Sustainable Fully Printed UV Sensors on Cork Using Zinc Oxide/Ethylcellulose Inks

Abstract

1. Introduction

2. Experimental Section

3. Results and Discussion

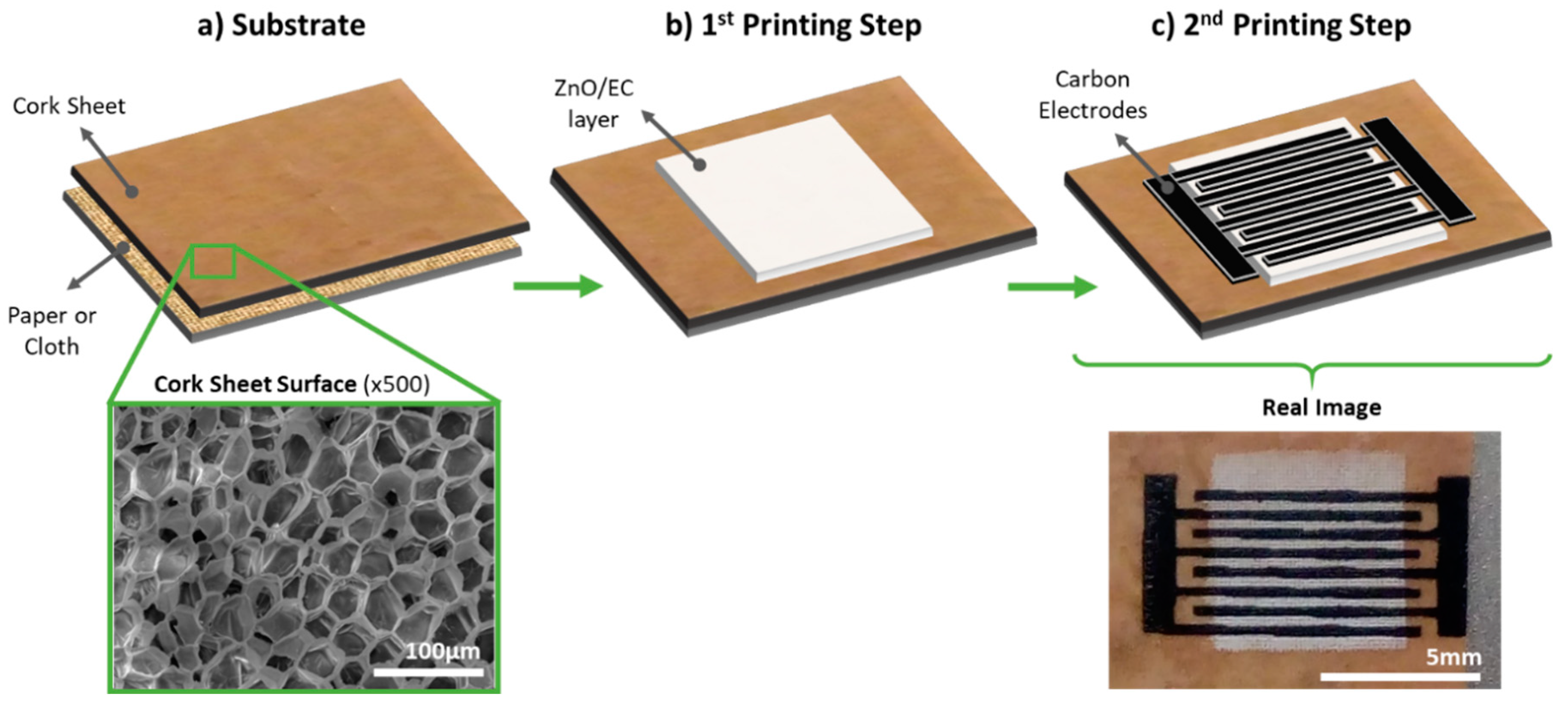

3.1. Substrate and Printing Process

3.2. Electrical Characterization

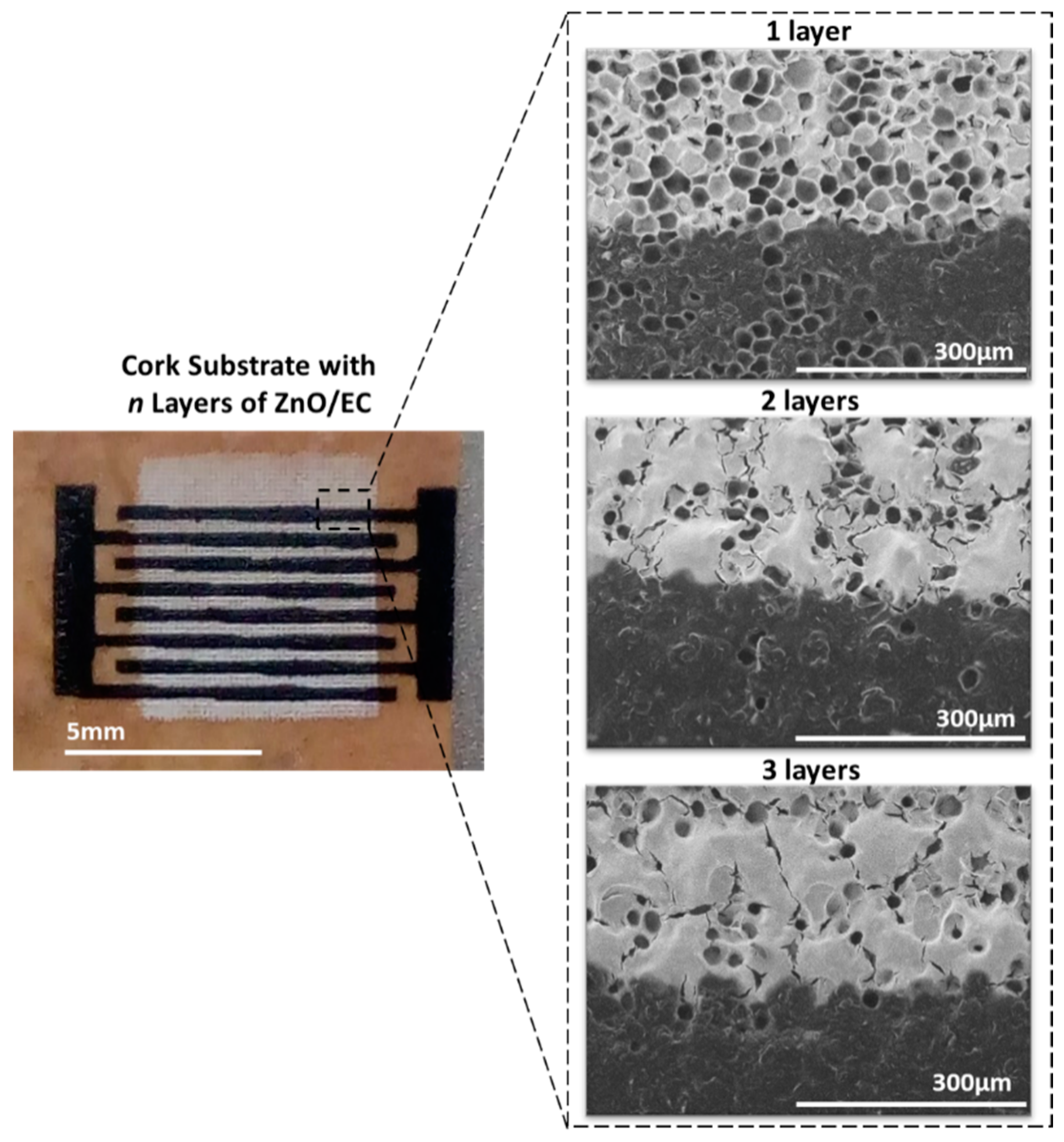

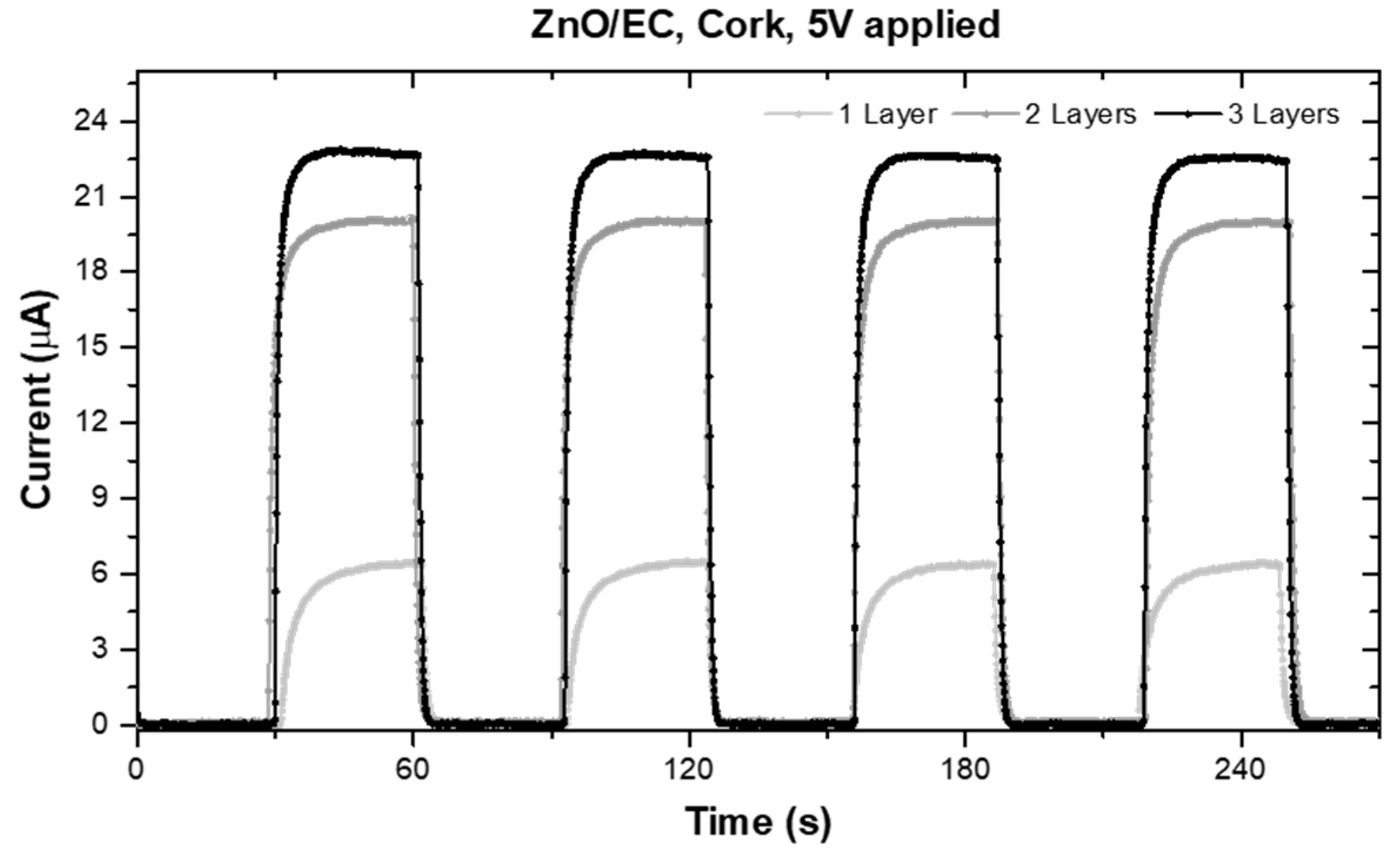

3.2.1. Number of printed ZnO/EC layers

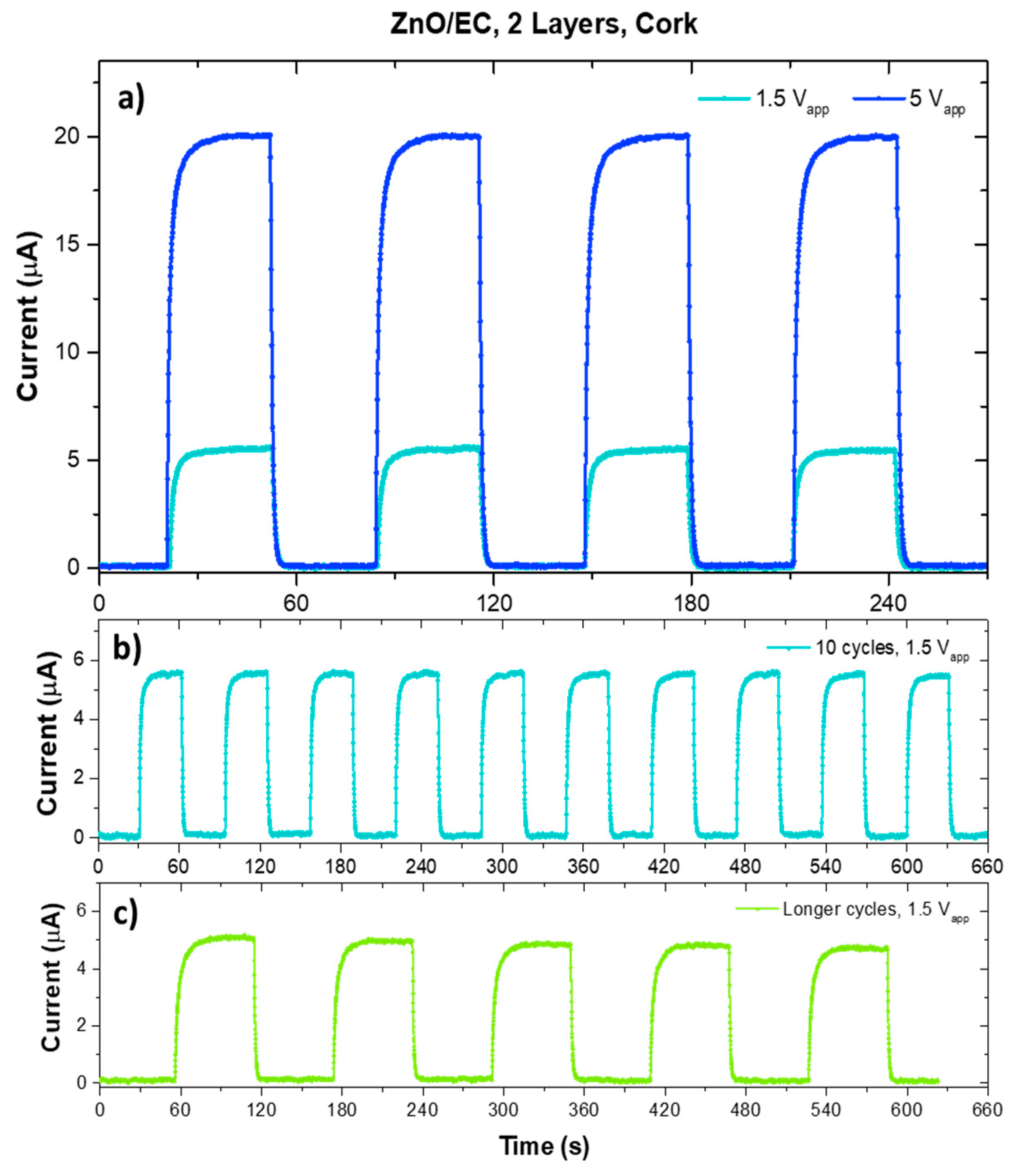

3.2.2. Voltage and Cycle Times

