Serrated Chips Formation in Micro Orthogonal Cutting of Ti6Al4V Alloys with Equiaxial and Martensitic Microstructures

Abstract

1. Introduction

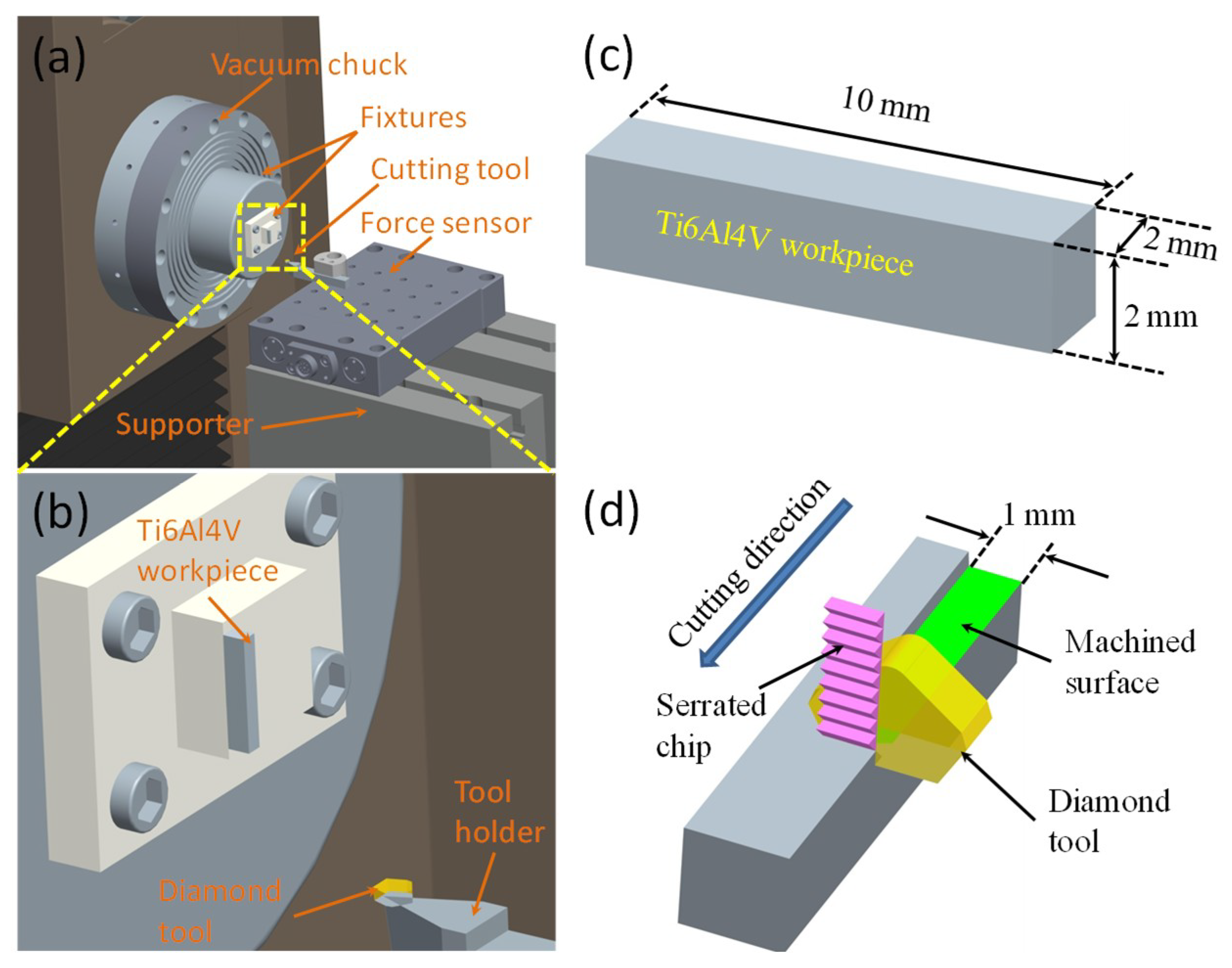

2. Experimental Procedures

3. Results and Discussion

