Combined Effect of Rarefaction and Effective Viscosity on Micro-Elasto-Aerodynamic Lubrication Performance of Gas Microbearings

Abstract

1. Introduction

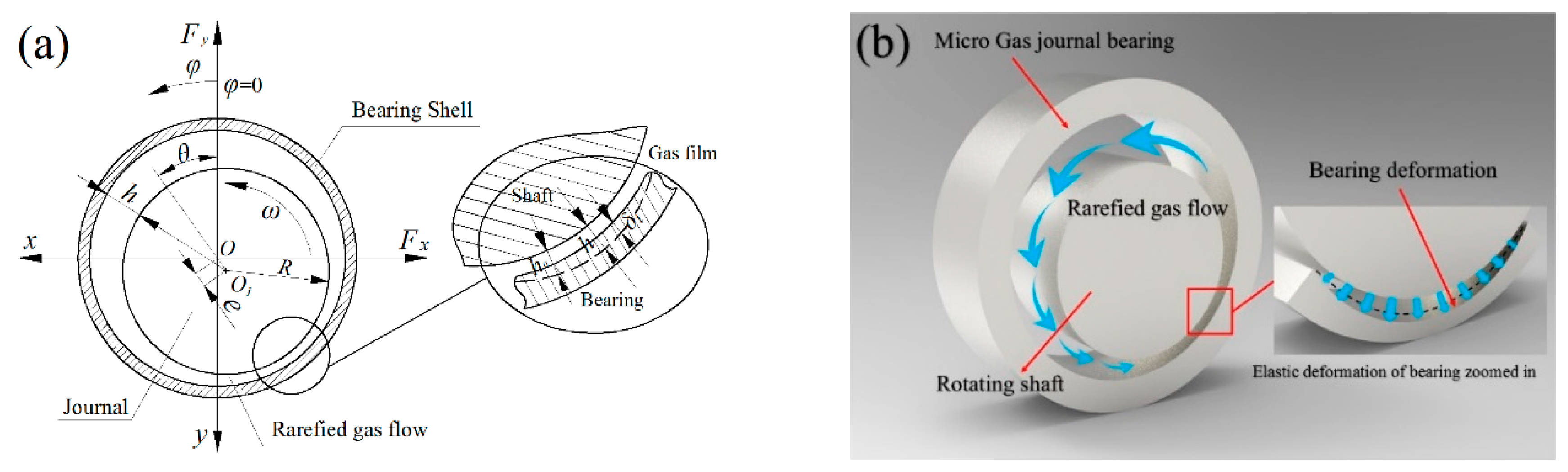

2. Governing Equations

3. Elastic Deformation and Fluid Film Thickness

4. Results and Discussion

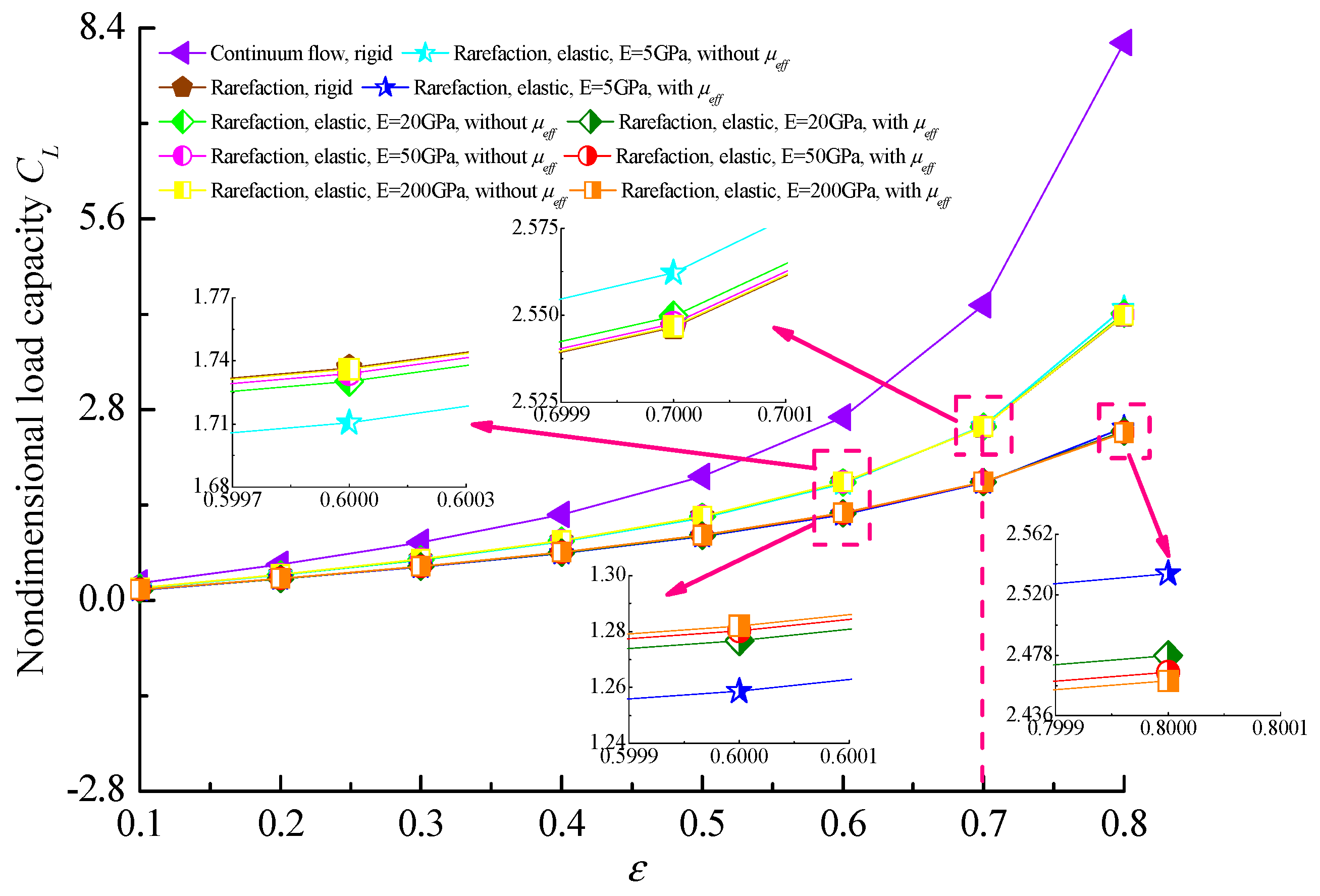

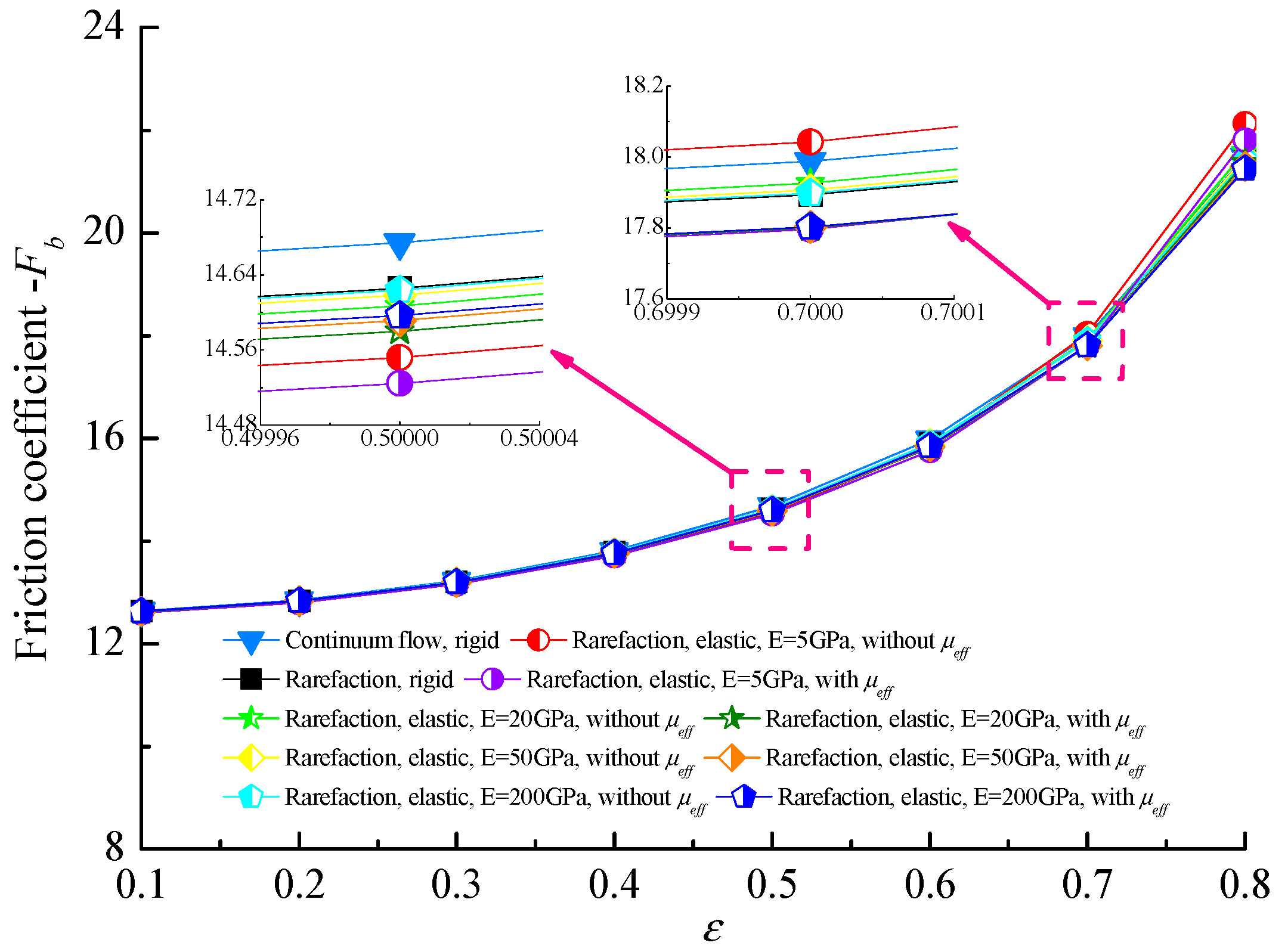

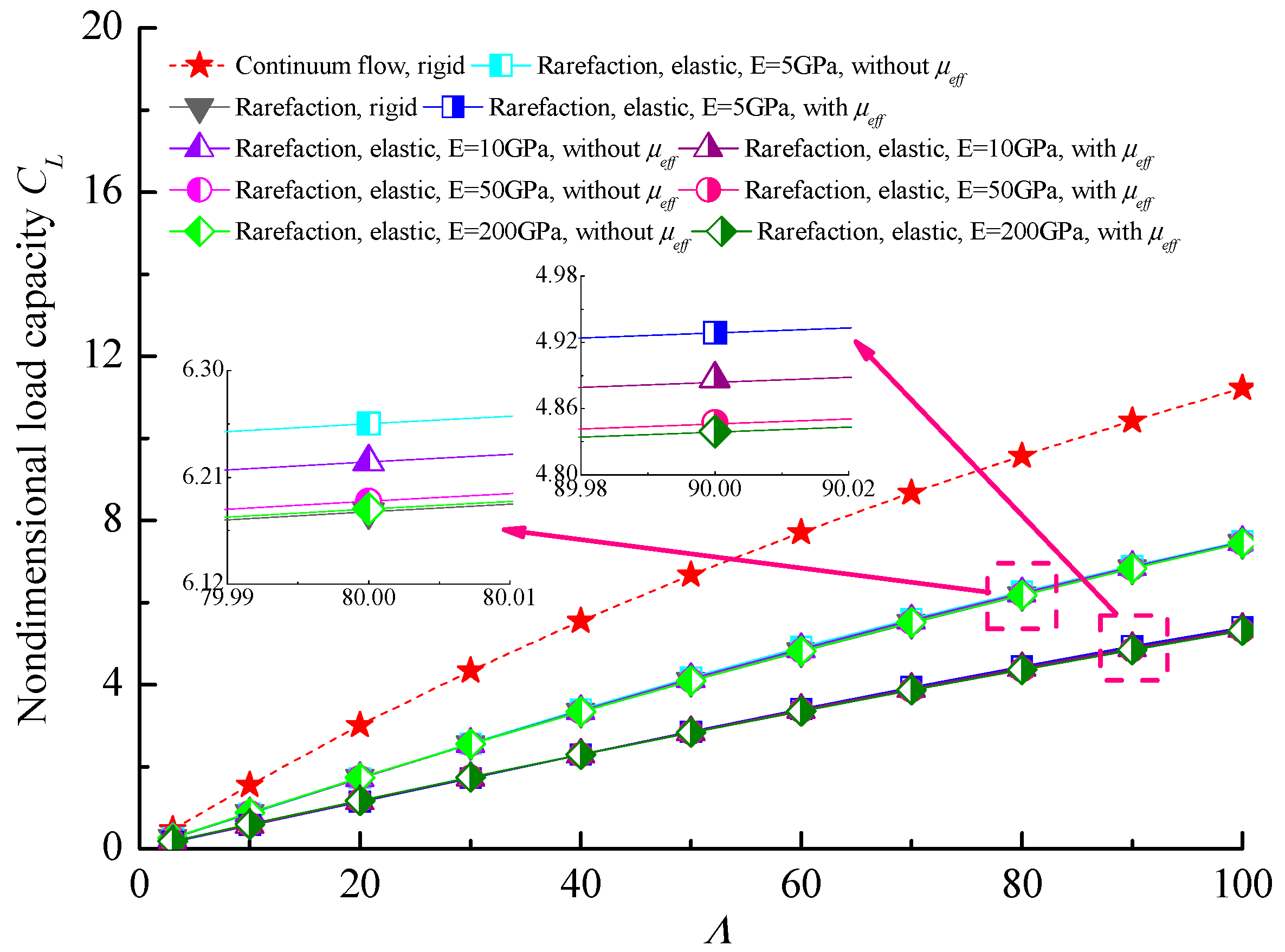

4.1. Steady-State Characteristics

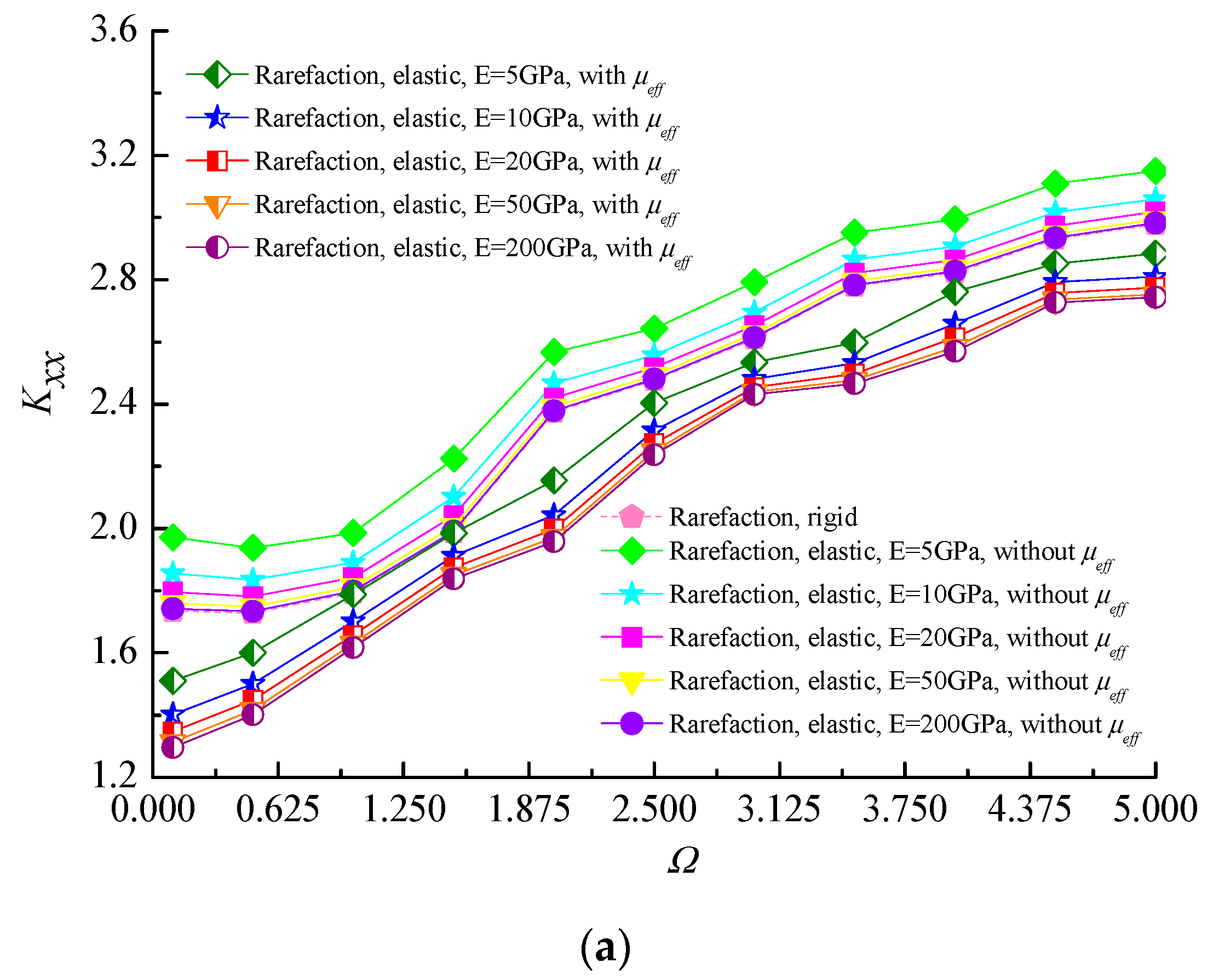

