Recent Advances in MEMS-Based Microthrusters

Abstract

1. Introduction

2. Chemical Fuel Propellant Microthruster

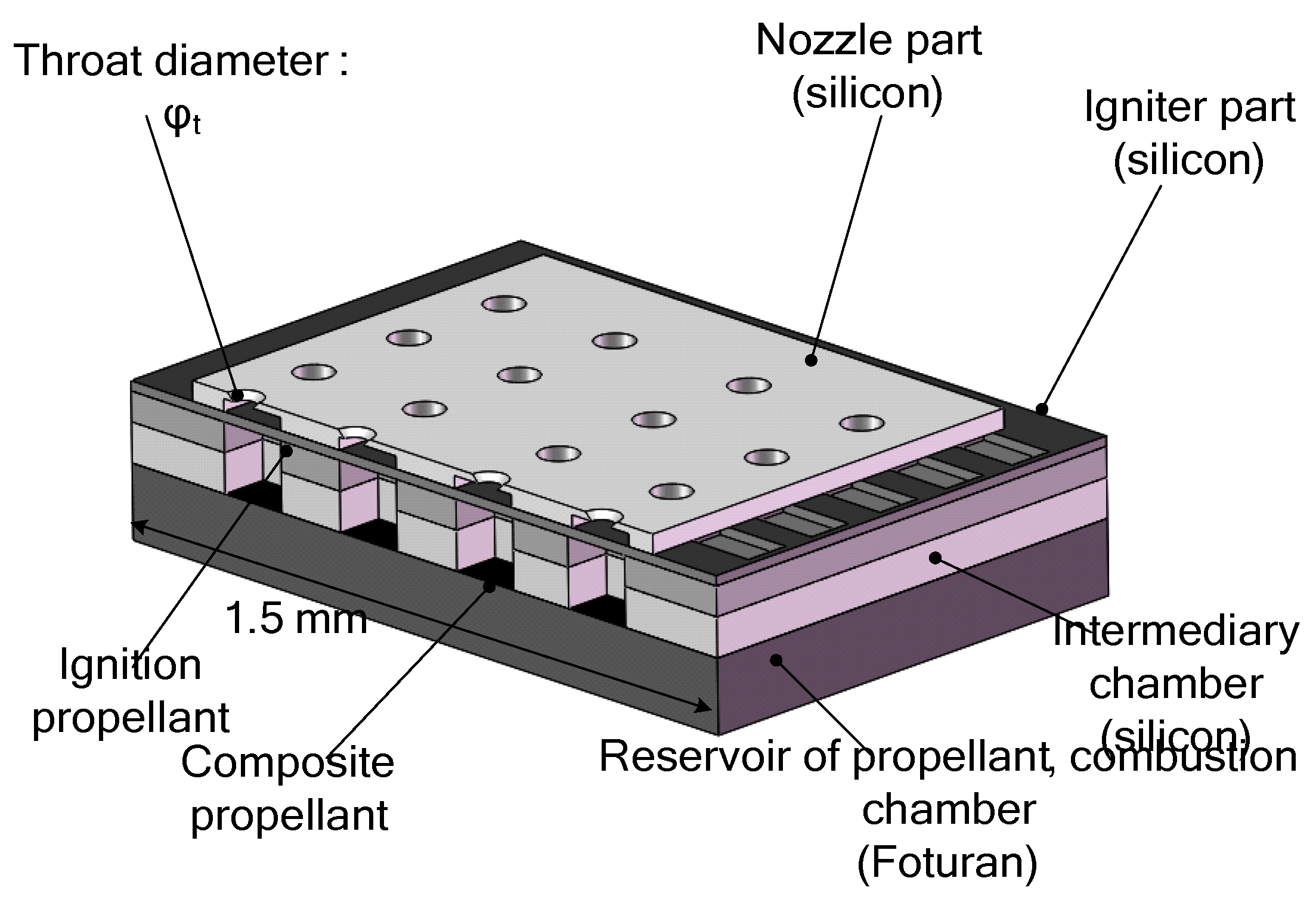

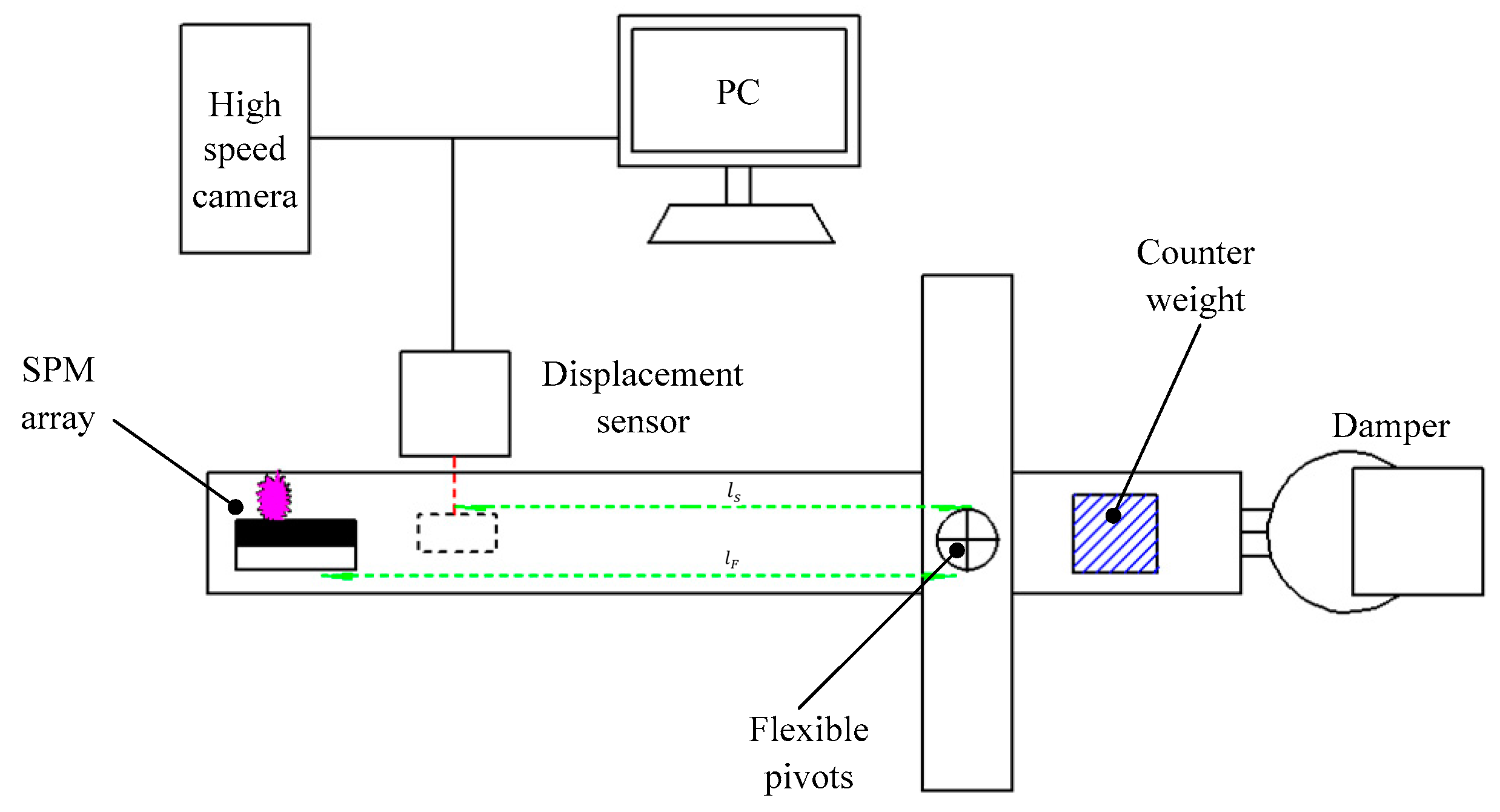

2.1. Solid Propellant Microthruster (SPM)

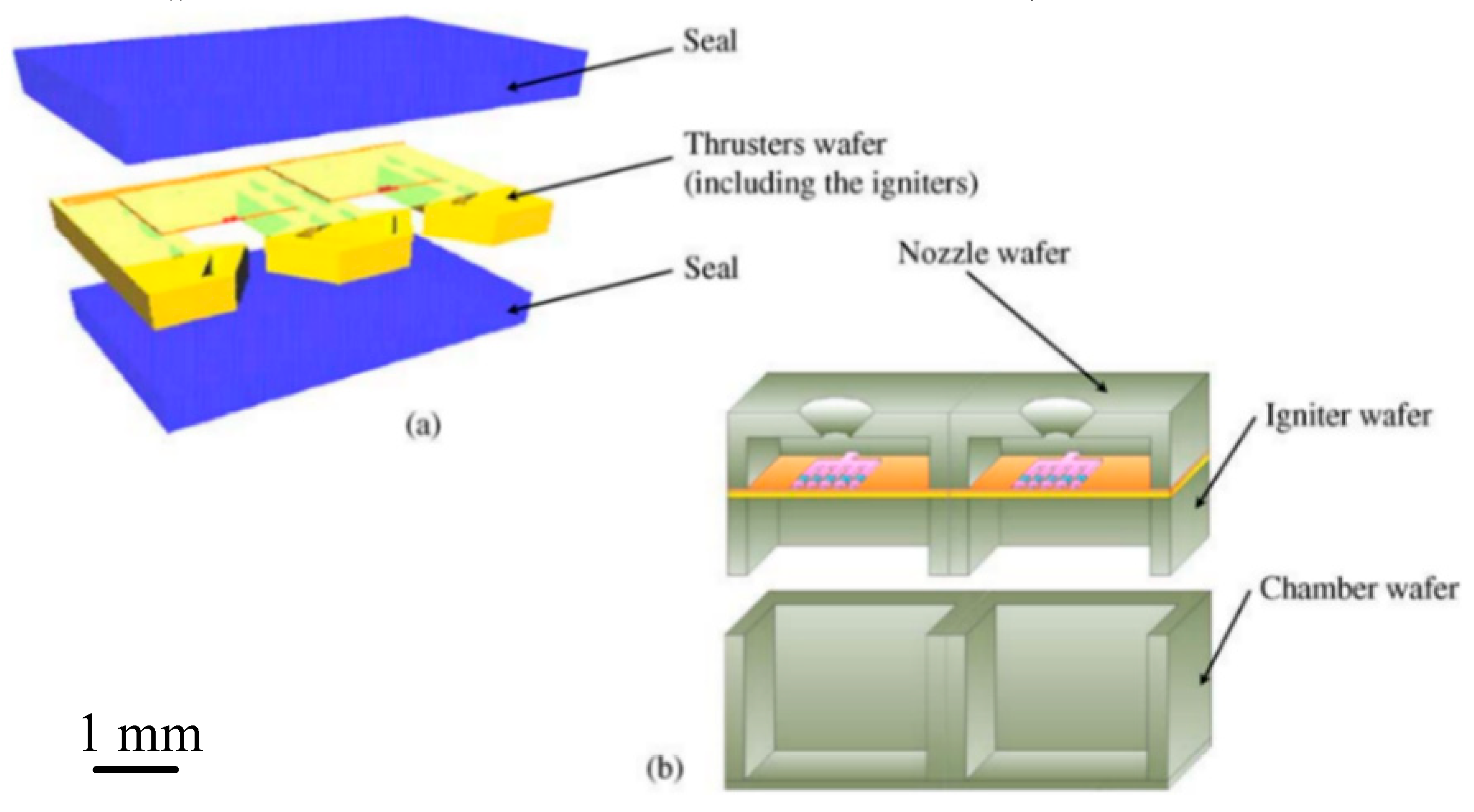

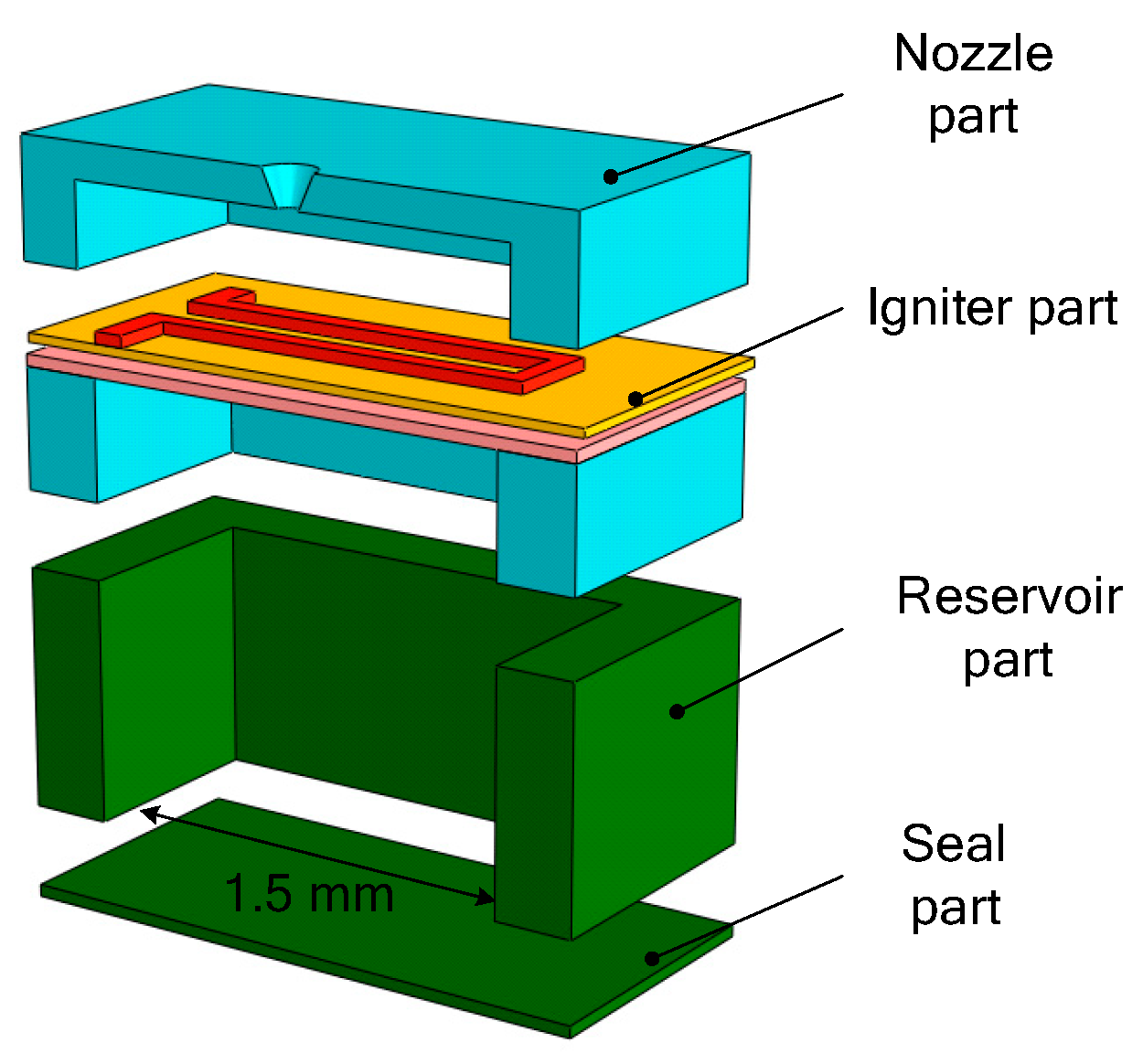

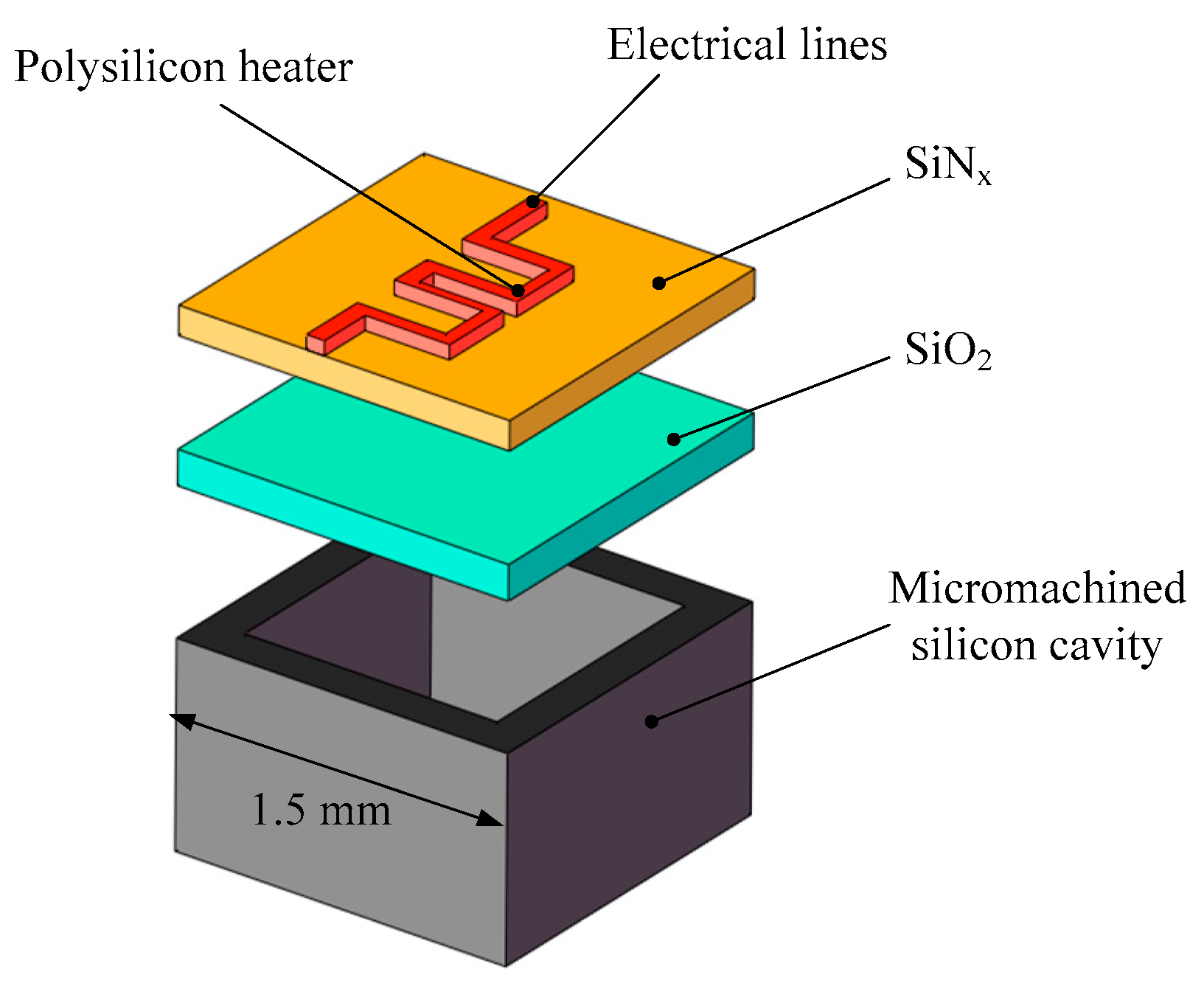

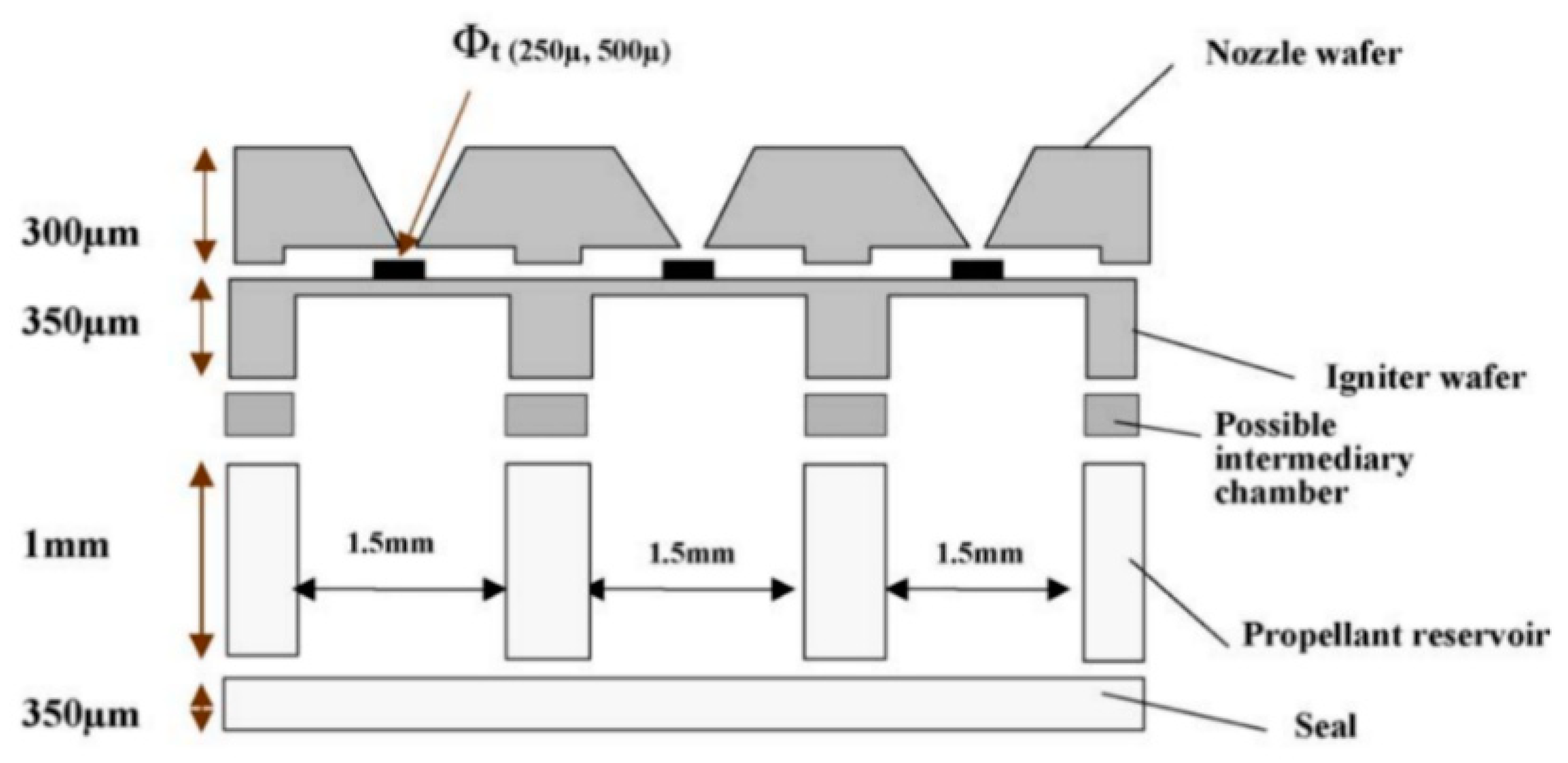

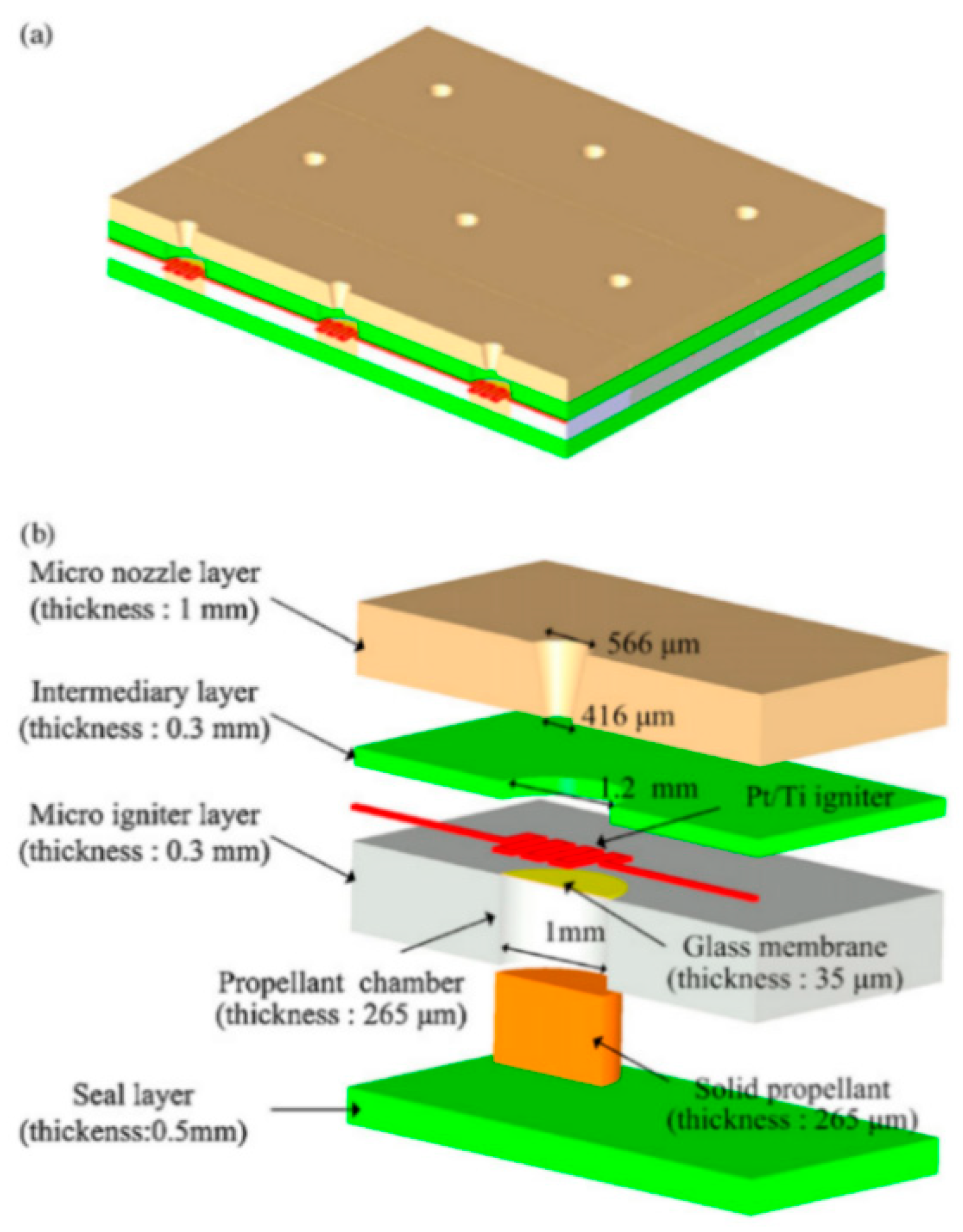

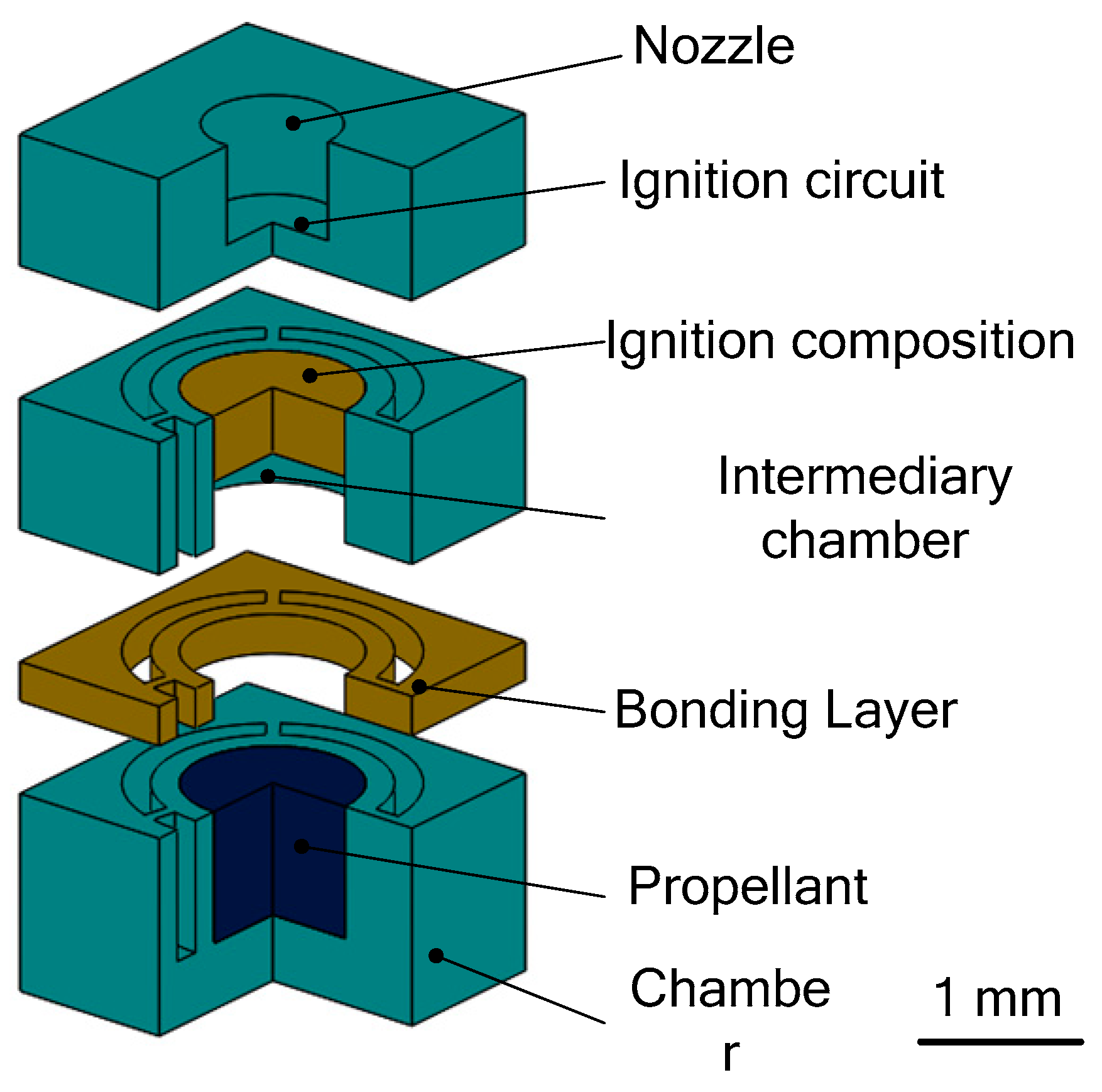

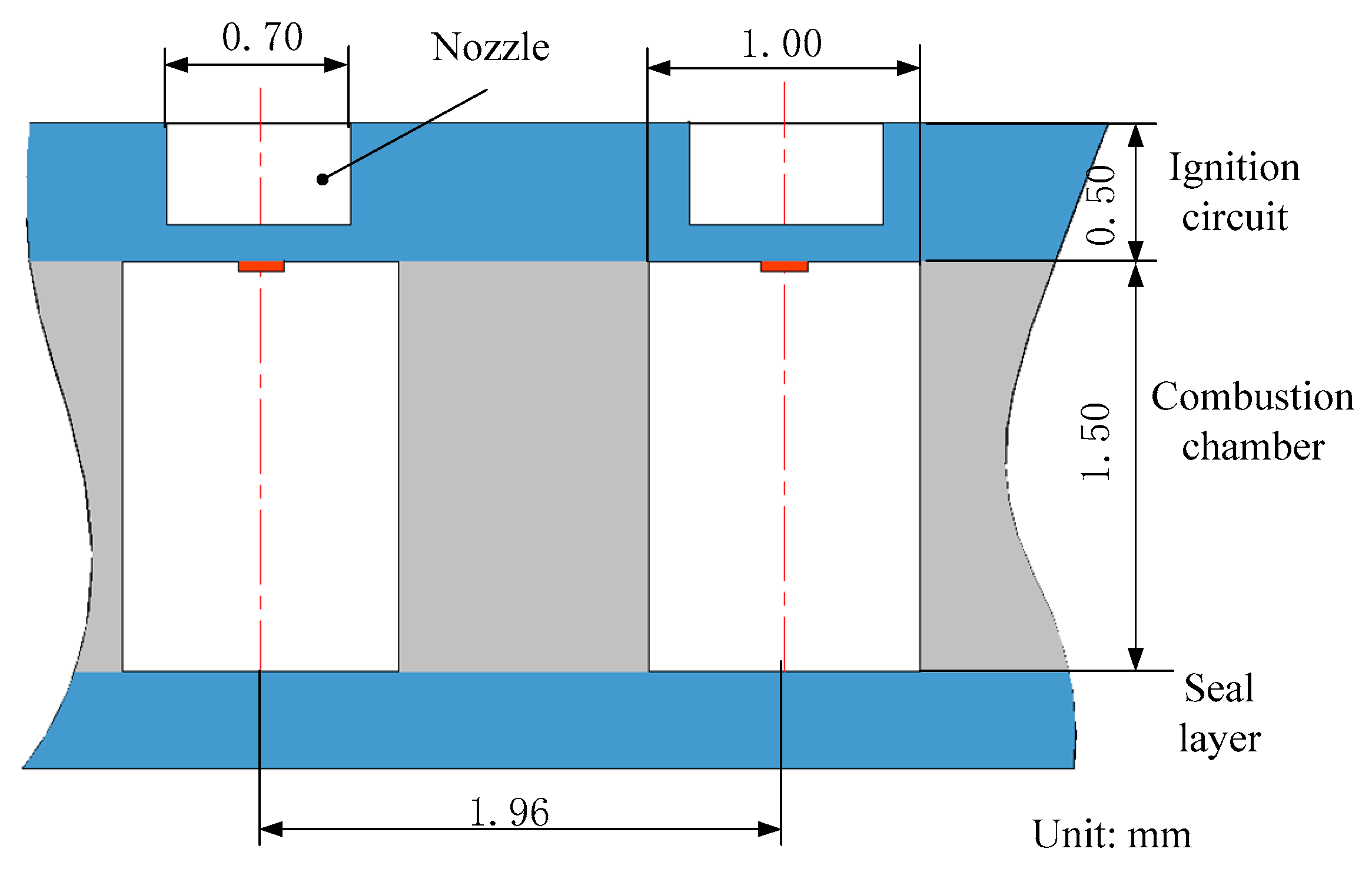

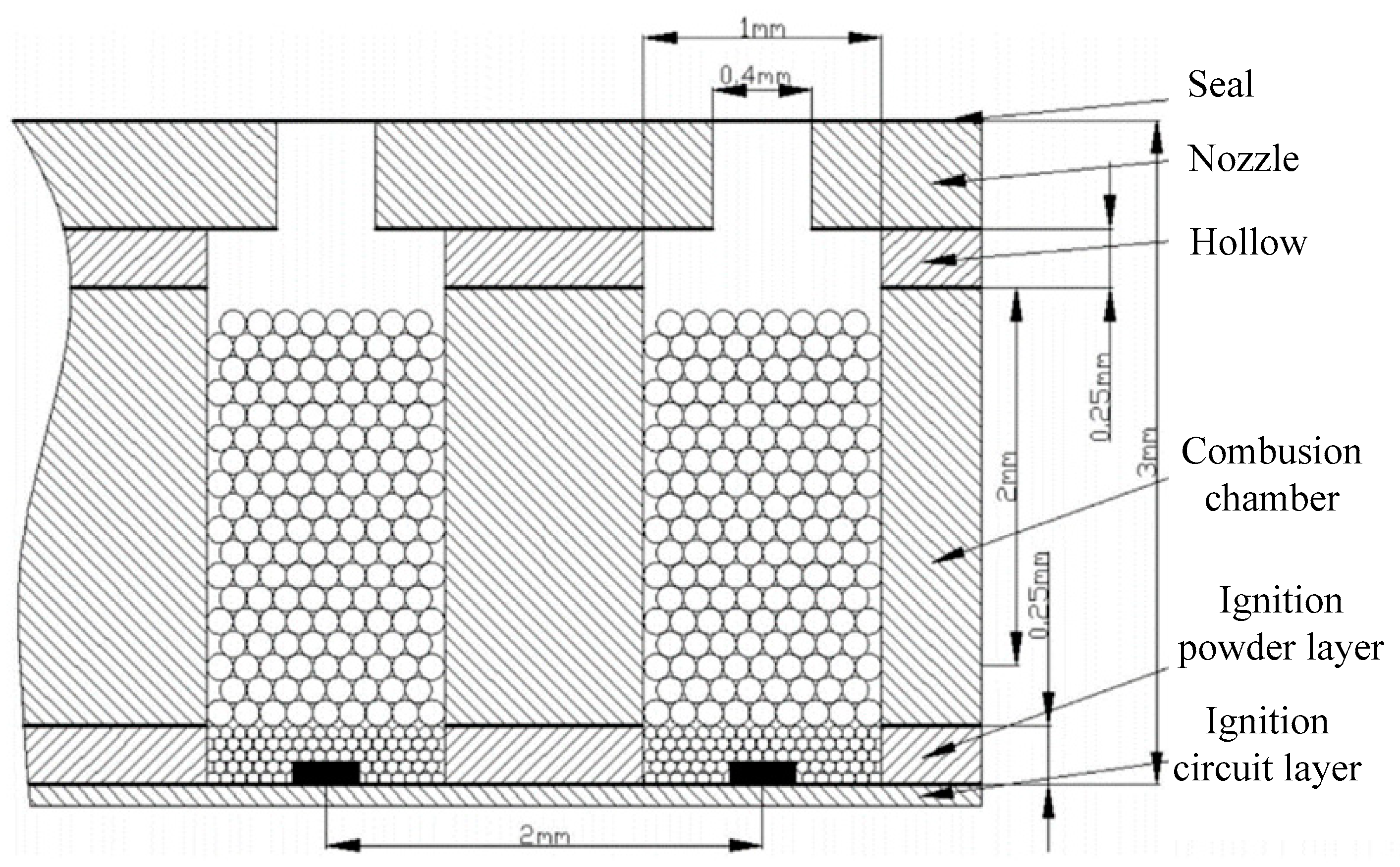

