Product and Process Fingerprint for Nanosecond Pulsed Laser Ablated Superhydrophobic Surface

Abstract

1. Introduction

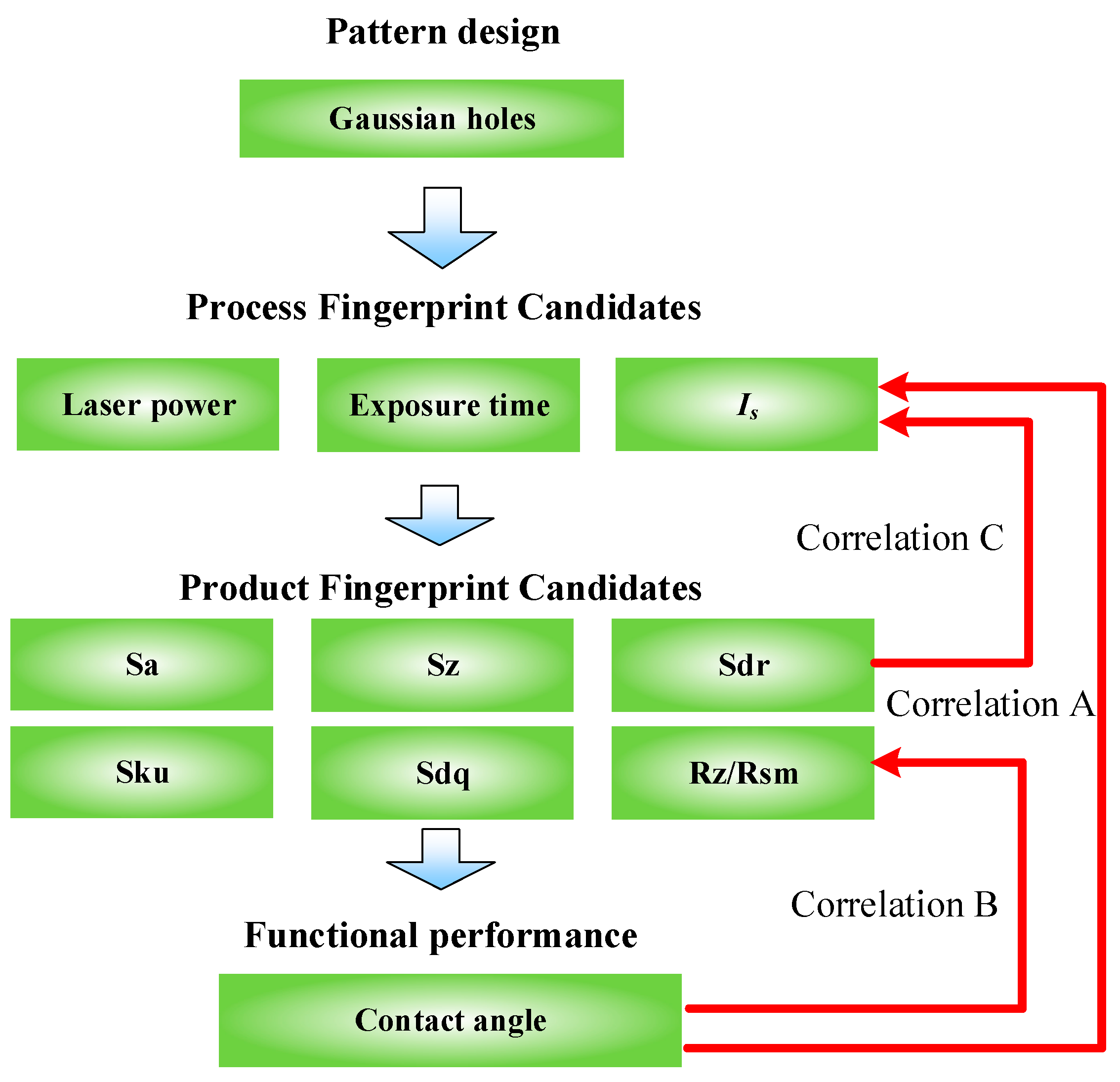

2. Analysis of Process and Product Fingerprints

2.1. Analysis of Process Fingerprint Candidates: Laser Power, Exposure Time, Laser Pulse Energy Per Unit Area of Specimen

