Mechanism of Unstable Material Removal Modes in Micro Cutting of Silicon Carbide

Abstract

1. Introduction

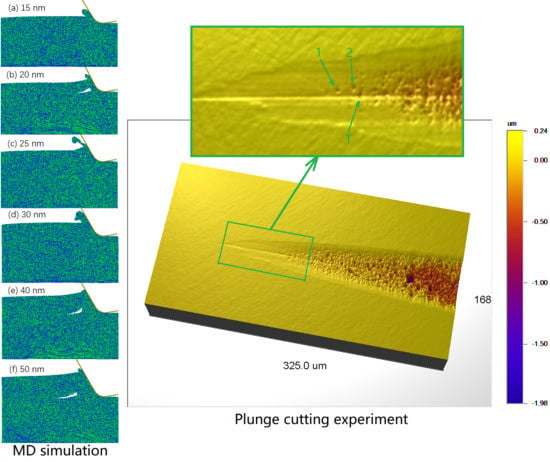

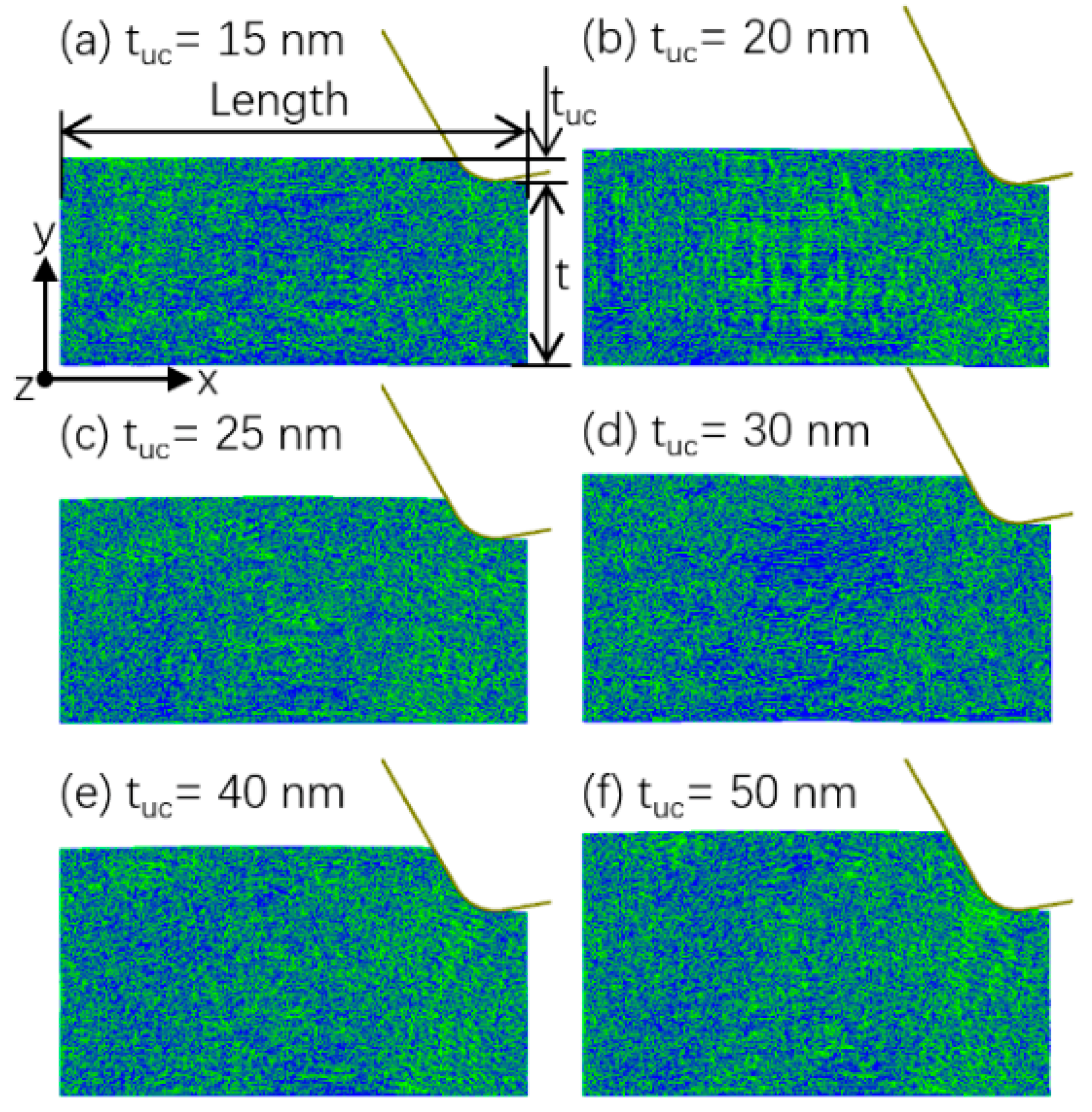

2. Molecular Dynamics Modelling

2.1. Methodology

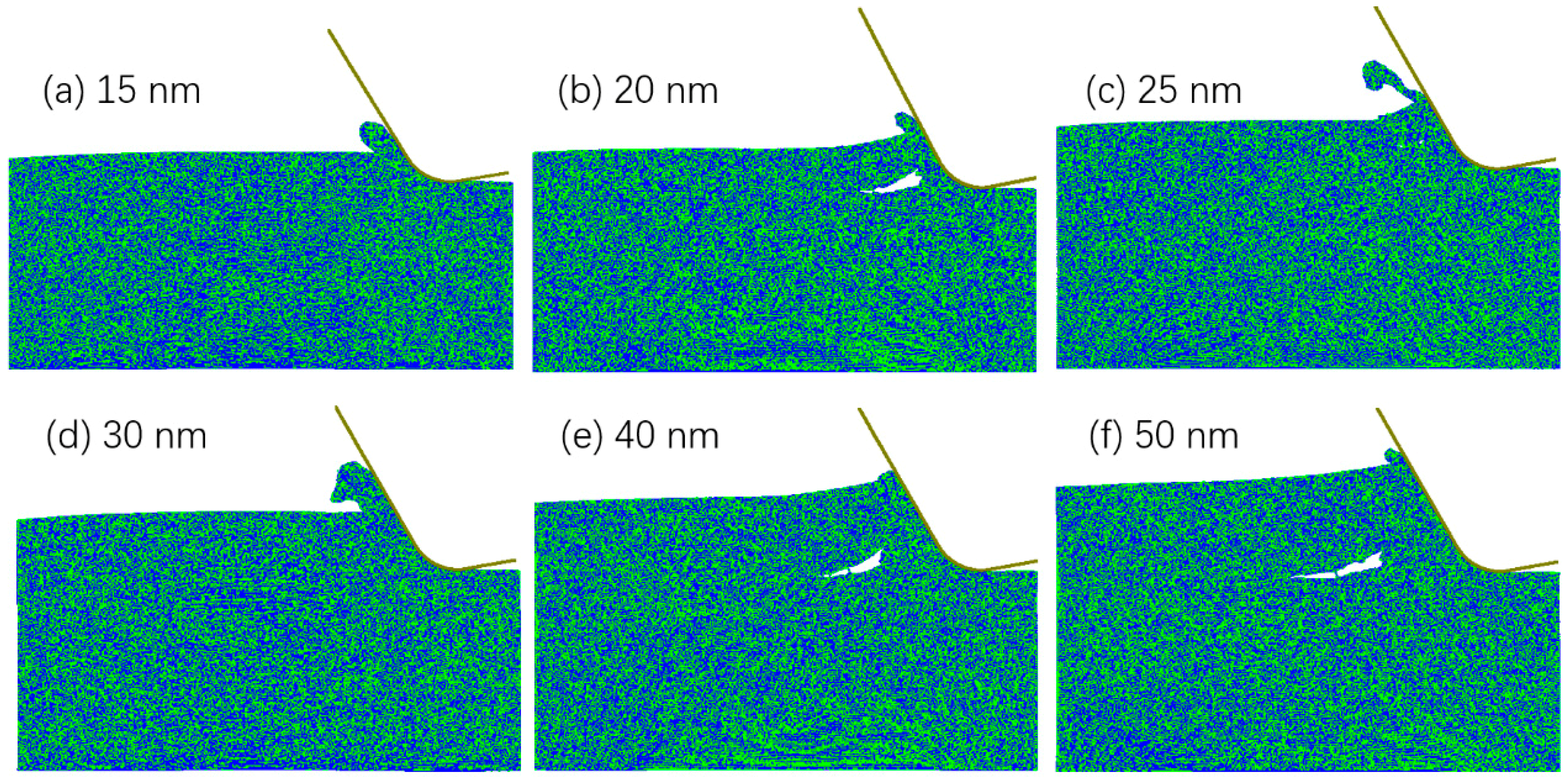

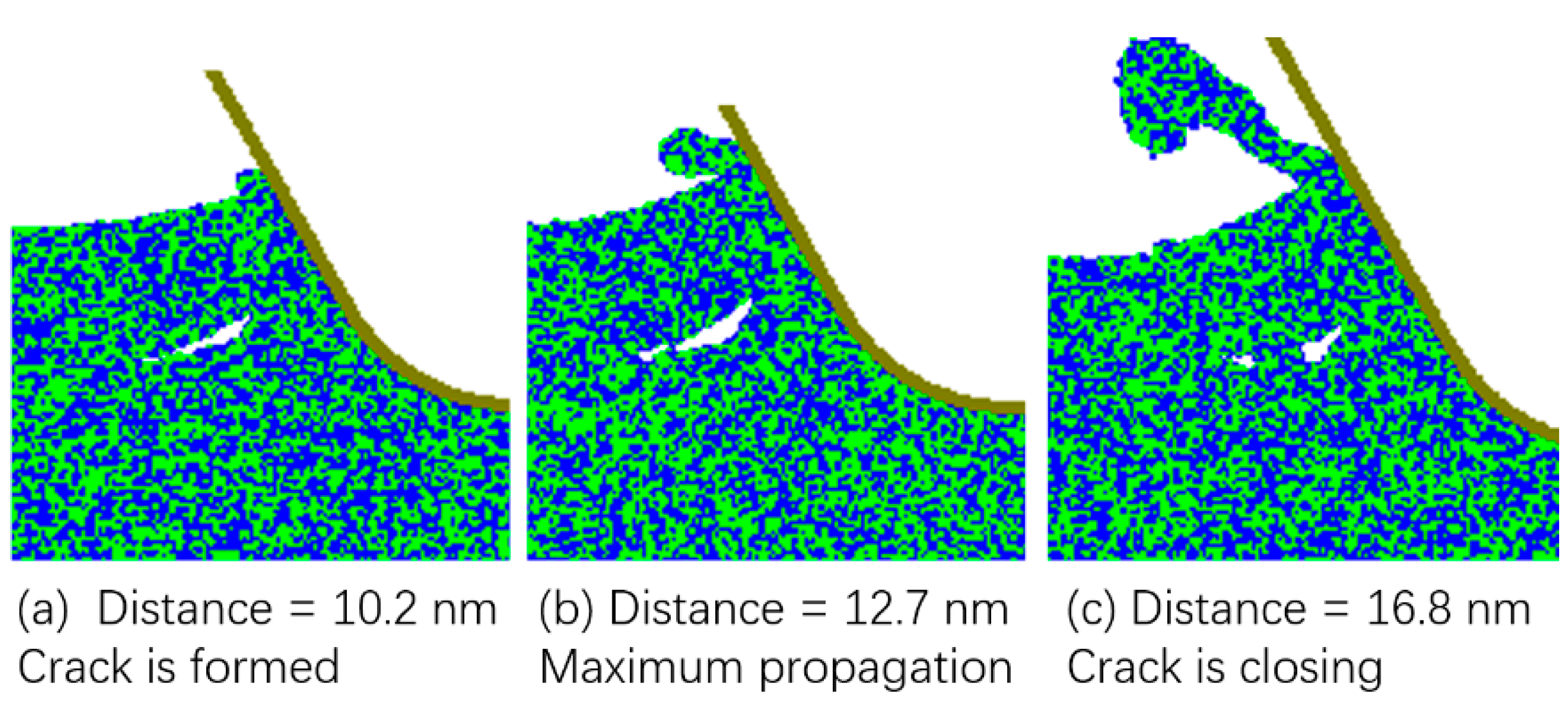

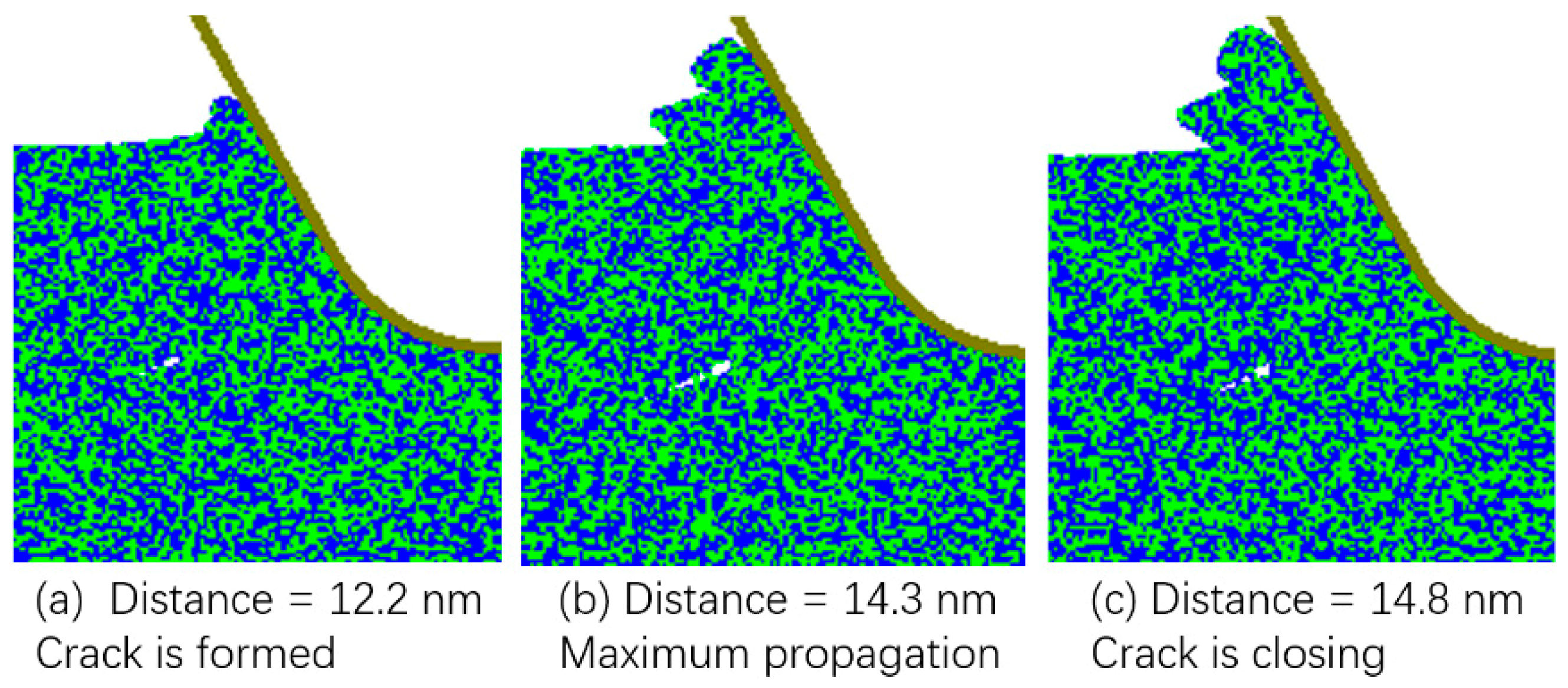

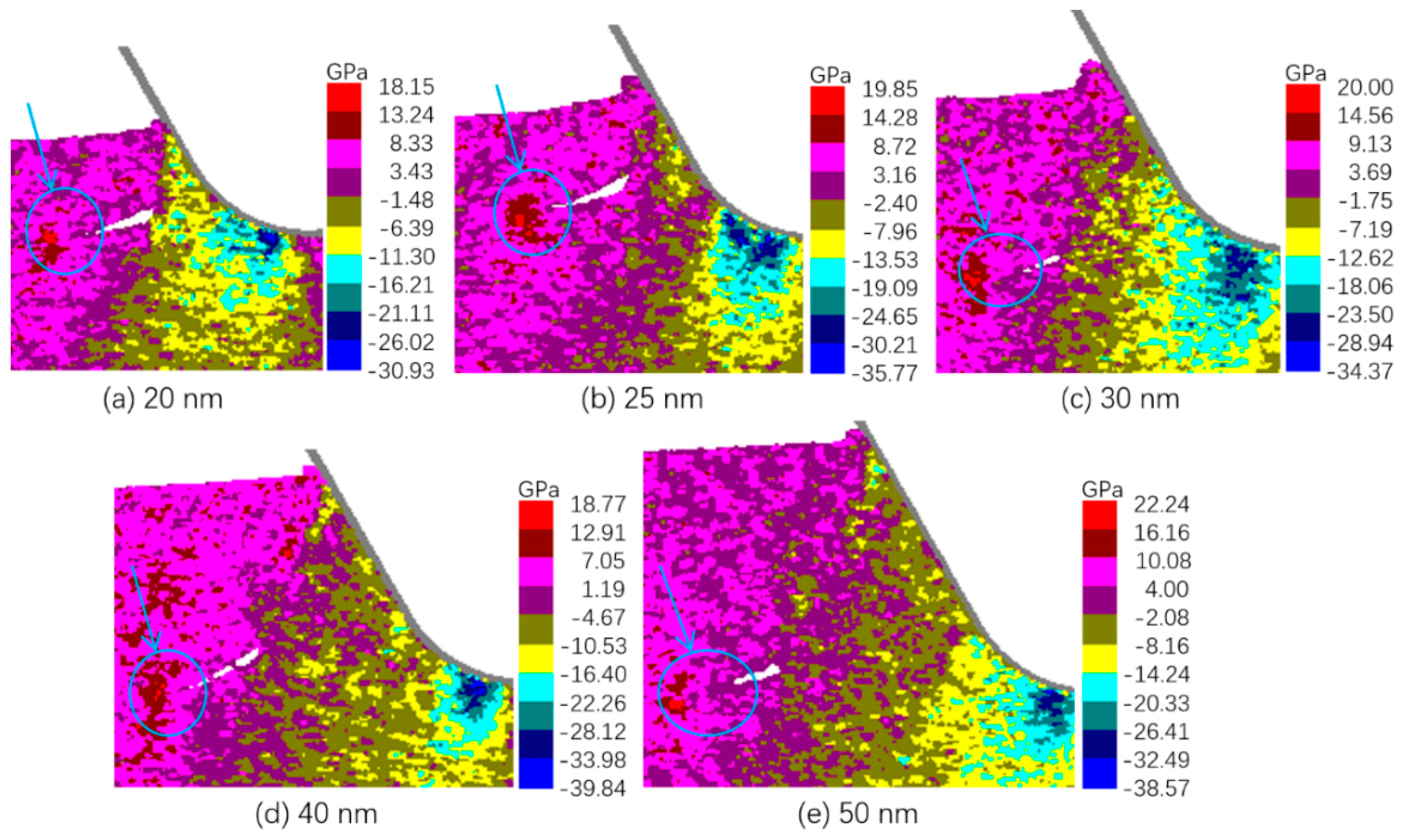

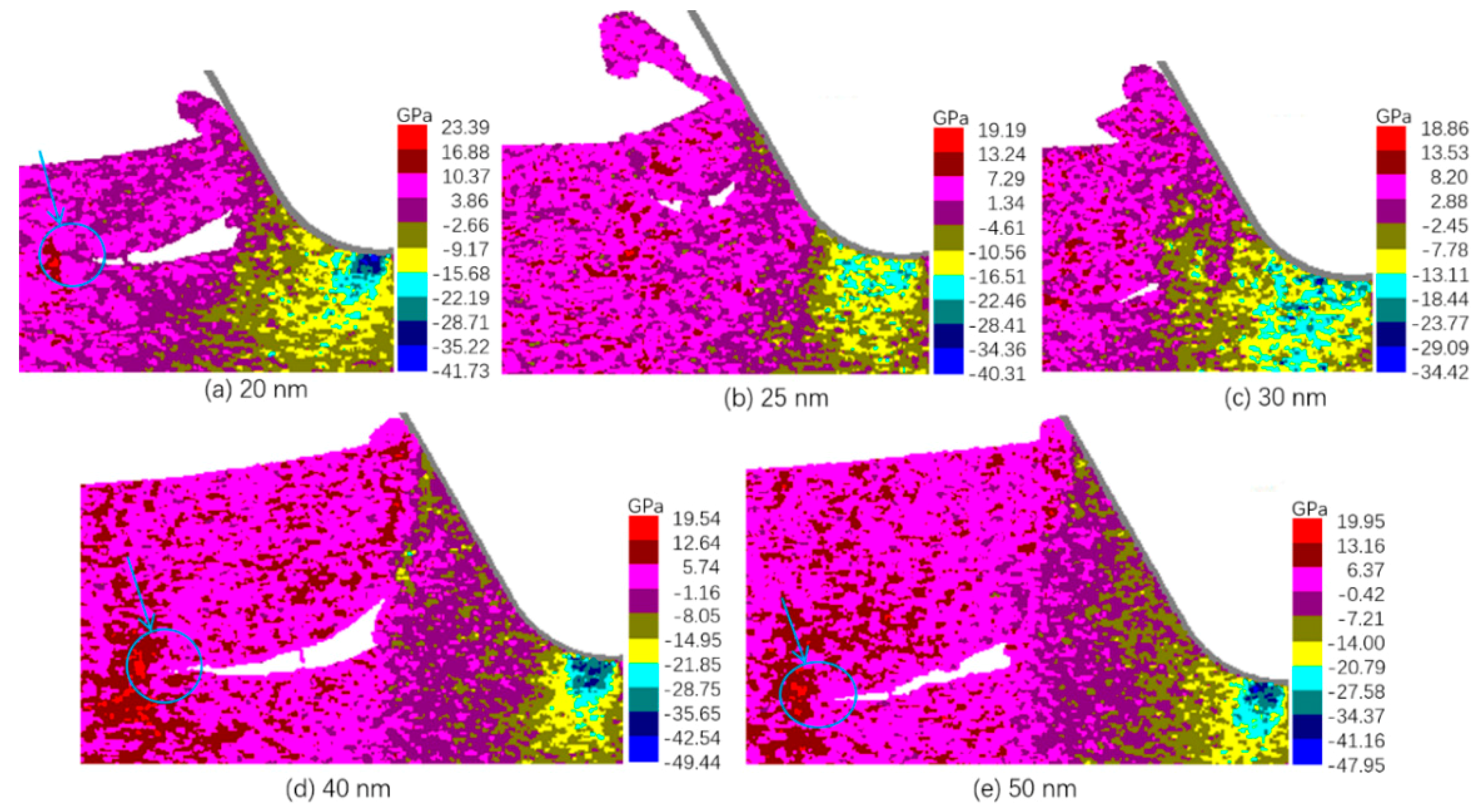

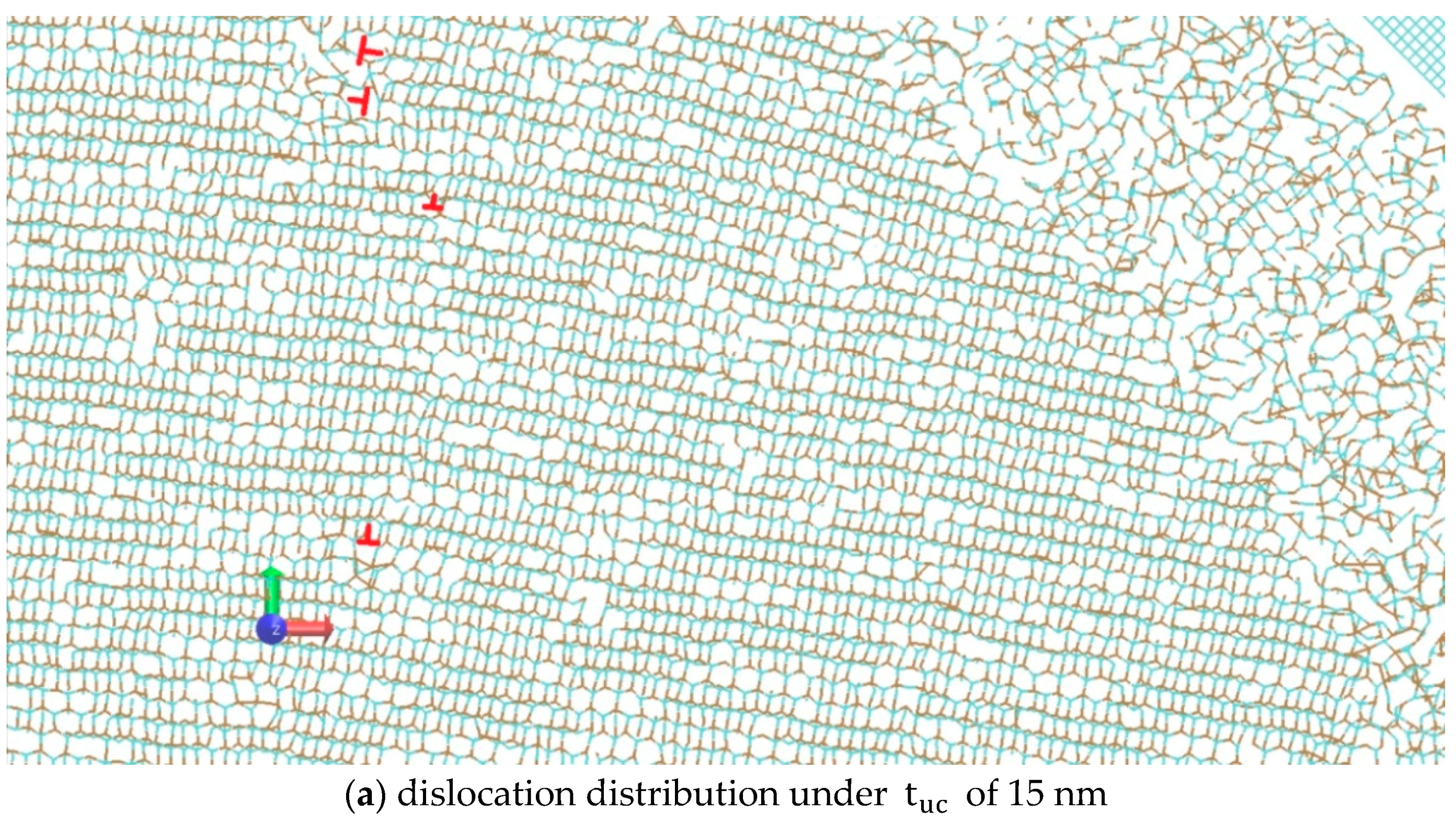

2.2. MD Modelling Results

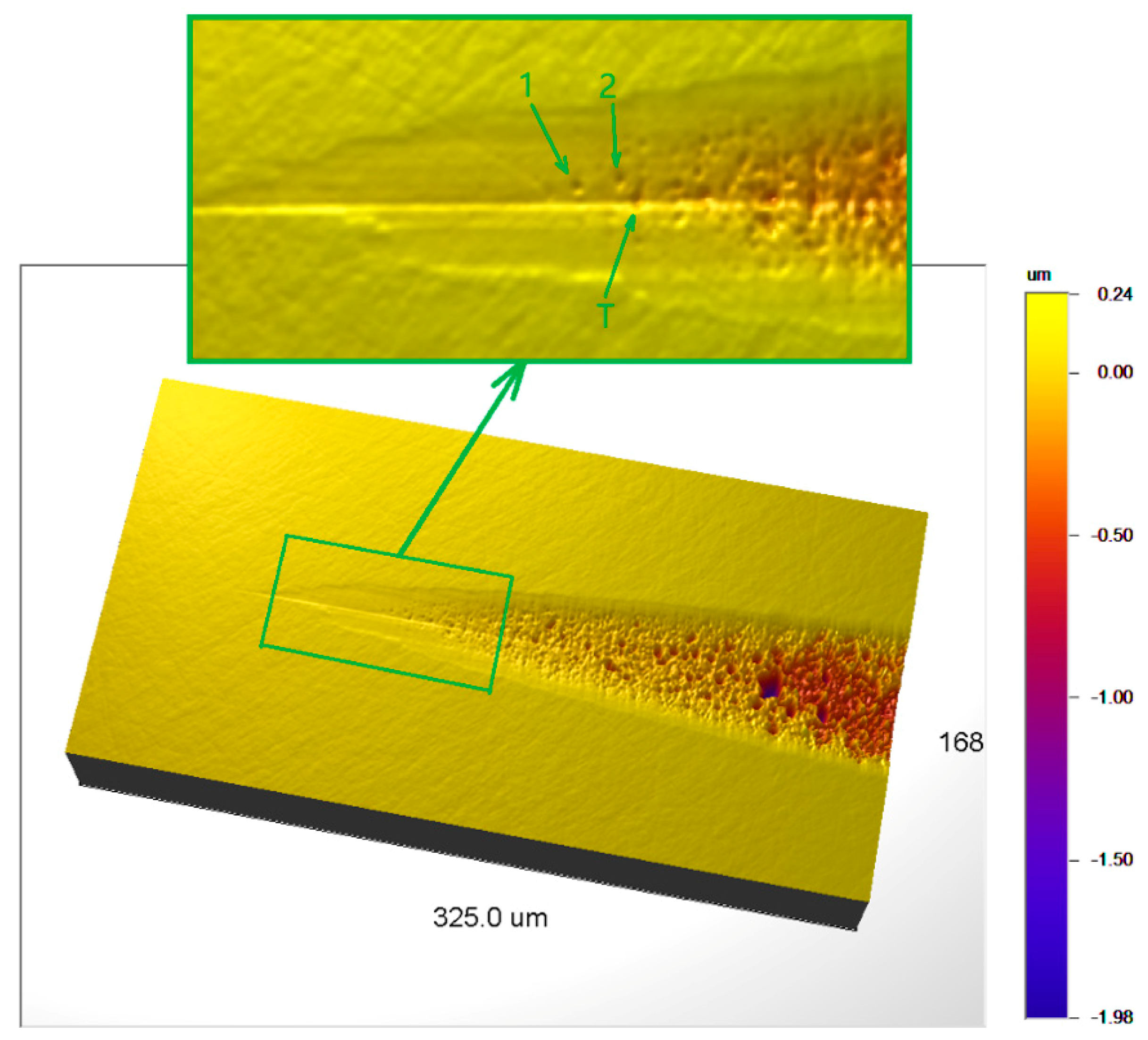

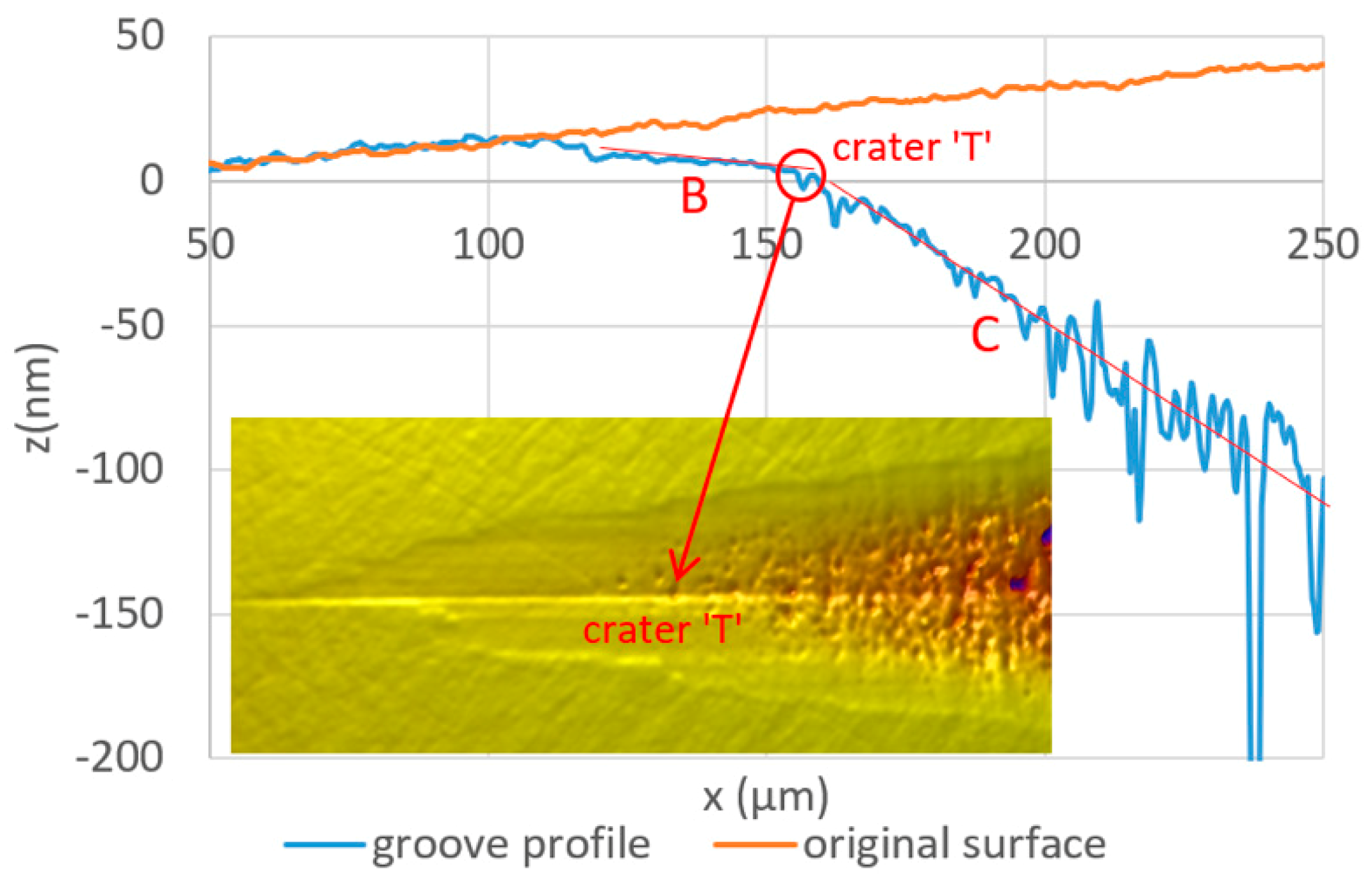

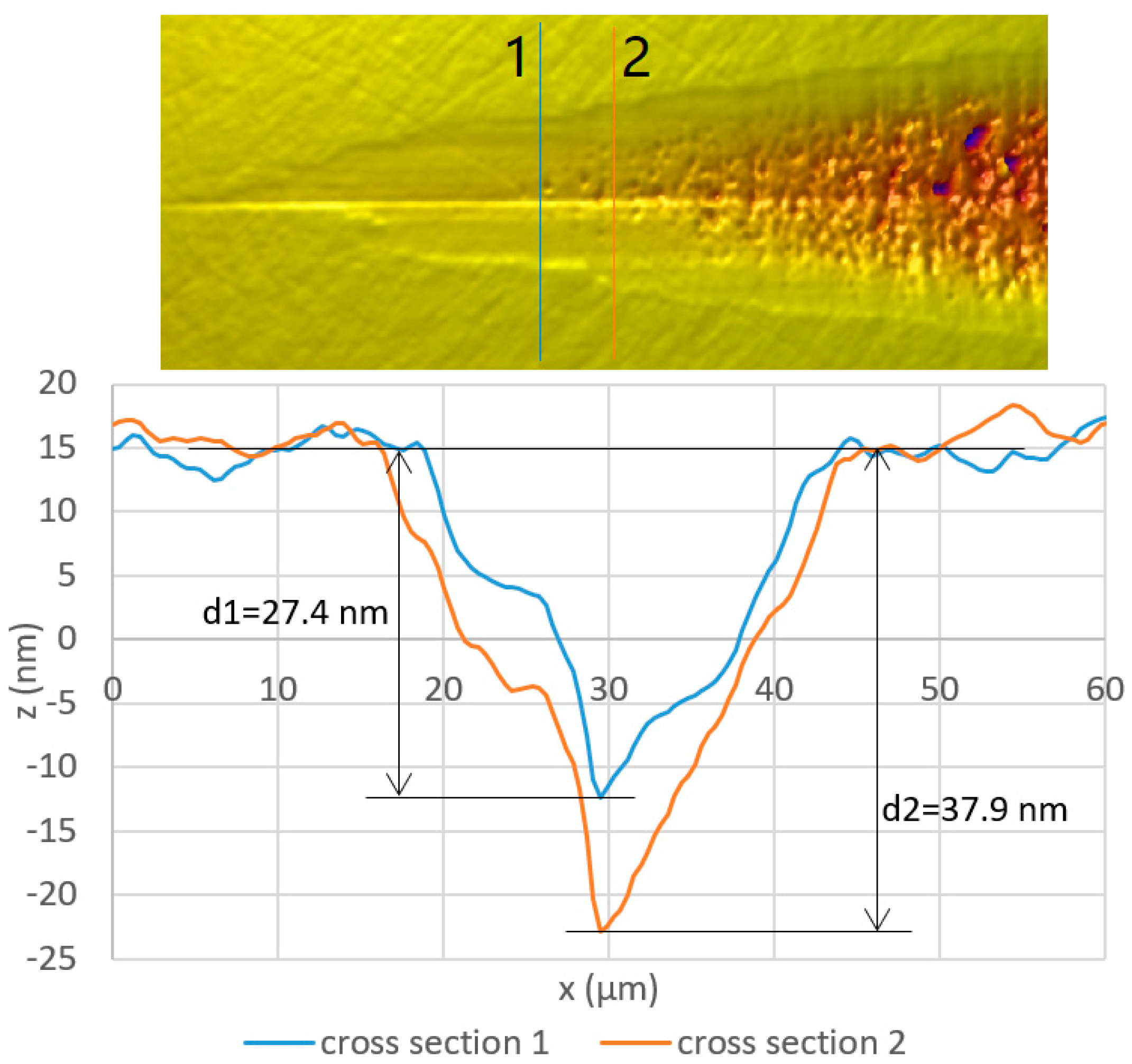

