Highly Sensitive Temperature Sensing Performance of a Microfiber Fabry-Perot Interferometer with Sealed Micro-Spherical Reflector

Abstract

1. Introduction

2. Materials and Methods

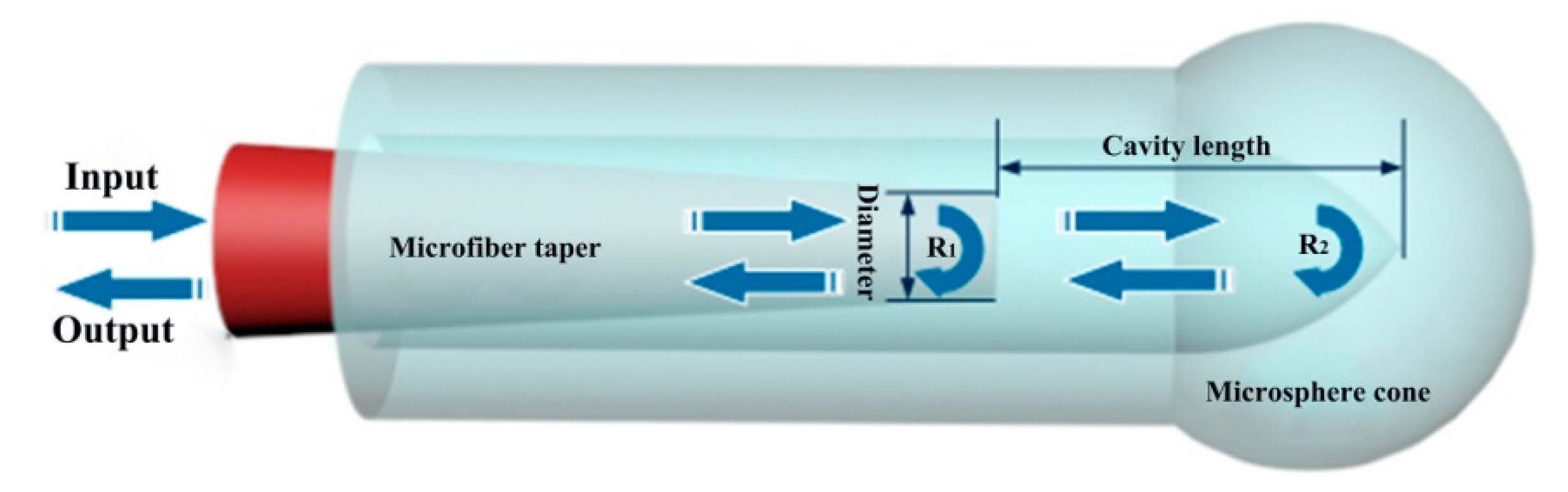

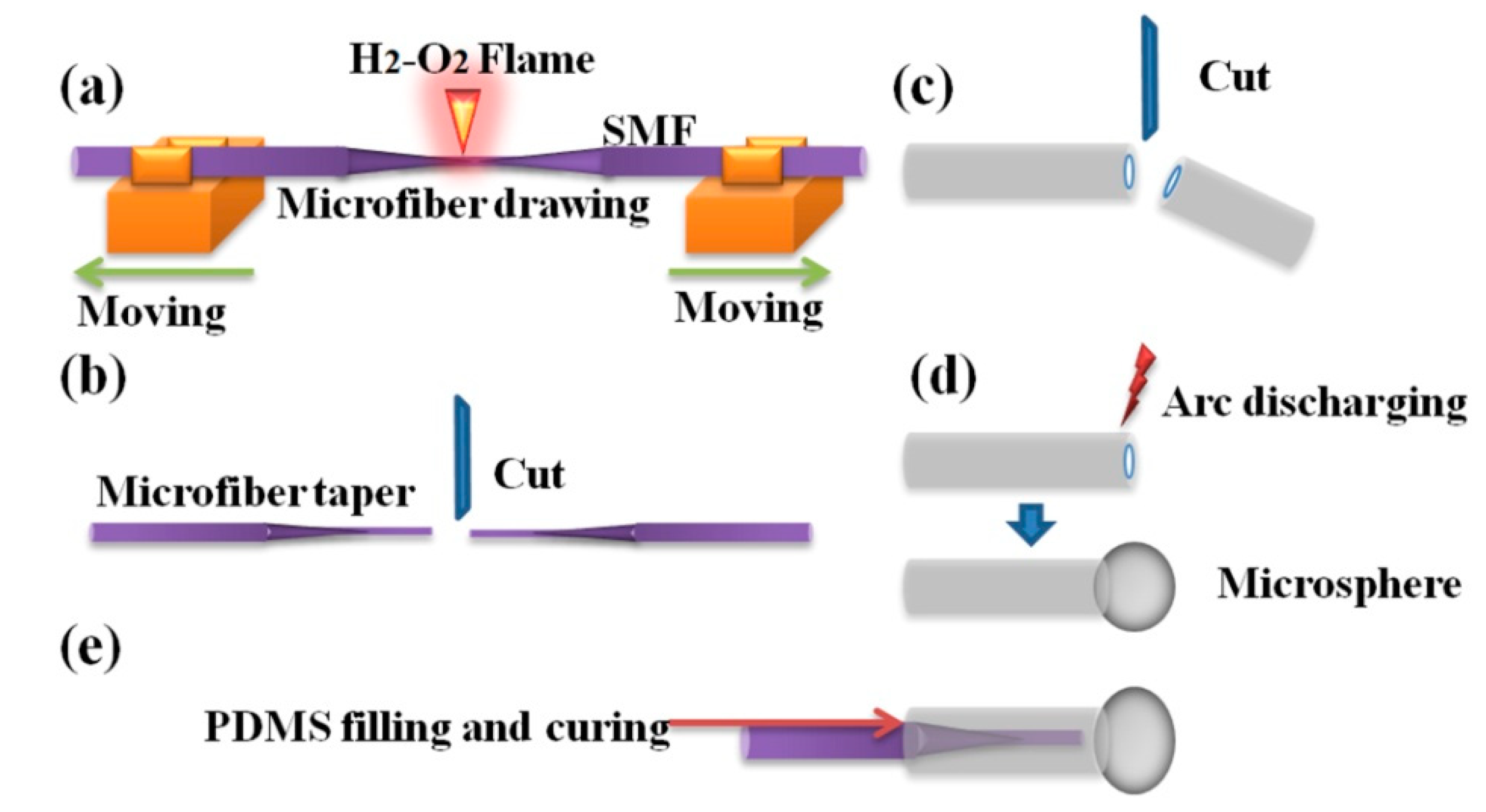

