Random Error Reduction Algorithms for MEMS Inertial Sensor Accuracy Improvement—A Review

Abstract

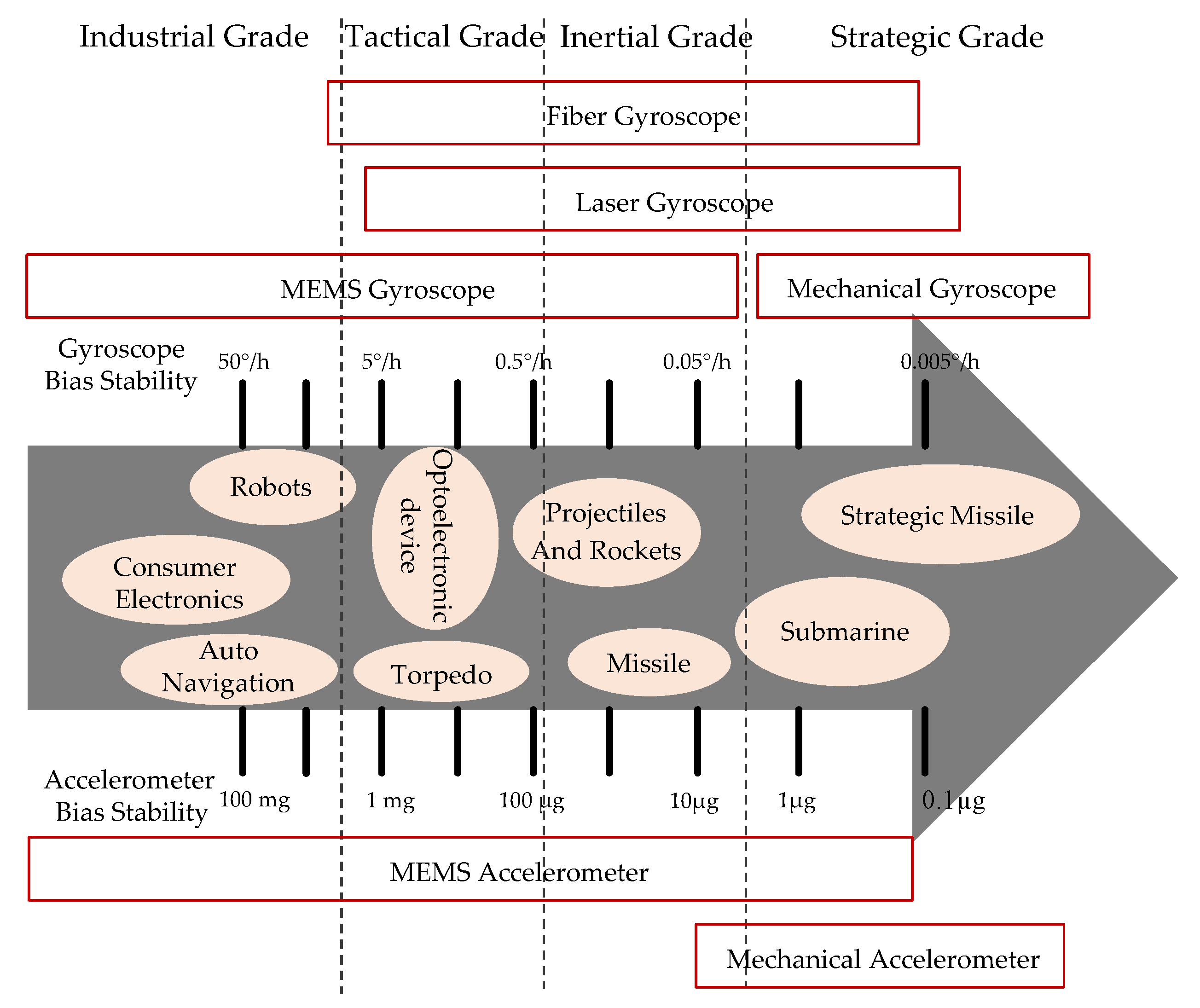

:1. Introduction

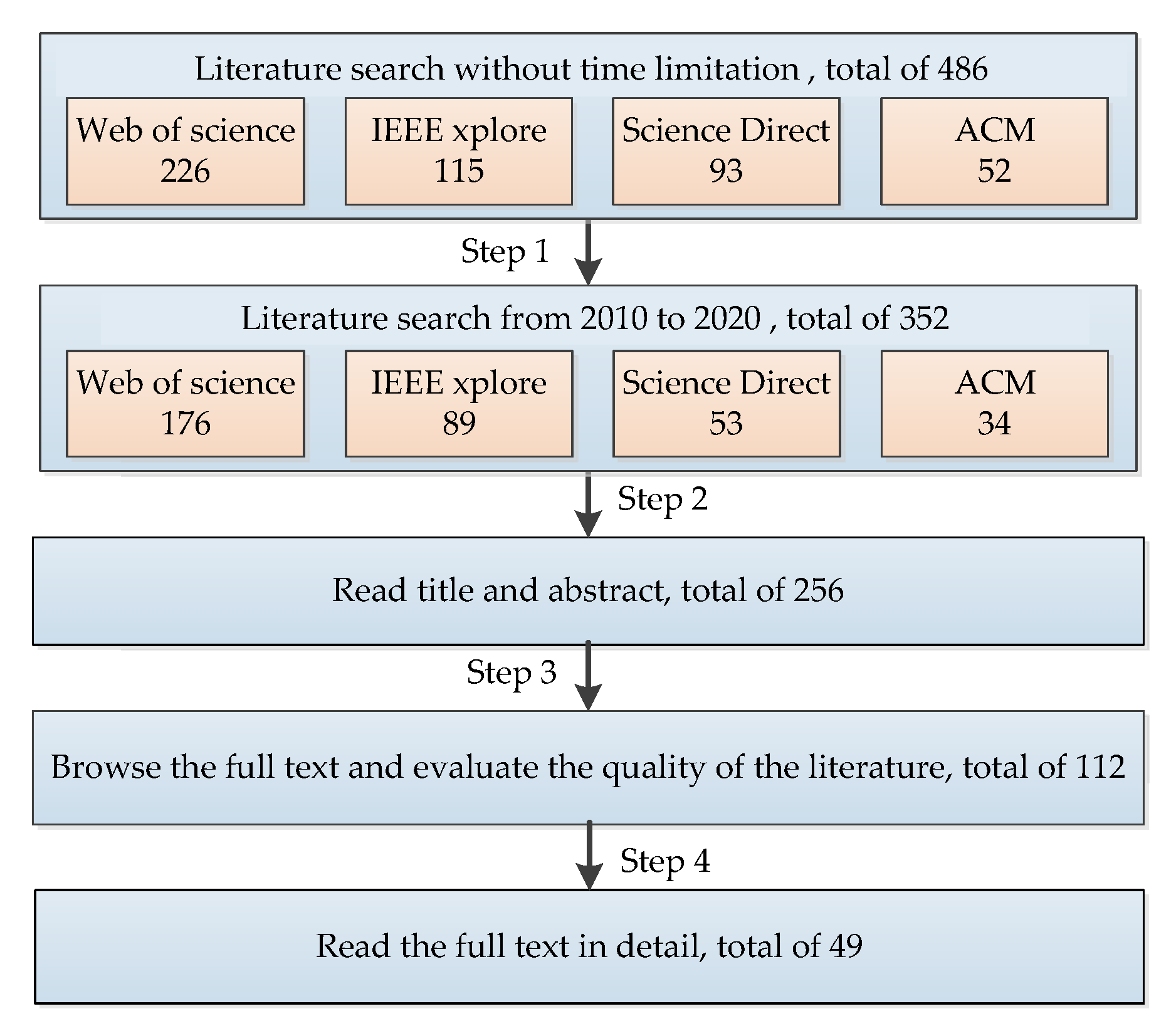

2. Materials and Methods

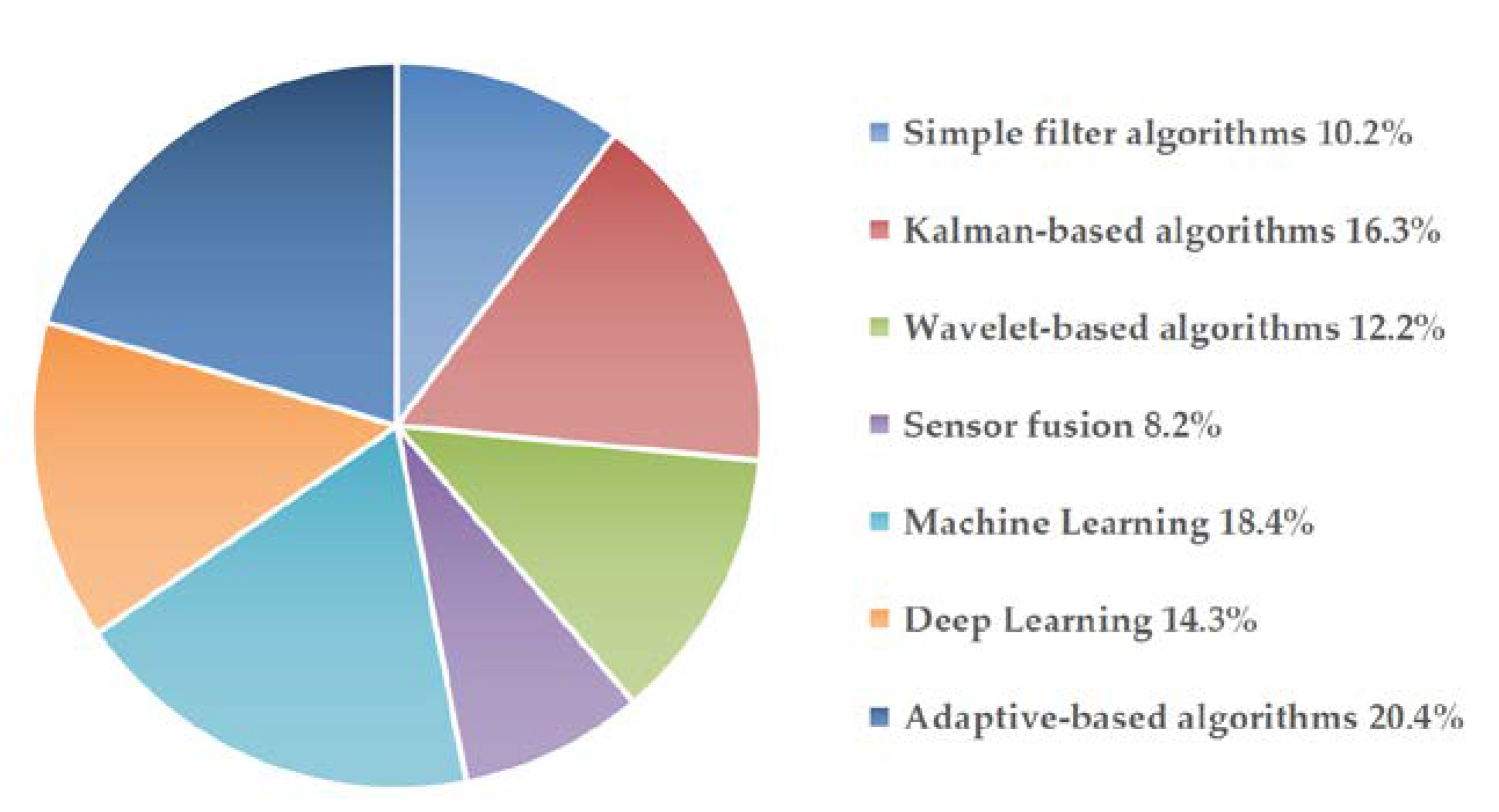

3. Results

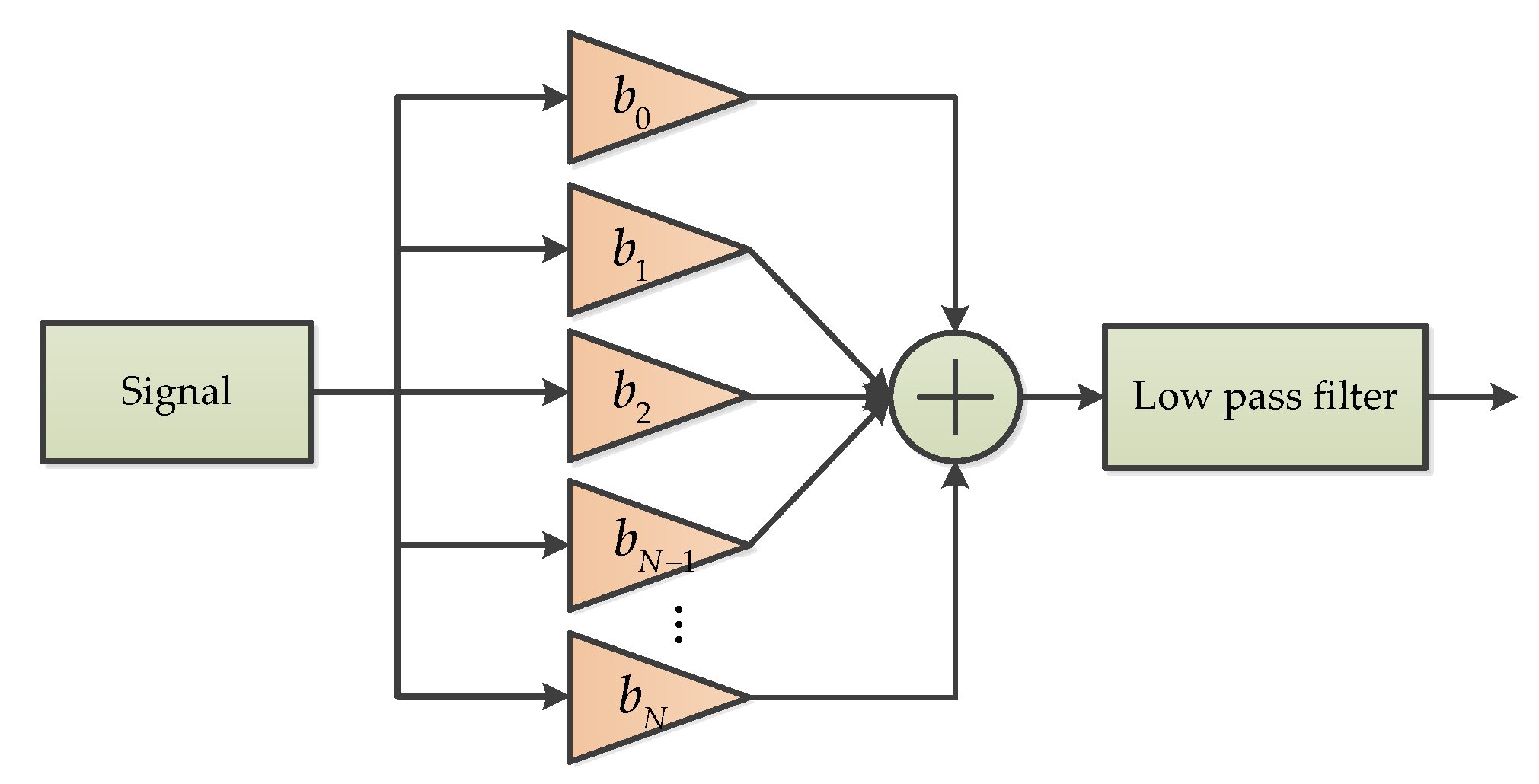

3.1. Simple Filter Algorithms

3.1.1. Fading Memory Filter (FMF)

3.1.2. Morphological Filter (MF)

3.1.3. Moving Average Filter (MAF)

3.1.4. Variable Bandwidth Filter (VBF)

3.2. Kalman-Based Algorithms

3.2.1. Kalman Filter (KF)

3.2.2. Extended Kalman Filter (EKF)

3.2.3. Incremental Kalman Filter (IKF)

3.2.4. Strong Tracking Kalman Filter (STKF)

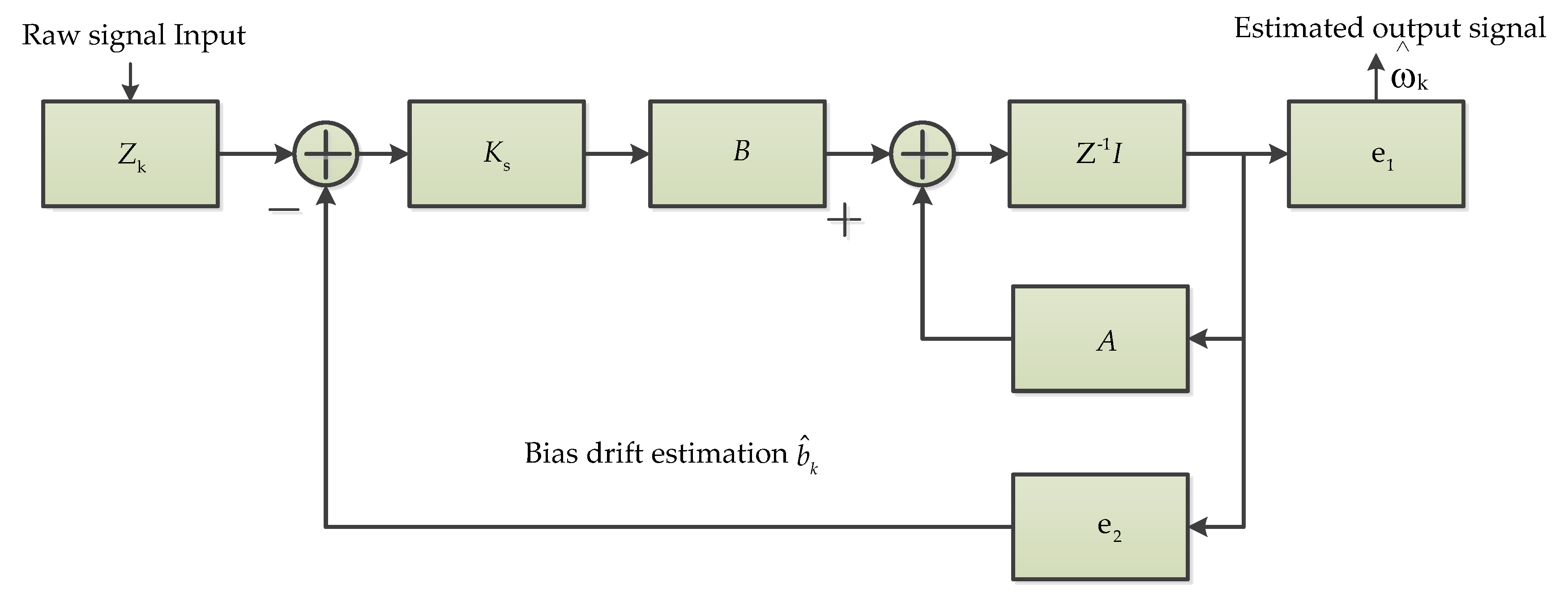

3.2.5. Discrete Time Kalman Filter (DTKF)

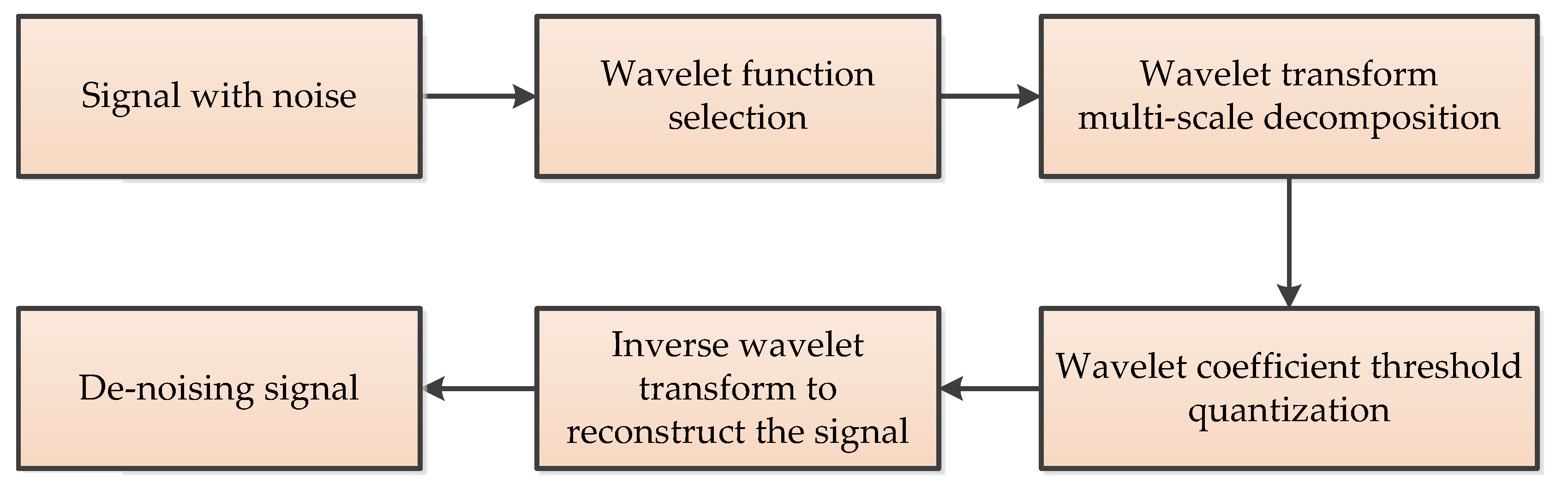

3.3. Wavelet-Based Algorithms

3.3.1. Wavelet Threshold (WT)

3.3.2. Improved Wavelet Threshold (IWT)

3.3.3. Adaptive Stationary Wavelet Threshold (ASWT)

3.3.4. EMD-Based Wavelet Threshold (EMD-WT)

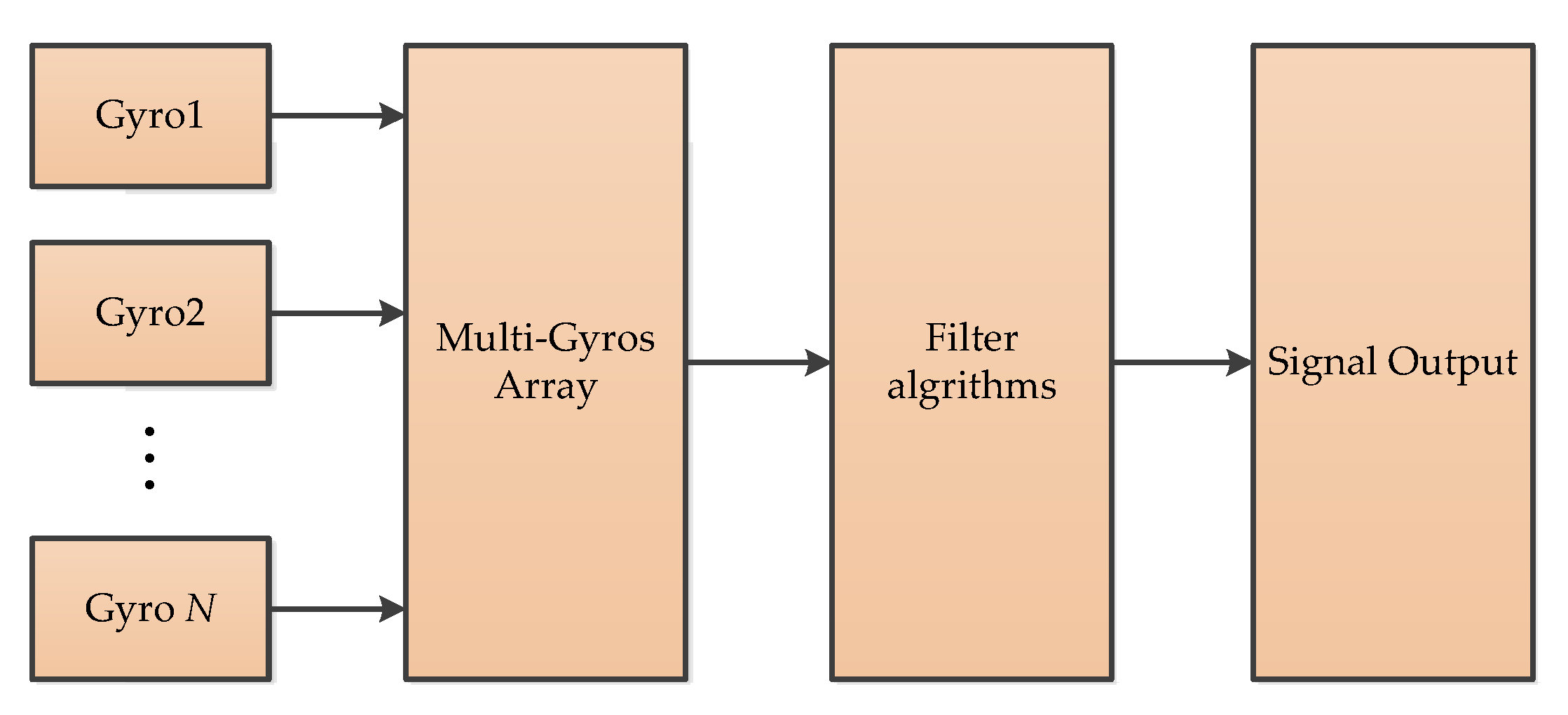

3.4. Sensor Fusion Algorithms

3.4.1. Virtual Gyroscope (VG)