3. Experimental Validation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cheng, J.; Wu, J.; Gong, Y.D.; Wen, X.L.; Wen, Q. Experimental study on the single grit interaction behaviour and brittle–ductile transition of grinding with a diamond micro-grinding tool. Int. J. Adv. Manuf. Technol. 2017, 91, 1209–1226. [Google Scholar] [CrossRef]

- Chen, J.B.; Fang, Q.H.; Wang, C.C.; Du, J.K.; Liu, F. Theoretical study on brittle–ductile transition behavior in elliptical ultrasonic assisted grinding of hard brittle materials. Precis. Eng. 2016, 46, 104–117. [Google Scholar] [CrossRef]

- Blackley, W.; Scattergood, R.O. Chip topography for ductile-regime machining of germanium. J. Manuf. Sci. Eng. 1994, 116, 263–266. [Google Scholar] [CrossRef]

- Fang, F.; Wu, H.; Zhou, W.; Hu, X. A study on mechanism of nano-cutting single crystal silicon. J. Mater. Process. Technol. 2007, 184, 407–410. [Google Scholar] [CrossRef]

- Xiao, G. Molecular Dynamics Modelling and Mechanics Analysis on the Mechanism of Brittle to Ductile Cutting Mode Transition in Ultra-Precision Machining. Ph.D. Thesis, The Hong Kong Polytechnic University, Hong Kong, China, 2015. [Google Scholar]

- Cai, M.; Li, X.; Rahman, M. Study of the mechanism of nanoscale ductile mode cutting of silicon using molecular dynamics simulation. Int. J. Mach. Tools Manuf. 2007, 47, 75–80. [Google Scholar] [CrossRef]

