Liquid Refractive Index Measurement System Based on Electrowetting Lens

Abstract

:1. Introduction

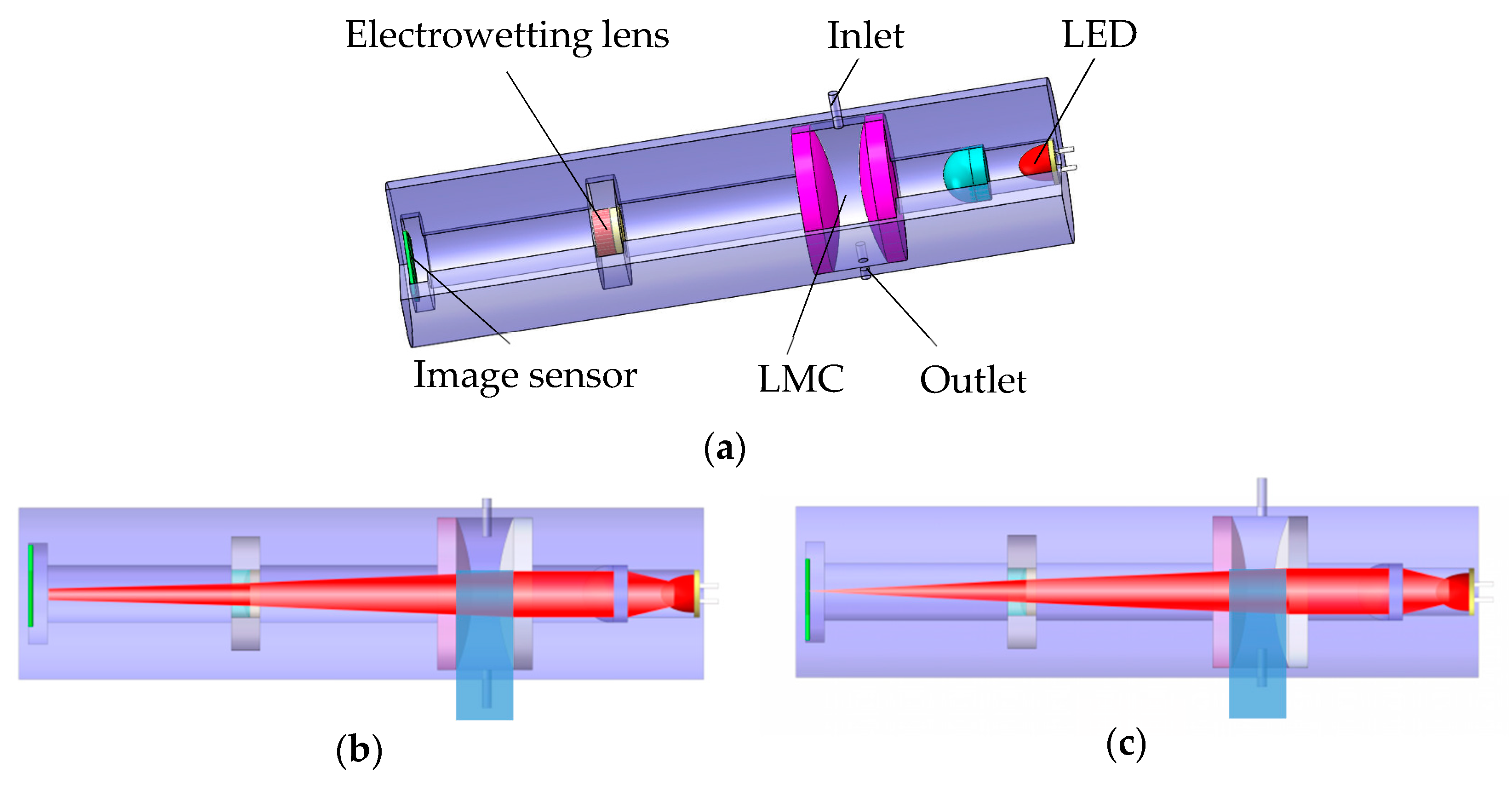

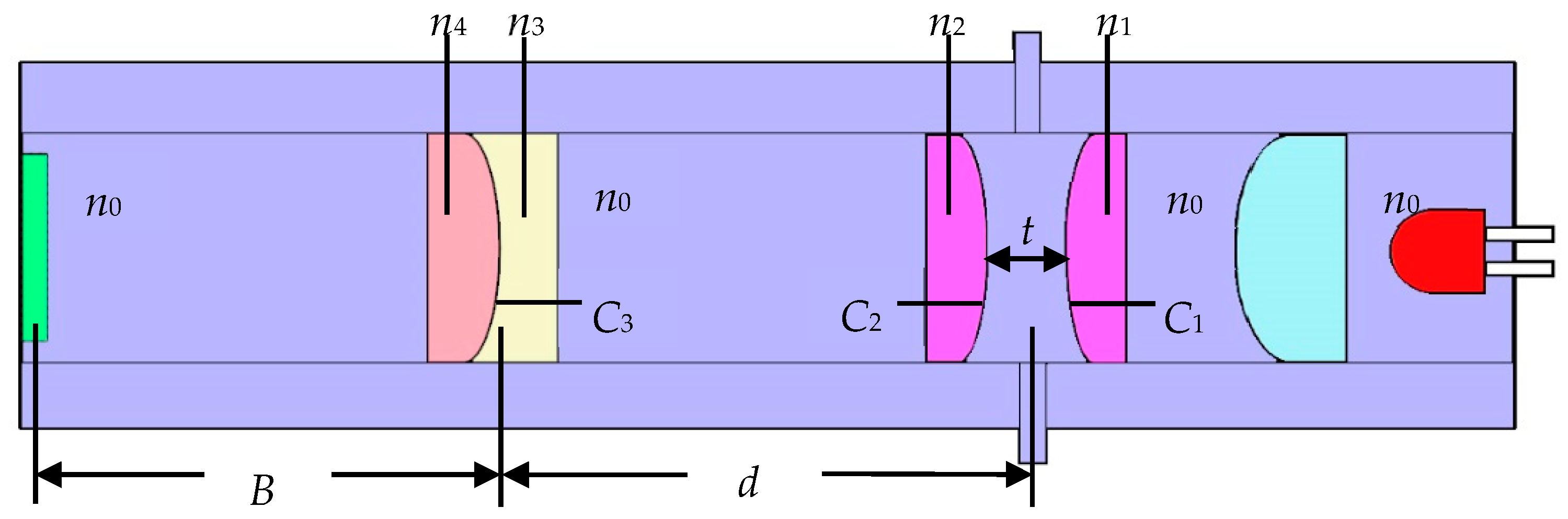

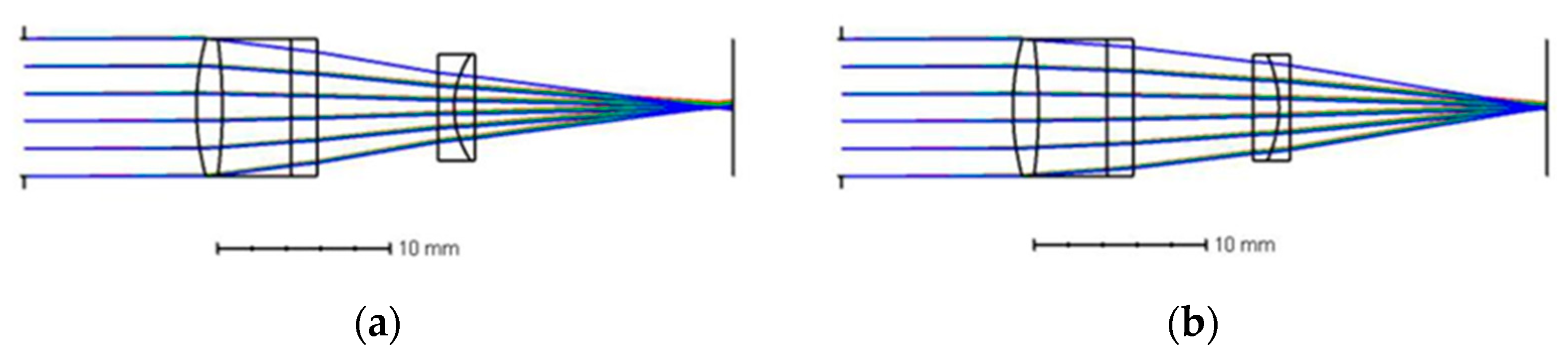