3.4.2. Heterogeneous Fusion (HF)

3.4.3. Combination Sensors (CS)

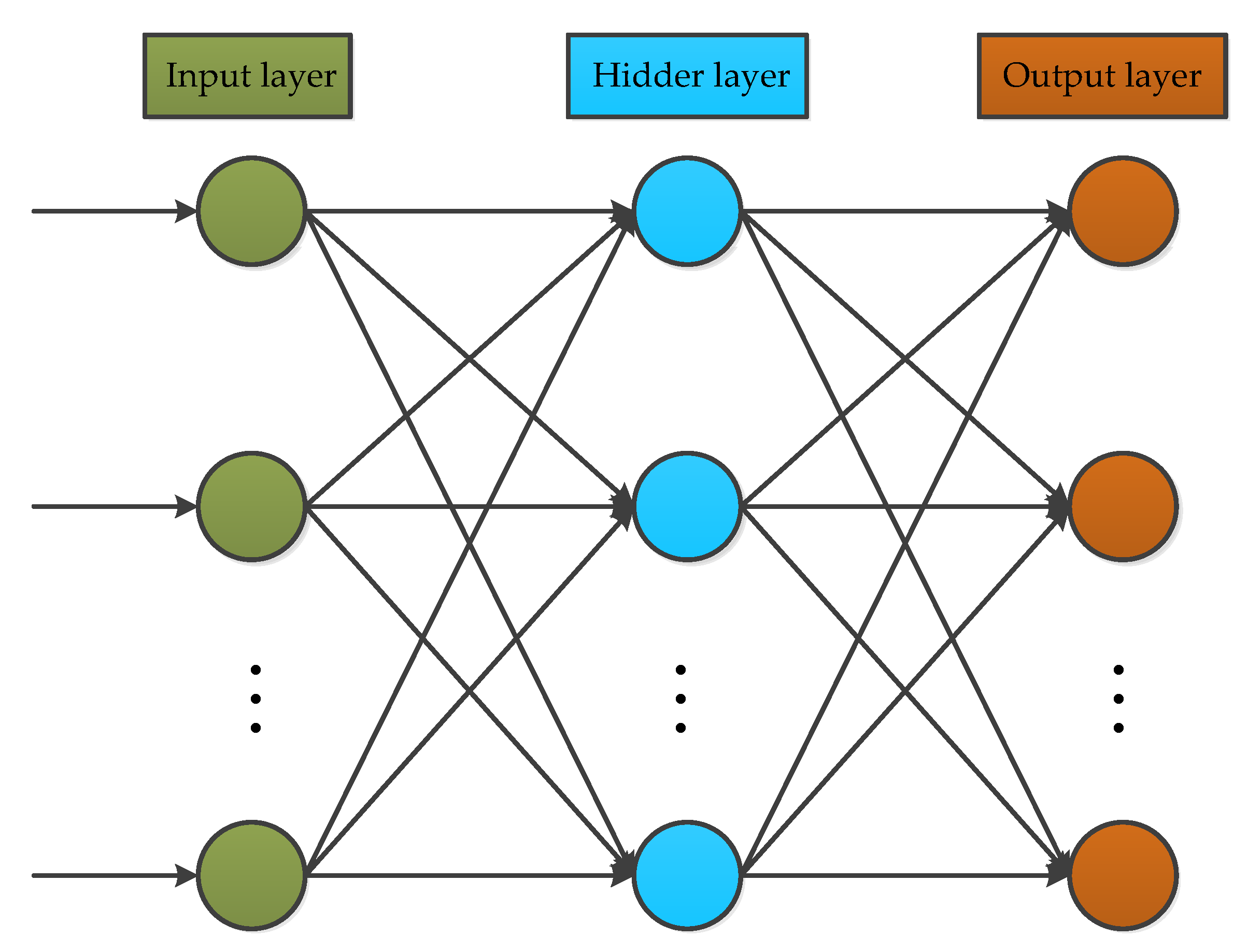

3.5. Machine Learning

3.5.1. Back Propagation Neural Network (BP)

3.5.2. Radial Basis Function Neural Network (RBF)

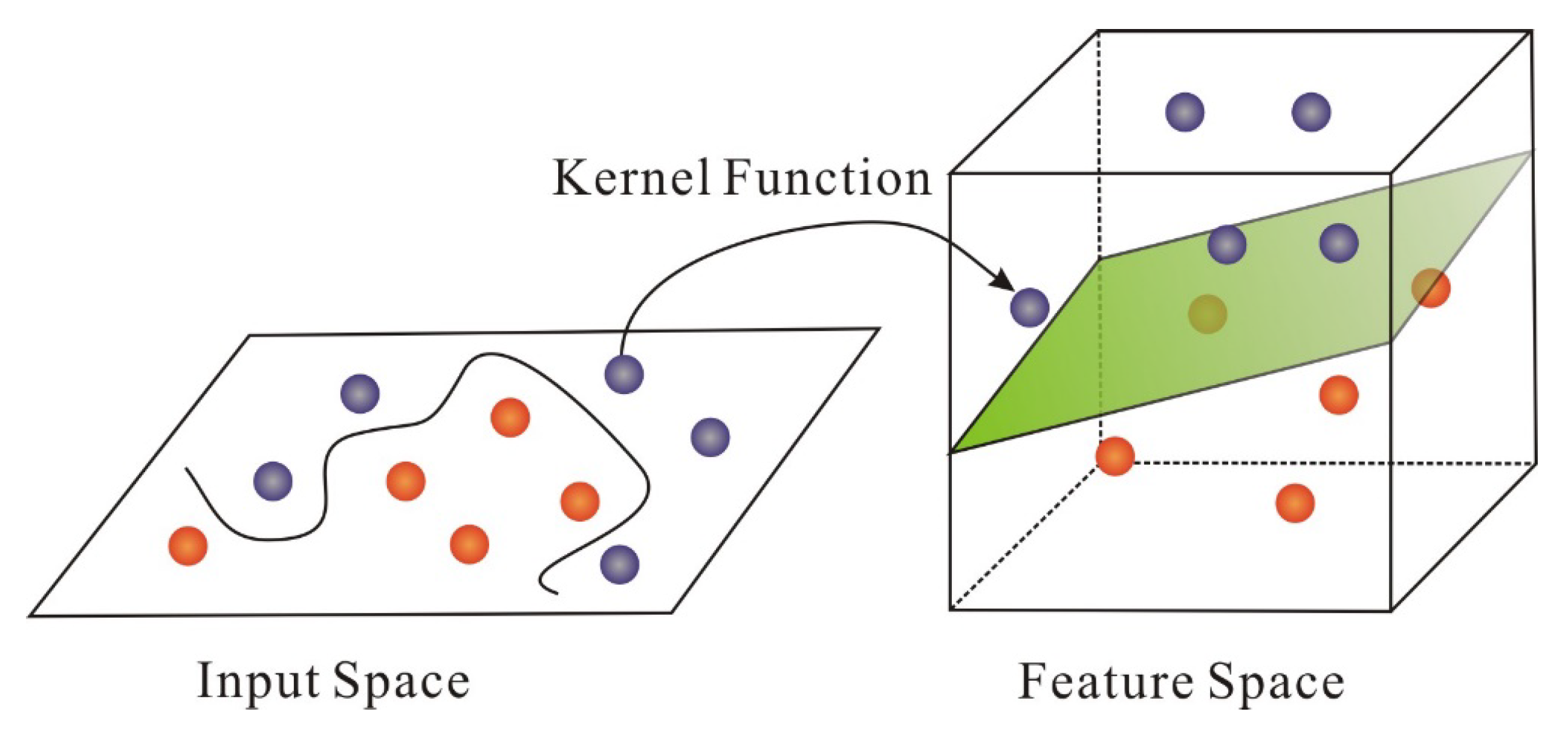

3.5.3. Support Vector Machine (SVM)

3.5.4. Relevance Vector Machine (RVM)

3.6. Deep Learning

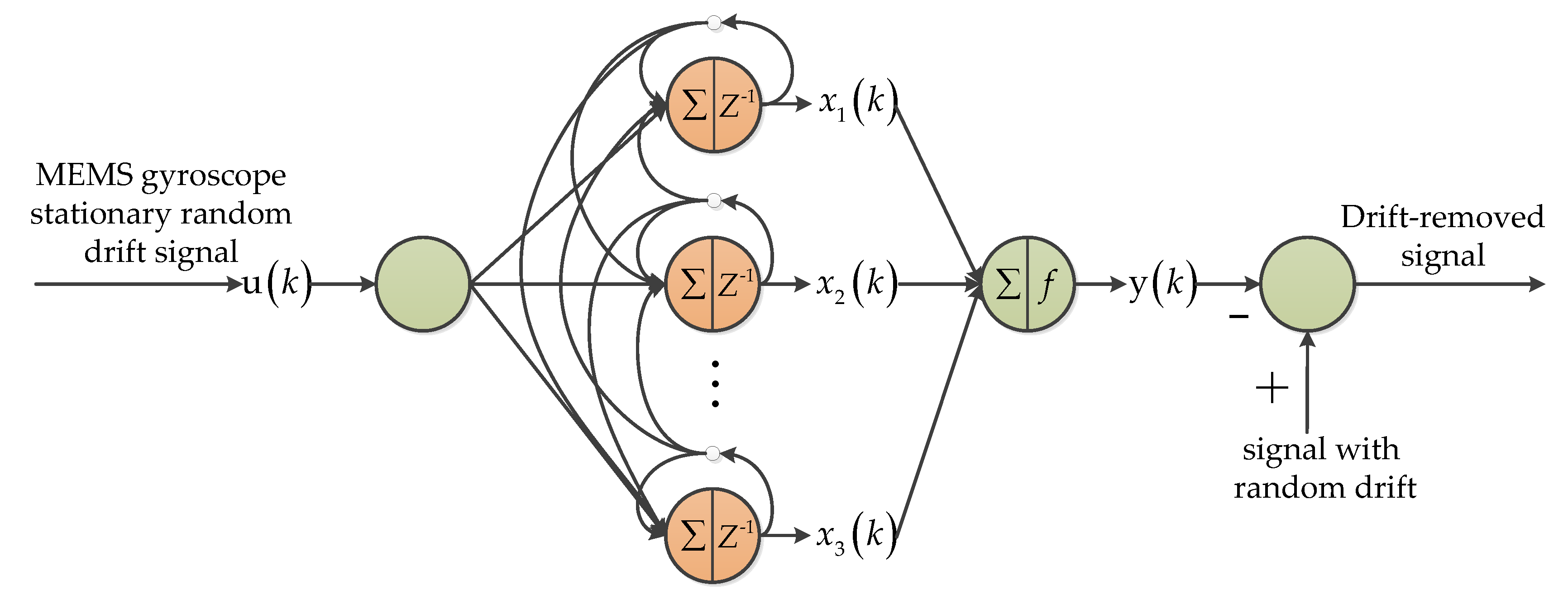

3.6.1. Wiener-Type Recurrent Neural Network (WRNN)

3.6.2. Neural Architecture Search Recurrent Neural Network (NAS-RNN)

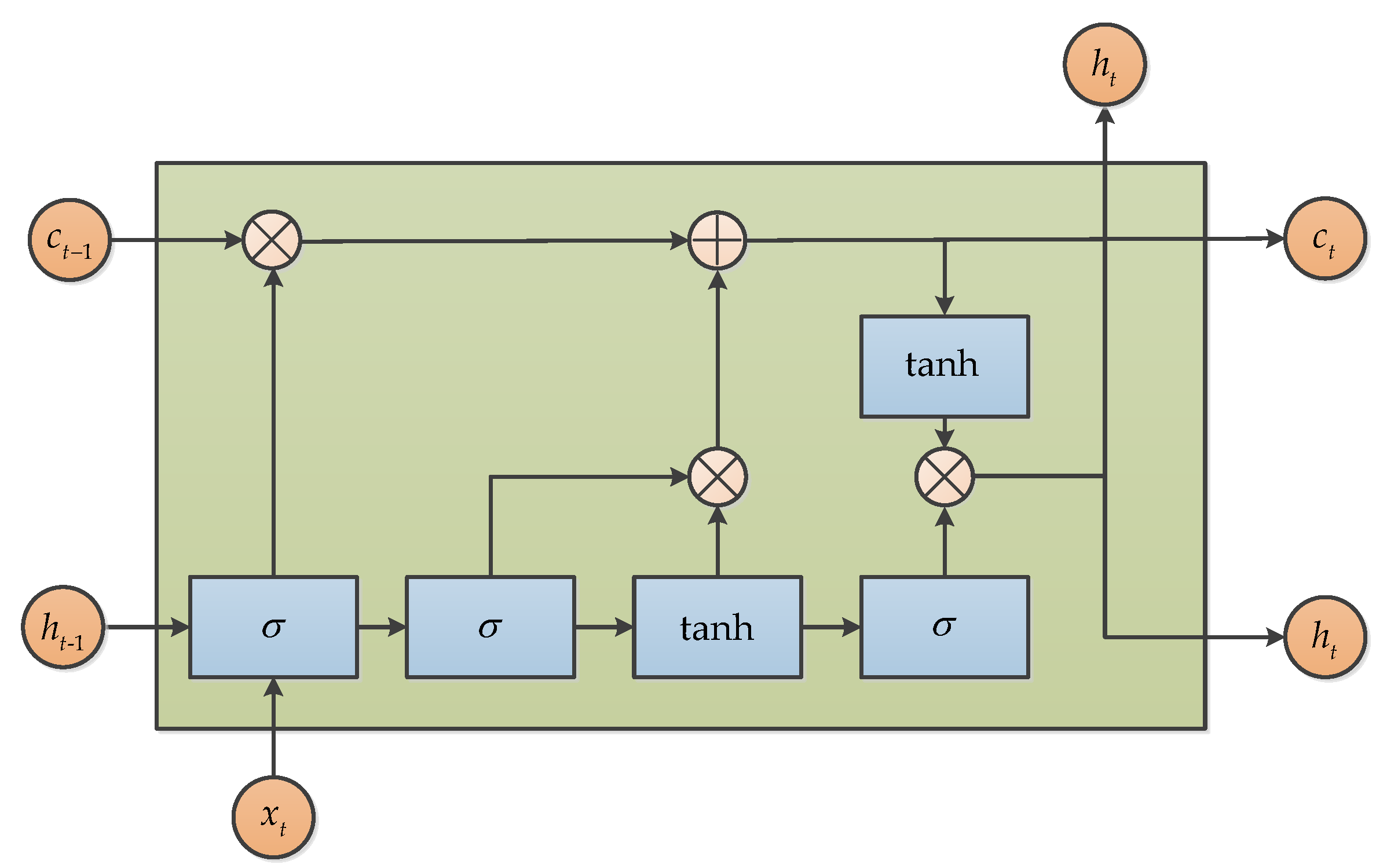

3.6.3. Long Short Term Memory (LSTM)

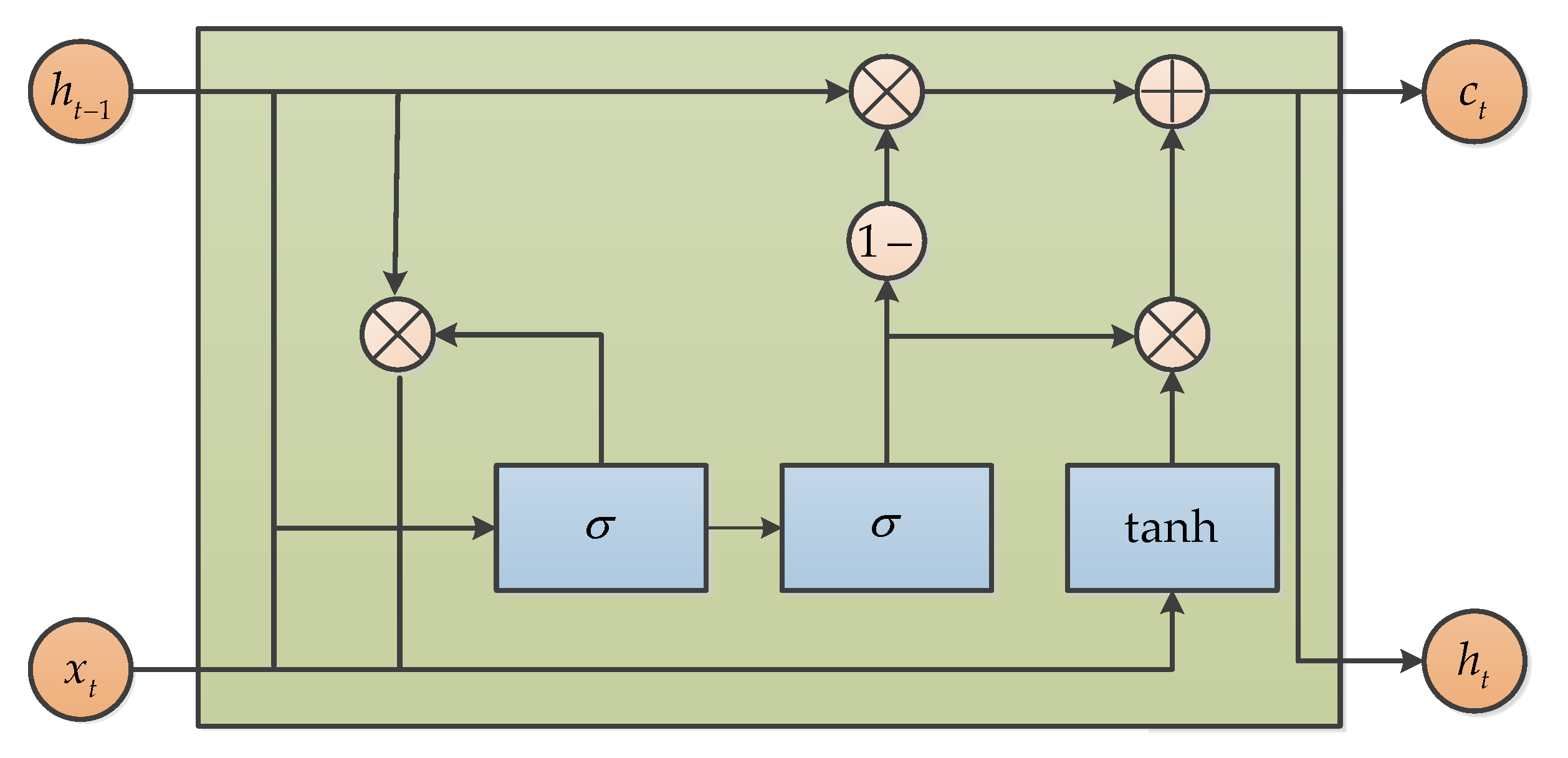

3.6.4. Gate Recurrent Unit (GRU)

3.6.5. Simple Recurrent Unit (SRU)

3.7. Adaptive-Based Algorithms

3.7.1. Recursive Least Squares (RLS)

3.7.2. Least Mean Squares (LMS)

3.7.3. Adaptive Sliding Mode Controller (ASMC)

3.7.4. Adaptive Kalman Filter (AKF)

3.7.5. Adaptive Filtering Based on Dynamic Variance Model (AF-DVM)

3.8. Comparative Analysis of Existing Algorithms

