Manufacturing of Al Alloy Microrods by Micro Cutting in a Micromachining Center

Abstract

:1. Introduction

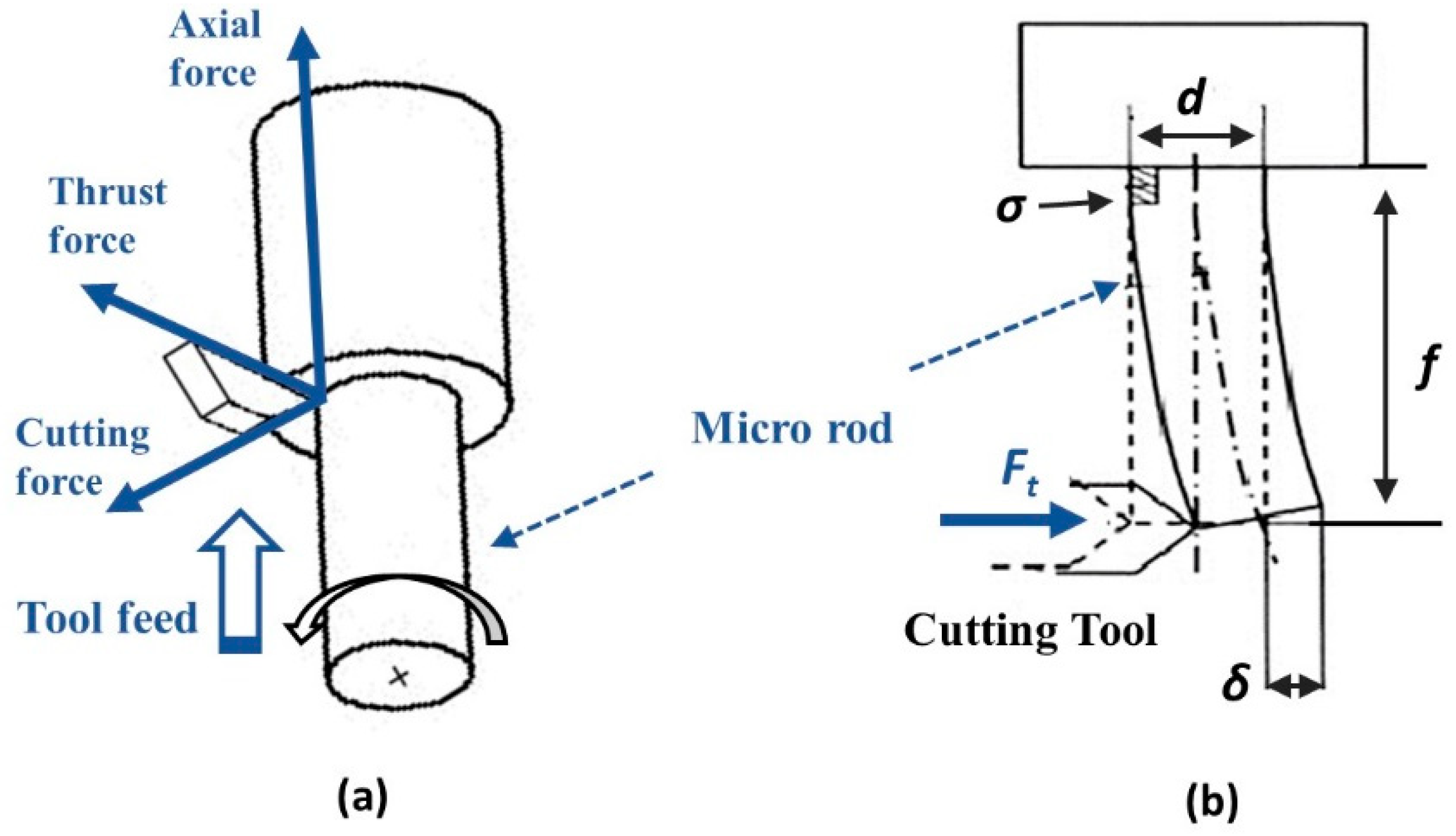

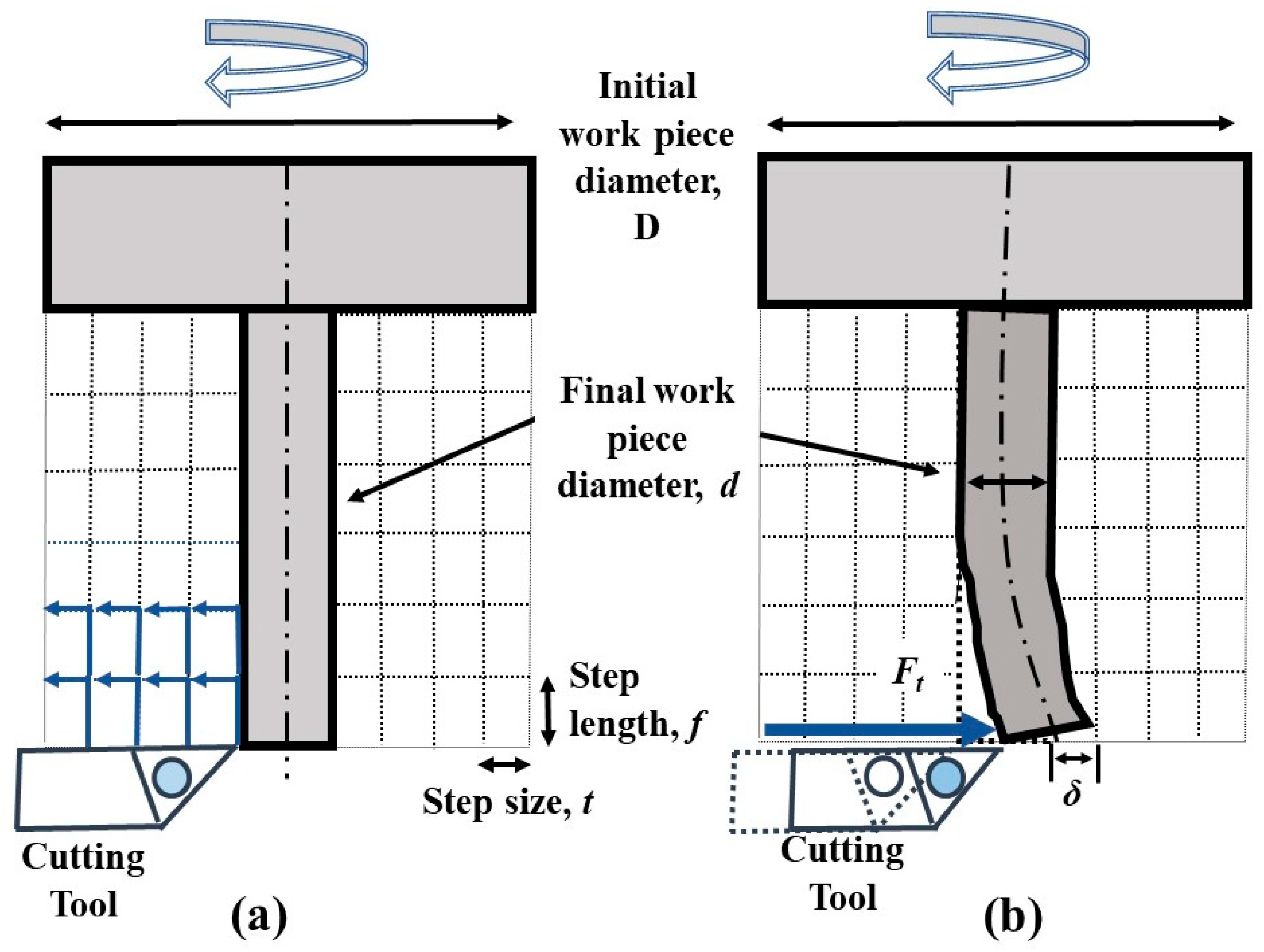

2. Micro Turning Process Development

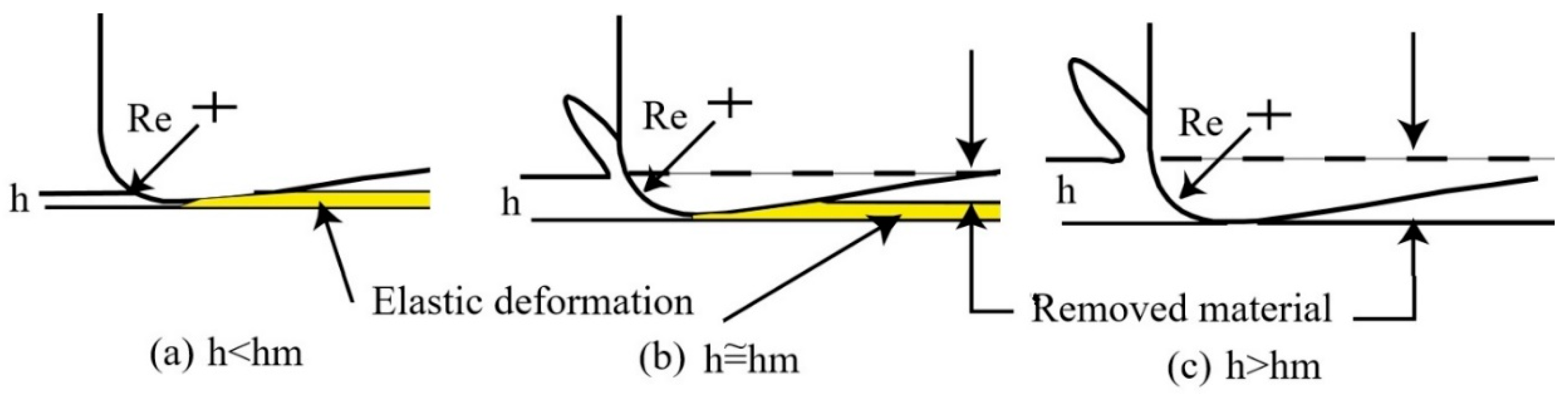

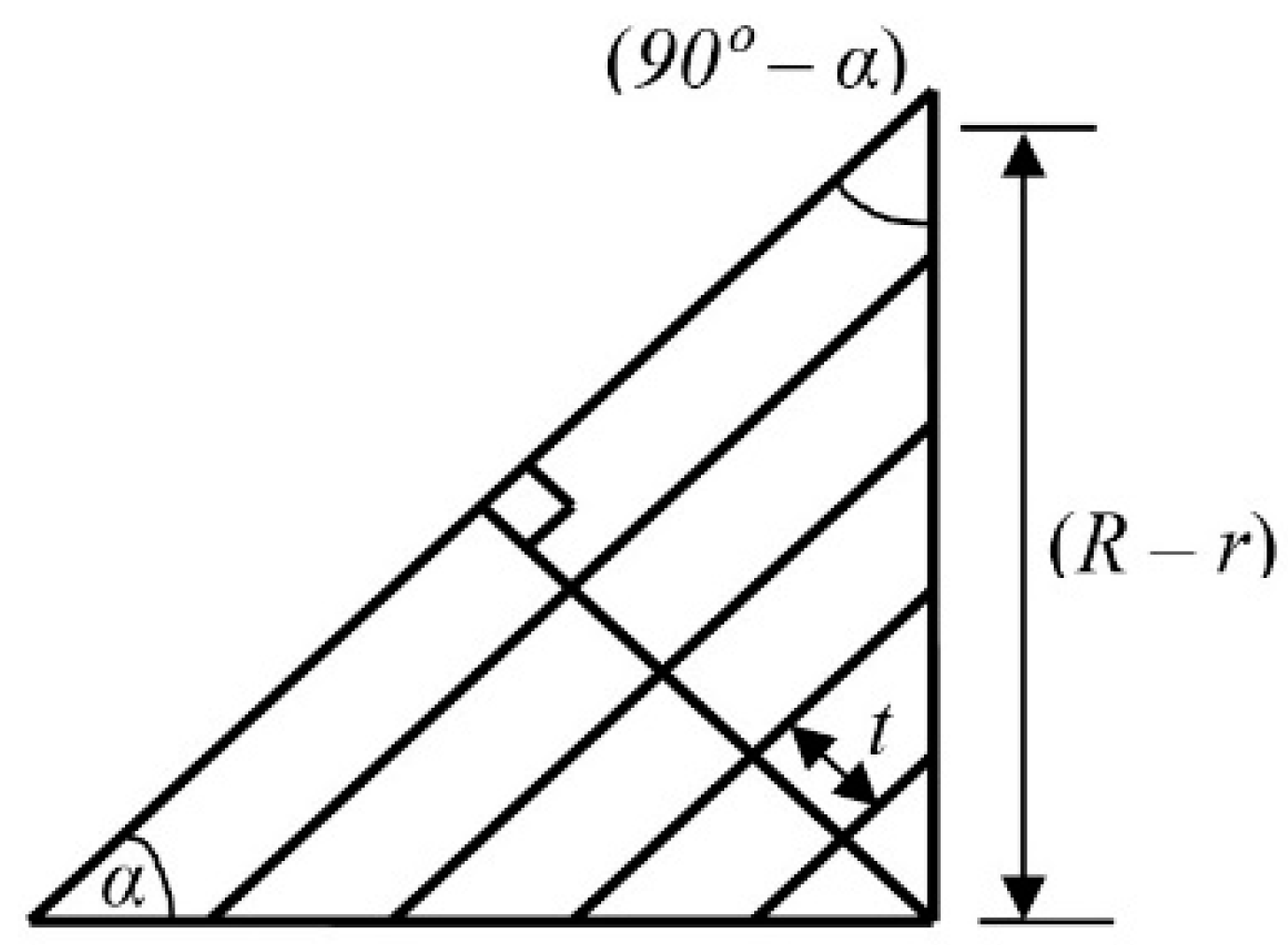