2. Structure and Operating Principle

2.1. Structure and Mechanism of the System

2.2. Theory of the Proposed System

2.3. Fabrication of the Proposed System

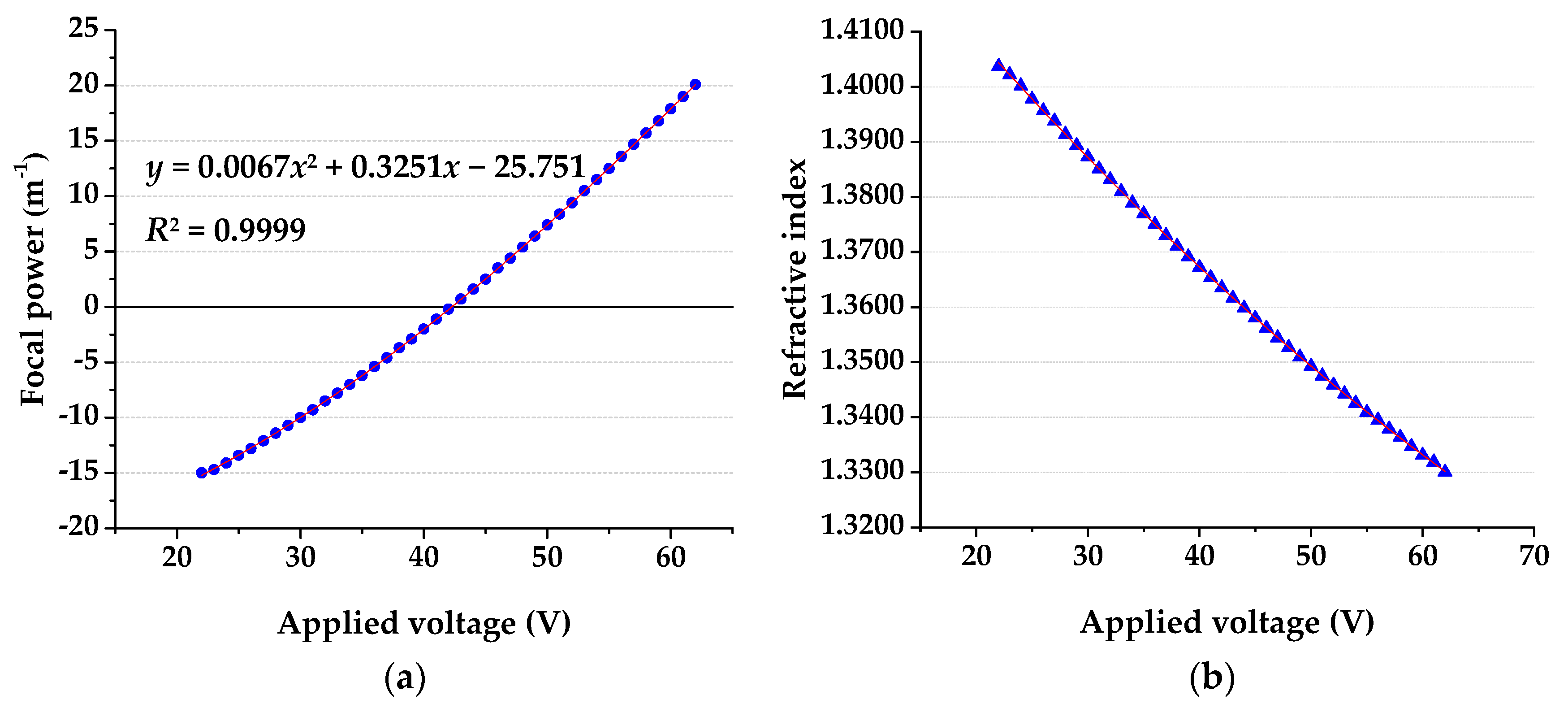