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, F.X.; Liang, Y. Analysis and design of the system of a total digital Si-gyroscope. Int. J. Mod. Phys. B 2017, 31, 1741008. [Google Scholar] [CrossRef]

- Li, X.Y.; Hu, J.P.; Liu, X.W. A High-Performance Digital Interface Circuit for a High-Q Micro-Electromechanical System Accelerometer. Micromachines 2018, 9, 675. [Google Scholar] [CrossRef] [Green Version]

- Aydemir, G.A.; Saranli, A. Characterization and calibration of MEMS inertial sensors for state and parameter estimation applications. Measurement 2012, 45, 1210–1225. [Google Scholar] [CrossRef]

- Geen, J.A.; Sherman, S.J.; Chang, J.F.; Lewis, S.R. Single-chip surface micromachined integrated gyroscope with 50 degrees/h allan deviation. IEEE J. Solid-State Circuits 2002, 37, 1860–1866. [Google Scholar] [CrossRef]

- Shih, W.L.; Jean, F.K. A CMOS-MEMS Single-Chip Dual-Axis Gyroscope. In Proceedings of the IEEE 4th International Conference on Microsystems, Packaging, Assembly and Circuits Technology (IMPACT 2009), Taipei, Taiwan, 21–23 October 2009; pp. 305–307. [Google Scholar]