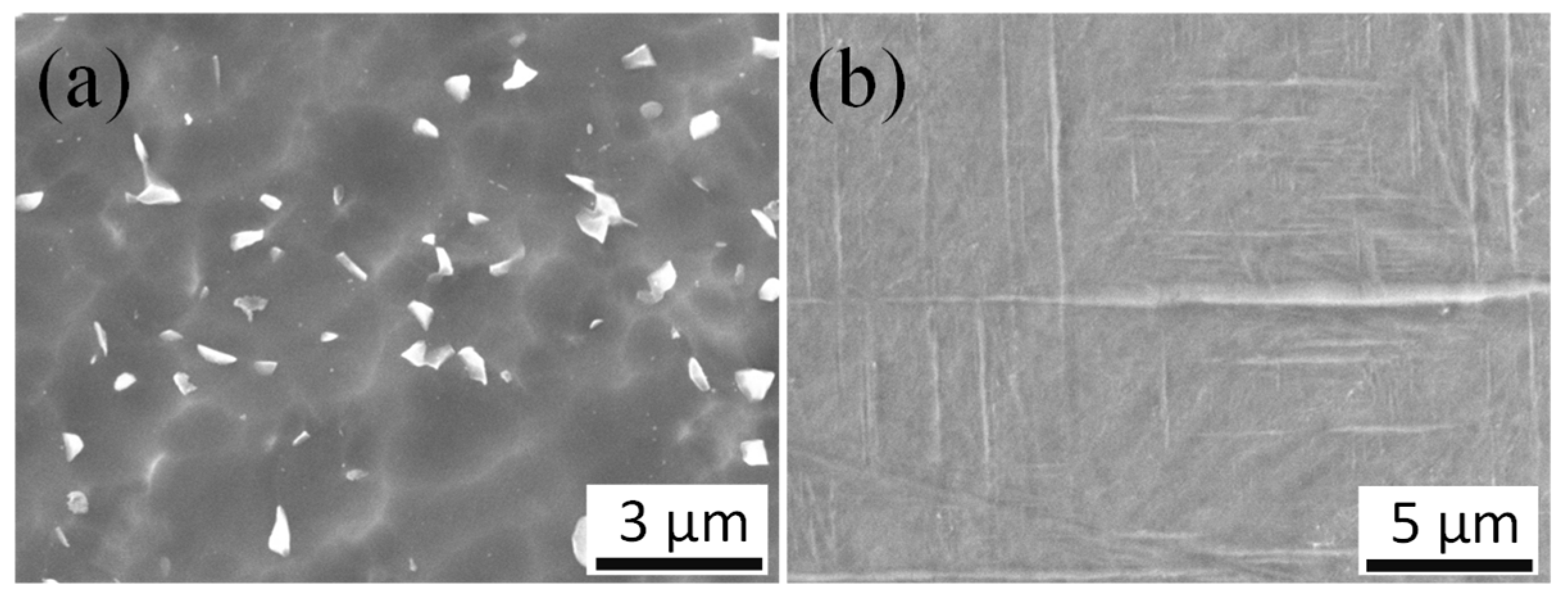

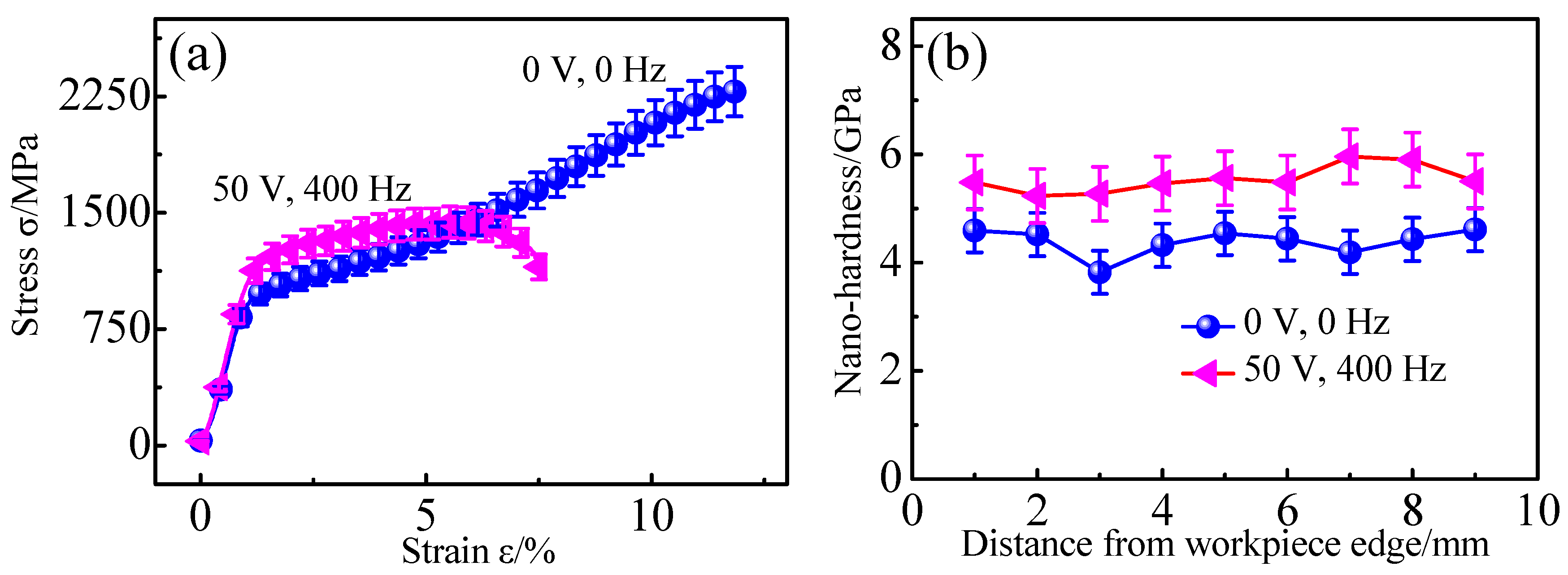

3.1. Microstructures, Stress–Strain Curves, and Nano-Hardness

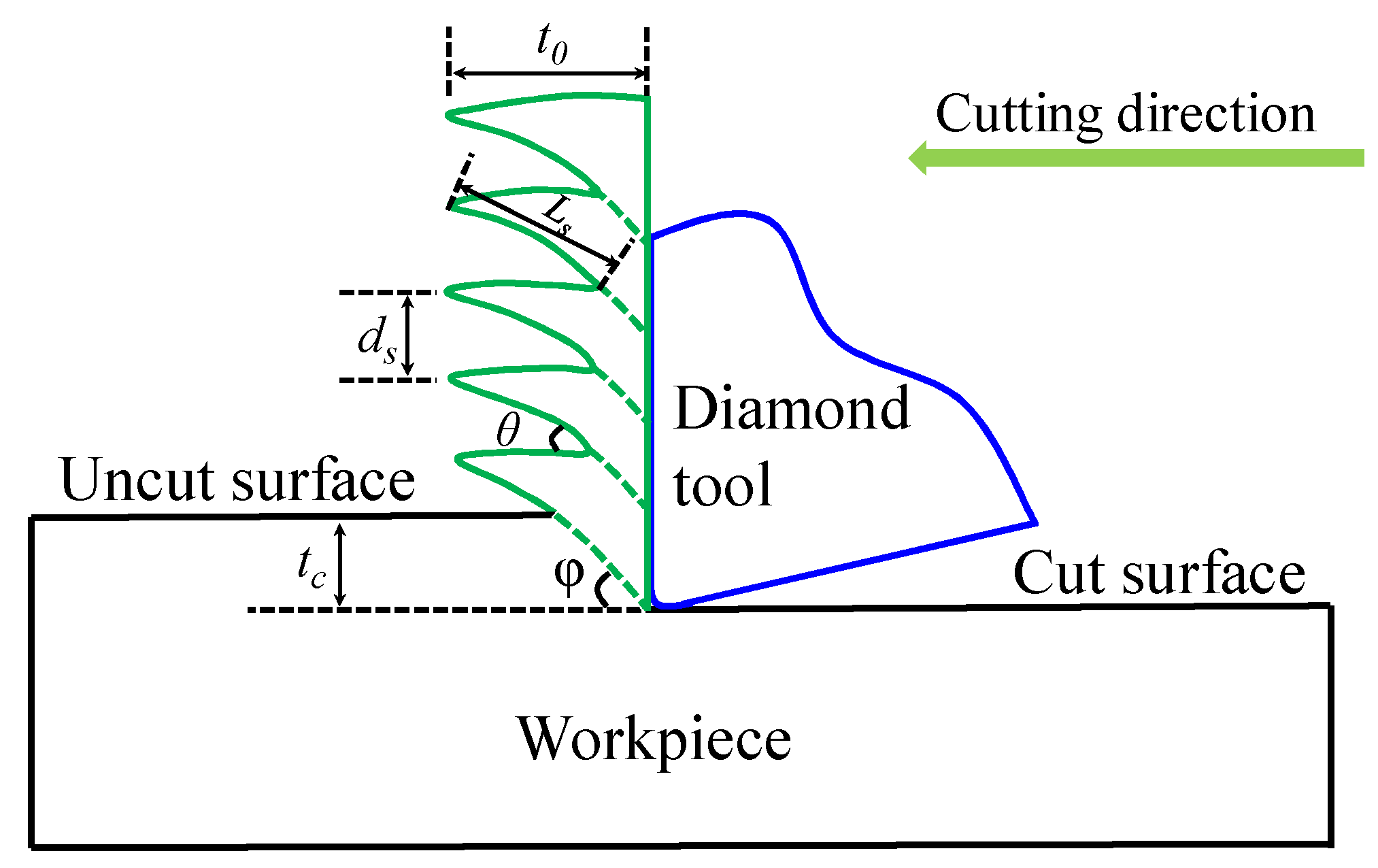

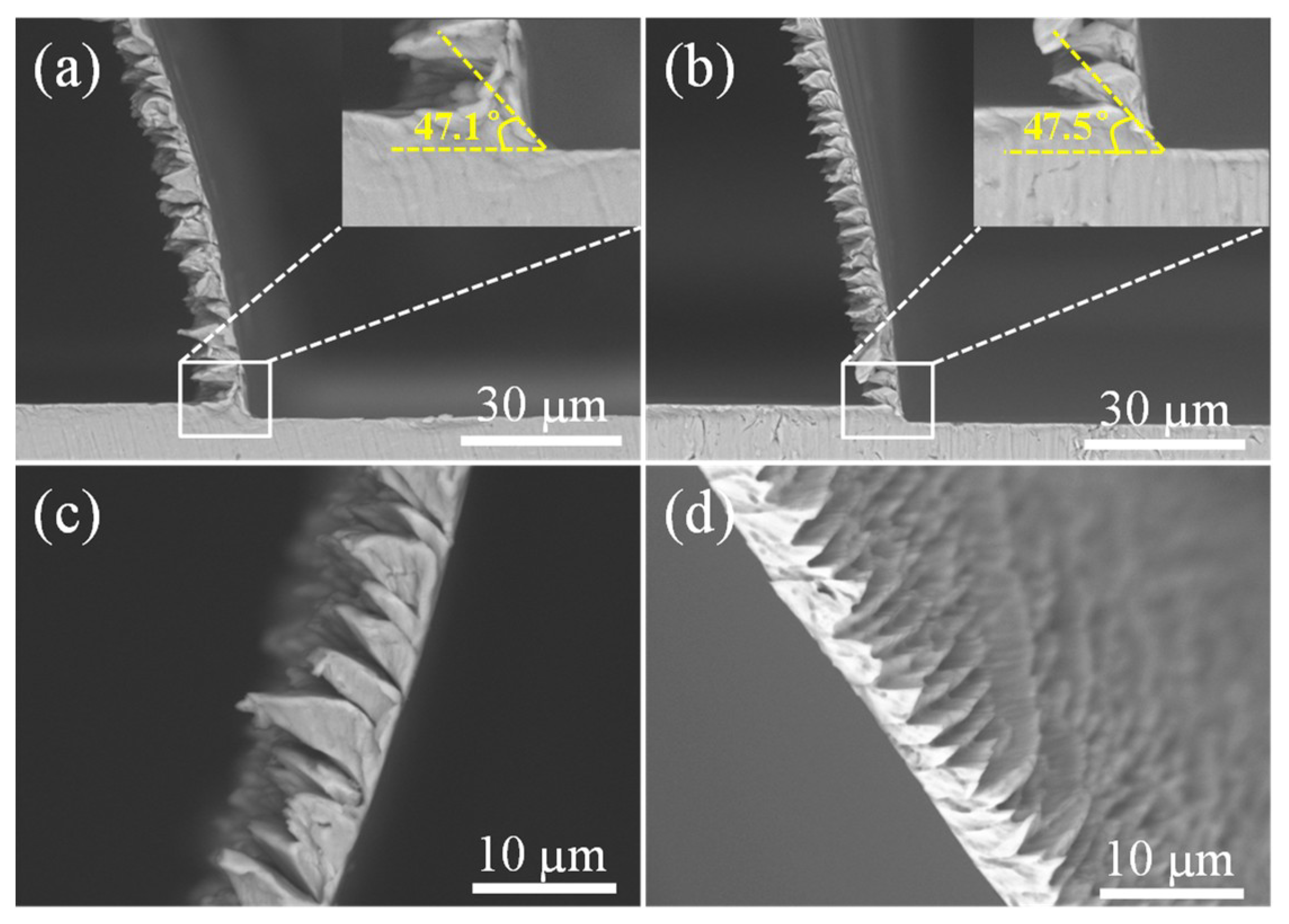