2.1. Modeling of the Machining Process

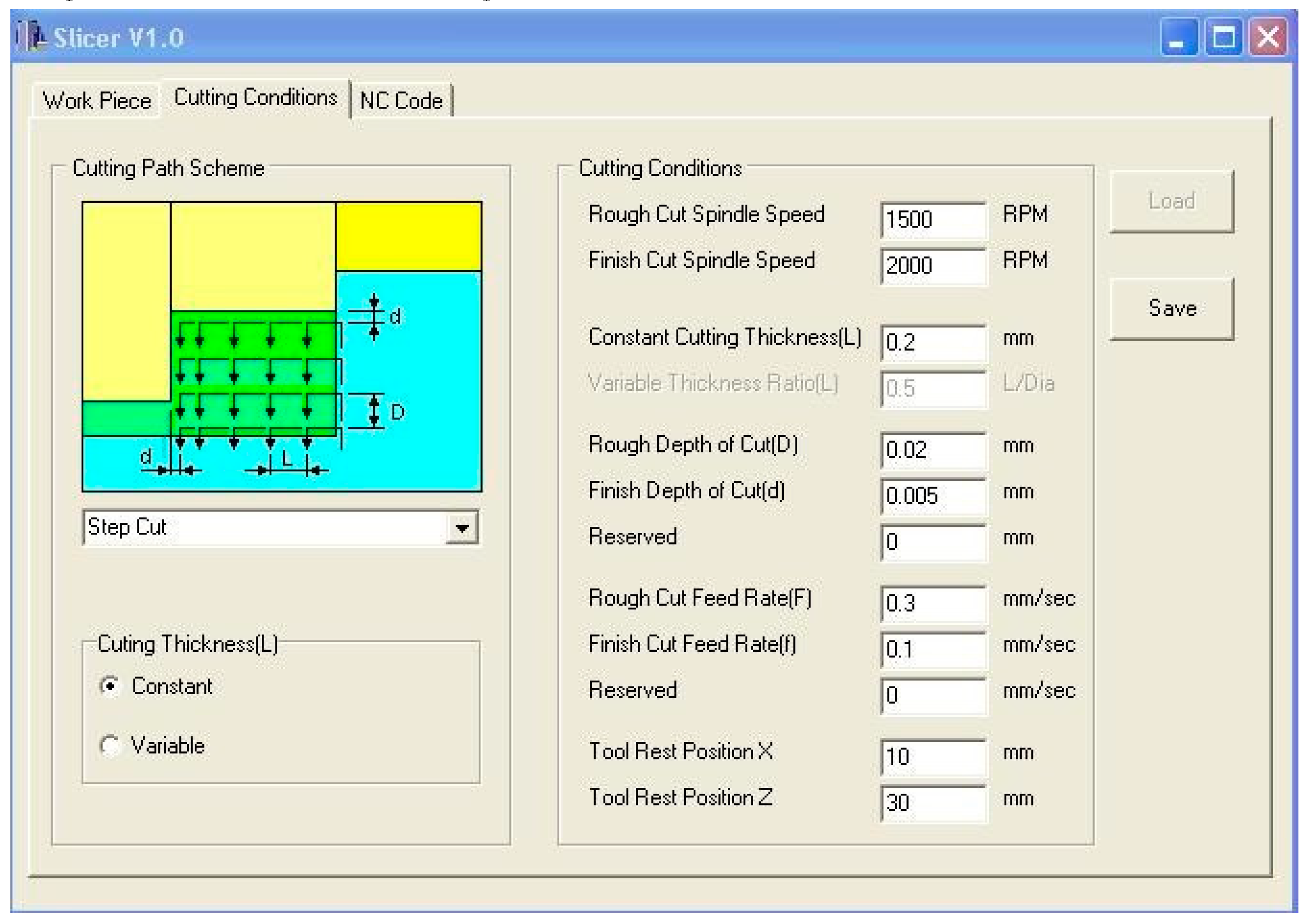

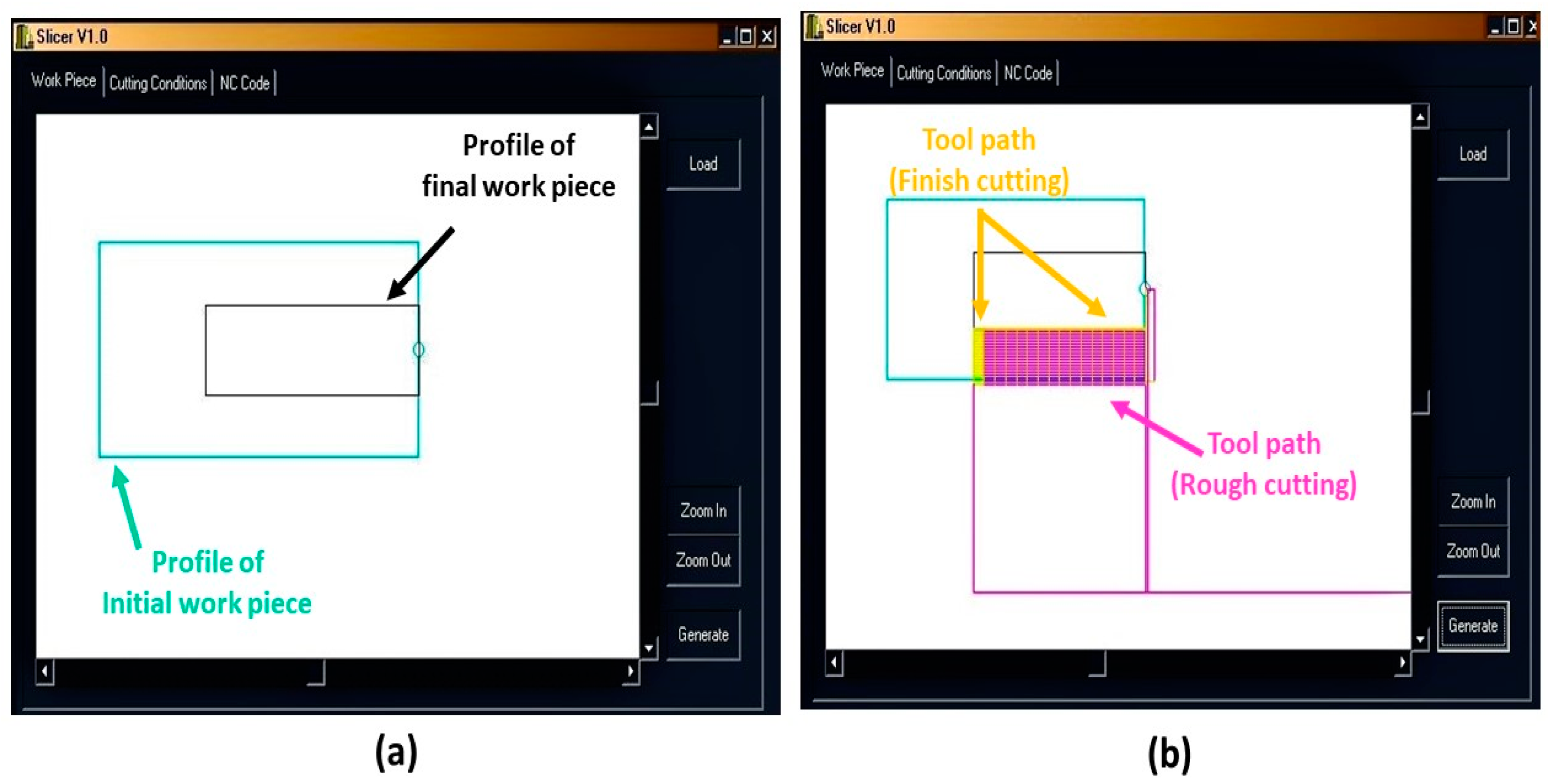

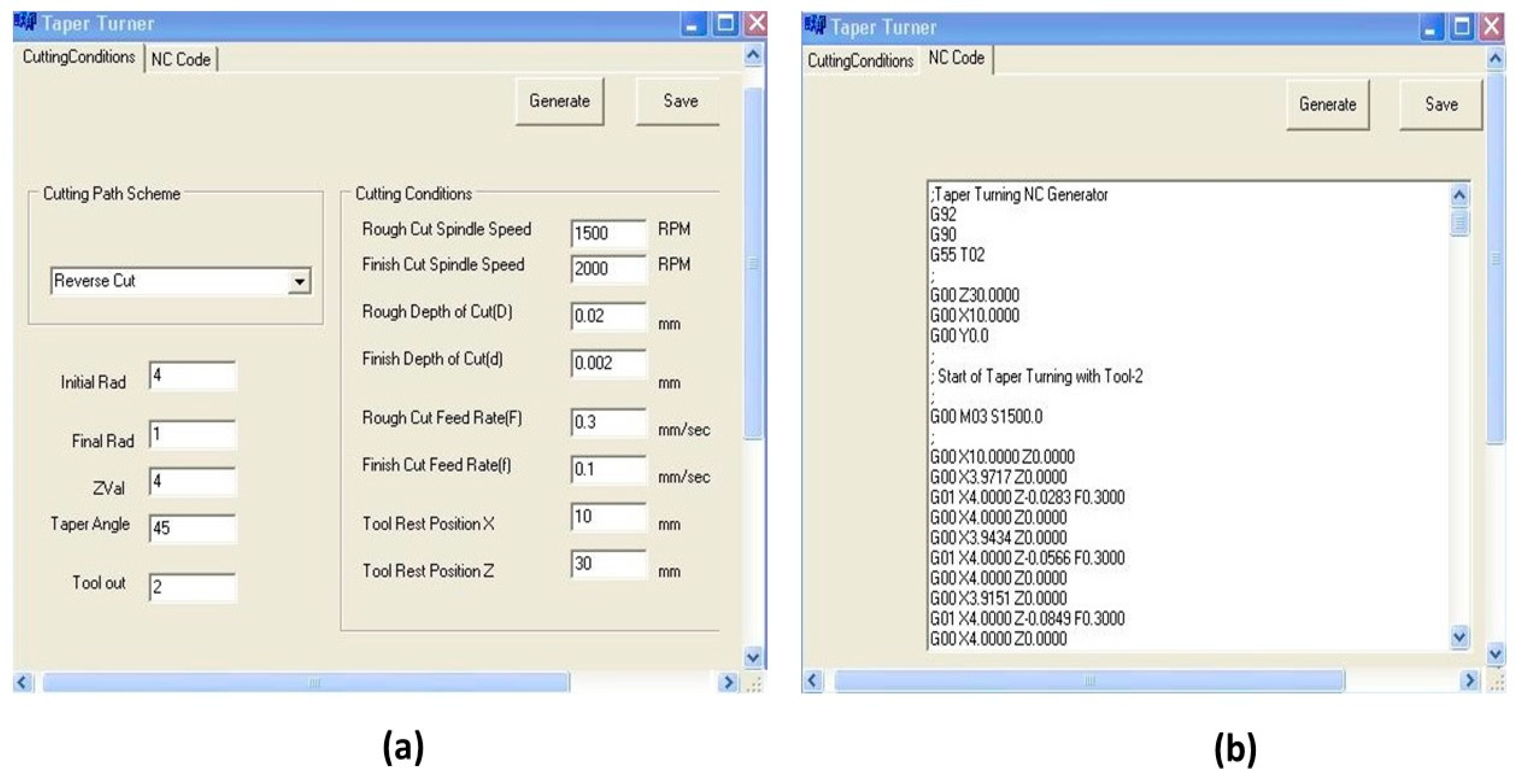

2.2. CNC Program Generation for Micromachining

3. Micromachining Experiment

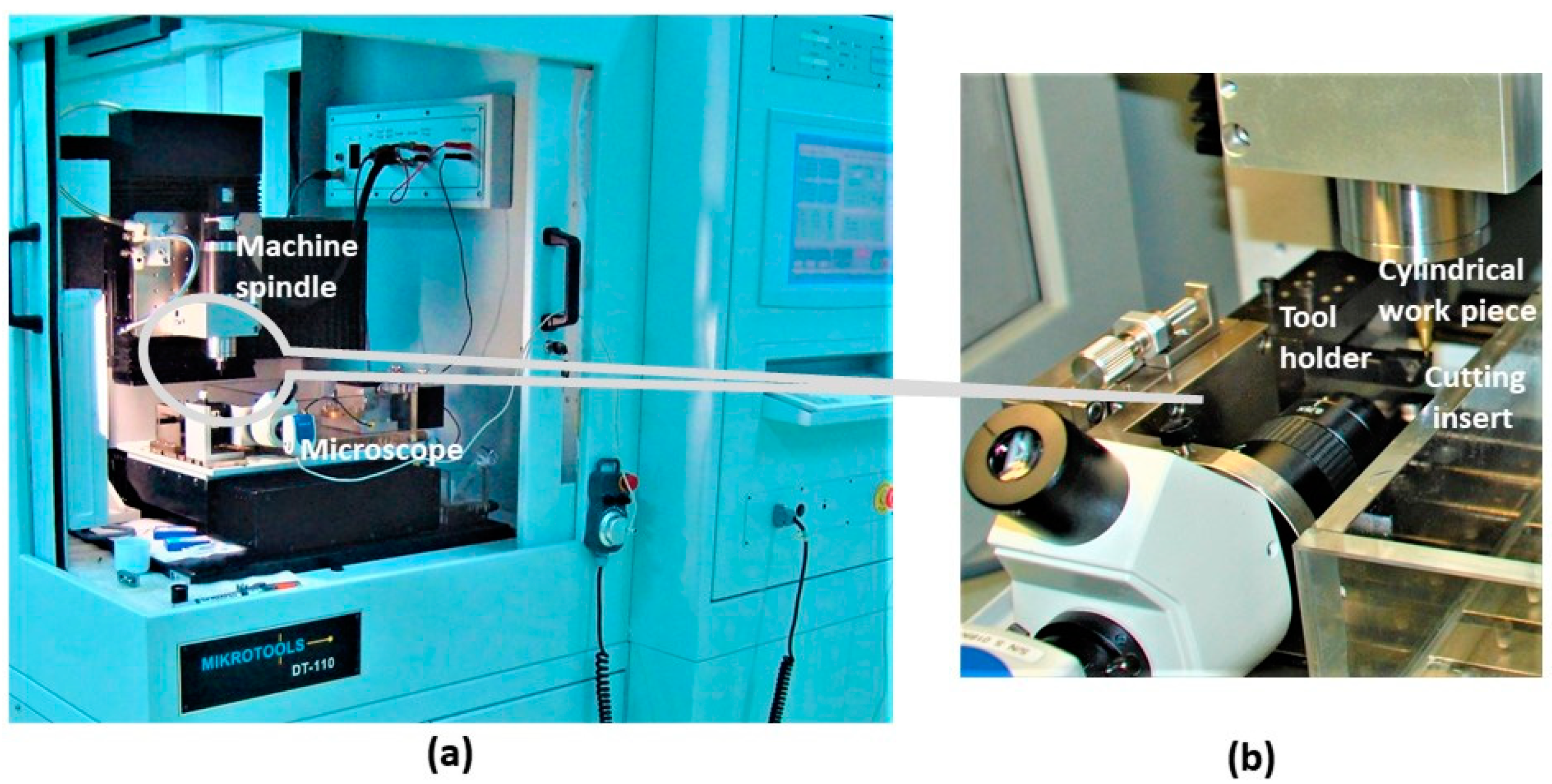

