Experimental Studies on MoS2-Treated Grinding Wheel Active Surface Condition after High-Efficiency Internal Cylindrical Grinding Process of INCONEL® Alloy 718

Abstract

1. Introduction

- The impregnating substance fills all intergranular free spaces, which reduces the ability to transport the CL to the GZ and to remove the products of the process;

- The apparatus used for carrying out the impregnation of abrasive wheels is complicated and creates many problems during its operation.

2. Materials and Methods

2.1. Main Goal

2.2. Characteristics of the Abrasive Tools and Workpiece

2.3. Conditions of the Grinding Process

2.4. Contact and Non-Contact Measurements of the Grinding Wheels

3. Results

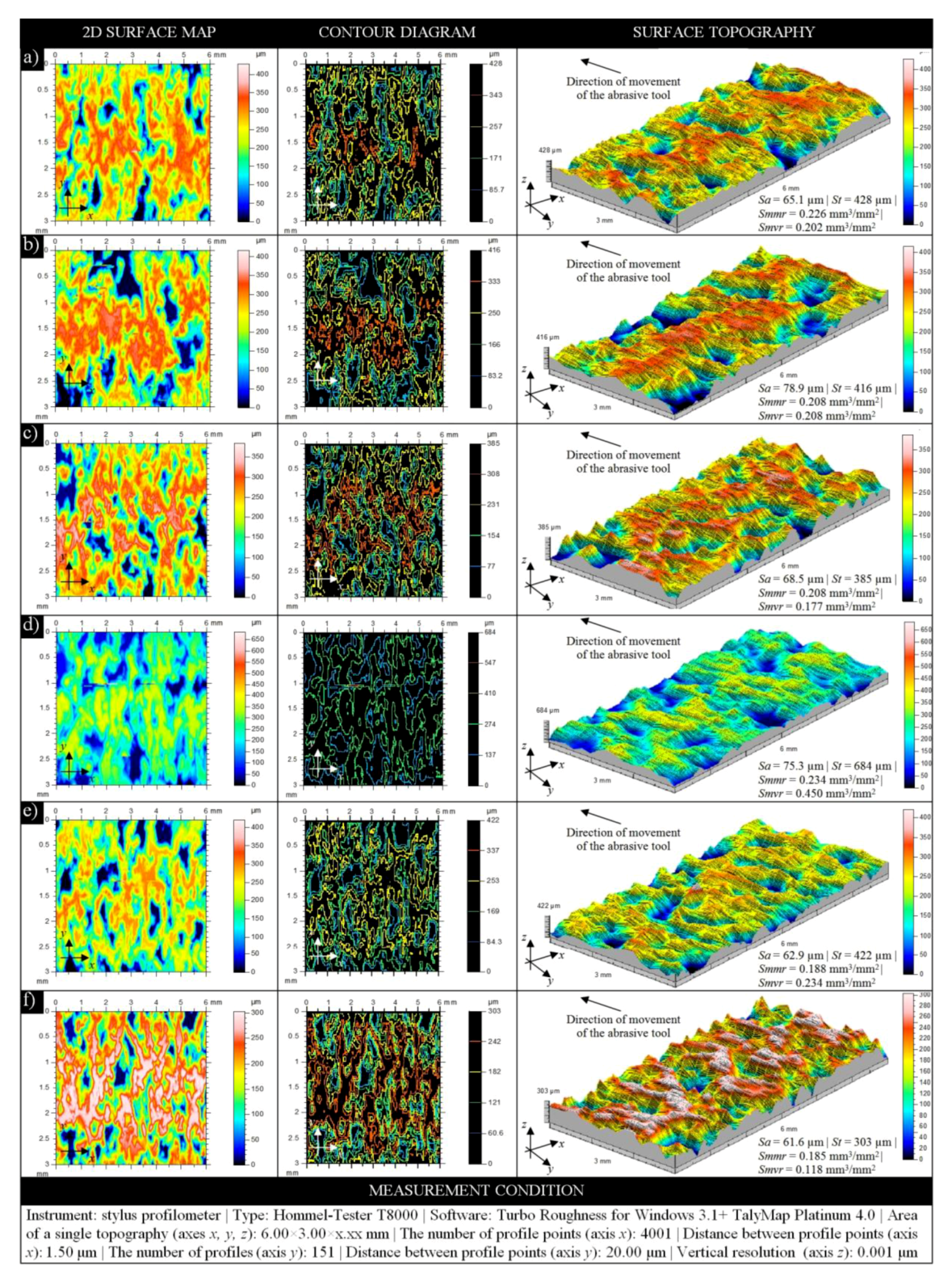

3.1. Profilometry-Based Analysis of the GWAS Microgeometry