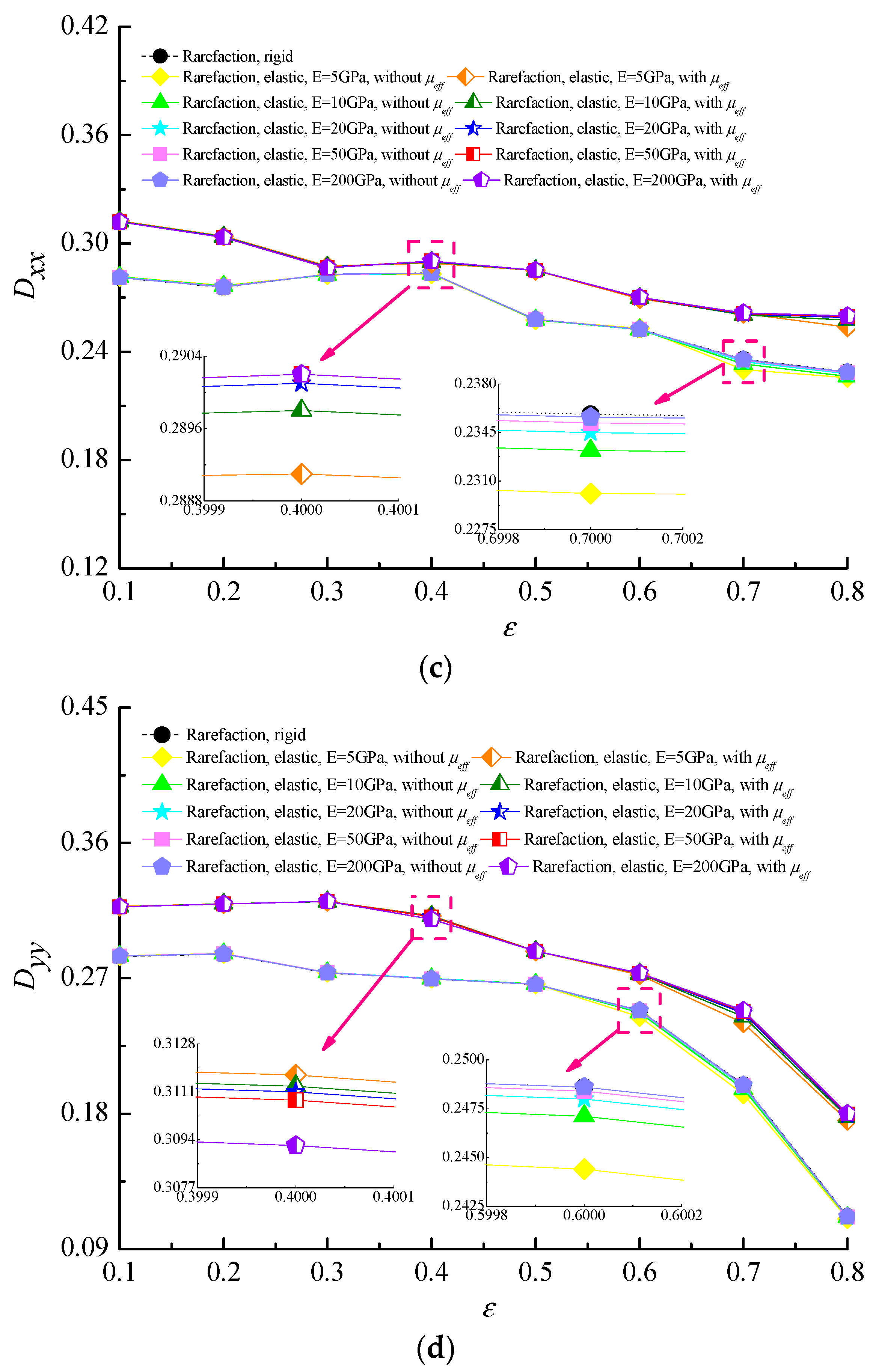

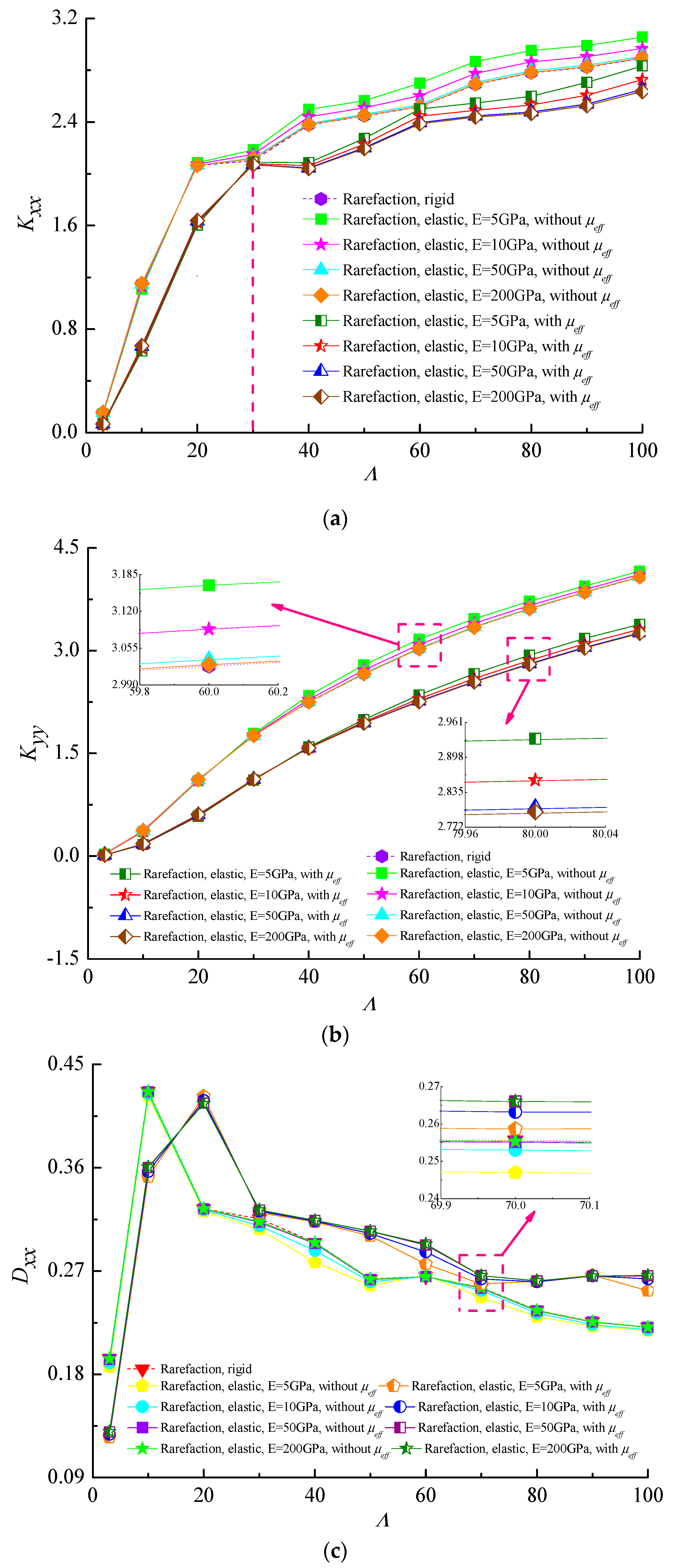

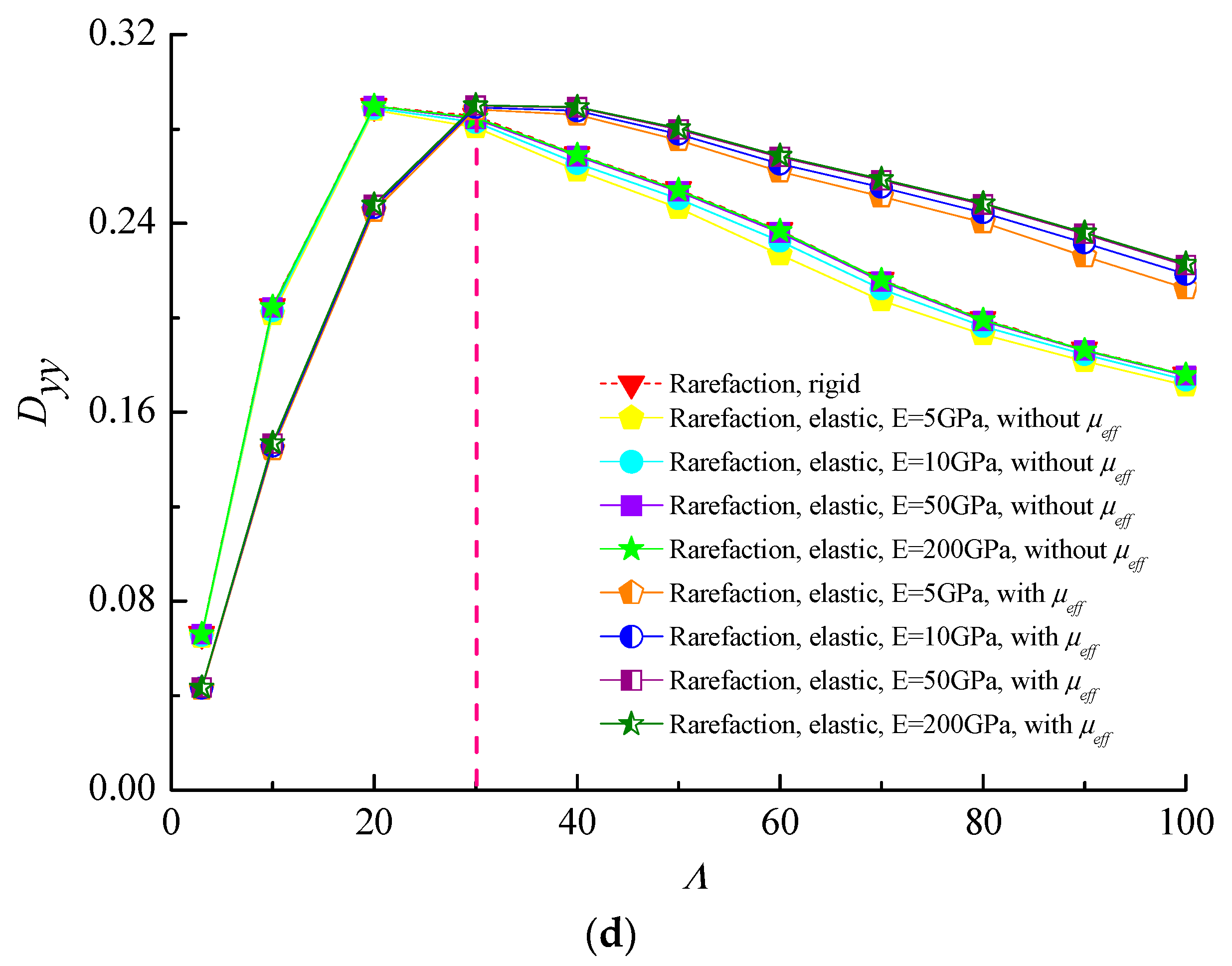

4.2. Dynamic Stiffness and Damping Coefficients

5. Conclusions

- (1)

- The presence of the elastic bearing liner is seen to decrease the maximum gas film pressure around the local pressure peak region and the elastic journal microbearings with effective viscosity carry less load as compared to the cases for rigid bearings lubricated with constant viscosity gas lubricant.