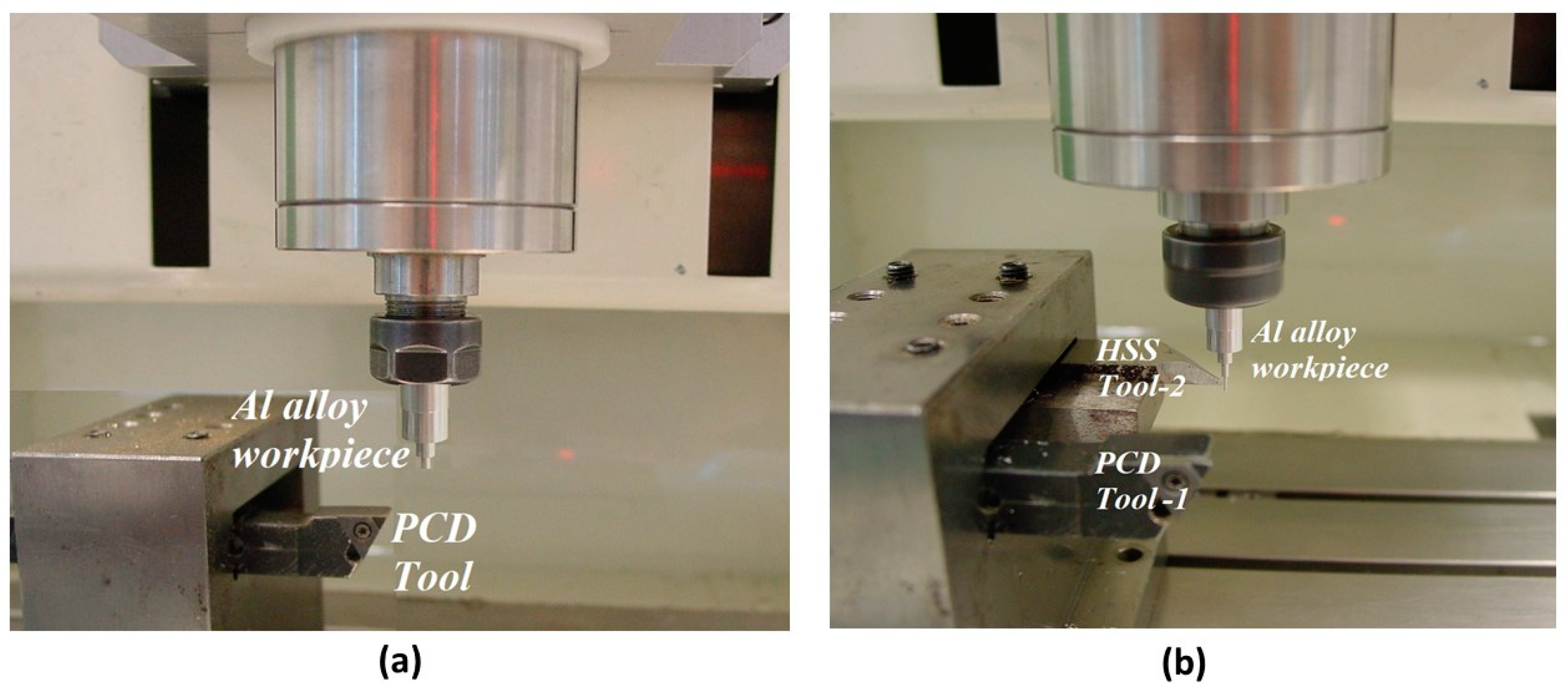

3.1. Machining Center

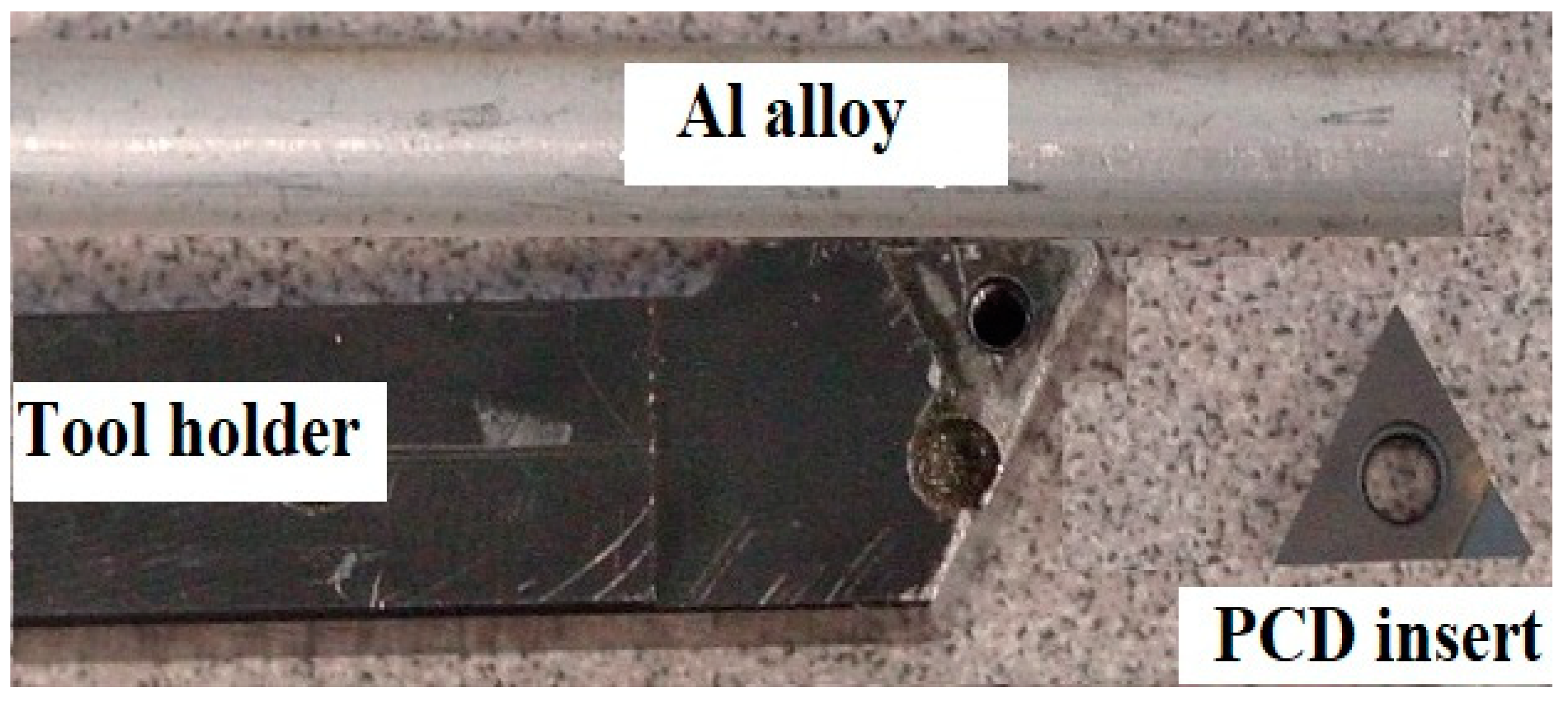

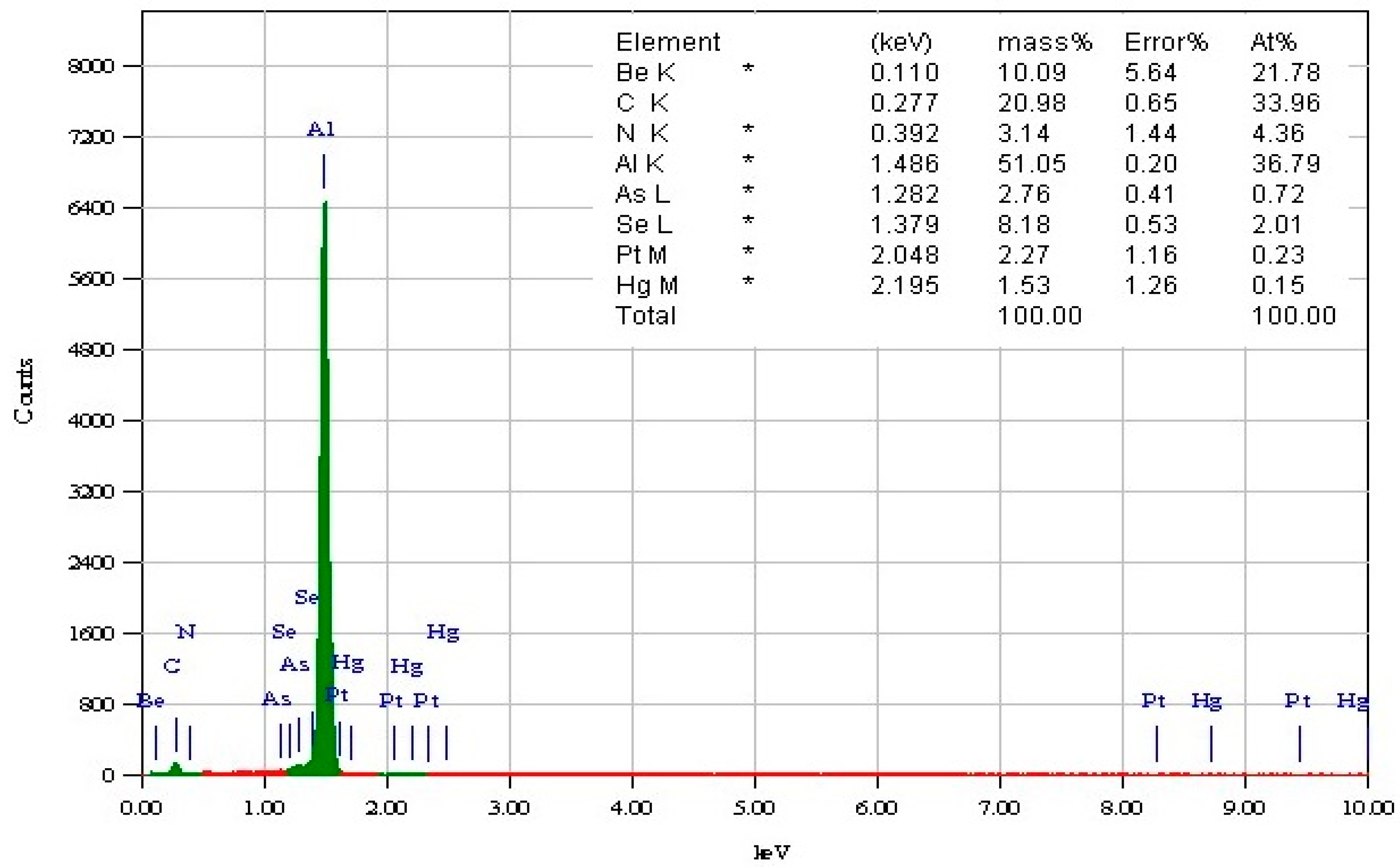

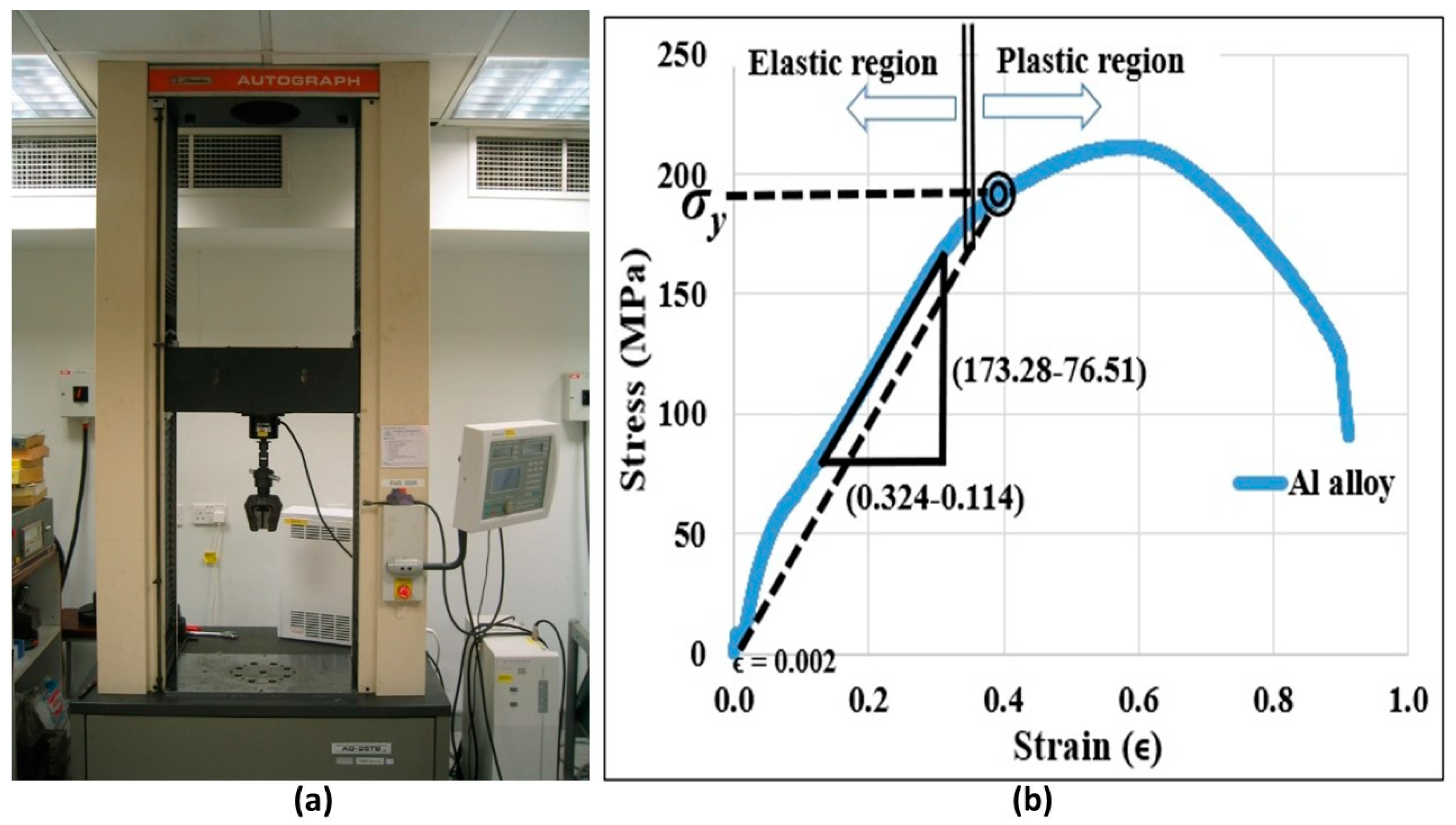

3.2. Material and Cutting Tool

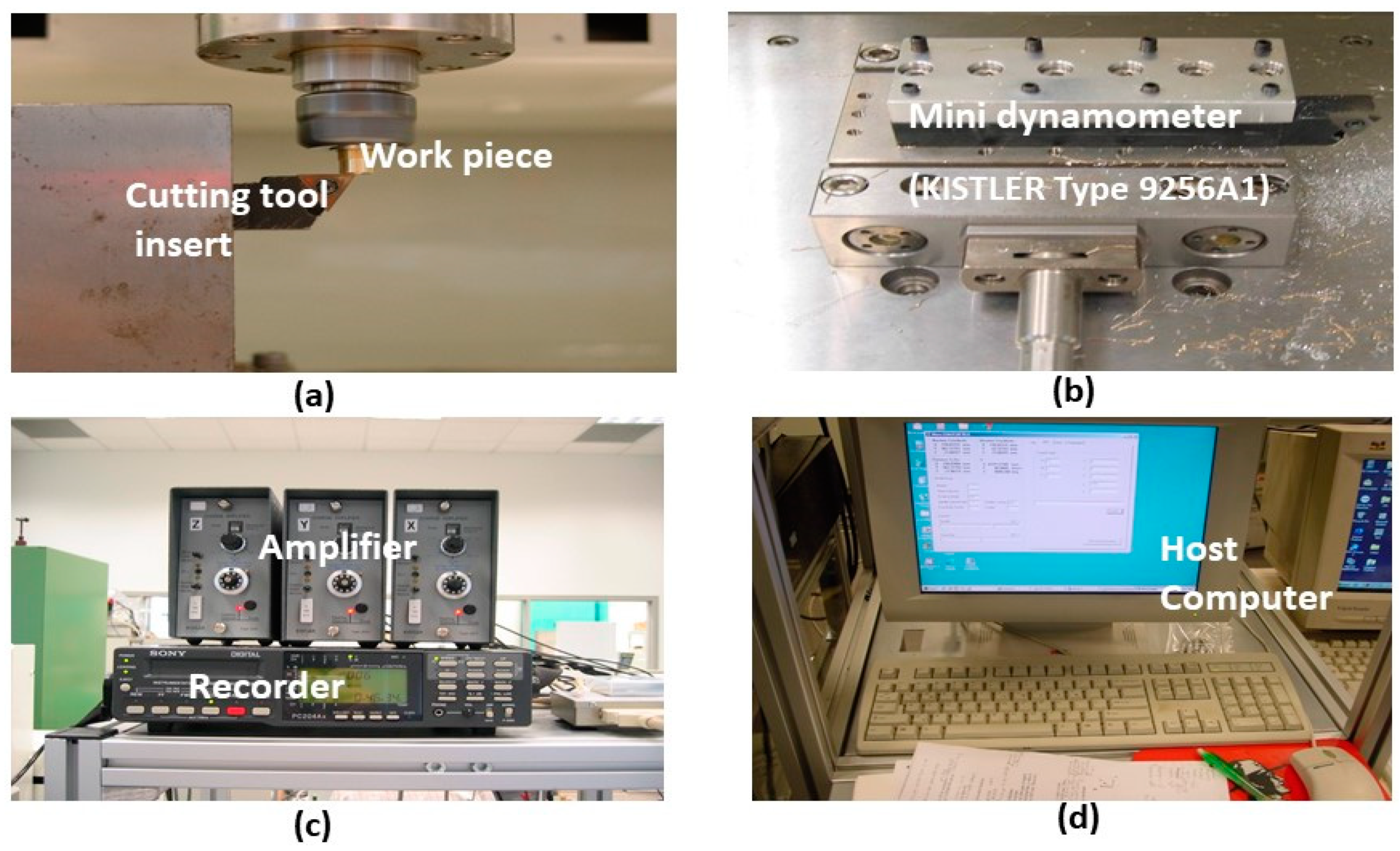

3.3. Cutting Force Measurement

4. Machining Results