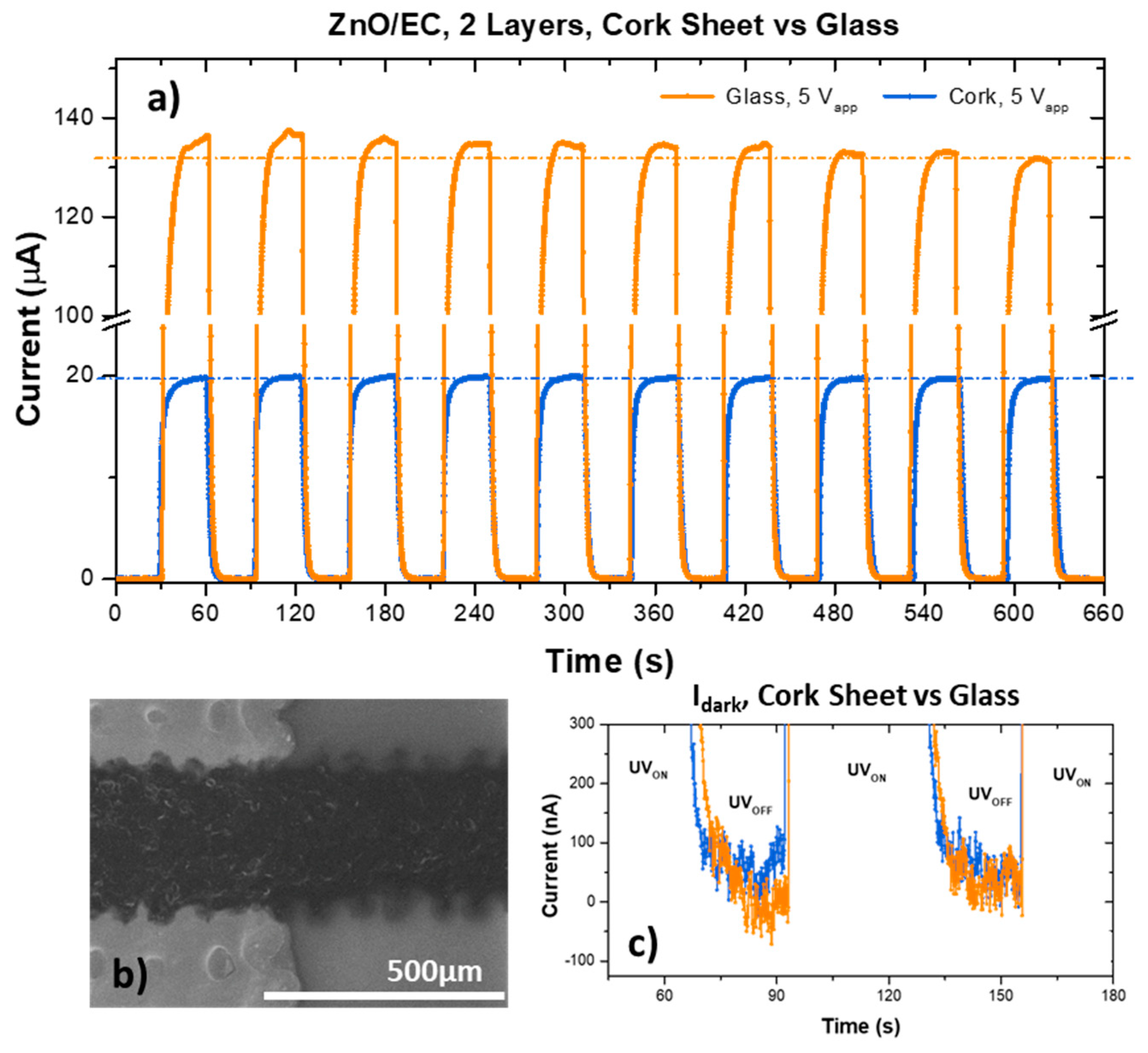

3.2.3. Cork vs. Glass Substrate

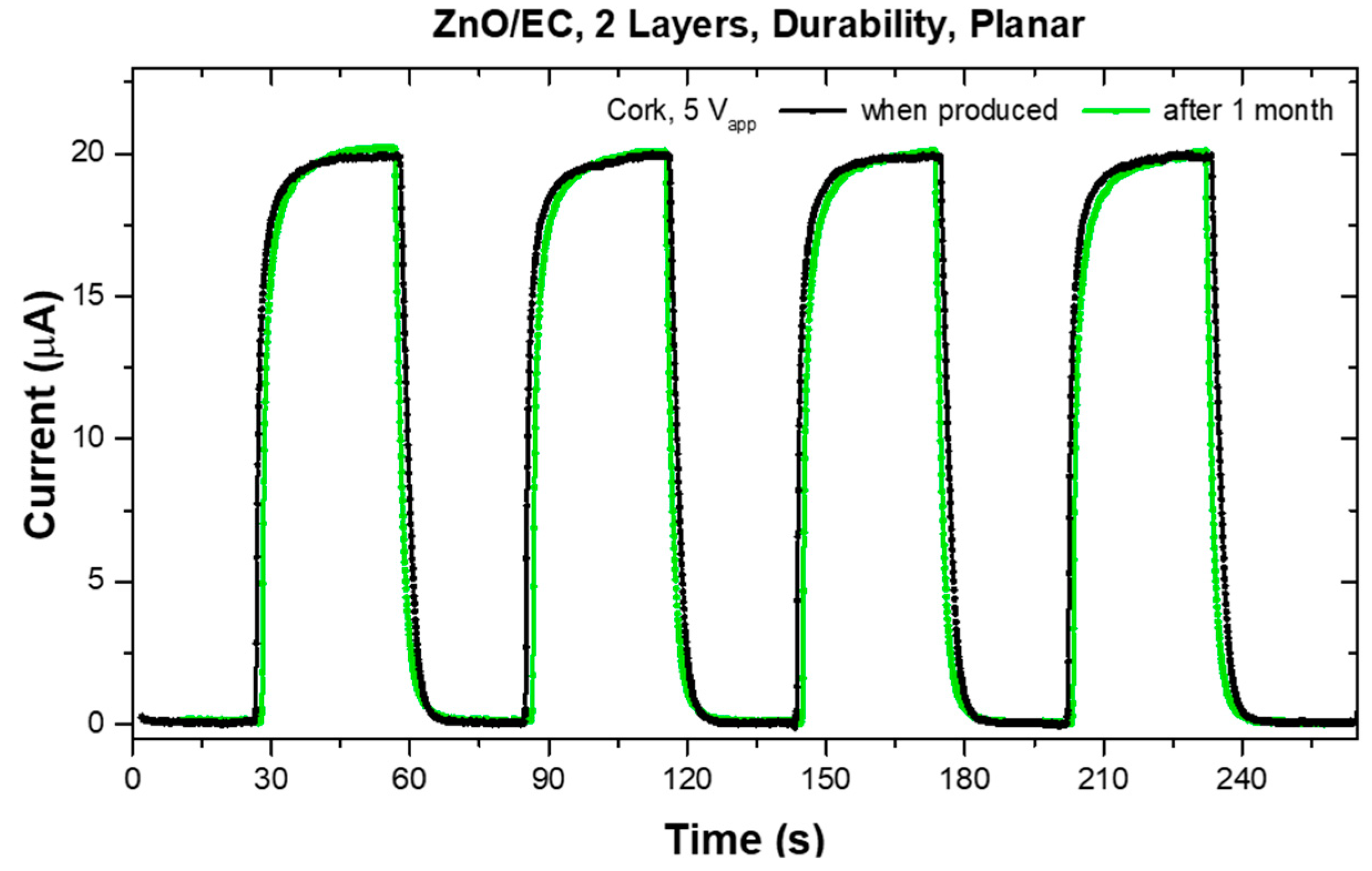

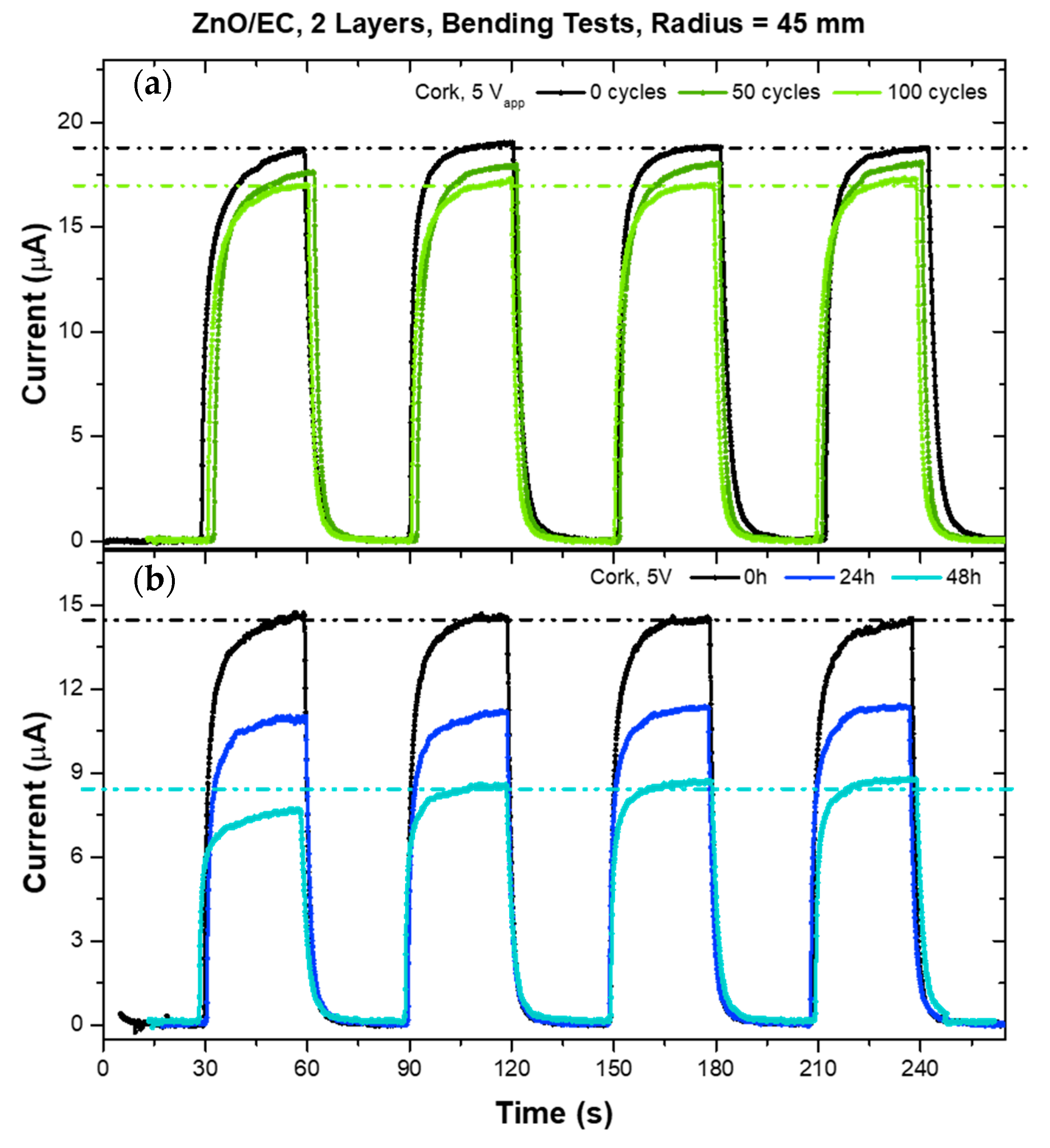

3.2.4. Adhesion, Bending, and Durability

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hayward, J. Wearable Technology 2018–2028: Markets Players Forecasts: IDTechEx. 2018. Available online: https://www.idtechex.com/en/research-report/wearable-technology-forecasts-2019-2029/680 (accessed on 6 September 2019).