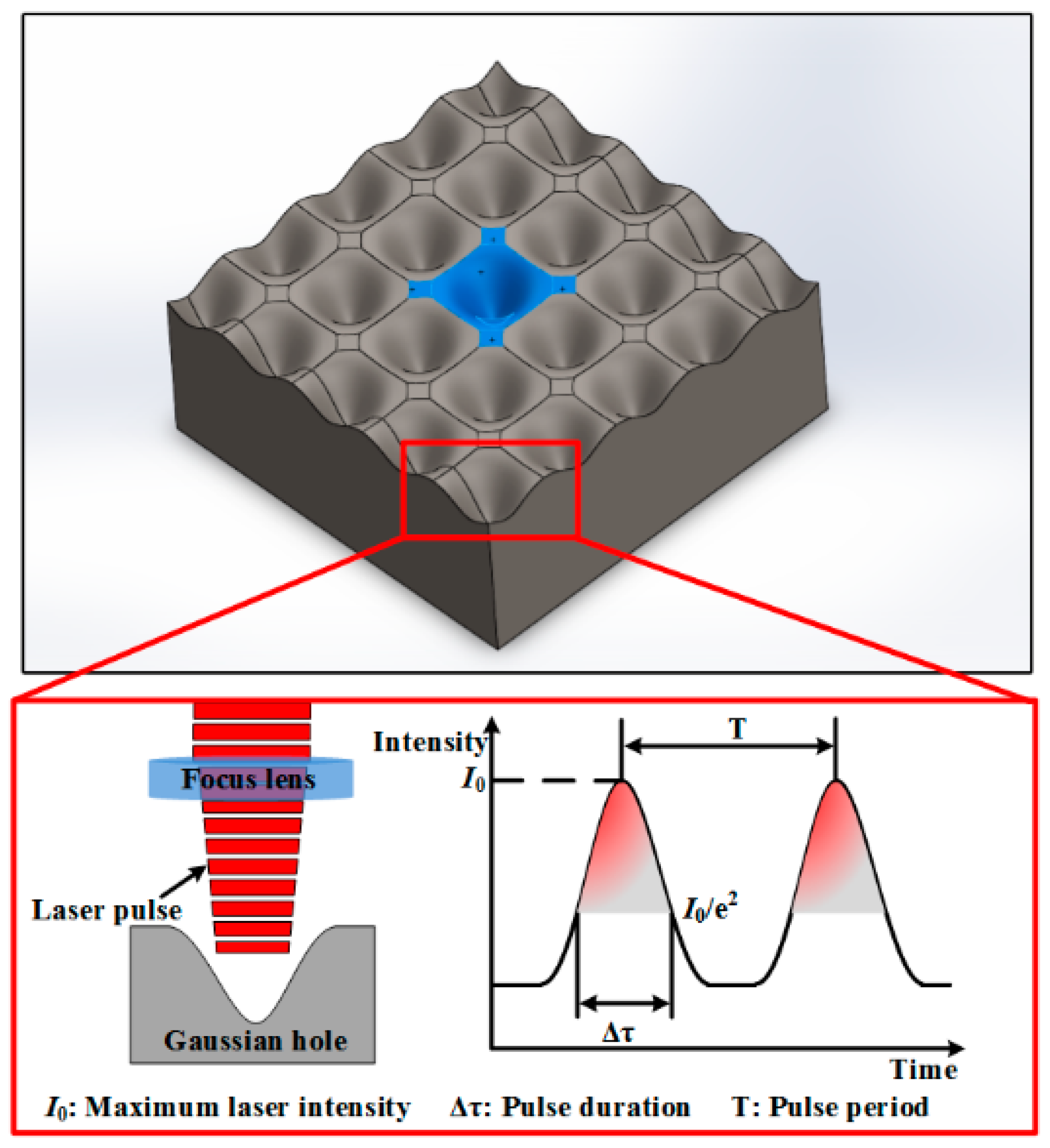

2.1.1. Laser Power (P)

2.1.2. Exposure Time (t)

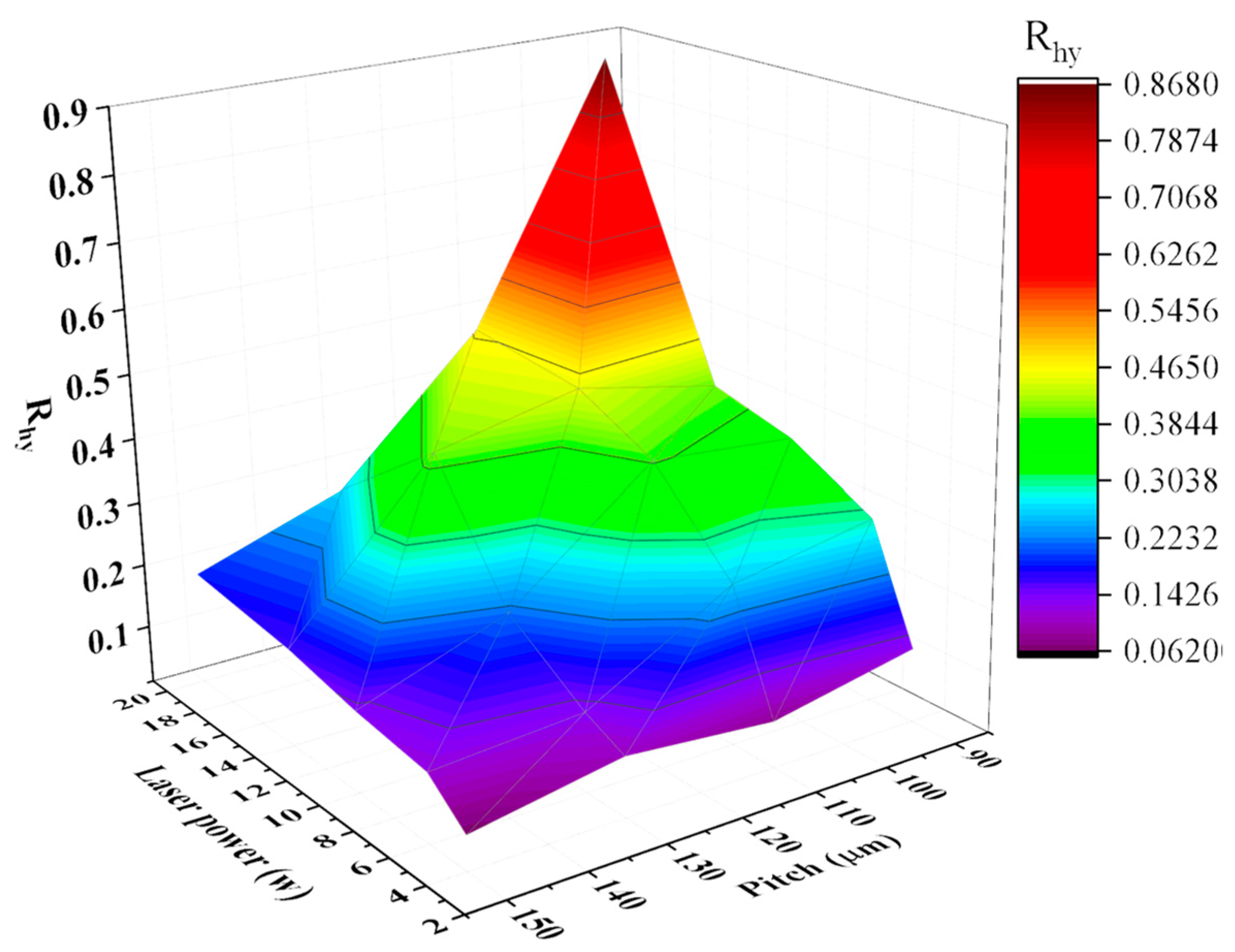

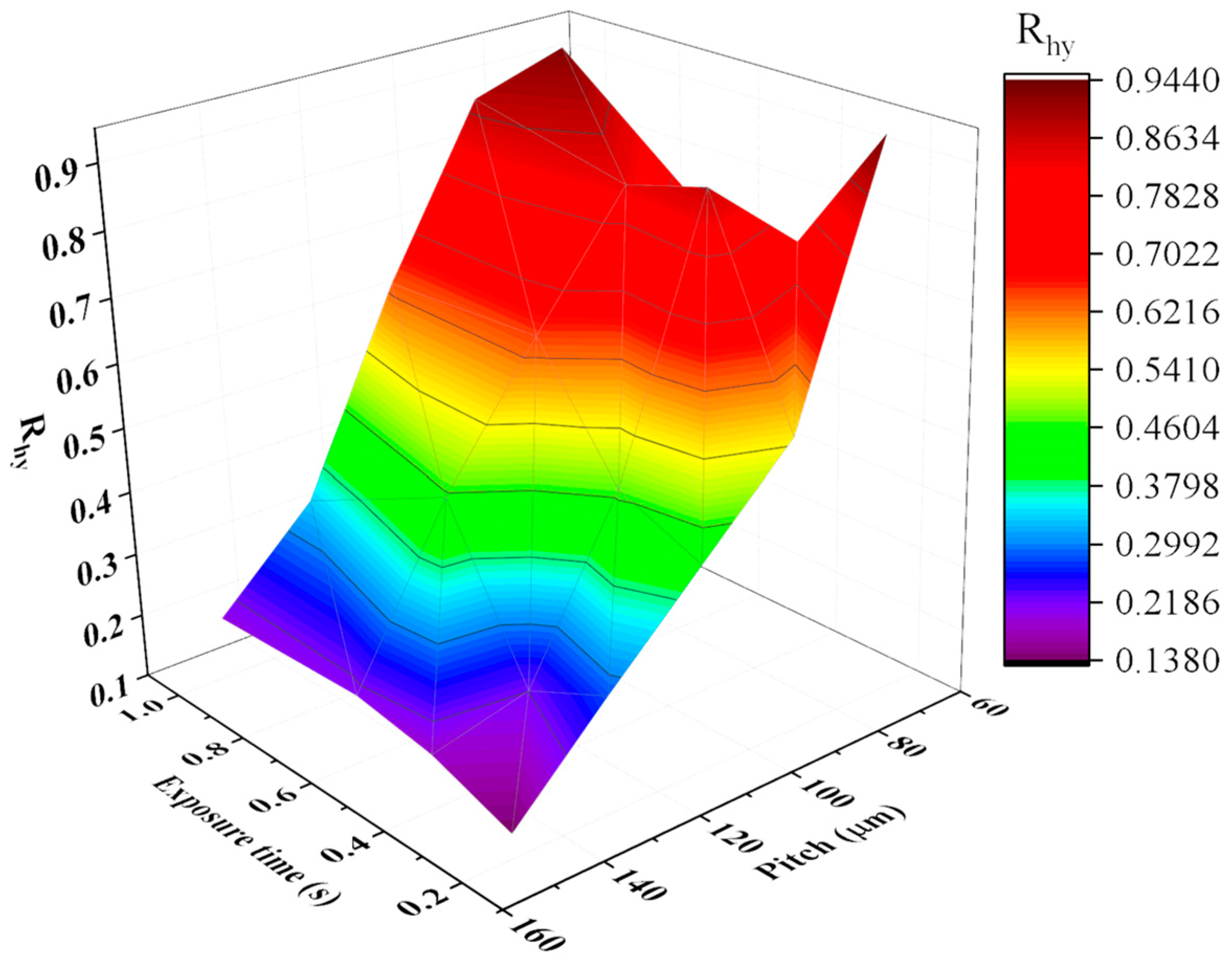

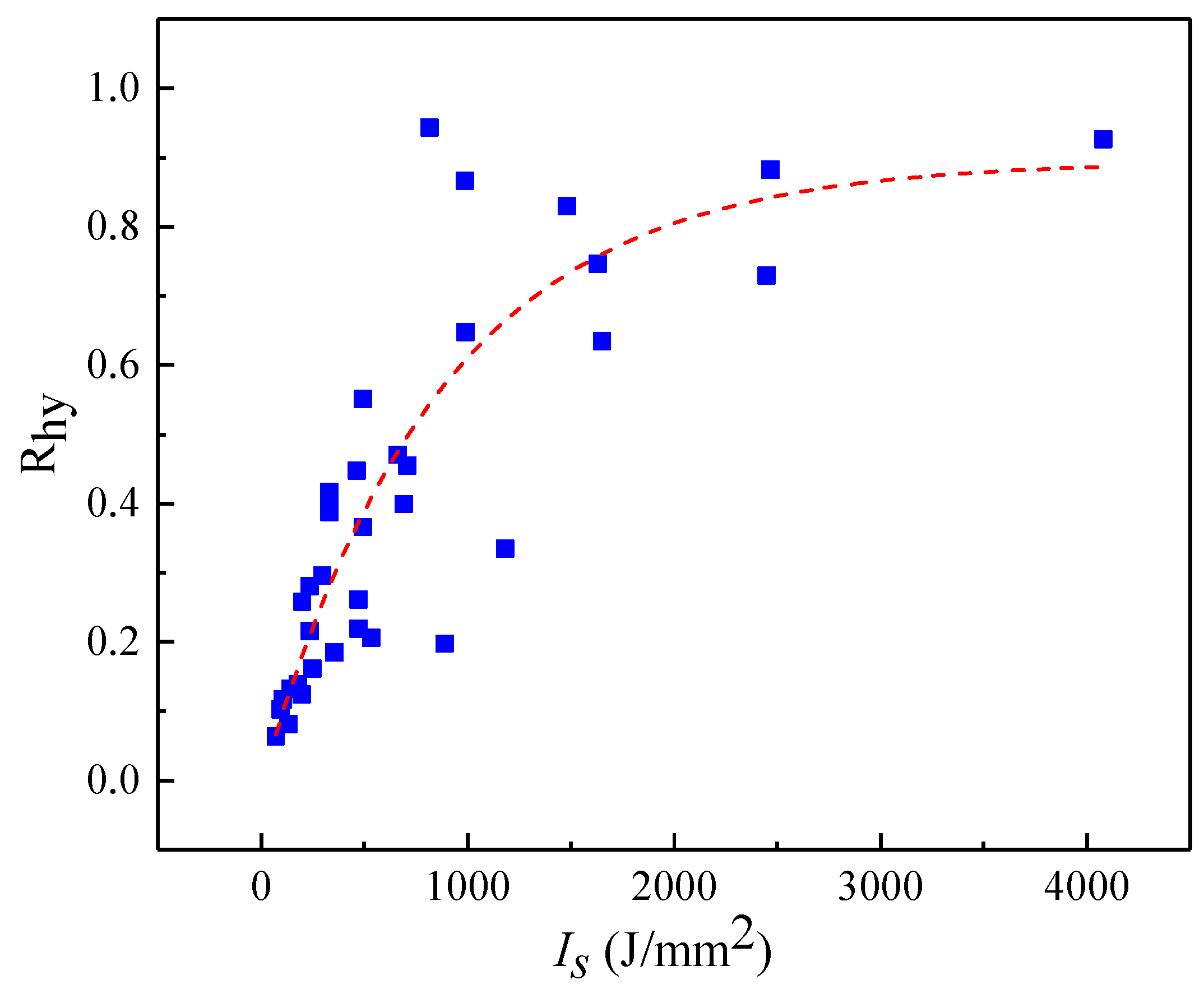

2.2. Analysis of Product Fingerprint Candidates: Sa, Sz, Sku, Sdr, Sdq, Rhy

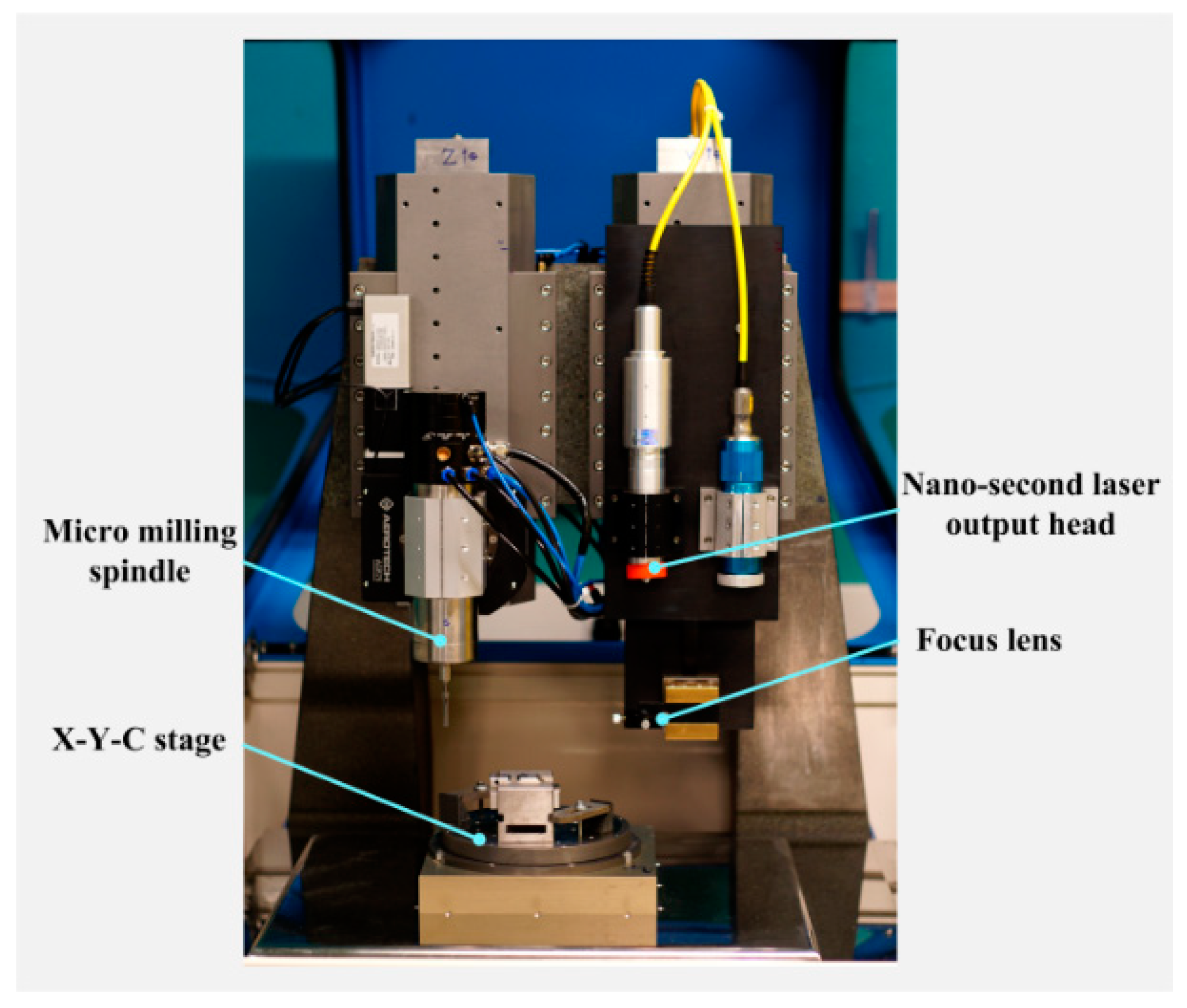

