A Cr Anti-Sticking Layer for Improving Mold Release Quality in Electrochemical Replication of PVC Optical Molds

Abstract

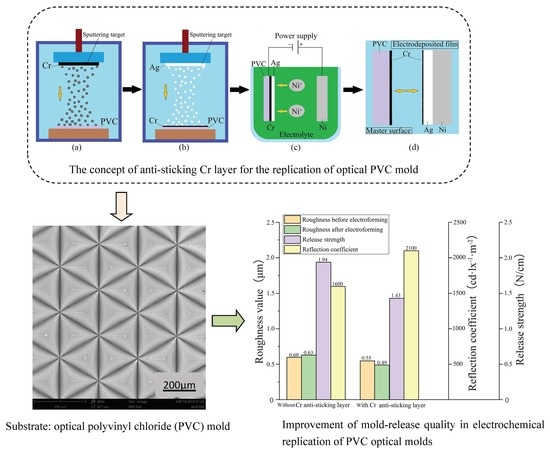

1. Introduction

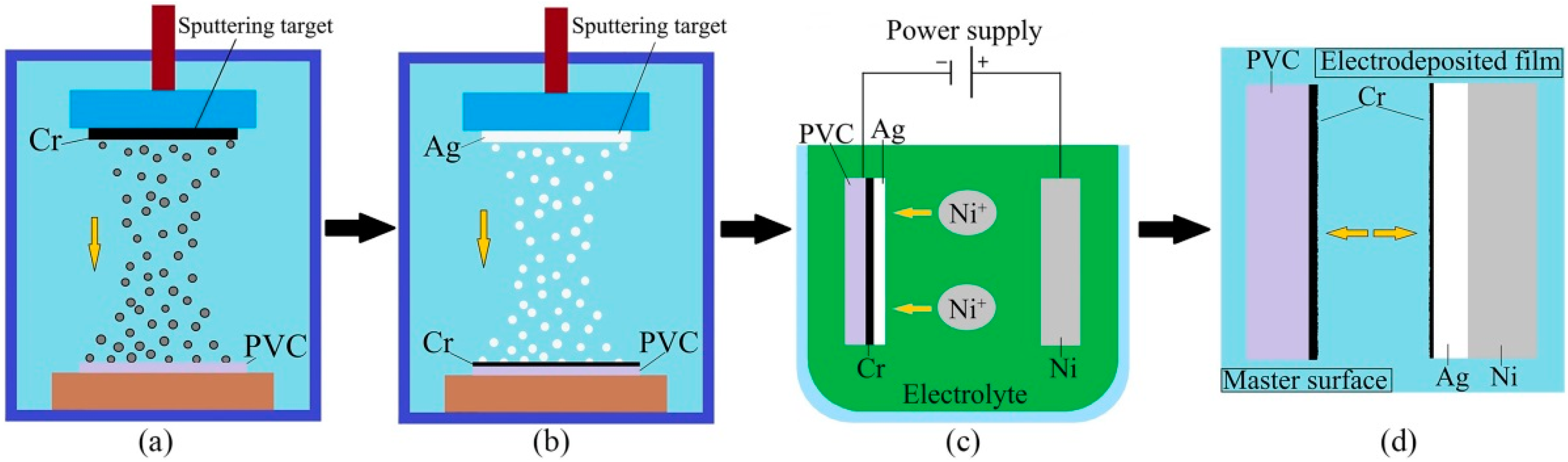

2. Experiment Description

2.1. Materials and Experiment Steps