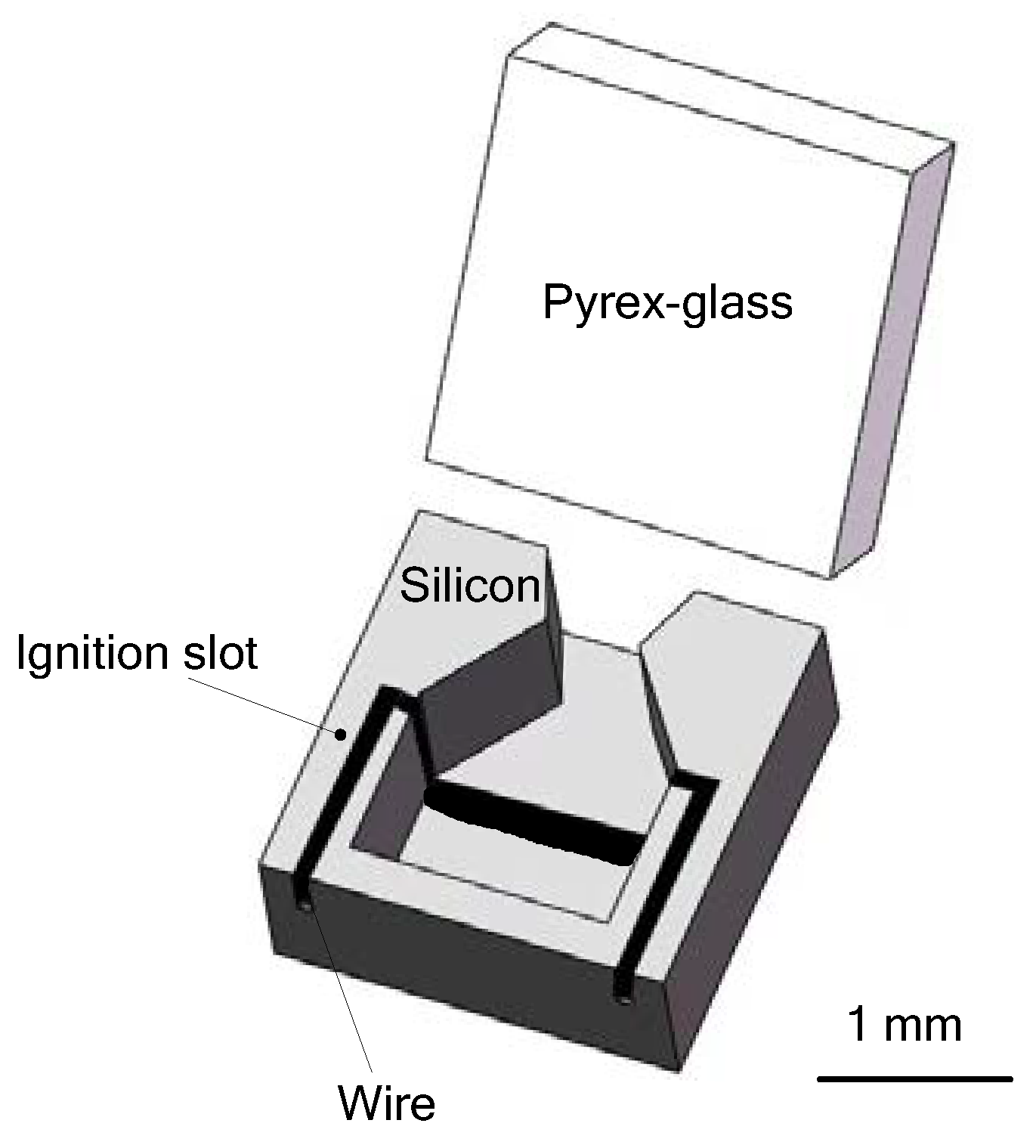

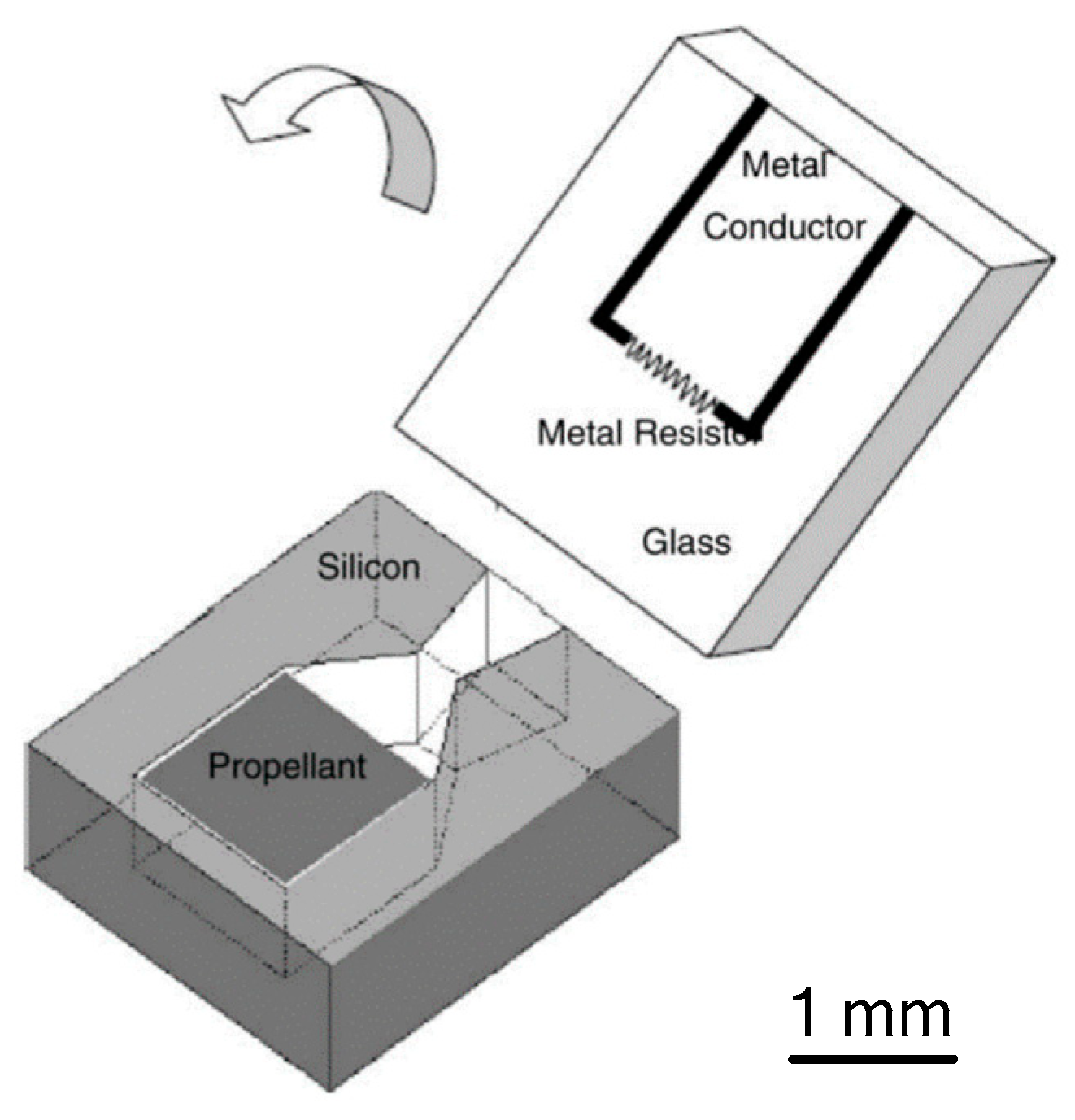

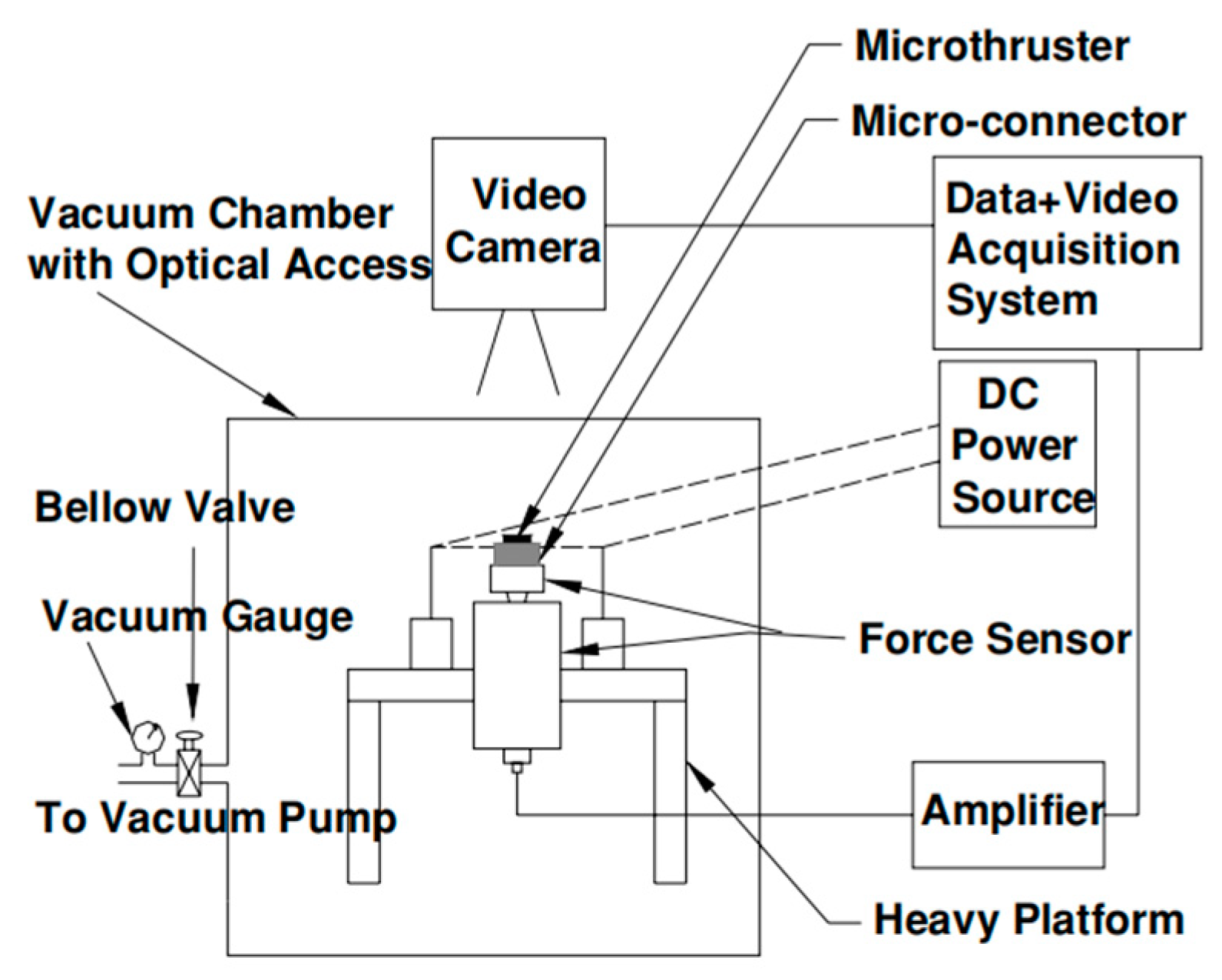

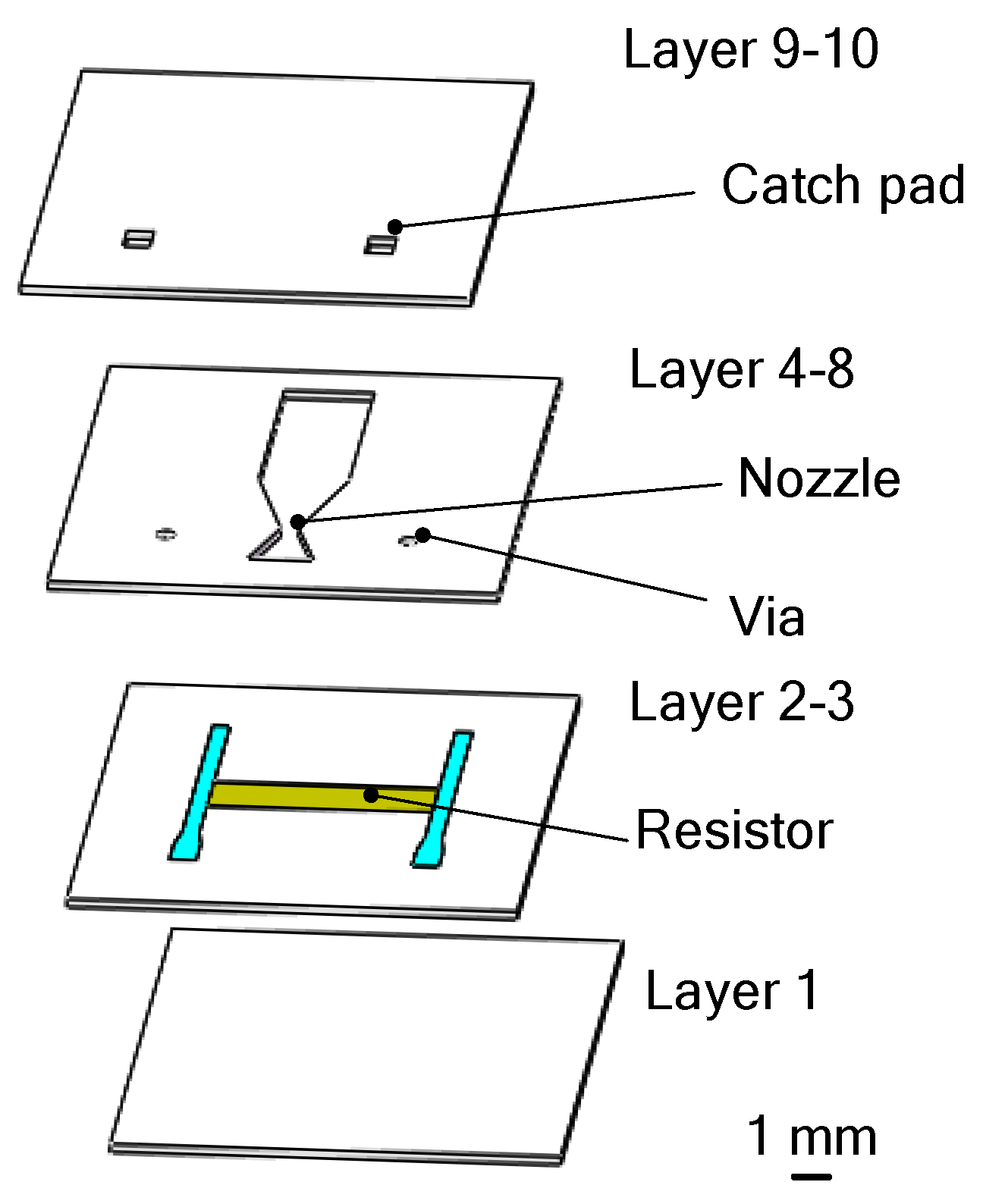

2.1.1. SPM with Vertical Structure

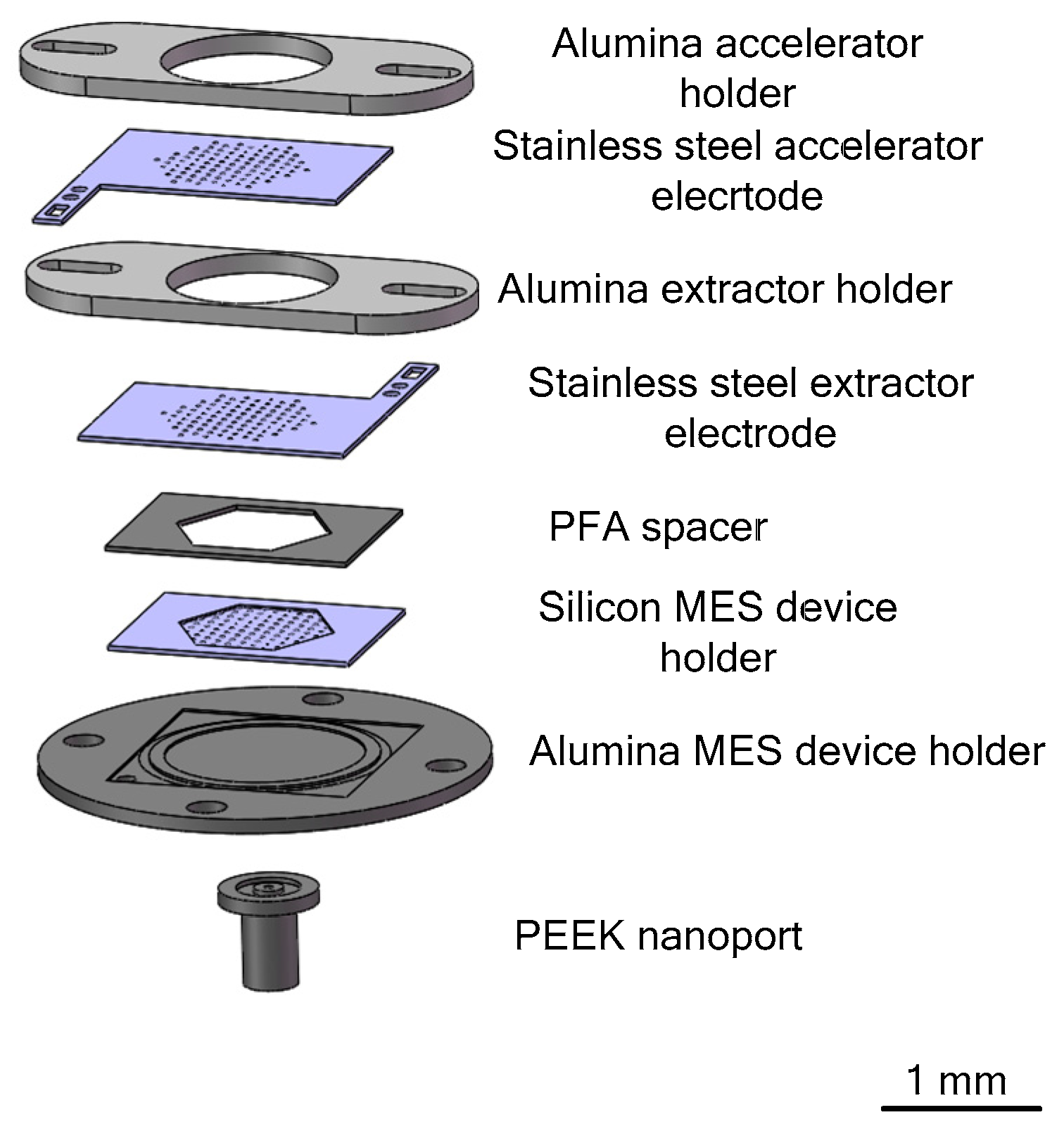

2.1.2. SPM with Planar Structure

2.1.3. Summary of SPM and SPM Arrays

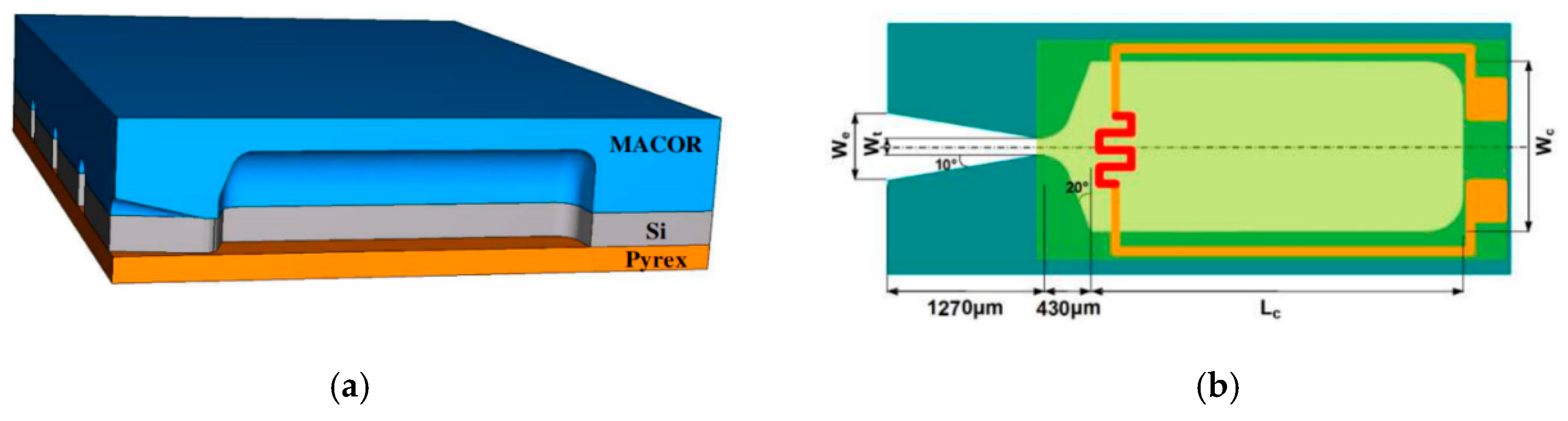

2.2. Liquid Monopropellant Microthruster

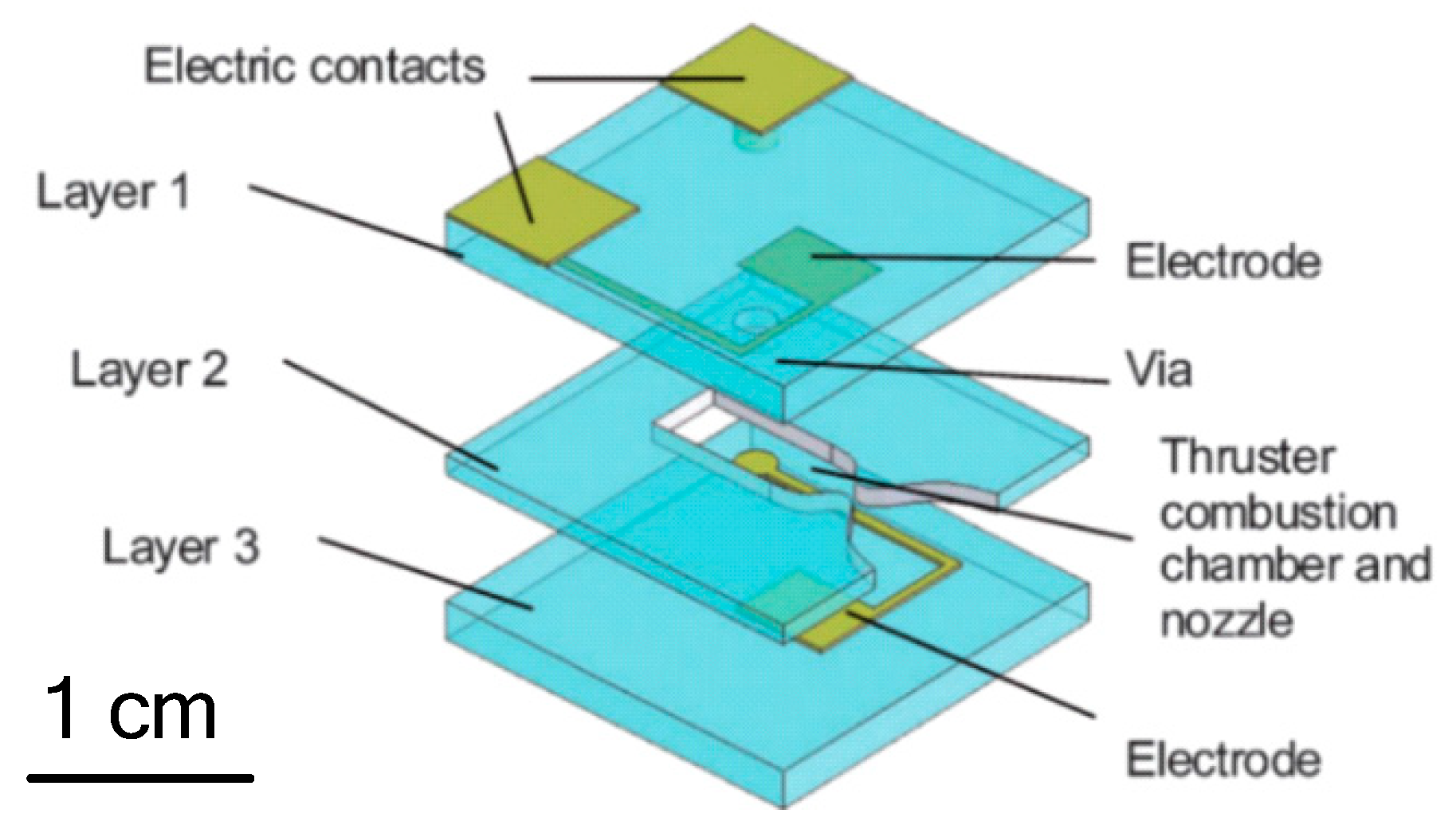

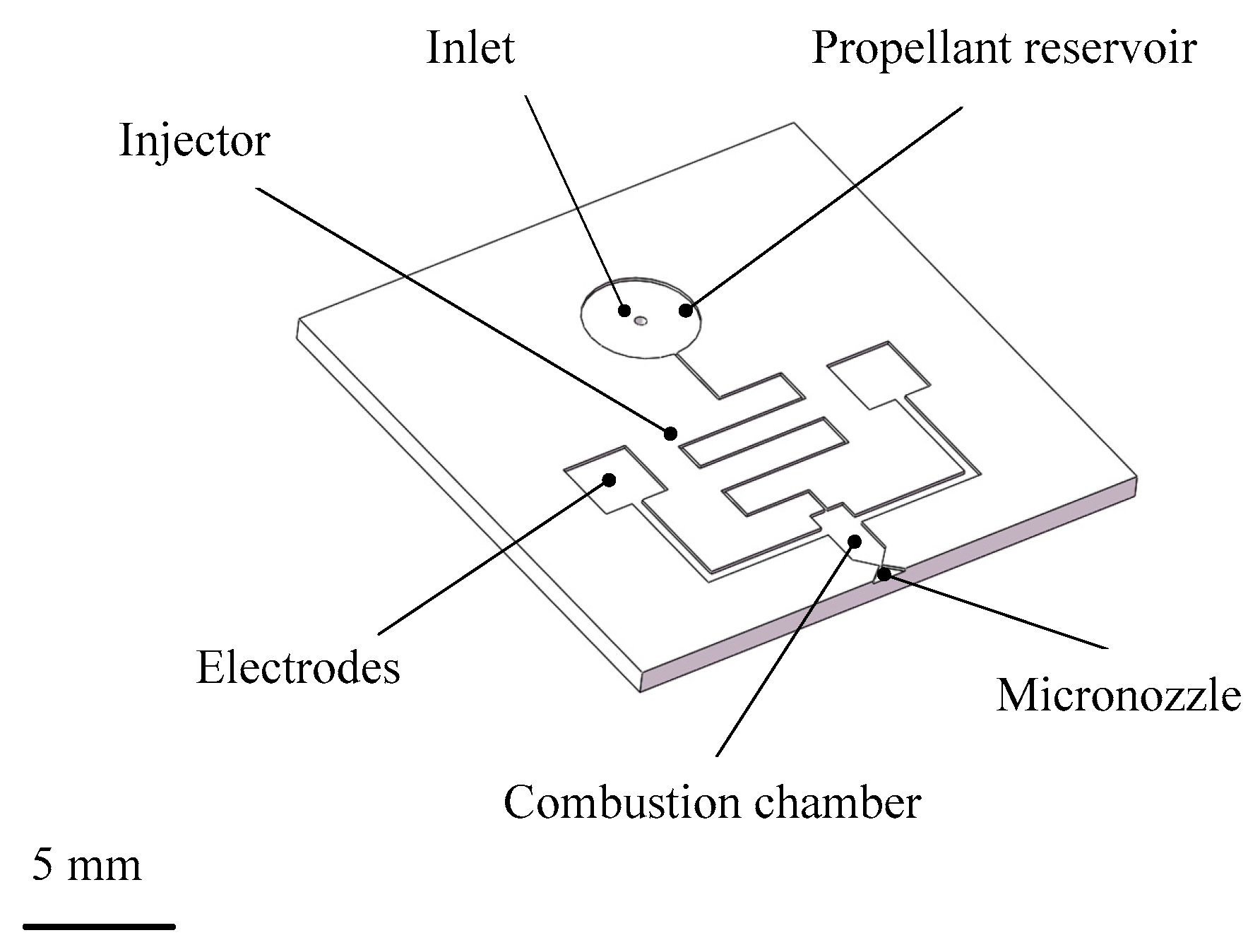

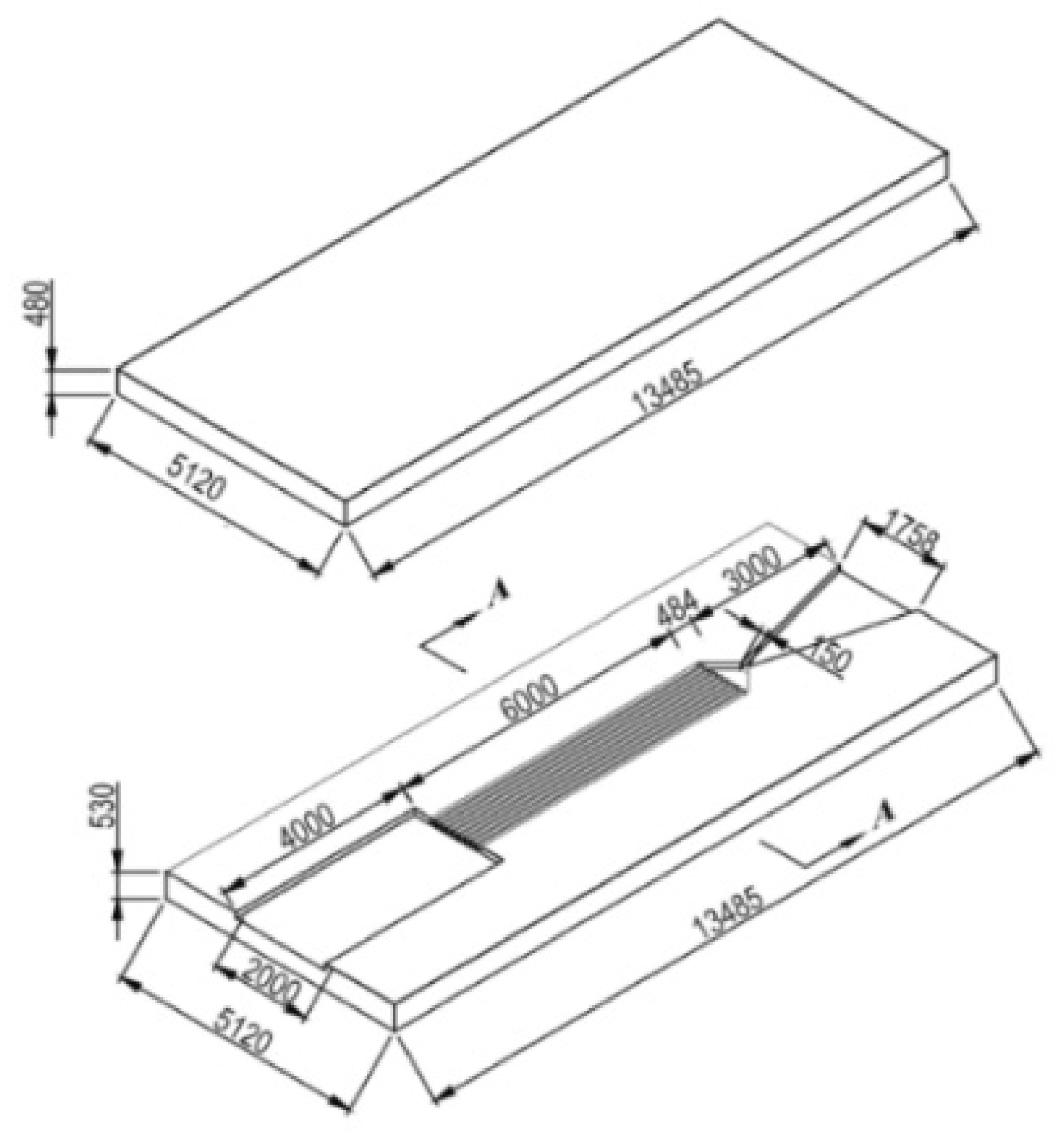

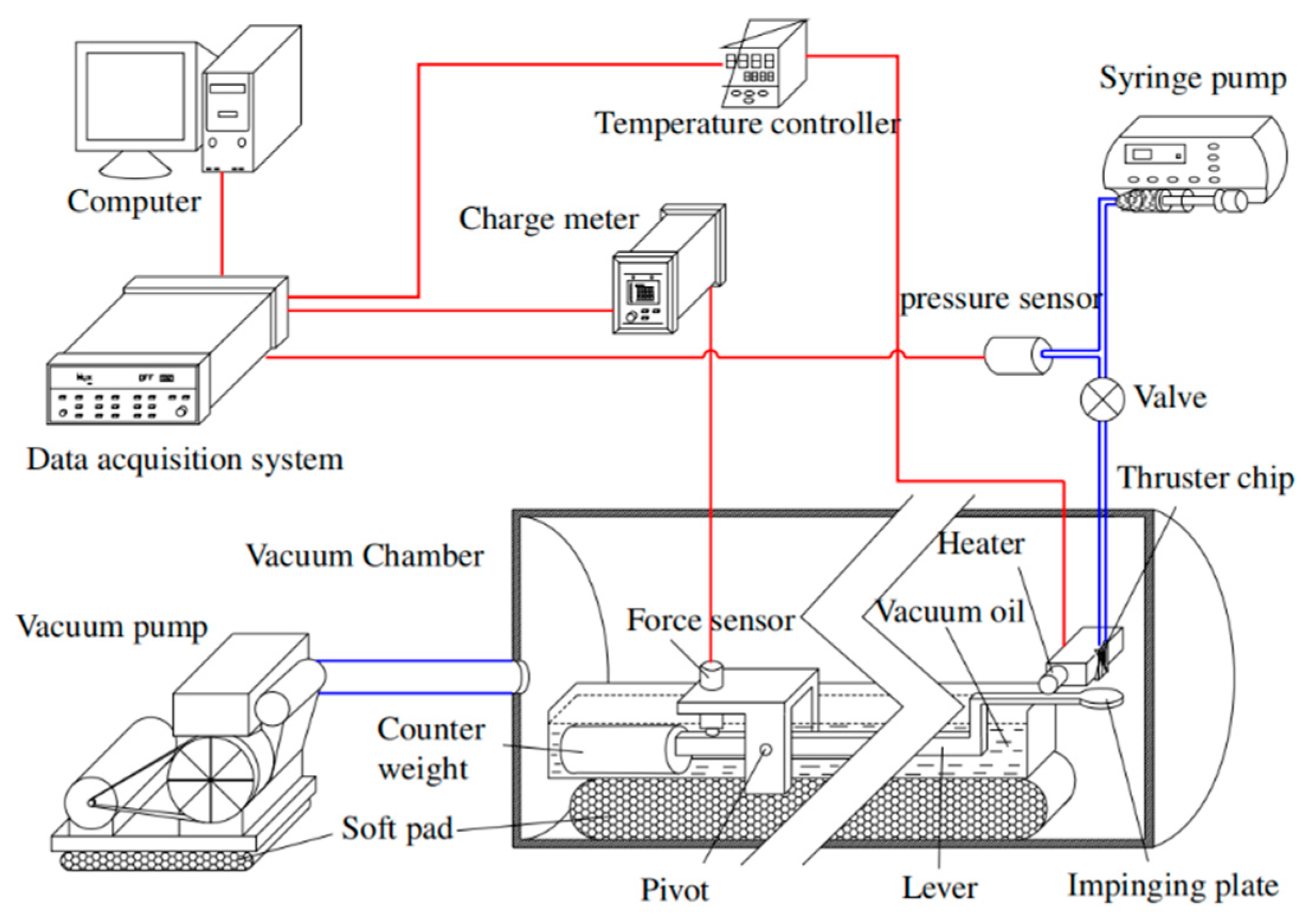

