Preparing Polypyrrole-Coated Stretchable Textile via Low-Temperature Interfacial Polymerization for Highly Sensitive Strain Sensor

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

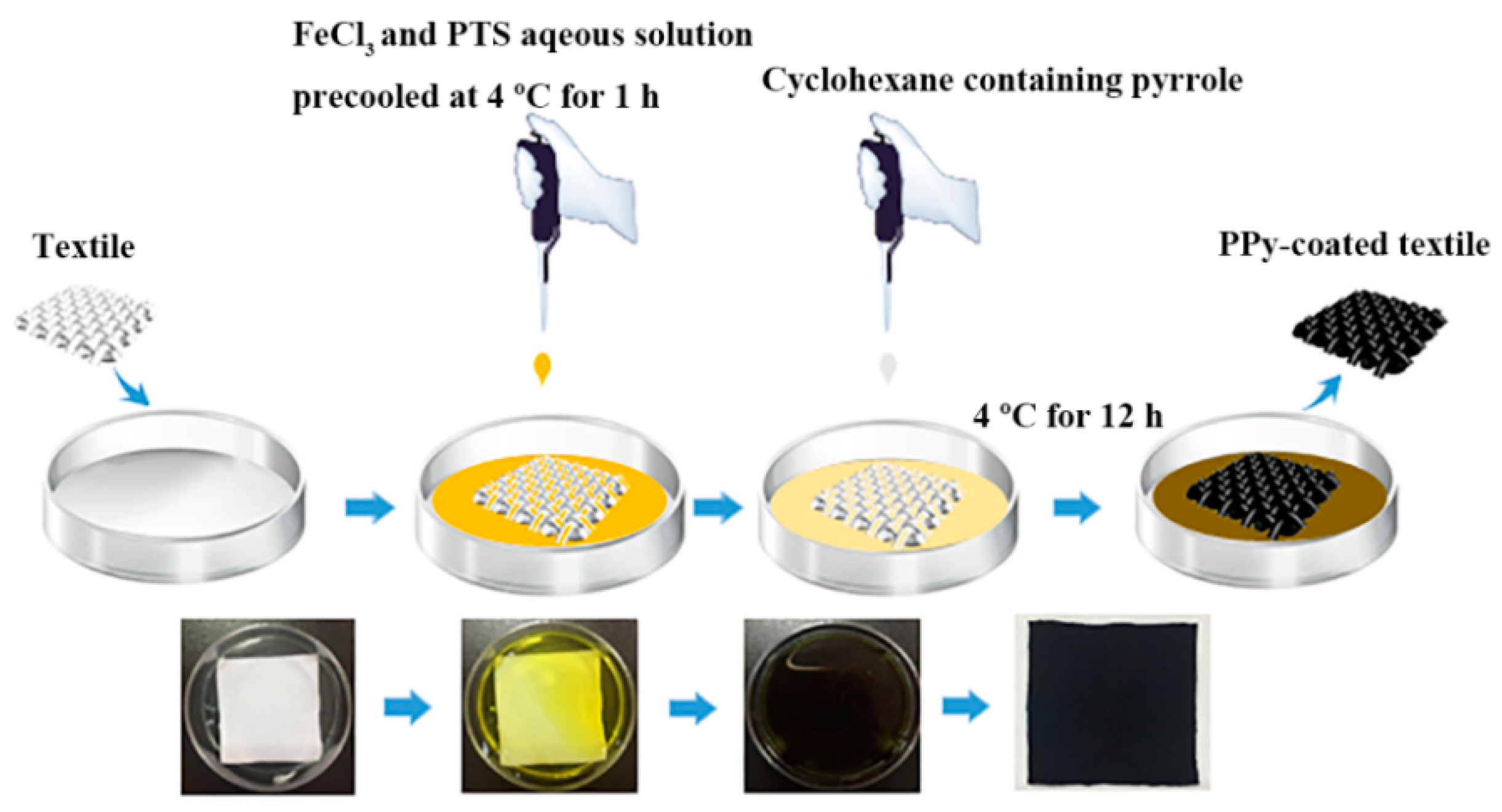

2.2. Preparation of PPy-Coated Textiles

2.3. Characterization

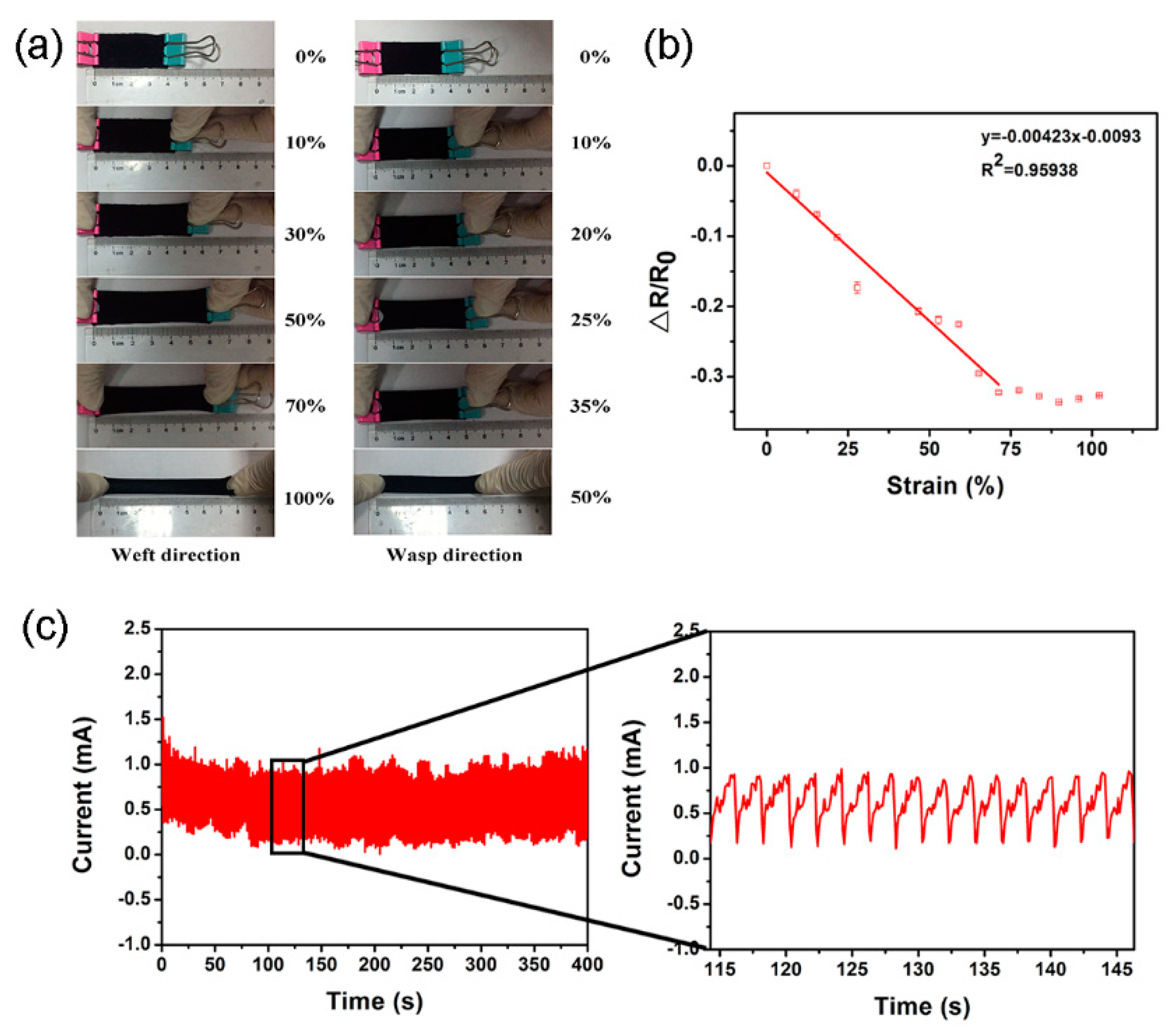

2.4. Strain Sensing Tests

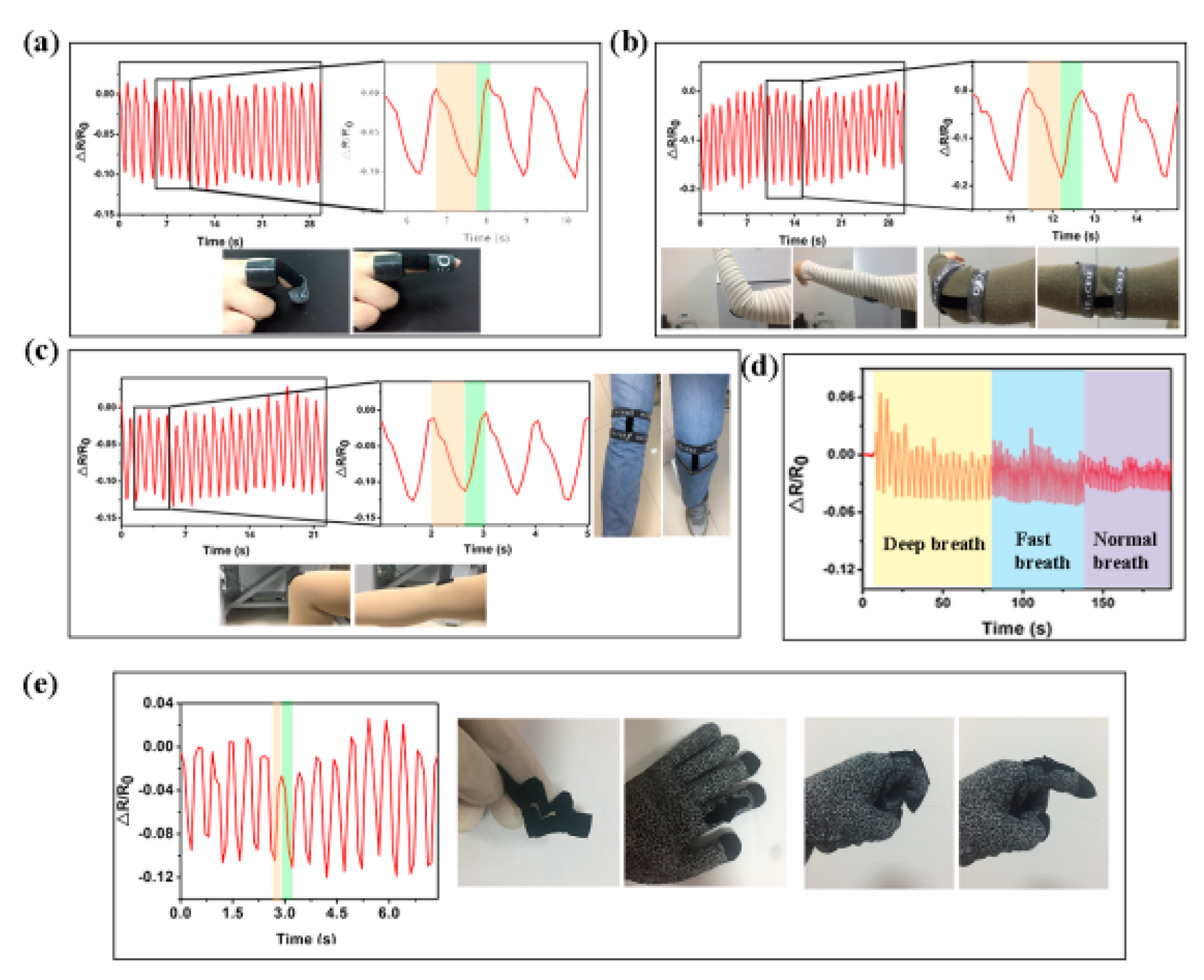

2.5. On-Body Tests

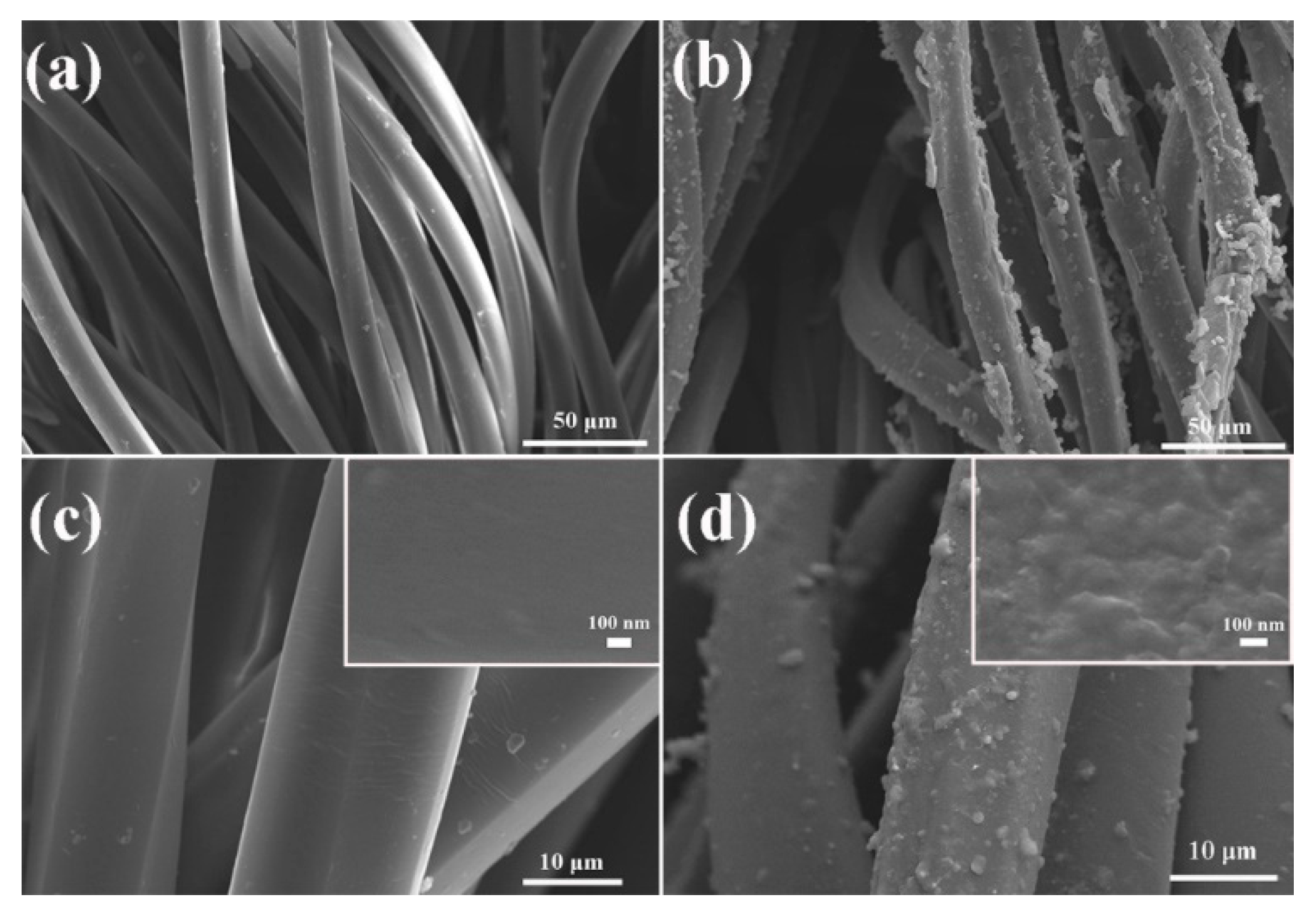

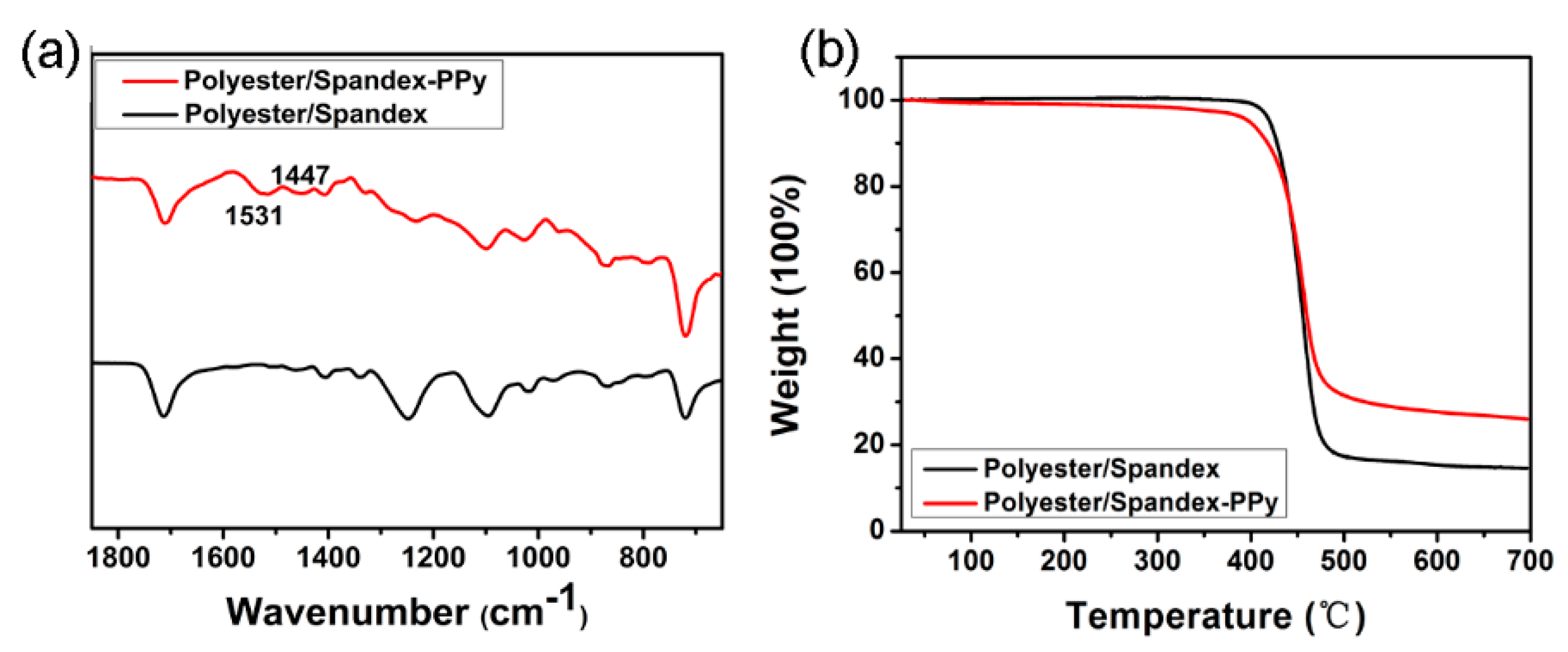

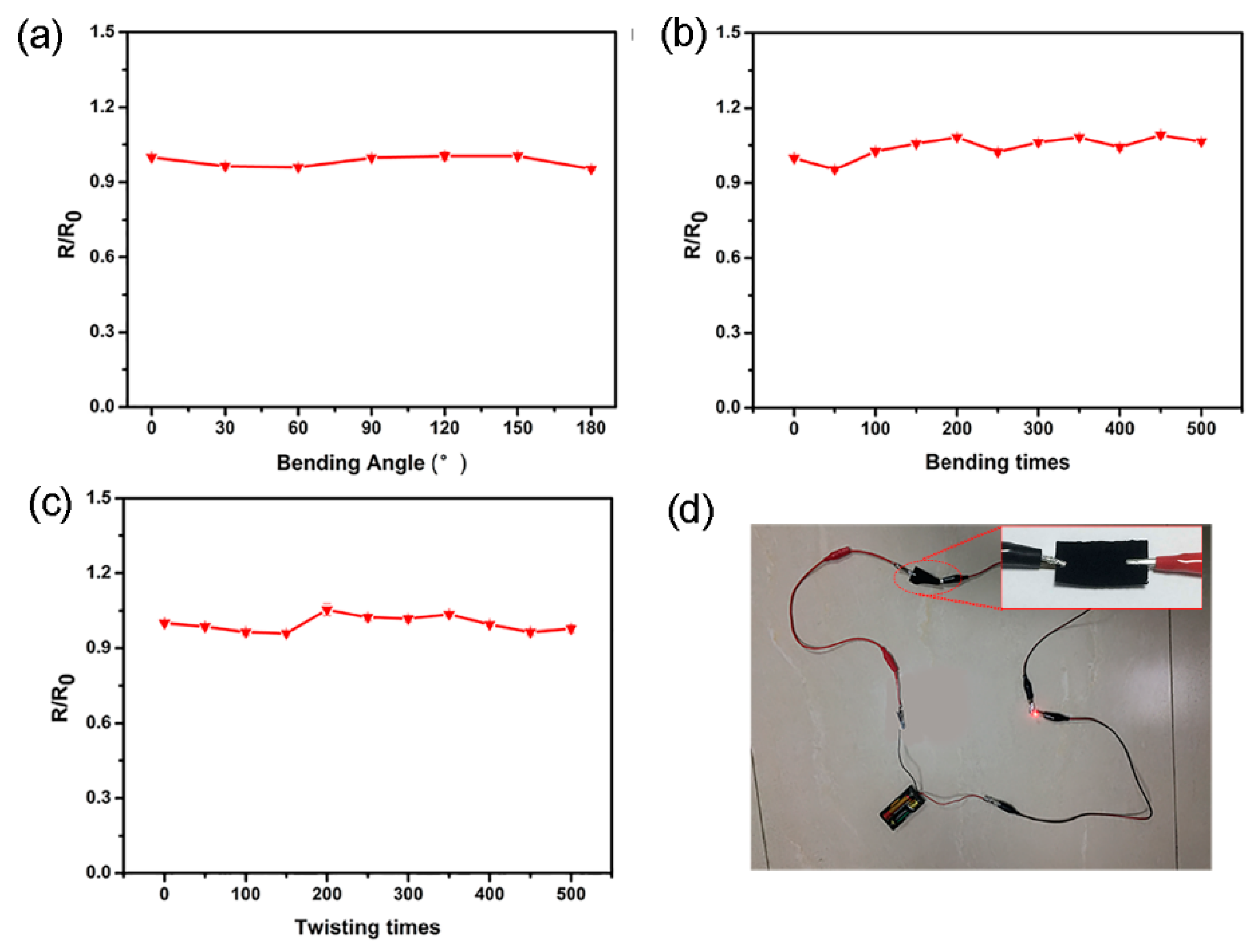

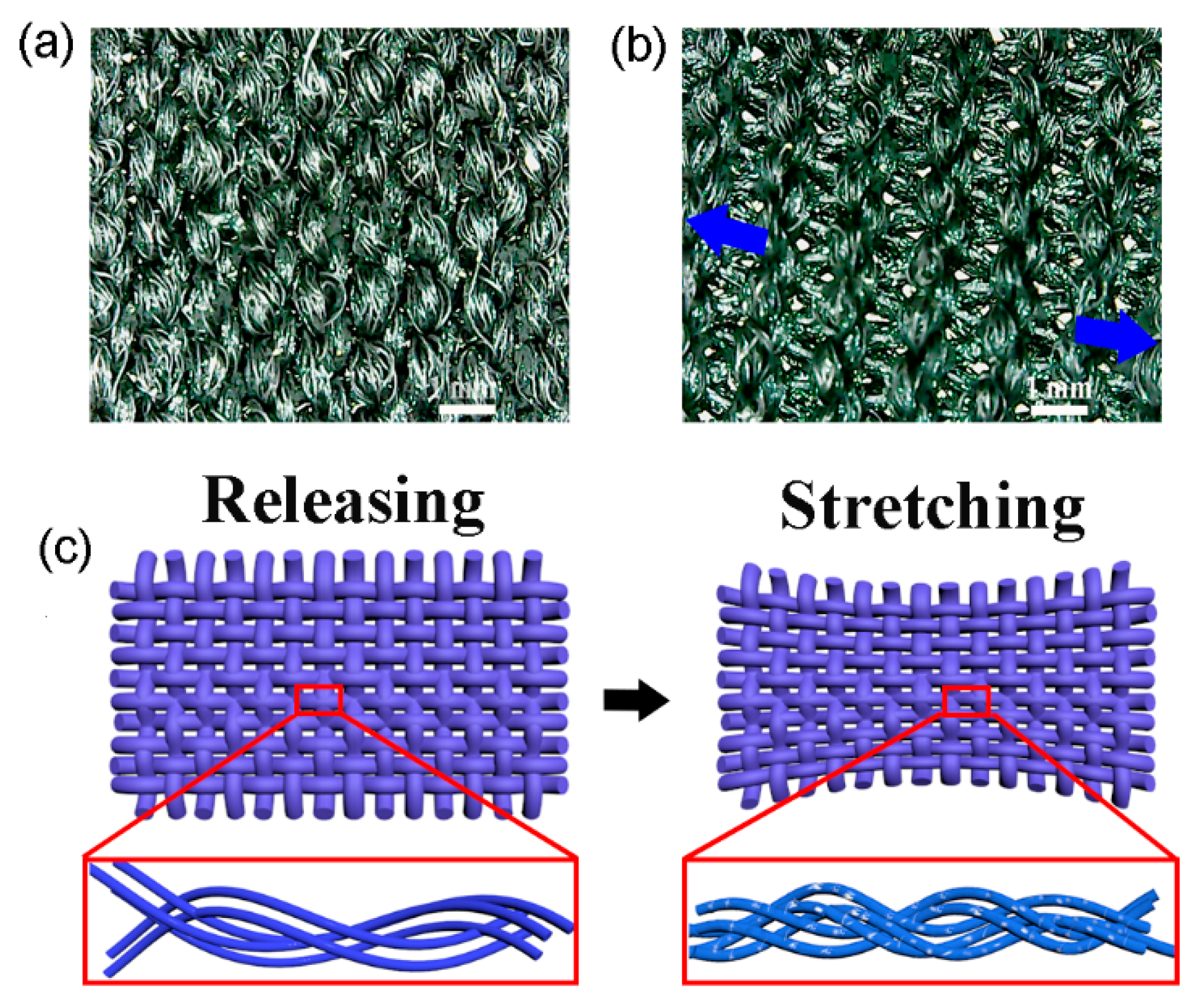