2.2. Experiment Parameters

2.3. Experiment Characterizations

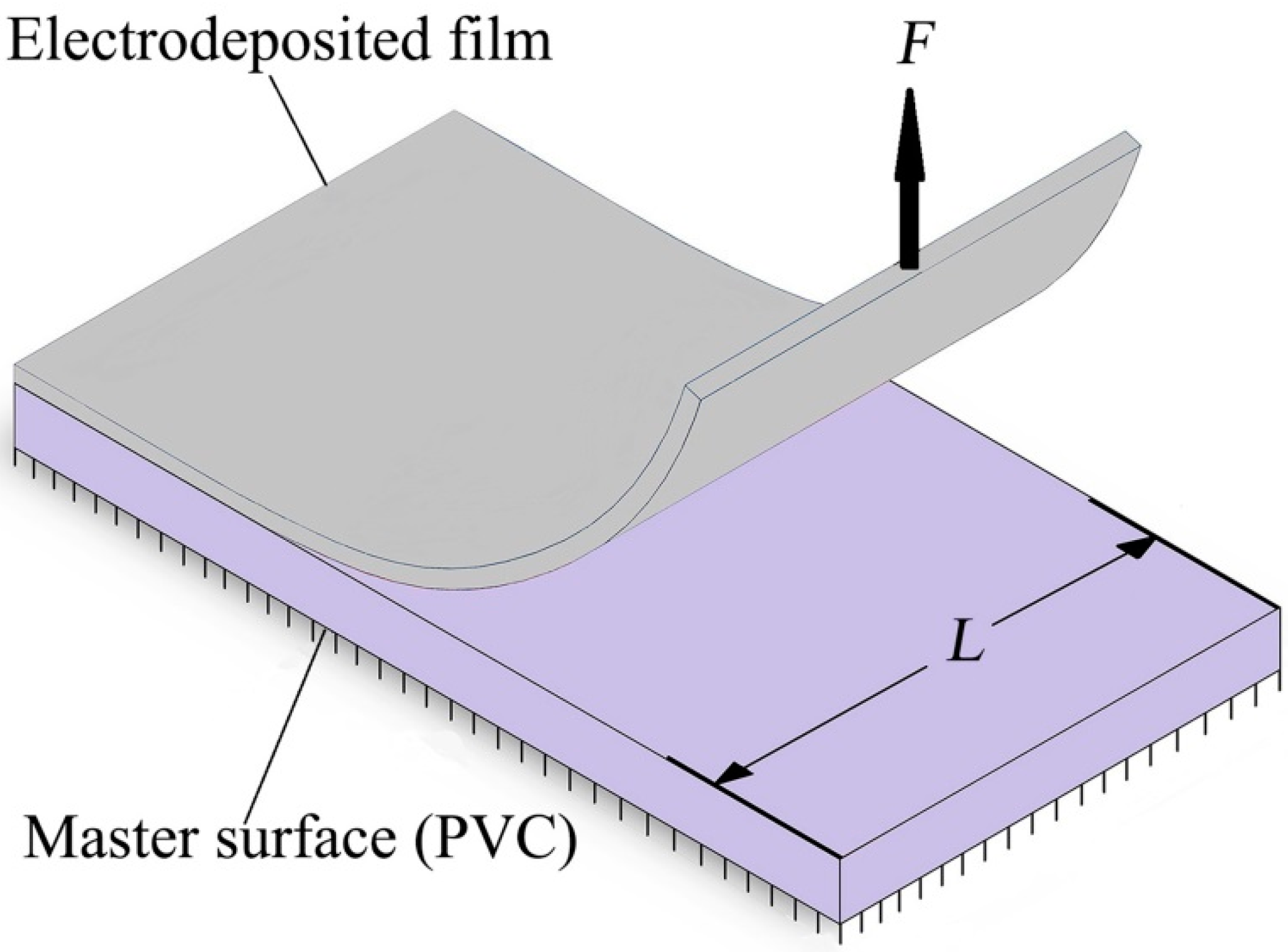

2.3.1. Release Strength

2.3.2. Surface Roughness

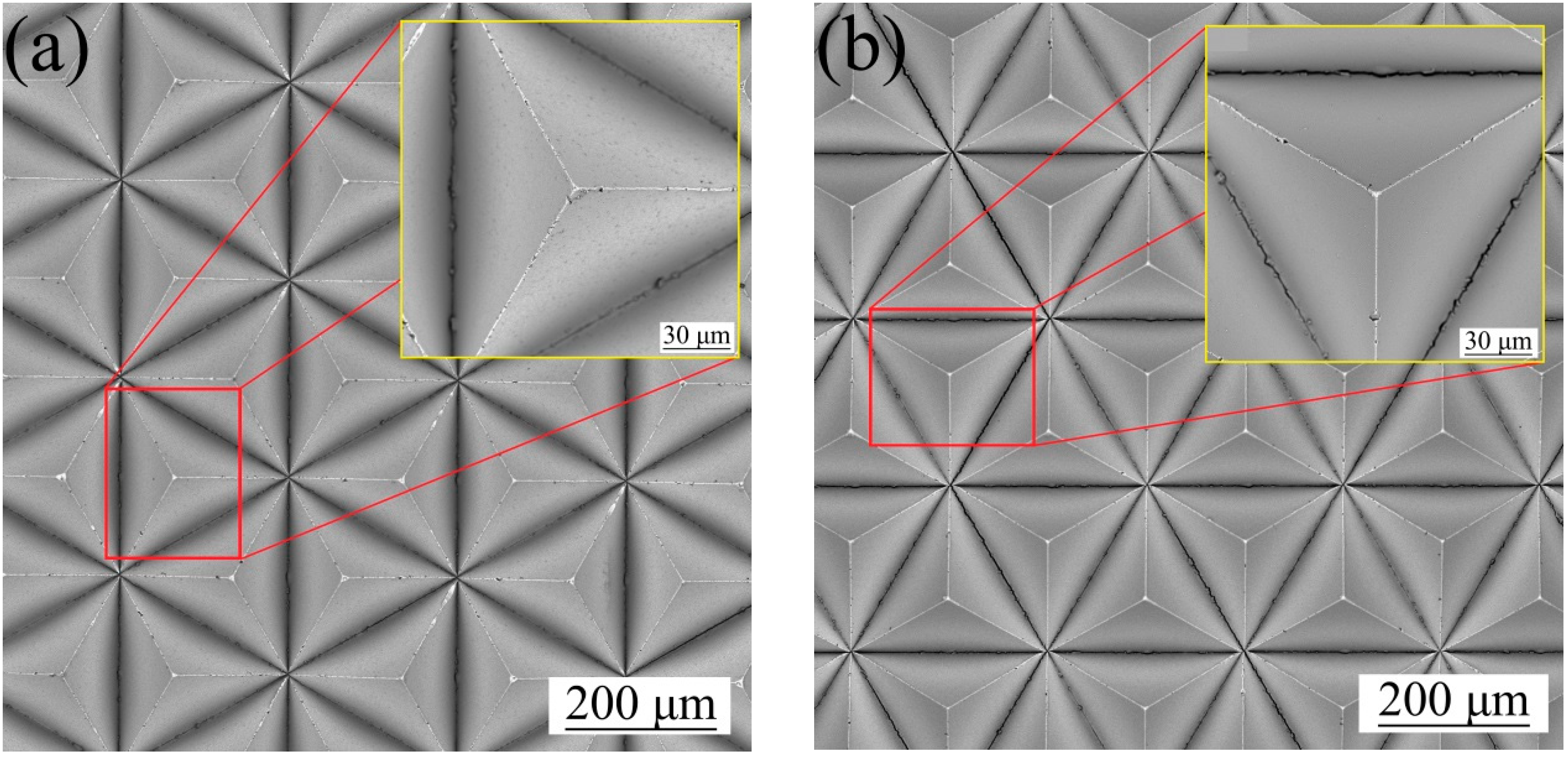

2.3.3. Microscopic Morphology

2.3.4. Surface Energy

2.3.5. Retro-Reflection Coefficient

3. Results