- Xu, W.; Yang, J.; Xie, G.F.; Wang, B.; Qu, M.S.; Wang, X.G.; Liu, X.X.; Tang, B. Design and Fabrication of a Slanted-Beam MEMS Accelerometer. Micromachines 2017, 8, 77. [Google Scholar] [CrossRef]

- Qureshi, U.; Golnaraghi, F. An Algorithm for the In-Field Calibration of a MEMS IMU. IEEE Sens. J. 2017, 17, 7479–7486. [Google Scholar] [CrossRef]

- Xia, D.Z.; Yu, C.; Kong, L. The Development of Micromachined Gyroscope Structure and Circuitry Technology. Sensors 2014, 14, 1394–1473. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nevlydov, I.; Filipenko, O.; Volkova, M.; Ponomaryova, G. MEMS-Based Inertial Sensor Signals and Machine Learning Methods for Classifying Robot Motion. In Proceedings of the IEEE 2th International Conference on Data Stream Mining & Processing (DSMP 2018), Lviv, Ukraine, 21–25 August 2018; pp. 13–16. [Google Scholar]

- Lou, L.; Xu, X.; Cao, J.; Chen, Z.L.; Xu, Y. Sensor fusion-based attitude estimation using low-cost MEMS-IMU for mobile robot navigation. In Proceedings of the 6th IEEE Joint International Information Technology and Artificial Intelligence Conference (ITAIC 2011), Chongqing, China, 20–22 August 2011; pp. 480–483. [Google Scholar]