2.2.1. Liquid Monopropellant Microthruster with Spark Ignition

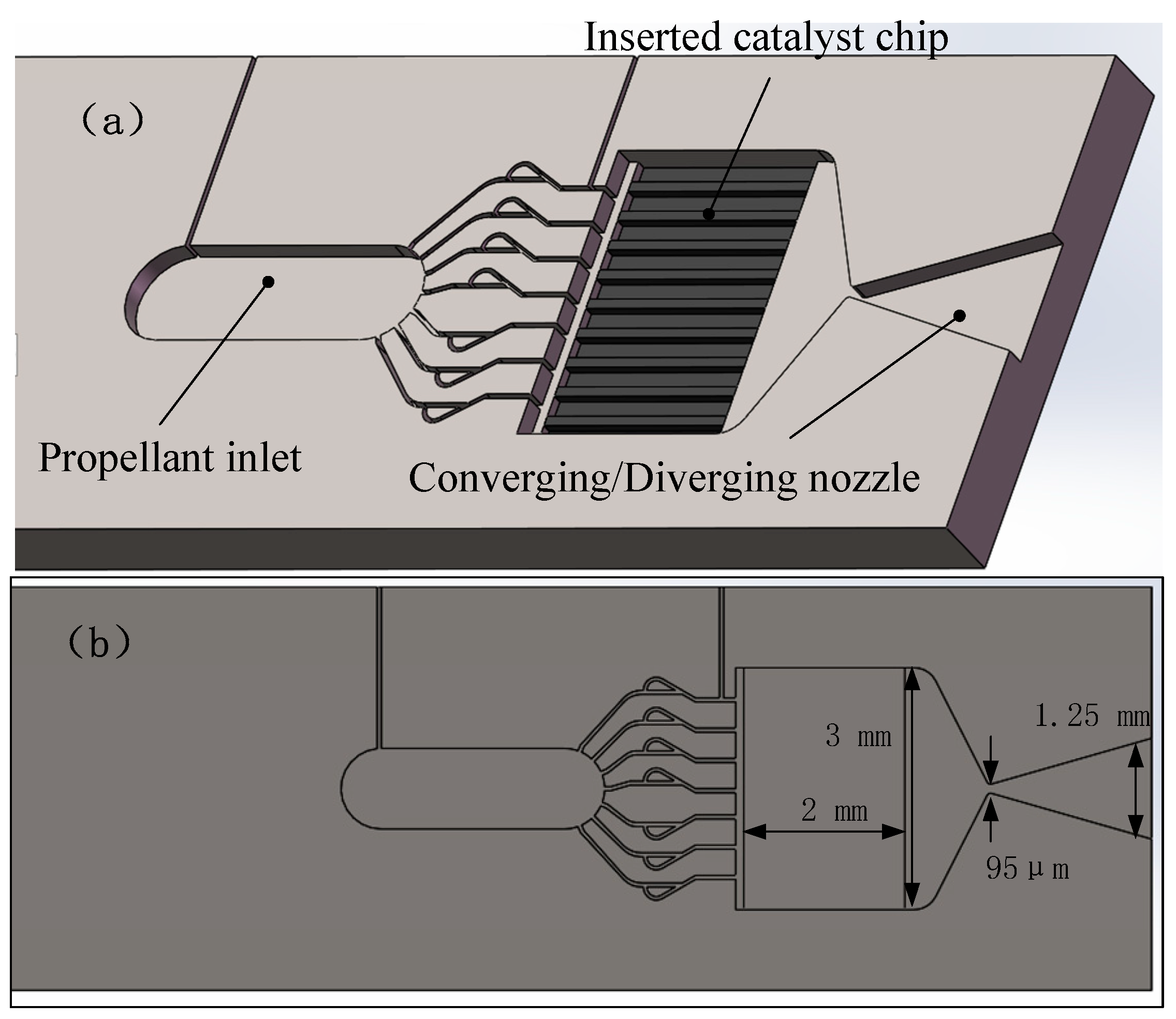

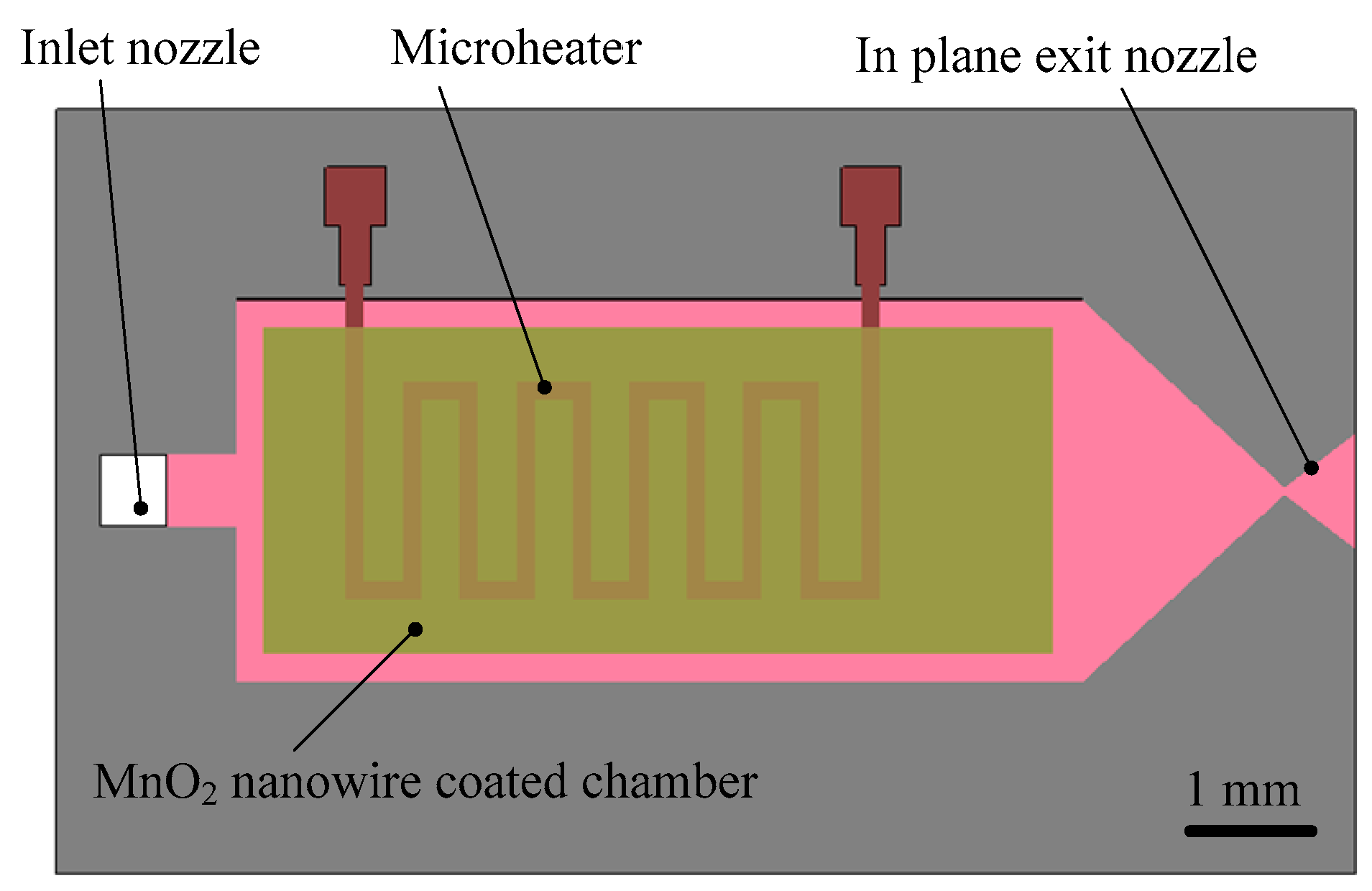

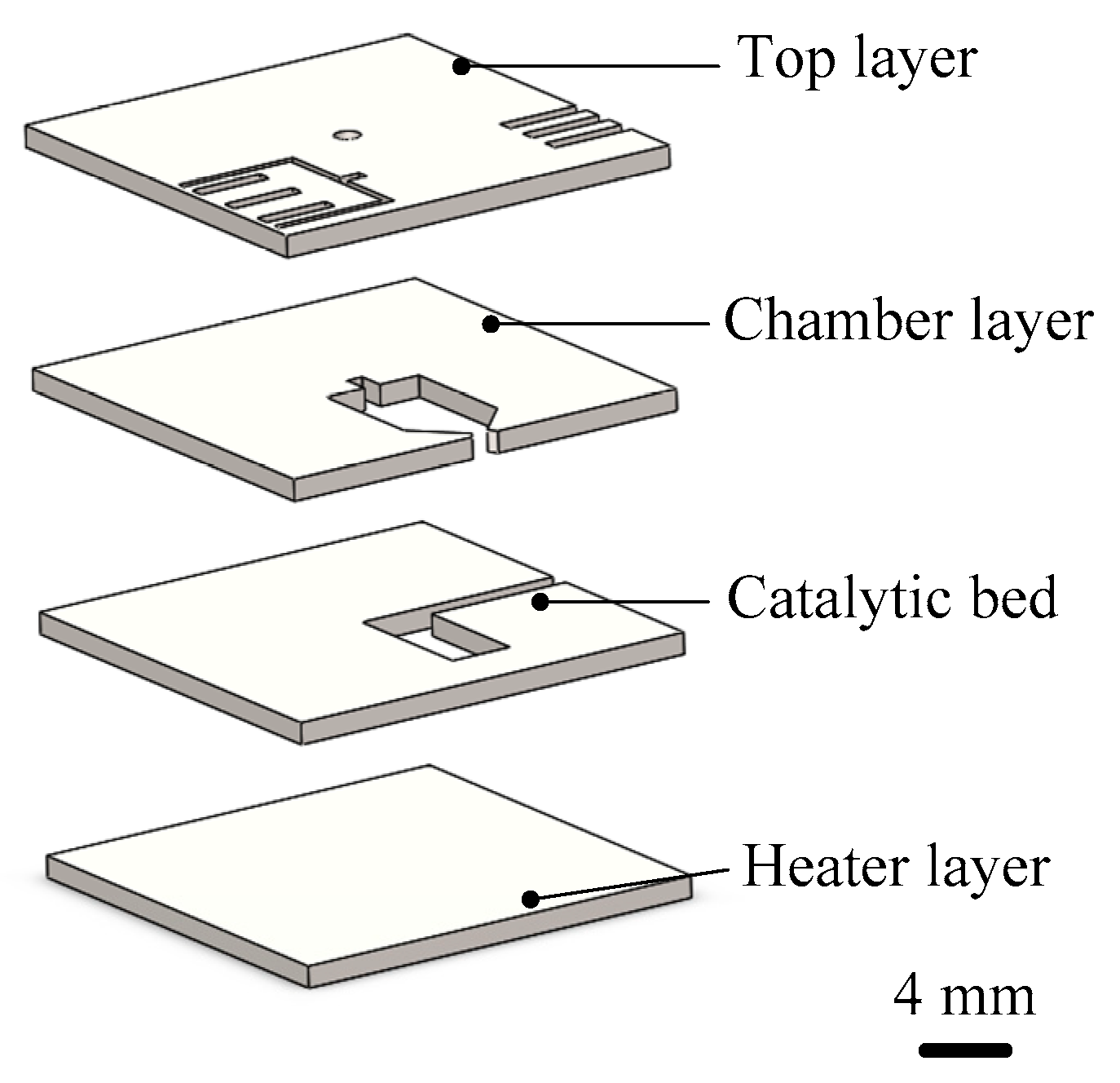

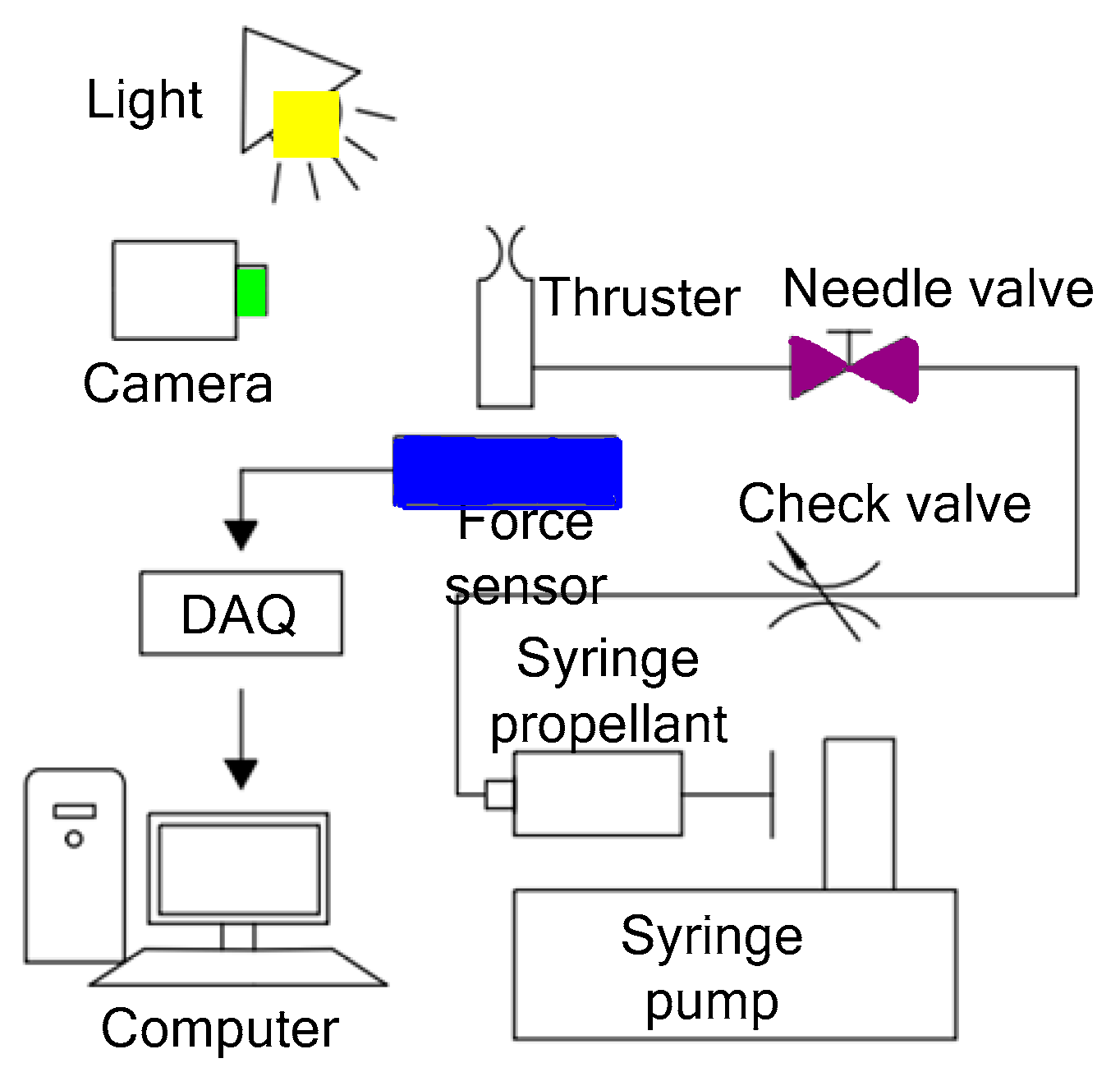

2.2.2. Liquid Monopropellant Microthruster with Catalytic Ignition

2.2.3. Summary of Liquid Monopropellant Microthruster

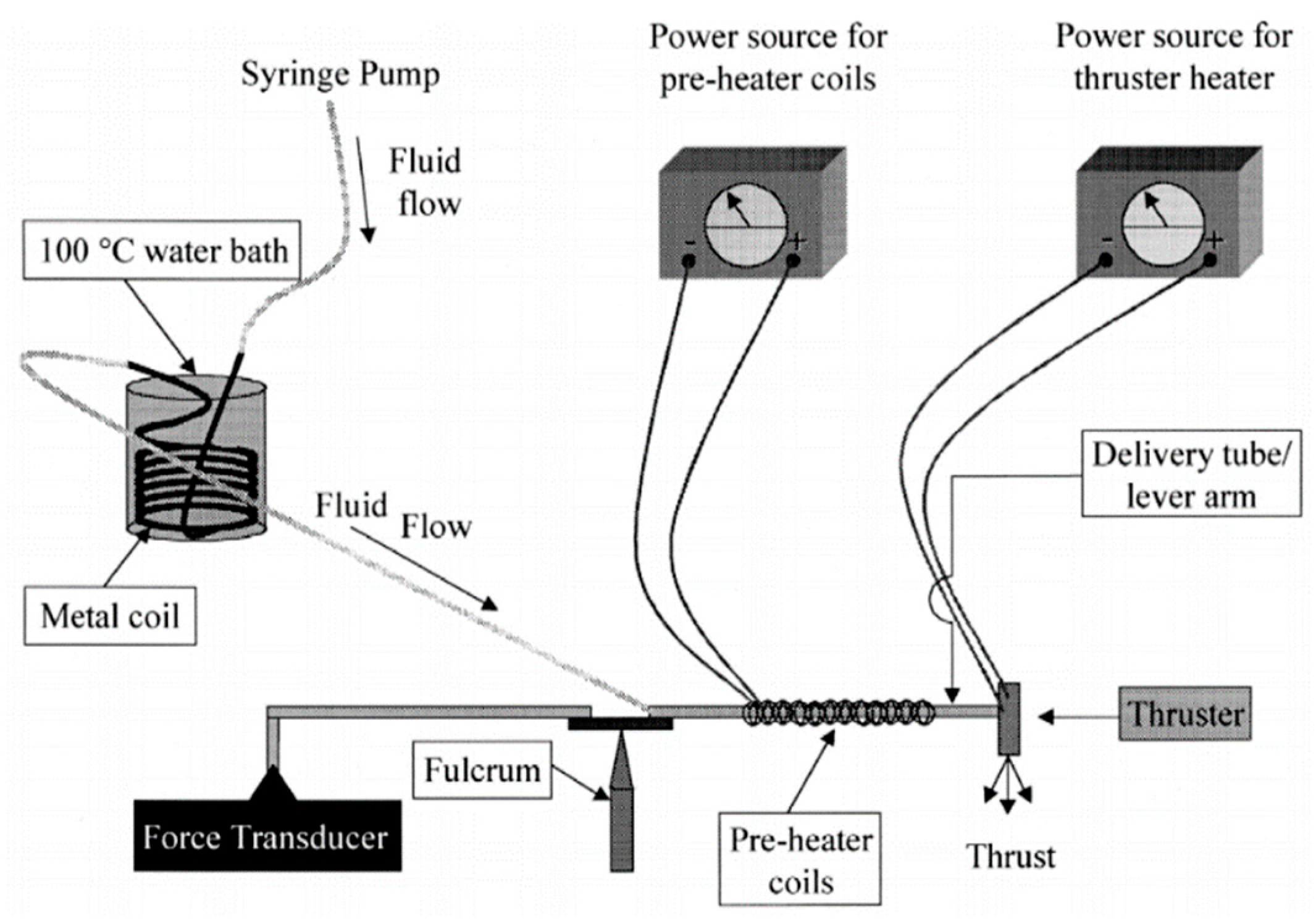

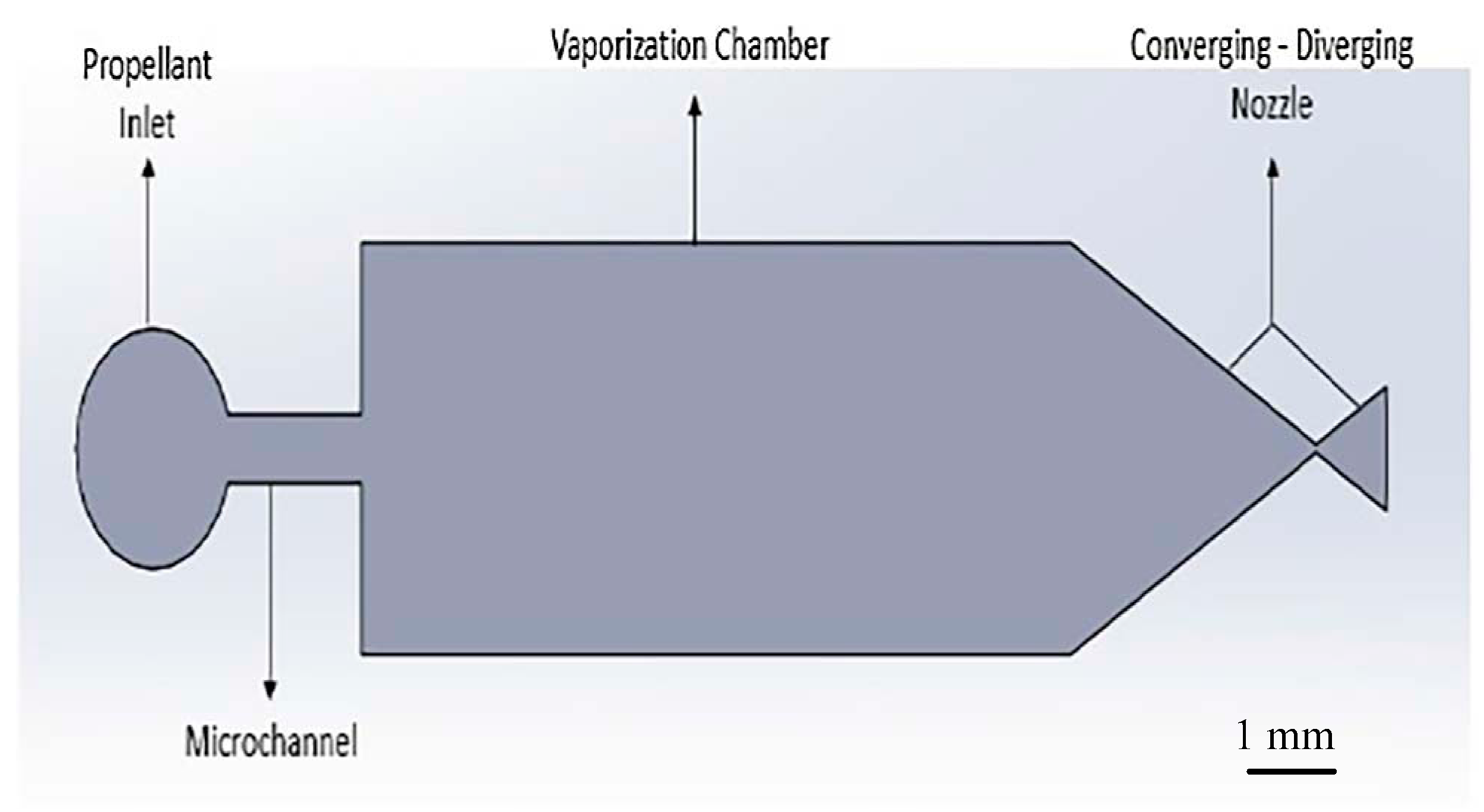

3. Vaporizing Liquid Microthrusters (VLM)

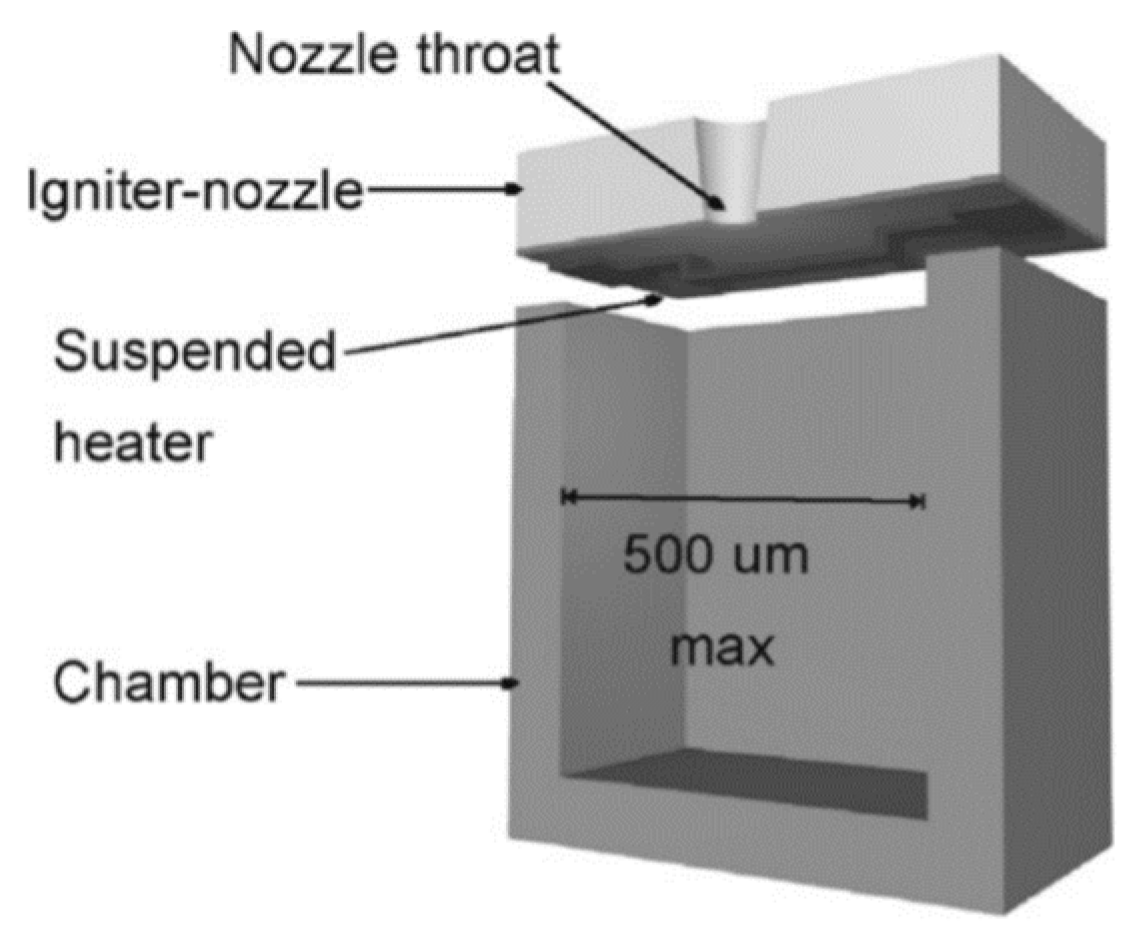

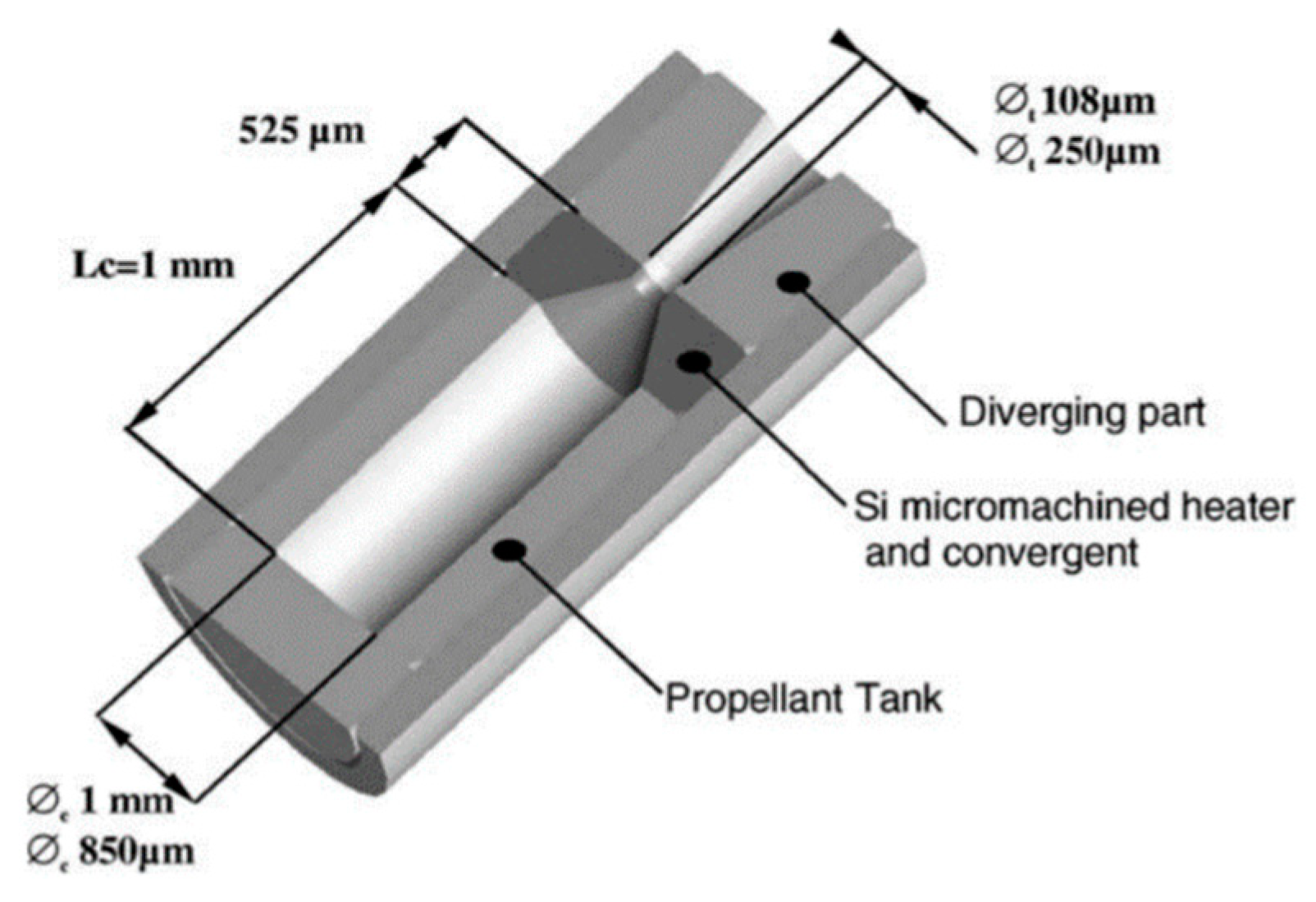