- Mizumoto, Y.; Maas, P.; Kakinuma, Y.; Min, S. Investigation of the cutting mechanisms and the anisotropic ductility of monocrystalline sapphire. CIRP Ann. 2017, 66, 89–92. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Zhang, Y.; Jia, D.; Zhang, X.; Hou, Y.; Li, R.; Wang, J. Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions. Int. J. Mach. Tools Manuf. 2017, 122, 55–65. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.; Fang, H.; Tian, R. Influence of cutting parameters on the ductile-brittle transition of single-crystal calcium fluoride during ultra-precision cutting. Int. J. Adv. Manuf. Technol. 2017, 89, 219–225. [Google Scholar] [CrossRef]

- Chen, H.; Dai, Y.; Zheng, Z.; Gao, H.; Li, X. Effect of crystallographic orientation on cutting forces and surface finish in ductile cutting of KDP crystals. Mach. Sci. Technol. 2011, 15, 231–242. [Google Scholar] [CrossRef]

- Leung, T.P.; Lee, W.B.; Lu, X.M. Diamond turning of silicon substrates in ductile-regime. J. Mater. Process. Technol. 1998, 73, 42–48. [Google Scholar] [CrossRef]

- Bifano, T.G.; Dow, T.A.; Scattergood, R.O. Ductile-regime grinding: A new technology for machining brittle materials. J. Eng. Ind. 1991, 113, 184–189. [Google Scholar] [CrossRef]

- Liu, K.; Li, X.; Rahman, M.; Neo, K.; Liu, X. A study of the effect of tool cutting edge radius on ductile cutting of silicon wafers. Int. J. Adv. Manuf. Technol. 2007, 32, 631–637. [Google Scholar] [CrossRef]