- Ravichandran, R.; Kumar, A.; Kumar, R. Joint Angle Measurement Using MEMs Based Inertial Sensors for Biped Robot. In Proceedings of the Second International Conference on Electronics, Communication and Aerospace Technology (ICECA 2018), Shanghai, China, 10–11 November 2018; pp. 225–231. [Google Scholar]

- Nokhodberiz, N.S.; Poshtan, J. Distributed Interacting Multiple Filters for Fault Diagnosis of Navigation Sensors in a Robotic System. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 1383–1393. [Google Scholar] [CrossRef]

- Sparks, D.; Sala, L. MEMS Inertial Sensors for Automotive and Consumer Applications. Equip. Electron. Prod. Manuf. 2016, 12, 39–43. [Google Scholar]

- Yazdi, N.; Ayazi, F.; Najafi, K. Micromachined inertial sensors. Proc. IEEE 1998, 86, 1640–1659. [Google Scholar] [CrossRef] [Green Version]

- Sasiadek, J.Z. Modern inertial technology: Navigation, guidance, and control. Control Eng. Pract. 1993, 93, 296. [Google Scholar] [CrossRef]

- Wen, H.; Daruwalla, A.; Jeong, Y.; Gupta, P.; Ayazi, F. A high-performance single-chip timing and inertial measurement unit with robust mode-matched gyroscopes. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS 2018), Belfast, UK, 21–25 January 2018; pp. 105–108. [Google Scholar]

- Ayazi, F.; Wen, H.R.; Jeong, Y.; Gupta, P.; Liu, C.S. High-Q Timing and Inertial Measurement Unit Chip (TIMU) with 3D Wafer-Level Packaging. In Proceedings of the 2019 IEEE Custom Integrated Circuits Conference (CICC 2019), Austin, TX, USA, 14–17 April 2019; pp. 1–8. [Google Scholar]

- Passaro, V.M.N.; Cuccovillo, A.; Vaiani, L.; De Carlo, M.; Campanella, C.E. Gyroscope Technology and Applications: A Review in the Industrial Perspective. Sensors 2017, 17, 2284. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.; Zaman, M.F.; Ayazi, F. A Sub-0.2 degrees/hr Bias Drift Micromechanical Silicon Gyroscope With Automatic CMOS Mode-Matching. IEEE J. Solid-State Circuits 2009, 44, 1593–1608. [Google Scholar] [CrossRef]

- Alper, S.E.; Azgin, K.; Akin, T. A high-performance silicon-on-insulator MEMS gyroscope operating at atmospheric pressure. Sens. Actuators A Phys 2007, 135, 34–42. [Google Scholar] [CrossRef] [Green Version]

- Guo, Z.S.; Cheng, F.C.; Li, B.Y.; Cao, L.; Lu, C.; Song, K. Research development of silicon MEMS gyroscopes: A review. Microsyst. Technol. 2015, 21, 2053–2066. [Google Scholar]

- Kepper, J.H.; Claus, B.C.; Kinsey, J.C. A Navigation Solution Using a MEMS IMU, Model-Based Dead-Reckoning, and One-Way-Travel-Time Acoustic Range Measurements for Autonomous Underwater Vehicles. IEEE J. Ocean. Eng. 2019, 44, 664–682. [Google Scholar] [CrossRef]

- Gill, W.A.; Ali, D.; An, B.H.; Syed, W.U.; Saeed, N.; Al-shaibah, M.; Elfadel, I.M.; Al Dahmani, S.; Choi, D.S. MEMS multi-vibrating ring gyroscope for space applications. Microsyst. Technol. 2020, 26, 2527–2533. [Google Scholar] [CrossRef]

- Huo, H.Q.; Liu, J.B.; Cai, W.Y.; Gao, Y.X. A deep-sea drilling rig MEMS gyroscope random drift error correction method. In Proceedings of the MTS/IEEE Oceans Conference 2013, San Diego, CA, USA, 23–27 September 2013; pp. 1–5. [Google Scholar]

- Ren, C.H.; Pan, Y.J.; He, T.; Xiong, N.X. Research and implementation of a new orientation & incline instrument used in oil and gas wells. In Proceedings of the 2009 9th International Conference on Electronic Measurement & Instruments (ICEMI 2009), Beijing, China, 16–19 August 2009; pp. 1027–1030. [Google Scholar]

- Zhang, H.C.; Wei, X.Y.; Ding, Y.Y.; Jiang, Z.D.; Ren, J. A low noise capacitive MEMS accelerometer with anti-spring structure. Sens. Actuators A Phys 2019, 296, 79–86. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Scudero, S.; Vitale, G. A Review of the Capacitive MEMS for Seismology. Sensors 2019, 19, 3093. [Google Scholar] [CrossRef] [Green Version]

- Middlemiss, R.P.; Samarelli, A.; Paul, D.J.; Hough, J.; Rowan, S.; Hammond, G.D. Measurement of the Earth tides with a MEMS gravimeter. Nature 2016, 531, 614–617. [Google Scholar] [CrossRef] [Green Version]

- Bhardwaj, R.; Kumar, N.; Kumar, V. Errors in micro-electro-mechanical systems inertial measurement and a review on present practices of error modelling. Trans. Inst. Meas. Control 2018, 40, 2843–2854. [Google Scholar] [CrossRef]

- Barbour, N.; Schmidt, G. Inertial Sensor Technology Trends. IEEE Sens. J. 2001, 1, 332–339. [Google Scholar] [CrossRef]

- Cole, J.; Cunningham, A.; MacDonald, R.; McGimpsey, S.; McQuaide, S.; McShain, D. Optimizing noise and stability of MEMS accelerometers for various applications. In Proceedings of the 2016 IEEE/ION Position, Location and Navigation Symposium (PLANS 2016), Savannah, GA, USA, 11–14 April 2016; pp. 9–14. [Google Scholar]

- Shaeffer, D.K. MEMS inertial sensors: A tutorial overview. IEEE Commun. Mag. 2013, 51, 100–109. [Google Scholar] [CrossRef]

- Nazemipour, A.; Manzuri, M.T. MEMS Gyroscope Raw Data Noise Reduction Using Fading Memory Filter. J. Sci. Ind. Res. 2018, 77, 553–558. [Google Scholar]

- Kenshi, S.; Masao, M. Performance analysis of α–β–γ tracking filters using position and velocity measurements. EURASIP J. Adv. Signal Process. 2015, 35, 1–15. [Google Scholar]

- Feng, J.B.; Ding, M.Y.; Zhang, X.M. Decision-based adaptive morphological filter for fixed-value impulse noise removal. Optik 2014, 125, 4288–4294. [Google Scholar] [CrossRef]

- Wu, Y.C.; Shen, C.; Cao, H.L.; Che, X. Improved Morphological Filter Based on Variational Mode Decomposition for MEMS Gyroscope De-Noising. Micromachines 2018, 9, 246. [Google Scholar] [CrossRef] [Green Version]

- Han, K.H.; Guo, W.L.; Gao, X.Q. A noise removal method for MEMS gyroscope. In Proceedings of the IEEE International Conference on Computer Science and Information Technology (ICCSIT 2010), Chengdu, China, 9–11 July 2010; pp. 274–277. [Google Scholar]

- Guo, X.; Sun, C.; Wang, P.; Huang, L. A hybrid method for MEMS gyroscope signal error compensation. Sens. Rev. 2018, 38, 517–525. [Google Scholar] [CrossRef]

- Alam, M.; Rohac, J. Adaptive Data Filtering of Inertial Sensors with Variable Bandwidth. Sensors 2015, 15, 3282–3298. [Google Scholar] [CrossRef] [Green Version]

- Kalman, R.E. A New Approach to Linear Filtering and Prediction Problems. J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef] [Green Version]

- Yong, S.G.; Chen, J.B.; Song, C.L.; Han, Y.Q. Research on the compensation in MEMS gyroscope random drift based on time-series analysis and Kalman filtering. In Proceedings of the 2015 34th Chinese Control Conference (CCC 2015), Hang Zhou, China, 28–30 July 2015; pp. 2078–2082. [Google Scholar]

- Feng, Y.B.; Li, X.S.; Zhang, X.J. An Adaptive Compensation Algorithm for Temperature Drift of Micro-Electro-Mechanical Systems Gyroscopes Using a Strong Tracking Kalman Filter. Sensors 2015, 15, 11222–11238. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, Z.X.; Gallacher, B. Extended Kalman filtering based parameter estimation and drift compensation for a MEMS rate integrating gyroscope. Sens. Actuators A Phys. 2016, 250, 96–105. [Google Scholar] [CrossRef] [Green Version]

- Chu, H.R.; Sun, T.T.; Zhang, B.Q.; Zhang, H.W.; Chen, Y. Rapid Transfer Alignment of MEMS SINS Based on Adaptive Incremental Kalman Filter. Sensors 2017, 17, 152. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Zhang, L.J. Design and Implementation of Strong Tracking Combined Filtering Algorithm for MEMS Gyroscope. In Proceedings of the 2018 5th International Conference on Information Science and Control Engineering (ICISCE2018), Zhengzhou, China, 20–22 July 2018; pp. 1098–1103. [Google Scholar]

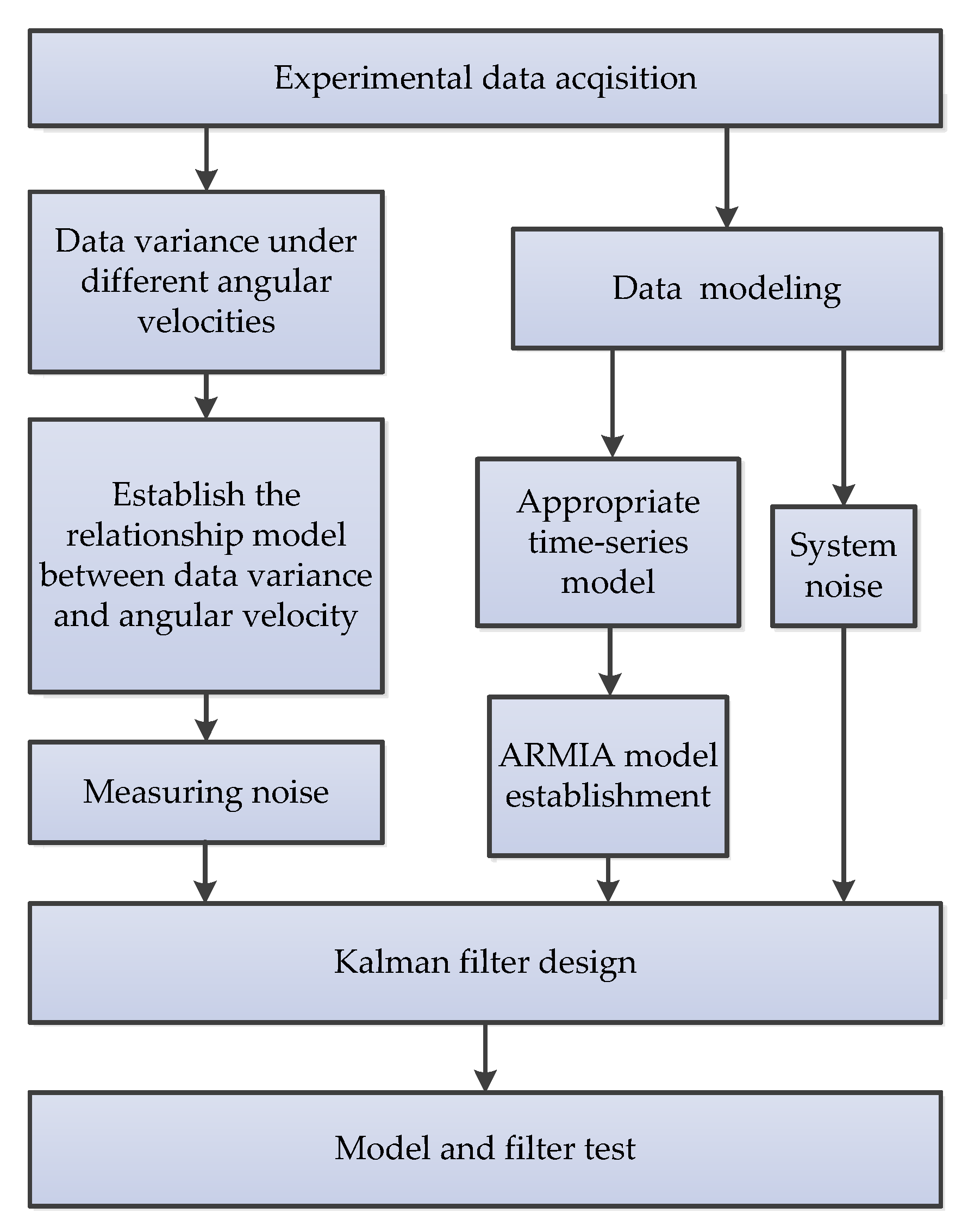

- Xue, L.; Jiang, C.Y.; Wang, L.X.; Liu, J.Y.; Yuan, W.Z. Noise Reduction of MEMS Gyroscope Based on Direct Modeling for an Angular Rate Signal. Micromachines 2015, 6, 266–280. [Google Scholar] [CrossRef]