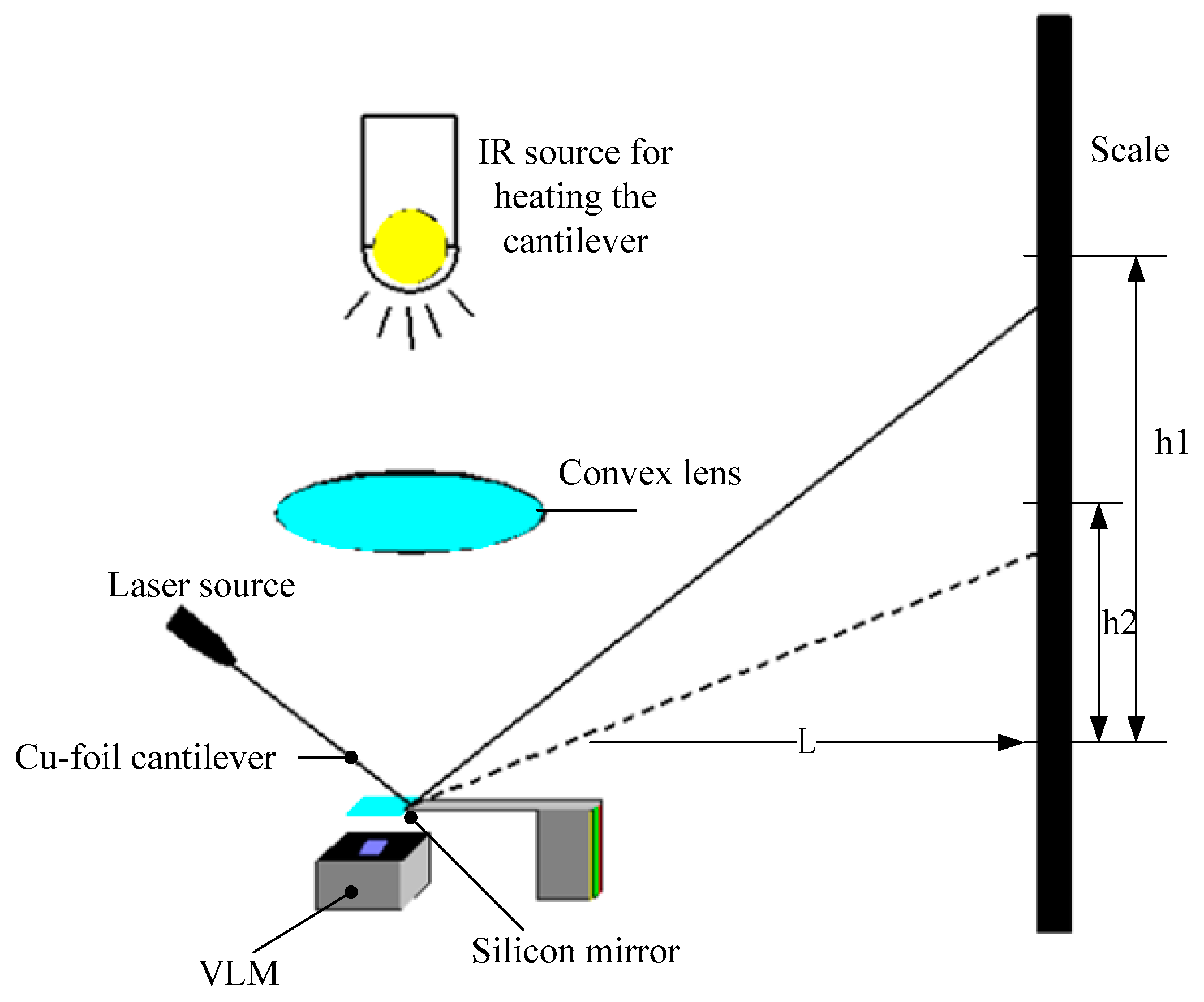

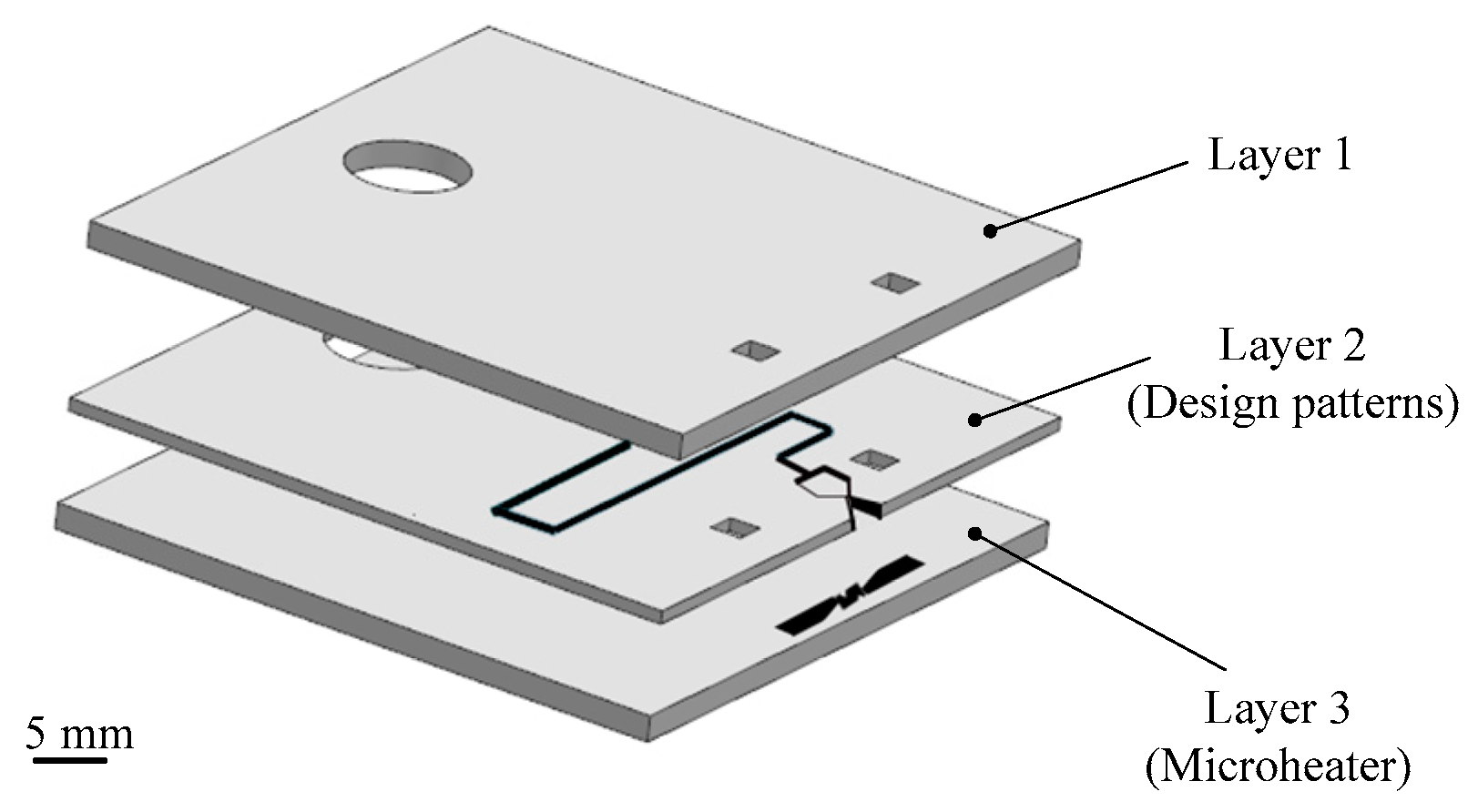

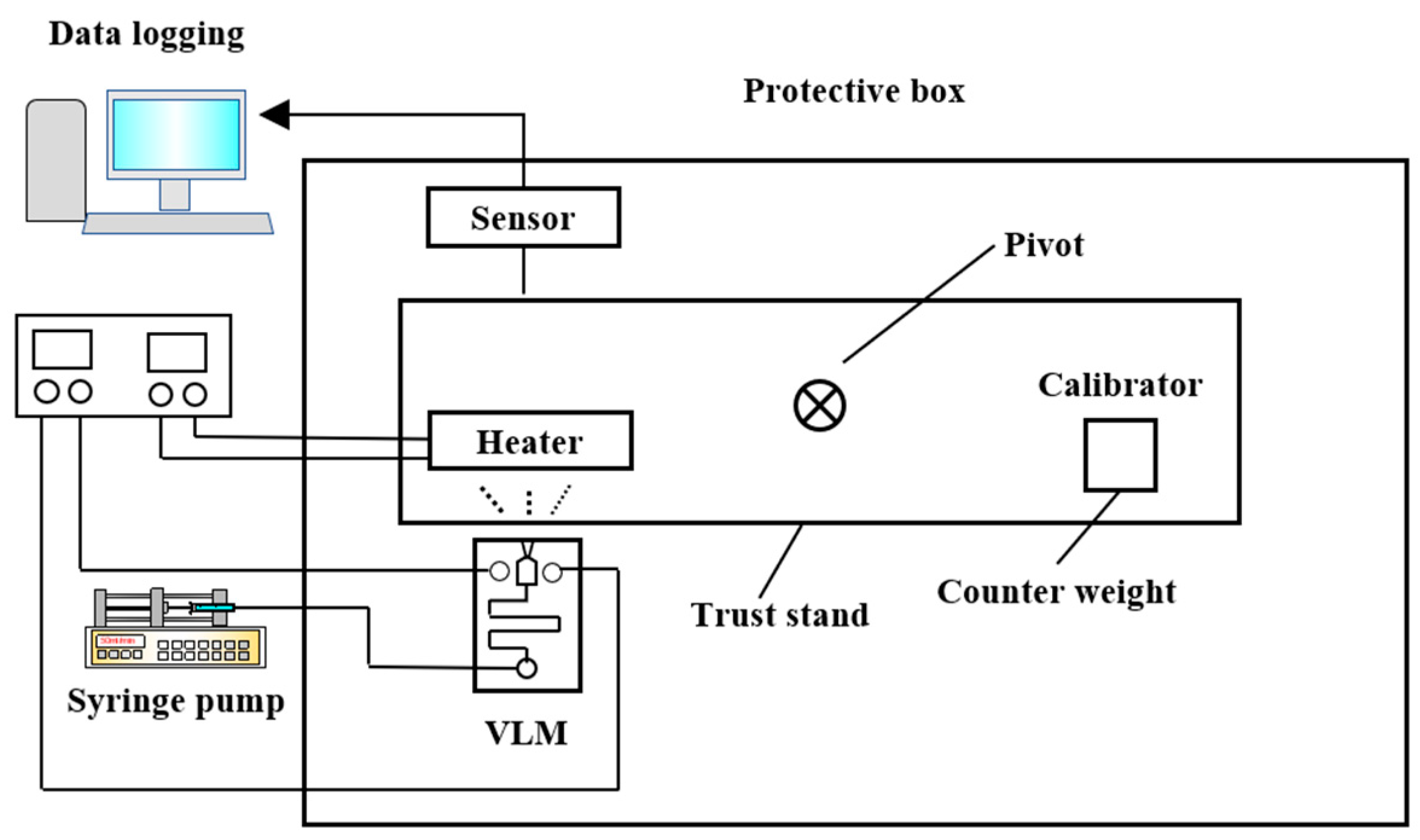

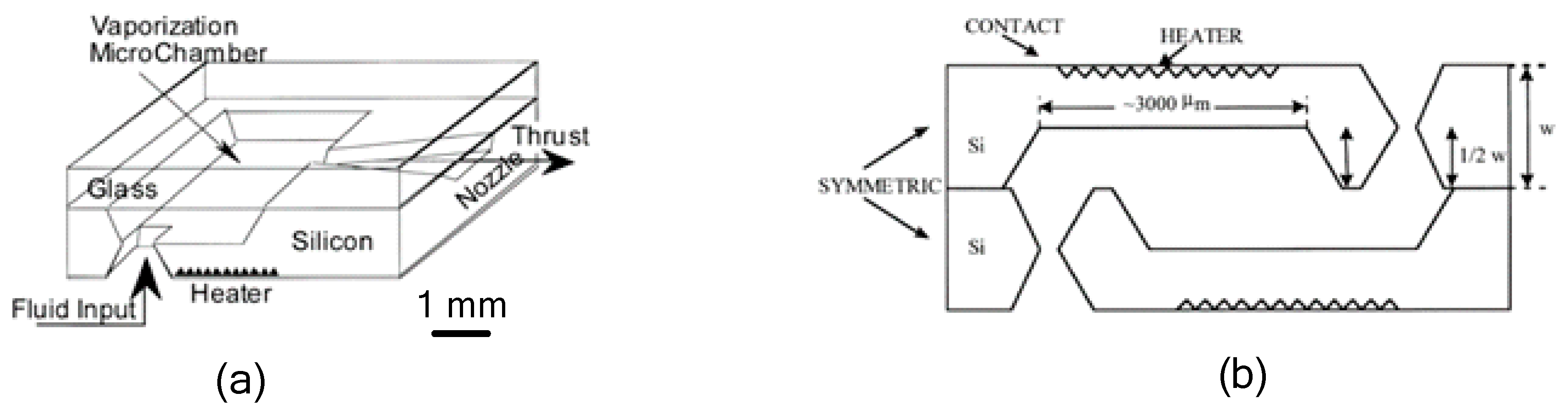

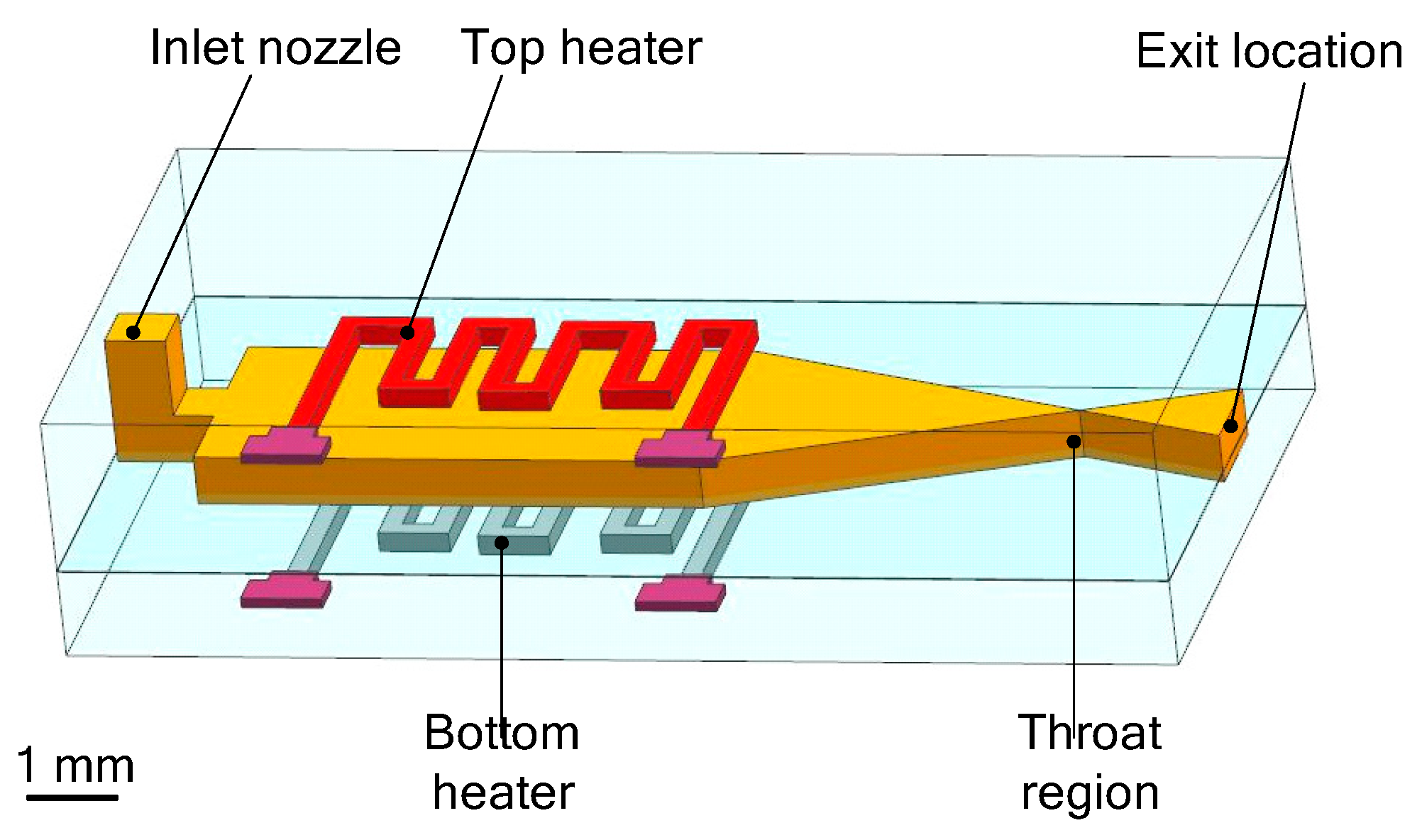

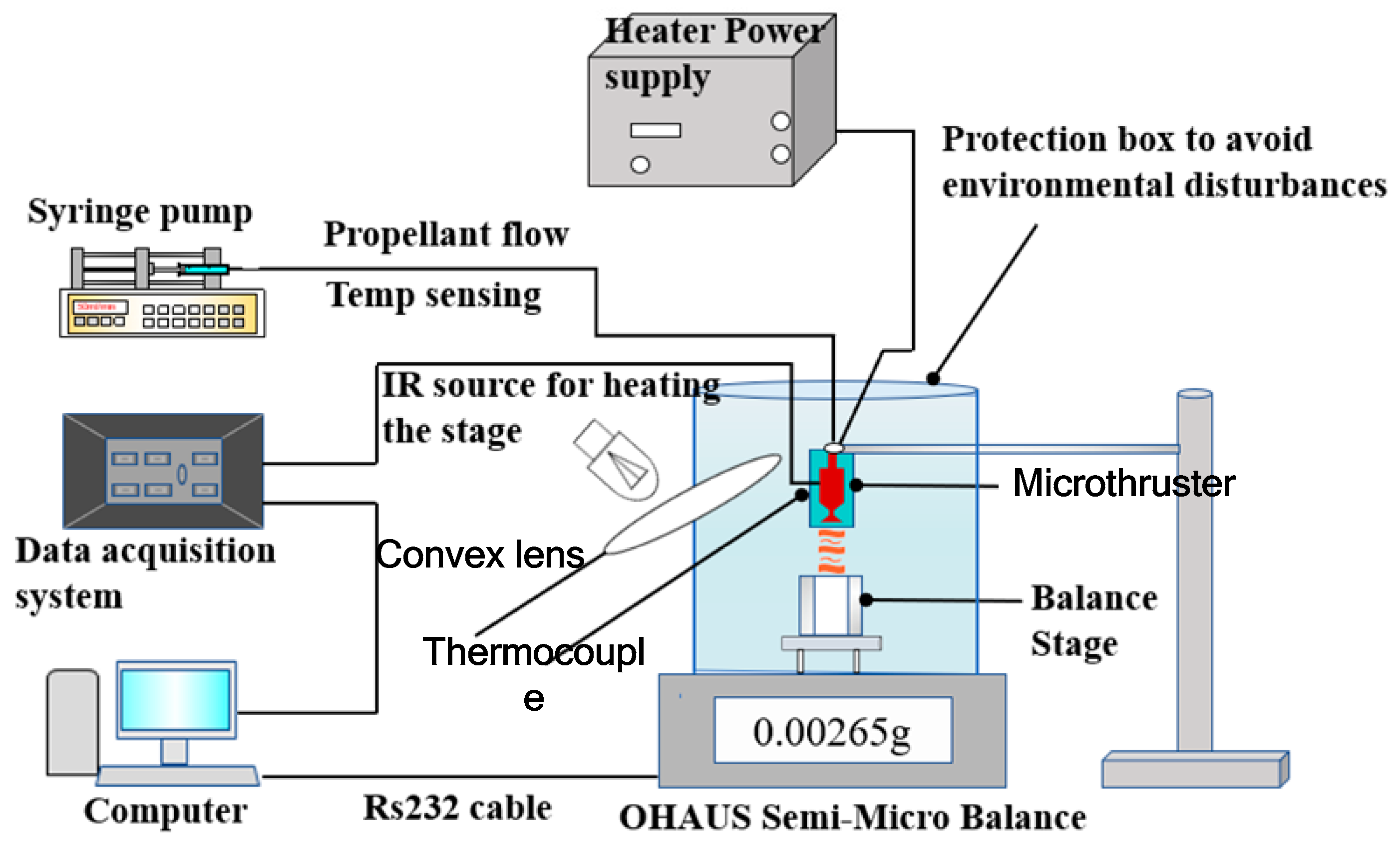

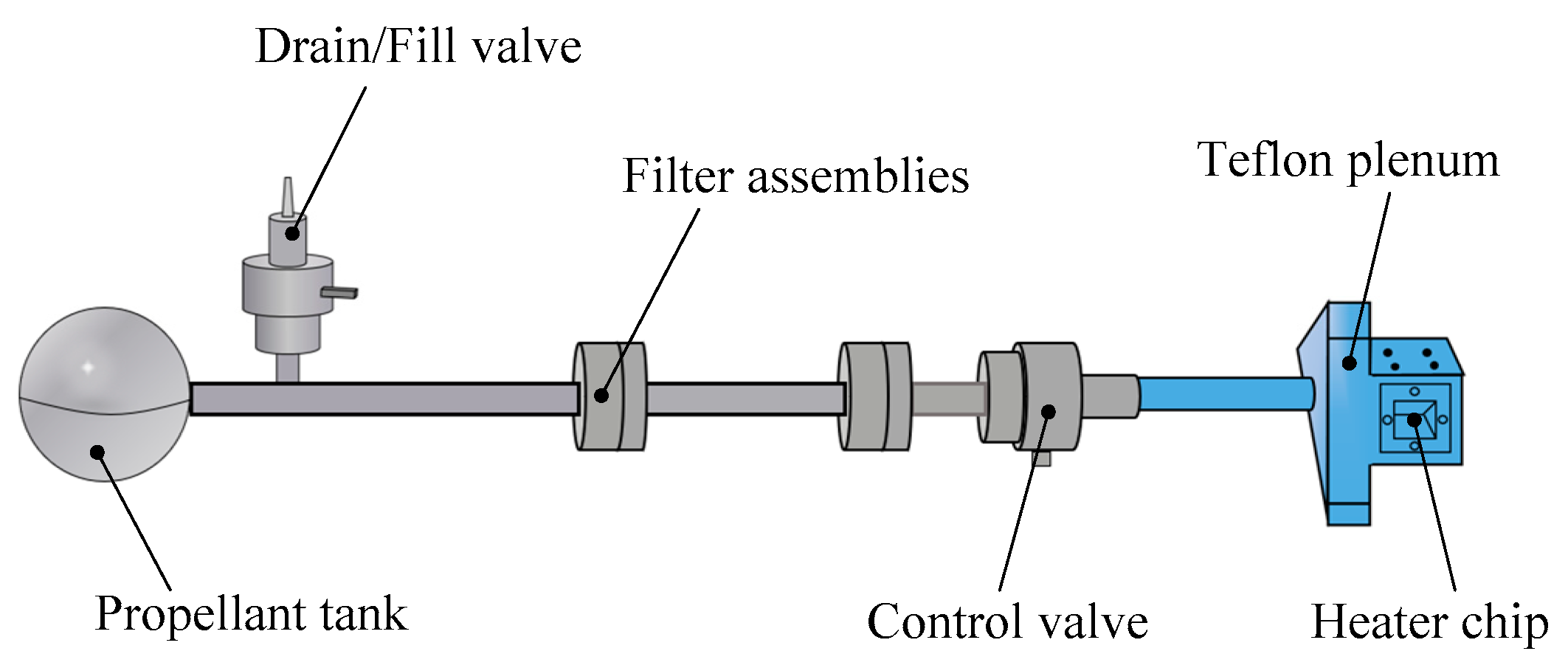

3.1. VLM with Internal Microheater

3.2. VLM with External Microheater

3.3. Summary of VLM

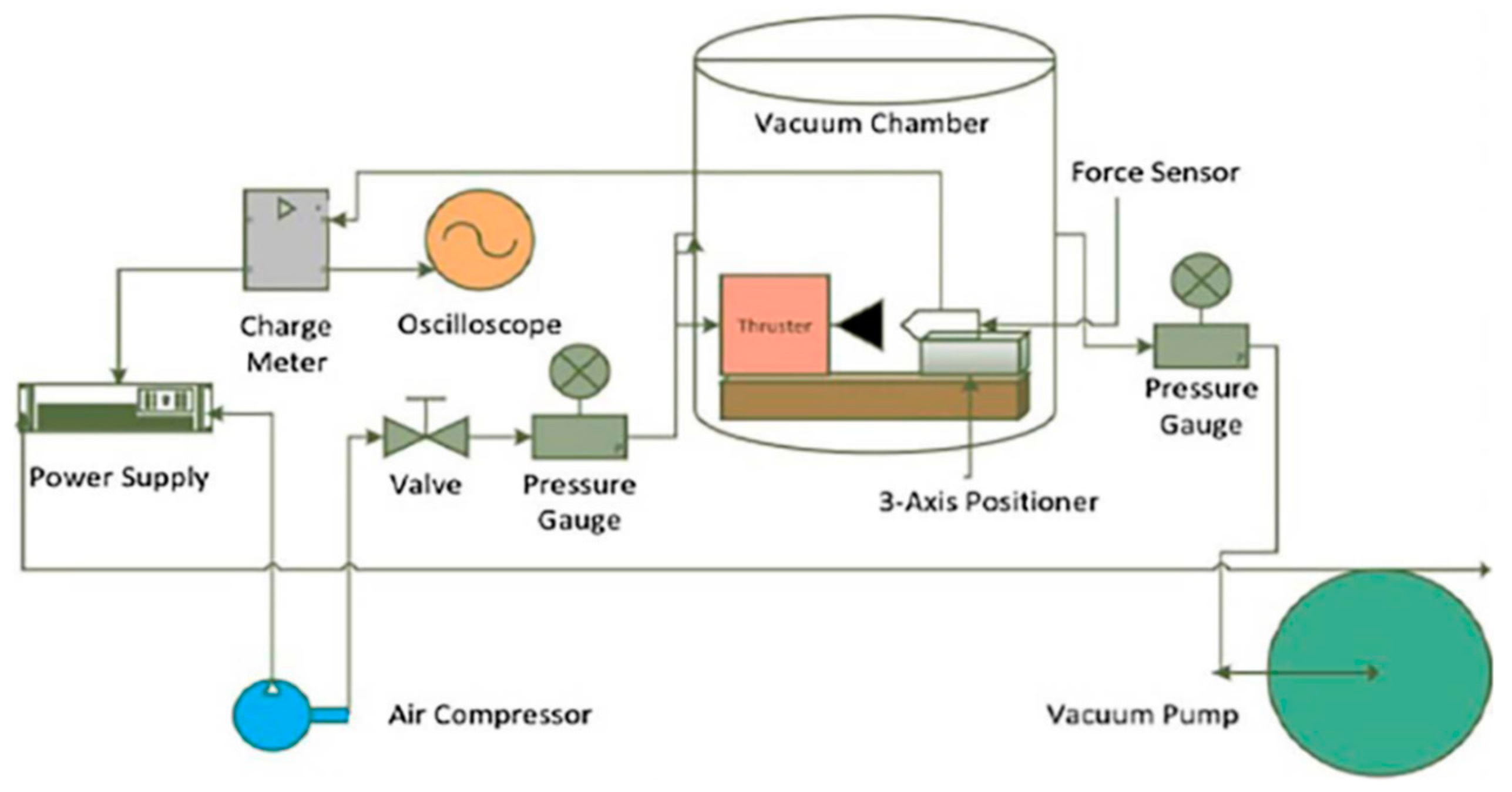

4. Plasma Microthruster

4.1. Electrothermal Plasma Microthruster

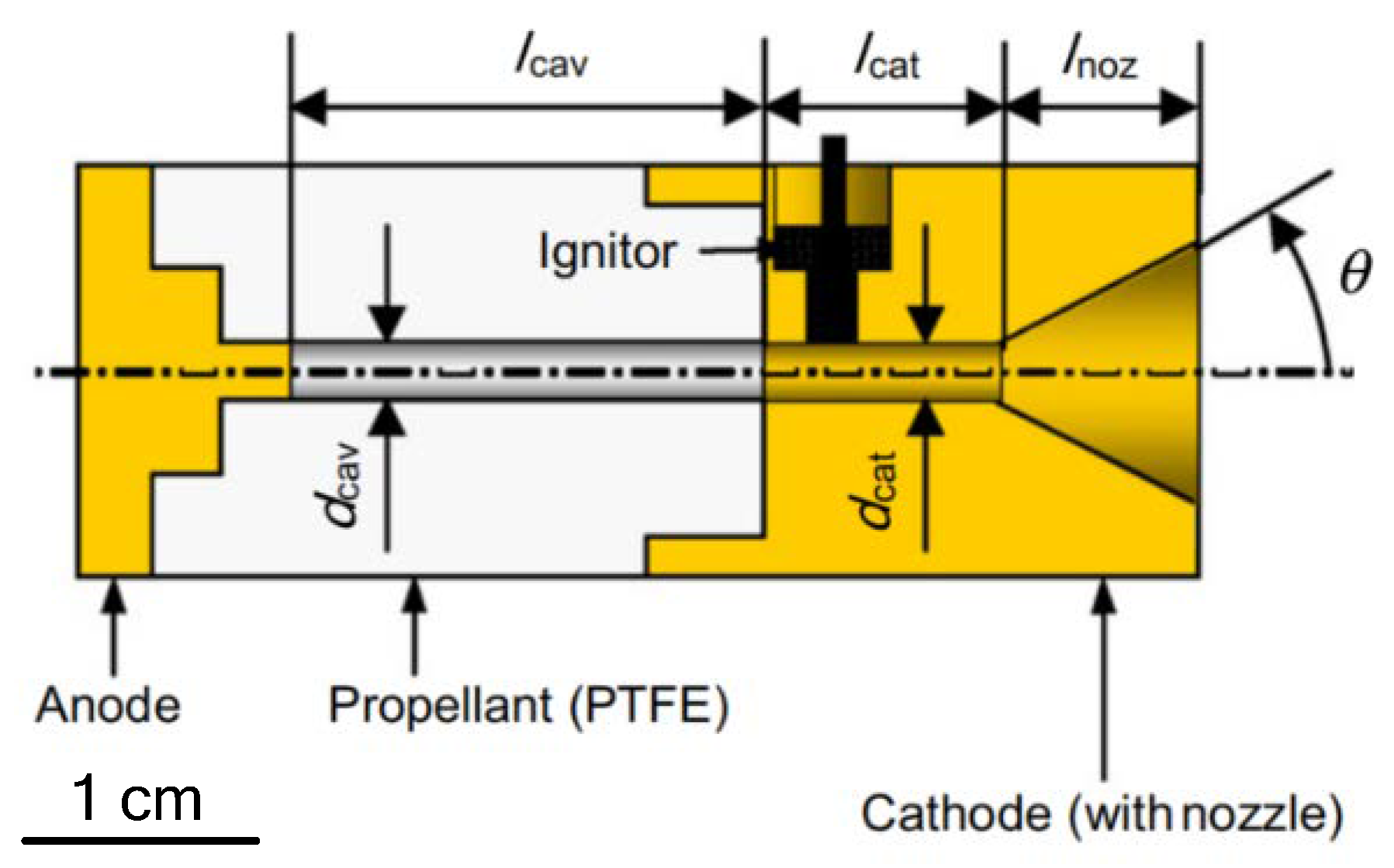

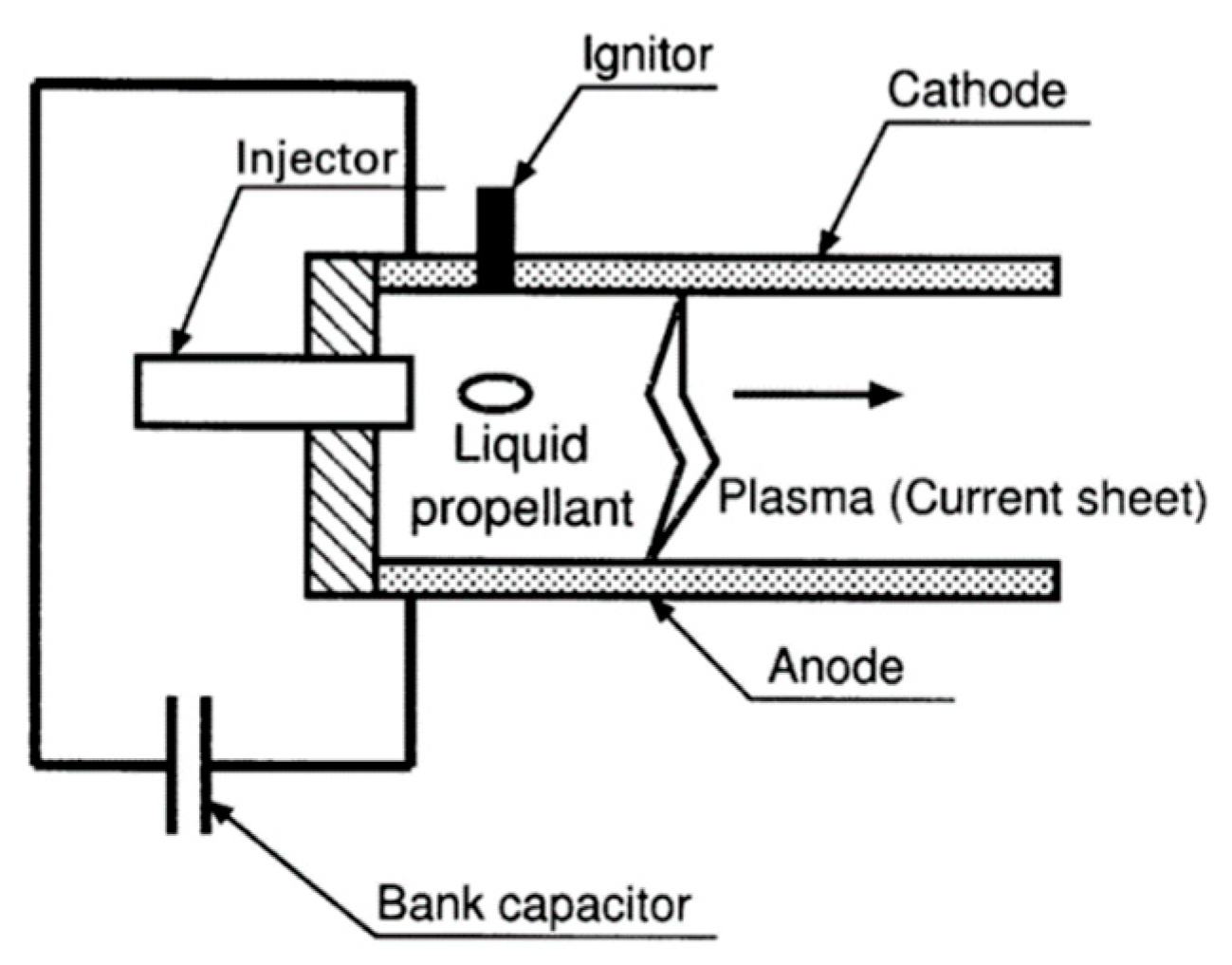