- Chen, M.; Zhao, Q.; Dong, S.; Li, D. The critical conditions of brittle–ductile transition and the factors influencing the surface quality of brittle materials in ultra-precision grinding. J. Mater. Process. Technol. 2005, 168, 75–82. [Google Scholar] [CrossRef]

- O’Connor, B.P.; Marsh, E.R.; Couey, J.A. On the effect of crystallographic orientation on ductile material removal in silicon. Precis. Eng. 2005, 29, 124–132. [Google Scholar] [CrossRef]

- Yan, J.; Asami, T.; Harada, H.; Kuriyagawa, T. Fundamental investigation of subsurface damage in single crystalline silicon caused by diamond machining. Precis. Eng. 2009, 33, 378–386. [Google Scholar] [CrossRef]

- Subhash, G.; Klecka, M. Ductile to Brittle Transition Depth During Single-Grit Scratching on Alumina Ceramics. J. Am. Ceram. Soc. 2007, 90, 3704–3707. [Google Scholar] [CrossRef]

- Zhou, M.; Zhao, P. Prediction of critical cutting depth for ductile-brittle transition in ultrasonic vibration assisted grinding of optical glasses. Int. J. Adv. Manuf. Technol. 2016, 86, 1775–1784. [Google Scholar] [CrossRef]

- Venkatachalam, S.; Li, X.; Liang, S.Y. Predictive modeling of transition undeformed chip thickness in ductile-regime micro-machining of single crystal brittle materials. J. Mater. Process. Technol. 2009, 209, 3306–3319. [Google Scholar] [CrossRef]