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Sekitani, T.; Someya, T. Stretchable, large-area organic electronics. Adv. Mater. 2010, 22, 2228–2246. [Google Scholar] [CrossRef] [PubMed]

- Zang, Y.P.; Zhang, F.J.; Di, C.A.; Zhu, D.B. Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horiz. 2015, 2, 140–156. [Google Scholar] [CrossRef]

- Trung, T.Q.; Lee, N.E. Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoring and personal healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef] [PubMed]

- Cho, J.H.; Ha, S.H.; Kim, J.M. Transparent and stretchable strain sensors based on metal nanowire microgrids for human motion monitoring. Nanotechnology 2018, 29, 155501. [Google Scholar] [CrossRef]

- Chen, S.; Liu, S.Q.; Wang, P.P.; Liu, H.Z.; Liu, L. Highly stretchable fiber-shaped e-textiles for strain/pressure sensing, full-range human motions detection, health monitoring, and 2D force mapping. J. Mater. Sci. 2018, 53, 2995–3005. [Google Scholar] [CrossRef]

- Sun, Q.; Seung, W.; Kim, B.J.; Seo, S.; Kim, S.W.; Cho, J.H. Active matrix electronic skin strain sensor based on piezopotential-powered graphene transistors. Adv. Mater. 2015, 27, 3411–3417. [Google Scholar] [CrossRef]