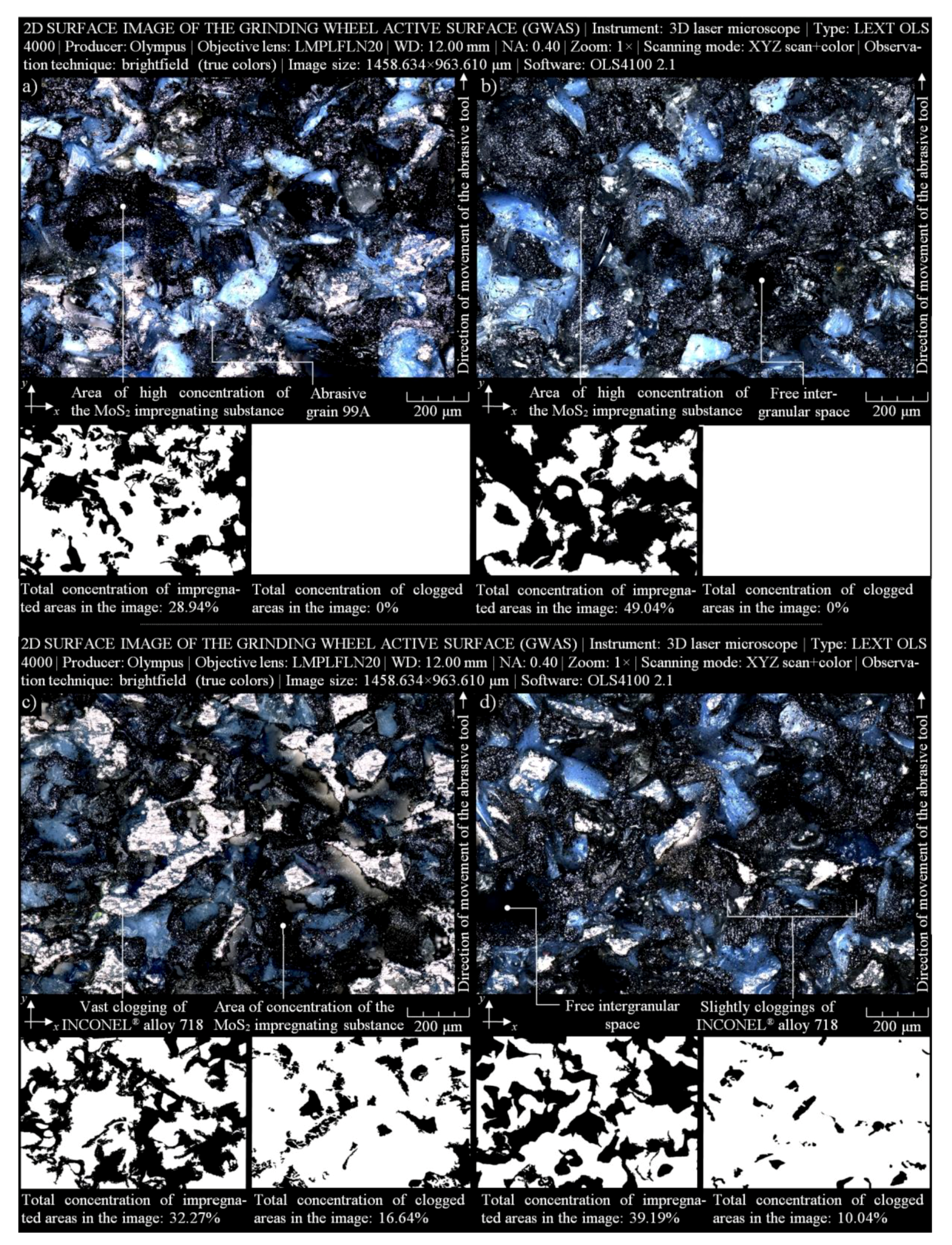

3.2. CLSM-Based Analysis of the GWAS Structure

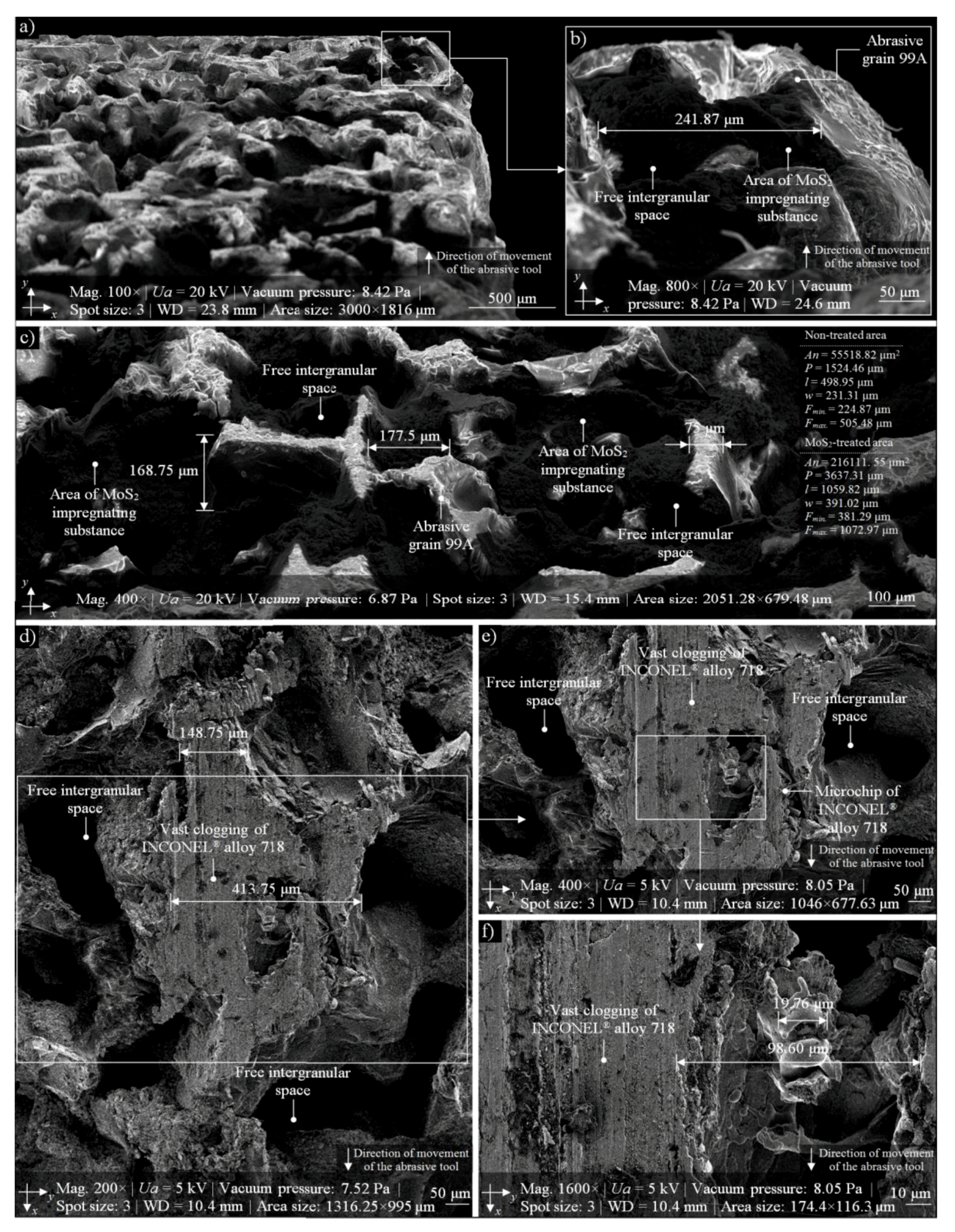

3.3. SEM-Based Analysis of the GWAS Structure

4. Conclusions

- Despite the passage of time, the impregnation of the abrasive tools seems to be a constantly developing industry of modern material engineering. The number of industrial applications in which impregnated abrasive tools are used is still large and systematically growing. Classic impregnating substances such as sulfur (Figure 1) were extended with new promising impregnates based on, e.g., graphene, hexagonal boron nitride, and molybdenum disulfide (Table 1). The last of these was used in experimental studies carried out by the authors, which are reported in detail in this work.