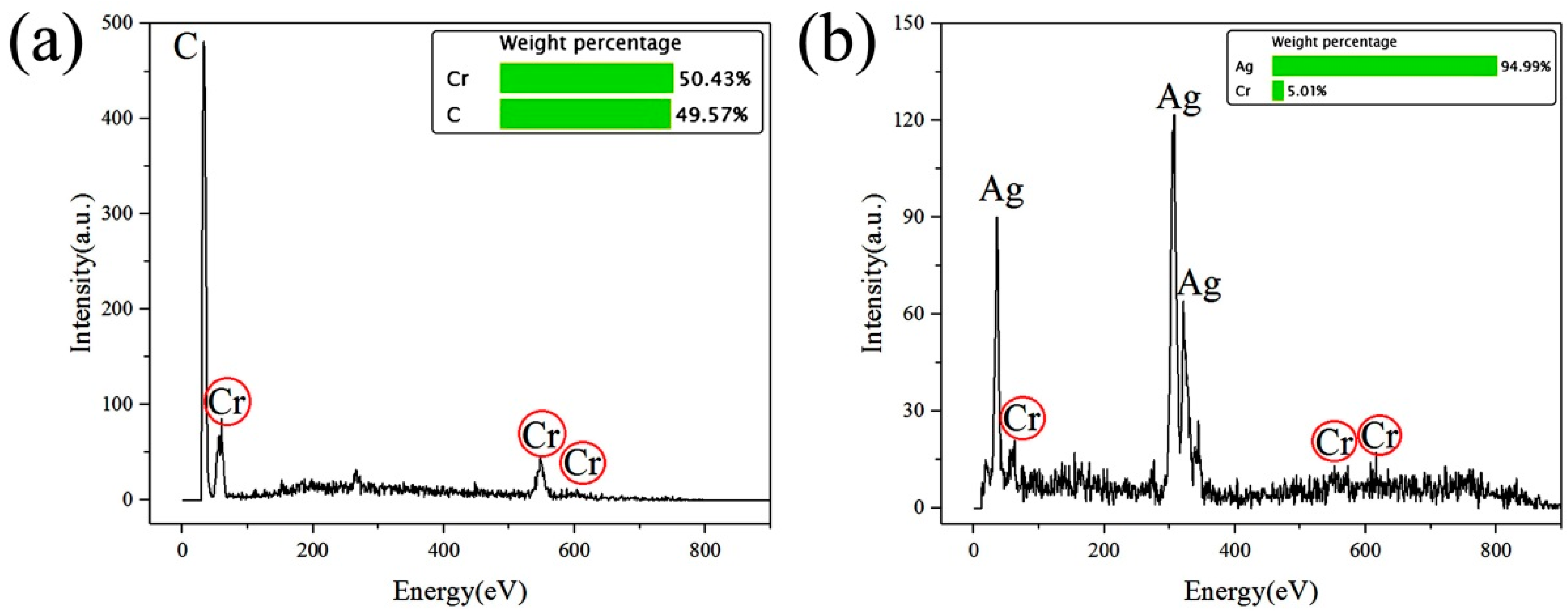

3.1. Surface Energy of the Original Mold

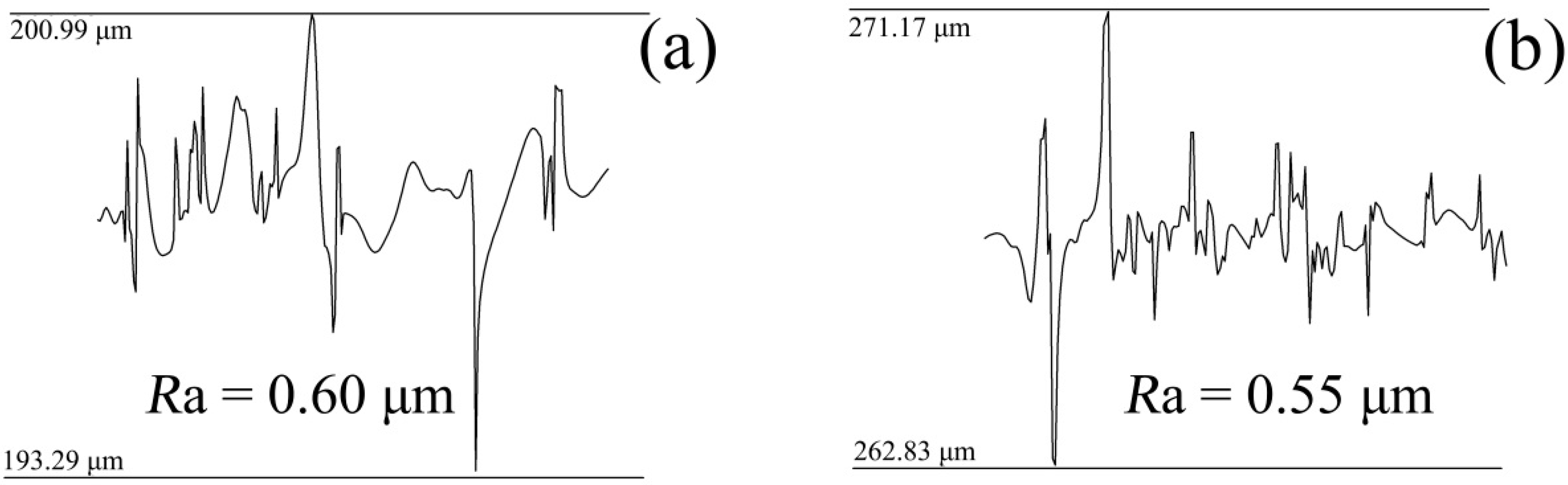

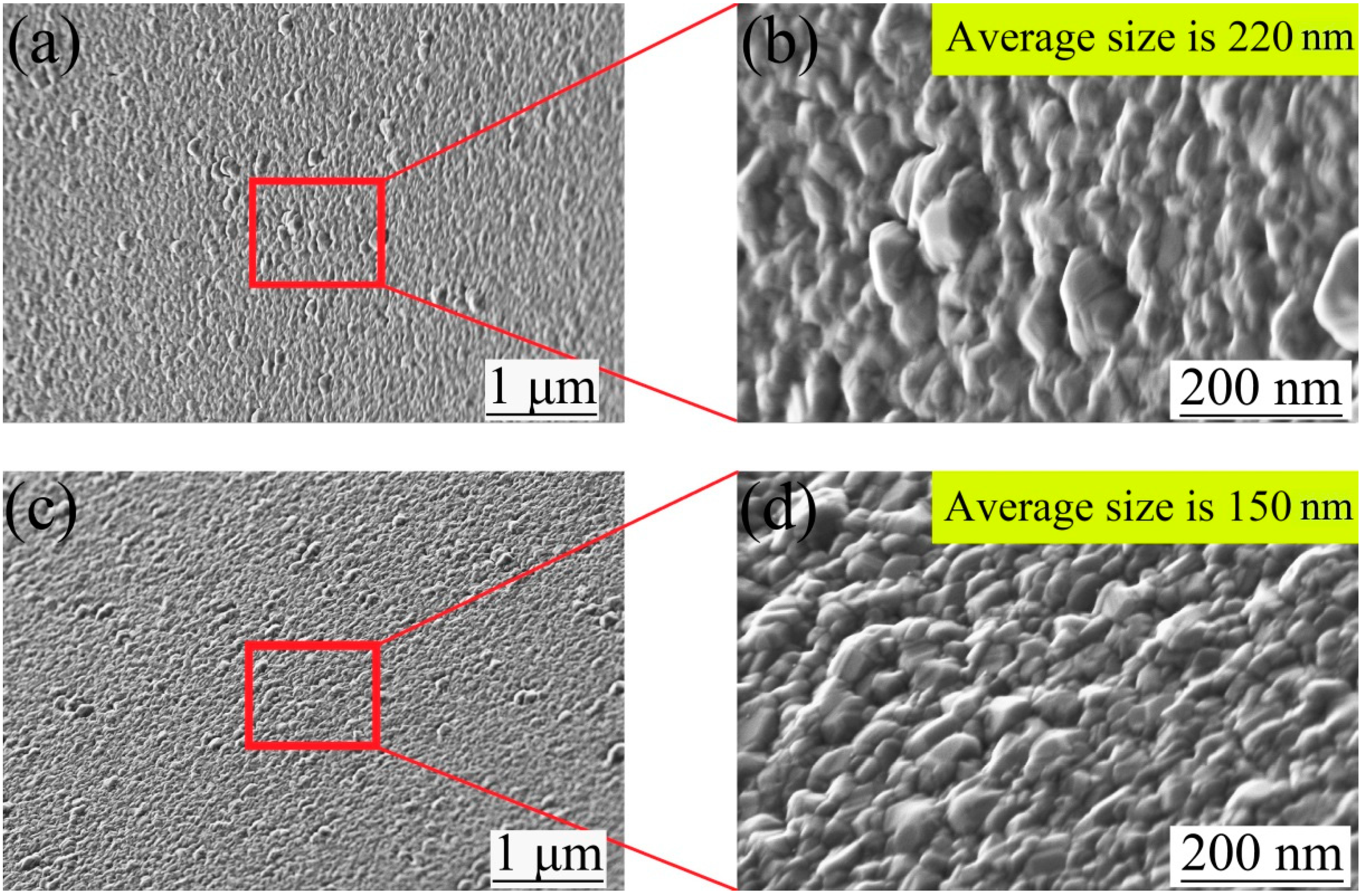

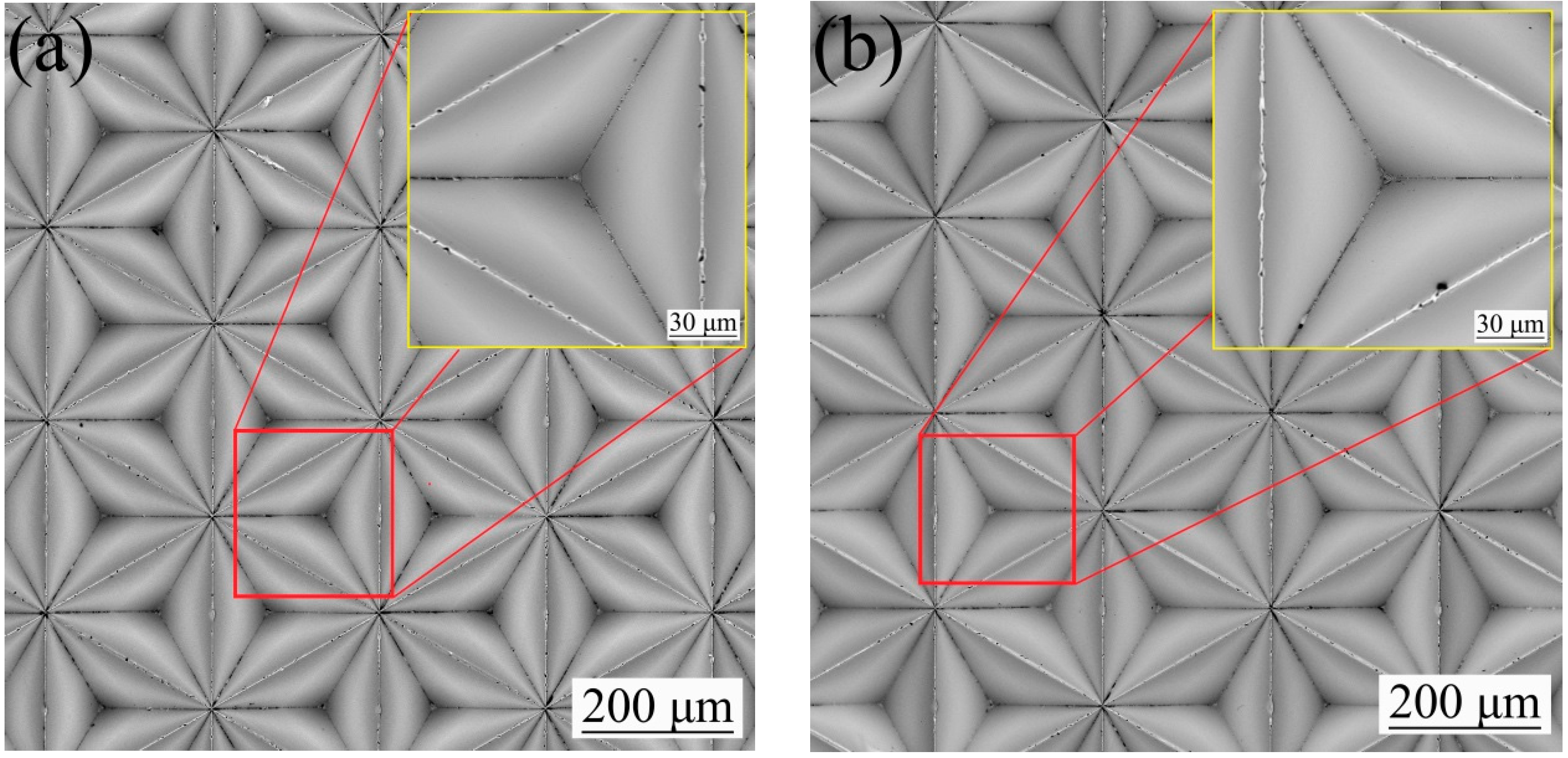

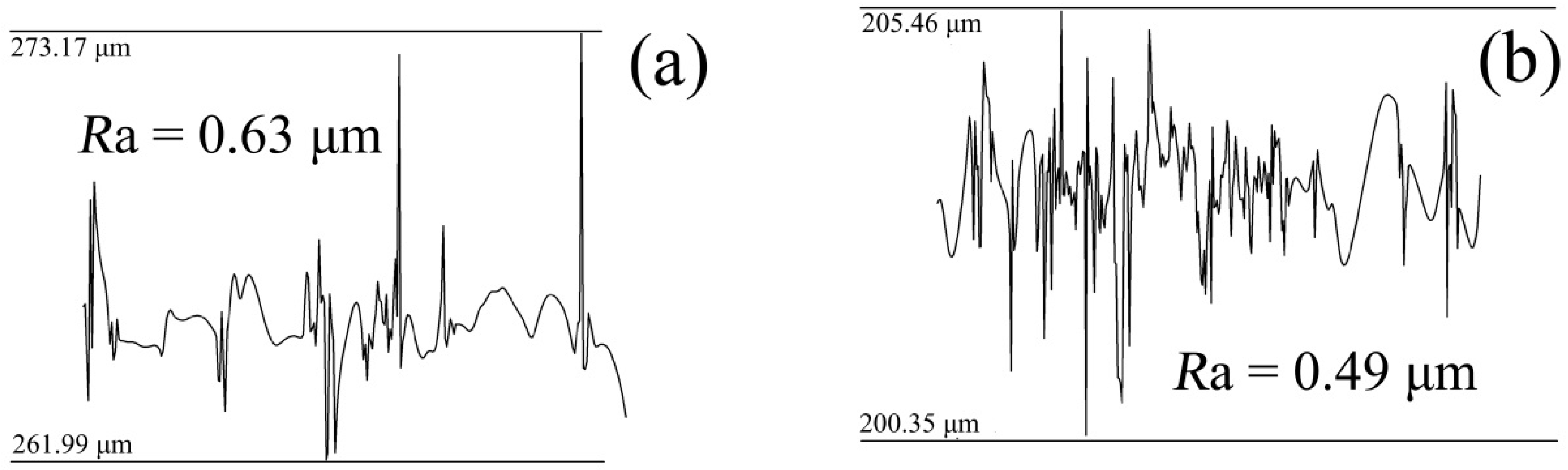

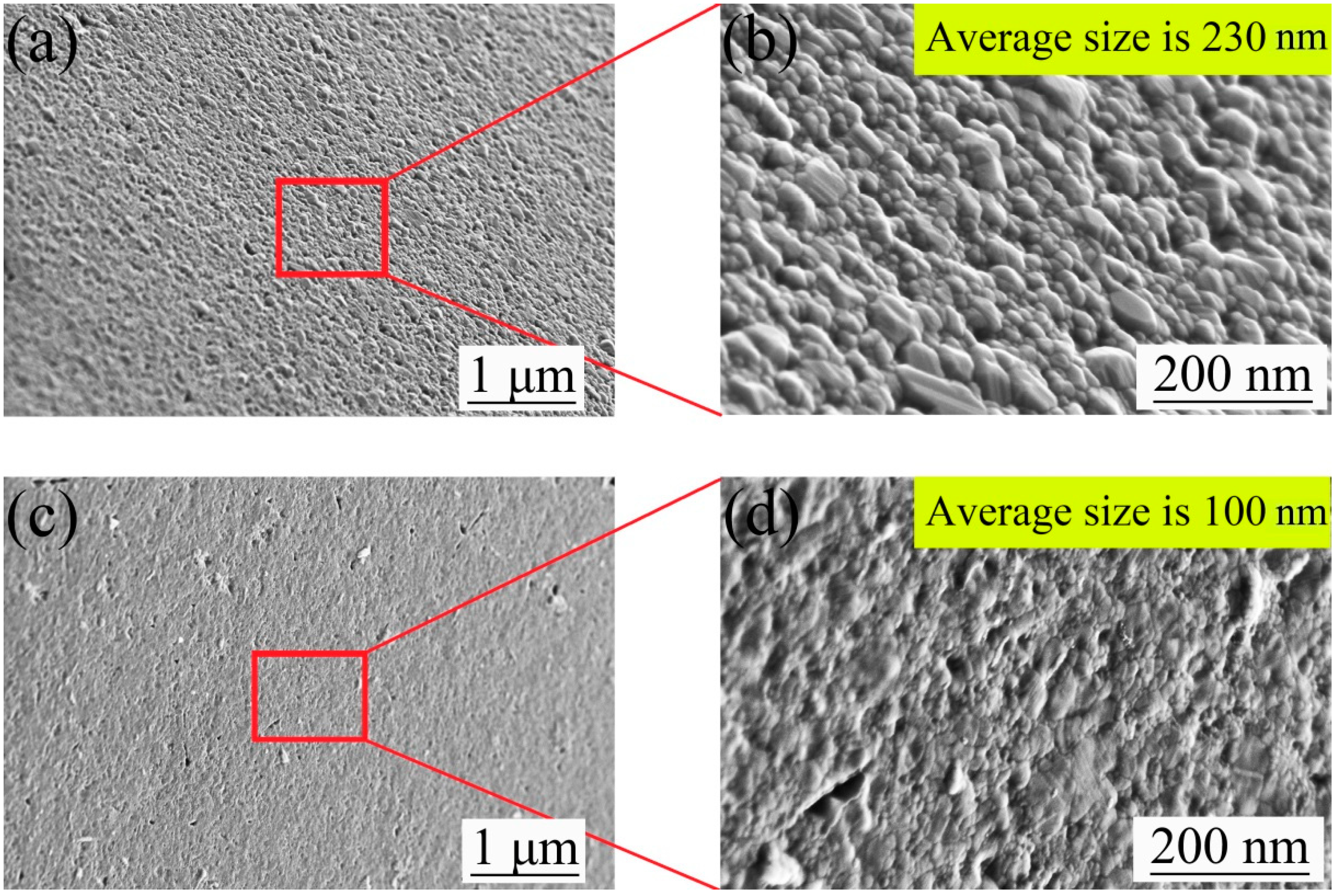