- Seyedin, M.Z.; Razal, J.M.; Innis, P.C.; Wallace, G.G. Strain-responsive polyurethane/PEDOT: PSS elastomeric composite fibers with high electrical conductivity. Adv. Funct. Mater. 2014, 24, 2957–2966. [Google Scholar] [CrossRef]

- Gong, S.; Lai, D.T.H.; Su, B.; Si, K.J.; Ma, Z.; Yap, L.W.; Guo, P.Z.; Cheng, W.L. Highly stretchy black gold E-skin nanopatches as highly sensitive wearable biomedical sensors. Adv. Electron. Mater. 2015, 1, 1400063. [Google Scholar] [CrossRef]

- Yan, C.Y.; Wang, J.X.; Kang, W.B.; Cui, M.Q.; Wang, X.; Foo, C.Y.; Chee, K.J.; Lee, P.S. Highly stretchable piezoresistive graphene-nanocellulose nanopaper for strain sensors. Adv. Mater. 2014, 26, 2022–2027. [Google Scholar] [CrossRef]

- Ge, J.; Sun, L.; Zhang, F.R.; Zhang, Y.; Shi, L.A.; Zhao, H.Y.; Zhu, H.W.; Jiang, H.L.; Yu, S.H. A stretchable electronic fabric artificial skin with pressure-, lateral strain-, and flexion-sensitive properties. Adv. Mater. 2016, 28, 722–728. [Google Scholar] [CrossRef]

- Hao, D.D.; Xu, B.; Cai, Z.S. Polypyrrole coated knitted fabric for robust wearable sensor and heater. J. Mater. Sci. Mater. El. 2018, 29, 9218–9226. [Google Scholar] [CrossRef]

- Geng, J.; Zhu, G.; Yuan, Y.K.; Han, G.Z. pH-mediated synthesis and mechanistic study of homogeneous magnetic Ag@Fe3O4 nanoparticles. J. Nanosci. Nanotechnol. 2020, 20, 2231–2238. [Google Scholar] [CrossRef] [PubMed]

- Orouji, A.; Abbasi-Moayed, S.; Hormozi-Nezhad, M.R. ThThnated Development of a pH assisted AgNP-based colorimetric sensor array for simultaneous identification of phosalone and azinphosmethyl pesticides. Spectrochim. Acta 2019, 223, 496–503. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Wang, K.; Song, H.Z.; Wu, H.; Yan, S.C.; Xu, X.; Shi, Y. Fabrication and electrical properties of silver telluride nanowires. J. Nanosci. Nanotechnol. 2020, 20, 2628–2632. [Google Scholar] [CrossRef] [PubMed]

