Low-Concentration Ammonia Gas Sensors Manufactured Using the CMOS–MEMS Technique

Abstract

1. Introduction

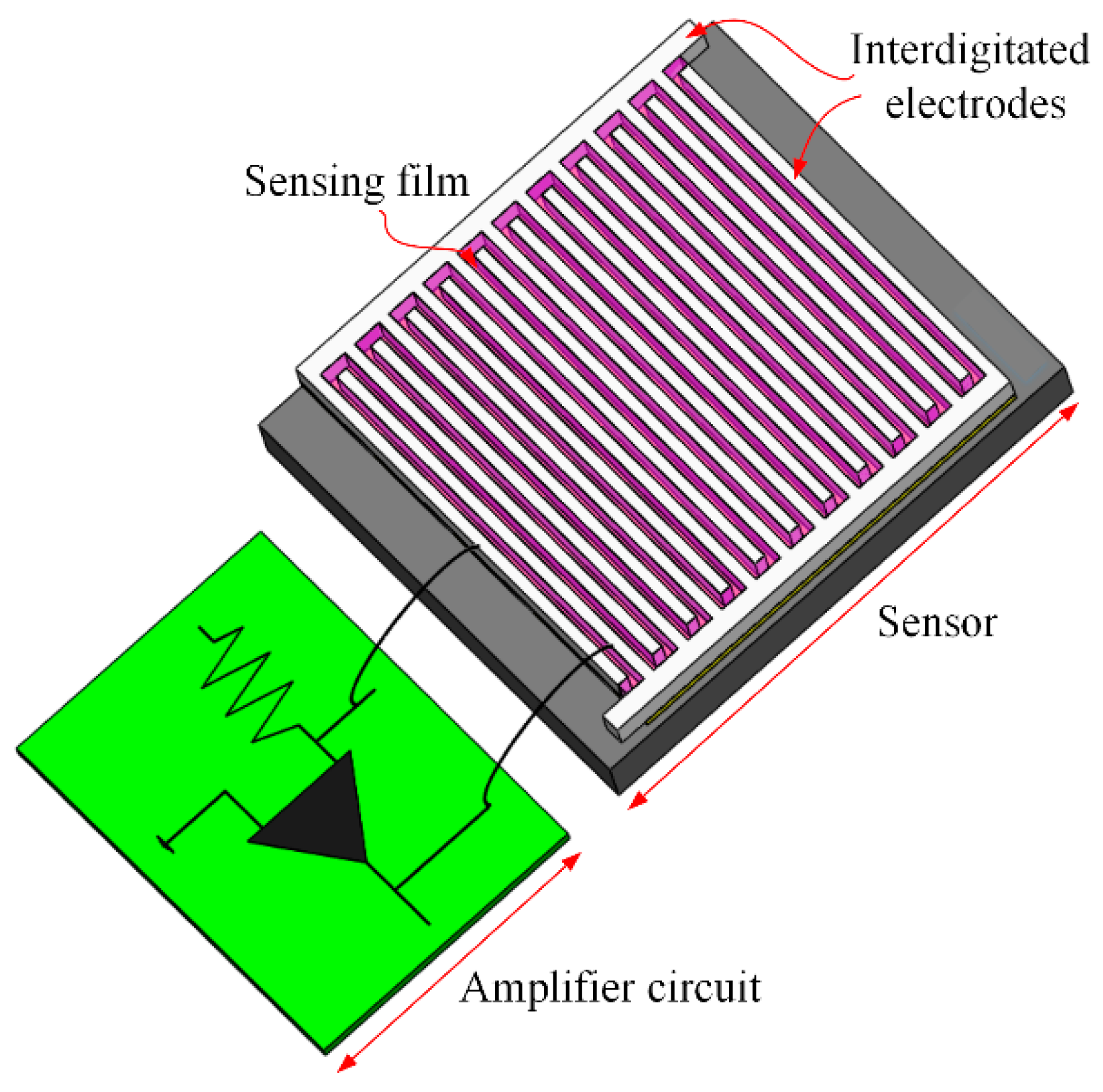

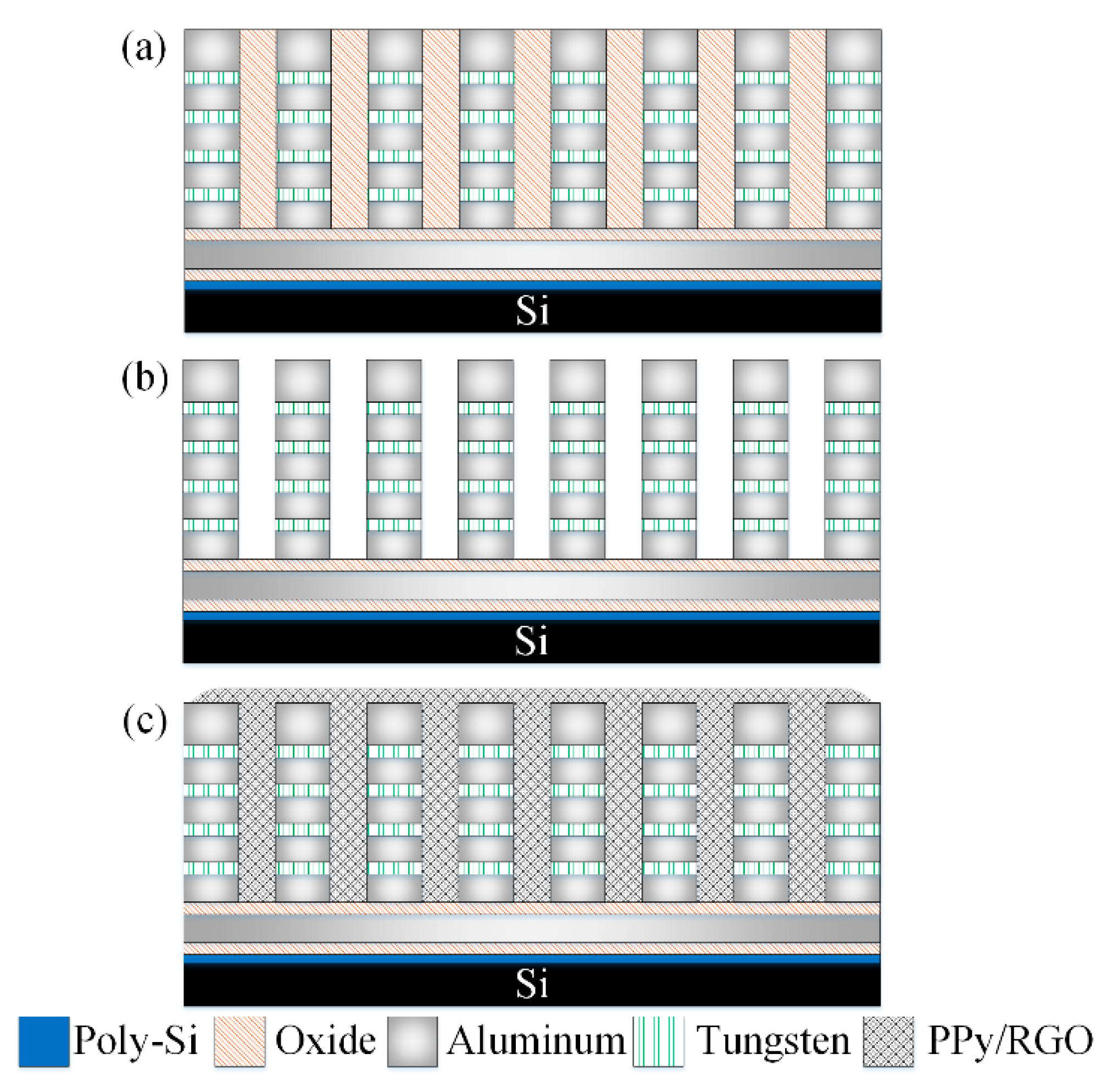

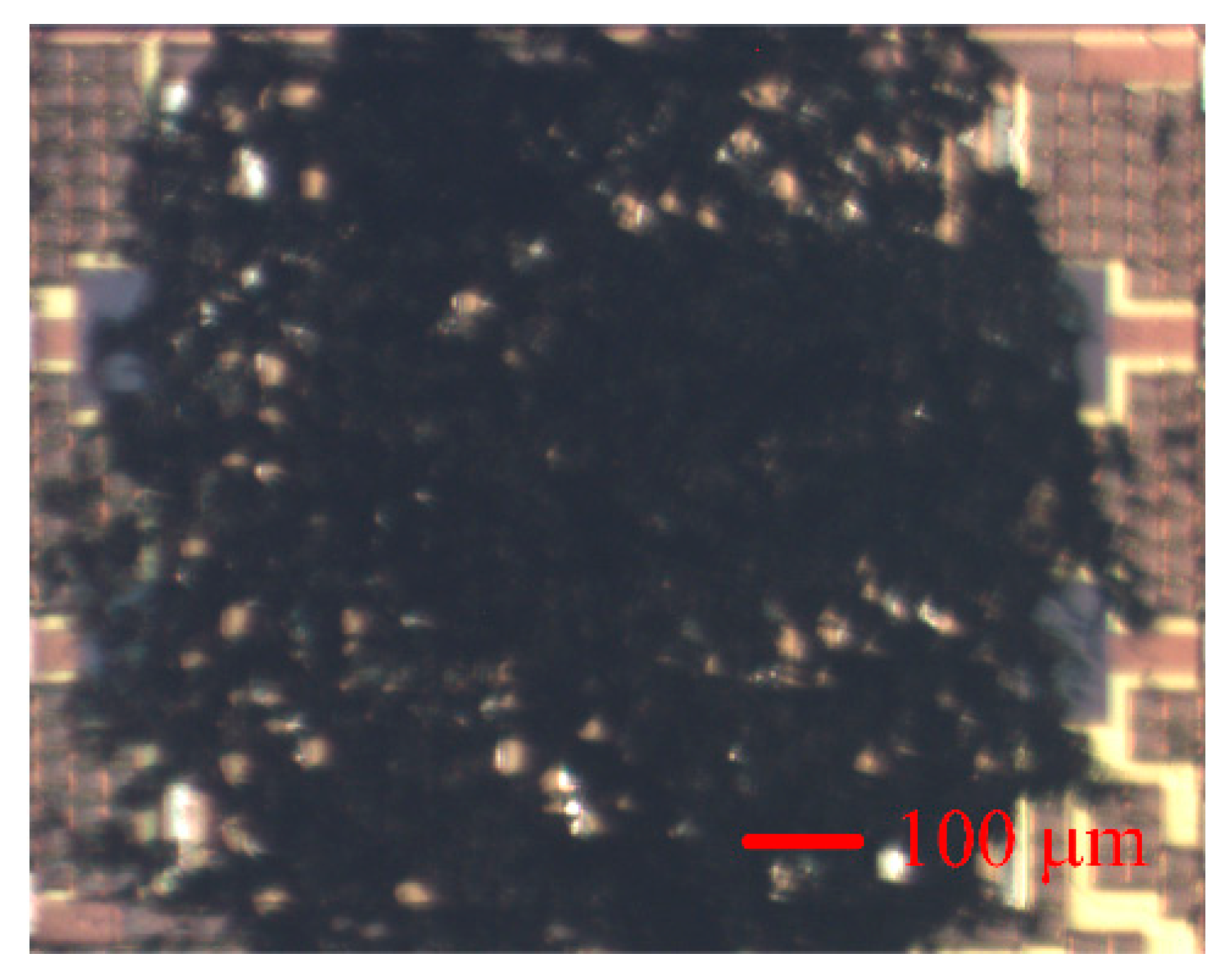

2. Structure of the Ammonia Sensor

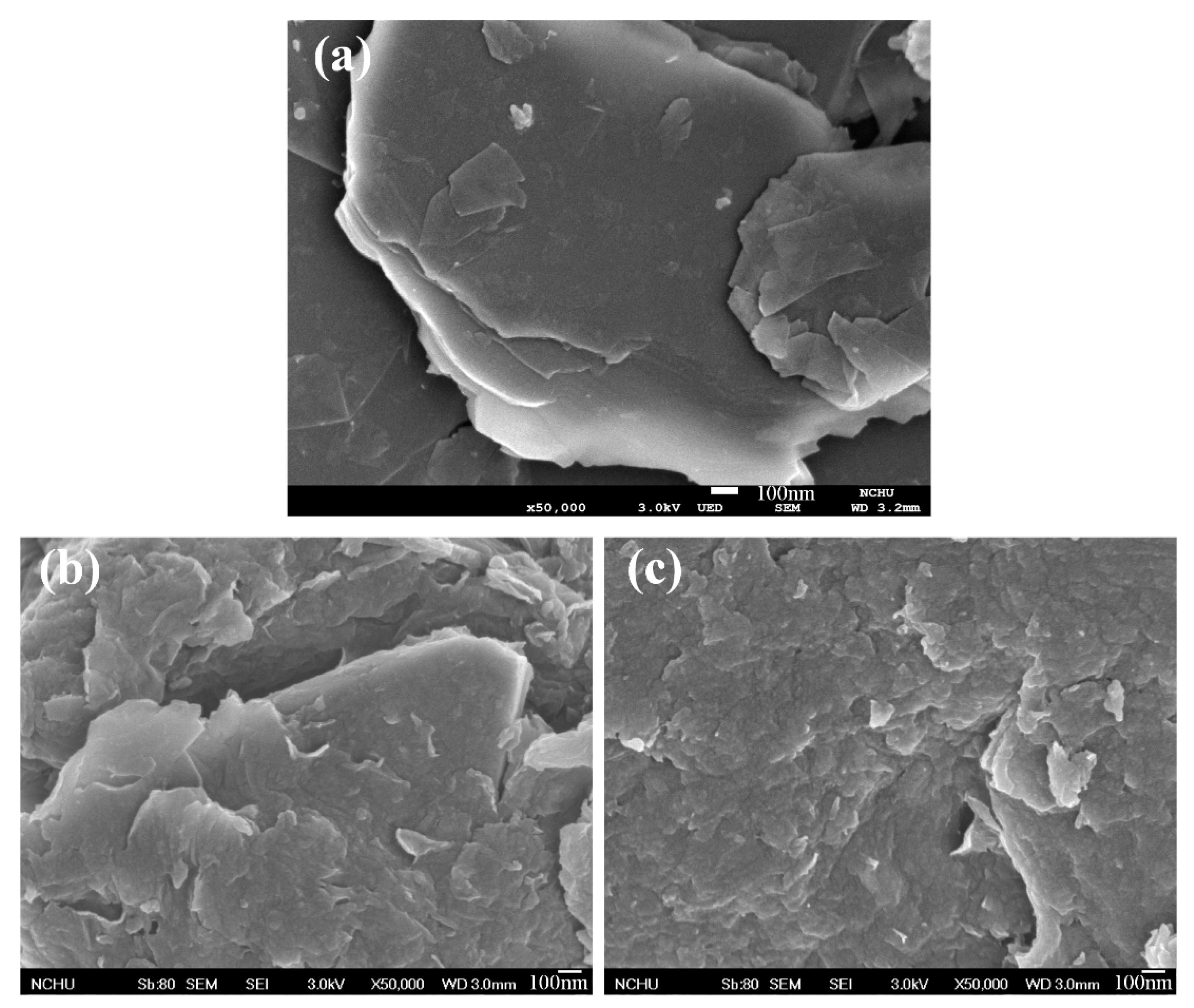

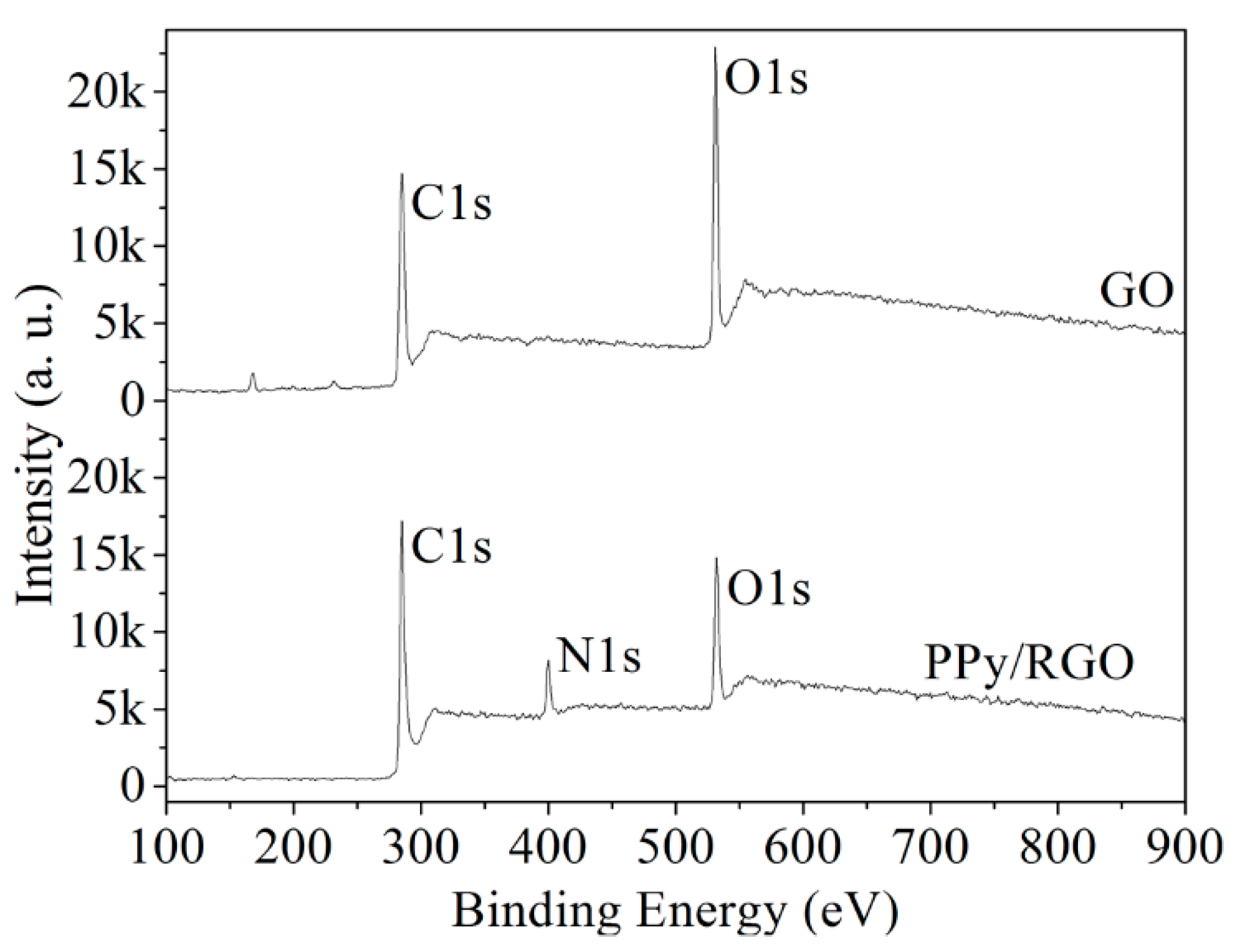

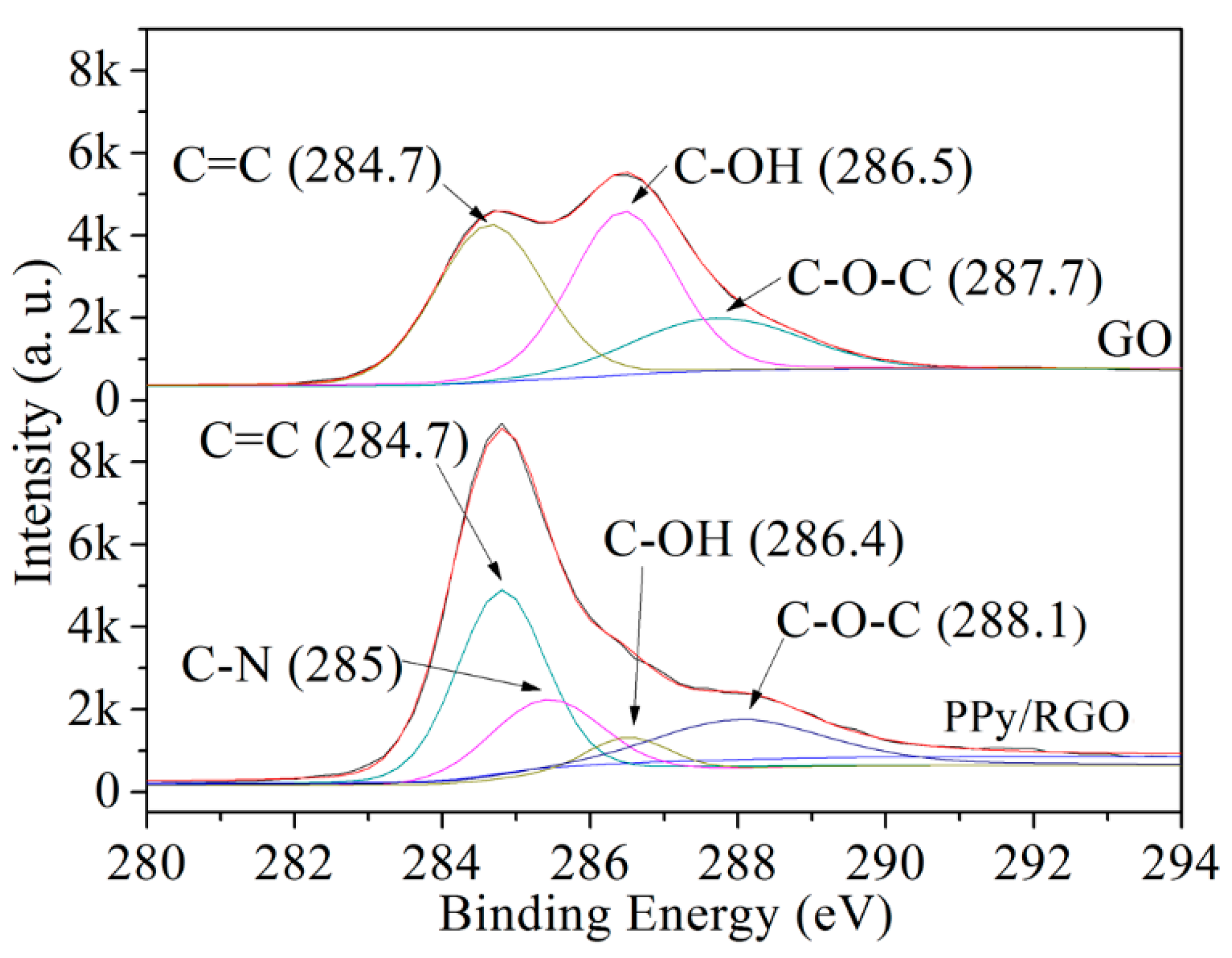

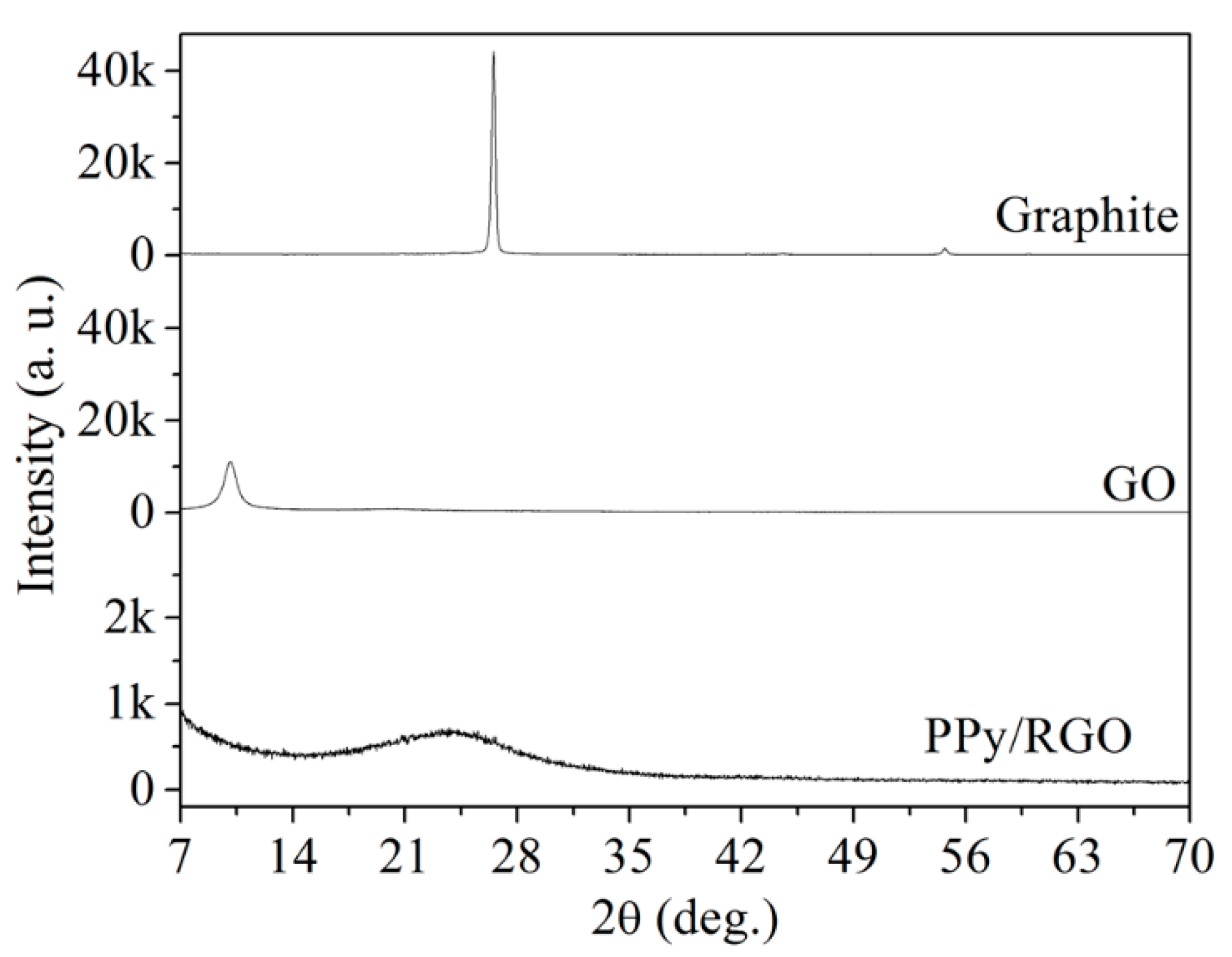

3. Preparation of the Sensing Film