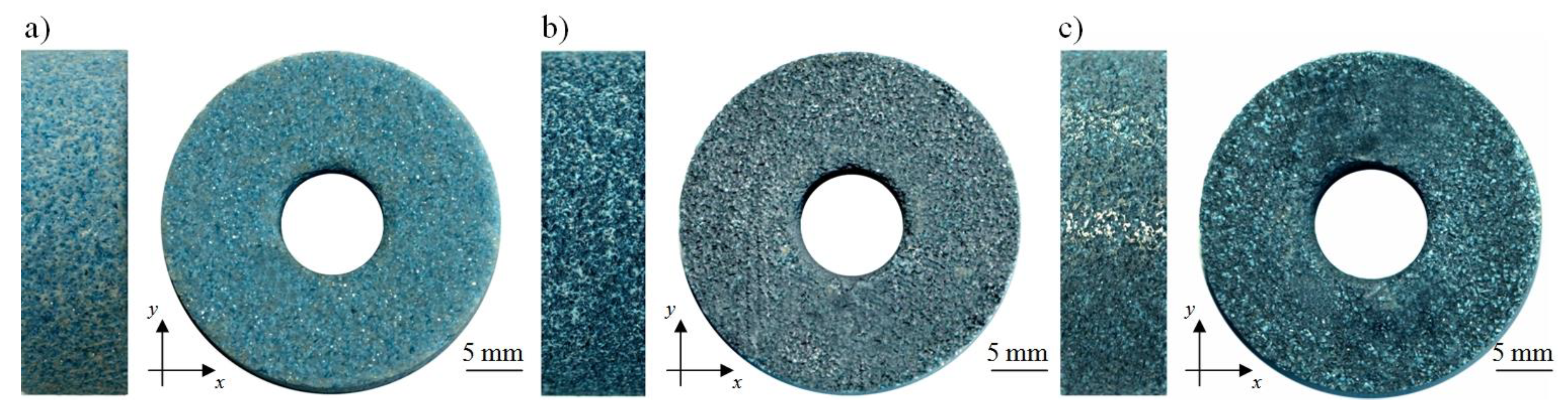

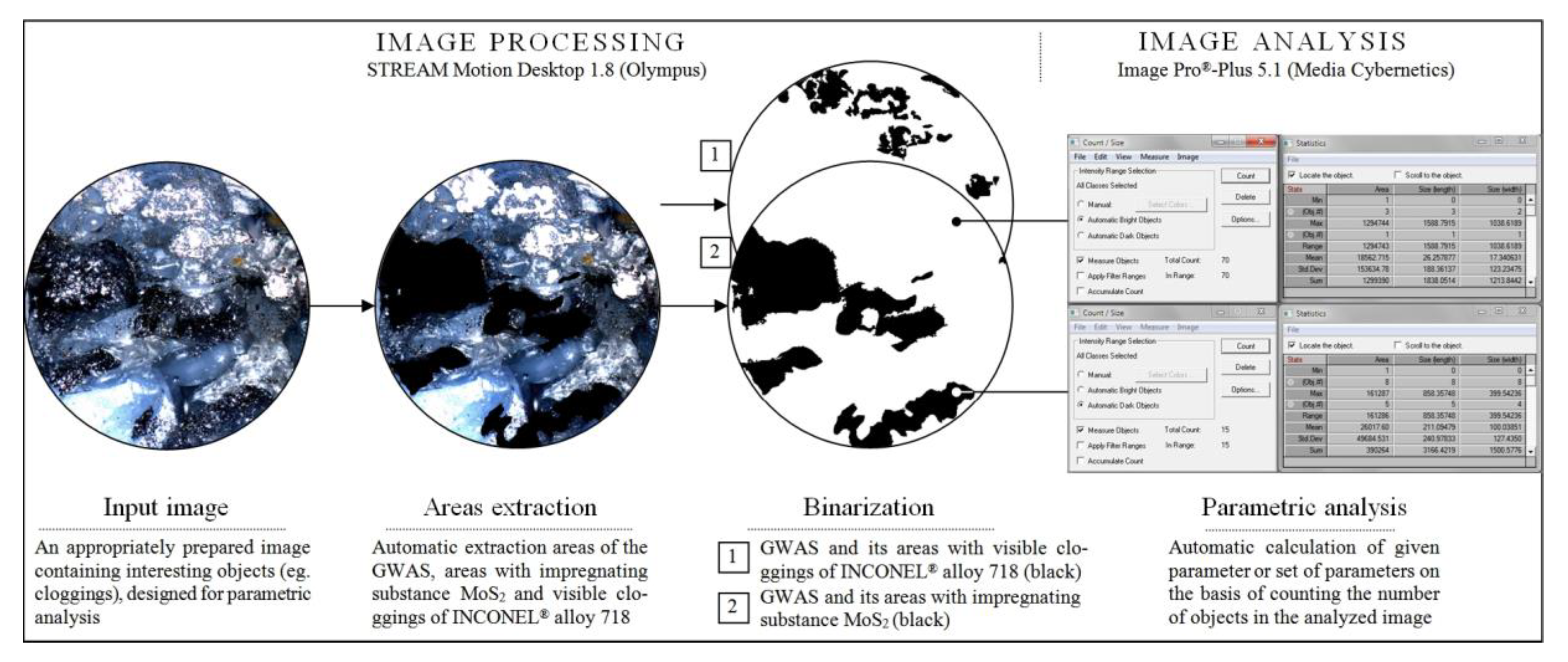

- The MoS2 impregnation process of 1-35×10×10-9A5X60L10VE01PI-50 grinding wheels (Figure 2) was realized using a new method (Section 2.2.) described by Wojtewicz [40]. This method allowed obtaining satisfactory results in the form of a correct and even introduction of the impregnating substance into the GWAS, which was confirmed based on images obtained by CLSM (Olympus LEXT OLS4000) and SEM (FEI Quanta™ 250) observation measurement systems (Figure 7 and Figure 8).

