Experimental Investigation on Rotating Electrochemical Etching of a Micro Spiral Cylindrical Electrode

Abstract

:1. Introduction

2. Analysis of Machining Mechanism

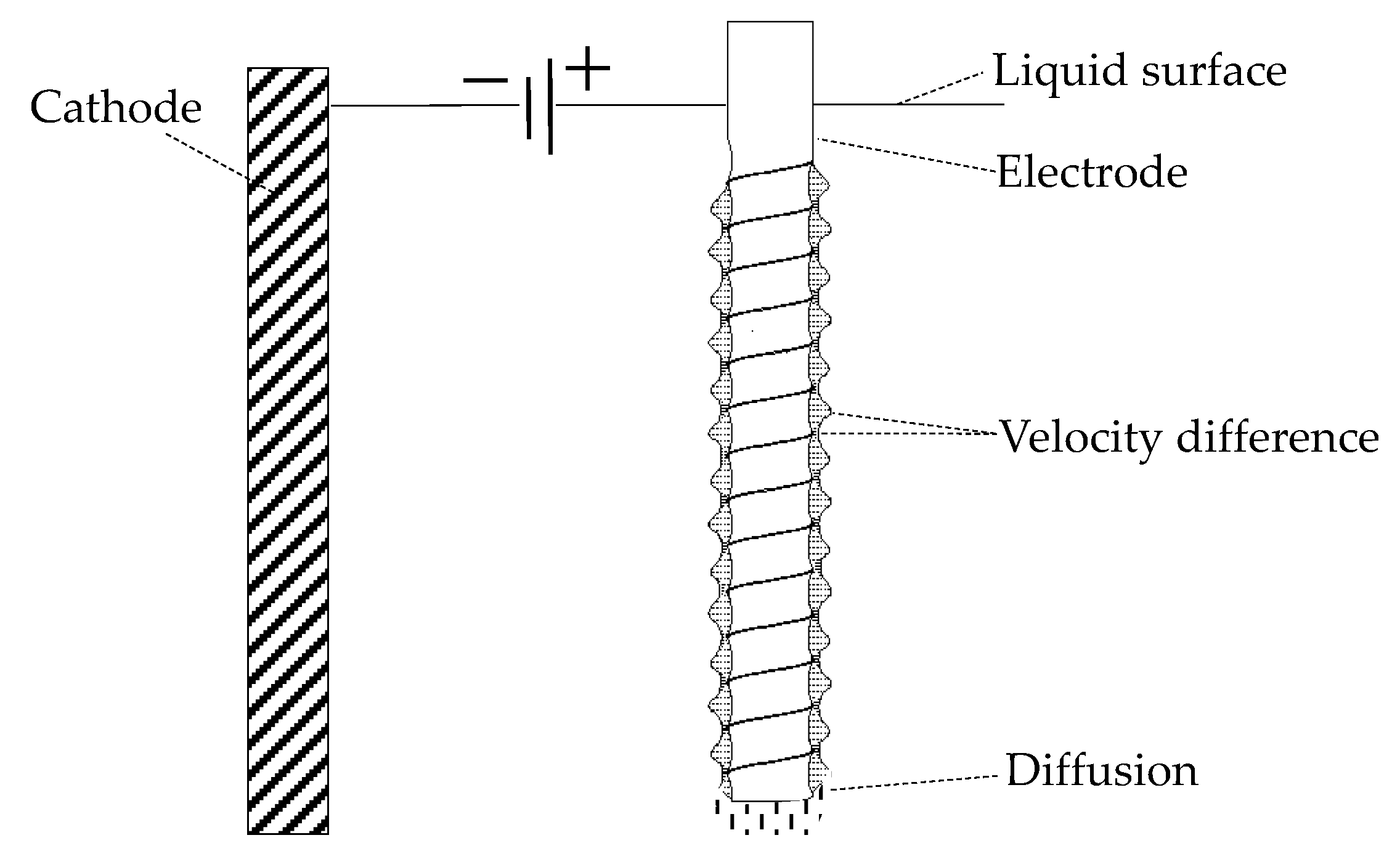

2.1. Machining Principle

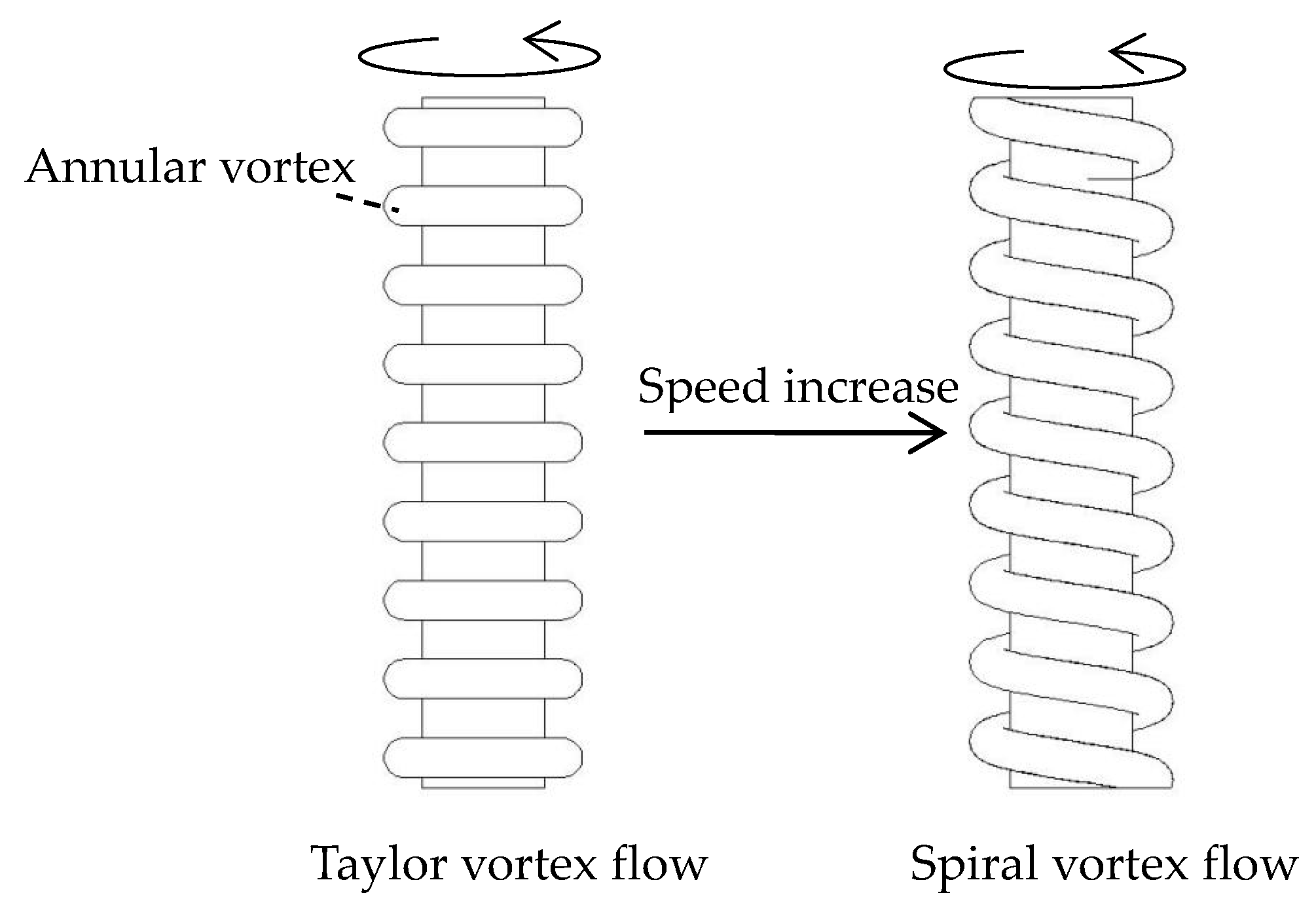

2.2. Flow Field Analysis of Electrode Surface

3. Experiments and discussion

3.1. Effect of Rotation Direction on Thread Structure