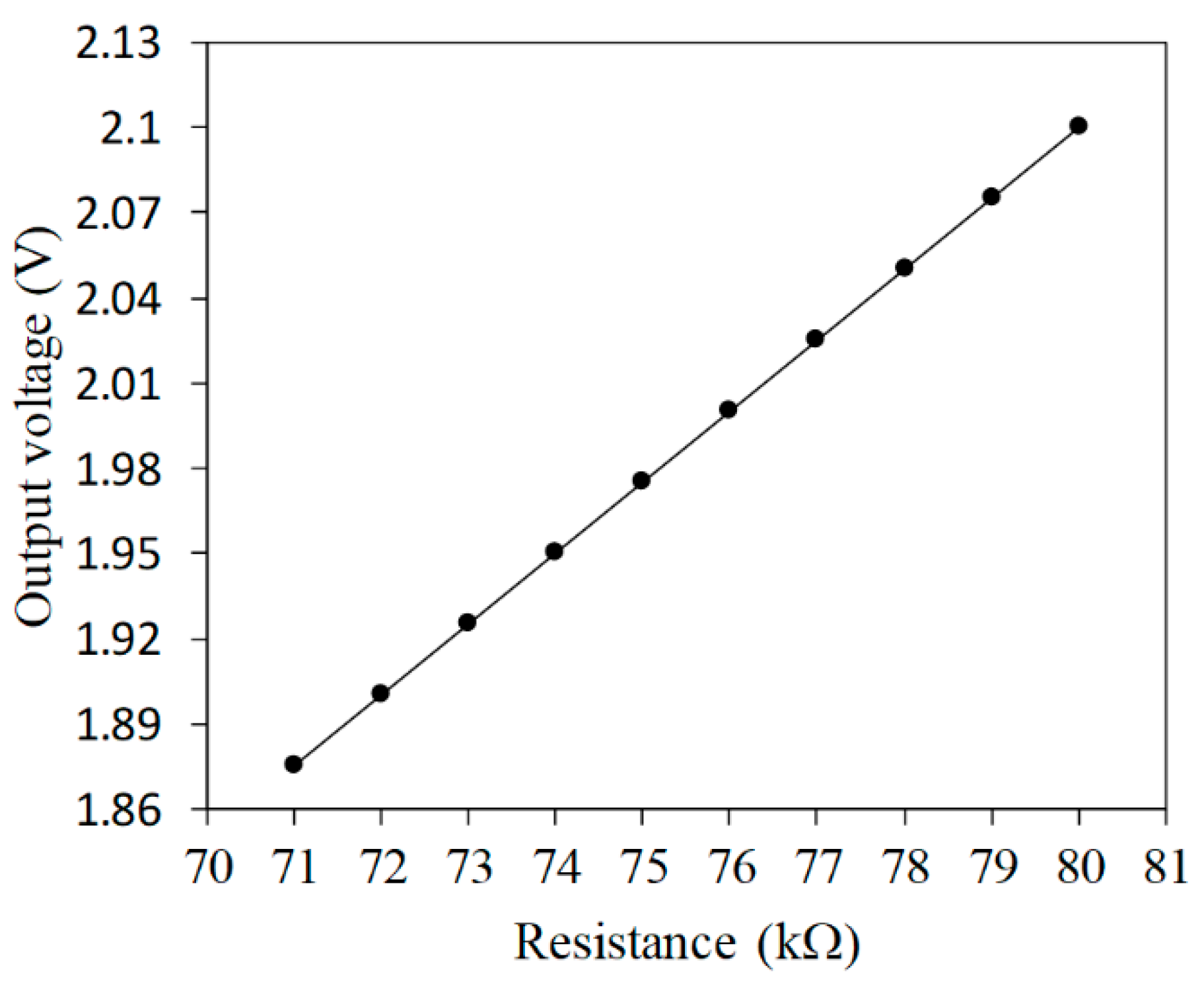

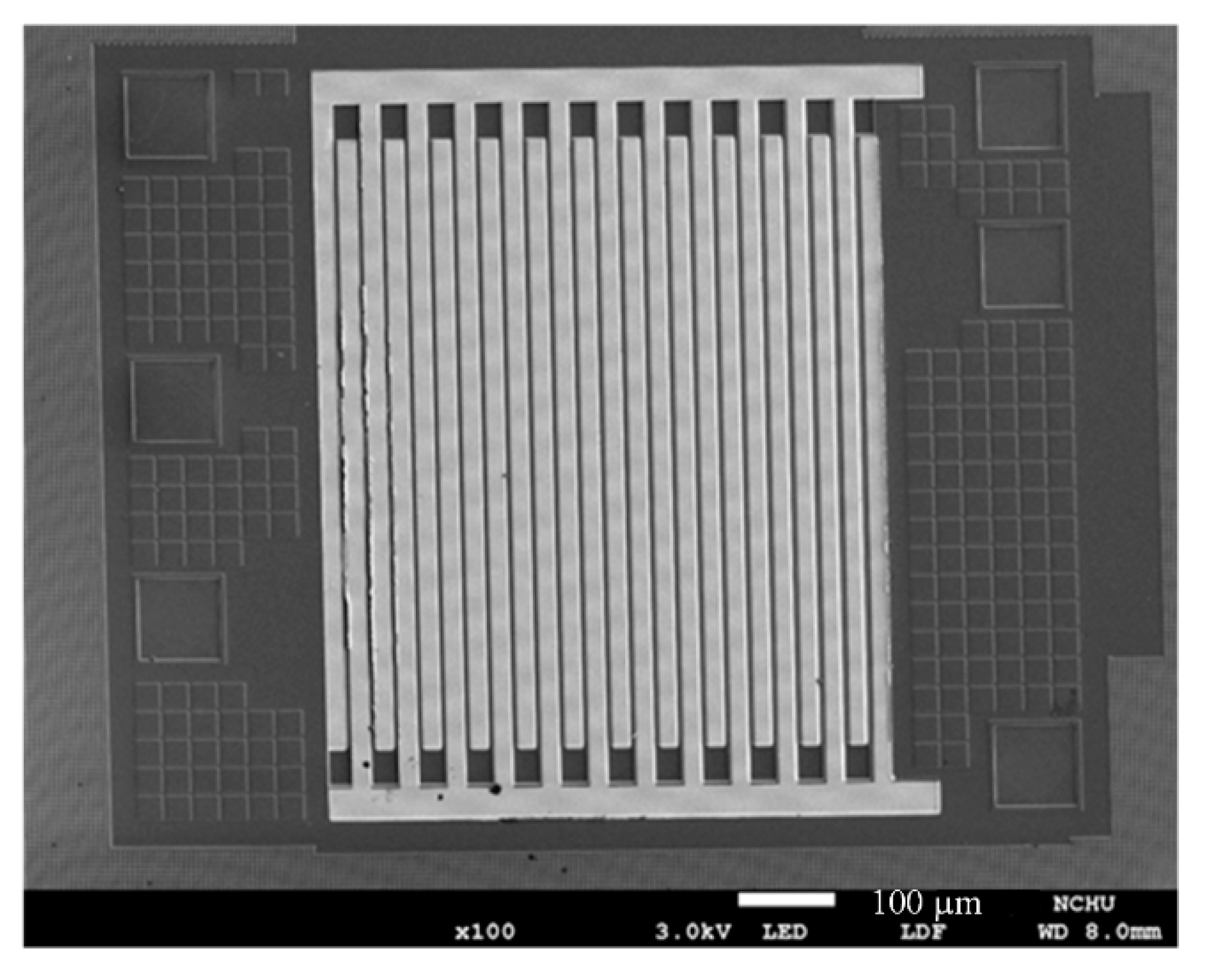

4. Fabrication of the Ammonia Sensor

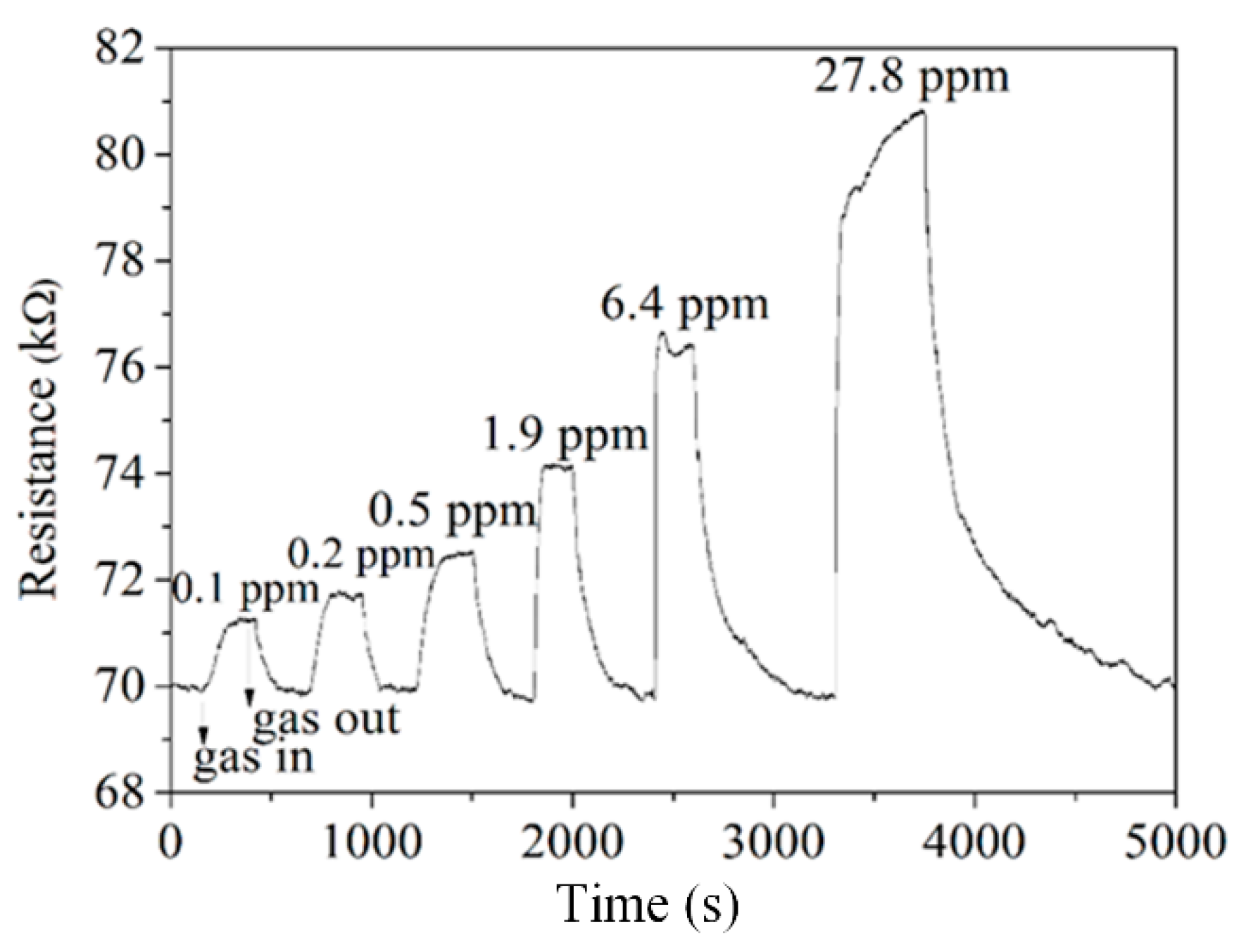

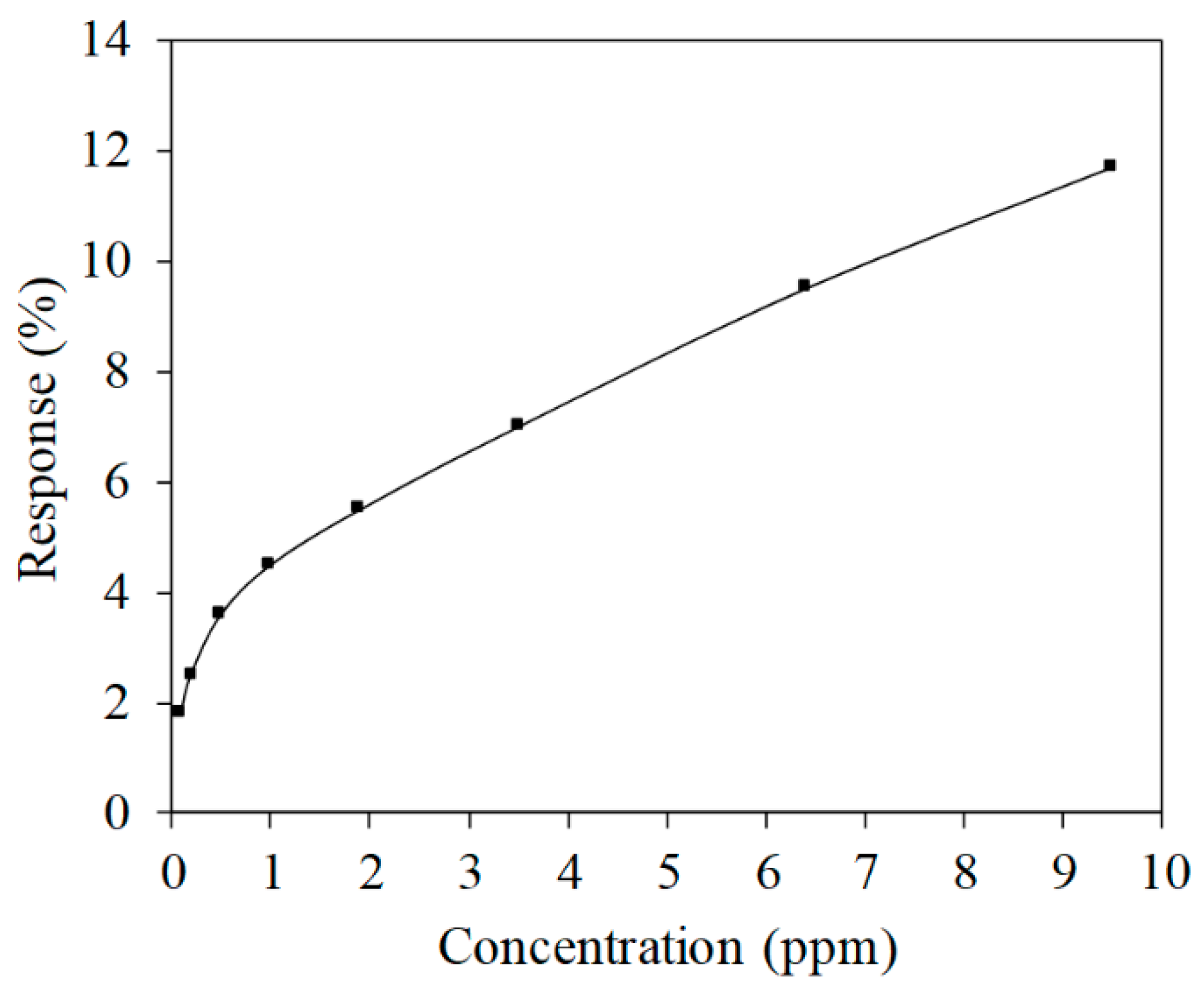

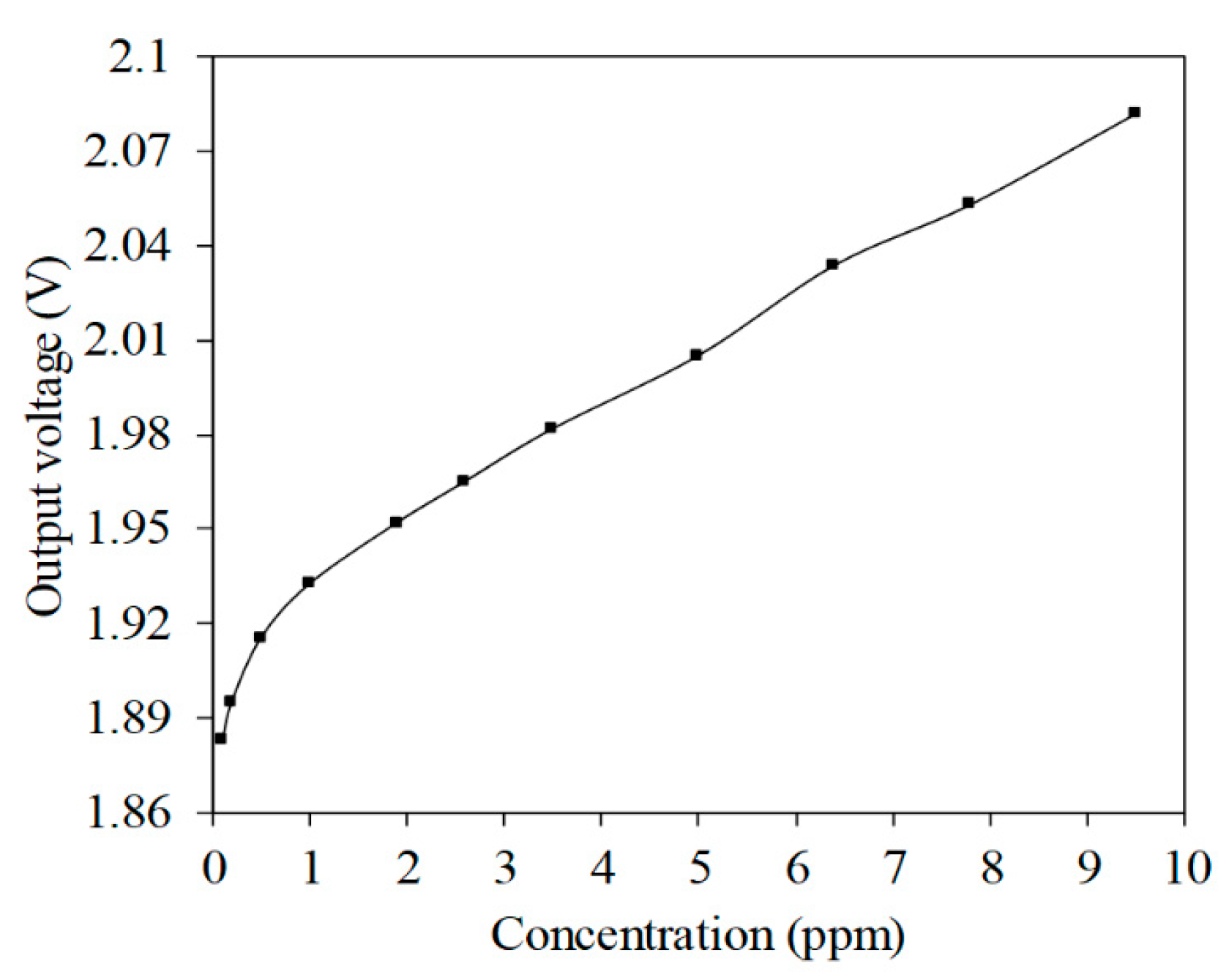

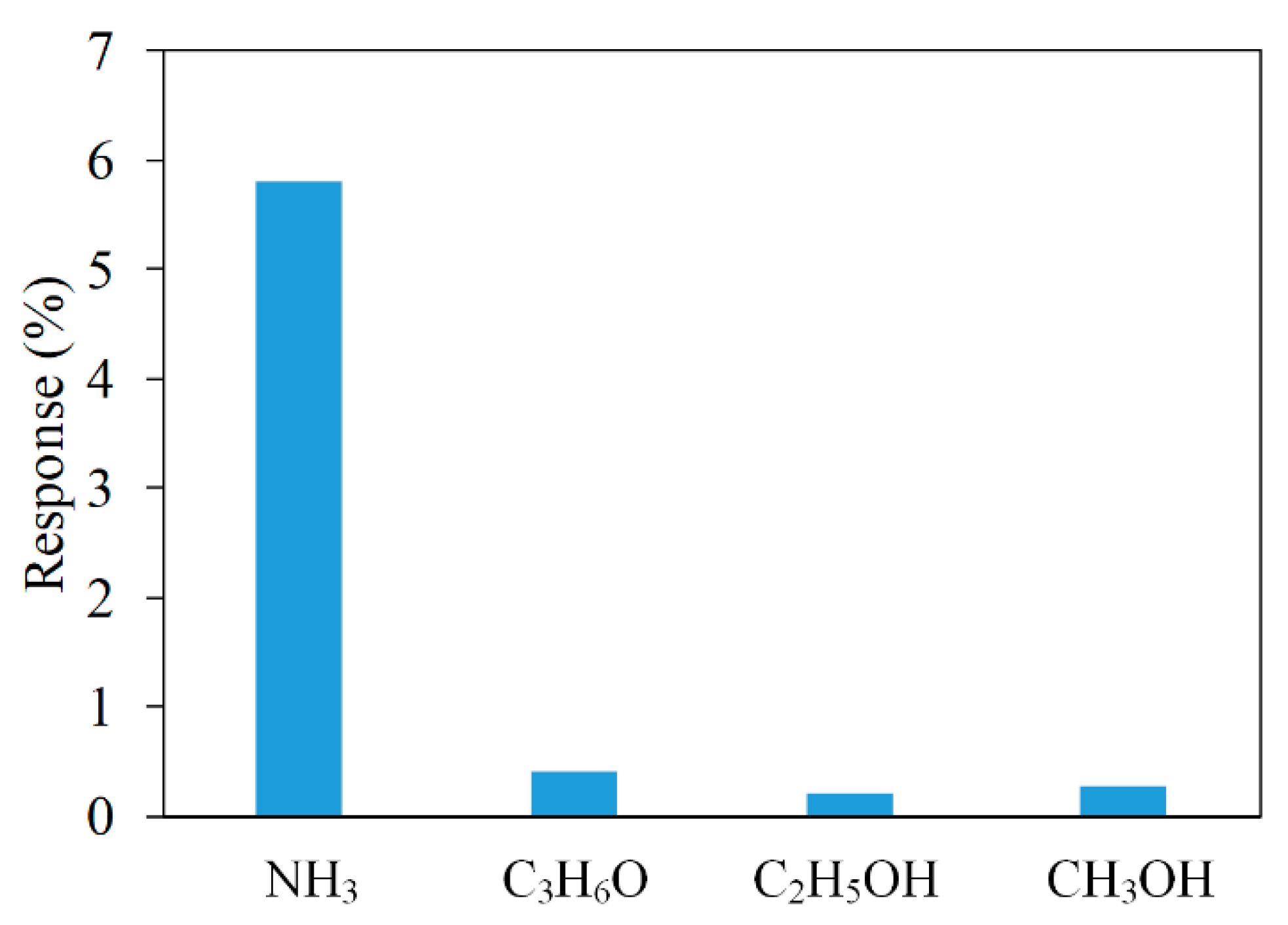

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pauling, L.; Robinson, A.B.; Teranishi, R.; Cary, P. Quantitative analysis of urine vapor and breath by gas-liquid