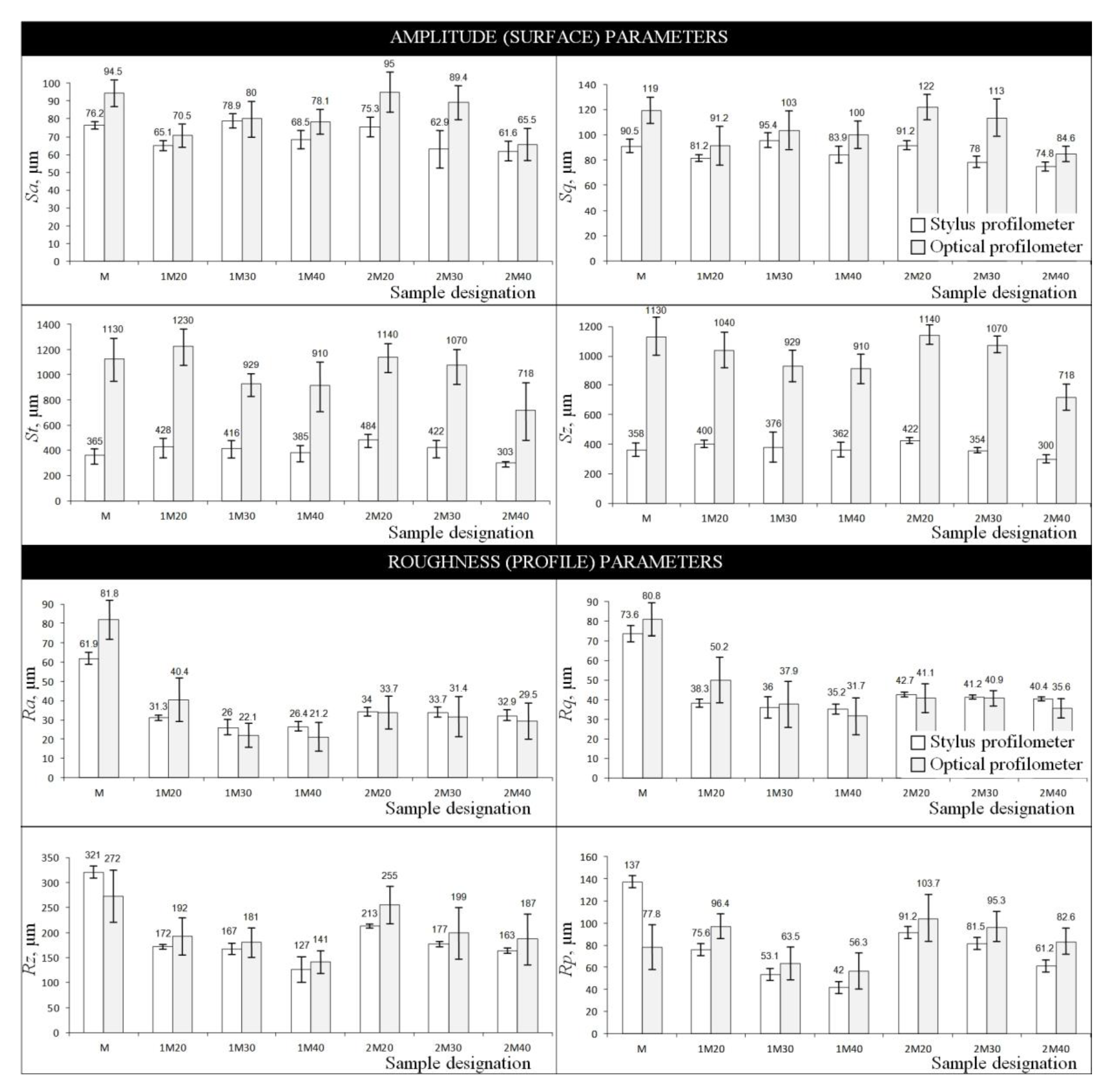

- Results obtained using contact and non-contact methods allowed stating that the values of parameters used during the GWAS microgeometry analysis (Section 3.1.) generally had a downward trend in relation to the reference values. This means that the introduction of MoS2 impregnating substance decreased the average values of the amplitude (surface) parameters (determined using the stylus method) by ~7%, while the average values of the roughness (profile) parameters decreased by ~54%. For MoS2-treated samples after the internal cylindrical grinding of INCONEL® alloy 718, a decrease in the surface texture parameters in relation to the reference values was also observed. The average values of the amplitude (surface) parameters measured after finishing the process (determined using the stylus method) were lower by ~12%, while the average values of the roughness (profile) parameters were lower by ~45% (Figure 5). Upon omitting the errors occurring during the measurements, the obtained results should be considered significant for the experiments.

- GWAS microgeometry was measured using stylus and optical profilometry. The analysis of the results of measurements obtained with both methods (Figure 5) allowed concluding that there was a relatively high agreement between them (differences did not exceed 10–15%), which indicated the proper selection of the apparatus for the measurement tasks being performed.

- In addition to the observations carried out using CLSM (Section 3.2.) and SEM (Section 3.3.) confirming the correctness of introduction of the impregnating substance into the GWAS structure, a number of geometrical analyses were realized with Media Cybernetics Image Pro®-Plus 5.1 software. Parametrically, the percentage share of MoS2-treated areas in relation to the non-treated areas was described (Table 8), as well as the percentage share of areas clogged by machined material (Figure 7).

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| BEI | Backscattered electron imaging |

| BSE | Backscattered electron mode |

| CF | Cutting force |

| CL | Cooling liquid |

| CLSM | Confocal laser scanning microscopy |

| CTM | Corporate test method |

| ESEM | Environmental scanning electron microscope |

| FOV | Field of view |

| GSED | Gaseous secondary electron detector |

| GWAS | Grinding wheel active surface |

| GZ | Grinding zone |

| HVM | High-vacuum mode |

| ISO | International organization for standardization |

| LVM | Low-vacuum mode |

| SE | Secondary electron |

| SED | Secondary electron detector |

| STEM | Scanning transmission electron microscope |

| WD | Working distance |

| ad | Dressing allowance, mm |

| ae | Working engagement (machining allowance), mm |

| ae tot | Total working engagement (machining allowance), mm |

| bw | Width, mm |

| ds | External diameter, mm |

| dw | Inner diameter, mm |

| id | Number of dressing passes |

| l | Length, μm |

| nsd | Grinding wheel rotational speed while dressing, min−1 |

| tg tot | Total grinding time, s |

| vfa | Axial table feed speed while grinding, mm·s−1 |

| vfd | Axial table feed speed while dressing, mm·s−1 |

| vs | Grinding wheel peripheral speed, m·s−1 |

| vw | Workpiece peripheral speed, m·s−1 |

| w | Width, μm |

| An | Surface area, μm2 |

| Ci | Mass concentration of impregnate in the suspension, % |

| Fmin. | Minimal value of the Feret diameter, μm |

| Fmax. | Maximal value of the Feret diameter, μm |

| P | Perimeter, μm |

| Qd | Diamond dresser mass, kt |

| Ra | Arithmetic mean deviation of the roughness profile, μm |

| Rp | Maximum profile peak height, μm |

| Rq | Root-mean-square deviation of the roughness profile, μm |

| Rz | Average maximum height of the profile, μm |

| Sa | Arithmetic mean deviation of the surface, μm |

| Smmr | Mean material volume ratio, mm3/mm2 |

| Smvr | Mean void volume ratio, mm3/mm2 |

| Sq | Root-mean-square deviation of the surface, μm |

| St | Total height of the surface, μm |

| Sz | Maximum height of the surface, μm |

| Ua | Accelerating voltage, kV |

| Vb | Volume of bond, % |

| Vg | Volume of grains, % |

| Vp | Volume of pores, % |

References

- Hou, Y.; Li, C.; Zhou, Y. Applications of high-efficiency abrasive process with CBN grinding wheel. Engineering 2010, 2, 184–189. [Google Scholar] [CrossRef][Green Version]