- Yuan, J.G.; Yuan, Y.T.; Liu, F.L.; Pang, Y.; Lin, J.Z. An improved noise reduction algorithm based on wavelet transformation for MEMS gyroscope. Front. Optoelectron. 2015, 8, 413–418. [Google Scholar] [CrossRef]

- Sheng, G.R.; Gao, G.W.; Zhang, B.Y. Application of Improved Wavelet Thresholding Method and an RBF Network in the Error Compensating of an MEMS Gyroscope. Micromachines 2019, 10, 608. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.S.; Gao, Z.F. Study on MEMS Gyro Signal De-Noising Based on Improved Wavelet Threshold Method. Appl. Mech. Mater. 2013, 433, 1558–1562. [Google Scholar] [CrossRef]

- Yang, X.H.; Ren, J.X.; Zhao, X.M.; Chen, R. MEMS Gyro Signal De-Noising Based on Adaptive Stationary Wavelet Threshold. Adv. Mater. Res. 2012, 466, 986–990. [Google Scholar] [CrossRef]

- Lu, Q.; Pang, L.X.; Huang, H.Q.; Shen, C.; Cao, H.L.; Shi, Y.B.; Liu, J. High-G Calibration Denoising Method for High-G MEMS Accelerometer Based on EMD and Wavelet Threshold. Micromachines 2019, 10, 134. [Google Scholar] [CrossRef] [Green Version]

- Xue, L.; Wang, L.X.; Xiong, T.; Jiang, C.Y.; Yuan, W.Z. Analysis of Dynamic Performance of a Kalman Filter for Combining Multiple MEMS Gyroscopes. Micromachines 2014, 5, 1034–1050. [Google Scholar] [CrossRef] [Green Version]

- Yuan, G.M.; Yuan, W.Z.; Xue, L.; Xie, J.B.; Chang, H.L. Dynamic Performance Comparison of Two Kalman Filters for Rate Signal Direct Modeling and Differencing Modeling for Combining a MEMS Gyroscope Array to Improve Accuracy. Sensors 2015, 15, 27590–27610. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nemec, D.; Janota, A.; Hrubos, M.; Simak, V. Intelligent Real-Time MEMS Sensor Fusion and Calibration. IEEE Sens. J. 2016, 16, 7150–7160. [Google Scholar] [CrossRef] [Green Version]

- Daniel, K.; Wahl, F.M. A sensor fusion approach to angle and angular rate estimation. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2011), San Francisco, CA, USA, 25–30 September 2011; pp. 2481–2488. [Google Scholar]

- Wen, J.; Zhao, J.L.; Luo, S.W.; Han, Z. The improvements of BP neural network learning algorithm. In Proceedings of the 2000 5th IEEE International Conference on Signal Processing (ICSP 2000), Beijing, China, 21–25 August 2000; pp. 1647–1649. [Google Scholar]

- Shiau, J.K.; Ma, D.M.; Huang, C.X.; Chang, M.Y. MEMS Gyroscope Null Drift and Compensation Based on Neural Network. Adv. Mater. Res. 2011, 255, 2077–2081. [Google Scholar] [CrossRef]

- Ali, M. Compensation of temperature and acceleration effects on MEMS gyroscope. In Proceedings of the 2016 13th International Bhurban Conference on Applied Sciences and Technology (IBCAST 2016), Islamabad, Pakistan, 12–16 January 2016; pp. 274–279. [Google Scholar]

- Cao, H.L.; Zhang, Y.J.; Shen, C.; Liu, Y.; Wang, X.W. Temperature Energy Influence Compensation for MEMS Vibration Gyroscope Based on RBF NN-GA-KF Method. Shock Vib. 2018, 2018, 2830686. [Google Scholar] [CrossRef]

- Zhu, M.; Pang, L.X.; Xiao, Z.J.; Shen, C.; Cao, H.L.; Shi, Y.B.; Liu, J. Temperature Drift Compensation for High-G MEMS Accelerometer Based on RBF NN Improved Method. Appl. Sci. 2019, 9, 695. [Google Scholar] [CrossRef] [Green Version]

- Sebald, D.J.; Bucklew, J.A. Support vector machine techniques for nonlinear equalization. IEEE Trans. Signal Process. 2000, 48, 3217–3226. [Google Scholar] [CrossRef]

- Suykens, J.A.K. Nonlinear modelling and support vector machines. In Proceedings of the 18th IEEE Instrumentation & Measurement Technology Conference (IMTC 2001), Budapest, Hungary, 21–23 May 2001; pp. 287–294. [Google Scholar]

- Xing, H.F.; Hou, B.; Lin, Z.H.; Guo, M.F. Modeling and Compensation of Random Drift of MEMS Gyroscopes Based on Least Squares Support Vector Machine Optimized by Chaotic Particle Swarm Optimization. Sensors 2017, 17, 2335. [Google Scholar] [CrossRef] [Green Version]

- Bhatt, D.; Aggarwal, P.; Bhattacharya, P.; Devabhaktuni, V. An Enhanced MEMS Error Modeling Approach Based on Nu-Support Vector Regression. Sensors 2012, 12, 9448–9466. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.S.; Yang, T. Modeling and compensation of MEMS gyroscope output data based on support vector machine. Measurement 2012, 45, 922–926. [Google Scholar] [CrossRef]

- Tipping, M.E. Sparse Bayesian learning and the relevance vector machine. J. Mach. Learn. Res. 2001, 1, 211–244. [Google Scholar]

- Liu, J.Y.; Shen, Q.; Qin, W.W. A signal processing technique for compensating random drift of MEMS gyros. In Proceedings of the 2014 IEEE Chinese Guidance, Navigation and Control Conference (CGNCC 2014), Yan Tai, China, 8–10 August 2014; pp. 1230–1234. [Google Scholar]

- Hsu, Y.L.; Chou, P.H.; Kuo, Y.C. Drift modeling and compensation for MEMS-based gyroscope using a Wiener-type recurrent neural network. In Proceedings of the 2017 IEEE International Symposium on Inertial Sensors and Systems (INERTIAL 2017), Kauai, HI, USA, 27–30 March 2017; pp. 1–4. [Google Scholar]

- Hsu, Y.L.; Wang, J.S. Random Drift Modeling and Compensation for MEMS-Based Gyroscopes and Its Application in Handwriting Trajectory Reconstruction. IEEE Access 2019, 7, 17551–17560. [Google Scholar] [CrossRef]

- Zoph, B.; Le, Q.V. Neural Architecture Search with Reinforcement Learning. In Proceedings of the 5th International Conference on Learning Representations (ICLR 2017), Toulon, France, 24–26 April 2017; pp. 1–16. [Google Scholar]

- Zhu, Z.S.; Bo, Y.M.; Jiang, C.H. A MEMS Gyroscope Noise Suppressing Method Using Neural Architecture Search Neural Network. Math. Probl. Eng. 2019, 2019, 5491243. [Google Scholar] [CrossRef] [Green Version]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.H.; Chen, S.; Chen, Y.W.; Zhang, B.Y.; Feng, Z.Y.; Zhou, H.; Bo, Y.M. A MEMS IMU De-Noising Method Using Long Short Term Memory Recurrent Neural Networks (LSTM-RNN). Sensors 2018, 18, 3470. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.H.; Chen, Y.W.; Chen, S.; Bo, Y.M.; Li, W.; Tian, W.X.; Guo, J. A Mixed Deep Recurrent Neural Network for MEMS Gyroscope Noise Suppressing. Electronics 2019, 8, 181. [Google Scholar] [CrossRef] [Green Version]

- Empirical Evaluation of Gated Recurrent Neural Networks on Sequence Modeling. Available online: http://pdfs.semanticscholar.org/25f0/625a92f6054b11057423111f9285c78376fe.pdf (accessed on 20 September 2020).

- Tao, L.; Zhang, Y.; Sida, I.; Wang, H.D.; Yoav, A. Simple Recurrent Units for Highly Parallelizable Recurrence. In Proceedings of the 2018 Conference on Empirical Methods in Natural Language Processing(EMNLP 2018), Brussels, Belgium, 31 October–4 November 2018; pp. 4470–4481. [Google Scholar]

- Jiang, C.H.; Chen, S.; Chen, Y.W.; Bo, Y.M.; Han, L.; Guo, J.; Feng, Z.Y.; Zhou, H. Performance Analysis of a Deep Simple Recurrent Unit Recurrent Neural Network (SRU-RNN) in MEMS Gyroscope De-Noising. Sensors 2018, 18, 4471. [Google Scholar] [CrossRef] [Green Version]

- Jiang, X.M.; Ma, L.; Cao, J.; Zhang, X.Y.; Xie, X.W.; Jin, Y.F.; Shi, G.Y. Research of On-Line Modeling and Real-Time Filtering for MEMS Gyroscope Random Noise. In Proceedings of the 2017 IEEE International Conference on Real-time Computing and Robotics (RCAR 2017), Okinawa, Japan, 14–18 July 2017; pp. 151–155. [Google Scholar]

- Abeywardena, D.M.W.; Munasinghe, S.R. Recursive least square based estimation of MEMS inertial sensor stochastic models. In Proceedings of the 2010 5th International Conference on Information and Automation for Sustainability (ICIAFS 2010), Colombo, Sri Lanka, 17–19 December 2010; pp. 424–428. [Google Scholar]

- Lu, N.N.; Liu, D.C.; Cui, J.; Lin, X.Z.; Yang, Z.C.; Yan, G.Z. An FPGA implementation of the LMS adaptive filter for MEMS gyroscope. In Proceedings of the 2010 IEEE 5th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS 2010), Xiamen, China, 20–23 January 2010; pp. 744–747. [Google Scholar]

- Fei, J.T.; Xin, M.Y.; Juan, W.R. Adaptive fuzzy sliding mode control using adaptive sliding gain for MEMS gyroscope. Trans Inst. Meas. Control 2013, 35, 551–558. [Google Scholar] [CrossRef]

- Fei, J.; Batur, C. Robust adaptive control for a MEMS vibratory gyroscope. Int. J. Adv. Manuf. Technol. 2009, 42, 293–300. [Google Scholar] [CrossRef]

- Bai, Y.T.; Wang, X.Y.; Jin, X.B.; Su, T.L.; Kong, J.L.; Zhang, B.H. Adaptive filtering for MEMS gyroscope with dynamic noise model. ISA Trans. 2020, 101, 430–441. [Google Scholar] [CrossRef]