- Dovjuu, O.; Kim, S.; Lee, A.; Kim, J.; Noh, J.; Huh, S.; Choi, B.; Jeong, H. A simple approach for heat transfer enhancement of carbon nanofluids in aqueous media. J. Nanosci. Nanotechnol. 2020, 20, 2337–2343. [Google Scholar] [CrossRef]

- Merlini, C.; Ramoa, S.D.A.S.; Barra, G.M.O. Conducting polypyrrole-coated banana fiber composites: Preparation and characterization. Polym. Compos. 2013, 34, 537–543. [Google Scholar] [CrossRef]

- Fedorkova, A.; Nacher-Alejos, A.; Gomez-Romero, P.; Orinakova, R.; Kaniansky, D. Structural and electrochemical studies of PPy/PEG-LiFePO4 cathode material for Li-ion batteries. Electrochim. Acta 2010, 55, 943–947. [Google Scholar] [CrossRef]

- Fedorkova, A.; Orinakova, R.; Orinak, A.; Heile, A.; Wiernhofer, H.D.; Arlinghaus, H.F. Electrochemical and TOF-SIMS investigations of PPy/PEG-modified LiFePO4 composite electrodes for Li-ion batteries. Solid State Sci. 2011, 13, 824–830. [Google Scholar] [CrossRef]

- Fedorkova, A.; Orinakova, R.; Orinak, A.; Talian, I.; Heile, A.; Wiemhofer, H.D.; Kaniansky, D.; Arlinghaus, H.F. PPy doped PEG conducting polymer films synthesized on LiFePO4 particles. J. Power Sources 2010, 195, 3907–3912. [Google Scholar] [CrossRef]

- Sharma, R.K.; Rastogi, A.C.; Desu, S.B. Pulse polymerized polypyrrole electrodes for high energy density electrochemical supercapacitor. Electrochem. Commun. 2008, 10, 268–272. [Google Scholar] [CrossRef]

- Sun, J.F.; Huang, Y.; Fu, C.X.; Wang, Z.Y.; Huang, Y.; Zhu, M.S.; Zhi, C.Y.; Hu, H. High-performance stretchable yarn supercapacitor based on PPy@CNTs@urethane elastic fiber core spun yarn. Nano Energy 2016, 27, 230–237. [Google Scholar] [CrossRef]

- Hu, J.Y.; Zhang, X.F.; Li, G.H.; Yang, X.D.; Ding, X. Electrical properties of Ppy-coated conductive fabrics for human joint motion monitoring. Autex Res. J. 2016, 16, 7–12. [Google Scholar]

- Li, M.F.F.; Li, H.Y.; Zhong, W.B.; Zhao, Q.H.; Wang, D. Stretchable conductive polypyrrole/polyurethane (PPy/PU) strain sensor with netlike microcracks for human breath detection. ACS Appl. Mater. Interface 2014, 6, 1313–1319. [Google Scholar] [CrossRef] [PubMed]

- Atobe, M.; Tsuji, H.; Asami, R.; Fuchigami, T. A study on doping-undoping properties of polypyrrole films electropolymerized under ultrasonication. J. Electrochem. Soc. 2006, 153, D10–D13. [Google Scholar] [CrossRef]

- Yang, J.J.; Di, S.C.; Blawert, C.; Lamaka, S.V.; Wang, L.Q.; Fu, B.L.; Jiang, P.L.; Wang, L.; Zheludkevich, M.L. Enhanced wear performance of hybrid epoxy-ceramic coatings on magnesium substrates. ACS Appl. Mater. Interface 2018, 10, 30741–30751. [Google Scholar] [CrossRef]

- Lenz, D.M.; Delamar, M.; Ferreira, C.A. Application of polypyrrole/TiO2 composite films as corrosion protection of mild steel. J. Electroanal. Chem. 2003, 540, 35–44. [Google Scholar] [CrossRef]

- Jamadade, S.; Jadhav, S.V.; Puri, V. Electromagnetic reflection, shielding and conductivity of polypyrrole thin film electropolymerized in P-Tulensulfonic acid. J. Non-Cryst. Solids 2011, 357, 1177–1181. [Google Scholar] [CrossRef]

- Olad, A.; Shakoori, S. Electromagnetic interference attenuation and shielding effect of quaternary Epoxy-PPy/Fe3O4-ZnO nanocomposite as a broad band microwave-absorber. J. Magn. Magn. Mater. 2018, 458, 335–345. [Google Scholar] [CrossRef]

- Zhao, H.; Hou, L.; Lu, Y.X. Electromagnetic shielding effectiveness and serviceability of the multilayer structured cuprammonium fabric/polypyrrole/copper (CF/PPy/Cu) composite. Chem. Eng. J. 2016, 297, 170–179. [Google Scholar] [CrossRef]

- Foroughi, J.; Spinks, G.M.; Wallace, G.G. Effect of synthesis conditions on the properties of wet spun polypyrrole fibres. Synth. Met. 2009, 159, 1837–1843. [Google Scholar] [CrossRef]

- Esfahani, M.I.M.; Taghinedjad, S.; Mottaghitalab, V.; Narimani, R.; Parnianpour, M. Novel printed body worn sensor for measuring the human movement orientation. Sens. Rev. 2016, 36, 321–331. [Google Scholar] [CrossRef]