4.1. Cutting Force Data

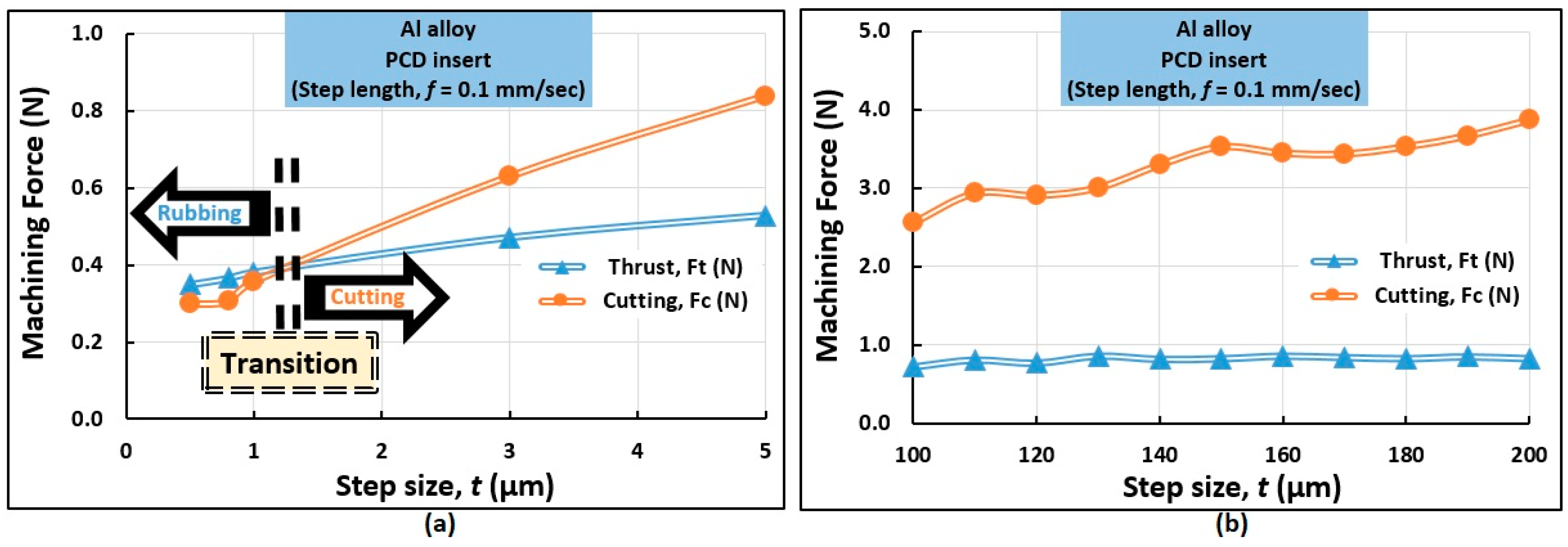

4.1.1. Influence of Step Size (t)

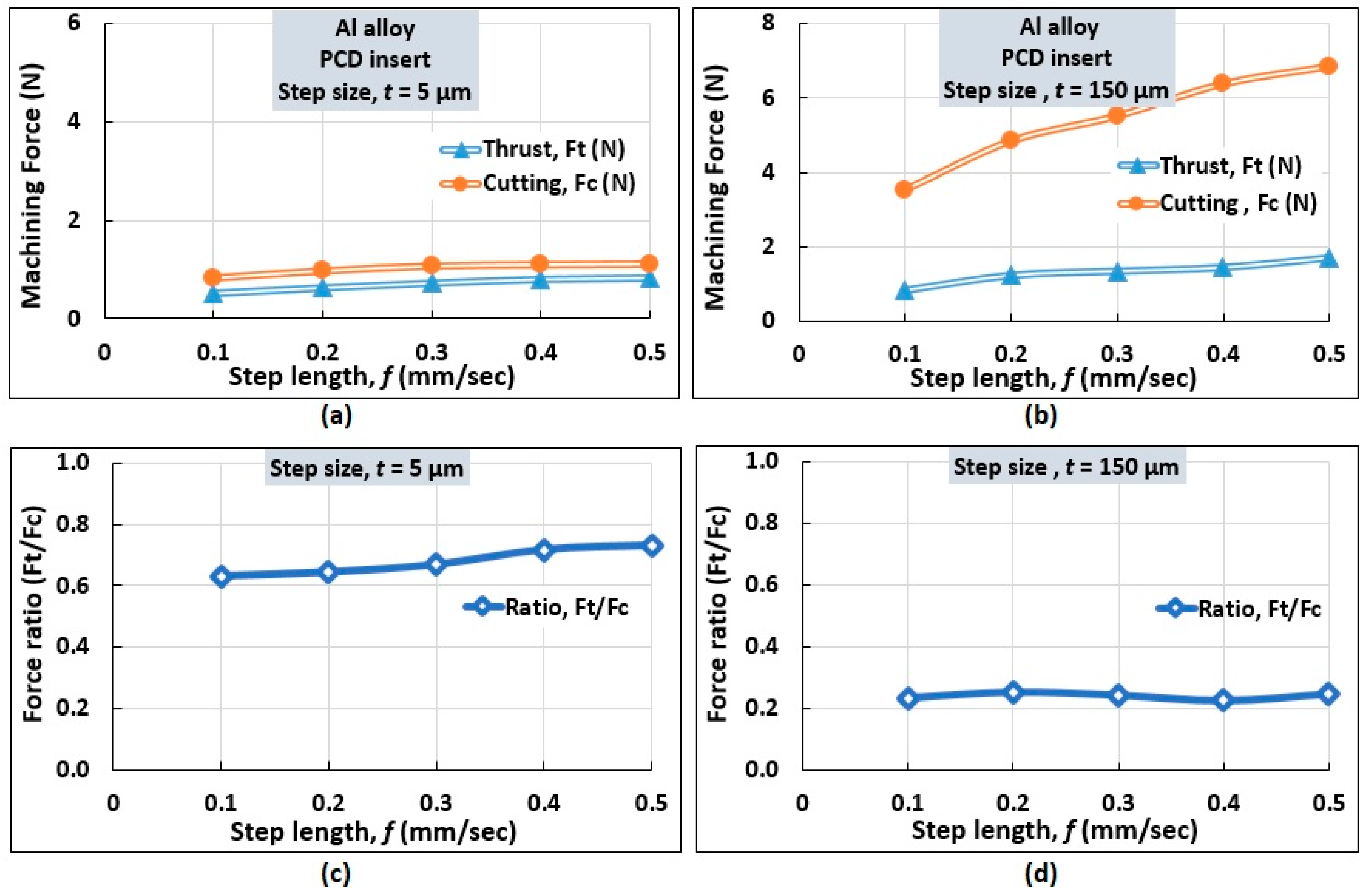

4.1.2. Influence of Step Length (f)

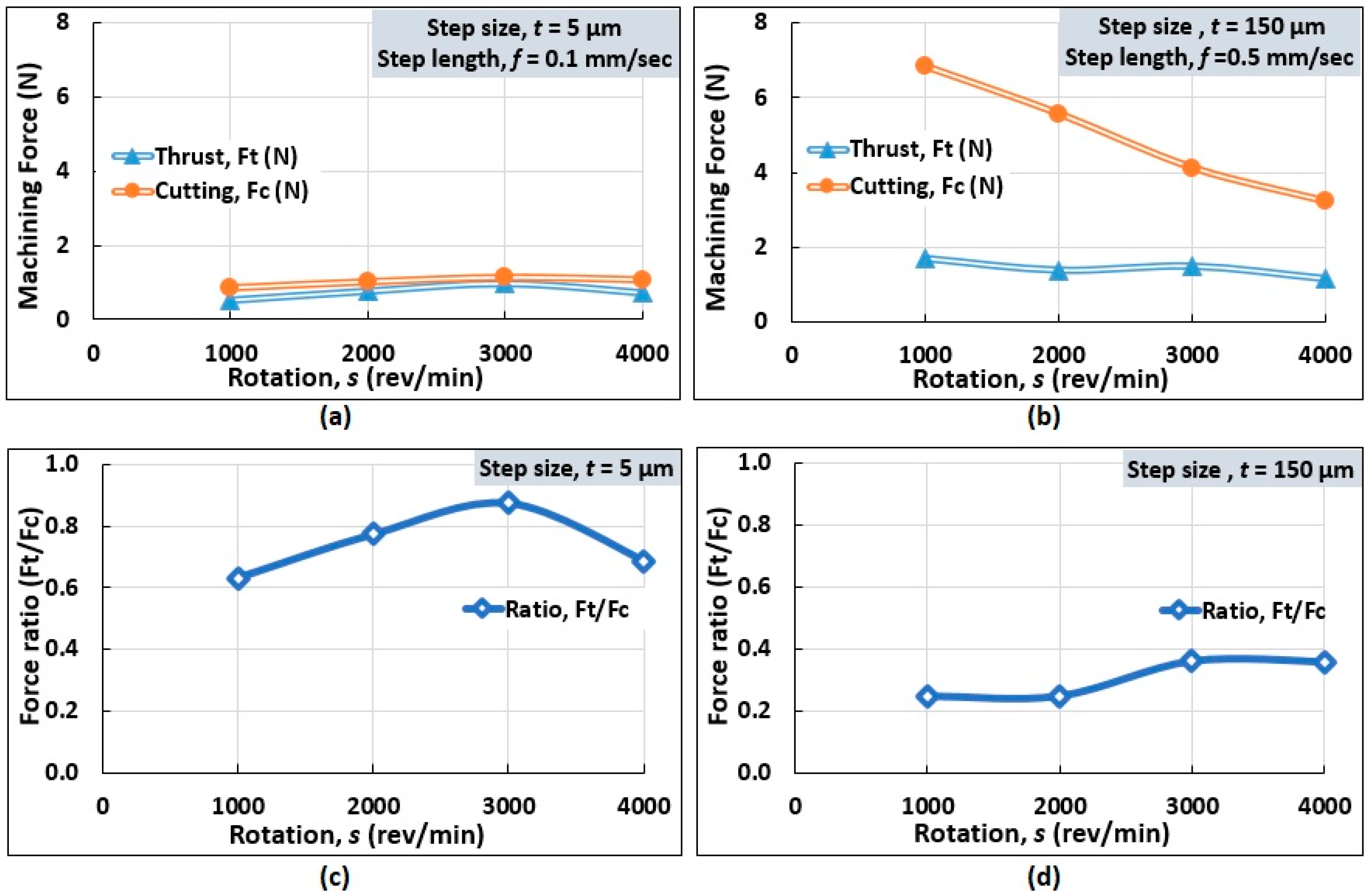

4.1.3. Influence of Rotation

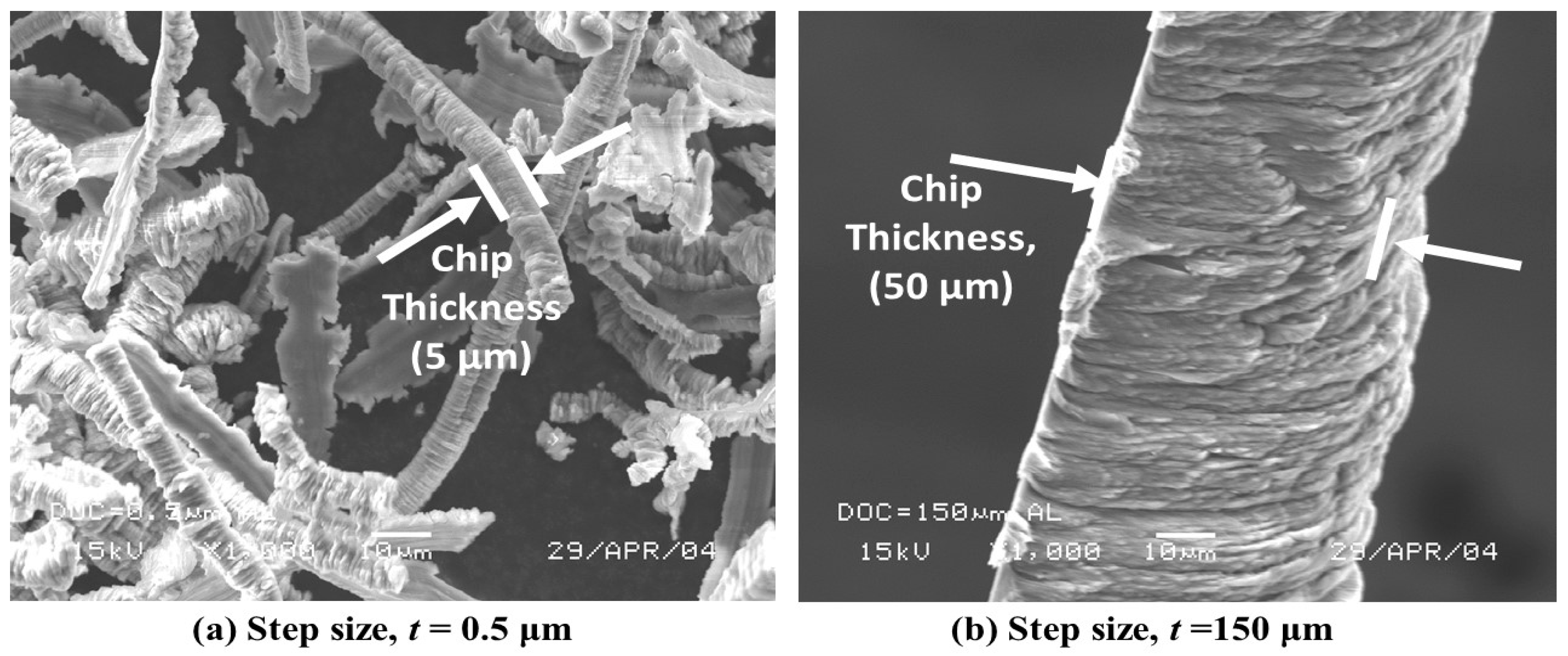

4.2. Chip Morphology