- Narasimhappa, M.; Mahindrakar, A.D.; Guizilini, V.C.; Terra, M.H.; Sabat, S.L. MEMS-Based IMU Drift Minimization: Sage Husa Adaptive Robust Kalman Filtering. IEEE Sens. J. 2020, 20, 250–260. [Google Scholar] [CrossRef]

- Fakharian, A.; Gustafsson, T.; Mehrfam, M. Adaptive Kalman filtering based navigation: An IMU/GPS integration approach. In Proceedings of the 2011 International Conference on Networking, Sensing and Control (ICNSC 2011), Delft, The Netherlands, 11–13 April 2011; pp. 181–185. [Google Scholar]

- Zhang, Y.S.; Peng, C.; Mou, D.; Li, M.; Quan, W. An Adaptive Filtering Approach Based on the Dynamic Variance Model for Reducing MEMS Gyroscope Random Error. Sensors 2018, 18, 3943. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, Y.C.; Sun, Y.L.; Luo, G.X.; Wu, G.G.; Zhang, T. Recent Advancements in Inertial Micro-Switches. Electronics 2019, 8, 648. [Google Scholar] [CrossRef] [Green Version]

- Platz, D.; Schmid, U. Vibrational modes in MEMS resonators. J. Micromech. Microeng. 2019, 29, 1–55. [Google Scholar] [CrossRef]

- Miller, J.M.L.; Ansari, A.; Heinz, D.B.; Chen, Y.H.; Flader, I.B.; Shin, D.D.; Villanueva, L.G.; Kenny, T.W. Effective quality factor tuning mechanisms in micromechanical resonators. Appl. Phys. Rev. 2018, 5, 041307. [Google Scholar] [CrossRef]

- Chen, F.; Li, X.X.; Kraft, M. Electromechanical sigma-delta modulators (Σ∆M) force feedback interfaces for capacitive MEMS inertial sensors: A review. IEEE Sens. J. 2016, 16, 6476–6495. [Google Scholar] [CrossRef]

- Fischer, A.C.; Forsberg, F.; Lapisa, M.; Bleiker, S.J.; Stemme, G.; Roxhed, N.; Niklaus, F. Integrating MEMS and ICs. Microsyst. Nanoeng. 2015, 1, 1–16. [Google Scholar] [CrossRef] [Green Version]

- STMicroelectronics Launches High-Precision Inclinometer with Built-in Machine Learning Core. Available online: http://www.eepw.com.cn/article/202008/417563.htm (accessed on 27 August 2020).

- Pei, J.; Deng, L.; Song, S.; Zhao, M.G.; Zhang, Y.H.; Wu, S.; Wang, G.R.; Zou, Z.; Wu, Z.Z.; He, W.; et al. Towards artificial general intelligence with hybrid Tianjic chip architecture. Nature 2019, 572, 106–125. [Google Scholar] [CrossRef]

- White Paper on Intelligent Microsystem Technologies. Available online: http://news.sciencenet.cn/htmlnews/2020/9/445580.shtm (accessed on 14 September 2020).

- Chang, L.K.; Cao, H.L.; Shen, C. Dual-Mass MEMS Gyroscope Parallel Denoising and Temperature Compensation Processing Based on WLMP and CS-SVR. Micromachines 2020, 11, 586. [Google Scholar] [CrossRef]

- Liang, S.Y.; Zhu, W.L.; Zhao, F.; Wang, C.Y. High-Efficiency Wavelet Compressive Fusion for Improving MEMS Array Performance. Sensors 2020, 20, 1662. [Google Scholar] [CrossRef] [Green Version]

- Babaei, A. Longitudinal vibration responses of axially functionally graded optimized MEMS gyroscope using Rayleigh-Ritz method, determination of discernible patterns and chaotic regimes. SN Appl. Sci. 2019, 1, 831–843. [Google Scholar] [CrossRef] [Green Version]

- Babaei, A.; Rahmani, A. Vibration analysis of rotating thermally-stressed gyroscope, based on modified coupled displacement field method. Mech. Based Des. Struct. 2020, 1, 1–11. [Google Scholar] [CrossRef]

- Babaei, A.; Noorani, M.R.S.; Ghanbari, A. Temperature-dependent free vibration analysis of functionally graded micro-beams based on the modified couple stress theory. Microsyst. Technol. 2017, 23, 4599–4610. [Google Scholar] [CrossRef]

- Babaei, A. Forced vibration analysis of non-local strain gradient rod subjected to harmonic excitations. Microsyst. Technol. 2020, 4, 1–11. [Google Scholar] [CrossRef]

- Ghanbari, A.; Babaei, A. The New Boundary Condition Effect on The Free Vibration Analysis of Micro-beams Based on The Modified Couple Stress Theory. Int. Res. J. Appl. Basic Sci. 2015, 9, 274–279. [Google Scholar]

- Bukhari, S.A.; Saleem, M.M.; Khan, U.S.; Hamza, A.; Iqbal, J.; Shakoor, S.I. Microfabrication Process-Driven Design, FEM Analysis and System Modeling of 3-DoF Drive Mode and 2-DoF Sense Mode Thermally Stable Non-Resonant MEMS Gyroscope. Micromachines 2020, 11, 862. [Google Scholar] [CrossRef]

- Rahmani, M. MEMS gyroscope control using a novel compound robust control. ISA Trans. 2018, 72, 37–43. [Google Scholar] [CrossRef]

- Rahmani, M.; Komijani, H.; Ghanbari, A.; Ettefagh, M.M. Optimal novel super-twisting PID sliding mode control of a MEMS gyroscope based on multi-objective bat algorithm. Microsyst. Technol. 2018, 24, 2835–2846. [Google Scholar] [CrossRef]

- Rahmani, M.; Rahman, M.H. A new adaptive fractional sliding mode control of a MEMS gyroscope. Microsyst. Technol. 2019, 25, 3409–3416. [Google Scholar] [CrossRef]

- Fei, J.T.; Fang, Y.M.; Yuan, Z.L. Adaptive Fuzzy Sliding Mode Control for a Micro Gyroscope with Backstepping Controller. Micromachines 2020, 11, 968. [Google Scholar] [CrossRef]

- Rahmani, M.; Rahman, M.H.; Nosonovsky, M. A new hybrid robust control of MEMS gyroscope. Microsyst. Technol. 2020, 26, 853–860. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, R.; Xu, B. Adaptive Fuzzy Sliding Mode Control of MEMS Gyroscope with Finite Time Convergence. J. Sens. 2016, 2016, 1572303. [Google Scholar] [CrossRef] [Green Version]

- Xu, B.; Zhang, R.; Li, S.; He, W.; Shi, Z.H. Composite Neural Learning-Based Nonsingular Terminal Sliding Mode Control of MEMS Gyroscopes. IEEE Trans Neural Netw. Learn. Syst. 2020, 31, 1375–1386. [Google Scholar] [CrossRef] [PubMed]

- Sága, M.; Bulej, V.; Čuboňova, N.; Kuric, I.; Virgala, I.; Eberth, M. Case study: Performance analysis and development of robotized screwing application with integrated vision sensing system for automotive industry. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420923997. [Google Scholar] [CrossRef]

- Pirník, R.; Hruboš, M.; Nemec, D.; Mravec, T.; Božek, P. Integration of Inertial Sensor Data into Control of the Mobile Platform. In Federated Conference on Software Development and Object Technologies; SDOT 2015; Advances in Intelligent Systems and Computing; Janech, J., Kostolny, J., Gratkowski, T., Eds.; Springer: Cham, Switzerland, 2017; Volume 511. [Google Scholar]

- Kilin, A.; Bozek, P.; Karavaev, Y.; Shestakov, V. Experimental investigations of a highly maneuverable mobile omniwheel robot. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417744570. [Google Scholar] [CrossRef]

- Pavol, B.; Aiman, A.A.M.; Peter, B.; Ibrahim, I.N. Navigation control and stability investigation of a mobile robot based on a hexacopter equipped with an integrated manipulator. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417738103. [Google Scholar]

- Blatnický, M.; Dižo, J.; Gerlici, J.; Sága, M.; Lack, T.; Kuba, E. Design of a robotic manipulator for handling products of automotive industry. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420906290. [Google Scholar] [CrossRef]

- Yunker, W.N.; Soobramaney, P.; Black, M.; Dean, R.N.; Flowers, G.T.; Ahmed, A. The Underwater Effects of High Power, High Frequency Acoustic Noise on MEMS Gyroscopes. In Proceedings of the ASME 2011 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, (IDETC/CIE2011), Washington, DC, USA, 28–31 August 2011; pp. 1–6. [Google Scholar]

- Braun, B. Performance Analysis of GNSS-Aided Inertial Navigation Systems on Spinning Flight Vehicles. J. Spacecr. Rockets 2019, 56, 1624–1635. [Google Scholar] [CrossRef]

- Vedachalam, N.; Ramesh, R.; Jyothi, V.B.N.; Prakash, D.; Ramadass, G.A. Autonomous underwater vehicles—Challenging developments and technological maturity towards strategic swarm robotics systems. Mar. Georesour. Geotechnol. 2018, 37, 525–538. [Google Scholar] [CrossRef]

- Emami, M.; Taban, M.R. A Low Complexity Integrated Navigation System for Underwater Vehicles. J. Navig. 2018, 71, 1161–1177. [Google Scholar] [CrossRef]

- Capriglione, D.; Carratu, M.; Catelani, M.; Ciani, L.; Patrizi, G.; Singuaroli, R.; Pietrosanto, A.; Sommella, P. Development of a Test plan and a Testbed for Performance Analysis of MEMS-based IMUs Under Vibration Conditions. Measurement 2020, 158, 107734. [Google Scholar] [CrossRef]

- Grip, H.; Nilsson, K.G.; Häger, C.K.; Lundström, R.; Öhberg, F. Does the Femoral Head Size in Hip Arthroplasty Influence Lower Body Movements during Squats, Gait and Stair Walking? A Clinical Pilot Study Based on Wearable Motion Sensors. Sensors 2019, 19, 3240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, S.Q.; Zhang, J.C.; Li, G.Z.; Zhu, R. A Wearable Flow-MIMU Device for Monitoring Human Dynamic Motion. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 637–645. [Google Scholar] [CrossRef] [PubMed]