- (2)

- The load-carrying capacity marginally increases in the range of high eccentricity ratio and bearing number for elastic bearing liner because of the larger integral area of film pressure. The effects of bearing shell flexibility provide an increase in the friction coefficient compared to the rigid bearing, whereas the influence of effective viscosity yield a reversed trend.

- (3)

- Improving the perturbation frequency, bearing number, and eccentricity ratio contributes to the increase in the direct stiffness coefficients while the direct damping coefficients become smaller and smaller with increasing dimensionless perturbation frequency and eccentricity ratios.

- (4)

- As the elastic moduli decreases, the direct stiffness coefficients increase while the direct damping coefficients decrease. The effective viscosity of gas lubricant decreases the direct stiffness coefficients of microbearings and the direct damping coefficients are larger than those predicted by the constant viscosity lubricant.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, D.; Lee, S.; Bryant, M.D.; Ling, F.F. Hydrodynamic performance of gas microbearings. J. Tribol. 2004, 126, 711–718. [Google Scholar] [CrossRef]

- Dongari, N.; Agrawal, A.; Agrawal, A. Analytical solution of gaseous slip flow in long microchannels. Int. J. Heat Mass Transf. 2007, 50, 3411–3421. [Google Scholar] [CrossRef]

- Ren, L.; Xia, D.H. Stability of slip flow in microbearings. Energy Procedia 2015, 66, 105–108. [Google Scholar] [CrossRef][Green Version]