- Wang, S.; Li, C.H. Application and development of high-efficiency abrasive process. Int. J. Adv. Sci. Technol. 2012, 47, 51–64. [Google Scholar]

- Khan, A.M.; Jamil, M.; Mia, M.; Pimenov, D.Y.; Gasiyarov, V.R.; Gupta, M.K.; He, N. Multi-objective optimization for grinding of AISI D2 steel with Al2O3 wheel under MQL. Materials 2018, 11, 2269. [Google Scholar] [CrossRef]

- Xu, X.; Yu, Y.; Huang, H. Mechanisms of abrasive wear in the grinding of titanium (TC4) and nickel (K417) alloys. Wear 2003, 255, 1421–1426. [Google Scholar] [CrossRef]

- Malkin, S.; Guo, C. Thermal analysis of grinding. CIRP Ann. Manuf. Techn. 2007, 56, 760–782. [Google Scholar] [CrossRef]

- Pashnyov, V.A.; Pimenov, D.Y.; Erdakov, I.N.; Koltsova, M.S.; Mikolajczyk, T.; Patra, K. Modeling and analysis of temperature distribution in the multilayer metal composite structures in grinding. Int. J. Adv. Manuf. Technol. 2017, 91, 4055–4068. [Google Scholar] [CrossRef]

- Pereverzev, P.P.; Pimenov, D.Y. A grinding force model allowing for dulling of abrasive wheel cutting grains in plunge cylindrical grinding. J. Frict. Wear 2016, 37, 60–65. [Google Scholar] [CrossRef]

- Shaji, S.; Radhakrishnan, V. Analysis of process parameters in surface grinding with graphite as lubricant based on the Taguchi method. J. Mater. Process. Technol. 2003, 14, 51–59. [Google Scholar] [CrossRef]

- Tsai, M.Y.; Jian, S.X. Development of a micro-graphite impregnated grinding wheel. Int. J. Mach. Tool. Manuf. 2012, 56, 94–101. [Google Scholar] [CrossRef]

- Shaji, S.; Radhakrishnan, V. An investigation on surface grinding using graphite as lubricant. Int. J. Mach. Tool. Manuf. 2002, 42, 733–740. [Google Scholar] [CrossRef]

- Marinescu, I.D.; Rowe, W.B.; Dimitrov, B.; Inasaki. Tribology of Abrasive Machining Processes; William Andrew Inc.: Norwich, NY, USA, 2004. [Google Scholar]

- Malkin, S.; Guo, C. Grinding Technology: Theory and Application of Machining with Abrasives, 2nd ed.; Industrial Press Inc.: New York, NY, USA, 2008. [Google Scholar]

- Dresel, W.; Mang, T. Lubricants and Lubrication, 3rd ed.; Wiley-VCH Verlag: Weinheim, Germany, 2017. [Google Scholar]

- Harmann, M.L. Abrasive Article. U.S. Patent 1615271, 1927. [Google Scholar]

- Jones, H.H. Composition for Impregnating Grinding Wheels. U.S. Patent 2240302, 1941. [Google Scholar]

- Jackson, L.P. Filled Abrasive Article and Filler for the Same. U.S. Patent 2333480, 1943. [Google Scholar]

- Gallagher, T.P. Process for Impregnating Porous Bodies with a Solid Fusible Substance. U.S. Patent 3341355, 1967. [Google Scholar]

- Krueger, M.K.; Yoon, S.C.; Forney, K.G.; Turchin, H.; Smits, C.A. Impregnated Grinding Wheel. U.S. Patent 6500220, 2002. [Google Scholar]

- Sakuma, K.; Tado, T. Characteristics of coated grinding wheels in creep feed grinding: Effect of coated wheel with high thermal conductivity metal (nickel). B. JSME 1983, 26, 468–475. [Google Scholar] [CrossRef]

- Younis, M.A.; Alawi, H. Effects of impregnation of grinding wheel on grinding hardened tool steel. Trans. Can. Soc. Mech. Eng. 1985, 9, 39–44. [Google Scholar] [CrossRef]

- Salmon, S.C. The effects of hard lubricant coatings on the performance of electro-plated superabrasive grinding wheels. Key Eng. Mat. 2003, 238-239, 283–288. [Google Scholar] [CrossRef]

- Nadolny, K.; Sienicki, W.; Wojtewicz, M. The effect upon the grinding wheel active surface condition when impregnating with non-metallic elements during internal cylindrical grinding of titanium. Arch. Civ. Mech. Eng. 2015, 15, 71–86. [Google Scholar] [CrossRef]

- Hunsberger, J.F.; Tucker, D.J. Method of Impregnating Lubricant into Abrasive Wheels. U.S. Patent 3321287A, 1967. [Google Scholar]

- Sioui, R.H.; Cohen, H.M. Resin Bonded Metal-coated Diamond or Cubic Boron Nitride Abrasive Tools Containing an Inorganic Crystalline Filler and Graphite. U.S. Patent No 3664819, 1971. [Google Scholar]

- Shaji, S.; Radhakrishnan, V. Application of solid lubricants in grinding: Investigations on graphite sandwiched grinding wheels. Mach. Sci. Technol. 2003, 7, 137–155. [Google Scholar] [CrossRef]

- Irani, R.A.; Bauer, R.J.; Warkentin, A. A review of cutting fluid application in the grinding process. Int. J. Mach. Tool. Manuf. 2005, 45, 1696–1705. [Google Scholar] [CrossRef]

- Alberts, M.; Kalaitzidou, K.; Melkote, S. An investigation of graphite nanoplatelets as lubricant in grinding. Int. J. Mach. Tool. Manuf. 2009, 49, 966–970. [Google Scholar] [CrossRef]

- Sienicki, W.; Wojtewicz, M.; Nadolny, K. Method of Modifying Ceramic Abrasive Tools by Impregnation. PL Patent P. 395441, 2011. [Google Scholar]

- Nadolny, K.; Wojtewicz, M.; Sienicki, W.; Herman, D. An analysis of centrifugal MQL supply system potential in the internal cylindrical grinding process. Arch. Civ. Mech. Eng. 2015, 15, 639–649. [Google Scholar] [CrossRef]

- Ravuri, B.P.; Goriparthi, B.K.; Revuru, R.S.; Anne, V.G. Performance evaluation of grinding wheels impregnated with graphene nanoplatelets. Int. J. Adv. Manuf. Technol. 2016, 85, 2235–2245. [Google Scholar] [CrossRef]