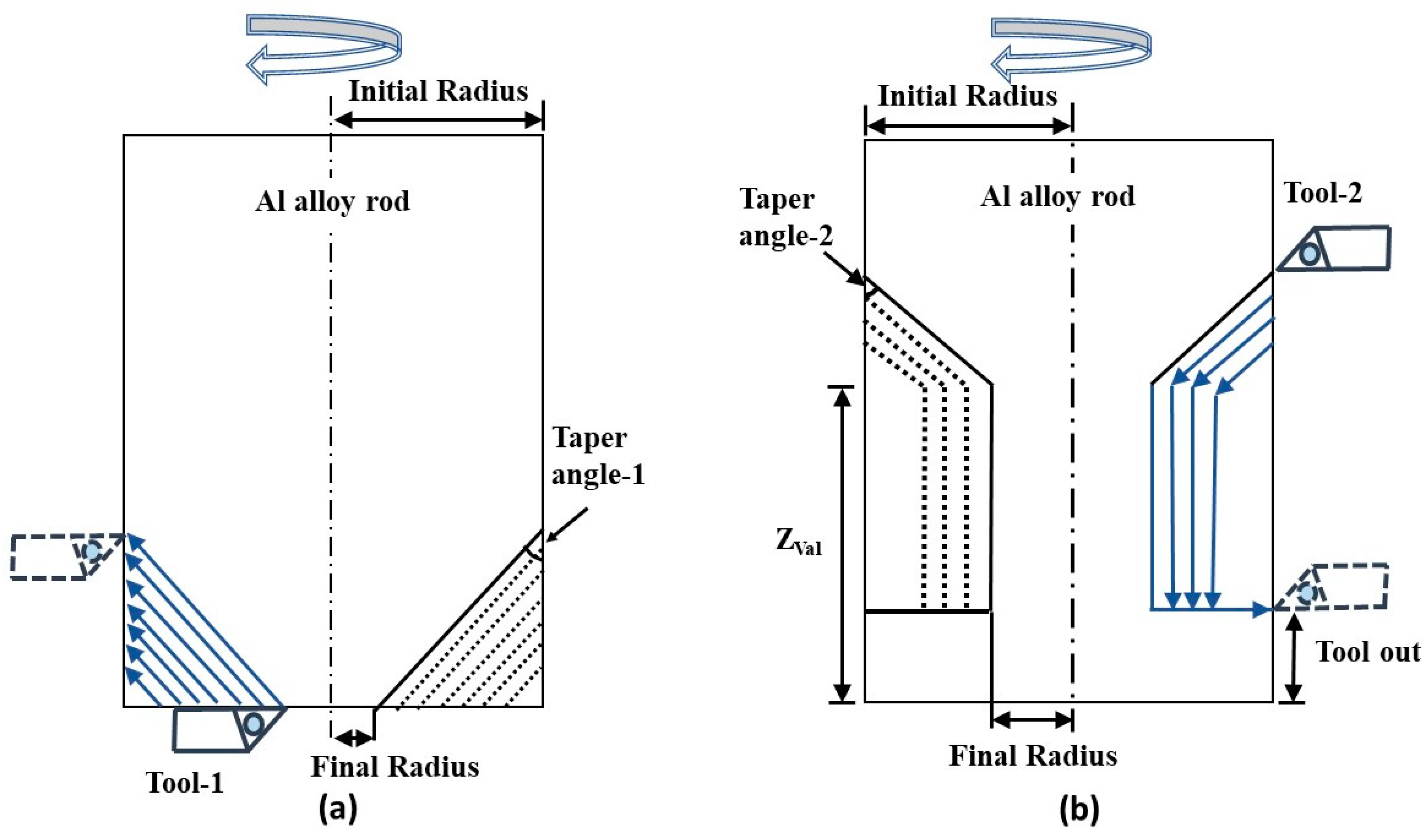

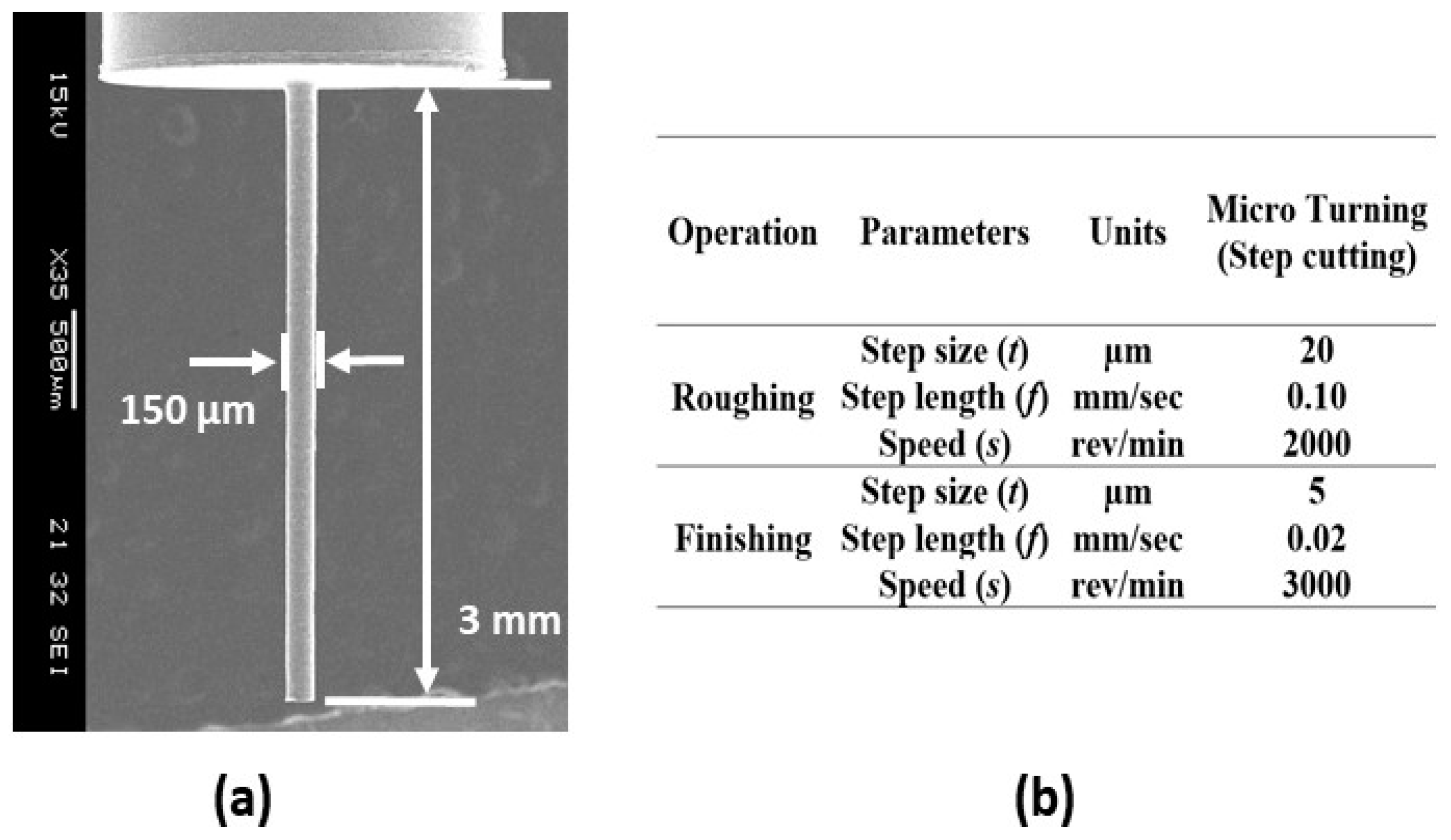

5. Manufacturing Process of Microscopic Rods

5.1. Determination of Step Length (f)

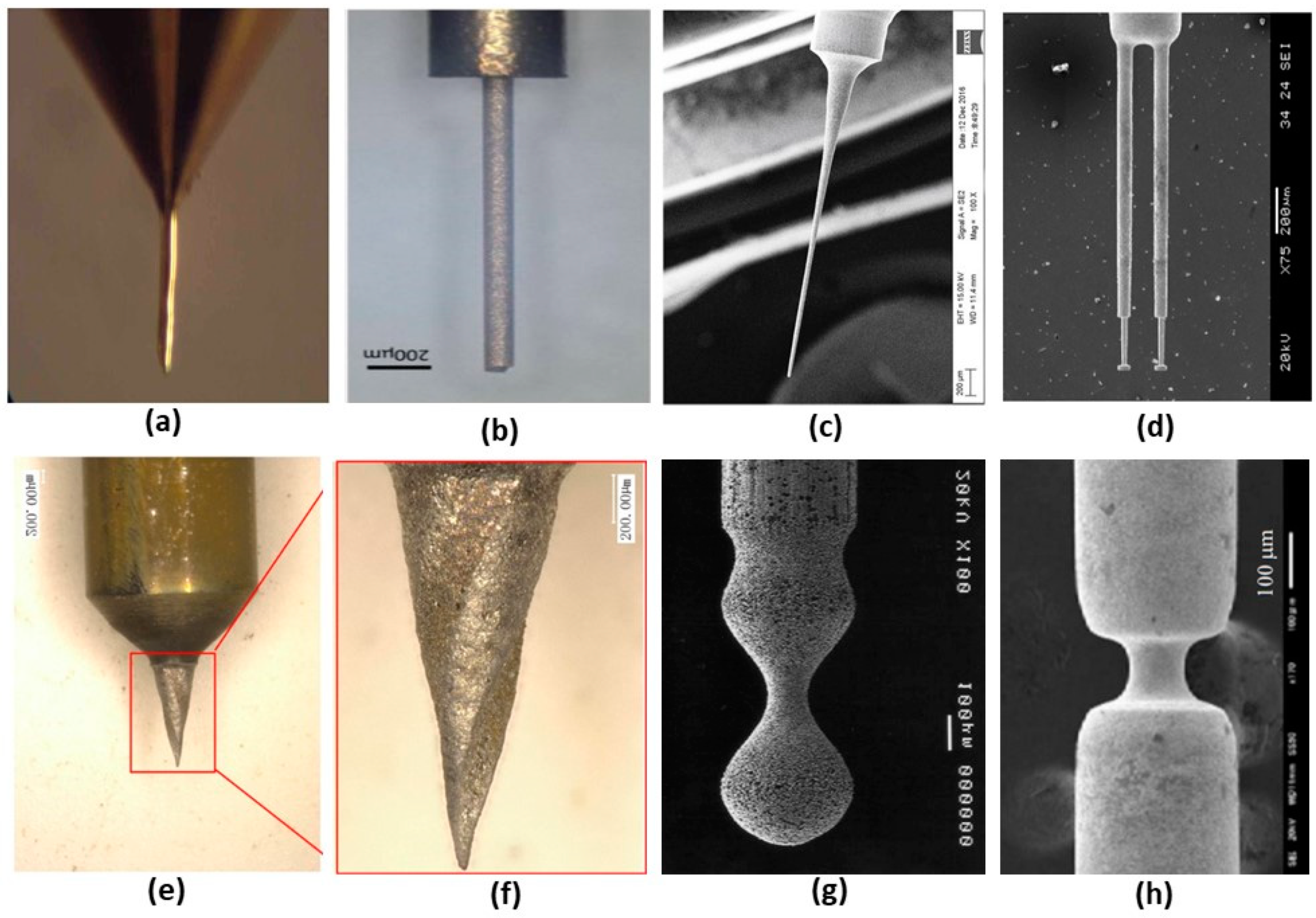

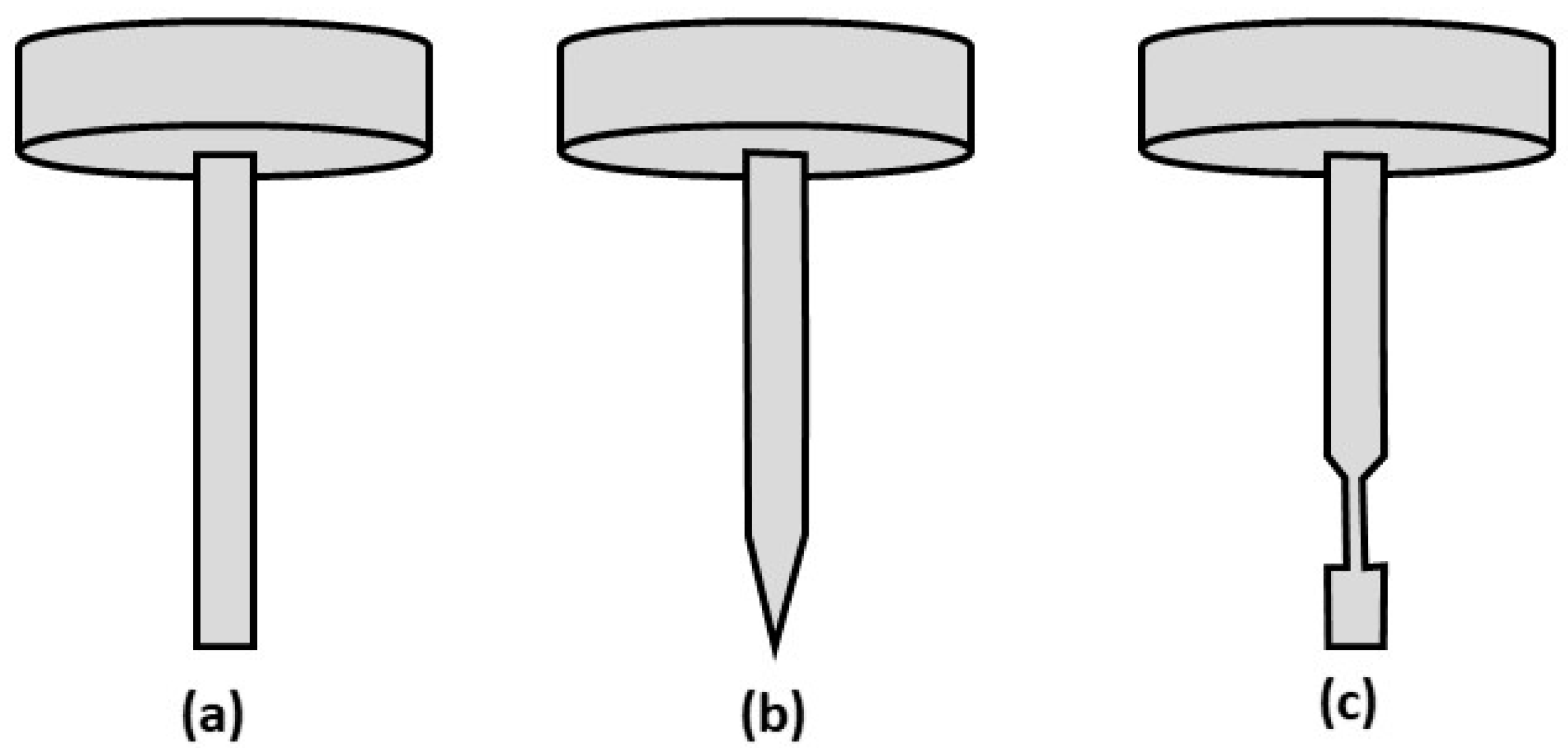

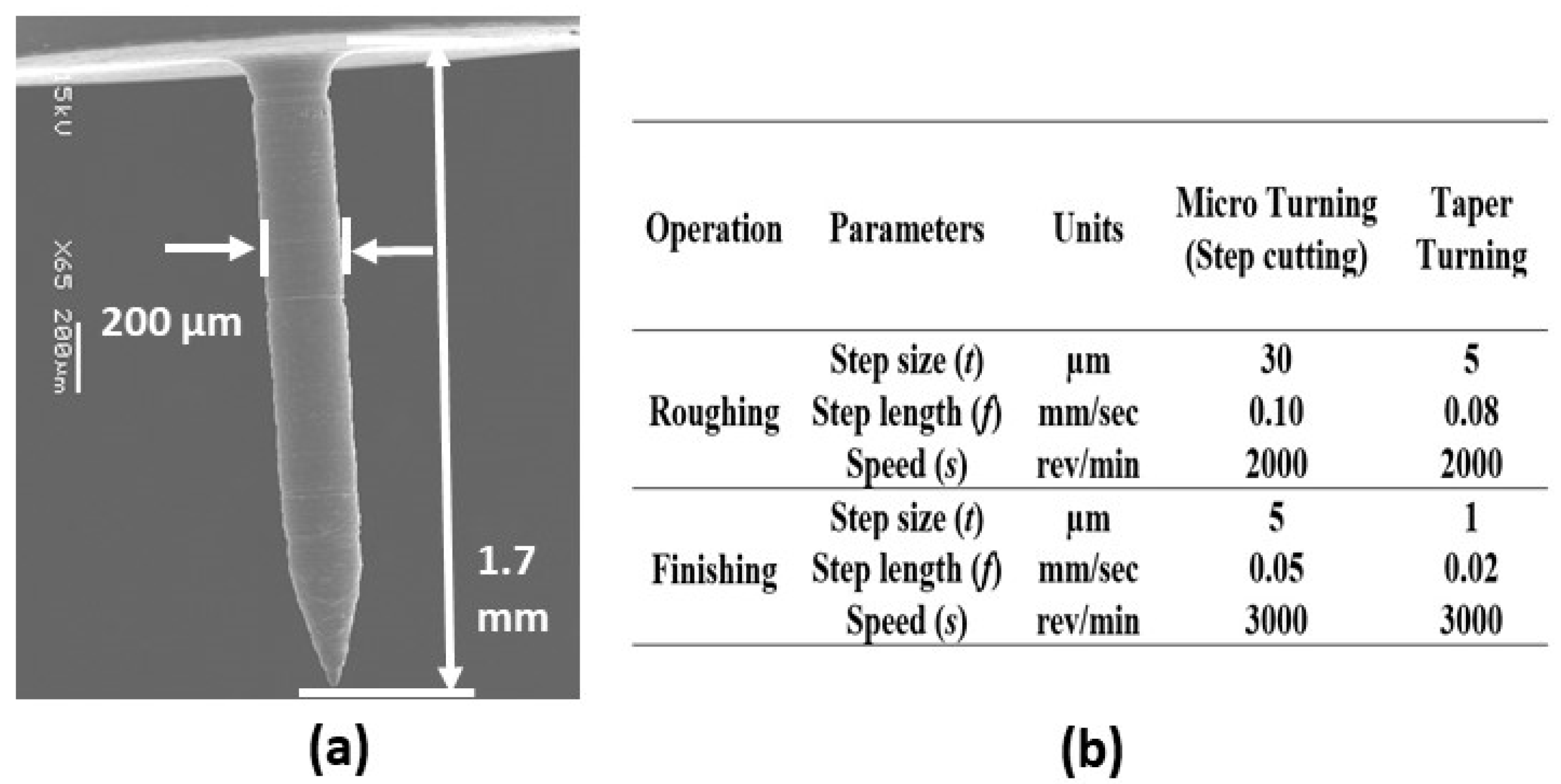