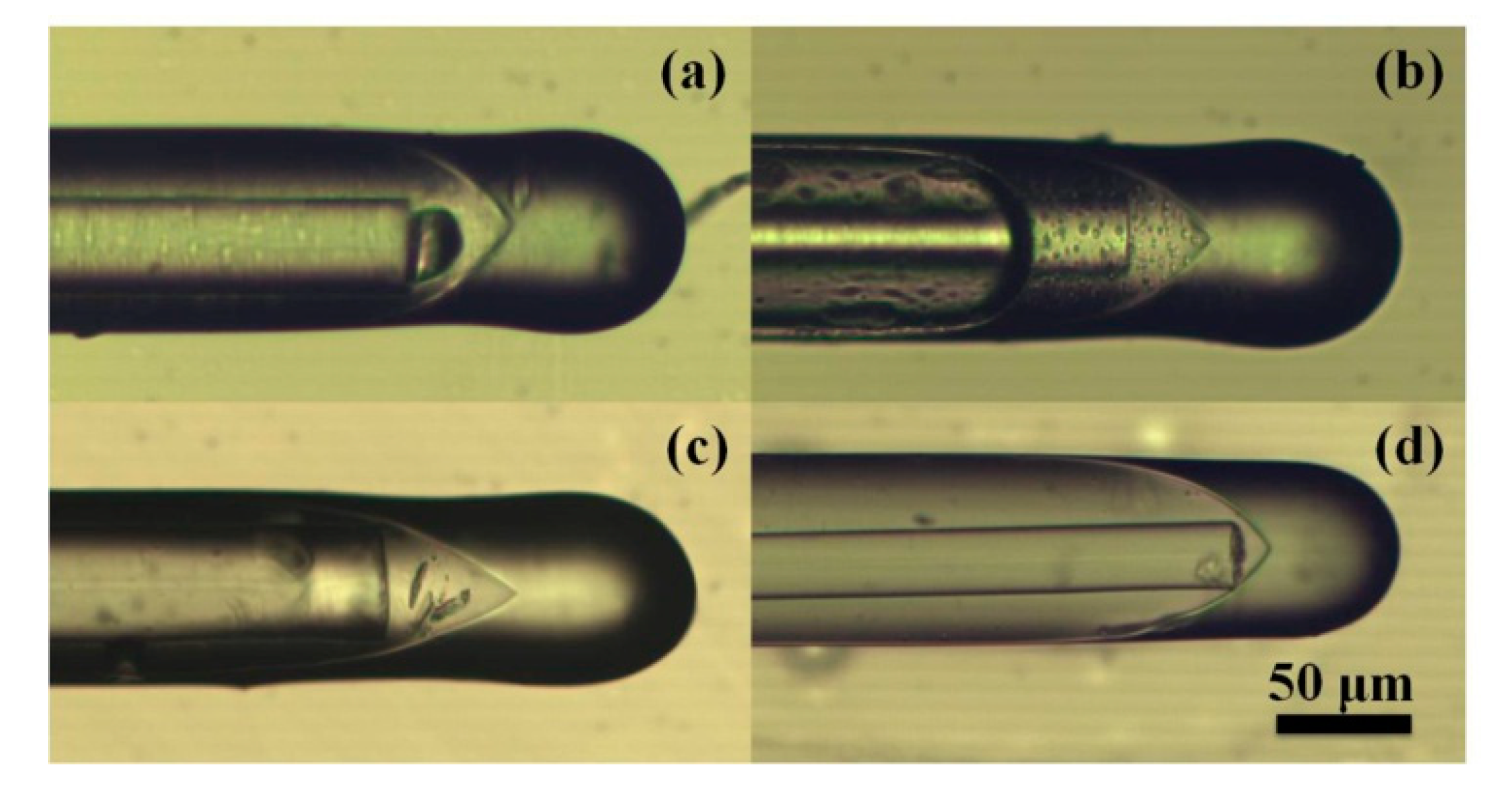

2.1. Temperature Probe Design and Fabrication

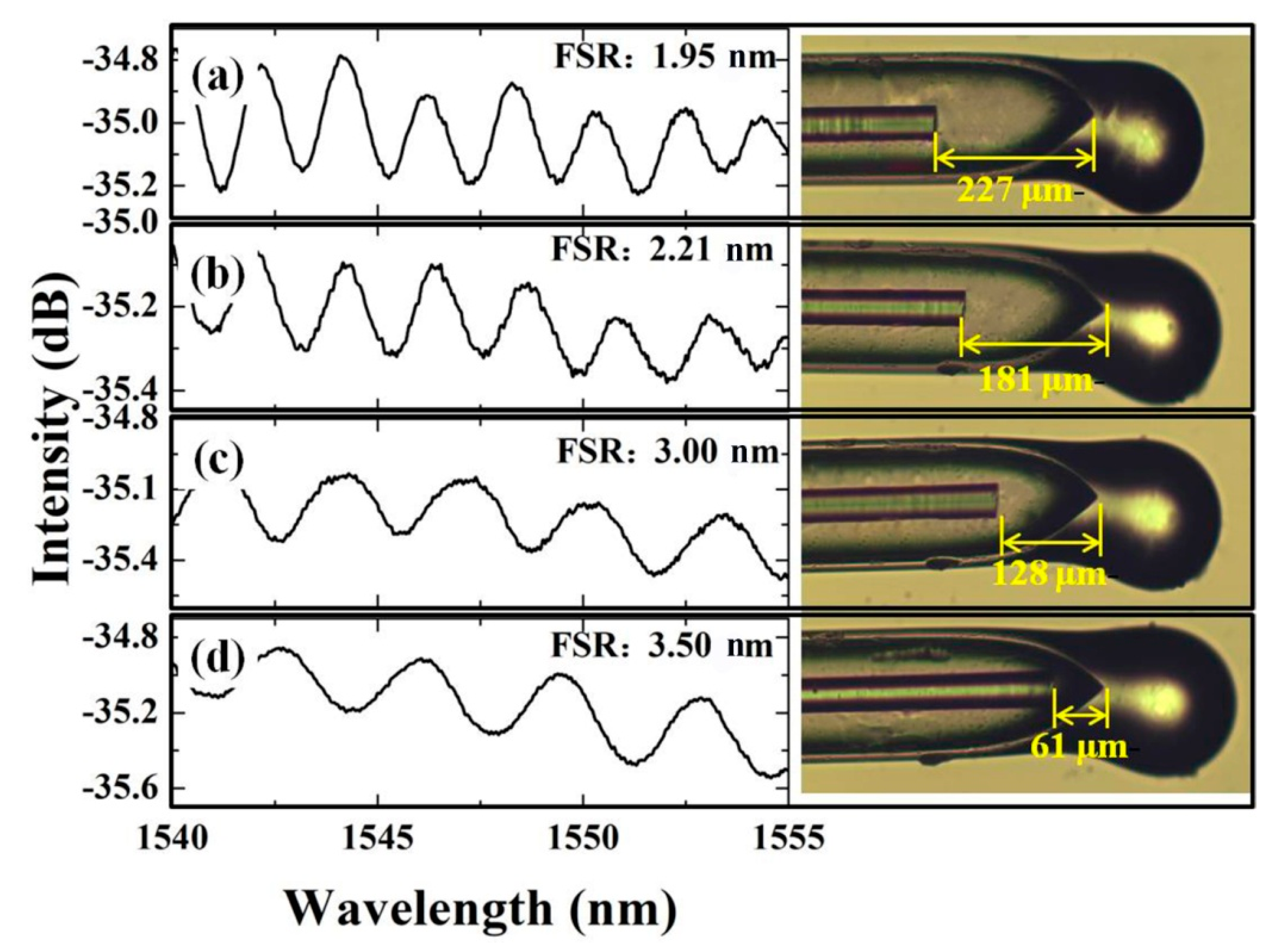

2.2. Cavity Length Optimization

2.3. Temperature Probe Package

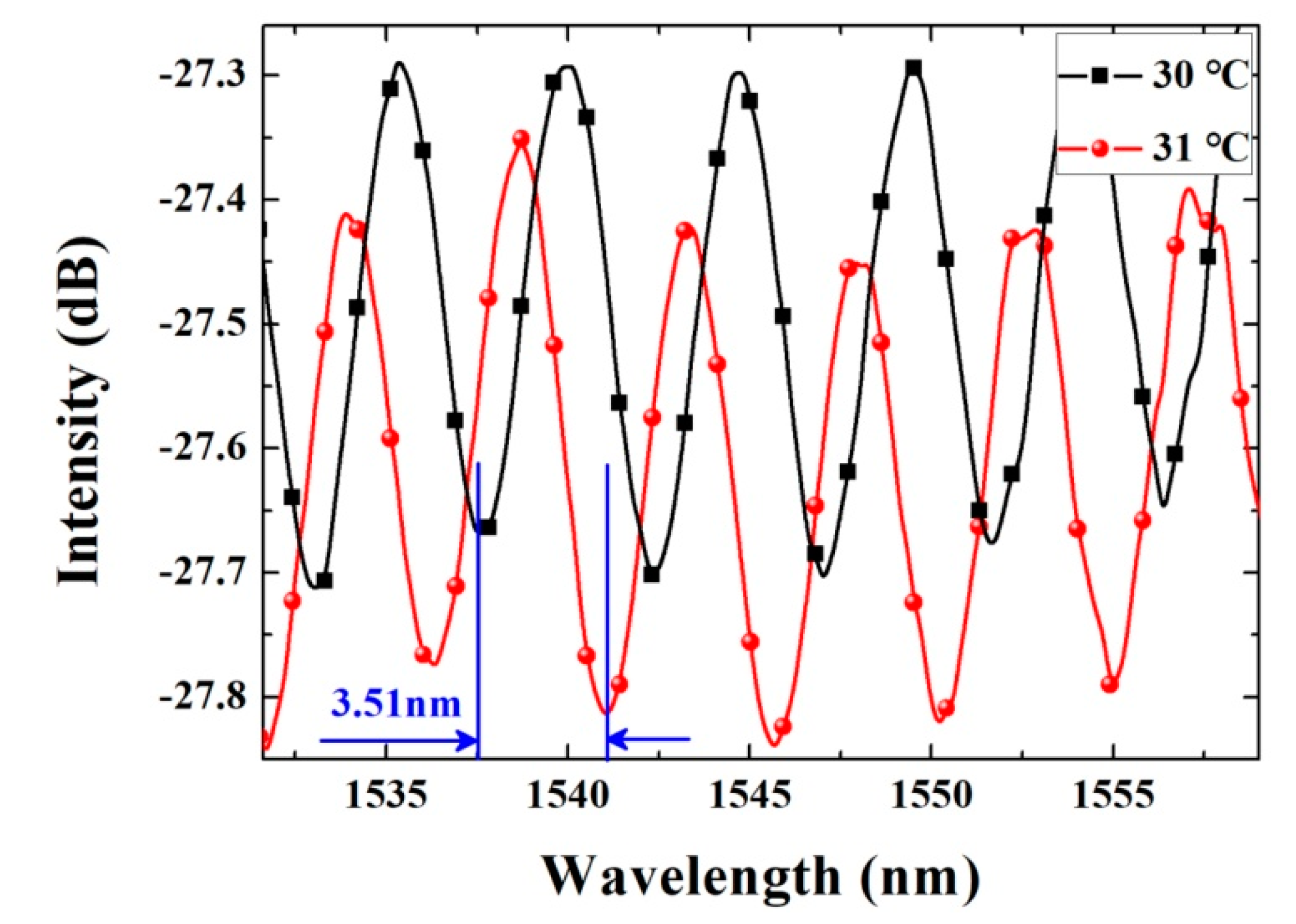

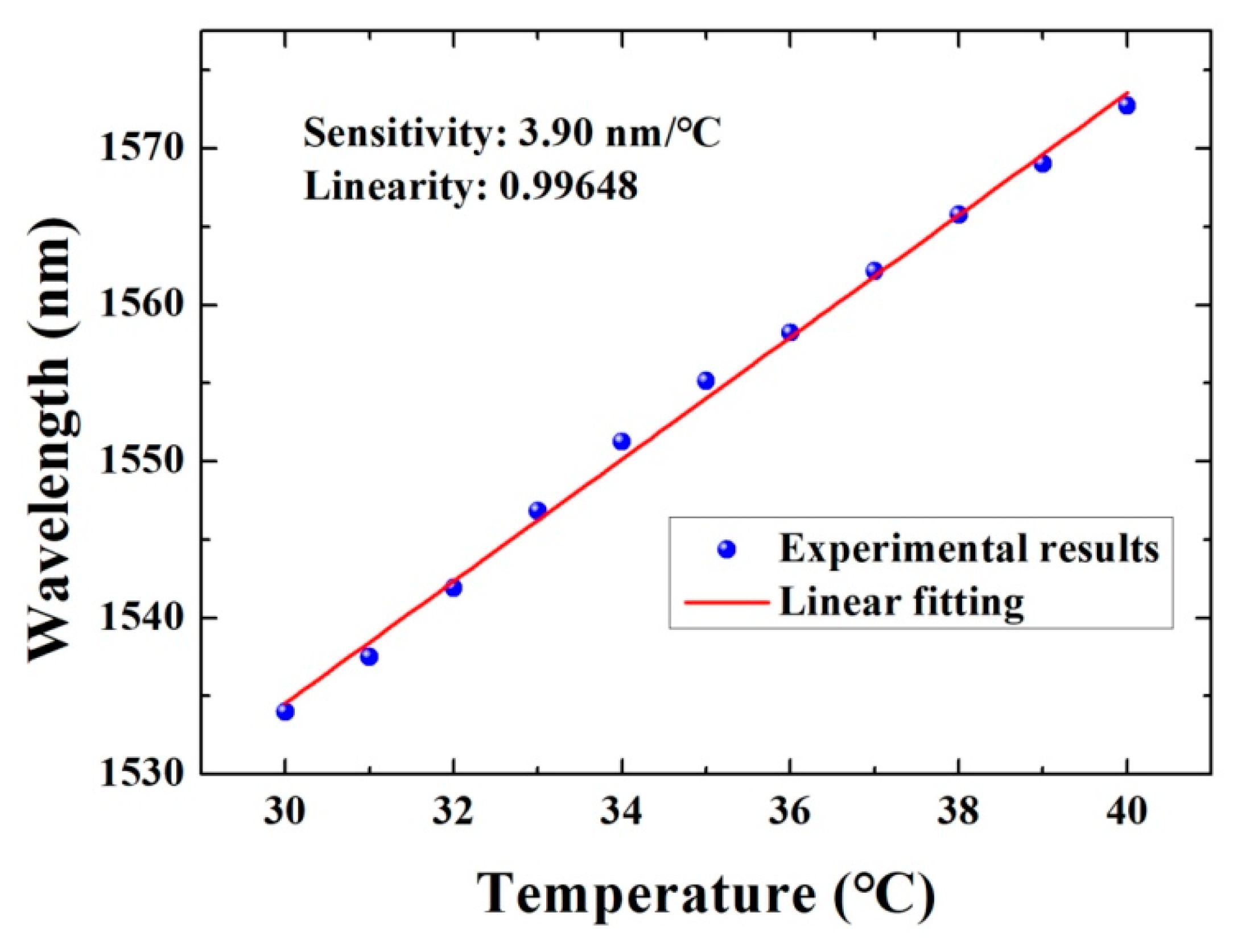