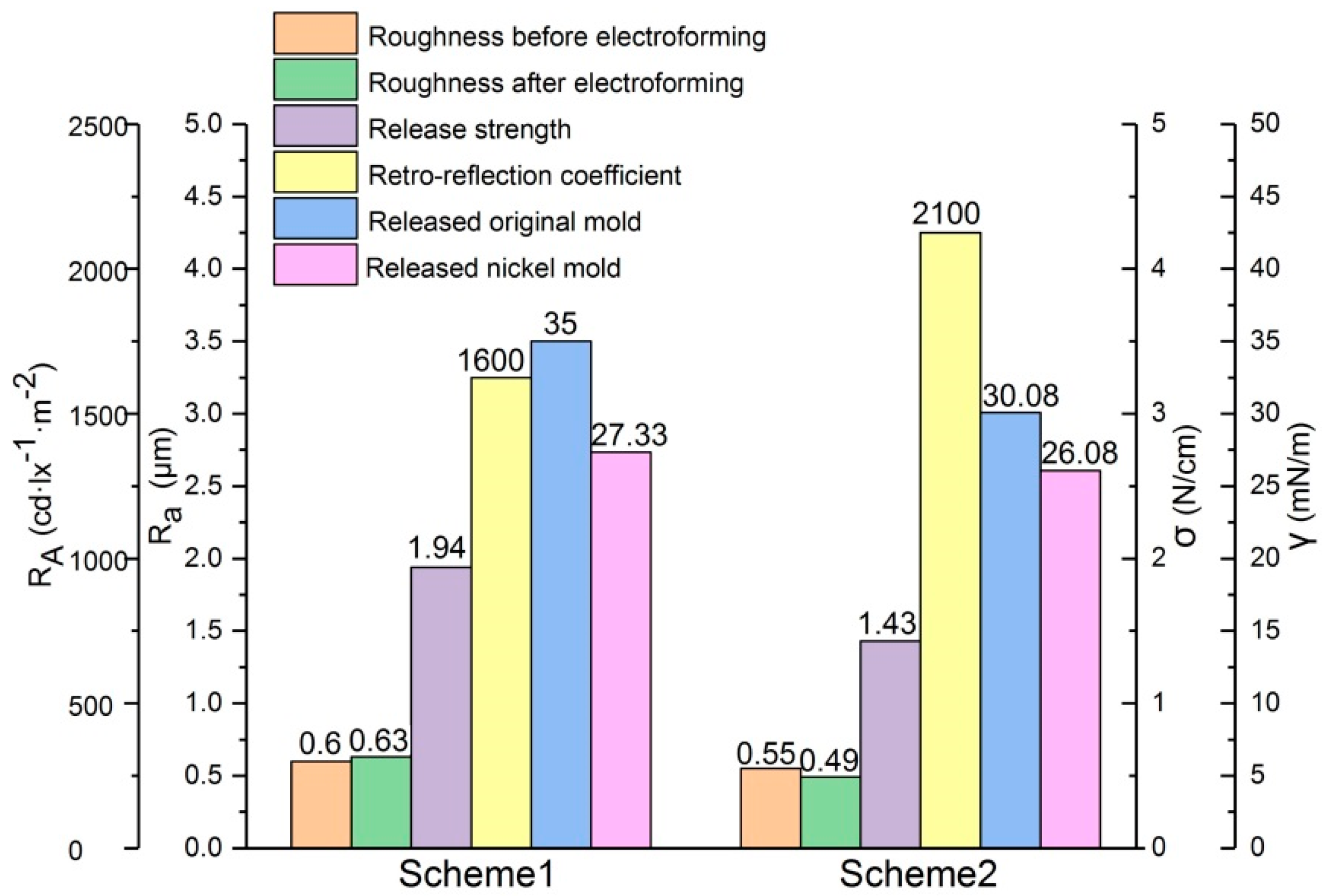

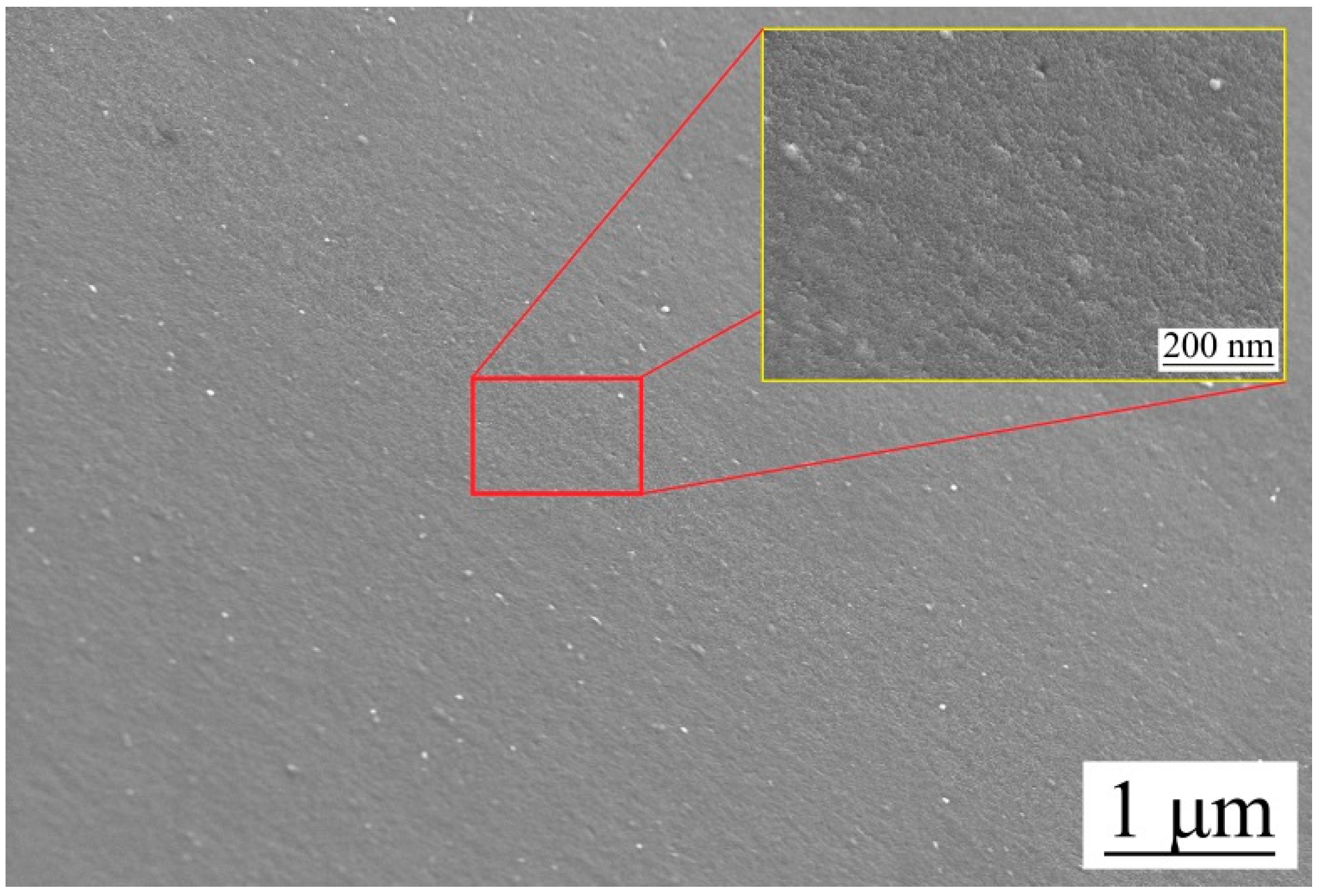

3.2. Roughness and Morphology under Two Different Sputtering Conditions

3.3. Release Strength

3.4. Retro-Reflection Coefficient

4. Discussion

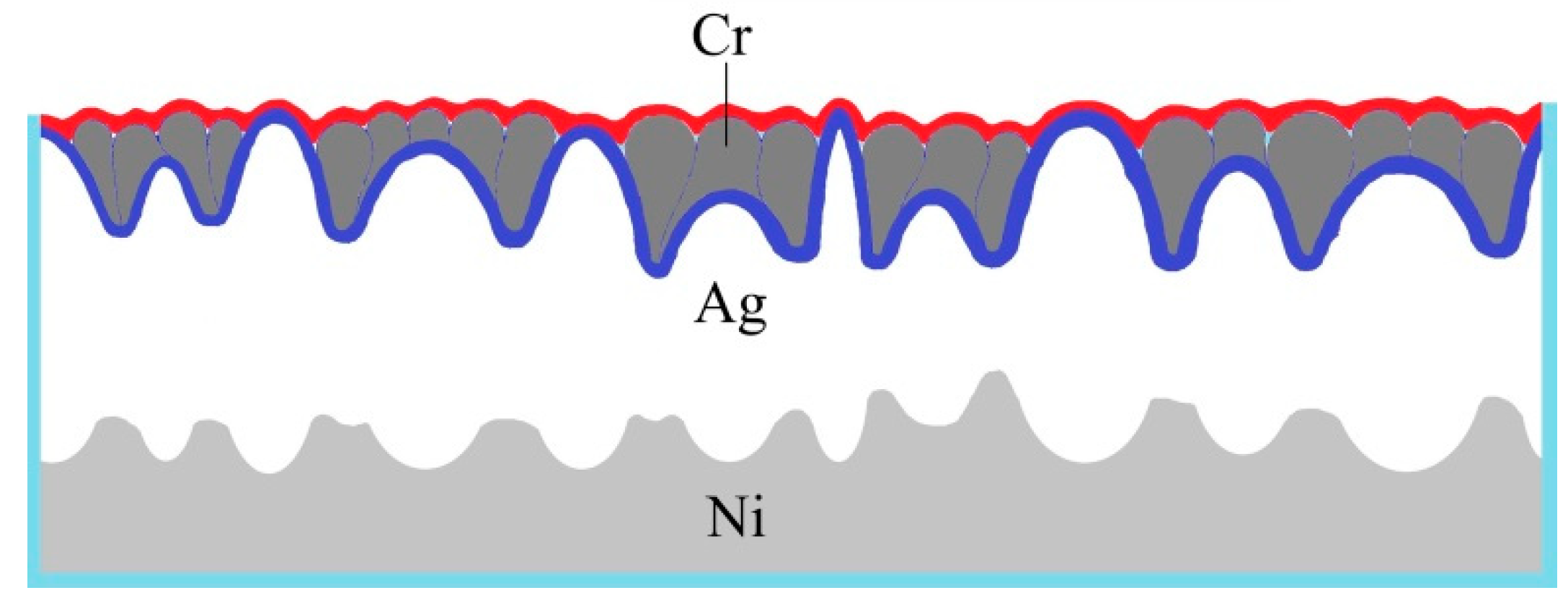

4.1. Mechanism of Anti-Sticking Layer Conducive to Demolding

4.2. Effect of Anti-Sticking Layer on Surface Roughness of Original Mold and Nickel Mold

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barranco, A.; Borras, A.; Gonzalez-Elipe, A.R.; Palmero, A. Perspectives on oblique angle deposition of thin films: From fundamentals to devices. Prog. Mater. Sci. 2016, 76, 59–153. [Google Scholar] [CrossRef]

- Li, W.J.; Zhai, Y.H.; Yi, P.Y.; Zhang, Y. Fabrication of micro-pyramid arrays on PETG films by roll-to-roll hot embossing. Microelectron. Eng. 2016, 164, 100–107. [Google Scholar] [CrossRef]