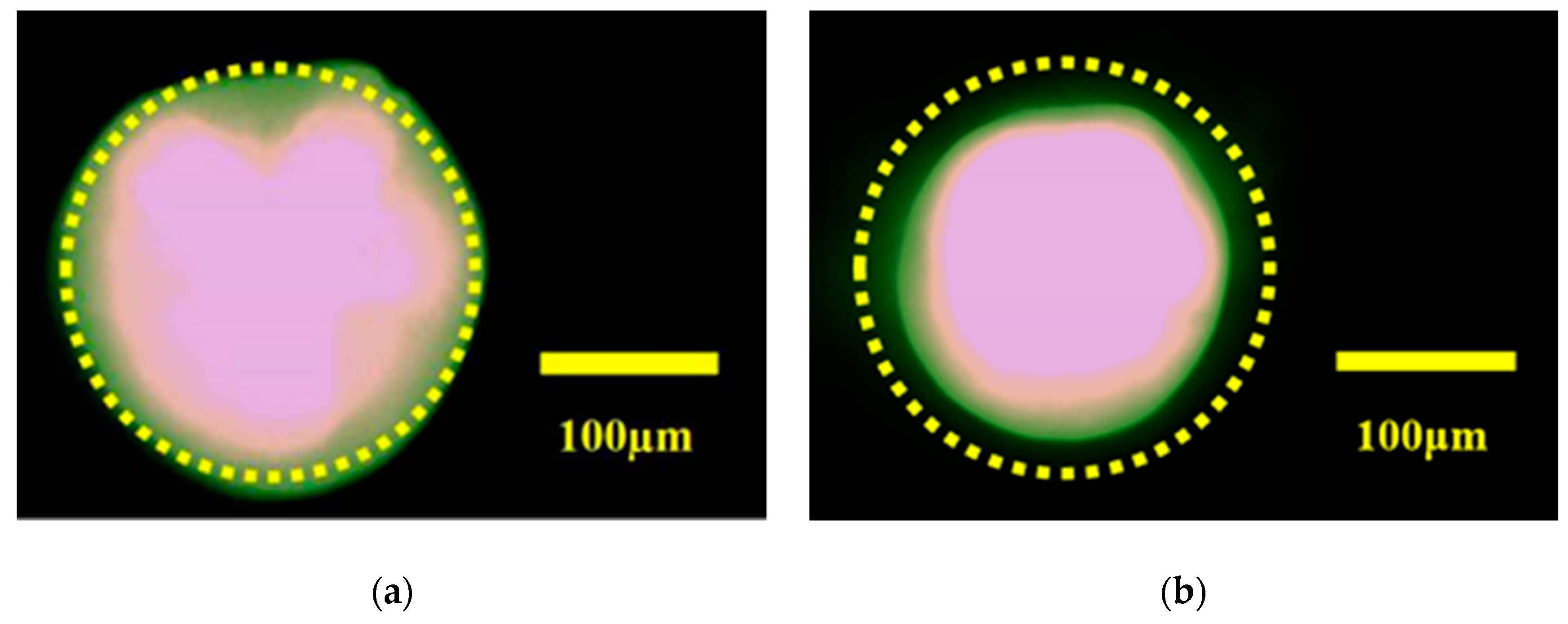

3. Experiments and Discussion

3.1. Experiment of the Proposed System

3.2. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yan, X.; Li, B.; Cheng, T.L.; Li, S.G. Analysis of high sensitivity photonic crystal fiber sensor based on surface plasmon resonance of refractive indexes of liquids. Sensors 2018, 18, 2922. [Google Scholar] [CrossRef] [PubMed]