- Arif, M.; Xinquan, Z.; Rahman, M.; Kumar, S. A predictive model of the critical undeformed chip thickness for ductile–brittle transition in nano-machining of brittle materials. Int. J. Mach. Tools Manuf. 2013, 64, 114–122. [Google Scholar] [CrossRef]

- Xiao, G.B.; To, S.; Jelenković, E.V. Effects of non-amorphizing hydrogen ion implantation on anisotropy in micro cutting of silicon. J. Mater. Process. Technol. 2015, 225, 439–450. [Google Scholar] [CrossRef]

- Shimada, S.; Ikawa, N.; Inamura, T.; Takezawa, N.; Ohmori, H.; Sata, T. Brittle-ductile transition phenomena in microindentation and micromachining. CIRP Ann. 1995, 44, 523–526. [Google Scholar] [CrossRef]

- Nakasuji, T.; Kodera, S.; Hara, S.; Matsunaga, H.; Ikawa, N.; Shimada, S. Diamond turning of brittle materials for optical components. CIRP Ann. 1990, 39, 89–92. [Google Scholar] [CrossRef]

- Goel, S.; Rashid, W.B.; Luo, X.; Agrawal, A.; Jain, V. A theoretical assessment of surface defect machining and hot machining of nanocrystalline silicon carbide. J. Manuf. Sci. Eng. 2014, 136, 021015. [Google Scholar] [CrossRef]

- Sundaram, M.; James, S. A Molecular Dynamics Simulation Study of Material Removal Mechanisms in Vibration Assisted Nano Impact-machining by Loose Abrasives. J. Manuf. Sci. Eng. 2017, 139, 081014. [Google Scholar]

- Xiao, G.; To, S.; Zhang, G. Molecular Dynamics modelling of brittle-ductile cutting mode transition: Case study on silicon carbide. Int. J. Mach. Tools Manuf. 2015, 88, 214–222. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.; Comley, P.; Reuben, R.L.; Cox, A. Brittle–ductile transition during diamond turning of single crystal silicon carbide. Int. J. Mach. Tools Manuf. 2013, 65, 15–21. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Mutlugünes, Y.; Klocke, F.; Aurich, J.; Shore, P.; Ohmori, H. Ultra-precision grinding. CIRP Ann. 2010, 59, 652–671. [Google Scholar] [CrossRef]

- Li, S.; Du, S.; Tang, A.; Landers, R.G.; Zhang, Y. Force Modeling and Control of SiC Monocrystal Wafer Processing. J. Manuf. Sci. Eng. 2015, 137, 061003. [Google Scholar] [CrossRef]

- Vashishta, P.; Kalia, R.K.; Nakano, A.; Rino, J.P. Interaction potential for silicon carbide: A molecular dynamics study of elastic constants and vibrational density of states for crystalline and amorphous silicon carbide. J. Appl. Phys. 2007, 101, 103515. [Google Scholar] [CrossRef]

- Yin, L.; Vancoille, E.; Lee, L.; Huang, H.; Ramesh, K.; Liu, X. High-quality grinding of polycrystalline silicon carbide spherical surfaces. Wear 2004, 256, 197–207. [Google Scholar] [CrossRef]

- Axinte, D.; Butler-Smith, P.; Akgun, C.; Kolluru, K. On the influence of single grit micro-geometry on grinding behavior of ductile and brittle materials. Int. J. Mach. Tools Manuf. 2013, 74, 12–18. [Google Scholar] [CrossRef]

- Volkov, N.A.; Posysoev, M.V.; Shchekin, A.K. The Effect of Simulation Cell Size on the Diffusion Coefficient of an Ionic Surfactant Aggregate. Colloid J. 2018, 80, 248–254. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Xiao, G.; Ren, M.; To, S. A Study of Mechanics in Brittle–Ductile Cutting Mode Transition. Micromachines 2018, 9, 49. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Liu, X.; Lu, W.; Hu, C.; Guo, X. Towards a traceable probe calibration method for white light interference based AFM. Precis. Eng. 2018, 51, 40–47. [Google Scholar] [CrossRef]

- Yang, W.; Liu, X.; Lu, W.; Guo, X. Influence of probe dynamic characteristics on the scanning speed for white light interference based AFM. Precis. Eng. 2018, 51, 348–352. [Google Scholar] [CrossRef]

- Cheng, Q.; Wu, H.A.; Wang, Y.; Wang, X.X. Atomistic simulations of shock waves in cubic silicon carbide. Comput. Mater. Sci. 2009, 45, 419–422. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Length of workpiece | 300 nm |

| Thickness | 3.5 nm |

| t | 120 nm |

| Undeformed chip thickness | 15, 20, 25, 30, 40, 50 nm |

| Atoms in workpiece | 11.8, 13.0, 14.2, 14.9, 17.9, 18.7 million |

| Total atoms in Tool | 0.28 million |

| Tool rake angle | −30° |

| Tool clearance angle | 10° |

| Cutting edge radius | 30 nm |

| Cutting speed | 0 m/s |

| Parameter | Value |

|---|---|

| Tool rake angle | −30° |

| Clearance angle | 10° |

| Tool nose radius | 1.507 mm |

| Cutting speed | 3 mm/s |

| Tilt angle | 0.01° |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, W.; Hong, H.; Wang, H. Mechanism of Unstable Material Removal Modes in Micro Cutting of Silicon Carbide. Micromachines 2019, 10, 696. https://doi.org/10.3390/mi10100696

Zhao W, Hong H, Wang H. Mechanism of Unstable Material Removal Modes in Micro Cutting of Silicon Carbide. Micromachines. 2019; 10(10):696. https://doi.org/10.3390/mi10100696

Chicago/Turabian StyleZhao, Wei, Haibo Hong, and Hongzhi Wang. 2019. "Mechanism of Unstable Material Removal Modes in Micro Cutting of Silicon Carbide" Micromachines 10, no. 10: 696. https://doi.org/10.3390/mi10100696

APA StyleZhao, W., Hong, H., & Wang, H. (2019). Mechanism of Unstable Material Removal Modes in Micro Cutting of Silicon Carbide. Micromachines, 10(10), 696. https://doi.org/10.3390/mi10100696