4.2. Liquid/Solid Propellant Pulsed Plasma Microthruster

4.3. Summary and Comparison

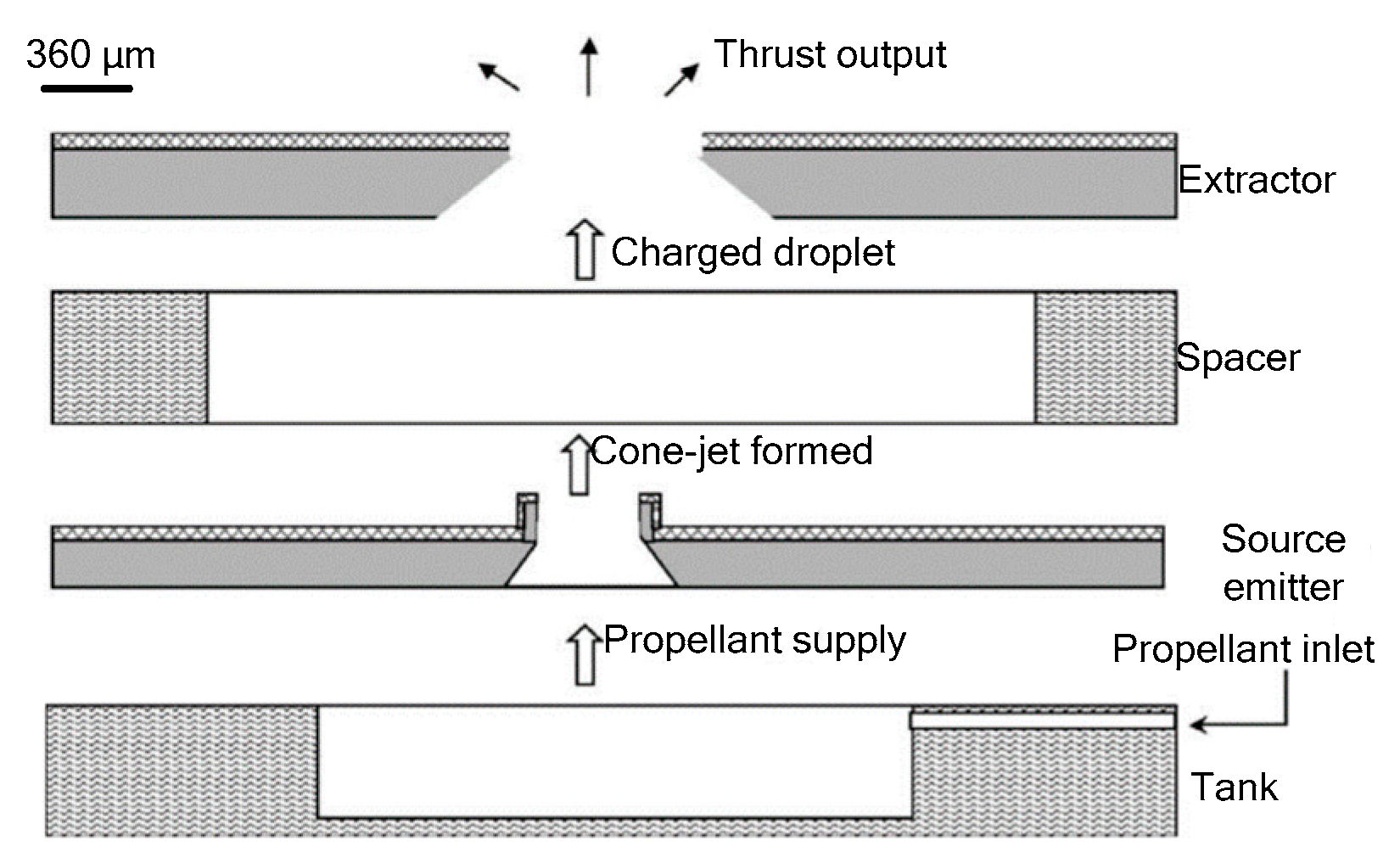

5. Colloid Microthruster

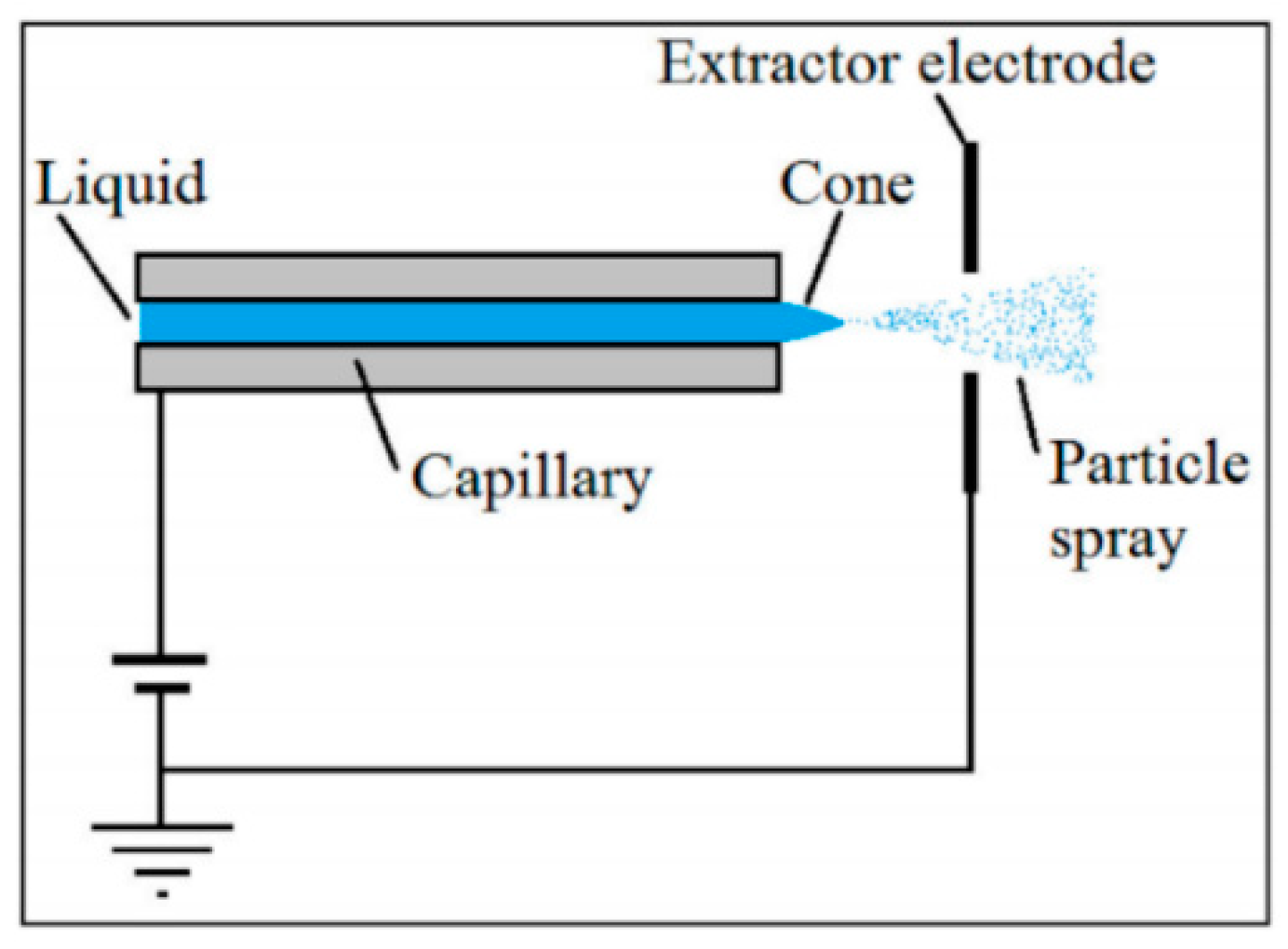

6. Electrospray Microthruster

7. Free Molecular Micro-Resistojet (FMMR)

8. Cold Gas Microthrusters (CGM)

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gao, Y.; Ma, Y.F.; Liu, J.T. A review of the vaporizing liquid microthruster technology. In Proceedings of the 6th International Symposium on Fluid Machinery and Fluid Engineering, Wuhan, China, 22–22 October 2014. [Google Scholar]