- Statista Research Department. Internet of Things (IoT) connected devices installed base worldwide from 2015 to 2025. Available online: https://www.statista.com/statistics/471264/iot-number-of-connected-devices-worldwide/ (accessed on 6 September 2019).

- Zaia, E.W.; Gordon, M.P.; Yuan, P.; Urban, J.J. Progress and Perspective: Soft Thermoelectric Materials for Wearable and Internet-of-Things Applications. Adv. Electron. Mater. 2019, 1800823, 1–20. [Google Scholar] [CrossRef]

- Barras, R.; Cunha, I.; Gaspar, D.; Fortunato, E.; Martins, R.; Pereira, L. Printable cellulose-based electroconductive composites for sensing elements in paper electronics. Flex. Print. Electron. 2017, 2, 1–12. [Google Scholar] [CrossRef]

- Hasan, K.; Nur, O.; Willander, M. Screen printed ZnO ultraviolet photoconductive sensor on pencil drawn circuitry over paper. Appl. Phys. Lett. 2012, 100, 211104. [Google Scholar] [CrossRef]

- Lezi, N.; Economopoulos, S.; Prodromidis, M.; Economou, A.; Tagmatarchis, N. Fabrication of a “Green” and Low-Cost Screen-Printed Graphene Sensor and Its Application to the Determination of Caffeine by Adsorptive Stripping Voltammetry. Int. J. Electrochem. Sci. 2017, 12, 6054–6067. [Google Scholar] [CrossRef]

- Ferri, J.; Vicente, J.; Moreno, J.; Martinez, G.; Garcia-Breijo, E. A Wearable Textile 2D Touchpad Sensor Based on Screen-Printing Technology. Materials 2017, 10, 1450. [Google Scholar] [CrossRef] [PubMed]