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wei, R.; Bao, X. A low power energy-efficient precision CMOS temperature sensor. Micromachines 2018, 9, 257. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Pei, K.; Peng, B.; Zhang, Z.; Wang, Z.; Wang, X.; Chan, P.K. A low-operating-power and flexible active-matrix organic-transistor temperature-sensor array. Adv. Mater. 2016, 28, 4832–4838. [Google Scholar] [CrossRef] [PubMed]

- Yan, D.; Yang, Y.; Hong, Y.; Liang, T.; Yao, Z.; Chen, X.; Xiong, J. AlN-based ceramic patch antenna-type wireless passive high-temperature sensor. Micromachines 2017, 8, 301. [Google Scholar] [CrossRef] [PubMed]

- Hernandez-Romano, I.; Cruz-Garcia, M.A.; Moreno-Hernandez, C.; Monzon-Hernandez, D.; Lopez-Figueroa, E.O.; Paredes-Gallardo, O.E.; Torres-Cisneros, M.; Villatoro, J. Optical fiber temperature sensor based on a microcavity with polymer overlay. Opt. Express 2016, 24, 5654–5661. [Google Scholar] [CrossRef] [PubMed]

- Fan, R.; Mu, Z.Z.; Li, J. Miniature temperature sensor based on polymer-packaged silica microfiber resonator. J. Phys. Chem. Solids 2019, 129, 307–311. [Google Scholar] [CrossRef]