- Peng, L.F.; Wu, H.; Shu, Y.Y.; Yi, P.Y.; Deng, Y.J.; Lai, X.M. Roll-to-roll hot embossing system with shape preserving mechanism for the large-area fabrication of microstructures. Rev. Sci. Instrum. 2016, 87, 105120. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Gao, J.; Yi, P.Y.; Peng, L.F.; Lai, X.M. Investigation of reflective performance for micro-pyramid arrays by roll-to-roll UV imprinting process. Microelectron. Eng. 2017, 182, 61–67. [Google Scholar] [CrossRef]

- Zhang, S.J.; Zhou, Y.P.; Zhang, H.J.; Xiong, Z.W.; To, S. Advances in ultra-precision machining of micro-structured functional surfaces and their typical applications. Int. J. Mach. Tool. Manuf. 2019, 142, 16–41. [Google Scholar] [CrossRef]

- Escarré, J.; Söderström, K.; Despeisse, M.; Nicolay, S.; Battaglia, C.; Bugnon, G.; Ding, L.; Meillaud, F.; Haug, F.J.; Ballif, C. Geometric light trapping for high efficiency thin film silicon solar cells. Sol. Energy Mater. Sol. Cells 2012, 98, 185–190. [Google Scholar] [CrossRef]

- Riemer, O. A review on machining of micro-structured optical molds. Key Eng. Mater. 2007, 364–366, 13–18. [Google Scholar] [CrossRef]

- Marcel, R.; Thomas, G.; André, Z. Review on fabrication technologies for optical mold inserts. Micromachines 2019, 10, 233–257. [Google Scholar]

- Bohling, M.; Seiler, T.; Wdowiak, B.; Jahns, J.; Mohr, J.; Börner, M. Highly precise micro-retroreflector array fabricatedby the LIGA process and its application as tapped delay line filter. Appl. Opt. 2012, 51, 5989–5995. [Google Scholar] [CrossRef]

- Rickard, J.J.S.; Farrer, I.; Oppenheimer, P.G. Tunable nanopatterning of conductive polymers via electrohydrodynamic lithography. ACS Nano 2016, 10, 3865–3870. [Google Scholar] [CrossRef]

- Tosello, G.; Hansen, H.N.; Marinello, F.; Gasparin, S. Replication and dimensional quality control of industrial nanoscale surfaces using calibrated AFM measurements and SEM image processing. CIRP Ann. 2010, 59, 563–568. [Google Scholar] [CrossRef]

- Weng, C.; Zhou, M.Y.; Jiang, B.Y.; Lv, H. Improvement on replication quality of electroformed nickel mold inserts with micro/nano-structures. Int. Commun. Heat Mass Transfer 2016, 75, 92–99. [Google Scholar] [CrossRef]

- Hansen, H.N.; Hocken, R.J.; Tosello, G. Replication of micro and nano surface geometries. CIRP Ann. 2011, 60, 695–714. [Google Scholar] [CrossRef]

- Zhou, G.Q.; Liu, S.Q.; Liu, W.; Yuan, D.; Zhou, G.F. Optimized soft lithography method for polymer cholesteric liquid crystal flakes fabrication. Micromachines 2019, 10, 441. [Google Scholar] [CrossRef]

- Yang, G.; Li, Y.; Pi, J.; Zhu, Q.Q.; Cai, J.W.; Huang, Z.J. Control of the adhesion strength between nickel replica and copper mold by electrochemical nucleation of lead. J. Appl. Electrochem. 2019, 49, 1003–1011. [Google Scholar] [CrossRef]

- Lee, C.H.; Jiang, K. Fabrication of thick electroforming micro mould using a KMPR negative tonephotoresist. J. Micromech. Microeng. 2008, 18, 055032. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, G.; Tian, Y.C.; Tian, X.H. The properties of demoulding of Ni and Ni-PTFE moulding inserts. Sens. Actuators A 2005, 118, 338–341. [Google Scholar]

- Mimural, H.; Ishikura, H.; Matsuyama, S.; Sano, Y.; Yamauchi, K. Electroforming for replicating nanometer-level smooth surface. J. Nanosci. Nanotechnol. 2011, 11, 2886–2889. [Google Scholar] [CrossRef]

- Kromer, R.; Cormier, J.; Costil, S. Role of powder granulometry and substrate topography in adhesion strength of thermal spray coatings. J. Therm. Spray Technol. 2016, 25, 933–945. [Google Scholar] [CrossRef]

- Kaynak, B.; Alpan, C.; Kratzer, M.; Ganser, C.; Teichert, C.; Kern, W. Anti-adhesive layers on stainless steel using thermally stable dipodal perfluoroalkyl silanes. Appl. Surf. Sci. 2017, 416, 824–833. [Google Scholar] [CrossRef]

- Taghvaei, E.; Moosavi, A.; Nouri-Borujerdi, A.; Daeian, M.A.; Vafaeinejad, S. Superhydrophobic surfaces with a dual-layer micro- and nanoparticle coating for drag reduction. Energy 2017, 125, 1–10. [Google Scholar] [CrossRef]

- Azzaroni, O.; Schilardi, P.L.; Salvarezza, R.C. Metal electrodeposition on selfassembled monolayers: A versatile tool for pattern transfer on metal thin films. Electrochim. Acta 2003, 48, 3107–3114. [Google Scholar] [CrossRef]

- Lee, M.J.; Cho, S.U.; Lee, S.M.; Kim, C.S.; Jeong, M.Y. Enhanced uniformity and durability of antisticking layer in imprinting stamps. Appl. Surf. Sci. 2012, 258, 6545–6549. [Google Scholar] [CrossRef]

- Beck, M.; Graczyk, M.; Maximov, I.; Sarwe, E.-L.; Ling, T.G.I.; Keil, M.; Montelius, L. Improving stamps for 10 nm level wafer scale nanoimprint lithography. Microelectron. Eng. 2002, 61–62, 441–448. [Google Scholar] [CrossRef]

- Steinberg, C.; Dhima, K.; Blenskens, D.; Mayer, A.; Wang, S.; Papenheim, M.; Scheer, H.-C.; Zajadacz, J.; Zimmer, K. A scalable anti-sticking layer process via controlled evaporation. Microelectron. Eng. 2014, 123, 4–8. [Google Scholar] [CrossRef]

- Lee, B.K.; Cha, K.J.; Kwon, T.H. Fabrication of polymer micro/nano-hybrid lens array by microstructured anodic aluminum oxide (AAO) mold. Microelectron Eng. 2009, 86, 857–860. [Google Scholar] [CrossRef]

- Whitesides, G.M.; Grzybowski, B. Self-assembly at all scales. Science 2002, 295, 2418–2421. [Google Scholar] [CrossRef]

- Talib, R.J.; Saad, S.; Toff, M.R.M.; Hashim, H. Thermal spray coating technology: A review. Solid State Sci. Technol. 2003, 11, 109–117. [Google Scholar]

- Fleming, M.G.; Hashmi, M.S.J. A comparison of Magnetron Sputtered and Arc Evaporated PVD thin films for wear applications in multipoint cutting tools. J. Mater. Process. Technol. 1992, 32, 481–488. [Google Scholar] [CrossRef]