3. Experimental Details

4. Results and Discussion

4.1. Analysis of Product Fingerprint: Sa, Sz, Sku, Sdr, Sdq, Rhy

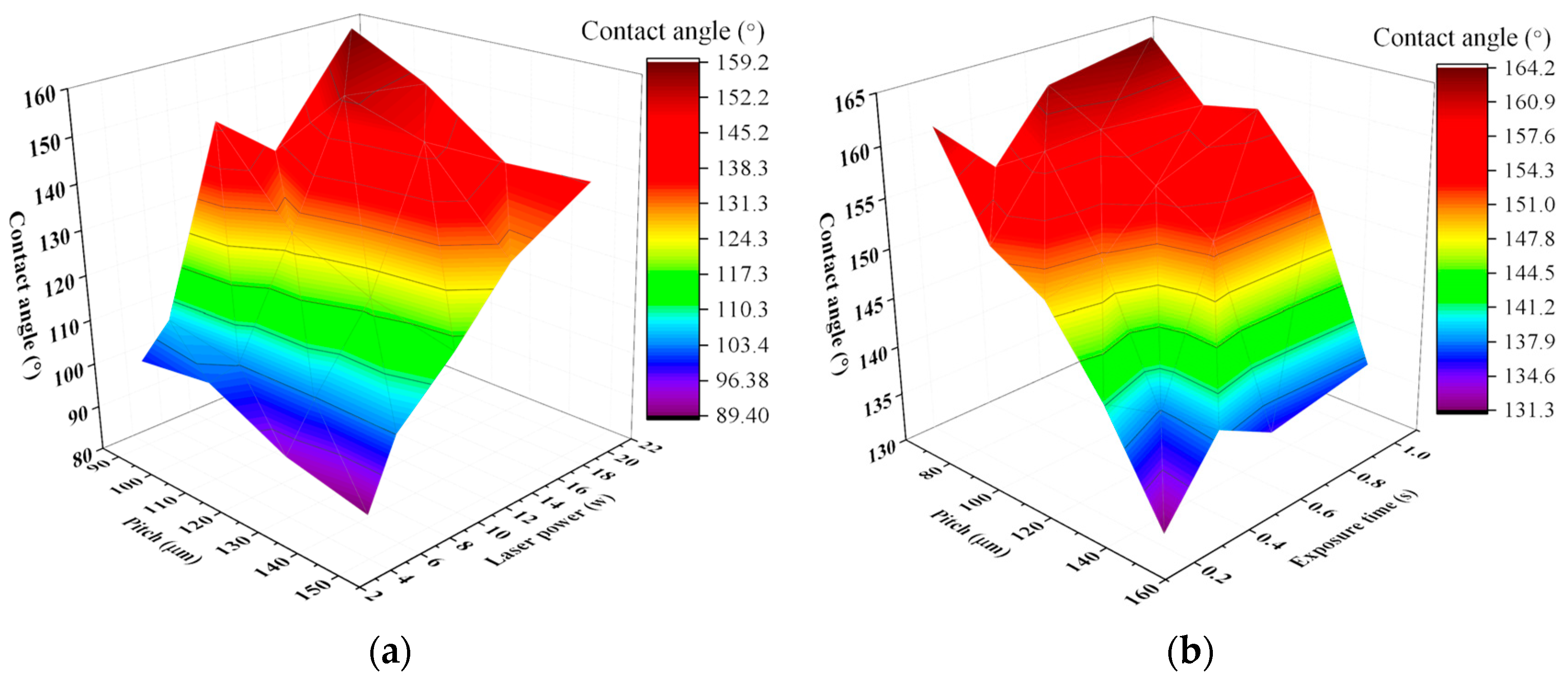

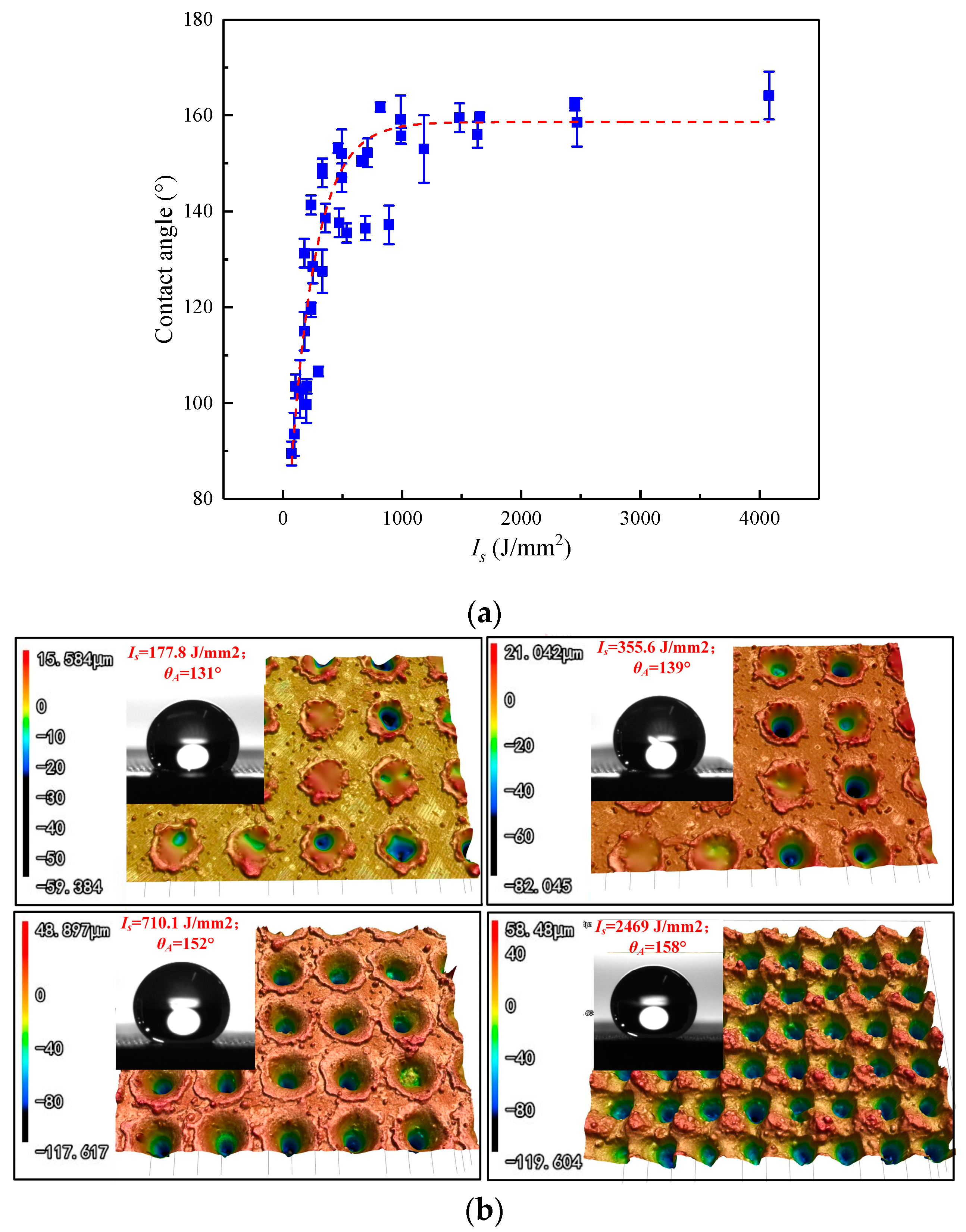

4.2. Analysis of Process Fingerprints: P, t and Is

4.3. Correlation Between Laser Machining Parameters and Contact Angle

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Data Statement

References

- Tong, W.; Xiong, D.; Wang, N.; Yan, C.; Tian, T. Green and timesaving fabrication of a superhydrophobic surface and its application to anti-icing, self-cleaning and oil-water separation. Surf. Coat. Technol. 2018, 352, 609–618. [Google Scholar] [CrossRef]

- Li, S.; Page, K.; Sathasivam, S.; Heale, F.; He, G.; Lu, Y.; Lai, Y.; Chen, G.; Carmalt, C.J.; Parkin, I.P. Efficiently texturing hierarchical superhydrophobic fluoride-free translucent films by AACVD with excellent durability and self-cleaning ability. J. Mater. Chem. A 2018, 6, 17633–17641. [Google Scholar] [CrossRef]

- Anitha, C.; Syed Azim, S.; Mayavan, S. Influence of particle size in fluorine free corrosion resistance superhydrophobic coating—Optimization and stabilization of interface by multiscale roughness. J. Alloys Compd. 2018, 765, 677–684. [Google Scholar] [CrossRef]