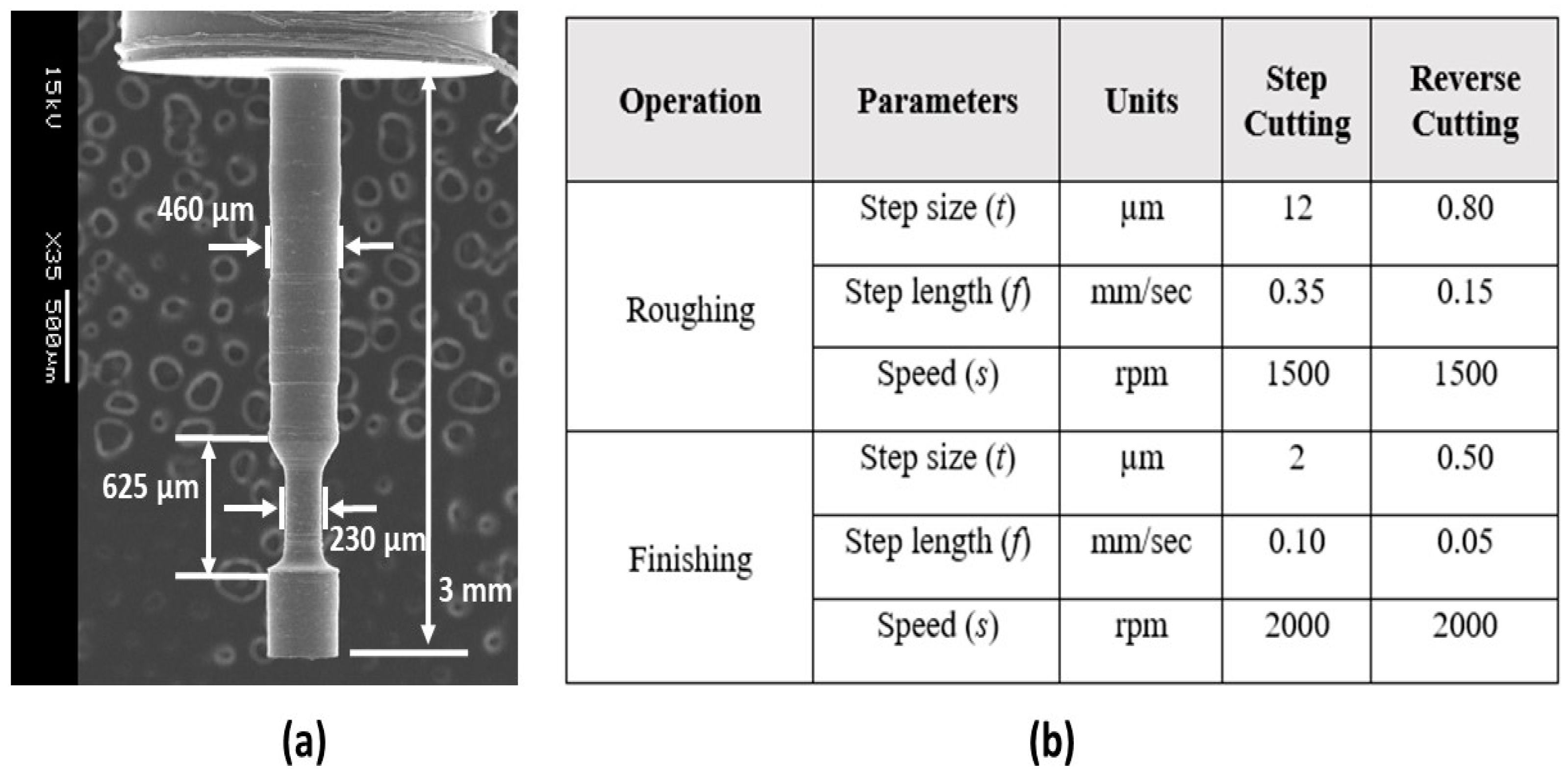

5.2. Microrod Fabrication

6. Conclusions

- The deflection (δ) of the microrod, a major issue in micro turning, has been addressed by the step cutting scheme. The appropriate step length (f) was computed from the strength of Al alloy material to avoid permanent rod deformation;