- Pavan, R.B.; Gopal, A.V.; Amrita, M.; Goriparthi, B.K. Experimental investigation of graphene nanoplatelets– based minimum quantity lubrication in grinding Inconel 718. P. I. Mech. Eng. B-J. Eng. 2019, 233, 400–410. [Google Scholar] [CrossRef]

- Maeda, S.; Yamaoka, T.; Tachibana, N.; Sakurai, M.; Aoki, Y. Artificial Grinding Wheel, and Its Manufacturing Method. JP Patent JP2001293660A, 2001. [Google Scholar]

- Kapłonek, W.; Nadolny, K. Review of the advanced microscopy techniques used for diagnostics of grinding wheels with ceramic bond. J. Mach. Eng. 2012, 12, 81–98. [Google Scholar]

- Rowse, R.A.; Nelson, R.S. Thermoset-resin Impregnated High-speed Vitreous Grinding Wheel. U.S. Patent 3615302, 1971. [Google Scholar]

- Ito, K. Resin-impregnated Vitrified Grinding Wheel and Its Manufacturing Method. JP Patent JP2001205566A, 2001. [Google Scholar]

- Serdyuk, V.V.; Kutsenok, B.; Stepanov, A.B.; Ashkinazi, L.A. Impregnator for Grinding Wheel. RU Patent RU2047476C1, 1995. [Google Scholar]

- Bo, Z.; Wei, L.; Qianjun, T. Impregnant for Impregnated Grinding Wheels and Application Thereof in Preparing Impregnated Grinding Wheels. CN Patent CN101791786B, 2012. [Google Scholar]

- Hashimoto, M.; Iketani, H. Vitrified Grinding Wheel, and Method for Manufacturing the Same. JAP Patent JP2010105126A, 2008. [Google Scholar]

- Zhiqi, W.; Wei, Y.; Xueren, L.; Penghui, S. One Kind of Grinding Wheel Impregnated Impregnation System and Method of the Grindstone. CN Patent CN105397654B, 2015. [Google Scholar]

- Wojtewicz, M. Original methods of ceramic grinding wheels impregnation. J. Mech. Energy. Eng. 2017, 1, 45–50. [Google Scholar]

- Mathewson, J.W.F.; Owens, R.S. Lubricating Composition Applied to Boron Nitride Grinding Wheels. U.S. Patent 3528789A, 1970. [Google Scholar]

- Meyer, R.S. Bismuth Alloy Impregnated Grinding Wheel. U.S. Patent 3520666, 1970. [Google Scholar]

- Nadolny, K.; Kapłonek, W.; Wojtewicz, M.; Sienicki, W. Effects of sulfurization of grinding wheels on internal cylindrical grinding of Titanium Grade 2®. Indian J. Eng. Mater. Sci. 2013, 20, 108–124. [Google Scholar]

- Kapłonek, W.; Nadolny, K.; Wojtewicz, M.; Sienicki, W. Characterisation of abrasive tools active surface after the impregnation process by modified ARS method based on imaging and analysis of the scattered light. Int. J. Mach. Mach. Mater. 2015, 17, 397–417. [Google Scholar] [CrossRef]

- ISO 2811-1:2016. Paints and Varnishes—Determination of Density—Part 1: Pycnometer Method; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- ISO 25178-2:2012. Geometrical Product Specification (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Stout, K.J. The Development of Methods for the Characterization of Roughness in Three Dimensions; European Community: Brussels, Belgium, 1993. [Google Scholar]

- ISO 4287:1997. Geometrical product specifications (GPS)—Surface Texture: Profile Method: Terms, Definitions and Surface Texture Parameters; International Organization for StandardizationP: Geneva, Switzerland, 1997. [Google Scholar]

| Impregnating Substance | References | |

|---|---|---|

| Common Name | Patent | Paper |

| Sulfur | Harmann [14], Jones [15], Jackson [16], Gallagher [17], Krueger et al. [18] | Sakuma and Tado [19], Younis and Alawi [20], Salmon [21], Nadolny et al. [22] |

| Graphite | Hunsberger and Tucker [23], Sioui and Cohen [24] | Shaji and Radhakrishnan [25], Irani et al. [26], Alberts et al. [27], Tsai and Jian [9] |

| Amorphous carbon | Sienicki et al. [28] | Nadolny et al. [22,29] |

| Graphene | - | Ravuri et al. [30], Paven et al. [31] |

| Silicone | Maeda et al. [32] | Kapłonek and Nadolny [33] |

| Epoxy resin | Rowse and Nelson [34], Ito [35] | - |

| Molybdenum disulfide | Serdyuk et al. [36], Bo et al. [37], Hashimoto and Iketani [38], Zhiqi et al. [39] | Wojtewicz [40] |

| Hexagonal boron nitride | Mathewson and Owens [41] | - |

| Bismuth alloy | Meyer [42] | - |

| Technical Designation | 1-35×10×10×109A5X60L10VE01PI-50 | |||||

| Producer | Andre Abrasive Articles Sp. z o. o., Sp. k. (Koło, Poland) | |||||

| Grinding wheel type | Flat grinding wheel | |||||

| Dimensions | External diameter ds = 35 mm, width bs = 10 mm, inner diameter hs = 10 mm | |||||

| Abrasive grain type | Microcrystalline sintered corundum SG™ (Norton, Worcester, MA, USA) | |||||

| Abrasive grain fracture number (No.) | 60 | |||||

| Hardness class | G | |||||

| Structure No. | 10 | |||||

| Bond | Vitrified (glass–crystalline) | |||||

| Volume of grains (Vg) | 42.0% | |||||

| Volume of bond (Vb) | 11.5% | |||||

| Volume of pores (Vp) | 46.5% | |||||

| Experimental studies | Designation | M | Pieces | 2 | Surface condition | Reference grinding wheel, non-impregnated |

| 1M20 1 | 3 | Impregnated by MoS2, after the dressing cut | ||||

| 1M30 2 | 3 | |||||

| 1M40 3 | 3 | |||||

| 2M20 1 | 3 | Impregnated by MoS2, after the reciprocal peripheral internal cylindrical grinding of INCONEL® alloy 718 | ||||

| 2M30 2 | 3 | |||||

| 2M40 3 | 3 | |||||

| Parameter | Value | Unit |

|---|---|---|

| Viscosity | 4/25–35 | mm/s |

| Density | 0.90 | g/cm3 |

| Solid content | 25 | % |

| Color | colorless | - |

| Efficiency | 10–12 | m2 |

| Parameter | Value | Unit |

|---|---|---|

| Color 1 | Black | - |

| Consistency | Free flowing powder | - |

| Purity (MoS2 content) | 98 | % |

| Particle size distribution (laser method: Malvern Mastersizer in 2-propanol) | 90% <11.82 50% <5.22 10% <1.97 | μm |