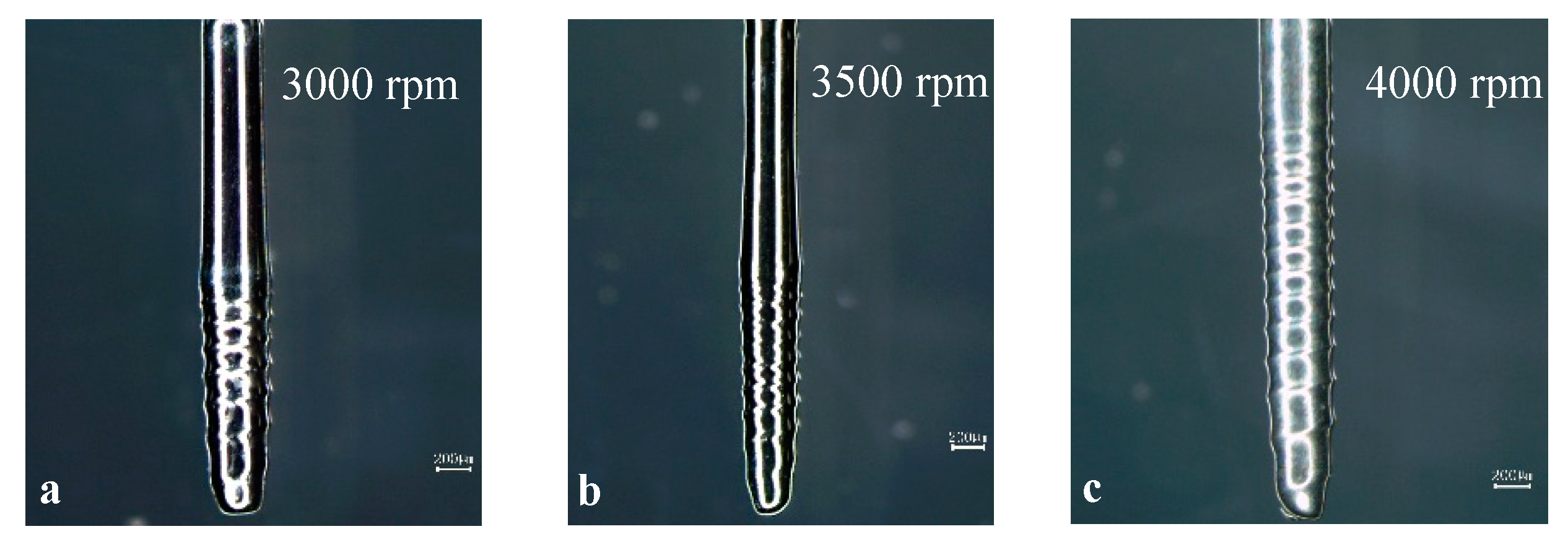

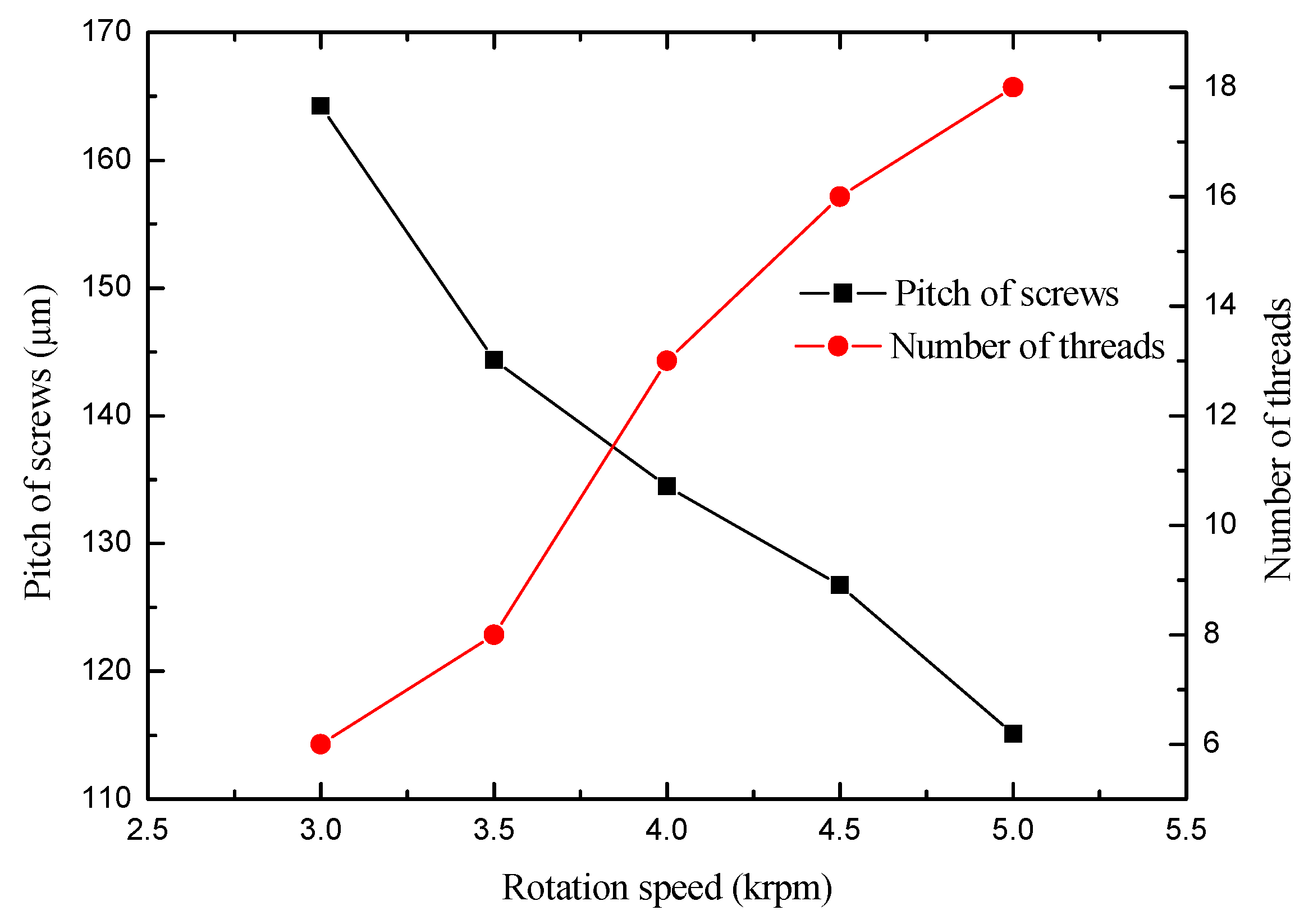

3.2. Effect of Rotation Speed on Thread Structure

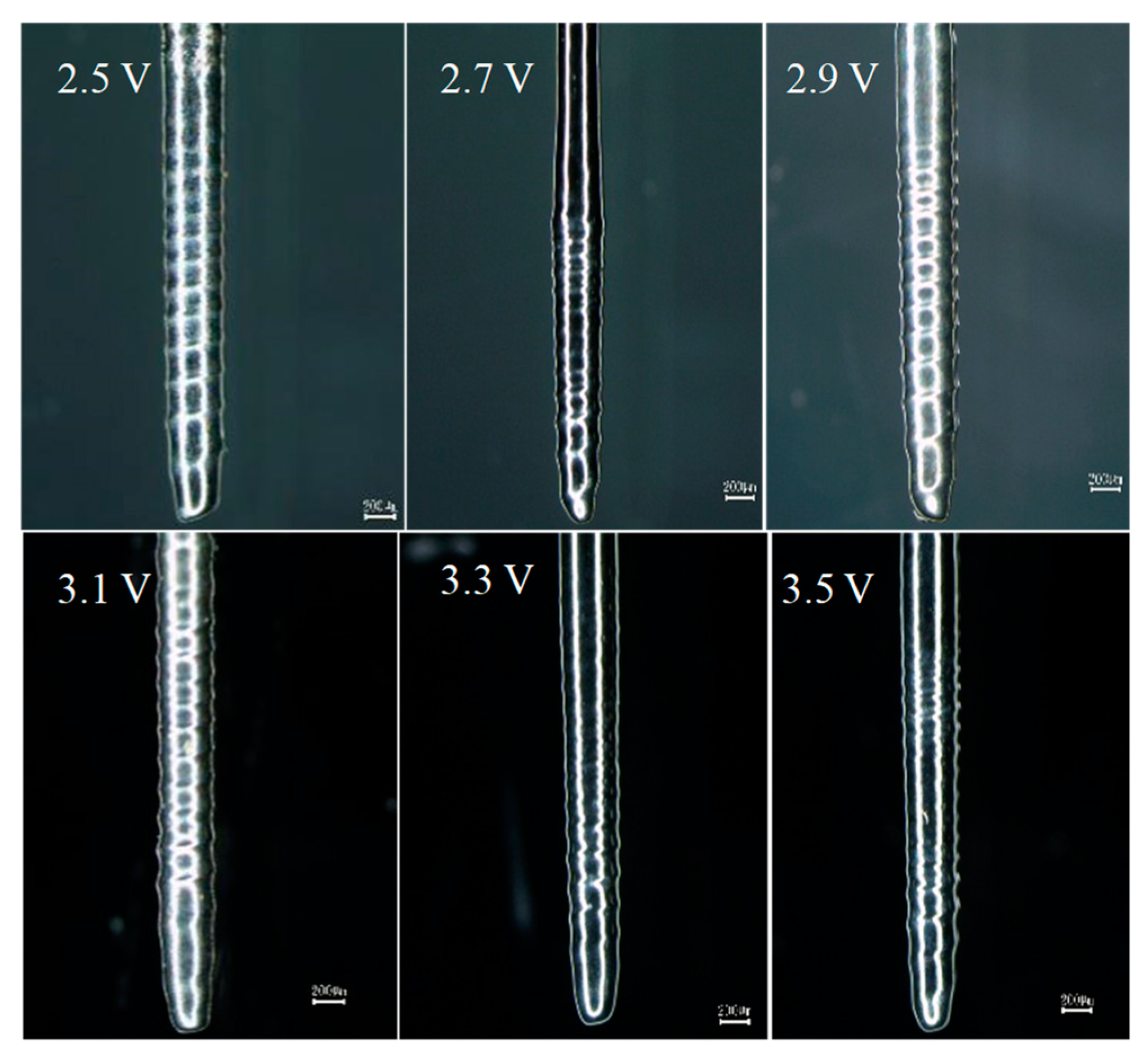

3.3. Effect of Machining Voltage on Depth of Spiral Groove

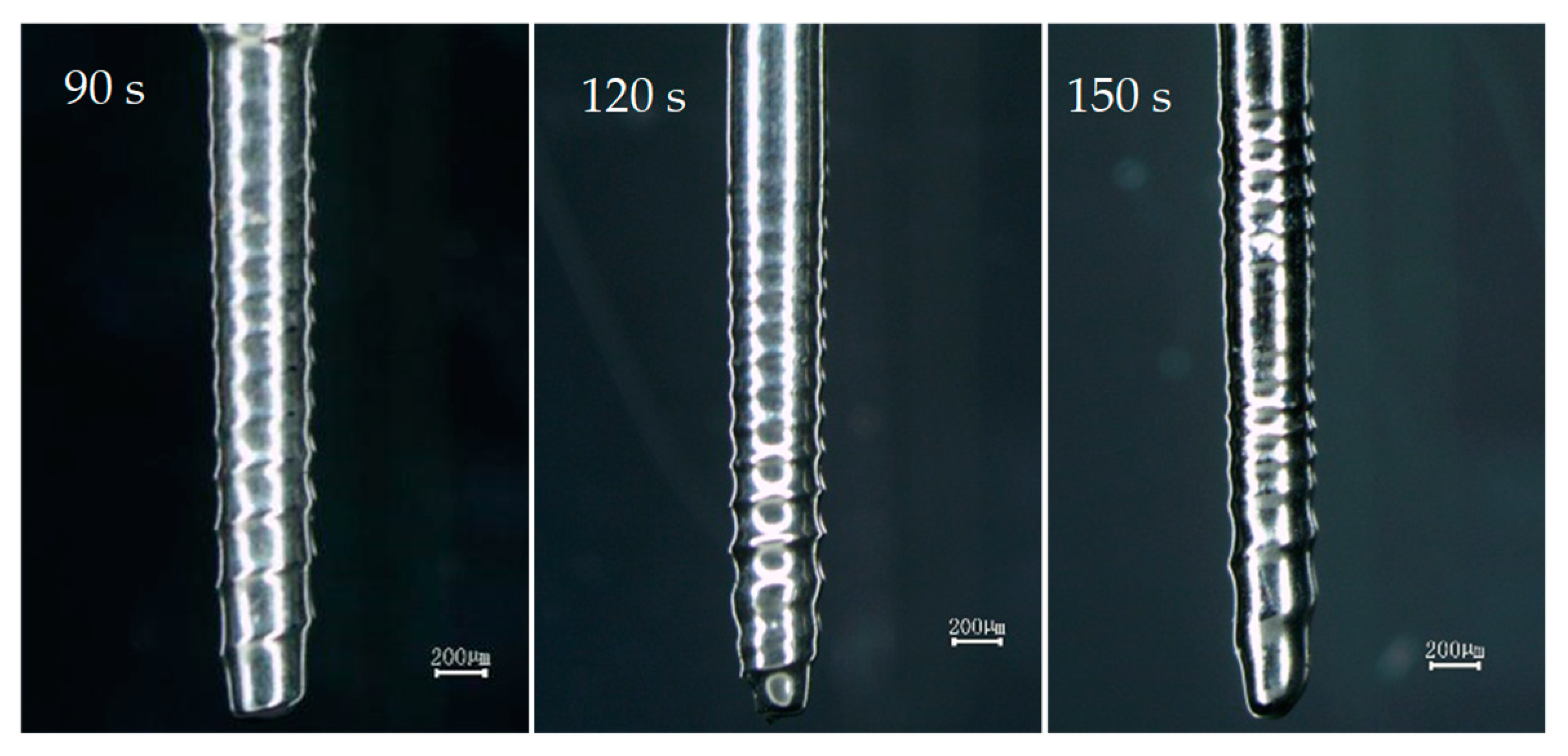

3.4. Effect of Machining Time on Depth of Spiral Groove

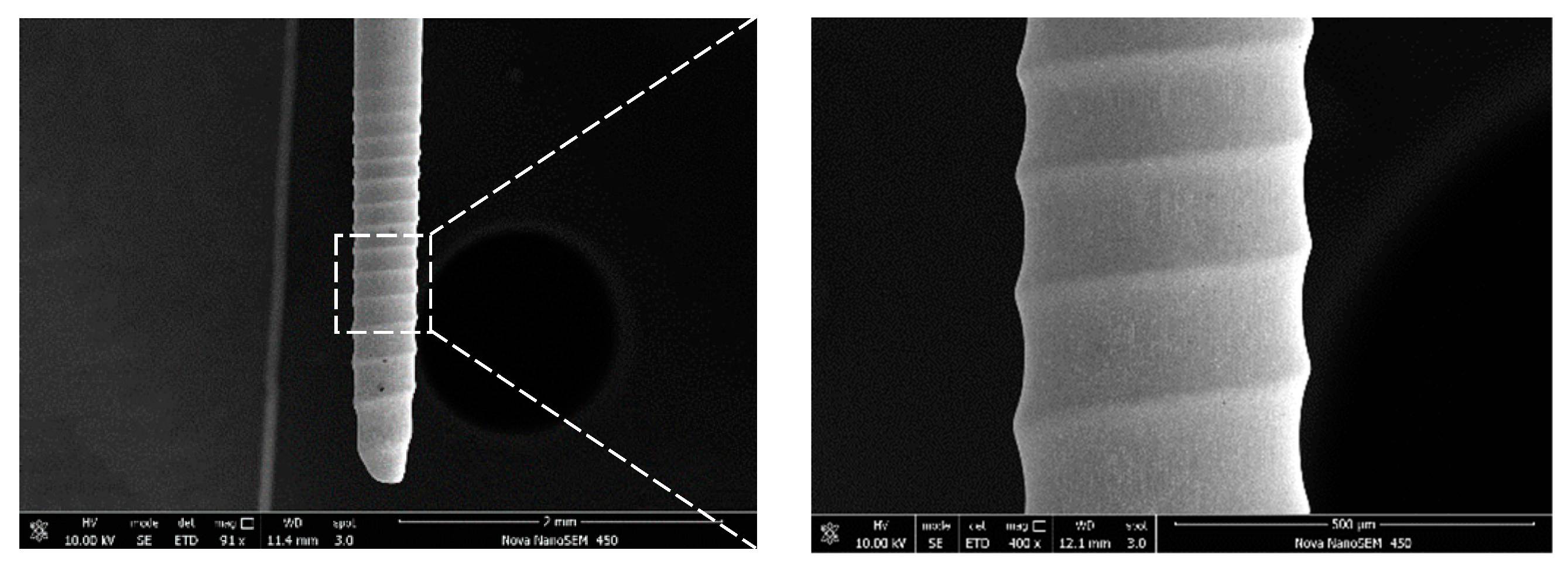

3.5. Experimental Results