- Rastegari, A.; Akhavan, R. The common mechanism of turbulent skin-friction drag reduction with superhydrophobic longitudinal microgrooves and riblets. J. Fluid Mech. 2018, 838, 68–104. [Google Scholar] [CrossRef]

- Xie, X.; Weng, Q.; Luo, Z.; Long, J.; Wei, X. Thermal performance of the flat micro-heat pipe with the wettability gradient surface by laser fabrication. Int. J. Heat Mass Transf. 2018, 125, 658–669. [Google Scholar] [CrossRef]

- Trdan, U.; Hočevar, M.; Gregorčič, P. Transition from superhydrophilic to superhydrophobic state of laser textured stainless steel surface and its effect on corrosion resistance. Corros. Sci. 2017, 123, 21–26. [Google Scholar] [CrossRef]

- Karlsson, M.; Forsberg, P.; Nikolajeff, F. From hydrophilic to superhydrophobic: Fabrication of micrometer-sized nail-head-shaped pillars in diamond. Langmuir 2010, 26, 889–893. [Google Scholar] [CrossRef] [PubMed]

- Nishino, T.; Meguro, M.; Nakamae, K.; Matsushita, M.; Ueda, Y. The Lowest Surface Free Energy Based on −CF 3 Alignment. Langmuir 1999, 15, 4321–4323. [Google Scholar] [CrossRef]

- Bell, M.S.; Shahraz, A.; Fichthorn, K.A.; Borhan, A. Effects of Hierarchical Surface Roughness on Droplet Contact Angle. Langmuir 2015, 31, 6752–6762. [Google Scholar] [CrossRef] [PubMed]

- Ta, D.V.; Dunn, A.; Wasley, T.J.; Kay, R.W.; Stringer, J.; Smith, P.J.; Connaughton, C.; Shephard, J.D. Nanosecond laser textured superhydrophobic metallic surfaces and their chemical sensing applications. Appl. Surf. Sci. 2015, 357, 248–254. [Google Scholar] [CrossRef]

- Ngo, C.V.; Chun, D.M. Fast wettability transition from hydrophilic to superhydrophobic laser-textured stainless steel surfaces under low-temperature annealing. Appl. Surf. Sci. 2017, 409, 232–240. [Google Scholar] [CrossRef]

- Ngo, C.V.; Chun, D.M. Effect of Heat Treatment Temperature on the Wettability Transition from Hydrophilic to Superhydrophobic on Laser-Ablated Metallic Surfaces. Adv. Eng. Mater. 2018, 20, 1–11. [Google Scholar] [CrossRef]

- Kim, J.H.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Facile fabrication of superhydrophobic surfaces from austenitic stainless steel (AISI 304) by chemical etching. Appl. Surf. Sci. 2018, 439, 598–604. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Reese, S.; Klink, A.; Langenhorst, L.; Lübben, T.; Meinke, M.; Meyer, D.; Riemer, O.; Sölter, J. Underlying Mechanisms for Developing Process Signatures in Manufacturing. Nanomanuf. Metrol. 2018, 1, 193–208. [Google Scholar] [CrossRef]

- Cai, Y.; Chang, W.; Luo, X.; Sousa, A.M.L.; Lau, K.H.A.; Qin, Y. Superhydrophobic structures on 316L stainless steel surfaces machined by nanosecond pulsed laser. Precis. Eng. 2018, 52, 266–275. [Google Scholar] [CrossRef]

- Yang, C.; Tartaglino, U.; Persson, B.N.J. Influence of surface roughness on superhydrophobicity. Phys. Rev. Lett. 2006, 97, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Long, J.; Cao, Z.; Lin, C.; Zhou, C.; He, Z.; Xie, X. Formation mechanism of hierarchical Micro- and nanostructures on copper induced by low-cost nanosecond lasers. Appl. Surf. Sci. 2019, 464, 412–421. [Google Scholar] [CrossRef]

- Gregorčič, P.; Šetina-Batič, B.; Hočevar, M. Controlling the stainless steel surface wettability by nanosecond direct laser texturing at high fluences. Appl. Phys. A Mater. Sci. Process. 2017, 123, 1–8. [Google Scholar] [CrossRef]

- Conradi, M.; Drnovšek, A.; Gregorčič, P. Wettability and friction control of a stainless steel surface by combining nanosecond laser texturing and adsorption of superhydrophobic nanosilica particles. Sci. Rep. 2018, 8, 2–10. [Google Scholar] [CrossRef] [PubMed]

- Long, J.; He, Z.; Zhou, C.; Xie, X.; Cao, Z.; Zhou, P.; Zhu, Y.; Hong, W.; Zhou, Z. Hierarchical micro- and nanostructures induced by nanosecond laser on copper for superhydrophobicity, ultralow water adhesion and frost resistance. Mater. Des. 2018, 155, 185–193. [Google Scholar] [CrossRef]

- Ngo, C.V.; Chun, D.M. Control of laser-ablated aluminum surface wettability to superhydrophobic or superhydrophilic through simple heat treatment or water boiling post-processing. Appl. Surf. Sci. 2018, 435, 974–982. [Google Scholar] [CrossRef]

- Park, K.C.; Choi, H.J.; Chang, C.H.; Cohen, R.E.; McKinley, G.H.; Barbastathis, G. Nanotextured silica surfaces with robust superhydrophobicity and omnidirectional broadband supertransmissivity. ACS Nano 2012, 6, 3789–3799. [Google Scholar] [CrossRef] [PubMed]