| Particle size (Fisher method) | 0.65 to 0.80 | μm |

| Service temperature range | −185 to +450 | °C |

| Service temperature range (in hydrogen) | 700 | °C |

| Service temperature range (in vacuum) | Up to 1100 | °C |

| Service temperature range (argon) | Up to 1300 | °C |

| Theoretical density (solid state) 2 | 4.8 | g/cm³ |

| Bulk density (powder state) 2 | 0.5 | g/cm³ |

| Water/moisture content | 0.05 | % |

| Almen Wieland machine | >20,000 | N |

| Press-fit test | 0.06 | μ |

| Element | Concentration (%) | Physical Properties | |||

|---|---|---|---|---|---|

| Ni + Co | 50.00–55.00 | Parameter | Value | Unit | |

| Cr | 17.00–21.00 | Density | 8.26 | g/cm 3 | |

| Fe | Remaining | Melting range | 1257–1342 | °C | |

| Nb + Ta | 4.75–5.50 | Modulus of | rigidity | 77.2 | kN/mm2 |

| Mo | 2.80–3.30 | elasticity | 204.9-122 2 | kN/mm2 | |

| Ti | 0.65–1.15 | Mechanical Properties | |||

| Al | 0.20–0.80 | Elongation at break | - | <15% | |

| Co | 1.00 max. | Hardness (Brinell) HB | 250–410 | kg/mm2 | |

| C | 0.08 max. | Yield strength | 1030–640 4 | MPa | |

| Mn | 0.35 max. | Tensile strength | 1280–780 4 | MPa | |

| Si | 0.35 max. | Elongation | 12 4 | % | |

| P | 0.015 max. | Thermal Properties | |||

| S | 0.015 max. | Coefficient of thermal expansion | 14.1–17.4 3 | μm/m | |

| B | 0.001–0.006 max. | Thermal conductivity | 11.5–28.7 2 | W/m·°C | |

| Cu | 0.03–0.15 max. | Specific heat | 460–658 2 | J/kg·°C | |

| Grinding Process | Reciprocal Peripheral Internal Cylindrical Grinding |

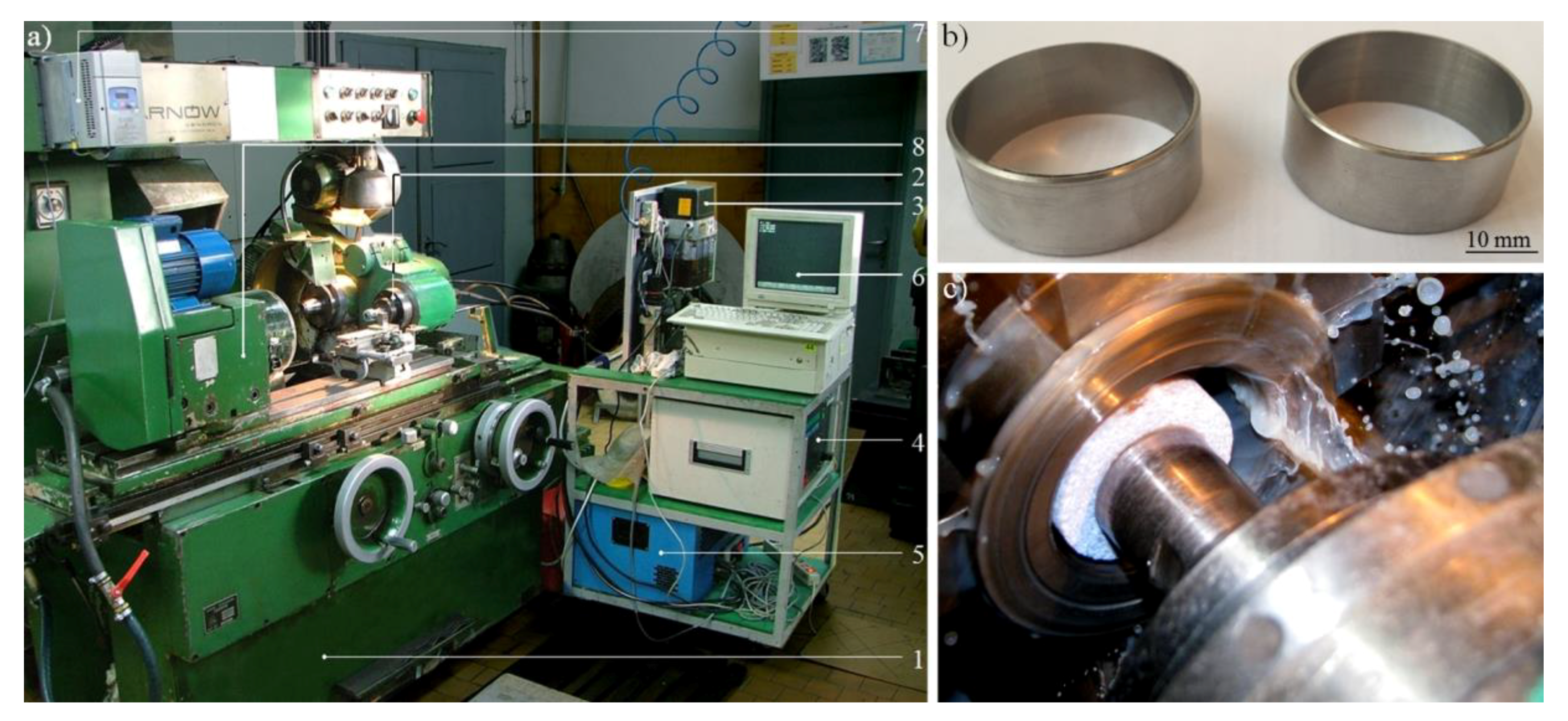

| Grinding machine | Universal grinding machine: RUP 28P (Tarnów Mechanical Works SA, Tarnów, Poland), high-speed spindle: EV-70/70-2WB (Fisher Spindle Group AG, Herzogenbuchsee, Switzerland) with max. rotation 60,000 min−1; power of machine cutting = 5.2 kW |

| Grinding wheel | 1-35×10×10×109A5X60L10VE01PI-50 |

| Grinding wheel dressing parameters | Dresser: single grain diamond dresser with mass: Qd = 1.25 kt, Grinding wheel rotational speed while dressing: nsd = 10,000 min−1 Dressing allowance: ad = 0.0125 mm Axial table feed speed while dressing: vfd = 10 mm·s−1 Number of dressing passes: id = 6 |