4. Conclusions

- The high-speed rotating cylindrical microelectrode causes the SVF, which affects the distribution of the diffusion layer and the mass transfer process around the surface of the microelectrode, and then the spiral groove is formed on the surface of the cylindrical microelectrode due to the velocity difference.

- The rotation direction of the cylindrical electrode can lead to a left-handed or right-handed spiral electrode. The voltage–current density curve was used to find the appropriate machining voltage within the range of the polishing voltage. Within a certain rotation speed range, the higher the rotational speed, the more the number of threads, the longer the axial coverage range of the threads, and the smaller the pitch of the threads. The machining time directly affects the spiral groove depth on the surface of the microelectrode. Only by choosing the appropriate machining time will an obvious threaded structure be formed on the electrode surface.

- For further research, in combination with other machining techniques, more shaped electrodes can be fabricated, such as spherical spiral electrodes and disc spiral electrodes.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, Y.; Cai, H.; Li, H. Fabrication of micro spherical electrode by one pulse EDM and their application in electrochemical micromachining. J. Manuf. Process. 2015, 17, 162–170. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, D.; Zeng, Y.B.; Yu, H.B. Development of microelectrodes for electrochemical micromachining. Int. J. Adv. Manuf. Technol. 2011, 55, 195–203. [Google Scholar] [CrossRef]

- Rathod, V.; Doloi, B.; Bhattacharyya, B. Fabrication of microgrooves with varied cross-sections by electrochemical micromachining. Int. J. Adv. Manuf. Technol. 2017, 92, 1–14. [Google Scholar] [CrossRef]

- Wang, M.H.; Bao, Z.Y.; Wang, X.F.; Xu, X.F. Fabrication of disk microelectrode arrays and their application to micro-hole drilling using electrochemical micromachining. Precis. Eng. 2016, 46, 184–192. [Google Scholar] [CrossRef]

