One-Step Coating Processed Phototransistors Enabled by Phase Separation of Semiconductor and Dielectric Blend Film

Abstract

1. Introduction

2. Experimental

2.1. Materials Preparation

2.2. Device Fabrication

2.3. Measurement and Characterization

3. Results and Discussion

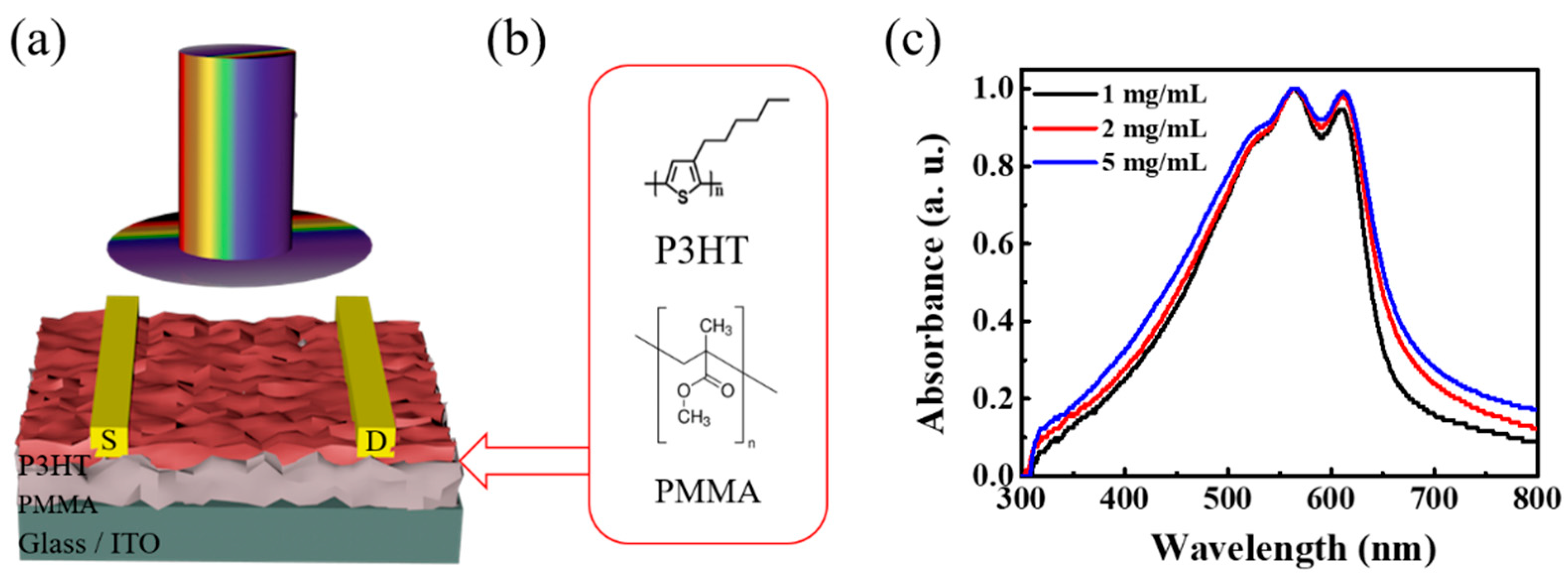

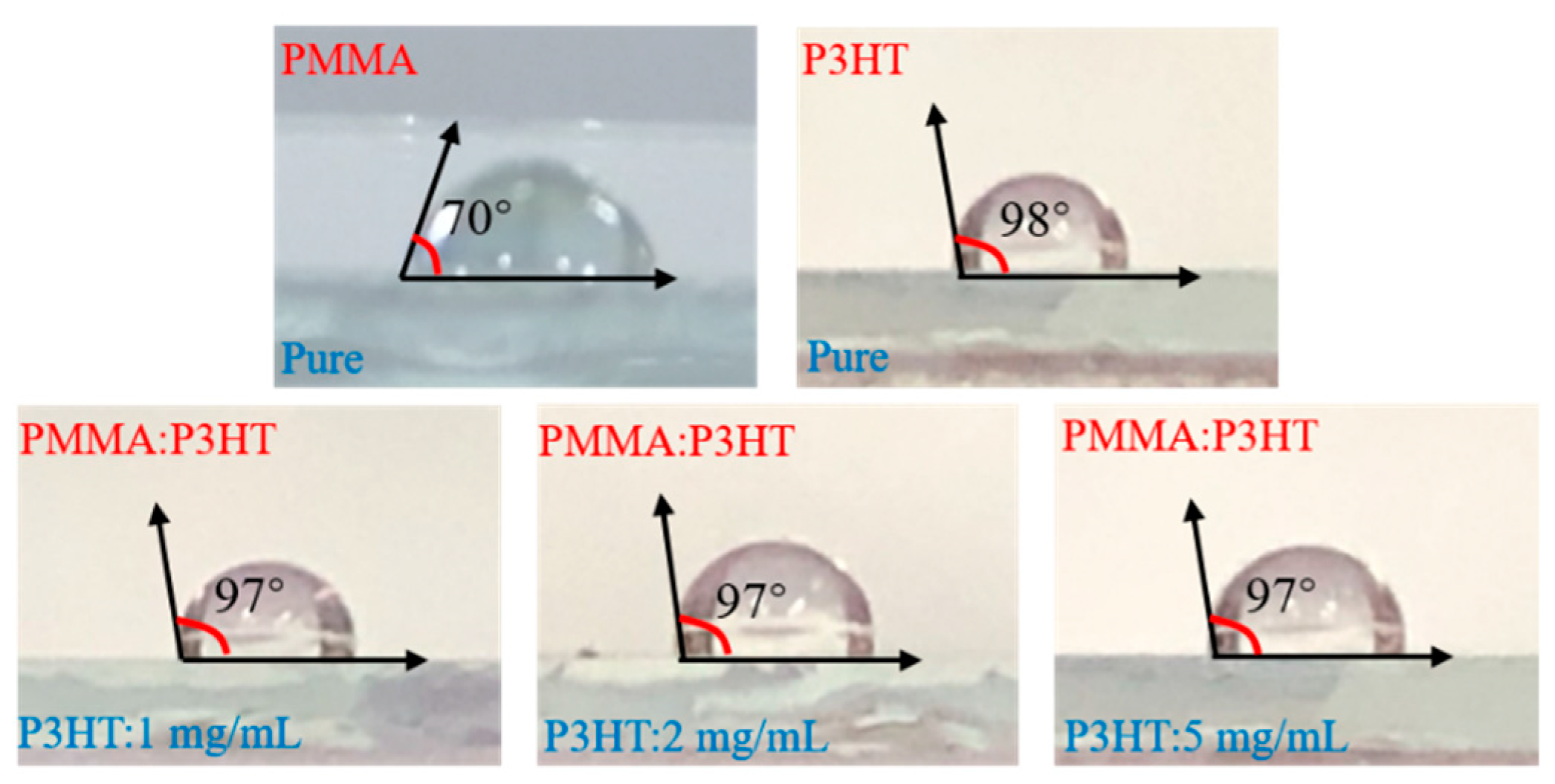

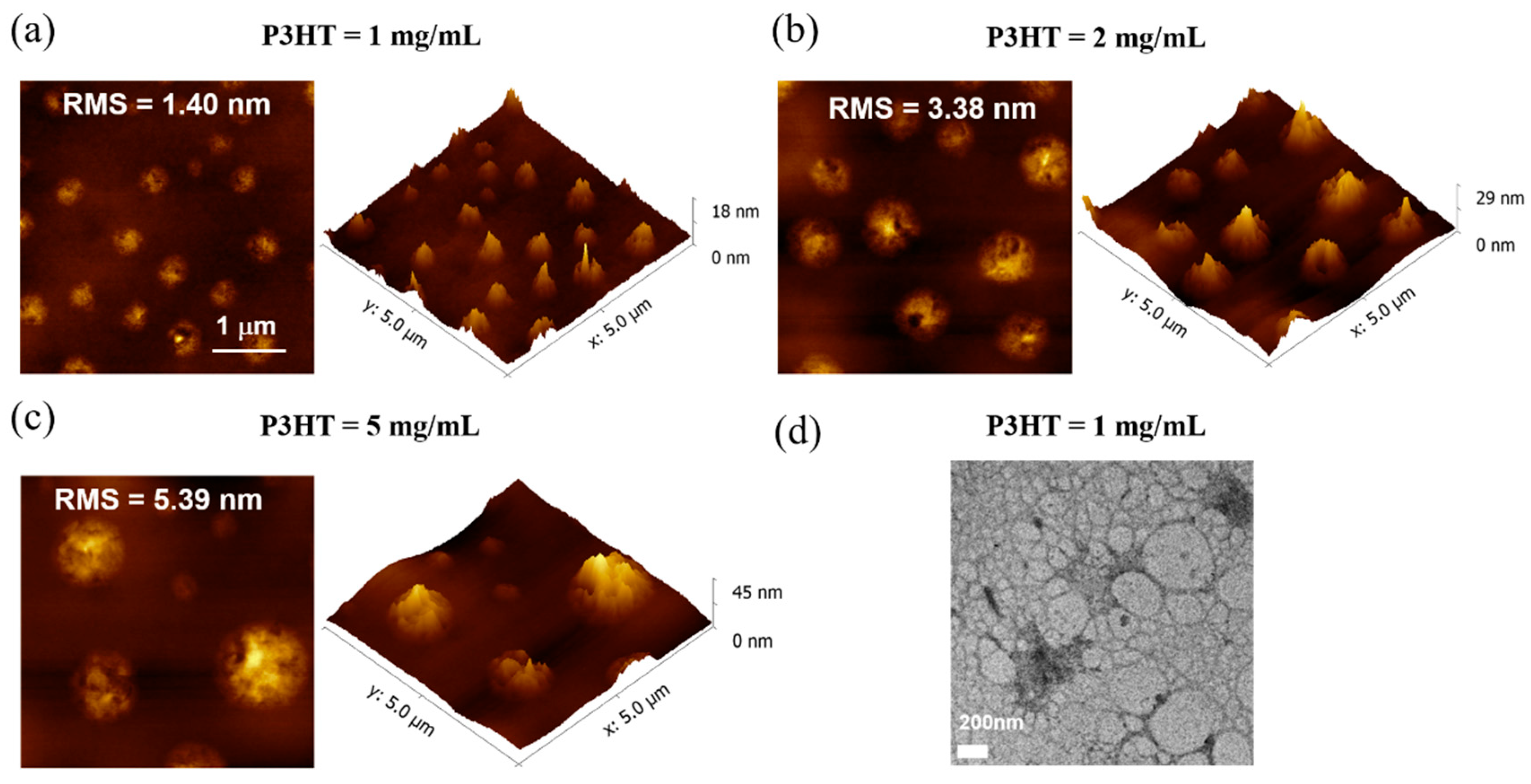

3.1. Thin Film Characterization of Devices

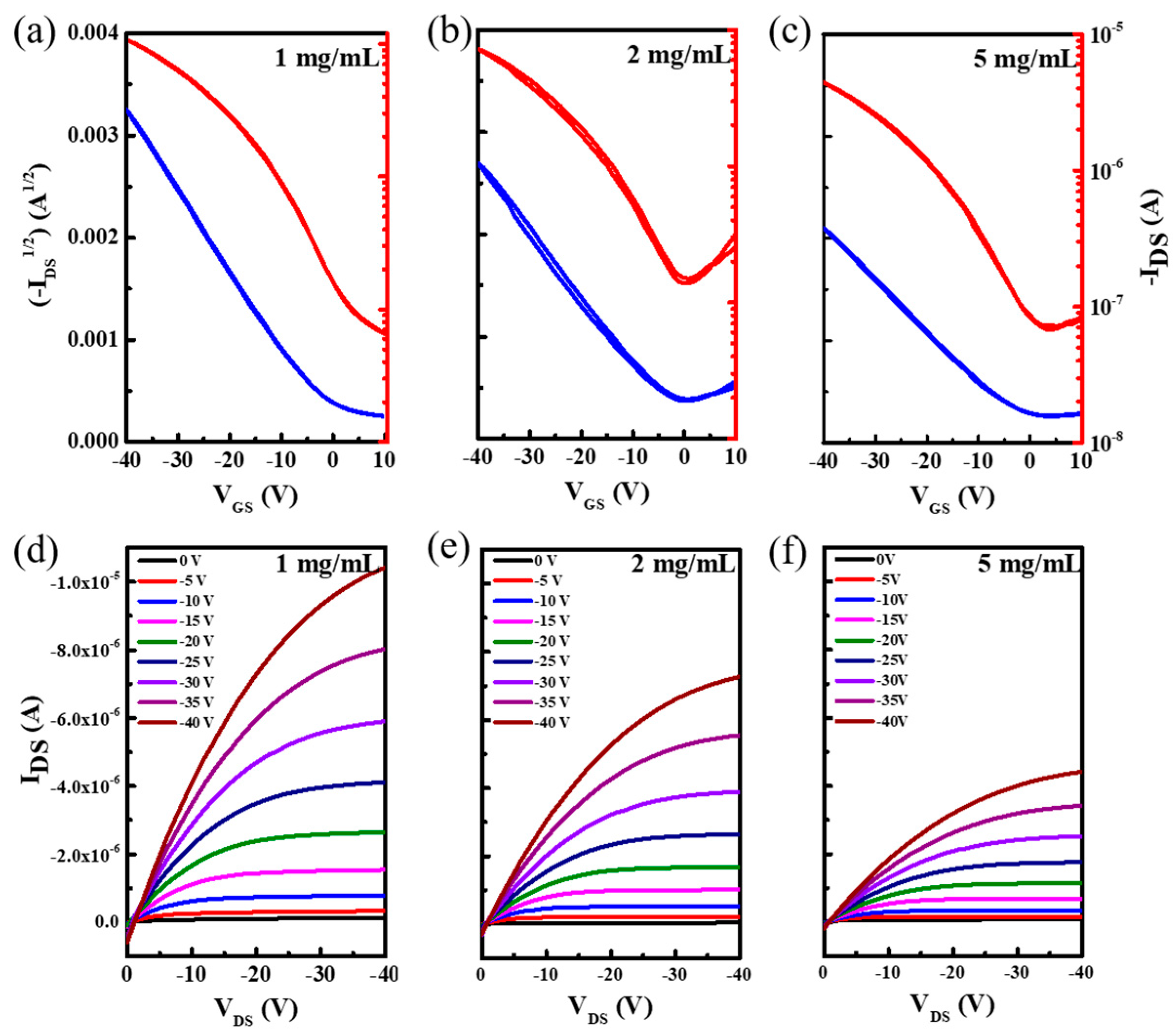

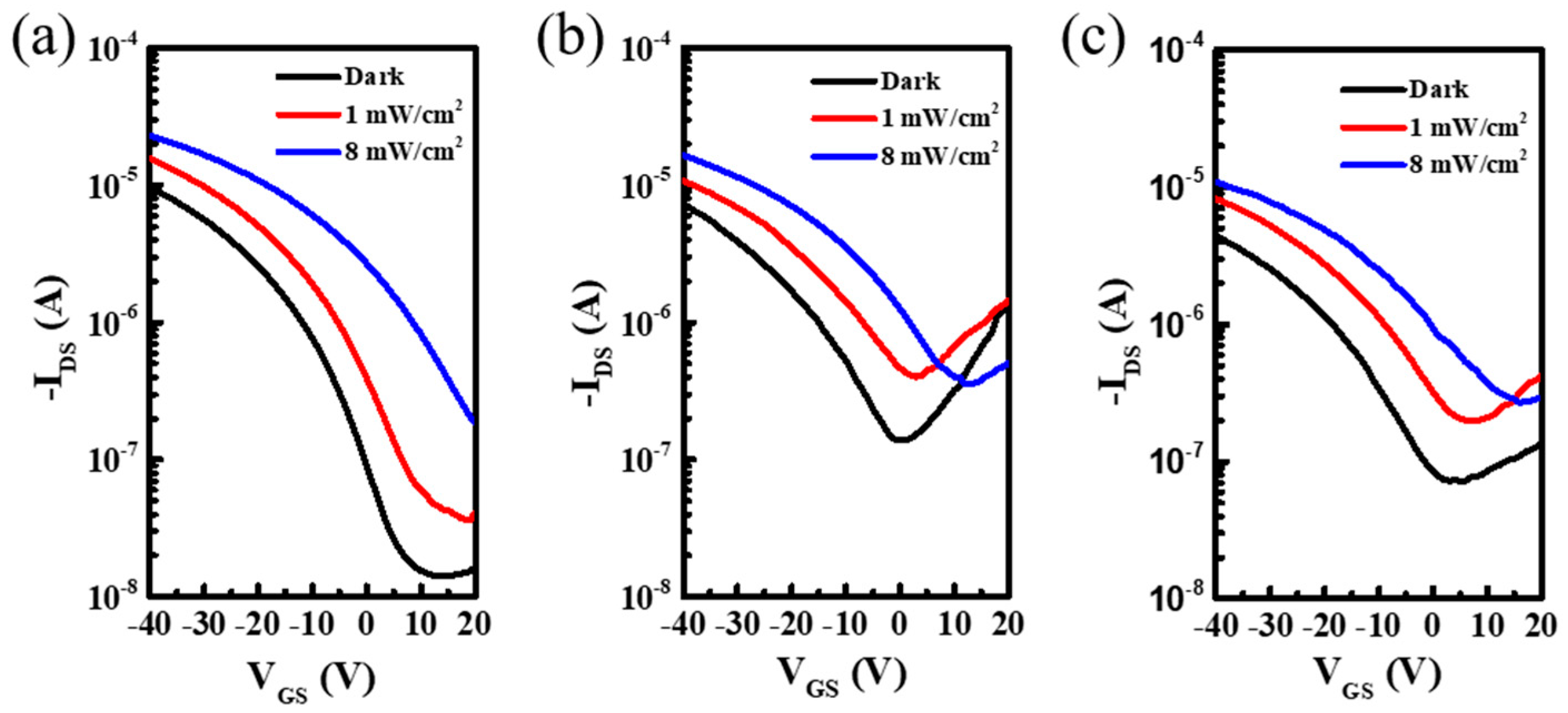