- Liu, B.; Yu, Z.H.; Hill, C.; Cheng, Y.J.; Homa, D.; Pickrell, G.; Wang, A.B. Sapphire-fiber-based distributed high-temperature sensing system. Opt. Lett. 2016, 41, 4405–4408. [Google Scholar] [CrossRef] [PubMed]

- Dominguez-Flores, C.E.; Monzon-Hernandez, D.; Moreno-Basulto, J.I.; Rodriguez-Quiroz, O.; Minkovich, V.P.; Lopez-Cortes, D.; Hernandez-Romano, I. Real-time temperature sensor based on in-fiber Fabry-Perot interferometer embedded in a resin. J. Light. Technol. 2019, 37, 1084–1090. [Google Scholar] [CrossRef]

- Wang, F.R.; Liu, Y.J.; Lu, Y.L.; Zhang, L.L.; Ma, J.; Wang, L.; Sun, W.M. High-sensitivity Fabry-Perot interferometer temperature sensor probe based on liquid crystal and the Vernier effect. Opt. Lett. 2018, 43, 5355–5358. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.G.; Sheng, Q.W.; Hou, W.L.; Han, M. High-resolution, large dynamic range fiber-optic thermometer with cascaded Fabry-Perot cavities. Opt. Lett. 2016, 41, 5134–5137. [Google Scholar] [CrossRef] [PubMed]

- Deng, J.; Wang, D.N. Construction of cascaded Fabry-Perot interferometers by four in-fiber mirrors for high-temperature sensing. Opt. Lett. 2019, 44, 1289–1292. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.G.; Liu, G.G.; Zhu, Y.P.; Sheng, Q.W.; Wang, X.; Liu, Y.; Jing, Z.G.; Peng, W.; Han, M. Unambiguous peak identification of a silicon Fabry-Perot temperature sensor assisted with an in-line fiber Bragg grating. J. Light. Technol. 2019, 37, 4210–4215. [Google Scholar] [CrossRef]

- Mathew, J.; Hauser, C.; Stoll, P.; Kenel, C.; Polyzos, D.; Havermann, D.; MacPherson, W.N.; Hand, D.P.; Leinenbach, C.; Spierings, A.; et al. Integrating fiber Fabry-Perot cavity sensor into 3-D printed metal components for extreme high-temperature monitoring applications. IEEE Sens. J. 2017, 17, 4107–4114. [Google Scholar] [CrossRef]

- Liu, S.Q.; Ji, Y.K.; Yang, J.; Sun, W.M.; Li, H.Y. Nafion film temperature/humidity sensing based on optical fiber Fabry-Perot interference. Sens. Actuator A-Phys. 2018, 269, 313–321. [Google Scholar] [CrossRef]

- Li, C.; Liu, Q.W.; Peng, X.B.; Fan, S.C. Analyzing the temperature sensitivity of Fabry-Perot sensor using multilayer graphene diaphragm. Opt. Express 2015, 23, 27494–27502. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.H.; Wang, Y.; Ma, J.; Zheng, Z.; Luo, Z.Z.; Zheng, Y. Fabry-Perot interferometric high-temperature sensing up to 1200 degrees C based on a silica glass photonic crystal fiber. Sensors 2018, 18, 273. [Google Scholar]

- Chen, Z.S.; Xiong, S.S.; Gao, S.C.; Zhang, H.; Wan, L.; Huang, X.C.; Huang, B.S.; Feng, Y.H.; Liu, W.P.; Li, Z.H. High-Temperature Sensor Based on Fabry-Perot Interferometer in Microfiber Tip. Sensors 2018, 18, 202. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.J.; Han, M. Fiber-optic temperature sensor using dual Fabry-Perot cavities filled with gas of different pressure. Sens. Actuator A-Phys. 2017, 261, 229–234. [Google Scholar] [CrossRef]