- The step size (t) is an important parameter, which influences the cutting force components (Fc and Ft) on the tip of the microrod. At a small step size (t), Ft was found to be greater than Fc due to the rubbing and burnishing action of the tool. However, the reverse phenomenon was observed at a larger step size (t) where Ft was the main force component;

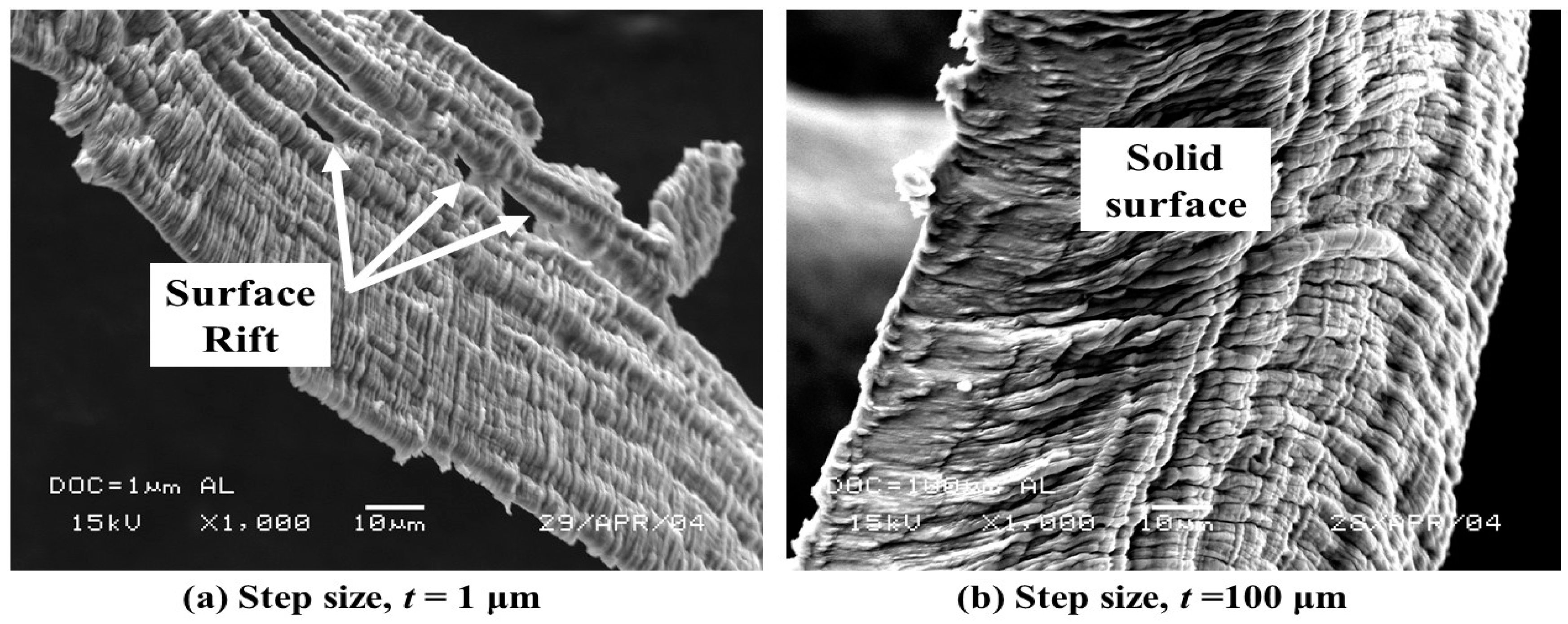

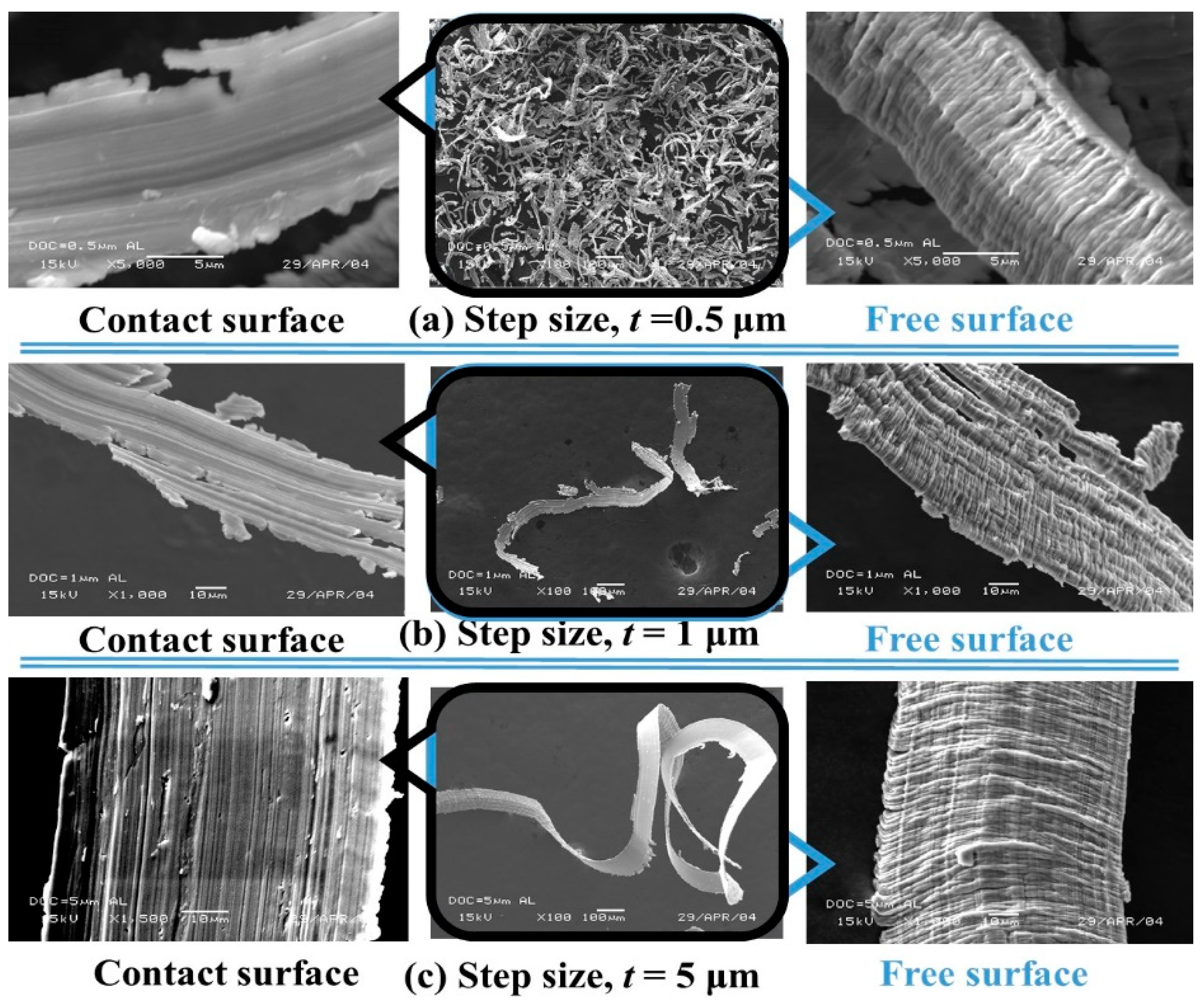

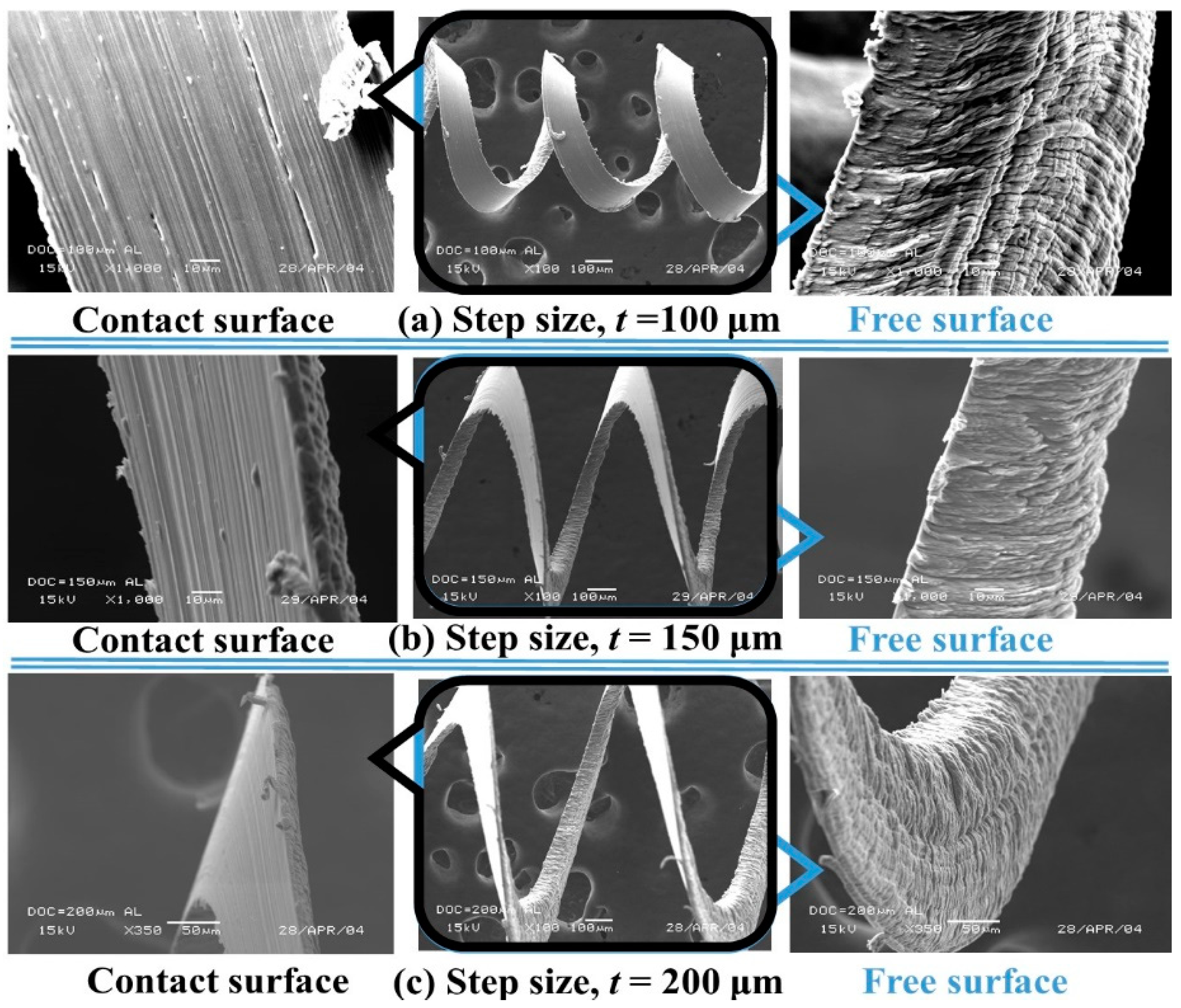

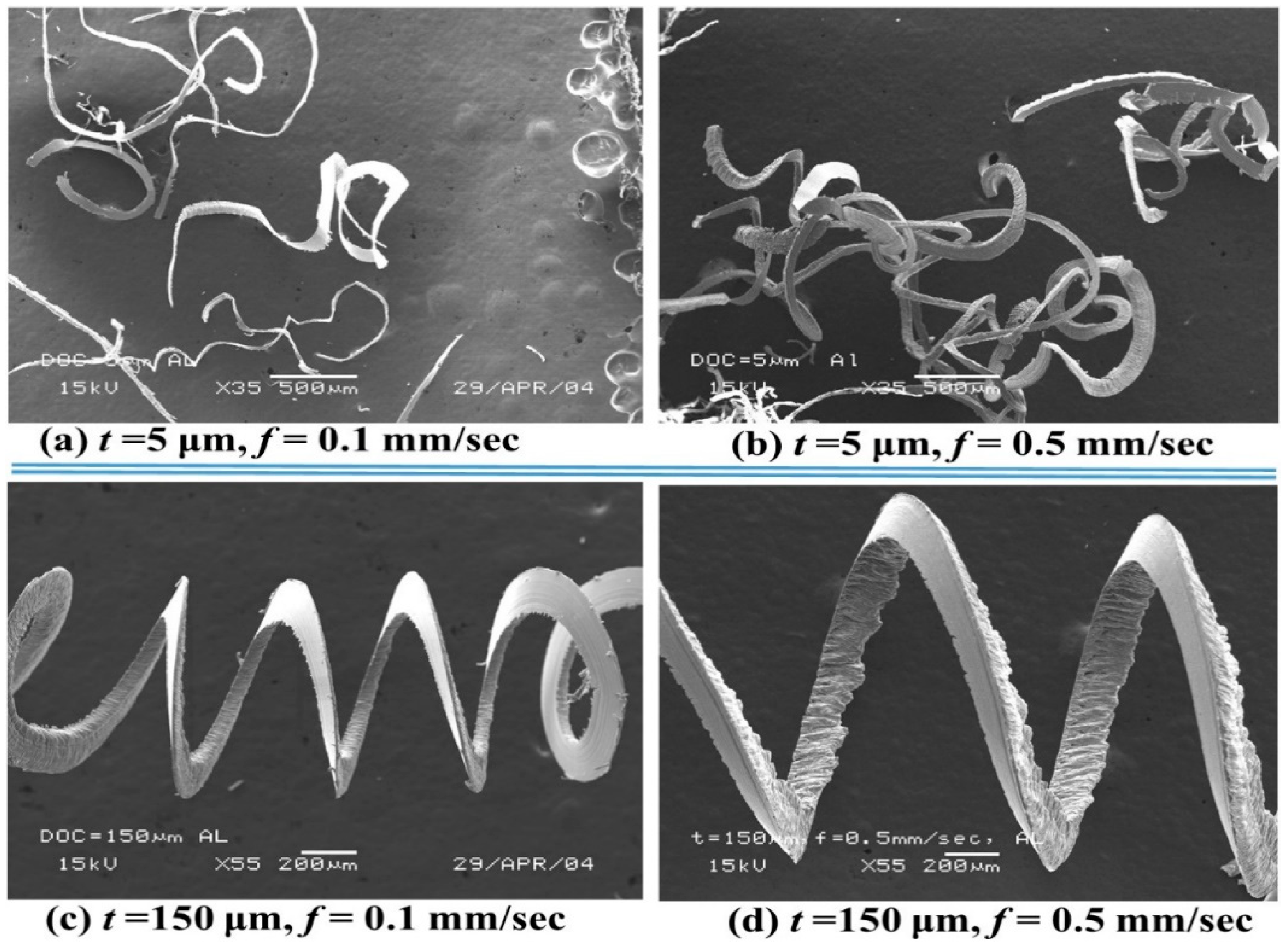

- The SEM observation revealed the mechanisms of microchip formation for different cutting parameters. At a small step size (t), partially continuous microchips were observed. An interesting phenomenon in the form of a rifted chip surface was noticed in micromachining of Al alloy due to the governance of the rubbing and ploughing mechanism. At higher step sizes (t), curly and long continuous chips, similar to that produced in conventional machining and macromachining were noticed;

- Finally, micro turning was implemented to manufacture microfeatures on milli-scale structures. Microrods with straight, conical, and grooved tips were fabricated using an Al alloy material;

- A sharp single crystal diamond (SCD) tool can be used for the fabrication of the grooved microrod through the reverse cutting process as the HSS form tool (Tool-2) wears away quickly.

Author Contributions

Funding

Conflicts of Interest

References

- Mohri, N.; Tani, T. Micro-pin Electrodes Formation by Micro-Scanning EDM Process. CIRP Ann. 2006, 55, 175–178. [Google Scholar] [CrossRef]

- Huang, C.A.; Chang, J.H.; Yang, S.Y.; Yang, C.C. Preparation of a needle probe with a sharp tip and high aspect ratio geometry by an electrochemical etching method. Corros. Sci. 2006, 48, 4294–4302. [Google Scholar] [CrossRef]

- Asad, A.B.M.A.; Masaki, T.; Rahman, M.; Lim, H.S.; Wong, Y.S. Tool-based micro-machining. J. Mater. Process. Technol. 2007, 192, 204–211. [Google Scholar] [CrossRef]

- Qingfeng, Y.; Xingqiao, W.; Ping, W.; Zhiqiang, Q.; Lin, Z.; Yongbin, Z. Fabrication of micro rod electrode by electrical discharge grinding using two block electrodes. J. Mater. Process. Technol. 2016, 234, 143–149. [Google Scholar] [CrossRef]

- Gao, C.; Cheng, J.; Wu, J. Experimental study of metal ceramic (WC-Co) micro-tool fabrication by controlled inclined grinding (CIG). Int. J. Adv. Manuf. Technol. 2019, 103, 2151–2167. [Google Scholar] [CrossRef]

- Fan, Z.-W.; Hourng, L.-W. The analysis and investigation on the microelectrode fabrication by electrochemical machining. Int. J. Mach. Tools Manuf. 2009, 49, 659–666. [Google Scholar] [CrossRef]

- Kim, B.H.; Park, B.J.; Chu, C.N. Fabrication of multiple electrodes by reverse EDM and their application in micro ECM. J. Micromech. Microeng. 2006, 16, 843–850. [Google Scholar] [CrossRef]

- Sun, Y.; Gong, Y. Experimental study on fabricating spirals microelectrode and micro-cutting tools by low speed wire electrical discharge turning. J. Mater. Process. Technol. 2018, 258, 271–285. [Google Scholar] [CrossRef]

- Kunieda, M.; Mizugai, K.; Watanabe, S.; Shibuya, N.; Iwamoto, N. Electrochemical micromachining using flat electrolyte jet. CIRP Ann. 2011, 60, 251–254. [Google Scholar] [CrossRef]

- Miyoshi, K.; Kunieda, M. Fabrication of Micro Rods of Cemented Carbide by Electrolyte Jet Turning. Procedia CIRP 2016, 42, 373–378. [Google Scholar] [CrossRef]

- Lim, Y.-M.; Kim, S.H. An electrochemical fabrication method for extremely thin cylindrical micropin. Int. J. Mach. Tools Manuf. 2001, 41, 2287–2296. [Google Scholar] [CrossRef]

- Masuzawa, T.; Tönshoff, H.K. Three-Dimensional Micromachining by Machine Tools. CIRP Ann. 1997, 46, 621–628. [Google Scholar] [CrossRef]

- Masuzawa, T. State of the Art of Micromachining. CIRP Ann. 2000, 49, 473–488. [Google Scholar] [CrossRef]

- McGeough, J.A.; Leu, M.C.; Rajurkar, K.P.; de Silva, A.K.M.; Liu, Q. Electroforming Process and Application to Micro/Macro Manufacturing. CIRP Ann. 2001, 50, 499–514. [Google Scholar] [CrossRef]

- Byrne, G.; Dornfeld, D.; Denkena, B. Advancing Cutting Technology. CIRP Ann. 2003, 52, 483–507. [Google Scholar] [CrossRef]

- Chae, J.; Park, S.S.; Freiheit, T. Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf. 2006, 46, 313–332. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, Y.; Zhang, H.; Xiong, Z.; To, S. Advances in ultra-precision machining of micro-structured functional surfaces and their typical applications. Int. J. Mach. Tools Manuf. 2019, 142, 16–41. [Google Scholar] [CrossRef]

- Lu, Z.; Yoneyama, T. Micro cutting in the micro lathe turning system. Int. J. Mach. Tools Manuf. 1999, 39, 1171–1183. [Google Scholar] [CrossRef]