- Syed, M.B. Analysis of biodiesel by high performance liquid chromatography using refractive index detector. Methods X 2017, 4C, 256–259. [Google Scholar] [CrossRef] [PubMed]

- Rheims, J.; Köser, J.; Wriedt, T. Refractive-index measurements in the near-IR using an Abbe refractometer. Meas. Sci. Technol. 1999, 8, 601. [Google Scholar] [CrossRef]

- Takeo, T.; Hattori, H. Optical fiber sensor for measuring refractive index. Jpn. J. Appl. Phys. 1982, 21, 1509. [Google Scholar] [CrossRef]

- Tai, Y.H.; Wei, P.K. Sensitive liquid refractive index sensors using tapered optical fiber tips. Opt. Lett. 2010, 35, 944–946. [Google Scholar] [CrossRef] [PubMed]

- Roth, N.; Klaus, A.; Arnold, F. Refractive-index measurements for the correction of particle sizing methods. Appl. Opt. 1991, 30, 4960–4965. [Google Scholar] [CrossRef] [PubMed]

- Singh, S. Measuring the refractive index of a liquid using a laser. Phys. Educ. 2002, 37, 152–153. [Google Scholar] [CrossRef]

- Wenzel, R.G.; Arnold, G.P. Measurement of refractive index of small liquid specimens in capillaries. Rev. Sci. Inst. 1969, 40, 1355–1360. [Google Scholar] [CrossRef]

- Sun, J.H.; Wang, M. Measuring the refractive index of liquid by optical fiber Young’s interference experiment. Phys. Exp. Coll. 2005, 18, 8–10. [Google Scholar]

- Deng, G.A.; Cai, Z.; Zhang, Y.; Xu, Y.; Wu, S.; Zhou, J. Refraction index measurement of transparent materials by using diffraction grating and CCD. Acta Opt. Sin. 2004, 24, 99–103. [Google Scholar]

- Shyam, S. Diffraction method measures refractive indices of liquids. Phys. Educ. 2004, 39, 235. [Google Scholar]

- Domachuk, P.; Littler, I.C.M.; Golomb, M.C.; Eggleton, B.J. Compact resonant integrated microfluidic refractometer. Appl. Phys. Lett. 2006, 88, 093513. [Google Scholar] [CrossRef]

- Campopiano, S.; Bernini, R.; Zeni, L.; Sarro, P.M. Microfluidic sensor based on integrated optical hollow waveguides. Opt. Lett. 2004, 29, 1894–1896. [Google Scholar] [CrossRef] [PubMed]

- Polynkin, P.; Polynkin, A.; Peyghambarian, N.; Mansuripur, M. Evanescent field-based optical fiber sensing device for measuring the refractive index of liquids in microfluidic channels. Opt. Lett. 2007, 30, 1273–1275. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Horak, P.; Brambilla, G. Optical microfiber coil resonator refractometric sensor. Opt. Express 2007, 15, 7888–7893. [Google Scholar] [CrossRef] [PubMed]

- Calixto, S.; Aguilar, M.R.; Hernandez, D.M.; Minkovich, V.P. Capillary refractometer integrated in a microfluidic configuration. Appl. Opt. 2008, 47, 843–848. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.H.; Jia, W.Y.; He, J.T.; Martial, G.; Zheng, G. A miniaturized system for measurement of the refractive index of sub-microliter liquid. Chin. Opt. Lett. 2019, 17, 51–55. [Google Scholar]

- Liu, C.; Wang, D.; Wang, Q.H. Variable aperture with graded attenuation combined with adjustable focal length lens. Opt. Express 2019, 27, 14075–14084. [Google Scholar] [CrossRef]

- Murade, C.U.; Oh, J.M.; Ende, D.V.D.; Mugele, F. Electrowetting driven optical switch and tunable aperture. Opt. Express 2011, 19, 15525–15531. [Google Scholar] [CrossRef]

- Ren, H.; Xu, S.; Ren, D.; Wu, S.T. Novel optical switch with a reconfigurable dielectric liquid droplet. Opt. Express 2011, 19, 1985–1990. [Google Scholar] [CrossRef]