| Grinding parameters | Grinding wheel peripheral speed: vs = 45 m·s−1 Axial table feed speed: vfa = 20 m·s−1 Working engagement (machining allowance): ae = 0.01 mm Total working engagement (machining allowance): ae tot = 0.75 mm Workpiece peripheral speed: vw = 0.56 m·s−1 Total grinding time tg tot = 900 s |

| Grinding fluid | 5% water solution of Syntilo RHS (Castrol, Liverpool, Great Britain) oil given by flood method |

| Workpieces | Internal cylindrical surface of rings, made of INCONEL® alloy 718 (dimensions: ds = 50 mm, bw = 42 mm, bw = 20 mm) |

| No. | System | Type | Producer | Configuration and Features |

|---|---|---|---|---|

| 1. | Stylus profilometer | Hommel-Tester T8000 | Hommelwerke GmbH (Villingen-Schwenningen, Germany) | Components: TKL100 pick-up with a diamond stylus tip (tip radius: r = 2.5 mm) + traverse unit Waveline™ 60 Basic (tracing length: l = 60 mm) + vertical displacement column Wavelift™ 400M (max. traverse: lmax = 400 mm) + granite plate Wavesystem™ 780 + motorized positioning stage (Y-Positioner) |

| Software: dedicated Turbo Roughness for Windows 3.1 + TalyMap Platinum 4.0 using Mountains Technology™ (Digital Surf, Besançon, France) | ||||

| 2. | Optical profilometer | TalySurf CLI2000 | Taylor Hobson Ltd. (Leicester, Great Britain) | Components: LK-031 optical displacement sensor (wavelength: λ = 670 nm, power: Pl = 0.95 mW, spot diameter: approximately 30 mm, resolution: 1 µm) + LK-2001 controller (Keyence, Osaka, Japan) |

| Software: Talyscan CLI 2000 2.6 + Taly Map Silver 4.1 using Mountains Technonology™ (Digital Surf, Besançon, France) | ||||

| 3. | Confocal laser scanning microscope | LEXT OLS4000 | Olympus Corp. (Shinjuku, Tokyo, Japan) | Components: motorized revolving nosepiece with a set of five objective lenses (BF Plan Semi Apochromat 5×, 10×, and LEXT-dedicated Plan Apochromat 20×, 50×, 100×) + motorized stage system ProScan III (Prior Scientific, Inc., Rockland, MA, USA) |

| Software: dedicated OLS4100 2.1 (Olympus) + TalyMap Platinum 4.0 using Mountains Technology™ (Digital Surf, Besançon, France) | ||||

| 4. | (Enviromental) scanning electron microscope | Quanta™ 250 | FEI Co., (Hillsboro, OR, USA) | Components: detectors: Everhadt-Thornley SED, large-field; low-vacuum SED (LFD), gaseous SED (GSED) (used in ESEM mode), BEI (solid-state (BSED)), 3-axis stage 50 × 50 × 50 mm, 8-port vacuum chamber, pressure: <6 × 10−4 Pa (HVM), <10 to 130 Pa (LVM) and <10 to 4000 Pa (ESEM vacuum), evacuation time: ≤150 s to high vacuum and ≤270 s to ESEM Features: magnification range: 14–1,000,000×, accelerating voltage: 0.2–30 kV, maximum horizontal FOV: 5 mm at WD = 10 mm, 8.8 mm at WD = 25 mm, resolution (using HVM): 0.8 nm at 30 kV (STEM), 1.0 nm at 30 kV (SE), 2.5 nm at 30 kV (BSE), 3.0 nm at 1 kV (SE); resolution (using LVM): 1.4 nm at 30 kV (SE), 2.5 nm at 30 kV (BSE), 3.0 nm at 3 kV (SE) |

| Software: dedicated FEI software |

| Sample | 1M30 | 1M40 | |||

| T | T + M | T | T + M | ||

| Parameter | Unit | Value | |||

| An | μm2 | 574,421.73 | - | 787,750.43 | - |

| P | μm | 9994.78 | 8469.56 | ||

| l | μm | 1455.96 | 1537.46 | ||

| w | μm | 999.91 | 1012.39 | ||

| Fmin. | μm | 893.04 | 885.05 | ||

| Fmax. | μm | 1546.90 | 1607.17 | ||

| Sample | 2M20 | 2M40 | |||

| T | T + M | T | T + M | ||

| Parameter | Unit | Value | |||

| An | μm2 | 530,242.60 | 45,518.26 | 773,795.65 | 28,318.26 |

| P | μm | 4873.89 | 1866.68 | 3800.86 | 477.08 |

| l | μm | 1370.90 | 457.15 | 805.83 | 190.77 |

| w | μm | 898.59 | 277.36 | 549.89 | 86.58 |

| Fmin. | μm | 882.77 | 274.22 | 531.68 | 79.00 |

| Fmax. | μm | 1371.05 | 460.00 | 833.20 | 1463.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapłonek, W.; Nadolny, K.; Sutowska, M.; Mia, M.; Pimenov, D.Y.; Gupta, M.K. Experimental Studies on MoS2-Treated Grinding Wheel Active Surface Condition after High-Efficiency Internal Cylindrical Grinding Process of INCONEL® Alloy 718. Micromachines 2019, 10, 255. https://doi.org/10.3390/mi10040255

Kapłonek W, Nadolny K, Sutowska M, Mia M, Pimenov DY, Gupta MK. Experimental Studies on MoS2-Treated Grinding Wheel Active Surface Condition after High-Efficiency Internal Cylindrical Grinding Process of INCONEL® Alloy 718. Micromachines. 2019; 10(4):255. https://doi.org/10.3390/mi10040255

Chicago/Turabian StyleKapłonek, Wojciech, Krzysztof Nadolny, Marzena Sutowska, Mozammel Mia, Danil Yurievich Pimenov, and Munish Kumar Gupta. 2019. "Experimental Studies on MoS2-Treated Grinding Wheel Active Surface Condition after High-Efficiency Internal Cylindrical Grinding Process of INCONEL® Alloy 718" Micromachines 10, no. 4: 255. https://doi.org/10.3390/mi10040255

APA StyleKapłonek, W., Nadolny, K., Sutowska, M., Mia, M., Pimenov, D. Y., & Gupta, M. K. (2019). Experimental Studies on MoS2-Treated Grinding Wheel Active Surface Condition after High-Efficiency Internal Cylindrical Grinding Process of INCONEL® Alloy 718. Micromachines, 10(4), 255. https://doi.org/10.3390/mi10040255