- Schmidt, J.; Spath, D.; Elsner, J.; Hüntrup, V.; Tritschler, H. Requirements of an industrially applicable microcutting process for steel micro-structures. Microsyst. Technol. 2002, 8, 402–408. [Google Scholar] [CrossRef]

- Moriwaki, T. Machinability of Copper in Ultra-Precision Micro Diamond Cutting. CIRP Ann. 1989, 38, 115–118. [Google Scholar] [CrossRef]

- Oraby, S.E.; Hayhurst, D.R. Tool life determination based on the measurement of wear and tool force ratio variation. Int. J. Mach. Tools Manuf. 2004, 44, 1261–1269. [Google Scholar] [CrossRef]

- Trent, E.M.; Wright, P.K. Metal Cutting; Butterworth-Heinemann: Oxford, UK, 2000. [Google Scholar]

- Manna, A.; Bhattacharayya, B. A study on machinability of Al/SiC-MMC. J. Mater. Process. Technol. 2003, 140, 711–716. [Google Scholar] [CrossRef]

- Rahman, M.A.; Woon, K.S.; Venkatesh, V.C.; Rahman, M. Modelling of the combined microstructural and cutting edge effects in ultraprecision machining. CIRP Ann. 2018, 67, 129–132. [Google Scholar] [CrossRef]

- Rahman, M.A.; Amrun, M.R.; Rahman, M.; Kumar, A.S. Investigation of the critical cutting edge radius based on material hardness. Int. J. Adv. Manuf. Technol. 2017, 88, 3295–3306. [Google Scholar] [CrossRef]

| Process | Advantage | Disadvantage |

|---|---|---|

| Electrochemical Etching [11] | Minute shapes | Difficulty in dimension control |

| Micro turning [3] | Defined dimensions | High force can deform μ-rod |

| Micro grinding [12] | Electrical conductivity does not affect the process | The grinding force causes deformity |

| EDM [12] | No contact force | Slow process with shape limitation |

| Electroforming [13,14] | Complex parts with close tolerances | Limited material options |

| Exp. | Machining Parameters | Measured Force Component | |||

|---|---|---|---|---|---|

| Run No. | Step Size, t (µm) | Step length, f (mm/s) | Rotation, s (rev/min) | Thrust, Ft (N) | Cutting, Fc (N) |

| 1 | 0.5 | 0.1 | 1000 | 0.35 | 0.30 |

| 2 | 0.8 | 0.1 | 1000 | 0.37 | 0.31 |

| 3 | 1 | 0.1 | 1000 | 0.38 | 0.36 |

| 4 | 3 | 0.1 | 1000 | 0.47 | 0.63 |

| 5 | 5 | 0.1 | 1000 | 0.53 | 0.84 |

| 6 | 5 | 0.1 | 2000 | 0.78 | 1.01 |

| 7 | 5 | 0.1 | 3000 | 0.99 | 1.13 |

| 8 | 5 | 0.1 | 4000 | 0.73 | 1.07 |

| 9 | 5 | 0.2 | 1000 | 0.63 | 0.98 |

| 10 | 5 | 0.3 | 1000 | 0.72 | 1.08 |

| 11 | 5 | 0.4 | 1000 | 0.80 | 1.11 |

| 12 | 5 | 0.5 | 1000 | 0.82 | 1.12 |

| 13 | 5 | 0.5 | 2000 | 1.63 | 2.17 |

| 14 | 5 | 0.5 | 3000 | 1.69 | 2.07 |

| 15 | 5 | 0.5 | 4000 | 1.57 | 1.84 |

| 16 | 10 | 0.1 | 1000 | 0.65 | 1.38 |

| 17 | 20 | 0.1 | 1000 | 0.68 | 1.47 |

| 18 | 30 | 0.1 | 1000 | 0.70 | 1.59 |

| 19 | 40 | 0.1 | 1000 | 0.70 | 1.77 |

| 20 | 50 | 0.1 | 1000 | 0.70 | 2.05 |

| 21 | 60 | 0.1 | 1000 | 0.83 | 2.27 |

| 22 | 70 | 0.1 | 1000 | 0.72 | 2.29 |

| 23 | 80 | 0.1 | 1000 | 0.77 | 2.29 |

| 24 | 90 | 0.1 | 1000 | 0.74 | 2.57 |

| 25 | 100 | 0.1 | 1000 | 0.72 | 2.56 |

| 26 | 110 | 0.1 | 1000 | 0.81 | 2.94 |

| 27 | 120 | 0.1 | 1000 | 0.77 | 2.91 |

| 28 | 130 | 0.1 | 1000 | 0.86 | 3.01 |

| 29 | 140 | 0.1 | 1000 | 0.82 | 3.30 |

| 30 | 150 | 0.1 | 1000 | 0.83 | 3.53 |

| 31 | 150 | 0.1 | 2000 | 0.98 | 2.70 |

| 32 | 150 | 0.1 | 3000 | 0.88 | 1.99 |

| 33 | 150 | 0.1 | 4000 | 0.81 | 1.81 |

| 34 | 150 | 0.2 | 1000 | 1.23 | 4.84 |

| 35 | 150 | 0.3 | 1000 | 1.34 | 5.51 |

| 36 | 150 | 0.4 | 1000 | 1.44 | 6.37 |

| 37 | 150 | 0.5 | 1000 | 1.69 | 6.84 |

| 38 | 150 | 0.5 | 2000 | 1.38 | 5.57 |

| 39 | 150 | 0.5 | 3000 | 1.49 | 4.12 |

| 40 | 150 | 0.5 | 4000 | 1.16 | 3.22 |

| 41 | 160 | 0.1 | 1000 | 0.86 | 3.45 |

| 42 | 170 | 0.1 | 1000 | 0.85 | 3.44 |

| 43 | 180 | 0.1 | 1000 | 0.83 | 3.53 |

| 44 | 190 | 0.1 | 1000 | 0.85 | 3.67 |

| 45 | 200 | 0.1 | 1000 | 0.83 | 3.87 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.A.; Rahman, M.; Mia, M.; Asad, A.B.M.A.; Fardin, A. Manufacturing of Al Alloy Microrods by Micro Cutting in a Micromachining Center. Micromachines 2019, 10, 831. https://doi.org/10.3390/mi10120831

Rahman MA, Rahman M, Mia M, Asad ABMA, Fardin A. Manufacturing of Al Alloy Microrods by Micro Cutting in a Micromachining Center. Micromachines. 2019; 10(12):831. https://doi.org/10.3390/mi10120831

Chicago/Turabian StyleRahman, M. Azizur, Mustafizur Rahman, Mozammel Mia, A.B.M.A. Asad, and Ahmed Fardin. 2019. "Manufacturing of Al Alloy Microrods by Micro Cutting in a Micromachining Center" Micromachines 10, no. 12: 831. https://doi.org/10.3390/mi10120831

APA StyleRahman, M. A., Rahman, M., Mia, M., Asad, A. B. M. A., & Fardin, A. (2019). Manufacturing of Al Alloy Microrods by Micro Cutting in a Micromachining Center. Micromachines, 10(12), 831. https://doi.org/10.3390/mi10120831