partition chromatography. Proc. Natl. Acad. Sci. USA 1971, 68, 2374–2376. [Google Scholar] [CrossRef]

- Turner, C.; Španěl, P.; Smith, D. A longitudinal study of ammonia, acetone and propanol in the exhaled breath of 30 subjects using selected ion flow tube mass spectrometry, SIFT-MS. Physiol. Meas. 2006, 27, 321. [Google Scholar] [CrossRef] [PubMed]

- Davies, S.; Spanel, P.; Smith, D. Quantitative analysis of ammonia on the breath of patients in end-stage renal failure. Kidney Int. 1997, 52, 223–228. [Google Scholar] [CrossRef] [PubMed]

- Gatty, H.K.; Stemme, G.; Roxhed, N. A Miniaturized amperometric hydrogen sulfide sensor applicable for bad breath monitoring. Micromachines 2018, 9, 612. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.-W.; Chiang, C.-C. Sandwiched long-period fiber grating fabricated by MEMS process for CO2 gas detection. Micromachines 2016, 7, 35. [Google Scholar] [CrossRef]

- Pranti, A.S.; Loof, D.; Kunz, S.; Zielasek, V.; Bäumer, M.; Lang, W. Design and fabrication challenges of a highly sensitive thermoelectric-based hydrogen gas sensor. Micromachines 2019, 10, 650. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Li, K.H.H.; Tan, O.K. Microhotplates for metal oxide semiconductor gas sensor applications—towards the CMOS-MEMS monolithic approach. Micromachines 2018, 9, 557. [Google Scholar] [CrossRef]