- Margarida, M.; Moura, J.; Galhano, R. Ultimate use of Cork–Unorthodox and innovative applications. Cienc. Tecnol. Mater. 2017, 29, 65–72. [Google Scholar]

- Aroso, I.M.; Araújo, A.R.; Pires, R.A.; Reis, R.L. Cork: current technological developments and future perspectives for this natural, renewable, and sustainable material. ACS Sustain. Chem. Eng. 2017, 5, 11130–11146. [Google Scholar] [CrossRef]

- Gonçalves, M.C.; Margarido, F.; SIMÕES, A. Cortiça. In Ciência e Engenharia de Materiais de Construção, Chapter: chapter 13; IST Press: Lisbon, Portugal, 2012; pp. 663–715. [Google Scholar]

- Mun, S.; Kim, H.C.; Ko, H.; Zhai, L.; Kim, J.W.; Kim, J. Flexible cellulose and ZnO hybrid nanocomposite and its UV sensing characteristics. Sci. Technol. Adv. Mater. 2017, 18, 437–446. [Google Scholar] [CrossRef] [PubMed]

- Grey, P.; Gaspar, D.; Cunha, I.; Barras, R.; Carvalho, J.T.; Ribas, J.R. Handwritten Oxide Electronics on Paper. Adv. Mater. Technol. 2017, 2, 1700009. [Google Scholar] [CrossRef]