- Ren, H.; Xu, S.; Liu, Y.F.; Wu, S.T. Liquid-based infrared optical switch. Appl. Phys. Lett. 2012, 101, 041104. [Google Scholar] [CrossRef]

- Liu, C.; Li, L.; Wang, D.; Yao, L.X.; Wang, Q.H. Liquid optical switch based on total internal reflection. IEEE Photonics Technol. Lett. 2015, 27, 2091–2094. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Q.H.; Wang, M.H.; Yao, L.X. Optical switch matrix based on a liquid-actuated mirror reflector. Opt. Eng. 2014, 53, 117107. [Google Scholar] [CrossRef]

- Liu, C.; Wang, D.; Wang, Q.H.; Fang, J.C. Electrowetting-actuated multifunctional optofluidic lens to improve the quality of computer-generated holography. Opt. Express 2019, 27, 12963–12975. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Wang, Q.H.; Shen, C.; Zhou, X.; Liu, C.M. Active optical zoom system. Appl. Opt. 2014, 53, 7402. [Google Scholar] [CrossRef]

- Calixto, S.; Aguilar, M.R.; Marin, F.J.S.; Solano, M.C.; Mariscal, C.L. Refractive index measurement through image analysis with an optofluidic device. Opt. Express 2012, 20, 2073–2080. [Google Scholar] [CrossRef]

- Cheng, C.C. Refractive index measurement by prism autocollimation. Am. J. Phys. 2014, 82, 214–216. [Google Scholar] [CrossRef]

| Concentration of NaCl Solution (%) | Refractive Index in the Literature | Measured Refractive Index | Error (%) | Applied Voltage (V) |

|---|---|---|---|---|

| 1 | 1.3347 | 1.3346 | −0.0075 | 59 |

| 5 | 1.3428 | 1.3425 | −0.0223 | 54 |

| 10 | 1.3515 | 1.3509 | −0.0444 | 49 |

| 15 | 1.3603 | 1.3598 | −0.0368 | 44 |

| 20 | 1.3709 | 1.3710 | 0.0073 | 38 |

| Sucrose Solution Concentration (%) | Measured Refractive Index | Applied Voltage (V) |

|---|---|---|

| 5 | 1.3409 | 55 |

| 10 | 1.3475 | 51 |

| 20 | 1.3635 | 42 |

| 30 | 1.3831 | 32 |

| 40 | 1.4002 | 24 |

| 41 | 1.4022 | 23 |

| 42 | 1.4040 | 22 |

| Liquid | DW | Ethanol (50%) | Isopropanol | Alcohol |

|---|---|---|---|---|

| Refractive index in the literature | 1.3330 | 1.3590 | 1.3750 | 1.3900 |

| Measured refractive index | 1.3330 | 1.3598 | 1.3749 | 1.3893 |

| Error (%) | 0.0098 | 0.0593 | 0.0001 | 0.0464 |

| Applied voltage (V) | 62 | 44 | 36 | 29 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.-L.; Nie, Z.-Q.; Tian, Y.-T.; Liu, C. Liquid Refractive Index Measurement System Based on Electrowetting Lens. Micromachines 2019, 10, 515. https://doi.org/10.3390/mi10080515

Li S-L, Nie Z-Q, Tian Y-T, Liu C. Liquid Refractive Index Measurement System Based on Electrowetting Lens. Micromachines. 2019; 10(8):515. https://doi.org/10.3390/mi10080515

Chicago/Turabian StyleLi, Shi-Long, Zhong-Quan Nie, Yan-Ting Tian, and Chao Liu. 2019. "Liquid Refractive Index Measurement System Based on Electrowetting Lens" Micromachines 10, no. 8: 515. https://doi.org/10.3390/mi10080515

APA StyleLi, S.-L., Nie, Z.-Q., Tian, Y.-T., & Liu, C. (2019). Liquid Refractive Index Measurement System Based on Electrowetting Lens. Micromachines, 10(8), 515. https://doi.org/10.3390/mi10080515