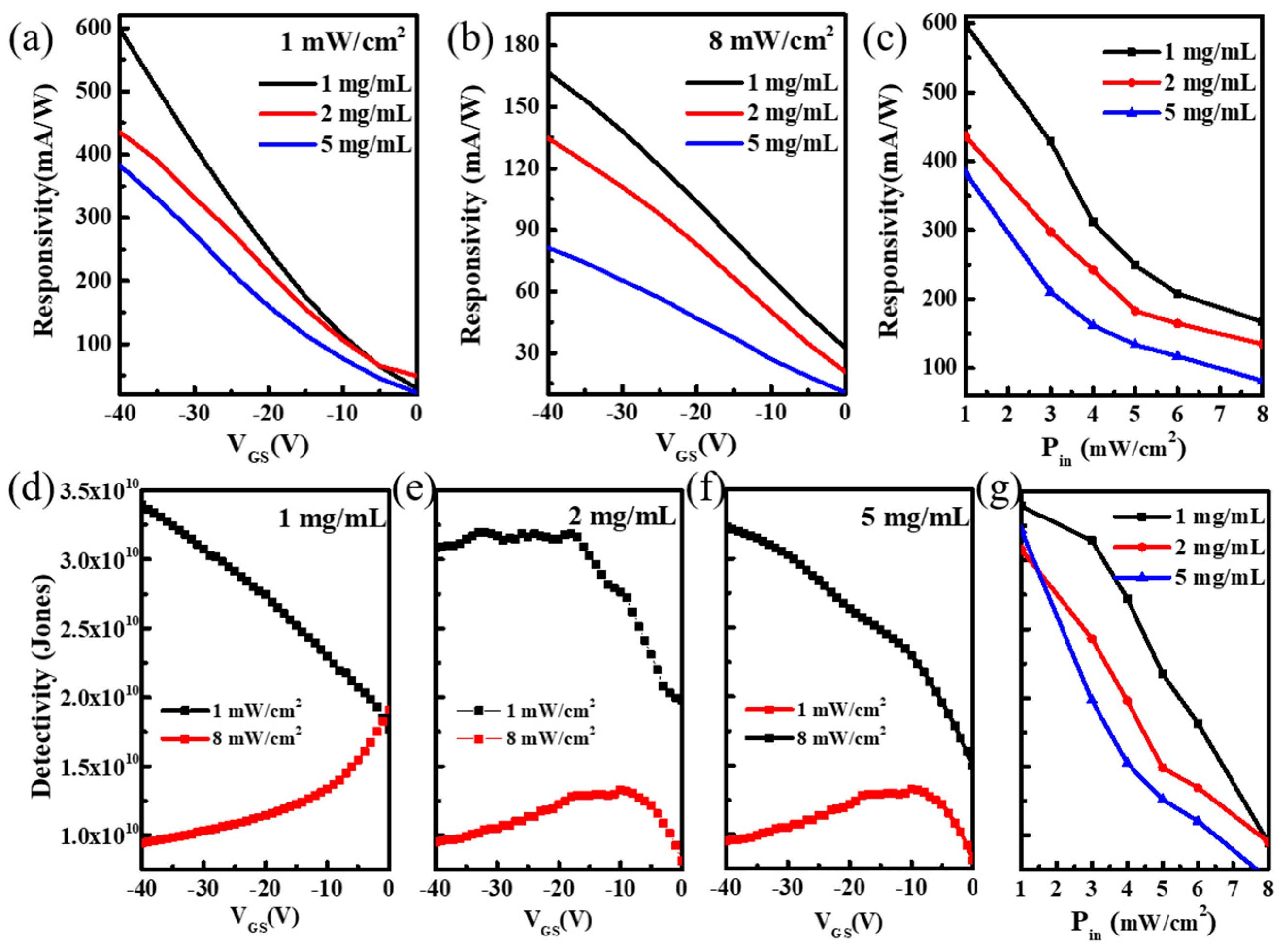

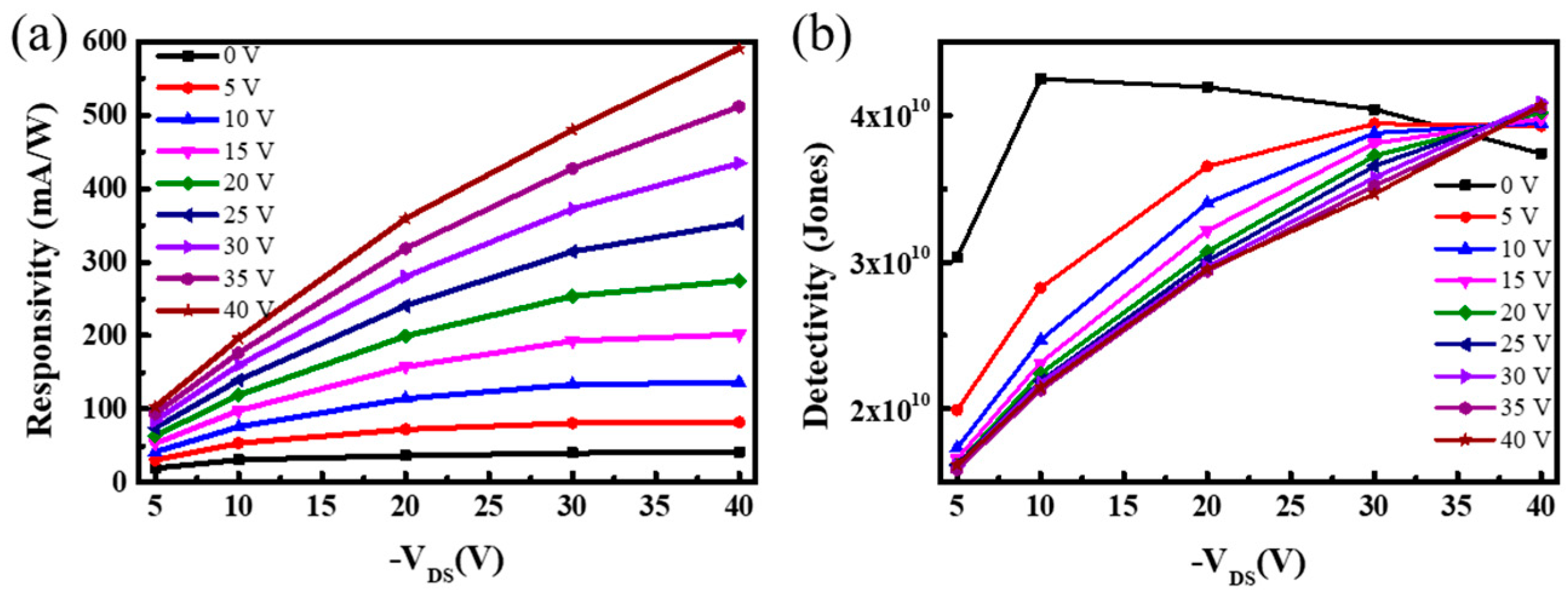

3.2. Phototransistor Performance

3.3. Exploration of Microscopic Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arquer, F.P.G.D.; Armin, A.; Meredith, P.; Sargent, E.H. Solution-processed semiconductors for next-generation photodetectors. Nat. Rev. Mater. 2017, 2, 16100. [Google Scholar] [CrossRef]

- Kang-Jun, B.; Maddalena, B.; Dario, N.; Mario, C.; Yong-Young, N. Organic light detectors: Photodiodes and phototransistors. Adv. Mater. 2013, 25, 4267–4295. [Google Scholar]