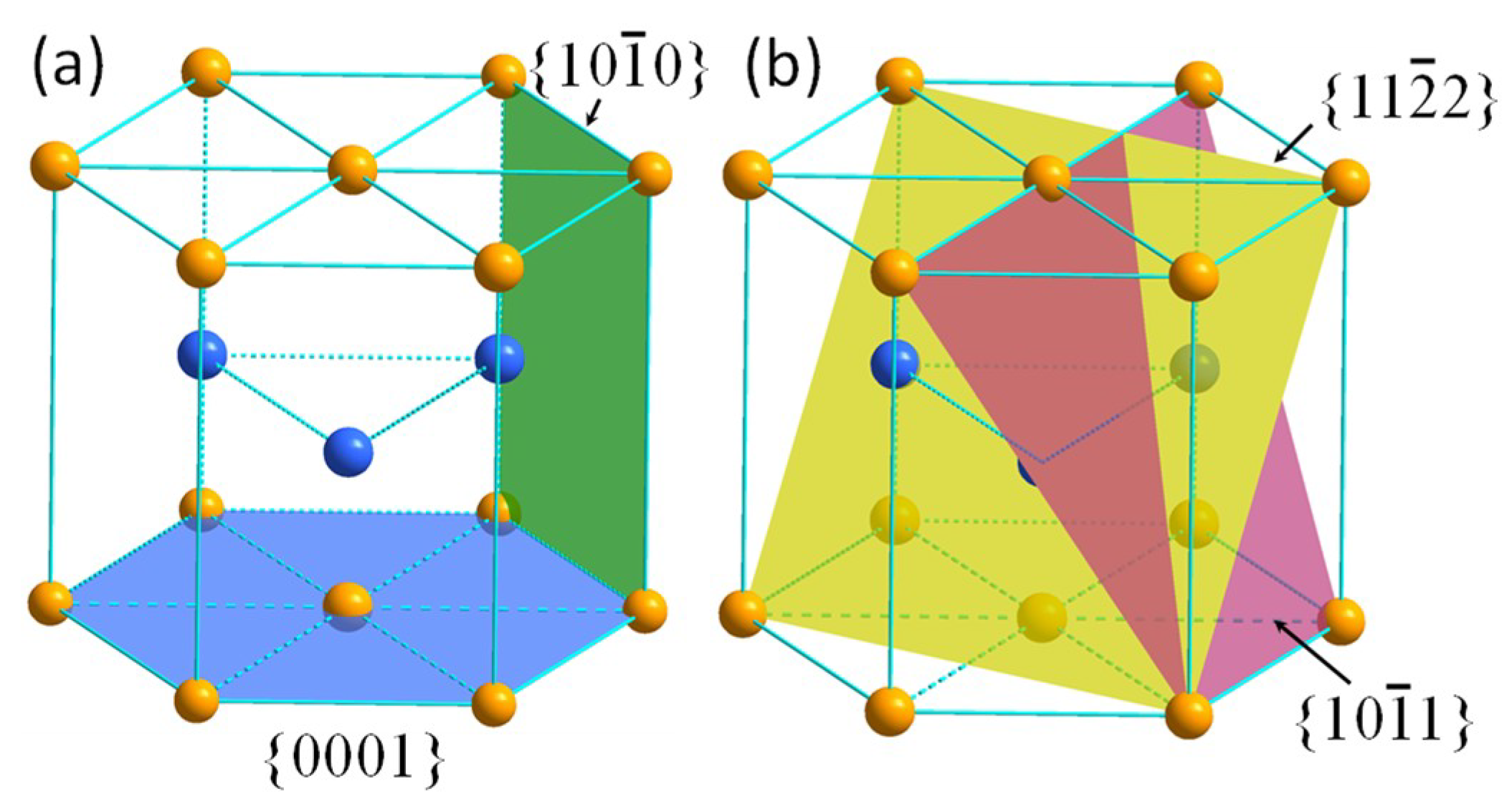

3.2. Cutting Chips

3.3. Cutting and Thrust Forces

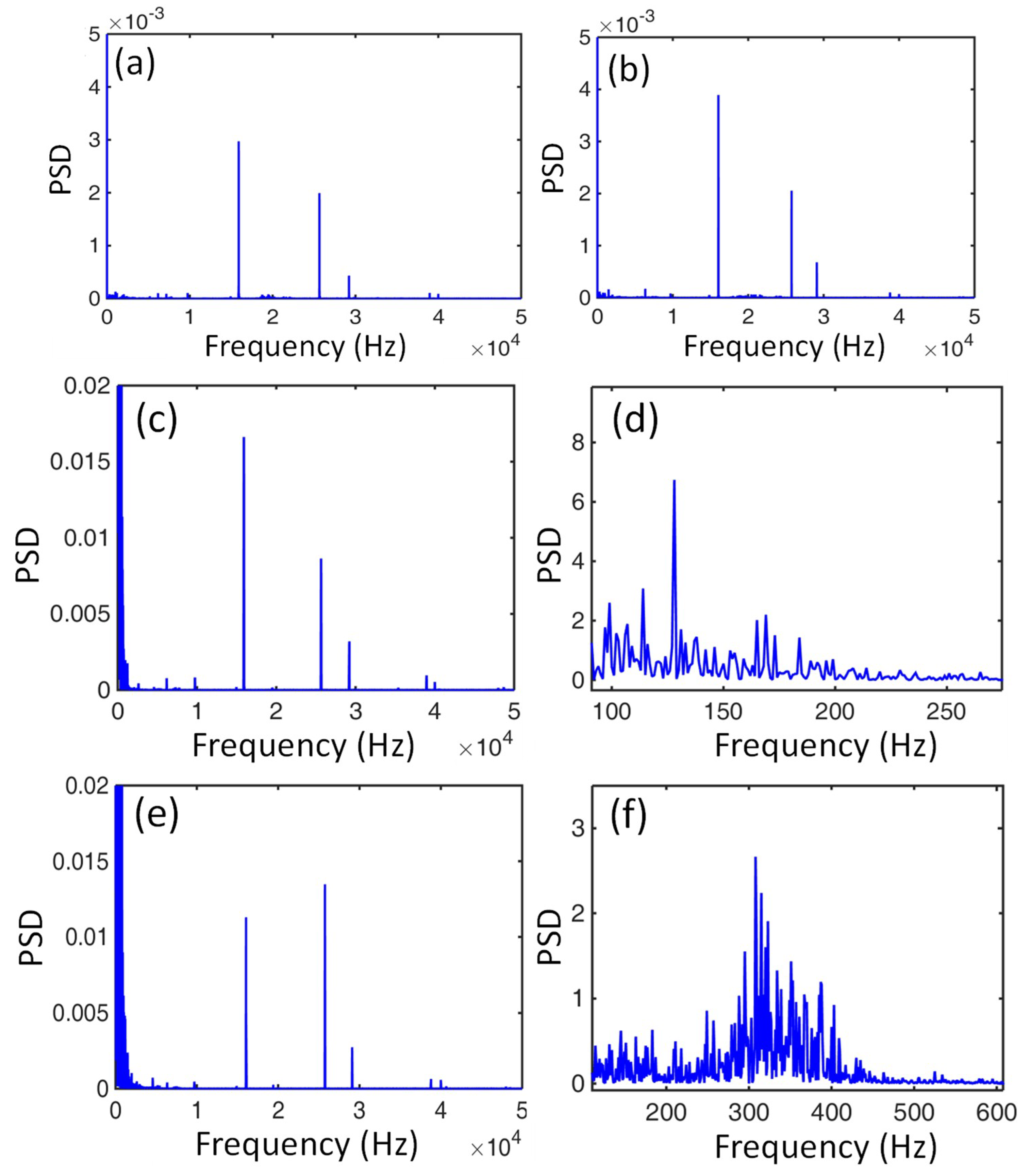

3.4. Power Spectral Density (PSD) of Cutting Forces

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sha, W.; Malinov, S. Titanium Alloys: Modelling of Microstructure, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Sachdev, A.K.; Kulkarni, K.; Fang, Z.Z.; Yang, R.; Girshov, V. Titanium for automotive applications: Challenges and opportunities in materials and processing. JOM 2012, 64, 553–565. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium; Springer Science & Business Media: Berlin, Germany, 2007. [Google Scholar]

- Matsumoto, H.; Yoneda, H.; Sato, K.; Kurosu, S.; Maire, E.; Fabregue, D.; Konno, T.J.; Chiba, A. Room-temperature ductility of Ti–6Al–4V alloy with α′ martensite microstructure. Mater. Sci. Eng. A 2011, 528, 1512–1520. [Google Scholar] [CrossRef]