- Chen, D.; Yang, L.; Yu, W.; Wu, M.; Wang, W.; Wang, H. Micro-electromechanical acoustic resonator coated with polyethyleneimine nanofibers for the detection of formaldehyde vapor. Micromachines 2018, 9, 62. [Google Scholar] [CrossRef]

- Peng, S.F.; Xie, D.C.; Wang, J.; Chen, M.Q.; Xu, L. Integration of SnO2 nanoparticles with micro-hotplatform for low-power-consumption gas sensors. Sens. Materal. 2018, 30, 2679–2692. [Google Scholar] [CrossRef]

- Kim, J.-H.; Zhou, Q.; Chang, J. Suspended graphene-based gas sensor with 1-mW energy consumption. Micromachines 2017, 8, 44. [Google Scholar] [CrossRef]

- Prajesh, R.; Jain, N.; Agarwal, A. Low power highly sensitive platform for gas sensing application. Microsyst. Technol. 2016, 22, 2185–2192. [Google Scholar] [CrossRef]

- Lee, H.J.; Yoon, J.H.; Kim, B.J.; Jang, H.D.; Kim, J.S. Gas sensing characteristics of Ru doped-WO3 micro gas sensors. Korean J. Met. Materal. 2011, 49, 395–399. [Google Scholar]