- Koppens, F.H.L.; Mueller, T.; Avouris, P.; Ferrari, A.C.; Vitiello, M.S.; Polini, M. Photodetectors based on graphene, other two-dimensional materials and hybrid systems. Nat. Nanotechnol. 2014, 9, 780–793. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.G.; Wang, H.L.; Xin, N.; Sun, R.J.; Albadawi, H.; Salomao, M.; Silva, A.C.; Yang, Y.; Tian, L.M.; Koh, A. Needle-shaped ultrathin piezoelectric microsystem for guided tissue targeting via mechanical sensing. Nat. Biomed. Eng. 2018, 2, 165–172. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.C.; Zhou, Z.; Chen, J.W.; Choy, T.H.; Wang, J.L.; Zhang, N.; Lin, Z.Y.; Yu, S.M.; Kang, J.F.; Wong, H.S.P.; et al. Optoelectronic resistive random access memory for neuromorphic vision sensors. Nat. Nanotechnol. 2019, 14, 776–782. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.G.; Marks, T.J.; Facchetti, A. Metal oxides for optoelectronic applications. Nat. Mater. 2016, 15, 383–396. [Google Scholar] [CrossRef]

- Yu, Z.Z.; Cheng, H.Y. Tunable adhesion for bio-integrated devices. Micromachines 2018, 9, 529. [Google Scholar] [CrossRef]

- Yu, H.; Kim, D.; Lee, J.; Baek, S.; Lee, J.; Singh, R.; So, F. High-gain infrared-to-visible upconversion light-emitting phototransistors. Nat. Photonics. 2016, 10, 129–134. [Google Scholar] [CrossRef]

- Li, H.; Shi, W.; Song, J.; Jang, H.J.; Dailey, J.; Yu, J.S.; Katz, H.E. Chemical and biomolecule sensing with organic field-effect transistors. Chem. Rev. 2019, 119, 3–35. [Google Scholar] [CrossRef]

- Gu, P.; Yao, Y.; Feng, L.; Niu, S.; Dong, H. Recent advances in polymer phototransistors. Polym. Chem. 2015, 6, 7933–7944. [Google Scholar] [CrossRef]

- Ren, X.C.; Yang, F.X.; Gao, X.; Cheng, S.S.; Zhang, X.T.; Dong, H.L.; Hu, W.P. Organic field-effect transistor for energy-related applications: Low-power-consumption devices, near-infrared phototransistors, and organic thermoelectric devices. Adv. Energy. Mater. 2019, 8, 1801003. [Google Scholar] [CrossRef]