- Mueller, J. A review and applicability assessment of MEMS-based microvalve technologies for microspacecraft propulsion. In Proceedings of the 35th AIAA Joint Propulsion Conference and Exhibit, Los Angeles, CA, USA, 20–24 June 1999. [Google Scholar]

- Mueller, J.; Yang, E.H.; Green, A.A. Design and fabrication of MEMS-based micropropulsion devices at JPL. In Proceedings of the SPIE-The International Society for Optical Engineering, San Francisco, CA, USA, 2 October 2001; pp. 57–71. [Google Scholar]

- Judy, J.W. Microelectromechanical systems (MEMS): Fabrication, design and applications. Smart Mater. Struct. 2001, 10, 1115–1134. [Google Scholar] [CrossRef]

- Seymour, J.; Wu, F.; Wise, K.; Yoon, E. State-of-the-art MEMS and microsystem tools for brain research. Microsyst. Nanoeng. 2017, 3, 16066. [Google Scholar] [CrossRef] [PubMed]

- Ru, C.B.; Ye, Y.H.; Wang, C.L.; Zhu, P.; Shen, R.Q.; Hu, Y.; Wu, L.Z. Design and fabrication of MEMS-based solid propellant microthrusters array. Appl. Mech. Mater. 2014, 490, 1042–1046. [Google Scholar] [CrossRef]

- Bartsch, M.S.; Mccrink, M.H.; Crocker, R.W.; Mosier, B.P.; Peterson, K.A.; Wally, K.; Patel, K.D. Electrokinetically pumped liquid propellant microthrusters for orbital station keeping. In Proceedings of the IEEE International Conference on Solid-state Sensors Actuators (Transducers) & Microsystem, Lyon, France, 10–14 June 2007; Volume 657, pp. 1–25. [Google Scholar]

- Huang, J.; Rozelle, S.; Zhang, L. Effect of micro cooling channels on a hydrogen peroxide monopropellant microthruster performance. In Proceedings of the 15th International Conference on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (PowerMEMS 2015), Boston, MA, USA, 1–4 December 2015. [Google Scholar]

- Ketsdever, A.D.; Micci, M.M. Vaporizing liquid microthruster concept: Preliminary results of initial feasibility studies. Micropropuls. Small Spacecr. 2012, 8, 215–230. [Google Scholar]

- Bidabadi, M.; Heidari, M.A.; Rahbari, A. A novel analytical model of a MEMS vaporizing liquid micro thruster. In Proceedings of the 2nd IEEE International Conference on Computer and Automation Engineering (ICCAE), Singapore, 26–28 February 2010; Volume 5, pp. 26–28. [Google Scholar]

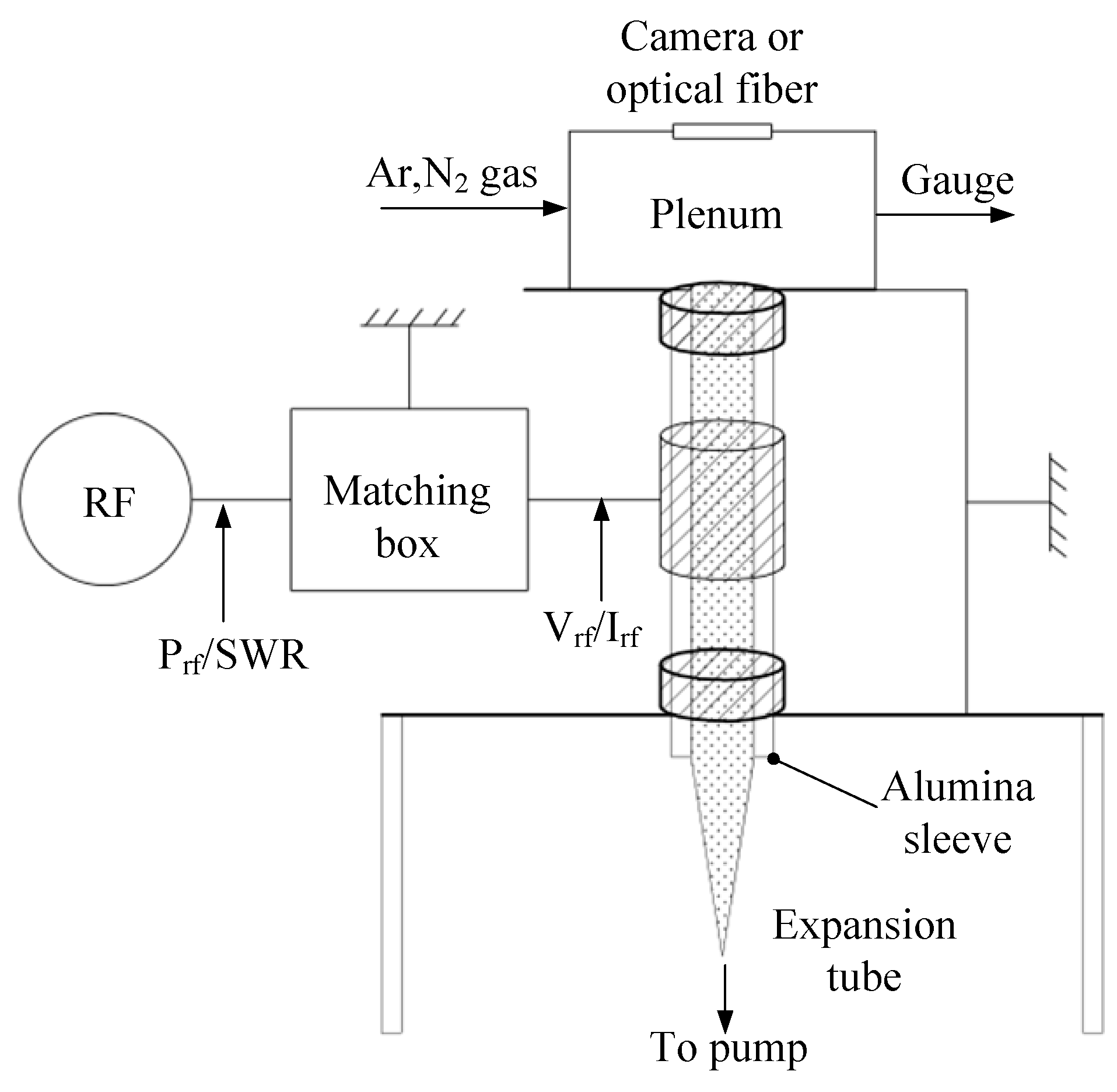

- Christine, C.; Roderick, B.; Andrew, B.; Vadim, K.; Edwin, S. Direct Measurement of Axial Momentum Imparted by an Electrothermal Radiofrequency Plasma Micro-Thruster. Frontiers in Physics. 2016, 4, 19. [Google Scholar]

- Greig, A.; Charles, C.; Boswell, R. Plume characteristics of an electrothermal plasma microthruster. IEEE Trans. Plasma Sci. 2014, 42, 2728–2729. [Google Scholar] [CrossRef]

- Dextre, R.A.; Xu, K.G. Effect of the Split-Ring Resonator Width on the Microwave Microplasma Properties. IEEE Trans. Plasma Sci. 2017, 45, 215–222. [Google Scholar] [CrossRef]

- Lenguito, G.; Gomez, A. Development of a multiplexed electrospray micro-thruster with post-acceleration and beam containment. J. Appl. Phys. 2013, 114, 154901. [Google Scholar] [CrossRef]

- Courtney, D.G.; Shea, H. Fragmentation in time-of-flight spectrometry-based calculations of ionic electrospray thruster performance. J. Propuls. Power. 2015, 38, 1–5. [Google Scholar] [CrossRef]

- Ober, S.; Branam, R.; Huffman, R.; Demmons, N.; Martin, R. Electrospray thruster for CubeSat. In Proceedings of the 49th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010. [Google Scholar]

- Beynon, J.C.; Zafran, S. Colloid microthruster system life test. J. Spacecr. Rocket. 2015, 8, 140–146. [Google Scholar]

- Zafran, S.; Kemp, R.F. Colloid microthruster test stand. J. Spacecr. Rocket. 2015, 6, 1144–1147. [Google Scholar] [CrossRef]

- Morris, T.; Forget, M.; Malardier-Jugroot, C.; Jugroot, M. Multi-scale investigation of a colloid micro-propulsion system. Plasma Process. Polym. 2011, 8, 478–489. [Google Scholar] [CrossRef]

- Ketsdever, A.; Green, A.; Muntz, E.P.; Vargo, S.E. Fabrication and testing of the free molecule micro-resistojet-initial results. In Proceedings of the 36th AIAA Joint Propulsion Conf. Exhibit, Las Vegas, NV, USA, 24–28 July 2000. [Google Scholar]

- Wong, J.T.S. Validation and optimization of a MEMS propulsion concept: The free molecule micro-resistojet. Diss. Abstr. Int. 2003, 64, 1350. [Google Scholar]

- Xu, X.M.; Li, X.C.; Zhou, J.; Zhang, B.J.; Xiao, D.B.; Huang, Y.Y.; Wu, X.Z. Numerical and experimental analysis of cold gas microthruster geometric parameters by univariate and orthogonal method. Microsyst. Tech. 2017, 23, 5003–5016. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, J.; Zhang, X.; Wang, Y. Optimization design of electromagnetic-driving schemes of a cold gas micro-thruster. China Mech. Eng. 2017, 28, 1034–1038. [Google Scholar]

- Sturesson, P.; Seton, R.; Klintberg, L.; Thornell, G.; Persson, A. Effect of Resistive and Plasma Heating on the Specific Impulse of a Ceramic Cold Gas Thruster. J. Microelectr. Syst. 2019, 28, 1–10. [Google Scholar] [CrossRef]

- Williams, K.L.; Eriksson, A.B.; Thorslund, R.; Köhler, J.; Boman, M.; Stenmark, L. The electrothermal feasibility of carbon microcoil heaters for cold/hot gas microthrusters. J. Micromech. Microeng. 2006, 16, 1154–1161. [Google Scholar] [CrossRef]

- Lewis, D.H., Jr.; Janson, S.W.; Cohen, R.B.; Antonsson, E.K. Digital micropropulsion. Sens. Actuators A Phys. 2000, 80, 143–154. [Google Scholar] [CrossRef]

- Rossi, C.; Briand, D.; Dumonteuil, M.; Camps, T.; Pham, P.Q.; Rooij, N.F. Matrix of 10 × 10 addressed solid propellant microthrusters: Review of the technologies. Sens. Actuators A Phys. 2006, 126, 241–252. [Google Scholar] [CrossRef]

- Rossi, C.; Scheid, E.; Estève, D. Theoretical and experimental study of silicon micromachined microheater with dielectric stacked membranes. Sens. Actuators A Phys. 1997, 63, 183–189. [Google Scholar] [CrossRef]

- Fabre, N.; Conedera, V. Design, fabrication, and thrust prediction of solid propellant microthrusters for space application. In Proceedings of the SPIE-The Int. Society for Optical Engineering, Paris, France, 10 March 1999; Volume 3680, pp. 906–916. [Google Scholar]

- Vondra, R.J.; Thomassen, K.I. Performance improvements in solid fuel microthrusters. J. Spacecr. Rocket. 1972, 9, 738–742. [Google Scholar] [CrossRef]

- Larangot, B.; Rossi, C.; Camps, T.; Berthold, A.; Pham, P.Q.; Briand, D.; Rooij, N.F.; Puig-Vidal, M.; Miribel, P.; Montane, E.; et al. Solid propellant micro-rockets-towards a new type of power MEMS. In Proceedings of the Nano Tech 2002—At the Edge of Revolution, Houston, TX, USA, 9–12 September 2002. [Google Scholar]

- Briand, D.; Phuong, Q.P.; Rooij, N.F.D. Reliability of freestanding polysilicon microheaters to be used as igniters in solid propellant microthrusters. Sens. Actuators A Phys. 2007, 135, 329–336. [Google Scholar] [CrossRef]

- Rossi, C.; Orieux, S.; Larangot, B.; Conto, T.D.; Esteve, D. Design, fabrication and modeling of solid propellant microrocket-application to micropropulsion. Sens. Actuators A Phys. 2002, 99, 125–133. [Google Scholar] [CrossRef]

- Rossi, C.; Larangot, B.; Pham, P.Q.; Briand, D.; Rooij, N.F. Solid Propellant Microthrusters on Silicon: Design, Modeling, Fabrication, and Testing. J. Microelectromech. Syst. 2006, 15, 1805–1815. [Google Scholar] [CrossRef]

- Tanaka, S.; Hosokawa, R.; Tokudome, S.; Hori, K.; Saito, H.; Watanabe, M.; Esashi, M. MEMS-based solid propellant rocket array thruster with electrical feedthroughs. Trans. Jpn. Soc. Aeronaut. Space Sci. 2003, 46, 47–51. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.; Kwon, S. Design, fabrication, and testing of MEMS solid propellant thruster array chip on glass wafer. Sens. Actuators A Phys. 2010, 157, 126–134. [Google Scholar] [CrossRef]

- Baroncini, M.; Placidi, P.; Scorzoni, A.; Cardinali, G.C.; Dori, L.; Nicoletti, S. Characterization of an embedded micro-heater for gas sensors application. In Proceedings of the International Symposium on VLSI Technology, Hsinchu, Taiwan, China, 18–20 April 2001; pp. 164–167. [Google Scholar]

- Niklaus, F.; Stemme, G.; Lu, J.Q.; Gutmann, R.J. Adhesive wafer bonding. J. Appl. Phys. 2006, 99, 2–27. [Google Scholar] [CrossRef]

- Tong, Q.Y.; Cha, G.; Gafiteanu, R.; Gosele, U. Low temperature wafer direct bonding. J. Microelectromech. Syst. 1994, 3, 29–35. [Google Scholar] [CrossRef]

- Ru, C.B.; Ye, Y.H.; Xu, J.B.; Zou, Z.Y.; Dai, J.; Zhu, P.; Shen, R.Q. Low temperature eutectic alloy bonding used in MEMS-based solid propellant microthrusters array. Key Eng. Mater. 2015, 645, 184–189. [Google Scholar] [CrossRef]

- Ru, C.B.; Wang, F.; Xu, J.B.; Dai, J.; Shen, Y.; Ye, Y.H.; Zhu, P.; Shen, R.Q. Superior performance of a MEMS-based solid propellant microthruster (SPM) array with nanothermites. Microsyst. Tech. 2017, 23, 3161–3174. [Google Scholar] [CrossRef]

- Staley, C.S.; Raymond, K.E.; Thiruvengadathan, R.; Apperson, S.J.; Gangopadhyay, K.; Swaszek, S.M.; Taylor, R.J.; Gangopadhyay, S. Fast-impulse nanothermite solid-propellant miniaturized thrusters. J. Propuls. Power 2014, 29, 1400–1409. [Google Scholar] [CrossRef]

- Staley, C.S.; Raymond, K.E.; Thiruvengadathan, R.; Herbst, J.J.; Swaszek, S.M.; Taylor, R.J.; Gangopadhyay, K.; Gangopadhyay, S. Effect of nitrocellulose gasifying binder on thrust performance and high-g launch tolerance of miniaturized nanothermite thrusters. Propellants Explos. Pyrotech. 2014, 39, 374–382. [Google Scholar] [CrossRef]

- Apperson, S.; Shende, R.; Subramanian, S.; Tappmeyer, D.; Gangopadhyay, S.; Chen, Z.; Gangopadhyay, K.; Redner, P.; Nicholich, S.; Kapoor, D. Generation of fast propagating combustion and shock waves with copper oxide/aluminum nanothermite composites. Appl. Phys. Lett. 2007, 91, 243109. [Google Scholar] [CrossRef]

- Apperson, S.J.; Bezmelnitsyn, A.V.; Thiruvengadathan, R.; Gangopadhyay, K.; Gangopadhyay, S.; Balas, W.A.; Anderson, P.E.; Nicolich, S.M. Characterization of nanothermite material for solid-fuel microthruster applications. J. Propuls. Power 2009, 25, 1086–1091. [Google Scholar] [CrossRef]

- Liu, X.; Li, T.; Li, Z.; Ma, H.P.; Fang, S.Z. Design, fabrication and test of a solid propellant microthruster array by conventional precision machining. Sens. Actuators A Phys. 2015, 236, 214–227. [Google Scholar] [CrossRef]

- Zhang, K.L.; Chou, S.K.; Ang, S.S. MEMS-based solid propellant microthruster design, simulation, fabrication and testing. J. Microelectromech. Syst. 2004, 13, 165–175. [Google Scholar] [CrossRef]

- Zhang, K.L.; Chou, S.K.; Ang, S.S.; Tang, X.S. A MEMS-based solid propellant microthruster with Au/Ti igniter. Sens. Actuators A Phys. 2005, 122, 113–123. [Google Scholar] [CrossRef]

- Zhang, K.L.; Chou, S.K.; Ang, S.S. Development of a low-temperature co-fired ceramic solid propellant microthruster. J. Micromech. Microeng. 2005, 15, 944–952. [Google Scholar] [CrossRef]

- Chaalane, A.; Chemam, R.; Houabes, M.; Yahiaoui, R.; Metatla, A.; Ouari, B.; Metatla, N.; Mahi, D.; Dkhissi, A.; Esteve, D. A MEMS-based solid propellant microthruster array for space and military applications. J. Phys. Conf. Ser. 2015, 660, 012137. [Google Scholar] [CrossRef]

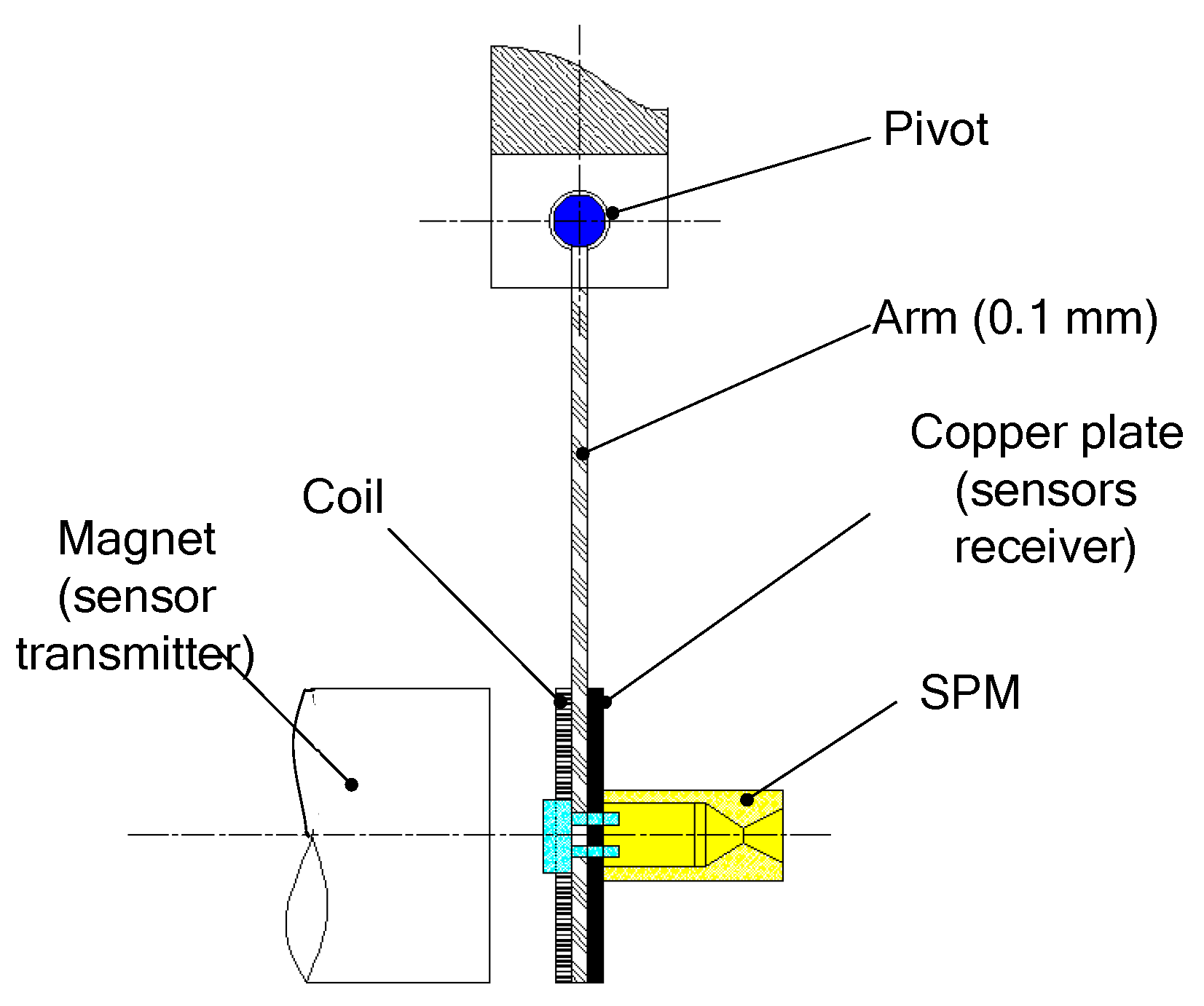

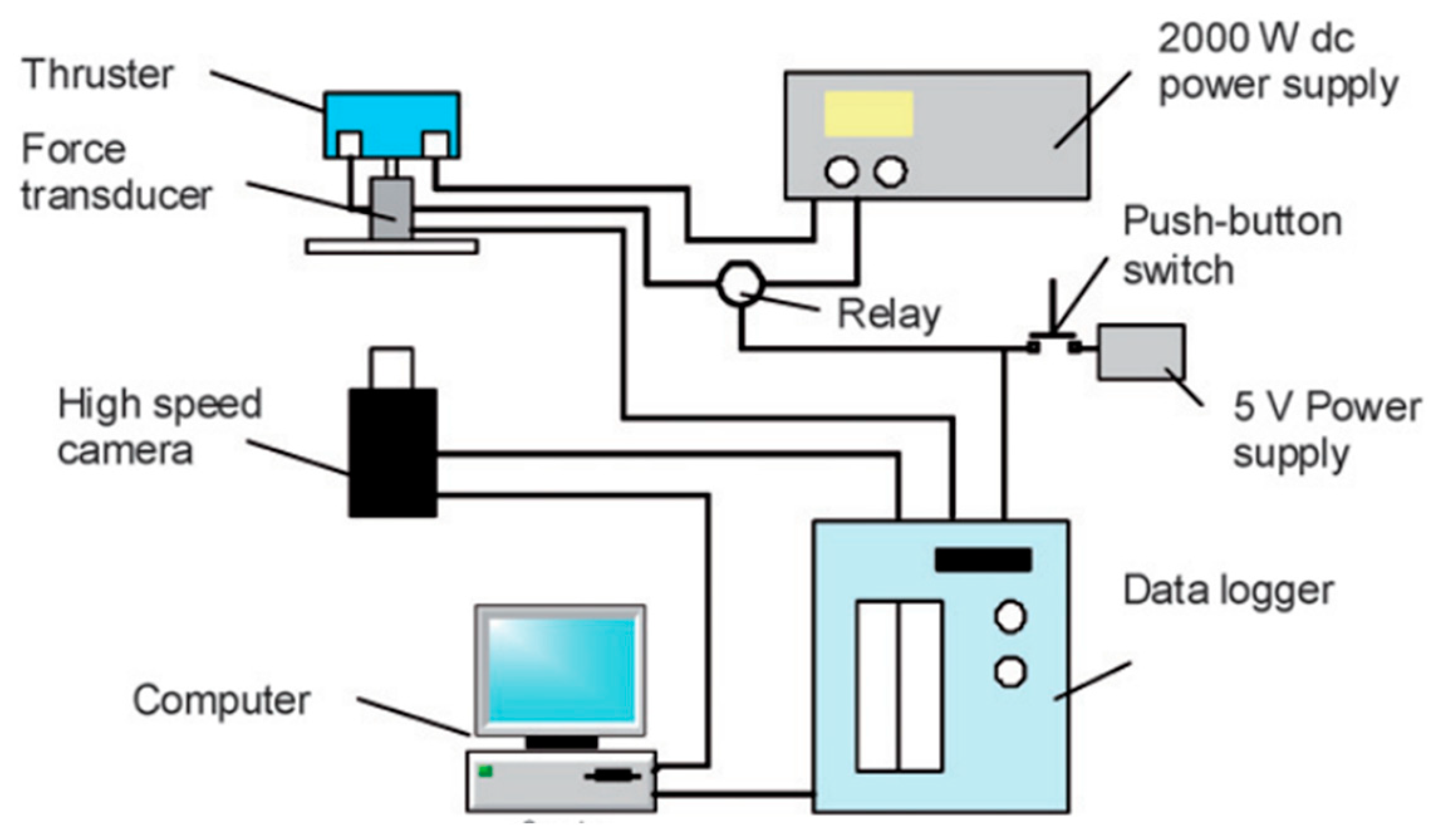

- Orieux, S.; Rossi, C.; EsteVe, D. Thrust stand for ground tests of solid propellant microthrusters. Rev. Sci. Instrum. 2002, 73, 2694–2698. [Google Scholar] [CrossRef]

- You, Z.; Zhang, G.; Lin, Y.; Songqi, H.; Li, B.; Liu, Z. MEMS-based propulsion with solid propellant for micro satellite. In Proceedings of the 2nd International Conference on Recent Advances in Space Technologies, Istanbul, Turkey, 9–11 June 2005; p. 213. [Google Scholar]

- Rossi, C.; Larangot, B.; Lagrange, D.; Chaalane, A. Final characterizations of MEMS-based pyrotechnical microthrusters. Sens. Actuators A Phys. 2005, 121, 508–514. [Google Scholar] [CrossRef]

- Sathiyanathan, K.; Lee, R.; Chesser, H.; Dubois, C.; Stowe, R.; Farinaccio, R.; Ringuette, S. Solid propellant microthruster design for nanosatellite applications. J. Propuls. Power 2013, 27, 1288–1294. [Google Scholar] [CrossRef]