- Ferlito, U.; Grasso, A.D.; Pennisi, S.; Vaiana, M.; Bruno, G. Sub-femto-Farad Resolution Electronic Inter faces for Integrated Capacitive Sensors: A Review. IEEE Access 2020, 8, 153969–153980. [Google Scholar] [CrossRef]

| Algorithm | # of Papers | Task Analysis | Real-Time and Online/Offline | Working Environment | Remark |

|---|---|---|---|---|---|

| FMF | 1 | Raw data noise reduction [33] | Online | AMD-Quadcore FX-8800pCPU platform | The results show that the proposed filter can effectively reduce the sensor’s noise. |

| MF | 2 | Noise suppression in the MEMS gyroscope [36]; MEMS gyroscope output signal denoising [37] | Real time | MATLAB | The simulation is better achieved in the static state and dynamic state; the principle is simple and has much less calculation in real time. |

| MAF | 1 | Suppress the signal’s unstable periods [38] | Collect data online and process the data offline | NA | Single and multiple rate dynamic experiment analysis, and synthetic signal denoising analysis. |

| VBF | 1 | Reduce the low frequency vibration and sensor noise [39] | Real time | MATLAB | Adaptive bandwidth filter provides smooth data in harsh environments and eliminates the low frequency vibration effects (<10 Hz). |

| KF | 3 | Random drift compensation [41]; Temperature drift compensation [42,44] | Offline | MATLAB | The proposed method can effectively reduce random drift and temperature drift not only on the conditions but also at constant rates. |

| EKF | 1 | Damping and stiffness imperfections compensation [43] | Offline | MATLAB and DSP | Numeric simulation and experiment EKF show consistent results. |

| IKF | 1 | To reduce large errors and improve the convergence of the KF [44] | Offline | MATLAB | Comparison of KF/AKF/AIKF |

| STKF | 2 | To compensate the temperature drift [42]; Error compensation and accuracy improvement [45] | Real time | DSP | Static and dynamic experiments; the algorithm is easily implemented; the measurement noise of the MEMS gyroscope in static and dynamic states can be reduced by 93.6% and 63.9%, respectively. |

| DTKF | 1 | Bias drift and noise reduction [46] | Real time | DSP | The greatest feature is the direct modeling for true angular rate to obtain an optimal estimate. |

| WT | 2 | Large noise reduction for low-precision MEMS gyroscope [47,50] | Real time | DSP | A large number of the constant and dynamic rates experiments were tested. |

| IWT | 2 | Error compensation [48]; High frequency noise reduction and random drift suppression [49] | Offline | NA | Experimental results indicate that the improved wavelet threshold is effective. |

| ASWT | 1 | High frequency noise restraint [50] | Real time | DSP | Experimental results show that the adaptive stationary wavelet threshold is better than traditional wavelet threshold denoising methods. |

| EMD-WT | 1 | To improve the performance of the high-G MEMS accelerometer [51] | Offline | NA | Experiment and verification in the Hopkinson Bar calibration system, and it decreases the noise of the original signal by 96%. |

| VG | 2 | To reduce the noise and improve the accuracy of the individual gyroscope [52,53] | Online | MATLAB/Simulink | Dynamic simulations and experiments with a six-gyroscope array were carried out. |

| HF | 1 | Real time calibration and long-term drift compensation [54] | Real time/Online | MATLAB | Intelligent Real-Time MEMS Sensor Fusion and Calibration. |

| CS | 1 | To eliminate the drift and offset [55] | Real time | DSP and FRGA | Various simulation and experimental results are presented demonstrating its effectiveness. |

| BP | 2 | Null drift, temperature compensation [57]; Compensation of temperature and acceleration effects [58] | Real time | NA | Bias instability shows 57% improvement; Temperature test from −40 to −80 °C; BP NN yields accurate temperature compensation. |

| RBF | 3 | Random error compensating [48]; Temperature compensation [60,63] | Real time [60] Offline [48,63] | NA | Good generalization ability, higher precision prediction, and compensation ability; A new fusion algorithm is proposed and proved in temperature test equipment. |

| SVM | 3 | Modeling and compensation [63,65]; Error modeling [64] | Offline | MATLAB/LibSVM | SVM has high precision and good generalization ability; thus, experimental results proved that the SVM approach reduced the noise standard deviation by 10–35% for gyroscopes and 61–76% for accelerometers. |

| RVM | 1 | Random drift compensation [67] | Offline | NA | Static and dynamic experiments were conducted. |

| WRNN | 2 | Random drift modeling and compensation [68,69] | Real time | MCU | The effectiveness of the proposed WRNN-based random drift modeling and compensation scheme for the MEMS-based gyroscopes was successfully validated. |

| NAS-RNN | 1 | Noise suppressing [71] | Offline | NA | The NAS-RNN was effective for MEMS gyroscope noise suppressing. |

| GRU | 1 | Noise suppressing [74] | Offline | Python | The mixed deep recurrent neural networks outperformed GRU-GRU and LSTM-LSTM. |

| SRU | 1 | Signal denoising [77] | Offline | Python | The results surely demonstrated the effectiveness of the employed SRU in this application. |

| RLS | 2 | Random noise reduction [78]; Online dynamic estimation of inertial sensor error model [79]; | Online | STM32 microcontroller [78]; DSP [79] | The results show that RLS can effectively reduce the prediction error compared with non-recursive estimation. |

| LMS | 1 | Signal error processing [80] | Online | DSP Builder/FPGA | The results show that it is reliable and has high precision. |

| ASMC | 2 | Estimate the angular velocity and the damping and stiffness coefficients [81,82] | Offline | MATLAB/Simulink | It has satisfactory performance and robustness in the presence of model uncertainty and external disturbance. |

| AKF | 4 | Noise reduction [78]; Static and dynamic noise reduction [83]; The drift error and random noise restraint [84]; Navigation precision improvement [85] | Real time [78,84,85] | STM32 microcontroller [78]; DSP [84,85] | It is shown that AKF has a better performance rather than conventional KF. |

| AF-DVM | 1 | Dynamic random error compensation [86] | Online | DSP | The proposed method was verified through a constant angular rate and continuous variable angular rate turntable experiments. |

| Group | Algorithms | Structure Characteristics | Advantages | Disadvantages | Strength in Application Domain |

|---|---|---|---|---|---|

| Simple filter algorithms | FMF | The FMF structure is very similar to KF | Very low computational overhead and KF divergence suppression | The optimal filter gain is not easy to find | To reduce the sensor’s noise and track moving objects in radar applications and medical devices |

| MF | Four basic operators as follows: dilation, erosion, opening, and closing | It is simple, fast, and real-time | MF generally suffers from different output biases and the scale selection problems of structural elements | In order to filter out the noise of the MEMS gyroscope in vehicle mobile satellite communication | |

| MAF | MAF is the first choice of time domain signal, and is the most common in DSP | Fast convergence rate and small steady-state errors | MAF shows certain lag | It is applicable for signal denoising under arbitrary motion state conditions | |

| VBF | VBF processes data by sinusoidal data estimation | It can be implemented real-time | As the bandwidth decreases, the time delay increases | Real flight conditions | |

| KF | Filter computation loop and gain computation loop | Small amount of calculation | It can only fit linear Gaussian systems. | Sensor data fusion | |

| EKF | EKF is a kind of pseudo nonlinear KF | Small and fast calculations | Less effective for highly nonlinear problems and poor robustness | Unmanned aerial vehicles | |

| Kalman-based algorithms | IKF | IKF also is a nonlinear KF | Better estimation accuracy and more robust to the unstable system | It has a larger calculation amount, but still can satisfy the real-time requirement. | In the airborne strapdown inertial navigation system application |

| STKF | Nonlinear adaptive filter | Strong robustness | The sequence of residuals should be orthogonal at all times | With potential to be used in adaptive control of flexible robot | |

| DTKF | A type of optimal KF | Direct modeling for angular rate signal | The filtered rate signal has an auto-correlation | Aviation and aerospace navigation | |

| WT | Hard threshold and soft threshold | No need to establish accurate error model; Fast computation, and broad adaptability | The Pseudo-Gibbs will appear at the discontinuity of the signal | Primarily applicable in the case of white noise in the signal processing | |

| Wavelet-based algorithms | IWT | In addition to soft and hard threshold function, a new threshold function is added | Better adaptability | It is very difficult to find an ideal threshold | Indoor inertial navigation systems |

| ASWT | Redundancy, translation-invariance, and more approximate estimation | Time invariance; simple and more smoothing | The computation load will increase | Application in the case of dynamic signal with high frequency noise restraining | |

| EMD-WT | Combination of two algorithms | Suitable for nonlinear and non-stationary signals; Faster, more reliable, and efficient than single methods | It is quite difficult to remove noise in real time | Monitoring natural disasters and various navigation control | |

| Sensor fusion algorithms | VG | Gyroscope array | Accuracy of virtual gyro is higher than single gyro | It still needs KF filter | Navigation and guidance |

| HF | Fusion of gyroscopes, accelerometers, and magnetometers | Faster dynamic response; Converges faster and take less computational time | Higher CPU load | Attitude and heading reference systems | |

| CS | Combines rotary encoders and gyroscopes; Low computational demands and negligible parameter tuning effort | A viable alternative to high-resolution encoders; | It still needs to further restrain the disturbance | Servo motors or robot joints | |

| BP | Input layer, hidden layer, and output layer | Nonlinear function relationship model | Time-consuming and its denoising accuracy depends on personal experience | To effectively improve the accuracy and practicability of flight attitude angle calculation | |

| Machine Learning | RBF | Input layer, hidden layer, and output layer | The training speed and convergence speed of the RBF are faster than BP | Need to combine with other algorithms for high accuracy | High-G MEMS accelerometer temperature compensation; Application in navigation, defense, and impact measurement. |

| SVM | It is a two-classification algorithm that classifies samples by constructing a hyperplane function | Better generalization ability for small samples | It is difficult to learn and predict large samples | North-seeking, navigation, pedestrian step estimation, pattern recognition, and many other fields | |

| RVM | It is a sparse probability model | The generalization ability of RVM is better than SVM | The training time is a little long | Guidance, navigation, and control systems for space vehicles | |

| WRNN | A dynamic linear model cascaded by a static nonlinear model | The algorithm is integrated into the real application | It still needs to integrate a lowpass filter | Handwriting Trajectory Reconstruction | |

| Deep Learning | NAS-RNN | Neural networks with reinforcement learning | The NAS-RNN superiority compared with the LSTM-RNN | More heavy computation load | Various vehicles, carriers, and smart devices |

| LSTM | A type of RNN | LSTM performs better in longer sequences | More parameters and more difficult training | Image processing, nature language processing, and sequential signal processing | |

| GRU | A type of RNN | GRU is much easier to train than LSTM and can greatly improve training efficiency | GRU parameters are fewer and therefore, easier to converge, but LSTM expression performance is better for large datasets | Image processing, nature language processing, and sequential signal processing | |

| SRU | A new type of RNN based on LSTM and GRU | The SRU has faster training speed than LSTM and GRU | It still needs further research | Image processing, nature language processing and sequential signal processing | |

| RLS | A type of adaptive filter | Convergence speed is very fast | Different inertial sensors need different forgetting factor | Automobile industry, flight vehicle, and robotics | |

| LMS | A widely used type of adaptive filter | Simple principle, few parameters, fast convergence speed and easy implementation | Need to combine other algorithms for good performance | It can be integrated into the FPGA for various real applications. | |

| Adaptive-based algorithms | ASMC | Sliding mode controller | More high robustness | The simulations are only performed | Environment variations and external disturbances from the real system |

| AKF | NA | AKF performs better than traditional KF | NA | Land vehicle applications | |

| AF-DVM | Algorithm combination | Adaptive dynamic random error compensation is validated | NA | Inertial measurement and inertial stabilization |

| Group | Main Tasks | Advantages | Disadvantages | Number of Studies |

|---|---|---|---|---|

| Simple filter algorithms |

|

|

| 5 |

| Kalman-based algorithms |

|

|

| 8 |

| Wavelet-based algorithms |

|

|

| 6 |

| Sensor fusion algorithms |

|

|

| 4 |

| Machine Learning |

|

|

| 9 |

| Deep Learning |

|

|

| 7 |

| Adaptive-based algorithms |

|

|

| 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.; Meng, Z.; Omisore, O.; Akinyemi, T.; Yan, Y. Random Error Reduction Algorithms for MEMS Inertial Sensor Accuracy Improvement—A Review. Micromachines 2020, 11, 1021. https://doi.org/10.3390/mi11111021

Han S, Meng Z, Omisore O, Akinyemi T, Yan Y. Random Error Reduction Algorithms for MEMS Inertial Sensor Accuracy Improvement—A Review. Micromachines. 2020; 11(11):1021. https://doi.org/10.3390/mi11111021

Chicago/Turabian StyleHan, Shipeng, Zhen Meng, Olatunji Omisore, Toluwanimi Akinyemi, and Yuepeng Yan. 2020. "Random Error Reduction Algorithms for MEMS Inertial Sensor Accuracy Improvement—A Review" Micromachines 11, no. 11: 1021. https://doi.org/10.3390/mi11111021

APA StyleHan, S., Meng, Z., Omisore, O., Akinyemi, T., & Yan, Y. (2020). Random Error Reduction Algorithms for MEMS Inertial Sensor Accuracy Improvement—A Review. Micromachines, 11(11), 1021. https://doi.org/10.3390/mi11111021