- Yu, H.; Bao, Z.; Oh, J.H. Organic phototransistors: High-performance phototransistors based on single-crystalline n-channel organic nanowires and photogenerated charge-carrier behaviors. Adv. Funct. Mater. 2013, 23, 629–639. [Google Scholar] [CrossRef]

- Ji, D.Y.; Li, T.; Liu, J.; Amirjalayer, S.; Zhong, M.Z.; Zhang, Z.Y.; Huang, X.H.; Wei, Z.M.; Dong, H.L.; Hu, W.P.; et al. Band-like transport in small-molecule thin films toward high mobility and ultrahigh detectivity phototransistor arrays. Nat. Commun. 2019, 10, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Yi, Y.; Wang, X.; Meng, H.; Lei, D.; Yu, X.F.; Chu, P.K.; Li, J. A novel hybrid-layered organic phototransistor enables efficient intermolecular charge transfer and carrier transport for ultrasensitive photodetection. Adv. Mater. 2019, 31, 1900763. [Google Scholar] [CrossRef] [PubMed]

- Chao, X.; Peng, Y.; Liu, Z.; Li, L.; Feng, Y. Ultrasensitive broadband phototransistors based on perovskite organic-semiconductor vertical heterojunctions. Light Sci. Appl. 2017, 6, e17023. [Google Scholar]

- Xie, C.; Yan, F. Perovskite/poly(3-hexylthiophene)/graphene multiheterojunction phototransistors with ultrahigh gain in broadband wavelength region. ACS Appl. Mater. Interfaces 2017, 9, 1569–1576. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Park, S.Y.; Shim, S.O.; Kang, H.; Hong, H. A polymer gate dielectric for high-mobility polymer thin-film transistors and solvent effects. Appl. Phys. Lett. 2004, 85, 3283–3285. [Google Scholar] [CrossRef]

- Kline, R.J.; Mcgehee, M.D.; Toney, M.F. Highly oriented crystals at the buried interface in polythiophene thin-film transistors. Nat. Mater. 2006, 5, 222–228. [Google Scholar] [CrossRef]

- Aguirre, J.C.; Hawks, S.A.; Ferreira, A.S.; Yee, P.; Schwartz, B. Sequential processing for organic photovoltaics: Design rules for morphology control by tailored semi-orthogonal solvent blends. Adv. Electron. Mater. 2015, 5, 1402020. [Google Scholar] [CrossRef]

- Shao, B.Y.; Liu, Y.M.; Zhuang, X.M.; Hou, S.H.; Han, S.J.; Yu, X.G.; Yu, J.S. Crystallinity and grain boundary control of TIPS-pentacene in organic thin-film transistors for the ultra-high sensitive detection of NO2. J. Mater. Chem. C 2019, 7, 10196. [Google Scholar] [CrossRef]

- Paterson, A.F.; Singh, S.; Fallon, K.J.; Hodsden, T.; Han, Y.; Schroeder, B.C.; Bronstein, H.; Heeney, M.; McCulloch, I.; Anthopoulos, T.D. Recent progress in high-mobility organic Transistors: A reality check. Adv. Mater. 2018, 30, 1801079. [Google Scholar] [CrossRef] [PubMed]

- Kang, B.; Ge, F.; Qiu, L.; Cho, K. Effective use of electrically insulating units in organic semiconductor thin films for high-performance organic transistors. Adv. Electron. Mater. 2017, 3, 1600240. [Google Scholar] [CrossRef]

- Gumyusenge, A.; Tran, D.T.; Luo, X.; Pitch, G.M.; Zhao, Y.; Jenkins, K.A.; Dunn, T.J.; Ayzner, A.L.; Savoie, B.M.; Mei, J. Semiconducting polymer blends that exhibit stable charge transport at high temperatures. Science 2018, 362, 1131–1134. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, A.P.; Temino, I.; Ocal, O.; Torrent, M.M.; Barrena, E. Decoding the vertical phase separation and its impact on C8-BTBT/PS transistors properties. ACS Appl. Mater. Interfaces 2018, 10, 7296–7303. [Google Scholar] [CrossRef]

- Ge, F.; Wei, S.; Liu, Z.; Wang, G.; Wang, X.; Zhang, G.; Lu, H.; Cho, K.; Qiu, L. Tailoring structure and field-effect characteristics of ultrathin conjugated polymer films via phase separation. ACS Appl. Mater. Interfaces 2018, 10, 9602–9611. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, Y.H.; Ha, Y.H.; Kwon, J.; Pyo, S.; Kim, Y.H.; Lee, W.H. Semiconducting/insulating polymer blends with dual phase separation for organic field-effect transistors. RSC Adv. 2017, 7, 7526–7530. [Google Scholar] [CrossRef]