- Ta, V.D.; Dunn, A.; Wasley, T.J.; Li, J.; Kay, R.W.; Stringer, J.; Smith, P.J.; Esenturk, E.; Connaughton, C.; Shephard, J.D. Laser textured superhydrophobic surfaces and their applications for homogeneous spot deposition. Appl. Surf. Sci. 2016, 365, 153–159. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, X.; Tian, Y. Insights into the wettability transition of nanosecond laser ablated surface under ambient air exposure. J. Colloid Interface Sci. 2019, 533, 268–277. [Google Scholar] [CrossRef] [PubMed]

- Cassie, B.D. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of Solid Surfaces To Wetting By Water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Roughness optimization for biomimetic superhydrophobic surfaces. Microsyst. Technol. 2005, 11, 535–549. [Google Scholar] [CrossRef]

- Spearman’s Rank Correlation Coefficient. Available online: https://en.wikipedia.org/wiki/Spearman%27s_rank_correlation_coefficient (accessed on 21 January 2019).

- Kendall Rank Correlation Coefficient. Available online: https://en.wikipedia.org/wiki/Kendall_rank_correlation_coefficient (accessed on 21 January 2019).

- Celia, E.; Darmanin, T.; Taffin de Givenchy, E.; Amigoni, S.; Guittard, F. Recent advances in designing superhydrophobic surfaces. J. Colloid Interface Sci. 2013, 402, 1–18. [Google Scholar] [CrossRef] [PubMed]

| Name | Symbol | Meaning |

|---|---|---|

| Arithmetical mean height | Sa | The difference in height of each point compared to the arithmetical mean of the surface. |

| Maximum height | Sz | The sum of the largest peak height value and the largest pit depth value within the defined area. |

| Kurtosis | Sku | A measure of the sharpness of the roughness profile. Sku < 3: Height distribution is skewed above the mean plane. Sku = 3: Height distribution is normal. (Sharp portions and indented portions co-exist.) Sku > 3: Height distribution is spiked. |

| Developed interfacial area ratio | Sdr | The percentage of the definition area’s additional surface area contributed by the texture as compared to the planar definition area. |

| Root mean square gradient | Sdq | Root mean square of slopes at all points in the definition area. When a surface has any slope, its Sdq value becomes larger. |

| Average ratio of Rz to Rsm | Rhy | Average ratio of the maximum height of profile (Rz) and mean width of the profile elements (RSm) |

| Pitch (μm) | Laser Power (W) | Pulse Repetition Rate | Feed Rate (mm/min) | Exposure Time (s) | Pattern Types |

|---|---|---|---|---|---|

| 90 | 4,6,10,14,20 | 100K | 200 | 0.4 | Gaussian holes |

| 110 | 4,6,10,14,20 | 100K | 200 | 0.4 | Gaussian holes |

| 130 | 4,6,10,14,20 | 100K | 200 | 0.4 | Gaussian holes |

| 150 | 4,6,10,14,20 | 100K | 200 | 0.4 | Gaussian holes |

| Pitch (μm) | Laser Power (W) | Pulse Repetition Rate | Feed Rate (mm/min) | Exposure Time (s) | Pattern Types |

|---|---|---|---|---|---|

| 70 | 20 | 100K | 200 | 0.2,0.4,0.6,1 | Gaussian holes |

| 90 | 20 | 100K | 200 | 0.2,0.4,0.6,1 | Gaussian holes |

| 110 | 20 | 100K | 200 | 0.2,0.4,0.6,1 | Gaussian holes |

| 130 | 20 | 100K | 200 | 0.2,0.4,0.6,1 | Gaussian holes |

| 150 | 20 | 100K | 200 | 0.2,0.4,0.6,1 | Gaussian holes |

| Value of Coefficient | Correlation Type |

|---|---|

| 1 | Perfect correlation |

| 0.81–0.99 | Strong correlation |

| 0.71–0.80 | Good correlation |

| 0.51–0.70 | Weak correlation |

| 0.01–0.50 | Poor correlation |

| 0 | No correlation |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Y.; Luo, X.; Liu, Z.; Qin, Y.; Chang, W.; Sun, Y. Product and Process Fingerprint for Nanosecond Pulsed Laser Ablated Superhydrophobic Surface. Micromachines 2019, 10, 177. https://doi.org/10.3390/mi10030177

Cai Y, Luo X, Liu Z, Qin Y, Chang W, Sun Y. Product and Process Fingerprint for Nanosecond Pulsed Laser Ablated Superhydrophobic Surface. Micromachines. 2019; 10(3):177. https://doi.org/10.3390/mi10030177

Chicago/Turabian StyleCai, Yukui, Xichun Luo, Zhanqiang Liu, Yi Qin, Wenlong Chang, and Yazhou Sun. 2019. "Product and Process Fingerprint for Nanosecond Pulsed Laser Ablated Superhydrophobic Surface" Micromachines 10, no. 3: 177. https://doi.org/10.3390/mi10030177

APA StyleCai, Y., Luo, X., Liu, Z., Qin, Y., Chang, W., & Sun, Y. (2019). Product and Process Fingerprint for Nanosecond Pulsed Laser Ablated Superhydrophobic Surface. Micromachines, 10(3), 177. https://doi.org/10.3390/mi10030177