- Chen, Y.X.; Cai, K.F.; Liu, C.C.; Song, H.J.; Yang, X.W. High-Performance and breathable polypyrrole coated air-laid paper for flexible all-solid-state supercapacitors. Adv. Energy Mater. 2017, 7, 1701247. [Google Scholar] [CrossRef]

- Mosnakova, K.; Chehimi, M.M.; Fedorko, P.; Omastova, M. Polyamide grafted with polypyrrole: Formation, properties, and stability. Chem. Pap. 2013, 67, 979–994. [Google Scholar] [CrossRef]

- Hu, W.H.; Li, C.M.; Cui, X.Q.; Dong, H.; Zhou, Q. In situ studies of protein adsorptions on poly (pyrrole-co-pyrrole propylic acid) film by electrochemical surface plasmon resonance. Langmuir 2007, 23, 2761–2767. [Google Scholar] [CrossRef]

- Lv, J.C.; Zhou, P.W.; Zhang, L.P.; Zhong, Y.; Sui, X.F.; Wang, B.J.; Chen, Z.Z.; Xu, H.; Mao, Z.P. High-performance textile electrodes for wearable electronics obtained by an improved in situ polymerization method. Chem. Eng. J. 2019, 361, 897–907. [Google Scholar] [CrossRef]

- Kim, I.; Cho, G. Polyurethane nanofiber strain sensors via in situ polymerization of polypyrrole and application to monitoring joint flexion. Smart Mater. Struct. 2018, 27, 075006. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, D.; Too, C.O.; Wallace, G.G. Conducting polymer coated lycra. Synth. Met. 2005, 155, 698–701. [Google Scholar] [CrossRef]

- Hu, J.Y.; Zhou, S.W.; Shi, J.H.; Zhang, H.L.; Zhu, F.; Yang, X.D. Determinants of electrical resistance change of in situ PPy-polymerized stretch plain woven fabric under uniaxial tensile strain. J. Text. Inst. 2017, 108, 1545–1551. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Zhai, Q.F.; Dong, D.S.; An, T.C.; Gong, S.; Shi, Q.Q.; Cheng, W.L. A highly stretchable and strain-insensitive fiber-based wearable electrochemical biosensor to monitor glucose in the sweat. Anal. Chem. 2019, 91, 6569–6576. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Dong, D.S.; Gong, S.; Brassart, L.; Wang, Y.; An, T.; Cheng, W.L. A moss-inspired electroless gold-coating strategy toward stretchable fiber conductors by dry spinning. Adv. Electron. Mater. 2019, 5, 1800462. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.W.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W.L. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef] [PubMed]

| Textile Types | Method | Resistance | Maximum Strain Range | Gauge Factor | References |

|---|---|---|---|---|---|

| Cotton spandex | In situ polymerization at 0 °C | 3.83 Ω/cm2 | 0–9% | −1.23 | [38] |

| Polyester/Spandex | In situ polymerization at 0 °C | 6.77 Ω/cm2 | 0–8% | −0.05 | [38] |

| Lycra | In situ polymerization at room temperature | 375 Ω/cm2 | 0–60% | −0.69 | [37] |

| Cotton/Spandex | In situ polymerization at 0 °C | 8.93 Ω/cm2 | 0–25% | 0.71(15−25%) 1.1(0−15%) | [22] |

| PU/PDMS | In situ polymerization at room temperature | 130.63 Ω/cm2 | 0.15 | [36] | |

| Cotton | In situ polymerization at 0–8 °C | 303 Ω sq−1 | 0–35% | 0.35 (0–15%) 2.39(15−35%) | [11] |

| Nylon/Lycra | Screen-printing/vapor | 0–20% | 8 | [31] | |

| Polyester/Spandex | Low-temperature interfacial polymerization | 21.25 Ω/cm2 | 0–71% | −0.46 | This study |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Li, B.; Qiao, Y.; Lu, Z. Preparing Polypyrrole-Coated Stretchable Textile via Low-Temperature Interfacial Polymerization for Highly Sensitive Strain Sensor. Micromachines 2019, 10, 788. https://doi.org/10.3390/mi10110788

Chen X, Li B, Qiao Y, Lu Z. Preparing Polypyrrole-Coated Stretchable Textile via Low-Temperature Interfacial Polymerization for Highly Sensitive Strain Sensor. Micromachines. 2019; 10(11):788. https://doi.org/10.3390/mi10110788

Chicago/Turabian StyleChen, Xiaodie, Bintian Li, Yan Qiao, and Zhisong Lu. 2019. "Preparing Polypyrrole-Coated Stretchable Textile via Low-Temperature Interfacial Polymerization for Highly Sensitive Strain Sensor" Micromachines 10, no. 11: 788. https://doi.org/10.3390/mi10110788

APA StyleChen, X., Li, B., Qiao, Y., & Lu, Z. (2019). Preparing Polypyrrole-Coated Stretchable Textile via Low-Temperature Interfacial Polymerization for Highly Sensitive Strain Sensor. Micromachines, 10(11), 788. https://doi.org/10.3390/mi10110788