- Bugaev, S.P.; Sochugov, S.N.; Oskomov, K.V.; Solovjev, A.A.; Zakharov, A.N. Improvement of coating deposition and target erosion uniformity in rotating cylindrical magnetrons. Laser Part. Beams 2003, 21, 279–283. [Google Scholar] [CrossRef]

- Paul, A.; Lim, J.; Choi, K.; Lee, C. Effects of deposition parameters on the properties of chromium carbide coatings deposited onto steel by sputtering. Mat. Sci. Eng. A-Struct. 2002, 332, 123–128. [Google Scholar] [CrossRef]

- Jiang, S.X.; Qin, W.F.; Guo, R.H.; Zhang, L. Surface functionalization of nanostructured silver-coated polyester fabric by magnetron sputtering. Surf. Coat. Technol. 2010, 204, 3662–3667. [Google Scholar] [CrossRef]

- Kim, K.-S.; Kim, J. Elasto-plastic analysis of the peel test for thin film adhesion. J. Eng. Mater. Technol. 1988, 110, 266–273. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Superhydrophobic surfaces and emerging applications: Non-adhesion, energy, green engineering. Curr. Opin. Colloid Interface Sci. 2009, 14, 270–280. [Google Scholar] [CrossRef]

- Whyman, G.; Bormashenko, E.; Stein, T. The rigorous derivation of Young, Cassie–Baxter and Wenzel equations and the analysis of the contact angle hysteresis phenomenon. Chem. Phys. Lett. 2008, 450, 355–359. [Google Scholar] [CrossRef]

- Patankar, N.A. Transition between superhydrophobic states on rough surfaces. Langmuir 2004, 20, 7097–7102. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Vazirinasab, E.; Jafari, R.; Momen, G. Application of superhydrophobic coatings as a corrosion barrier: A review. Surf. Coat. Technol. 2018, 341, 40–56. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Wang, S.J.; Li, X. The effects of tensile residual stress and sliding boundary on measuring the adhesion work of membrane by pull off test. Thin Solid Films 2007, 515, 7227–7231. [Google Scholar] [CrossRef]

- Miedema, A.R.; de Châtel, P.F.; de Boer, F.R. Cohesion in alloys-fundamentals of a semi-empirical model. Phys. B+C 1980, 100, 1–28. [Google Scholar] [CrossRef]

- Sidelev, D.V.; Bleykher, G.A.; Bestetti, M.; Krivobokov, V.P.; Vicenzo, A.; Franz, S.; Brunella, M.F. A comparative study on the properties of chromium coatings deposited by magnetron sputtering with hot and cooled target. Vacuum 2017, 143, 479–485. [Google Scholar] [CrossRef]

- Grudinin, V.A.; Bleykher, G.A.; Sidelev, D.V.; Krivobokov, V.P.; Bestetti, M.; Vicenzo, A.; Franz, S. Chromium films deposition by hot target high power pulsed magnetron sputtering: Deposition conditions and film properties. Surf. Coat. Technol. 2019, 375, 352–362. [Google Scholar] [CrossRef]

- Bormashenko, E.; Stein, T.; Whyman, G.; Pogreb, R.; Sutovsky, S.; Danoch, Y.; Shoham, Y.; Bormashenko, Y.; Sorokov, B.; Aurbach, D. Superhydrophobic metallic surfaces and their wetting properties. J. Adhes. Sci. Technol. 2008, 22, 379–385. [Google Scholar] [CrossRef]

- Dirckx, M.E.; Hardt, D.E. Analysis and characterization of demolding of hot embossed polymer microstructures. J. Micromech. Microeng. 2011, 21, 085024. [Google Scholar] [CrossRef]

- Worgull, M.; Hétu, J.F.; Kabanemi, K.K.; Heckele, M. Hot embossing of microstructures: Characterization of friction during demolding. Microsyst. Technol. 2008, 14, 767–773. [Google Scholar] [CrossRef]

- Kawata, H.; Kubo, K.; Watanabe, Y.; Sakamoto, J.; Yasuda, M.; Hirai, Y. Effects of mold side wall profile on demolding characteristics. Jpn. J. Appl. Phys. 2010, 49, 06GL15. [Google Scholar] [CrossRef]

- Taylor, H.; Boning, D.; Iliescu, C. A razor-blade test of the demolding energy in a thermoplastic embossing process. J. Micromech. Microeng. 2011, 21, 067002. [Google Scholar] [CrossRef]

| Target Material | Power (W) | Time (s) | Temperature (°C) |

|---|---|---|---|

| Cr | 200 | 15 | 30 |

| Ag | 200 | 300 | 30 |

| Parameters of Electrodeposition | Value |

|---|---|

| Nickel aminosulfonate | 250–450 g·L−1 |

| Nickel dichloride | 5–30 g·L−1 |

| Boric acid | 30–40 g·L−1 |

| Lauryl sodium sulfate | 0.06–0.2 g·L−1 |

| current density | 4 A·dm−2 |

| temperature | 50 °C |

| time | 3.5 h |

| pH | 3.5–4.0 |

| Testing Liquids | Temperature (°C) | γp (mN/m) | γd (mN/m) | γ (mN/m) |

|---|---|---|---|---|

| Pure water | 20 | 51.00 | 21.80 | 72.8 |

| Diiodomethane | 20 | 0 | 50.80 | 50.8 |

| Different States | Contact Angle (°C) | Contact Angle of CB Model (°C) | γ (mN/m) | ||

|---|---|---|---|---|---|

| Pure Water Diiodomethane | Pure Water Diiodomethane | ||||

| Before sputtering | 87.56 | 56.89 | 88.47 | 60.25 | 31.47 |

| After sputtering | 97.41 | 86.73 | 106.40 | 86.97 | 15.53 |

| Scheme | Release Strength |

|---|---|

| 1 | 1.94 N/cm |

| 2 | 1.43 N/cm |

| Scheme | Retro-Reflection Coefficient |

|---|---|

| 1 | 1600 cd·lx−1·m−2 |

| 2 | 2100 cd·lx−1·m−2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Yang, G.; Wu, Q.; Cheng, J.; Hu, Z. A Cr Anti-Sticking Layer for Improving Mold Release Quality in Electrochemical Replication of PVC Optical Molds. Micromachines 2019, 10, 702. https://doi.org/10.3390/mi10100702

Li Y, Yang G, Wu Q, Cheng J, Hu Z. A Cr Anti-Sticking Layer for Improving Mold Release Quality in Electrochemical Replication of PVC Optical Molds. Micromachines. 2019; 10(10):702. https://doi.org/10.3390/mi10100702

Chicago/Turabian StyleLi, Yue, Guang Yang, Qihui Wu, Jun Cheng, and Zhichao Hu. 2019. "A Cr Anti-Sticking Layer for Improving Mold Release Quality in Electrochemical Replication of PVC Optical Molds" Micromachines 10, no. 10: 702. https://doi.org/10.3390/mi10100702

APA StyleLi, Y., Yang, G., Wu, Q., Cheng, J., & Hu, Z. (2019). A Cr Anti-Sticking Layer for Improving Mold Release Quality in Electrochemical Replication of PVC Optical Molds. Micromachines, 10(10), 702. https://doi.org/10.3390/mi10100702