- Wang, X.; Lee, W.H.; Zhang, G.; Wang, X.; Kang, B.; Lu, H.; Qiu, L.; Cho, K.J. Self-stratified semiconductor/dielectric polymer blends: Vertical phase separation for facile fabrication of organic transistors. J. Mater. Chem. C 2013, 1, 3989–3998. [Google Scholar] [CrossRef]

- Wang, X.H.; Liu, Z.; Wei, S.Y.; Ge, F.; Liu, L.Y.; Zhang, G.B.; Ding, Y.S.; Qiu, L.Z. Ultrathin semiconductor films for NH3 gas sensors prepared by vertical phase separation. Synth. Met. 2018, 244, 20–26. [Google Scholar] [CrossRef]

- Qiu, L.; Lim, J.A.; Wang, X.; Lee, W.H.; Hwang, M.; Cho, K. Versatile use of vertical-phase-separation-induced bilayer structures in organic thin-film transistors. Adv. Mater. 2010, 20, 1141–1145. [Google Scholar] [CrossRef]

- Li, S.; Xue, D.; Xu, W.; Feng, Y.; Shu, C. Improving the photo current of the PCBM/P3HT photodetector device by using wavelength-matched photonic crystals. J. Mater. Chem. C 2014, 2, 1500–1504. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, F.; Li, L.; Gao, M.; Hu, B. Improved performance of photomultiplication polymer photodetectors by adjustment of P3HT molecular arrangement. ACS Appl. Mater. Interfaces 2015, 7, 22660–22668. [Google Scholar] [CrossRef]

- Chen, L.; Tian, W.; Sun, C.X.; Cao, F.R.; Li, L. Structural engineering of Si/TiO2/P3HT heterojunction photodetectors for a tunable response range. ACS Appl. Mater. Interfaces 2019, 11, 3241–3250. [Google Scholar] [CrossRef]

- Clark, J.; Silva, C.; Friend, R.H.; Spano, F.C. Role of intermolecular coupling in the photophysics of disordered organic semiconductors: Aggregate emission in regioregular polythiophene. Phys. Rev. Lett. 2007, 98, 206406. [Google Scholar] [CrossRef]

- Han, S.J.; Yang, Z.C.; Li, Z.K.; Zhuang, X.M.; Akinwande, D.; Yu, J.S. Improved room temperature NO2 sensing performance of organic field-effect transistor by directly blending a hole-transporting. ACS Appl. Mater. Interfaces 2018, 10, 38280–38286. [Google Scholar] [CrossRef]

- Dang, M.T.; Hirsch, L.; Wantz, G. P3HT:PCBM, best seller in polymer photovoltaic research. Adv. Mater. 2011, 23, 3597–3602. [Google Scholar] [CrossRef]

- Kim, M.; Lee, J.; Jo, S.B.; Sin, D.H.; Ko, H.; Lee, H.; Lee, S.G.; Cho, K. Critical factors governing vertical phase separation in polymer-PCBM blend films for organic solar cells. J. Mater. Chem. A 2016, 4, 15522–15535. [Google Scholar] [CrossRef]

- Schmidt-Hansberg, B.; Sanyal, M.; Klein, M.F.; Pfaff, M.; Schnabel, N.; Jaiser, S.; Vorobiev, A.; Muller, E.; Colsmann, A.; Scharfer, P. Moving through the phase diagram: Morphology formation in solution cast polymer-fullerene blend films for organic solar cells. ACS Nano 2011, 5, 8579–8590. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, L.; Hou, S.; Wang, Z.; Gao, Z.; Yu, X.; Yu, J. One-Step Coating Processed Phototransistors Enabled by Phase Separation of Semiconductor and Dielectric Blend Film. Micromachines 2019, 10, 716. https://doi.org/10.3390/mi10110716

Gao L, Hou S, Wang Z, Gao Z, Yu X, Yu J. One-Step Coating Processed Phototransistors Enabled by Phase Separation of Semiconductor and Dielectric Blend Film. Micromachines. 2019; 10(11):716. https://doi.org/10.3390/mi10110716

Chicago/Turabian StyleGao, Lin, Sihui Hou, Zijun Wang, Zhan Gao, Xinge Yu, and Junsheng Yu. 2019. "One-Step Coating Processed Phototransistors Enabled by Phase Separation of Semiconductor and Dielectric Blend Film" Micromachines 10, no. 11: 716. https://doi.org/10.3390/mi10110716

APA StyleGao, L., Hou, S., Wang, Z., Gao, Z., Yu, X., & Yu, J. (2019). One-Step Coating Processed Phototransistors Enabled by Phase Separation of Semiconductor and Dielectric Blend Film. Micromachines, 10(11), 716. https://doi.org/10.3390/mi10110716