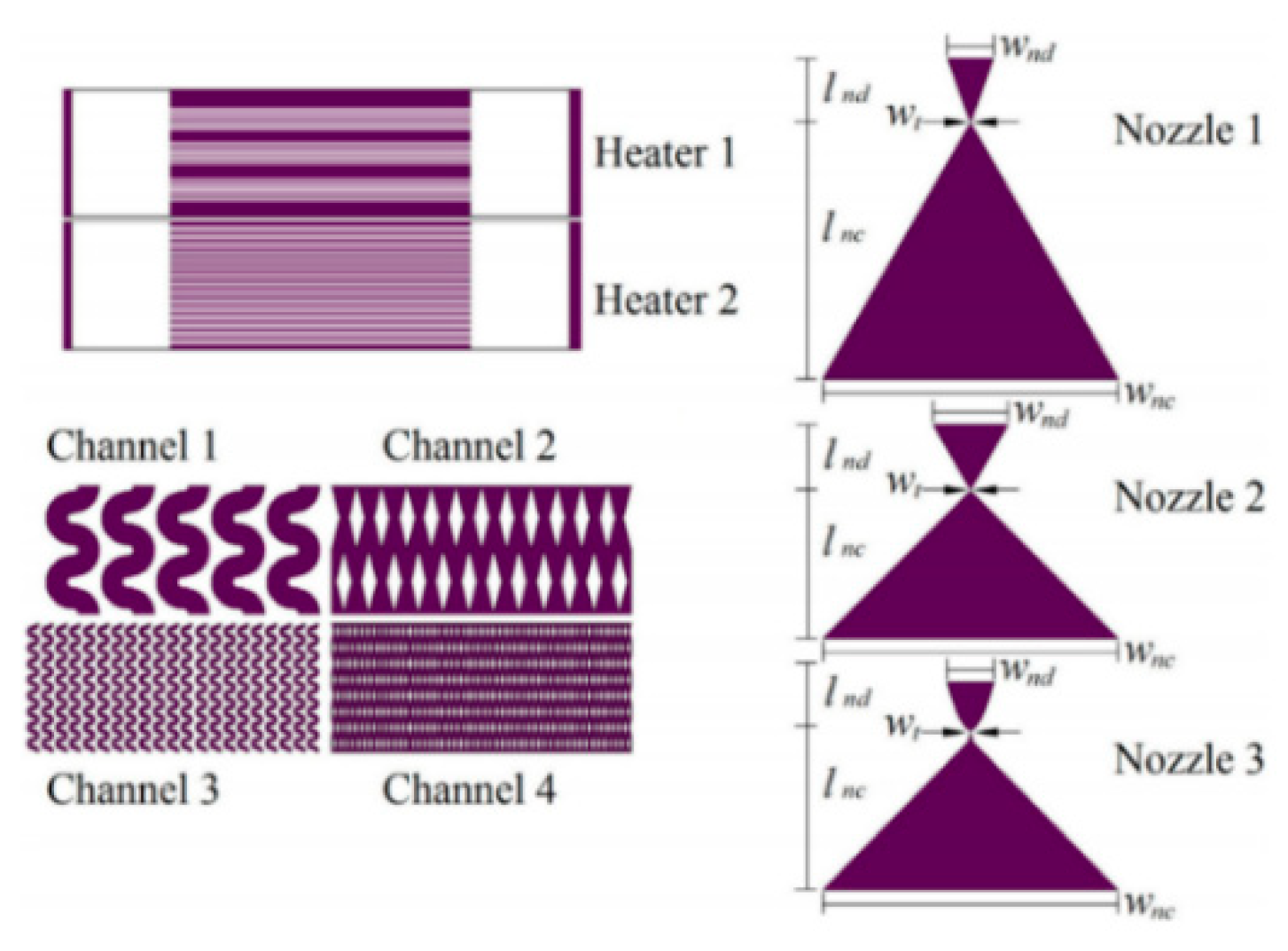

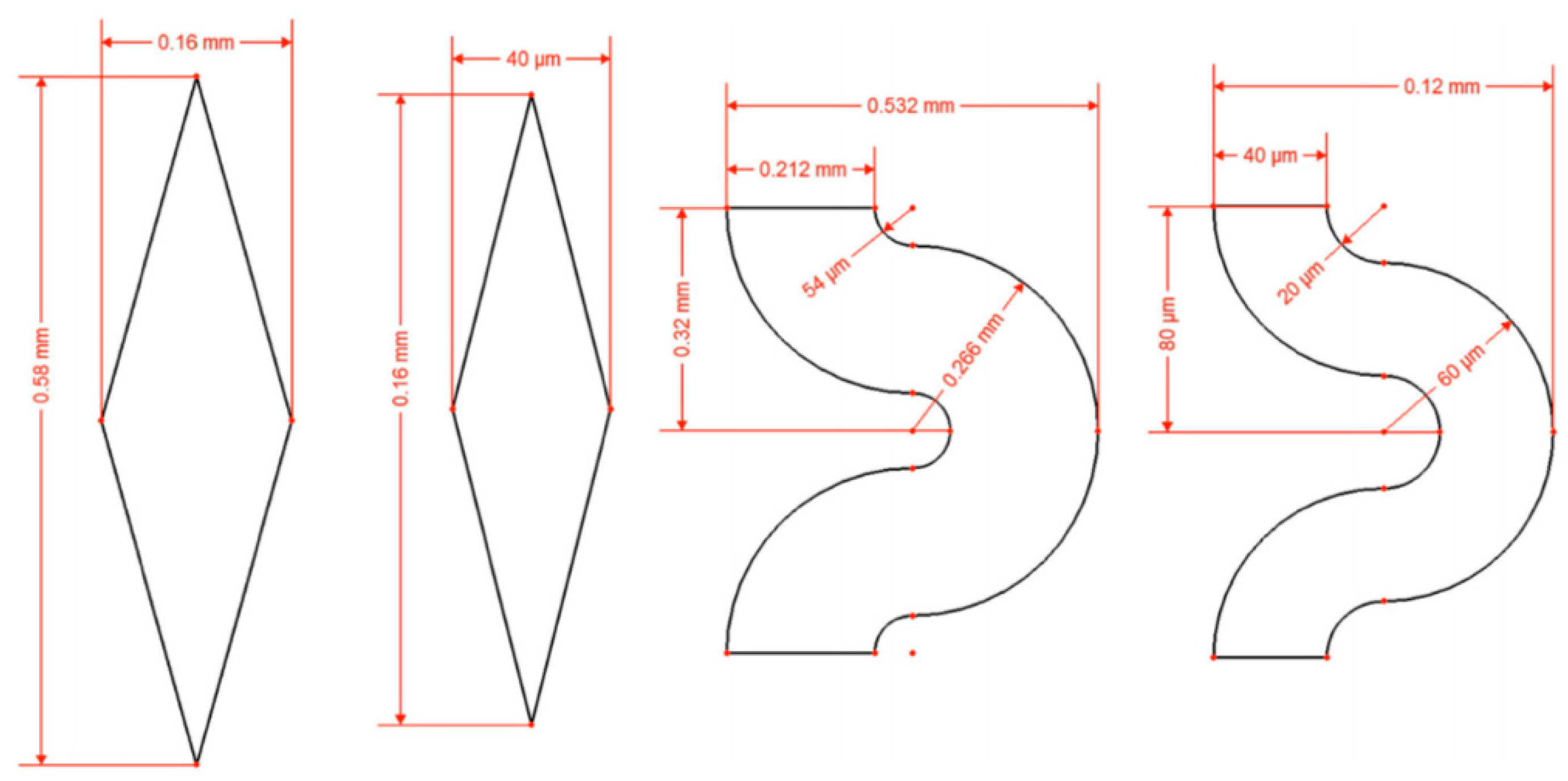

- Shen, Q.; Yuan, W.; Li, X.; Xie, J.; Chang, H. An orthogonal analysis method for decoupling the nozzle geometrical parameters of microthrusters. Microsyst. Tech. 2014, 21, 1157–1166. [Google Scholar] [CrossRef]

- Teasdale, D.; Milanovic, V.; Chang, P.; Pister, K.S.J. Microrockets for smart dust. Smart Mater. Struct. 2001, 10, 1145–1155. [Google Scholar] [CrossRef]

- Rusek, J.J. Future of hydrogen peroxide for space propulsion and power applications. In Proceedings of the First International Conference on Green Propellants for Space Propulsion, European Space Agency, Noordwyk, The Netherland, 20–22 January 2001. [Google Scholar]

- Wu, M.H.; Yetter, R.A. A novel electrolytic ignition monopropellant microthruster based on low temperature co-fired ceramic tape technology. Lab. Chip 2009, 9, 910–916. [Google Scholar] [CrossRef]

- Vissotski, A. Towards optimization of a low temperature co-fired ceramic catalyst chamber for a monopropellant microthruster. Mech. Eng. 2010, 87–99. [Google Scholar]

- Cheah, K.H.; Khiew, P.S.; Chin, J.K. Fabrication of a zirconia MEMS-based microthruster by gel casting on PDMS soft molds. J. Micromech. Microeng. 2012, 22, 095013. [Google Scholar] [CrossRef]

- Rao, G.R.; Sahu, H.R.; Mishra, B.G. Surface and catalytic properties of Cu-Ce-O composite oxides prepared by combustion method. Colloids Surf. A Physicochem. Eng. Asp. 2003, 220, 261–269. [Google Scholar] [CrossRef]

- Selim, M.M.; El-Aiashi, M.K.; Mazhar, H.S.; Kamal, S.M. Decomposition of H2O2 over manganese chromium oxide catalyst in aqueous and alkaline solutions. Mater. Lett. 1996, 28, 417–421. [Google Scholar] [CrossRef]

- Parida, K.M.; Dash, S.S.; Mallik, S.; Das, J. Effect of heat treatment on the physico-chemical properties and catalytic activity of manganese nodules leached residue towards decomposition of hydrogen peroxide. J. Colloid Interface Sci. 2005, 290, 431–436. [Google Scholar] [CrossRef]

- Luo, X.L.; Xu, J.J.; Zhao, W.; Chen, H.Y. A novel glucose ENFET based on the special reactivity of MnO2 nanoparticles. Biosens. Bioelectron. 2004, 19, 1295–1300. [Google Scholar] [CrossRef] [PubMed]

- Hitt, D.L.; Zakrzwski, C.M.; Thomas, M.A. MEMS-based satellite micropropulsion via catalyzed hydrogen peroxide decomposition. Smart Mater. Struct. 2001, 10, 1163–1175. [Google Scholar] [CrossRef]

- Kuan, C.K.; Chen, G.B.; Chao, Y.C. Development and ground tests of a 100-millinewton hydrogen peroxide monopropellant microthruster. J. Propuls. Power 2007, 23, 1313–1320. [Google Scholar] [CrossRef]

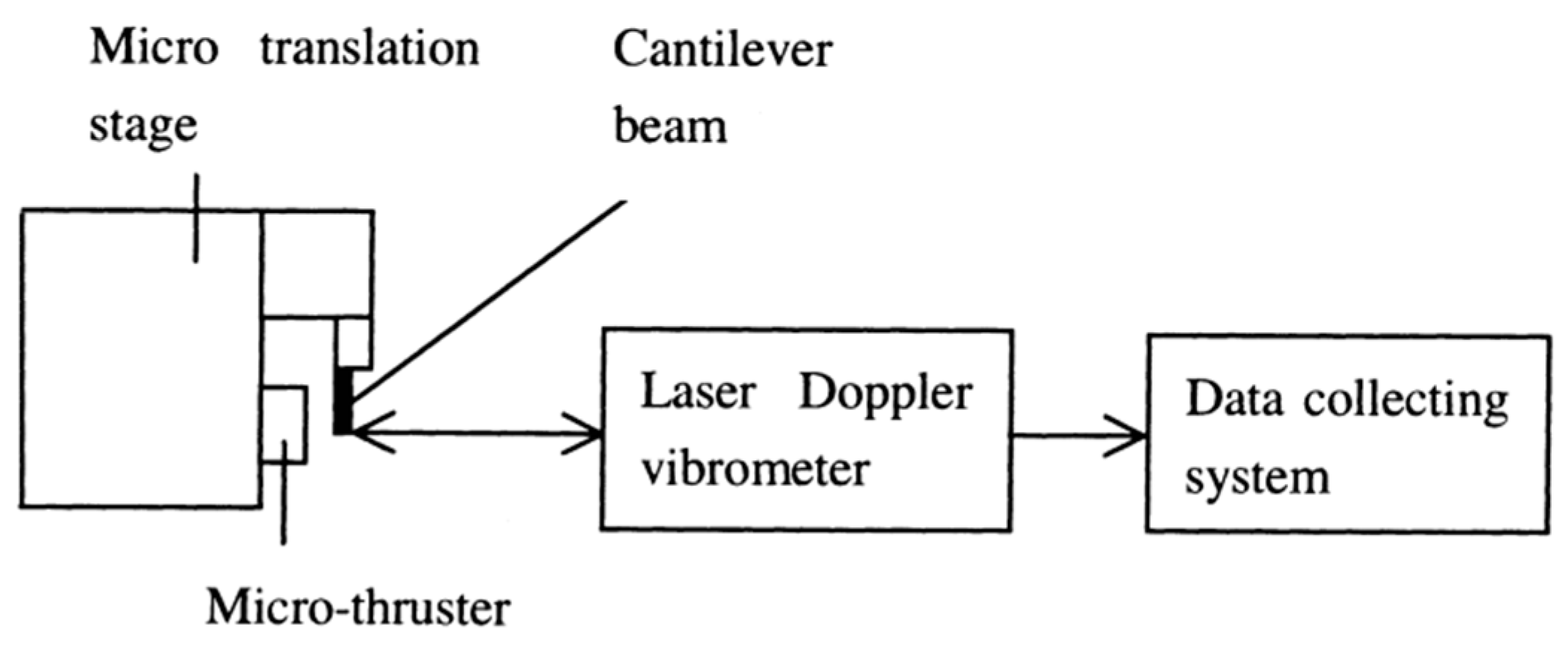

- Cen, J.W.; Xu, J.L. Performance evaluation and flow visualization of a MEMS based vaporizing liquid micro-thruster. Acta Astronaut. 2010, 67, 468–482. [Google Scholar] [CrossRef]

- Miyakawa, N.; Legner, W.; Ziemann, T.; Telitschkin, D.; Fecht, H.; Friedberger, A. MEMS-based microthruster with integrated platinum thin film resistance temperature detector (RTD), heater meander and thermal insulation for operation up to 1000 °C. Microsyst. Tech. 2012, 18, 1077–1087. [Google Scholar] [CrossRef]

- Kundu, P.; Sinha, A.K.; Bhattacharyya, T.K.; Das, S. Nanowire embedded hydrogen peroxide monopropellant MEMS thruster. J. Microelectromech. Syst. 2013, 22, 406–417. [Google Scholar] [CrossRef]

- Khaji, Z.; Klintberg, L.; Barbade, D.; Palmer, K.; Thornell, G. Alumina-based monopropellant microthruster with integrated heater, catalytic bed and temperature sensors. J. Phys. Conf. Ser. 2016, 757, 012–025. [Google Scholar] [CrossRef]

- Khaji, Z.; Klintberg, L.; Barbade, D.; Palmer, K.; Thornell, G. Endurance and failure of an alumina-based monopropellant microthruster with integrated heater, catalytic bed and temperature sensors. J. Micromech. Microeng. 2017, 27, 055011. [Google Scholar] [CrossRef]

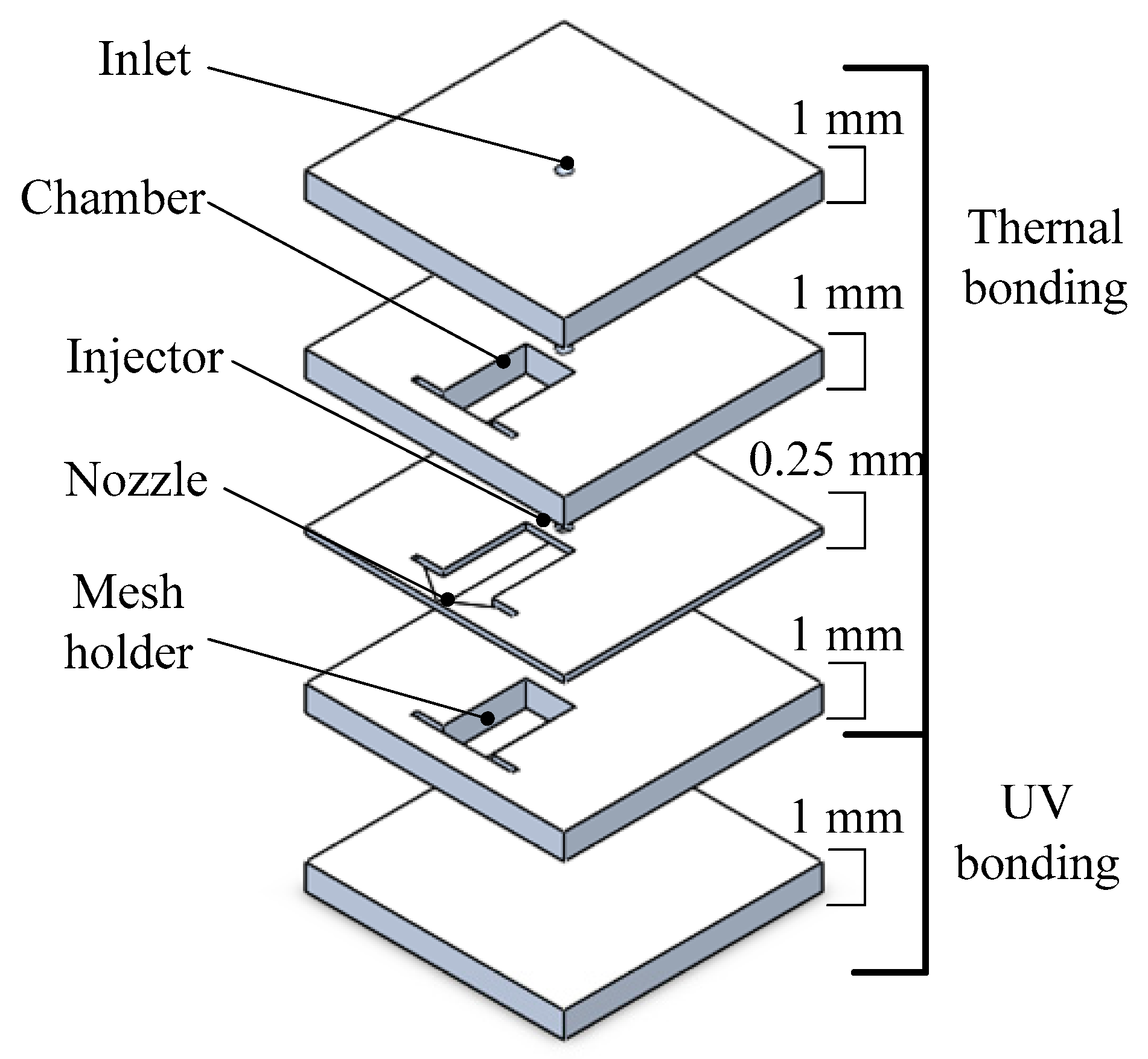

- Huh, J.; Kwon, S. Design, fabrication and thrust measurement of a micro liquid monopropellant thruster. J. Micromech. Microeng. 2014, 24, 104001. [Google Scholar] [CrossRef]

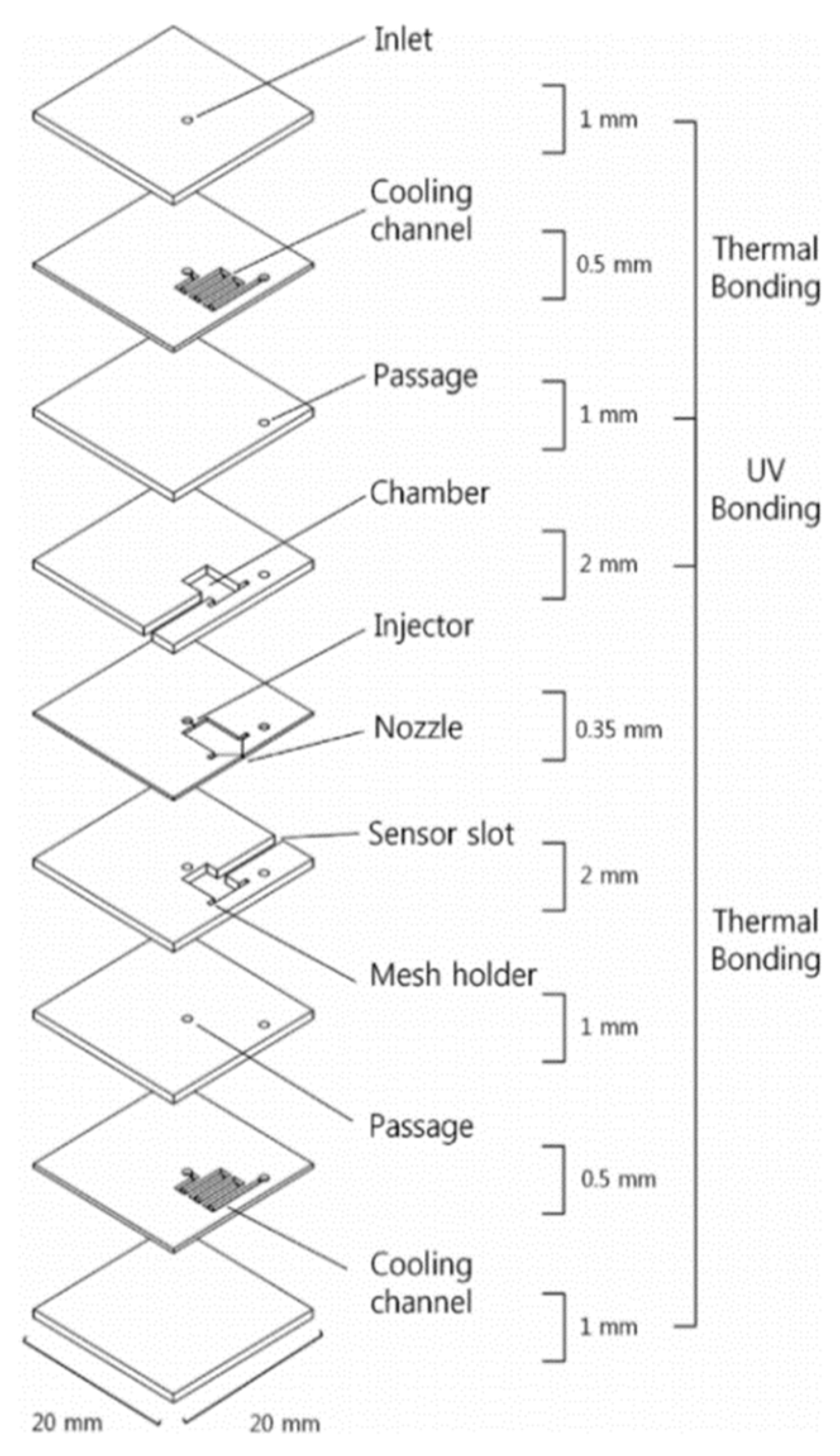

- Huh, J.; Seo, D.; Kwon, S. Fabrication of a liquid monopropellant microthruster with built-in regenerative micro-cooling channels. Sens. Actuators A Phys. 2017, 263, 332–430. [Google Scholar] [CrossRef]

- Mueller, J.; Tang, W.; Wallace, A. Design, analysis and fabrication of a vaporizing liquid micro-thruster. In Proceedings of the 33rd AIAA Joint Propulsion Conference Exhibit, Seattle, WA, USA, 6–9 July 1997. [Google Scholar]

- Ye, X.Y.; Tang, F.; Ding, H.Q. Study of a vaporizing water micro-thruster. Sens. Actuators A Phys. 2001, 89, 159–165. [Google Scholar] [CrossRef]

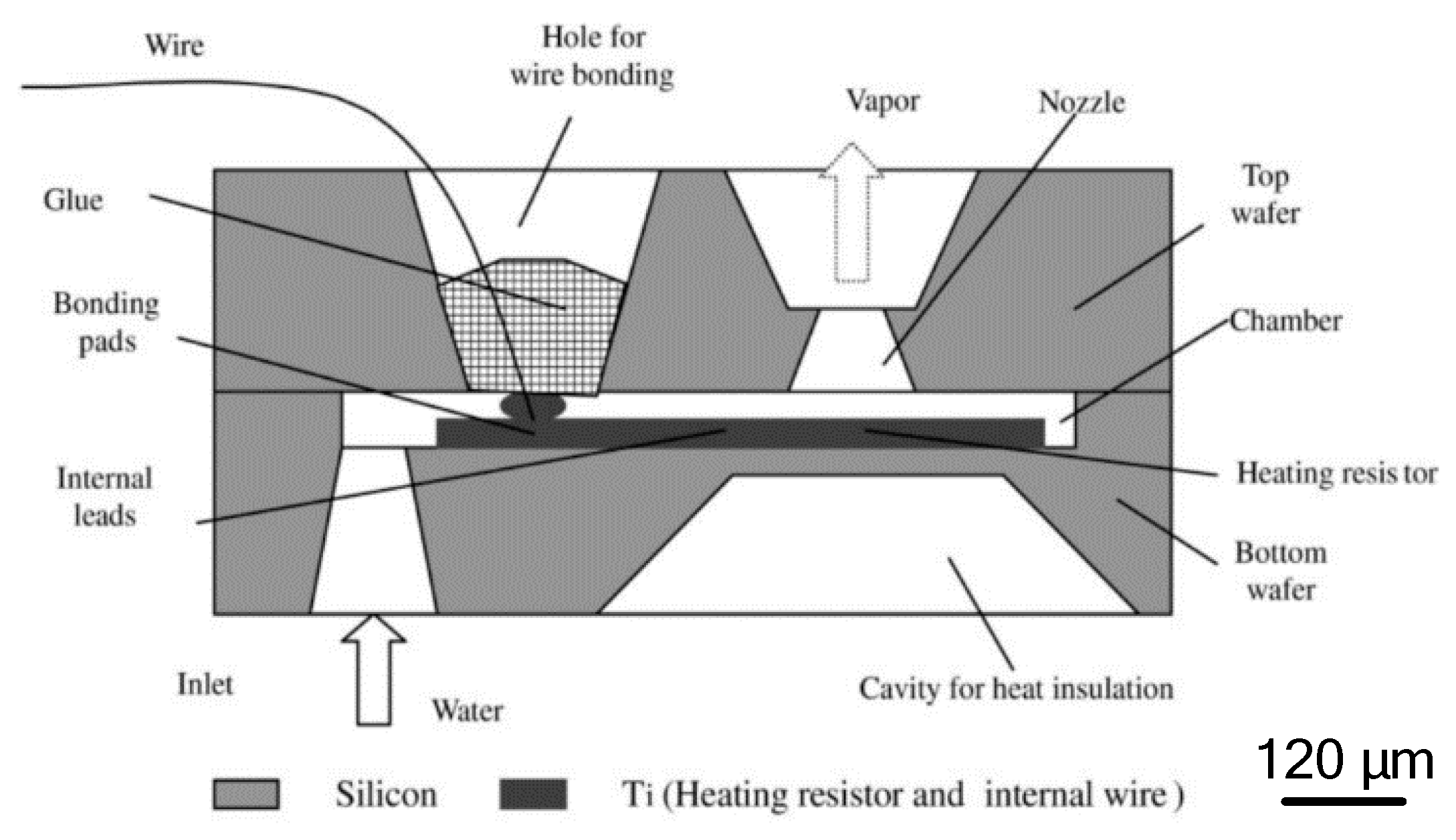

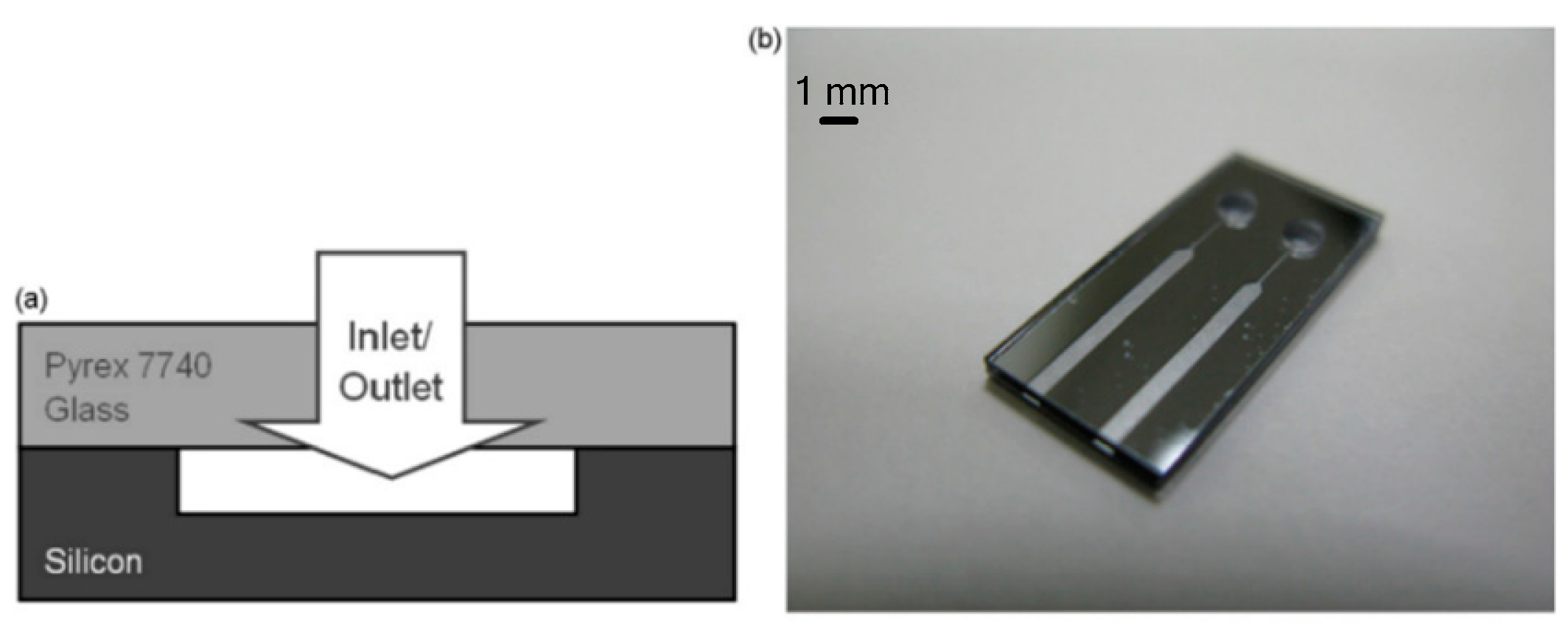

- Maurya, D.K.; Das, S.; Lahiri, S.K. Silicon MEMS vaporizing liquid microthruster with internal microheater. J. Micromech. Microeng. 2005, 15, 966–970. [Google Scholar] [CrossRef]

