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 1119–1122. [Google Scholar]

- Hecht, N. Theory of the backpropagation neural network. In Proceedings of the International Joint Conference on Neural Networks, Washington, DC, USA, 18–22 June 1989; Volume 1, pp. 593–605. [Google Scholar]

- Wu, H.; Chen, J.; Su, Y.; Li, Z.; Ye, J. New tactile sensor for position detection based on distributed planar electric field. Sens. Actuators A Phys. 2016, 242, 146–161. [Google Scholar] [CrossRef]

- Ye, J.; Chen, J.; Wang, H.; Wu, H. A New Flexible Tactile Sensor for Contact Position Detection Based on Refraction of Electric Field Lines. Sens. Mater. 2018, 30, 1953–1975. [Google Scholar] [CrossRef]

- Wu, H.; Wang, H.; Huang, J.; Zhang, Y.; Ye, J. A flexible annular sectorial sensor for detecting contact position based on constant electric field. Micromachines 2018, 9, 309. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Ye, J.; Wang, H.; Huang, S.; Wu, H. A Flexible Tactile Sensor with Irregular Planar Shape Based on Uniform Electric Field. Sensors 2018, 18, 4445. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, J.; Lin, Z.; You, J.; Huang, S.; Wu, H. Inconsistency Calibrating Algorithms for Large Scale Piezoresistive Electronic Skin. Micromachines 2020, 11, 162. https://doi.org/10.3390/mi11020162

Ye J, Lin Z, You J, Huang S, Wu H. Inconsistency Calibrating Algorithms for Large Scale Piezoresistive Electronic Skin. Micromachines. 2020; 11(2):162. https://doi.org/10.3390/mi11020162

Chicago/Turabian StyleYe, Jinhua, Zhengkang Lin, Jinyan You, Shuheng Huang, and Haibin Wu. 2020. "Inconsistency Calibrating Algorithms for Large Scale Piezoresistive Electronic Skin" Micromachines 11, no. 2: 162. https://doi.org/10.3390/mi11020162

APA StyleYe, J., Lin, Z., You, J., Huang, S., & Wu, H. (2020). Inconsistency Calibrating Algorithms for Large Scale Piezoresistive Electronic Skin. Micromachines, 11(2), 162. https://doi.org/10.3390/mi11020162