- Lahoz, F.; Martin, I.R.; Soler-Carracedo, K.; Caceres, J.M.; Gil-Rostra, J.; Yubero, F. Holmium doped fiber thermal sensing based on an optofluidic Fabry-Perot microresonator. J. Lumin. 2019, 206, 492–497. [Google Scholar] [CrossRef]

- Li, M.; Liu, Y.; Gao, R.X.; Li, Y.; Zhao, X.L.; Qu, S.L. Ultracompact fiber sensor tip based on liquid polymer-filled Fabry-Perot cavity with high temperature sensitivity. Sens. Actuator B-Chem. 2016, 233, 496–501. [Google Scholar] [CrossRef]

- Lin, C.P.; Wang, Y.; Huang, Y.J.; Liao, C.R.; Bai, Z.Y.; Hou, M.X.; Li, Z.Y.; Wang, Y.P. Liquid modified photonic crystal fiber for simultaneous temperature and strain measurement. Photonics Res. 2017, 5, 129–133. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.; Ren, C.Q.; Sui, Z.Q.; Li, J. A high sensitivity temperature sensing probe based on microfiber Fabry-Perot interference. Sensors 2019, 19, 1819. [Google Scholar] [CrossRef] [PubMed]

| Structure or Materials | Sensitivity | Range | Reference |

|---|---|---|---|

| TiO2 film/PDMS overlay | 0.13 dB/°C | 22–60 °C | [4] |

| SMF/Capillary | −60.79 nW/°C | 20–35 °C | [7] |

| Cascaded Fabry-Perot interferometers/Liquid crystal filling/Vernier effect | 19.55 nm/°C | 30–120 °C | [8] |

| Silicon/UV glue | 84.4 pm/°C | −50–130 °C | [9] |

| Air cavity | 9.91 pm/°C 15.88 pm/°C | 100–400 °C 400–1100 °C | [10] |

| FBG/UV glue | 81.0 pm/°C | −60–140 °C | [11] |

| Cr/Capillary/Ni jacket | ~7.7 mrad/°C | −25–950 °C | [12] |

| Nafion film | 2.71 nm/°C | −15–65 °C | [13] |

| Graphene films | 352 pm/°C | 20–60 °C | [14] |

| Photonics crystal fiber (PCF) | 15.61 pm/°C | 300–1200 °C | [15] |

| Microfiber tip | 13.6 pm/°C | 25–1000 °C | [16] |

| Gas filled capillaries | 74.6 pm/°C | 127–327 °C | [17] |

| Ho3+ doped fibers | 75 pm/°C | 20–50 °C | [18] |

| Liquid polymer | 877 pm/°C | 30–60 °C | [19] |

| Refractive index liquid/PCF | ~14.72 nm/°C | 18–21 °C | [20] |

| Microfiber/PDMS | 11.86 nm/°C | 43–50 °C | [21] |

| Microfiber/Microsphere/PDMS | 3.9 nm/°C | 30–40 °C | This work |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Yang, J.; Ma, J. Highly Sensitive Temperature Sensing Performance of a Microfiber Fabry-Perot Interferometer with Sealed Micro-Spherical Reflector. Micromachines 2019, 10, 773. https://doi.org/10.3390/mi10110773

Li J, Yang J, Ma J. Highly Sensitive Temperature Sensing Performance of a Microfiber Fabry-Perot Interferometer with Sealed Micro-Spherical Reflector. Micromachines. 2019; 10(11):773. https://doi.org/10.3390/mi10110773

Chicago/Turabian StyleLi, Jin, Juntong Yang, and Jinna Ma. 2019. "Highly Sensitive Temperature Sensing Performance of a Microfiber Fabry-Perot Interferometer with Sealed Micro-Spherical Reflector" Micromachines 10, no. 11: 773. https://doi.org/10.3390/mi10110773

APA StyleLi, J., Yang, J., & Ma, J. (2019). Highly Sensitive Temperature Sensing Performance of a Microfiber Fabry-Perot Interferometer with Sealed Micro-Spherical Reflector. Micromachines, 10(11), 773. https://doi.org/10.3390/mi10110773