- Wu, T.C.; De Luca, A.; Zhong, Q.Y.; Zhu, X.X.; Ogbeide, O.; Um, D.S.; Hu, G.H.; Albrow-Owen, T.; Udrea, F.; Hasan, T. Inkjet-printed CMOS-integrated graphene metal oxide sensors for breath analysis. Npj 2D Mater. Appl. 2019, 3, 42. [Google Scholar] [CrossRef]

- Patois, T.; Sanchez, J.B.; Berger, F.; Rauch, J.Y.; Fievet, P.; Lakard, B. Ammonia gas sensors based on polypyrrole films: Influence of electrodeposition parameters. Sens. Actuators B 2012, 171, 431–439. [Google Scholar] [CrossRef]

- Tiwari, D.C.; Atri, P.; Sharma, R. Sensitive detection of ammonia by reduced graphene oxide/polypyrrole nanocomposites. Synth. Met. 2015, 203, 228–234. [Google Scholar] [CrossRef]

- Lin, C.Y.; Hsu, C.C.; Dai, C.L. Fabrication of a micromachined capacitive switch using the CMOS-MEMS technology. Micromachines 2015, 6, 1645–1654. [Google Scholar] [CrossRef]

- Dai, C.L.; Peng, H.J.; Liu, M.C.; Wu, C.C.; Hsu, H.M.; Yang, L.J. A micromachined microwave switch fabricated by the complementary metal oxide semiconductor post-process of etching silicon dioxide. Jpn. J. Appl. Phys. 2005, 44, 6804–6809. [Google Scholar] [CrossRef]

- Yang, M.Z.; Dai, C.L.; Wu, C.C. Sol-gel zinc oxide humidity sensors integrated with a ring oscillator circuit on-a-chip. Sensors 2014, 14, 20360–20371. [Google Scholar] [CrossRef]

- Dai, C.L.; Chen, Y.C.; Wu, C.C.; Kuo, C.F. Cobalt oxide nanosheet and CNT micro carbon monoxide sensor integrated with readout circuit on chip. Sensors 2010, 10, 1753–1764. [Google Scholar] [CrossRef]

- Yang, M.Z.; Dai, C.L.; Shih, P.J. An acetone microsensor with a ring oscillator circuit fabricated using the commercial 0.18 μm CMOS Process. Sensors 2014, 14, 12735–12747. [Google Scholar] [CrossRef]

- Gustafsson, G.; Lundström, I.; Liedberg, B.C.; Wu, R.; Inganäs, O. The interaction between ammonia and poly(pyrrole). Synth. Met. 1989, 31, 163–179. [Google Scholar] [CrossRef]

- Sedra, A.S.; Smith, K.C. Microelectronic Circuits; Oxford University Press: New York, NY, USA, 1998. [Google Scholar]

- Hummers, W.S.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Amarnath, C.A.; Hong, C.E.; Kim, N.H.; Ku, B.C.; Kuila, T.; Lee, J.H. Efficient synthesis of graphene sheets using pyrrole as a reducing agent. Carbon 2011, 49, 3497–3502. [Google Scholar] [CrossRef]

- Dai, C.L.; Chen, H.L.; Chang, P.Z. Fabrication of a micromachined optical modulator using the CMOS process. J. Micromech. Microeng. 2001, 11, 612–615. [Google Scholar] [CrossRef]

- Dai, C.L.; Chiou, J.H.; Lu, M.S.C. A maskless post-CMOS bulk micromachining process and its application. J. Micromech. Microeng. 2005, 15, 2366–2371. [Google Scholar] [CrossRef]

- Khuspe, G.D.; Navale, S.T.; Chougule, M.A.; Patil, V.B. Ammonia gas sensing properties of CSA doped PANi-SnO2 nanohybrid thin films. Synth. Met. 2013, 185, 1–8. [Google Scholar] [CrossRef]

- Bandgar, D.K.; Navale, S.T.; Navale, Y.H.; Ingole, S.M.; Stadler, F.J.; Ramgir, N. Flexible camphor sulfonic acid-doped PAni/α-Fe2O3 nanocomposite films and their room temperature ammonia sensing activity. Mater. Chem. Phys. 2017, 189, 191–197. [Google Scholar] [CrossRef]

- Merian, T.; Redon, N.; Zujovic, Z.; Stanisavljev, D.; Wojkiewicz, J.L.; Gizdavic-Nikolaidis, M. Ultra sensitive ammonia sensors based on microwave synthesized nanofibrillar polyanilines. Sens. Actuators B 2014, 203, 626–634. [Google Scholar] [CrossRef]

| Authors | Process | Sensing Material | Heater | Working Temperature |

|---|---|---|---|---|

| Peng [9] | MEMS (microelectromechanical system) | Tin dioxide | Yes | 225 °C |

| Kim [10] | Micromachining | Graphene sheet | Yes | 200 °C |

| Prajesh [11] | Microfabrication | Metal oxide | Yes | 230 °C |

| Lee [12] | MEMS | Tungsten trioxide/Ru | Yes | 333 °C |

| Wu [13] | Micromachining/inkjet printing | Graphene metal oxide | Yes | 325 °C |

| Patois [14] | Microfabrication | Polypyrrole | No | Room temperature |

| Tiwari [15] | Micromachining | Pyrrole/reduced graphene oxide | No | Room temperature |

| Authors | Gas | Response | Detectability | Formula of Response |

|---|---|---|---|---|

| Lee [12] | NH3 | 3.4 (5 ppm) | 1 ppm | S = Rg/Ra |

| Wu [13] | NH3 | 15 (10 ppm) | 1 ppm | S = Rg/Ra |

| Patois [14] | NH3 | 16% (40 ppm) | 3 ppm | S = (Rg− Ra)/Ra × 100% |

| Tiwari [15] | NH3 | 1.1% (3 ppm) | 3 ppm | S = (Rg− Ra)/Ra × 100% |

| Bandgar [28] | NH3 | 72% (100 ppm) | 2.5 ppm | S = (Rg− Ra)/Ra × 100% |

| Khuspe [27] | NH3 | 91% (100 ppm) | 10 ppm | S = (Rg− Ra)/Ra × 100% |

| Merian [29] | NH3 | 350% (5 ppm) | 0.1 ppm | S = (Rg− Ra)/Ra × 100% |

| This work | NH3 | 4.5% (1 ppm) | 0.1 ppm | S = (Rg− Ra)/Ra × 100% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, W.-C.; Shih, P.-J.; Tsai, Y.-C.; Hsu, C.-C.; Dai, C.-L. Low-Concentration Ammonia Gas Sensors Manufactured Using the CMOS–MEMS Technique. Micromachines 2020, 11, 92. https://doi.org/10.3390/mi11010092

Shen W-C, Shih P-J, Tsai Y-C, Hsu C-C, Dai C-L. Low-Concentration Ammonia Gas Sensors Manufactured Using the CMOS–MEMS Technique. Micromachines. 2020; 11(1):92. https://doi.org/10.3390/mi11010092

Chicago/Turabian StyleShen, Wei-Chun, Po-Jen Shih, Yao-Chuan Tsai, Cheng-Chih Hsu, and Ching-Liang Dai. 2020. "Low-Concentration Ammonia Gas Sensors Manufactured Using the CMOS–MEMS Technique" Micromachines 11, no. 1: 92. https://doi.org/10.3390/mi11010092

APA StyleShen, W.-C., Shih, P.-J., Tsai, Y.-C., Hsu, C.-C., & Dai, C.-L. (2020). Low-Concentration Ammonia Gas Sensors Manufactured Using the CMOS–MEMS Technique. Micromachines, 11(1), 92. https://doi.org/10.3390/mi11010092