- Wang, M.H.; Zhang, Y.B.; He, Z.W.; Peng, W. Deep micro-hole fabrication in EMM on stainless steel using disk micro-tool assisted by ultrasonic vibration. J. Mater. Process. Technol. 2016, 229, 475–483. [Google Scholar] [CrossRef]

- Deng, S.H.; Li, M.H.; Liu, Y.; Sun, L.Y. Experimental study on electrochemical etching of multi-stepped cylindrical microelectrode with high rotary accuracy. Recent Pat. Mech. Eng. 2017, 10, 242–251. [Google Scholar] [CrossRef]

- Sheu, D.Y. Multi-spherical probe machining by EDM: combining WEDG technology with one-pulse electro-discharge. J. Mater. Process. Technol. 2004, 149, 597–603. [Google Scholar]

- Sheu, D.Y. Micro-spherical probes machining by EDM. J. Micromech. Microeng. 2004, 15, 185–189. [Google Scholar] [CrossRef]

- Kim, B.H.; Park, B.J.; Chu, C.N. Fabrication of multiple electrodes by reverse EDM and their application in micro ECM. J. Micromech. Microeng. 2006, 16, 843–850. [Google Scholar] [CrossRef]

- Tsui, H.P.; Hung, J.C.; You, J.C.; Yan, B.H. Improvement of electrochemical microdrilling accuracy using helical tool. Mater. Manuf. Processes. 2008, 23, 499–505. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Niu, J.; Lu, S.Z.; Jiang, Y. Fabrication of Taper Free Micro-Holes Utilizing a Combined Rotating Helical Electrode and Short Voltage Pulse by ECM. Micromachines 2019, 10, 28. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Xu, X.; Guo, C.S.; Kong, H.H. Analysis on Machining Performance of Nickel-Base Superalloy by Electrochemical Micro-milling with High-Speed Spiral Electrode. Micromachines 2019, 10, 476. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, M.H.; Deng, S.H. Theoretical modeling and experimental study on electrochemical etching of micro cylindrical electrode with high rotation precision. Int. J. Adv. Manuf. Technol. 2018, 98, 395–403. [Google Scholar] [CrossRef]

- Abcha, N.; Crumeyrolle, O.; Ezersky, A.B.; Mutabazi, I. Velocity field of the spiral vortex flow in the Couette-Taylor System. Eur. Phys. J. E 2013, 36, 1–7. [Google Scholar]

- Hoffmann, C.H.; Altmeyer, S.; Pinter, A.; Lücke, M. Transitions between Taylor vortices and spirals via wavy Taylor vortices and wavy spirals. New J. Phys. 2009, 11, 1–24. [Google Scholar] [CrossRef]

- Altmeyer, S.; Hoffmann, C.H. Secondary bifurcation of mixed-cross-spirals connecting travelling wave solutions. New J. Phys. 2010, 12, 1–19. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Q.; Wang, H.; Wang, X.; Deng, S.; Liu, Y.; Lv, Z. Experimental Investigation on Rotating Electrochemical Etching of a Micro Spiral Cylindrical Electrode. Micromachines 2019, 10, 704. https://doi.org/10.3390/mi10100704

Xiong Q, Wang H, Wang X, Deng S, Liu Y, Lv Z. Experimental Investigation on Rotating Electrochemical Etching of a Micro Spiral Cylindrical Electrode. Micromachines. 2019; 10(10):704. https://doi.org/10.3390/mi10100704

Chicago/Turabian StyleXiong, Qiuju, Huali Wang, Xueliang Wang, Shihui Deng, Yong Liu, and Zhen Lv. 2019. "Experimental Investigation on Rotating Electrochemical Etching of a Micro Spiral Cylindrical Electrode" Micromachines 10, no. 10: 704. https://doi.org/10.3390/mi10100704

APA StyleXiong, Q., Wang, H., Wang, X., Deng, S., Liu, Y., & Lv, Z. (2019). Experimental Investigation on Rotating Electrochemical Etching of a Micro Spiral Cylindrical Electrode. Micromachines, 10(10), 704. https://doi.org/10.3390/mi10100704