- Pimentel, A.; Samouco, A.; Nunes, D.; Fortunato, E. Ultra-Fast Microwave Synthesis of ZnO Nanorods on Cellulose Substrates for UV Sensor Applications. Materials 2017, 10, 1308. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, T.; Dubceac, V.; Grey, P.; Fortunato, E. Fully Printed Zinc Oxide Electrolyte-Gated Transistors on Paper. Nanomaterials 2019, 6, 169. [Google Scholar] [CrossRef] [PubMed]

- Al-hardan, N.H.; Azmi, M.; Hamid, A. Ultraviolet Sensors Based on Two-Dimensional Zinc Oxide Structures. In Optoelectronics—Advanced Device Structures, Chapter: Chapter 12; IntechOpen: London, UK, 2017; pp. 251–267. [Google Scholar]

- Hennessy, M.G.; Ferretti, G.L.; Cabral, J.T.; Matar, O.K. A minimal model for solvent evaporation and absorption in thin films. J Colloid Interface Sci. 2017, 488, 61–71. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.P.; Das, K.C.; Tripathy, N. Ultraviolet photodetection characteristics of Zinc oxide thin films and nanostructures. In Conference Series: Materials Science and Engineering; IOP Publishing: Lisboa, Portugal, 2016; p. 012035. [Google Scholar]

- Pattamang, P.; Jiramitmonkon, K.; Piyakulawat, P. Photoresponse of composites of zinc oxide and poly(3-hexythiophene) under selective UV and white-light illumination. Org. Electron. 2016, 39, 105–112. [Google Scholar] [CrossRef]

- Panda, S.K.; Jacob, C. Solid-State Electronics Preparation of transparent ZnO thin films and their application in UV sensor devices. Solid-State Electron. 2012, 73, 44–50. [Google Scholar] [CrossRef]

- Bender, M.; Fortunato, E.; Nunes, P. Highly Sensitive ZnO Ozone detectors at Room Temperature. Jpn. J. Appl. Phys. 2003, 42, L435–L437. [Google Scholar] [CrossRef]

- Soci, C.; Zhang, A.; Xiang, B.; Dayeh, S.A.; Aplin, D.P.R.; Park, J. ZnO Nanowire UV Photodetectors with High Internal Gain. Nano Lett. 2007, 7, 1003–1009. [Google Scholar] [CrossRef] [PubMed]

- Mallampati, B.; Nair, S.V.; Ruda, H.E.; Philipose, U. Role of surface in high photoconductive gain measured in ZnO nanowire-based photodetector. J. Nanopart. Res. 2015, 17, 176–186. [Google Scholar] [CrossRef]

| Applied Voltage (V) | Rise Time (s) | Fall Time (s) |

|---|---|---|

| 1.5 | 4.4 ± 0.5 | 1.9 ± 0.1 |

| 5.0 | 3.6 ± 0.2 | 1.5 ± 0.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Figueira, J.; Gaspar, C.; Carvalho, J.T.; Loureiro, J.; Fortunato, E.; Martins, R.; Pereira, L. Sustainable Fully Printed UV Sensors on Cork Using Zinc Oxide/Ethylcellulose Inks. Micromachines 2019, 10, 601. https://doi.org/10.3390/mi10090601

Figueira J, Gaspar C, Carvalho JT, Loureiro J, Fortunato E, Martins R, Pereira L. Sustainable Fully Printed UV Sensors on Cork Using Zinc Oxide/Ethylcellulose Inks. Micromachines. 2019; 10(9):601. https://doi.org/10.3390/mi10090601

Chicago/Turabian StyleFigueira, Joana, Cristina Gaspar, José Tiago Carvalho, Joana Loureiro, Elvira Fortunato, Rodrigo Martins, and Luís Pereira. 2019. "Sustainable Fully Printed UV Sensors on Cork Using Zinc Oxide/Ethylcellulose Inks" Micromachines 10, no. 9: 601. https://doi.org/10.3390/mi10090601

APA StyleFigueira, J., Gaspar, C., Carvalho, J. T., Loureiro, J., Fortunato, E., Martins, R., & Pereira, L. (2019). Sustainable Fully Printed UV Sensors on Cork Using Zinc Oxide/Ethylcellulose Inks. Micromachines, 10(9), 601. https://doi.org/10.3390/mi10090601