- Zareena, A.; Veldhuis, S. Tool wear mechanisms and tool life enhancement in ultra-precision machining of titanium. J. Mater. Process. Technol. 2012, 212, 560–570. [Google Scholar] [CrossRef]

- Lu, M.; Zhou, J.; Lin, J.; Gu, Y.; Han, J.; Zhao, D. Study on Ti-6Al-4V alloy machining applying the non-resonant three-dimensional elliptical vibration cutting. Micromachines 2017, 8, 306. [Google Scholar] [CrossRef] [PubMed]

- Balaji, M.; Rao, K.V.; Rao, N.M.; Murthy, B. Optimization of drilling parameters for drilling of TI-6Al-4V based on surface roughness, flank wear and drill vibration. Measurement 2018, 114, 332–339. [Google Scholar] [CrossRef]

- Ng, C.K.; Melkote, S.N.; Rahman, M.; Kumar, A.S. Experimental study of micro-and nano-scale cutting of aluminum 7075-T6. Int. J. Mach. Tools Manuf. 2006, 46, 929–936. [Google Scholar] [CrossRef]

- Wang, Q.; Bai, Q.; Chen, J.; Sun, Y.; Guo, Y.; Liang, Y. Subsurface defects structural evolution in nano-cutting of single crystal copper. Appl. Surf. Sci. 2015, 344, 38–46. [Google Scholar] [CrossRef]

- Rahman, M.A.; Rahman, M.; Kumar, A.S. Modelling of flow stress by correlating the material grain size and chip thickness in ultra-precision machining. Int. J. Mach. Tools Manuf. 2017, 123, 57–75. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S.T. Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tools Manuf. 2012, 57, 83–101. [Google Scholar] [CrossRef]

- Sutter, G.; List, G. Very high speed cutting of Ti–6Al–4V titanium alloy–change in morphology and mechanism of chip formation. Int. J. Mach. Tools Manuf. 2013, 66, 37–43. [Google Scholar] [CrossRef]

- Childs, T.H.; Arrazola, P.-J.; Aristimuno, P.; Garay, A.; Sacristan, I. Ti6Al4V metal cutting chip formation experiments and modelling over a wide range of cutting speeds. J. Mater. Process. Technol. 2018, 255, 898–913. [Google Scholar] [CrossRef]

- Komanduri, R.; von Turkovich, B. New observations on the mechanism of chip formation when machining titanium alloys. Wear 1981, 69, 179–188. [Google Scholar] [CrossRef]

- Komanduri, R.; Hou, Z.-B. On thermoplastic shear instability in the machining of a titanium alloy (Ti-6Al-4V). Metall. Mater. Trans. A 2002, 33, 2995. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Dargusch, M. Characteristics of cutting forces and chip formation in machining of titanium alloys. Int. J. Mach. Tools Manuf. 2009, 49, 561–568. [Google Scholar] [CrossRef]

- Vyas, A.; Shaw, M. Mechanics of saw-tooth chip formation in metal cutting. J. Manuf. Sci. Eng. 1999, 121, 163–172. [Google Scholar] [CrossRef]

- Hua, J.; Shivpuri, R. Prediction of chip morphology and segmentation during the machining of titanium alloys. J. Mater. Process. Technol. 2004, 150, 124–133. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z. Investigations on the chip formation mechanism and shear localization sensitivity of high-speed machining Ti6Al4V. Int. J. Adv. Manuf. Technol. 2014, 75, 1065–1076. [Google Scholar] [CrossRef]

- Wu, H.; To, S. Serrated chip formation and their adiabatic analysis by using the constitutive model of titanium alloy in high speed cutting. J. Alloy. Compd. 2015, 629, 368–373. [Google Scholar] [CrossRef]

- Sima, M.; Özel, T. Modified material constitutive models for serrated chip formation simulations and experimental validation in machining of titanium alloy Ti–6Al–4V. Int. J. Mach. Tools Manuf. 2010, 50, 943–960. [Google Scholar] [CrossRef]

- Che, J.; Zhou, T.; Liang, Z.; Wu, J.; Wang, X. Serrated chip formation mechanism analysis using a modified model based on the material defect theory in machining Ti-6Al-4 V alloy. Int. J. Adv. Manuf. Technol. 2018, 96, 3575–3584. [Google Scholar] [CrossRef]