- Maurya, D.K.; Das, S.; Lahiri, S.K. An analytical model of a silicon MEMS vaporizing liquid microthruster and some experimental studies. Sens. Actuators A Phys. 2005, 122, 159–166. [Google Scholar] [CrossRef]

- Gongora-Rubio, M.R.; Espinoza-Vallejos, P.; Sola-Laguna, L.; Santiago-Avileas, J.J. Overview of low temperature co-fired ceramics tape technology for mesosystem technology (MsST). Sens. Actuators A Phys. 2001, 89, 222–224. [Google Scholar] [CrossRef]

- Karthikeyan, K.; Chou, S.K.; Khoong, L.E. Low temperature co-fired ceramic vaporizing liquid microthruster for microspacecraft applications. J. Appl. Energy 2012, 97, 577–583. [Google Scholar] [CrossRef]

- Cheah, K.H.; Low, K.S. Fabrication and performance evaluation of a high temperature co-fired ceramic vaporizing liquid microthruster. J. Micromech. Microeng. 2015, 25, 013–015. [Google Scholar] [CrossRef]

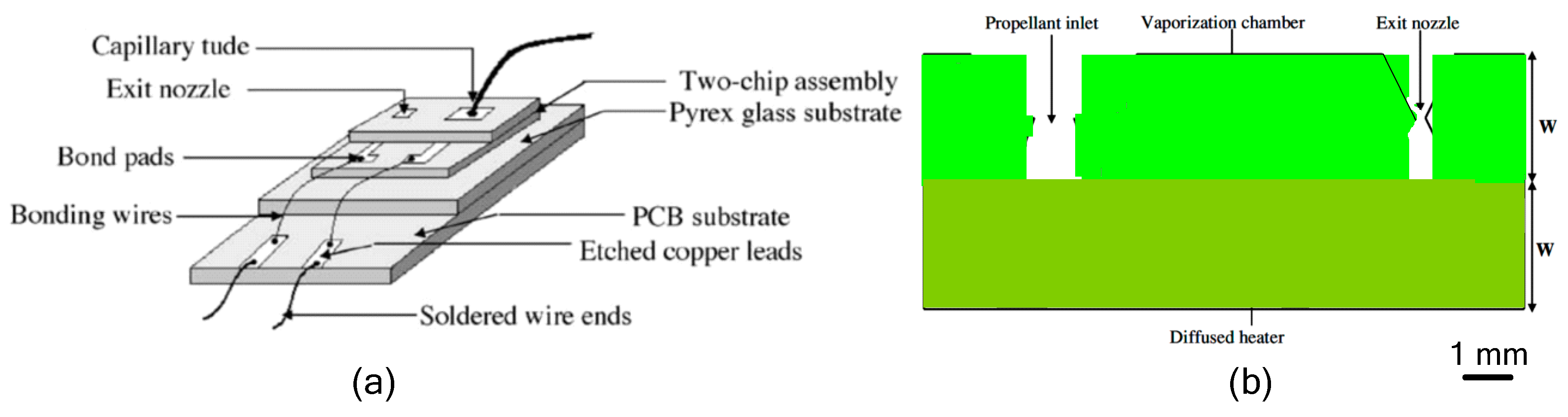

- Mukerjee, E.V.; Wallace, A.P.; Yan, K.Y. Vaporizing liquid microthruster. Sens. Actuators A Phys. 2000, 83, 231–236. [Google Scholar] [CrossRef]

- Kundu, P.; Bhattacharyya, T.K.; Das, S. Design, fabrication and performance evaluation of a vaporizing liquid microthruster. J. Micromech. Microeng. 2012, 22, 016–025. [Google Scholar] [CrossRef]

- Silva, M.A.C.; Guerrieri, D.C.; Henk, V.Z.; Cervone, A.; Gill, E. Vaporizing liquid microthrusters with integrated heaters and temperature measurement. Sens. Actuators A Phys. 2017, 265, 261–274. [Google Scholar] [CrossRef]

- Chen, C.C.; Liu, C.W.; Kan, H.C. Simulation and experiment research on vaporizing liquid micro-thruster. Sens. Actuators A Phys. 2010, 157, 140–149. [Google Scholar] [CrossRef]

- Guman, W.J.; Peko, P.E. Solid-propellant pulsed plasma microthruster studies. J. Spacecr. Rocket. 1968, 5, 732–733. [Google Scholar] [CrossRef]

- Greig, A.; Charles, C.; Paulin, N.; Boswell, R.W. Volume and surface propellant heating in an electrothermal radio-frequency plasma micro-thruster. Appl. Phys. Lett. 2014, 105, 054102. [Google Scholar] [CrossRef]

- Charles, C.; Boswell, R.W.; Bish, A. Low-weight fixed ceramic capacitor impedance matching system for an electrothermal plasma microthruster. J. Propuls. Power 2014, 30, 1117–1121. [Google Scholar] [CrossRef]

- Charles, C.; Bish, A.; Boswell, R.W.; Dedrick, J.; Greig, A.; Hawkins, R.; Ho, T.S. A short review of experimental and computational diagnostics for radiofrequency plasma micro-thrusters. Plasma Chem. Plasma Process. 2016, 36, 29–44. [Google Scholar] [CrossRef]

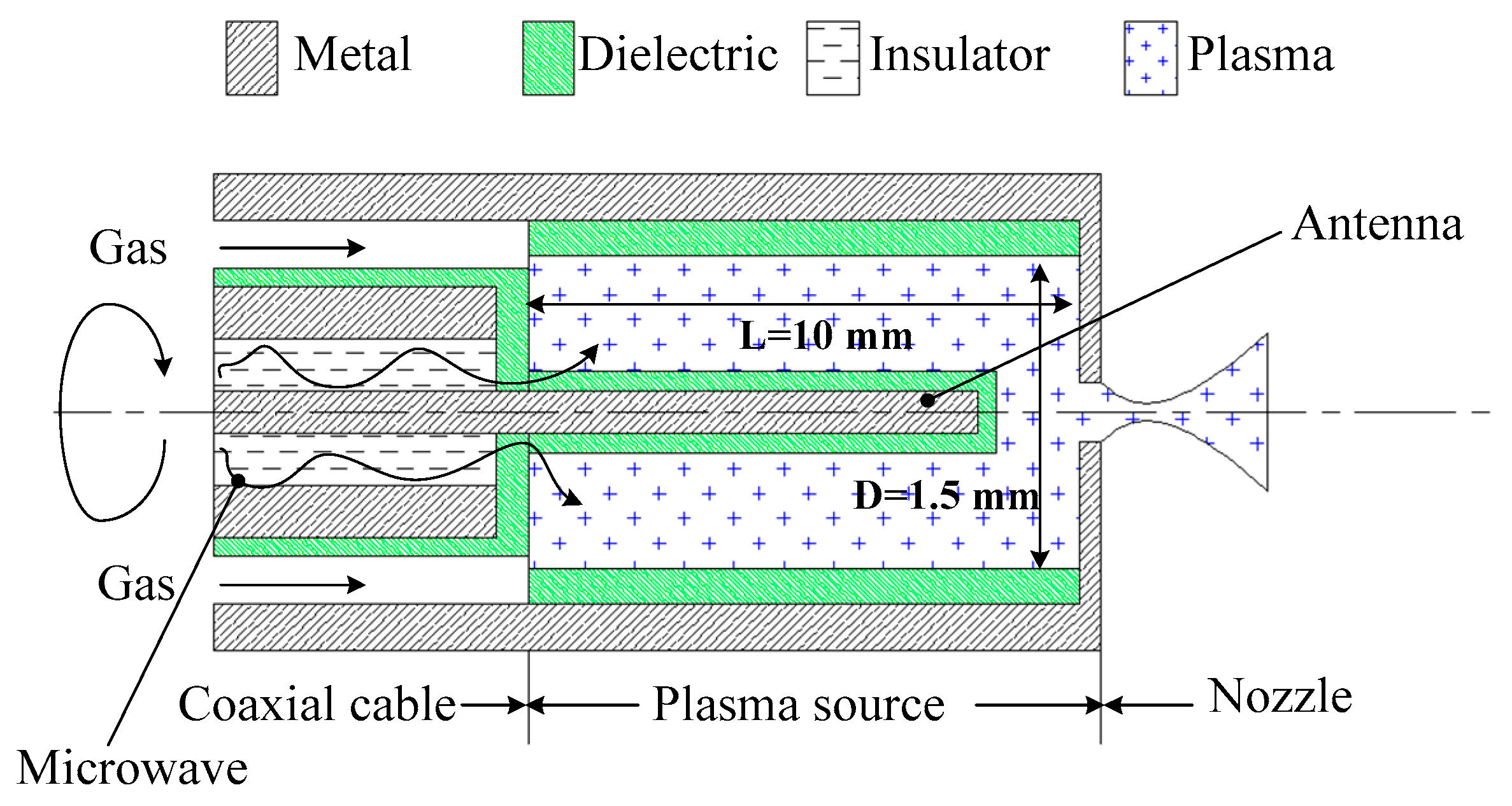

- Takahashi, T.; Takao, Y.; Eriguchi, K. Numerical and experimental study of microwave-excited microplasma and micronozzle flow for a microplasma thruster. Phys. Plasmas 2009, 16, 083505. [Google Scholar] [CrossRef]

- Takahashi, T.; Takao, Y.; Ichida, Y.; Eriguchi, K.; Ono, K. Microwave-excited microplasma thruster with helium and hydrogen propellants. Phys. Plasmas 2011, 18, 063505. [Google Scholar] [CrossRef]

- Greig, A.; Charles, C.; Hawkins, R.; Boswell, R. Direct measurement of neutral gas heating in a radio-frequency electrothermal plasma micro-thruster. Appl. Phys. Lett. 2013, 103, 163001. [Google Scholar] [CrossRef]

- Greig, A.; Charles, C.; Boswell, R.W. Spatiotemporal study of gas heating mechanisms in a radio-frequency electrothermal plasma micro-thruster. Front. Phys. 2015, 3, 00084. [Google Scholar] [CrossRef]

- Guman, W.J. Solid propellant pulsed plasma propulsion system design. J. Spacecr. Rocket. 1976, 13, 51–53. [Google Scholar] [CrossRef]

- Aoyagi, J.; Mukai, M.; Kamishima, Y.; Sasaki, T.; Shintani, K.; Takegahara, H.; Wakizono, T.; Sugiki, M. Total impulse improvement of coaxial pulsed plasma thruster for small satellite. Vacuum 2008, 83, 72–76. [Google Scholar] [CrossRef]

- Cooley, J.E.; Choueiri, E.Y. IR-assisted discharge initiation in pulsed plasma thrusters. In Proceedings of the 38th AIAA Joint Propulsion Conference Exhibit, Indianapolis, IN, USA, 7–10 July 2002. [Google Scholar]

- Kakami, A.; Koizumi, H.; Komurasaki, K.; Arakawa, Y. Design and performance of liquid propellant pulsed plasma thruster. Vacuum 2004, 73, 419–425. [Google Scholar] [CrossRef]

- Pranajaya, F.; Cappelli, M. Development of a colloid micro-thruster for flight demonstration on the Emerald nanosatellite. In Proceedings of the 37th AIAA Joint Propulsion Conference Exhibit, Salt Lake City, UT, USA, 8–11 July 2001. [Google Scholar]

- Velasquez, L.F.; Carretero, J.A.; Akinwande, A.I.; Martinez-Sanchez, M. The concept and development of a micro-fabricated colloid thruster array. In Proceedings of the 39th AIAA Joint Propulsion Conference Exhibit, Huntsville, AL, USA, 20–23 July 2003. [Google Scholar]

- Xiong, J.; Zhou, Z.; Sun, D.; Ye, X. Development of a MEMS based colloid thruster with sandwich structure. Sens. Actuators A Phys. 2005, 117, 168–172. [Google Scholar] [CrossRef]

- Xiong, J.; Zhou, Z.; Ye, X.; Wang, X.; Feng, Y.; Li, Y. A colloid micro-thruster system. Microelectron. Eng. 2002, 61, 1031–1037. [Google Scholar] [CrossRef]

- Martinez-Sanchez, M.; de la Mora, J.F.; Gamero-Castano, H.M.; Khayms, V. Research on colloid thrusters. In Proceedings of the 26th International Electric Propulsion Conference, Kitakyushu, Japan, 17–21 October 1999. [Google Scholar]

- Paine, M.; Gabriel, S. A micro-fabrication colloidal thruster array. In Proceedings of the 37th AIAA Joint Propulsion Conference Exhibit, Salt Lake City, UT, USA, 8–11 July 2005. [Google Scholar]

- Ziemer, J.K.; Gamero, M. Colloid micro-newton thruster development for the ST7-DRS and LISA missions. In Proceedings of the 41st AIAA Joint Propulsion Conference Exhibit, Tucson, AZ, USA, 10–13 July 2005. [Google Scholar]

- Ziemer, J.K.; Randolph, T.M.; Franklin, G.W. Delivery of colloid micro-newton thrusters for the space technology 7 mission. In Proceedings of the 44th Joint Propulsion Conference and Exhibit, Hartford, CT, USA, 21–23 July 2008. [Google Scholar]

- Randolph, T.; Ziemer, J.K. Microthruster propulsion for the space technology 7 (ST7) technology demonstration mission. In Proceedings of the 42nd Joint Propulsion Conference Exhibit, Sacramento, CA, USA, 9–12 July 2006. [Google Scholar]

- Gamero-Castano, M.; Hruby, V. Electrospray as a source of nanoparticles for efficient colloid thrusters. J. Propuls. Power 2000, 17, 977. [Google Scholar] [CrossRef]

- Taylor, G. Disintegration of water drops in an electric field. Proceedings A 1964, 280, 383–397. [Google Scholar]

- Berg, S.P.; Rovey, J.L.; Prince, B.D.; Miller, S.W.; Bemish, R.J. Electrospray of an energetic ionic liquid monopropellant for multi-mode micropropulsion applications. In Proceedings of the 51st AIAA Joint Propulsion Conference, Orlando, FL, USA, 27–29 July 2015. [Google Scholar]

- Simon, D.; Ataman, C.; Chakraborty, S.; Shea, H. Progress towards a miniaturized electrospray thruster for flexible propulsion of small spacecraft. In Proceedings of the 48th AIAA Joint Propulsion Conference Exhibit, Atlanta, GA, USA, 30 July–1 August 2012. [Google Scholar]

- Silva, M.A.C.; Guerrieri, D.C.; Cervone, A.; Gill, E. A review of MEMS micropropulsion technologies for CubeSats and PocketQubes. Acta Astronaut. 2018, 143, 234–243. [Google Scholar] [CrossRef]

- Lenguito, G.; Fernandez, D.L.M.J.; Gomez, A. Scaling up the power of an electrospray microthruster. J. Micromech. Microeng. 2014, 24, 055003. [Google Scholar] [CrossRef]

- Berg, S.P.; Rovey, J.L. Decomposition of a double salt ionic liquid monopropellant on heated metallic surfaces. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar]

- Hagelberg, C.; Jackson, F.; Jortner, D. An operational electrothermal propulsion system for spacecraft reaction control. In Proceedings of the 5th Electric Propulsion Conference, San Diego, CA, USA, 7–9 March 1966. [Google Scholar]

- Lee, R.H.; Lilly, T.C.; Killingsworth, M.D.; Lilly, T.C.; Duncan, J.A. Free-molecule-microresistojet performance using water propellant for nanosatellite applications. J. Spacecr. Rocket. 2008, 45, 264–269. [Google Scholar] [CrossRef]

- Lee, R.H.; Lilly, T.C.; Muntz, E.P. Free molecule micro-resistojet: Nanosatellite propulsion. In Proceedings of the 41st AIAA Joint Propulsion Conference Exhibit, Tucson, AZ, USA, 10–13 July 2005. [Google Scholar]

- Ketsdever, A.D.; Lee, R.H.; Lilly, T.C. Performance testing of a microfabricated propulsion system for nanosatellite applications. J. Micromech. Microeng. 2005, 15, 11. [Google Scholar] [CrossRef]

- Ahmed, Z.; Gimelshein, S.F.; Ketsdever, A.D. Numerical snalysis of free-molecule microresistojet performance. J. Propuls. Power 2006, 22, 749–756. [Google Scholar] [CrossRef]

- Cervone, A.; Zandbergen, B.; Guerrieri, D.C.; Sliva, M.A.C.; Krusharev, I.; Zeijl, H. Green micro-resistojet research at delft university of technology: New options for Cubesat propulsion. CEAS Space J. 2017, 9, 111–125. [Google Scholar] [CrossRef]

- Eriksson, A.; Stenmark, L. Cold gas micro thrusters. In Proceedings of the Nano Tech 2002—“At the Edge of Revolution”, Houston, TX, USA, 9–12 September 2002. [Google Scholar]

- Kohler, J.; Bejhed, J.; Kratz, H.; Bruhn, F.; Lindberg, U.; Hjort, K.; Stenmark, L. A hybrid cold gas microthruster system for spacecraft. Sens. Actuator. A Phys. 2002, 97, 587–598. [Google Scholar] [CrossRef]

- Rhee, M.S.; Zakrzwski, C.M.; Thomas, M.A. Highlights of nanosatellite propulsion development program at NASA-Goddard space flight center. In Proceedings of the AIAA/USU Conference on Small Satellites, Logan, UT, USA, 21–24 August 2000. [Google Scholar]

- Ranjan, R.; Karthikeyan, K.; Riaz, F.; Chou, S.K. Cold gas propulsion microthruster for feed gas utilization in micro satellites. Appl. Energy 2018, 220, 921–933. [Google Scholar] [CrossRef]

- Rossi, C.; Conto, T.D.; Larangot, B. Design, fabrication and modelling of MEMS-based microthrusters for space application. Smart Mater. Struct. 2001, 10, 1156–1162. [Google Scholar] [CrossRef]

| Main Features | Categories | Types | Sections |

|---|---|---|---|

| Chemical fuel propellant | Solid propellant microthrusters (SPM) Liquid monopropellant microthruster | Vertical structure Planar structure | 2.1.1 2.1.2 |

| With spark ignition With catalytic ignition | 2.2.1 2.2.2 | ||

| Electric driving | Vaporizing liquid microthruster (VLM) | Internal microheater | 3.1 |

| External microheater | 3.2 | ||

| Plasma microthruster | Electrothermal plasma microthruster | 4.1 | |

| Liquid/Solid propellant pulse plasma microthruster | 4.2 | ||

| Colloid microthruster | 5 | ||

| Electrospray microthruster | 6 | ||

| Free molecule micro–resistojet (FMMR) | 7 | ||

| Gas propellant | Cold gas microthruster (CGM) | 8 |

| Researchers | Structure | Ignition | Propellant | Thrust(mN) | Specific Impulse (s) |

|---|---|---|---|---|---|

| Rossi et al. [34] | Vertical | Top | GAP/ZPP | 0.3–22.0 | N/A |

| Rossi et al. [53] | Vertical | Top | GAP/AP/Zr,ZPP | 0.3–2.3 | 0.059–24.333 |

| Briand et al. [32] | Vertical | Top | ZPP | N/A | N/A |

| Lee et al. [36] | Vertical | Top | LTNR | 3840 (peak value) | 62.3 (average) |

| Ru et al. [41] | Vertical | Top | Nano-Al/Cuo + 10 wt% NC | 479–645 | 10.2–27.2 |

| Liu et al. [46] | Vertical | Bottom | HTPB/AP | N/A | 6.443–23.366 |

| Zhang et al. [48] | Planar | Top | Gunpowder | 130 (peak value) | 2.68–14.65 (sea level) |

| Zhang et al. [49] | Planar | Top | Gunpowder | 380 (peak value) | 5.55–14.41 (sea level) |

| Chaalane et al. [50] | Planar | Top | DB + x % BP | 0.1–3.5 | N/A |

| Lewis et al. [26] | Vertical | Bottom | LTNR | N/A | 0.1 (impulse/mN·s) |

| You et al. [52] | Planar | Bottom | HTPB/AP | N/A | 0.004–0.011 (impulse/mN·s) |

| Sathiyanathan et al. [54] | Vertical | Top | GAP/AP | 0.18–0.29 | 0.138–5.556 |

| Shen et al. [55] | Planar | Bottom | LTNR | 25 (peak value) | 0.00025 |

| Authors | Material | Electric Energy | Propellant | Catalyst/ Microheater | Input Flow Rate (mL/min) | Thrust (mN) | Specific Impulse (s) |

|---|---|---|---|---|---|---|---|

| Wu et al. [58] | Ceramic | 45 V | HAN | Ag | N/A | 100–200 | 32.3–64.5 |

| Kuan et al. [66] | N/A | 10–15 W | 92 wt% H2O2 | Ag | 9.56 | 182 | 101 |

| Cen and Xu [67] | Si-Pyrex glass | 0–10 V | H2O2 | Pt | 0.09–0.44 | 2.0–6.5 | 65–105 |

| Kundu et al. [69] | Si-Pyrex glass | 44 J | 50 wt% H2O2 | MnO2 | 0.20–1.25 (mg/s) | 0.3–1.1 | 80–180 |

| Khaji et al. [71] | Ceramic | 3.7 W | 30 wt% H2O2 | Pt/Al2O3 | 0.05 | 0.84–0.96 | 92–106 |

| Huh and Kwon [72] | Glass | N/A | 90 wt% H2O2 + Ethanol | Pt/Al2O3 | 1.7 | 30.2 | 77.6 |

| Huh et al. [73] | Glass | N/A | 90 wt% H2O2 | Pt/Al2O3 | 3 | 48 | 70.4 |

| Ignition Methods | Advantages | Disadvantages |

|---|---|---|

| Spark ignition |

| (1) Connecting wires are complex (2) It consumes more electricity |

| Catalytic ignition |

| (1) The efficiency of propellant decomposition may be insufficient (2) Trouble in different propellants may require different catalysts (3) Shorter service life |

| Authors | Material | Microthroat Size (µm) | Input Flow Rate (mg/s) | Input Power (W) | Thrust (mN) | Specific Impulse (s) |

|---|---|---|---|---|---|---|

| Ye et al. [75] | Si | N/A | 0.038 | 30 | 0.003 | 7.78 |

| Maurya et al. [77] | Si | 30 × 30 | 1.6 | 1.0–2.4 | 0.005–0.120 | N/A |

| Karthikeyan et al. [79] | LTCC | 220 × 220 | 1 | 7.1–9.2 | 0.034–0.068 | 3.42–6.90 |

| Cheah et al. [80] | HTCC | 250 × 125 | 0.2–1.6 | 4.01 | 0.634 | 31 |

| Mukerjee et al. [81] | Si | N/A | 8.83 | 10.8 | 0.15–0.46 | 5.33 |

| Kundu et al. [82] | Si | 0.20–2.04 | 1.4–3.6 | 0.15–1.01 | 50–105 | |

| Silva et al. [83] | Si | 0.55–0.83 (simulation) | 7.29–8.76 (simulation) | 0.67–0.98 (simulation) | 119.8–124.0 (simulation) | |

| Chen et al. [84] | Si | 1000 × 100 | 2.08–16.67 (simulation) | N/A | 1–6 (simulation) | N/A |

| Heating Methods | Advantages | Disadvantages |

|---|---|---|

| External microheater | Fabrication of structure is easier | Consumes more heat for heat conduction |

| Internal microheater | Contacting with the water directly can reduce the heat loss | Complex for fabricating and connecting with external wire |

| Types of Microthruster | Advantages | Disadvantages |

|---|---|---|

| Electrothermal | Produces high temperature plasmas at around atmospheric pressures by using RF power or microwave power |

|

| Liquid/Solid propellant pulsed plasma |

|

|

| Types of Microthruster | Performances | Advantages | Disadvantages |

|---|---|---|---|

| (1) Solid propellant microthrusters (SPM) | High thrust (>100 mN) Low specific impulse (< 100 s) | Easy propellant loading, no leakage of propellant, low cost and power consumption | One-shot use, lack of restart ability, and combustion instability |

| (2) Liquid monopropellant microthruster | High thrust (0.3–200 mN) High specific impulse (5–180 s) | Small demand for electricity, simplified fabrication and low cost, non-toxic combustion products. | Propellants are easily to decompose, heat preservation, and ventilation of storage tanks. |

| (3) Vaporizing liquid microthruster (VLM) | Low thrust (0.03–1 mN) Low specific impulse (3.42 –105 s) | Simple structure, low voltage, low cost and easy to fabricate, no pollution of propellants | Too difficult to reach more than 1mN of thrust, relatively small level of specific impulse |

| (4) Plasma microthruster | Low thrust (0.04–1.4 mN) High specific impulse (50–4300 s) | Low-volume, low-cost, low-weight, and high reliability | Needs a higher operating voltage |

| (5) Colloid microthruster | Low thrust (< 20 μN) High specific impulse (500–1300 s) | Relatively large specific impulse range, high thrust accuracy, and low thrust noise | Needs a higher working voltage |

| (6) Electrospray microthruster | Low thrust (30–65 μN) High specific impulse (>1000 s) | A high specific impulse with low flow rate, high efficiency and operational flexibility | Too low thrust, in the micro Newton-scale |

| (7) Free molecule micro–resistojet (FMMR) | Low thrust (< 35 μN) High specific impulse (4000–8000 s) | Low thrust noise, high thrust accuracy, and repeatability. | Relatively bigger volume, short lifetimes, require a large power |

| (8) Cold gas microthruster (CGM) | Low thrust (0.8–2.24 mN) Low specific impulse (< 50 s) | Simple structure, reliable, low energy consumption, and easy to be miniaturized | Needs high pressure gas storage tank, large volume and weight, difficult to prevent leakage |

| Bonding Methods | Advantages | Disadvantages |

|---|---|---|

| Adhesive bonding | Simple operation, convenient to fabricated, low cost, no limit to the use of the material. | The sealing effect is poor, and the epoxy resin adhesive used must be high-temperature resistant. |

| Anodic bonding | No intermediate layer, good airtightness and long-term stability, high degree of combination. | Stress is easily generated after bonding. |

| Eutectic bonding | No need for high temperature (only about 400 °C) and high voltage, the required for the surface smoothness of silicon is also not high. | A strong electrostatic field is required, which may cause deformation of the fragile structure. |

| LTCC/HTCC process bonding | Complete bonding in sintering of the ceramic, has good airtightness. | Has limited in use condition of material. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Li, X.; Yang, J.; Gao, G. Recent Advances in MEMS-Based Microthrusters. Micromachines 2019, 10, 818. https://doi.org/10.3390/mi10120818

Liu B, Li X, Yang J, Gao G. Recent Advances in MEMS-Based Microthrusters. Micromachines. 2019; 10(12):818. https://doi.org/10.3390/mi10120818

Chicago/Turabian StyleLiu, Bendong, Xinrui Li, Jiahui Yang, and Guohua Gao. 2019. "Recent Advances in MEMS-Based Microthrusters" Micromachines 10, no. 12: 818. https://doi.org/10.3390/mi10120818

APA StyleLiu, B., Li, X., Yang, J., & Gao, G. (2019). Recent Advances in MEMS-Based Microthrusters. Micromachines, 10(12), 818. https://doi.org/10.3390/mi10120818