- Calamaz, M.; Coupard, D.; Girot, F. A new material model for 2D numerical simulation of serrated chip formation when machining titanium alloy Ti–6Al–4V. Int. J. Mach. Tools Manuf. 2008, 48, 275–288. [Google Scholar] [CrossRef]

- Liu, G.; Shah, S.; Özel, T. Material Ductile Failure Based Finite Element Simulations of Chip Serration in Orthogonal Cutting of Titanium Alloy Ti-6Al-4V. J. Manuf. Sci. Eng. 2019, 141, 041017. [Google Scholar] [CrossRef]

- Barge, M.; Hamdi, H.; Rech, J.; Bergheau, J.-M. Numerical modelling of orthogonal cutting: Influence of numerical parameters. J. Mater. Process. Technol. 2005, 164, 1148–1153. [Google Scholar] [CrossRef]

- Nouari, M.; Makich, H. On the physics of machining titanium alloys: Interactions between cutting parameters, microstructure and tool wear. Metals 2014, 4, 335–358. [Google Scholar] [CrossRef]

- Nouari, M.; Makich, H. Experimental investigation on the effect of the material microstructure on tool wear when machining hard titanium alloys: Ti–6Al–4V and Ti-555. Int. J. Refract. Met. Hard Mater. 2013, 41, 259–269. [Google Scholar] [CrossRef]

- Ahmadi, M.; Karpat, Y.; Acar, O.; Kalay, Y.E. Microstructure effects on process outputs in micro scale milling of heat treated Ti6Al4V titanium alloys. J. Mater. Process. Technol. 2018, 252, 333–347. [Google Scholar] [CrossRef]

- Berezvai, S.; Molnar, T.G.; Bachrathy, D.; Stepan, G. Experimental investigation of the shear angle variation during orthogonal cutting. Mater. Today Proc. 2018, 5, 26495–26500. [Google Scholar] [CrossRef]

- Wan, L.; Wang, D.; Gao, Y. The investigation of mechanism of serrated chip formation under different cutting speeds. Int. J. Adv. Manuf. Technol. 2016, 82, 951–959. [Google Scholar] [CrossRef]

- Dargusch, M.S.; Sun, S.; Kim, J.W.; Li, T.; Trimby, P.; Cairney, J. Effect of tool wear evolution on chip formation during dry machining of Ti-6Al-4V alloy. Int. J. Mach. Tools Manuf. 2018, 126, 13–17. [Google Scholar] [CrossRef]

- Liu, R.; Melkote, S.; Pucha, R.; Morehouse, J.; Man, X.; Marusich, T. An enhanced constitutive material model for machining of Ti–6Al–4V alloy. J. Mater. Process. Technol. 2013, 213, 2238–2246. [Google Scholar] [CrossRef]

- Zhao, Z.; To, S.; Sun, Z.; Ji, R.; Yu, K.M. Microstructural effects of Ti6Al4V alloys modified by electropulsing treatment on ultraprecision diamond turning. J. Manuf. Process. 2019, 39, 58–68. [Google Scholar] [CrossRef]

- Zhao, Z.; To, S. An investigation of resolved shear stress on activation of slip systems during ultraprecision rotary cutting of local anisotropic Ti-6Al-4V alloy: Models and experiments. Int. J. Mach. Tools Manuf. 2018, 134, 69–78. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; To, S.; Zhuang, Z. Serrated Chips Formation in Micro Orthogonal Cutting of Ti6Al4V Alloys with Equiaxial and Martensitic Microstructures. Micromachines 2019, 10, 197. https://doi.org/10.3390/mi10030197

Zhao Z, To S, Zhuang Z. Serrated Chips Formation in Micro Orthogonal Cutting of Ti6Al4V Alloys with Equiaxial and Martensitic Microstructures. Micromachines. 2019; 10(3):197. https://doi.org/10.3390/mi10030197

Chicago/Turabian StyleZhao, ZeJia, Suet To, and ZhuoXuan Zhuang. 2019. "Serrated Chips Formation in Micro Orthogonal Cutting of Ti6Al4V Alloys with Equiaxial and Martensitic Microstructures" Micromachines 10, no. 3: 197. https://doi.org/10.3390/mi10030197

APA StyleZhao, Z., To, S., & Zhuang, Z. (2019). Serrated Chips Formation in Micro Orthogonal Cutting of Ti6Al4V Alloys with Equiaxial and Martensitic Microstructures. Micromachines, 10(3), 197. https://doi.org/10.3390/mi10030197