- Wang, Z.; Wang, X.; Tong, Y.; Wang, Y. Impact of structure and flow-path on in situ synthesis of AlN: Dynamic microstructural evolution of Al-AlN-Si materials. Sci. China Mater. 2018, 61, 948–960. [Google Scholar] [CrossRef]

- Zhe, W.; Wang, Y. Impact of convection-diffusion and flow-path interactions on the dynamic evolution of microstructure: Arc erosion behavior of Ag-SnO2 contact materials. J. Alloy. Compd. 2019, 774, 1046–1058. [Google Scholar]

- Veijola, T.; Kuisma, H.; Lahdenperä, J. The influence of gas-surface interaction on gas-film damping in a silicon accelerometer. Sens. Actuators A 1998, 66, 83–92. [Google Scholar] [CrossRef]

- Veijola, T.; Turowski, M. Compact damping models for laterally moving microstructures with gas-rarefaction effects. J. Microelectromechanical Syst. 2001, 10, 263–273. [Google Scholar] [CrossRef]

- Lin, W. A slip model for rarefied gas flows at arbitrary Knudsen number. Appl. Phys. Lett. 2008, 93, 94. [Google Scholar]

- White, J. A lubrication equation incorporating two-dimensional roughness effects, with emphasis on the patterned data islands of a recording disk. J. Tribol. 2012, 134, 011901. [Google Scholar] [CrossRef]

- Burgdorfer, A. The influence of the molecular mean free path on the performance of hydrodynamic gas lubricated bearings. J. Basic Eng. 1959, 81, 94–98. [Google Scholar] [CrossRef]

- Hsia, Y.T.; Domoto, G.A.; Hsia, Y.T.; Domoto, G.A. An experimental investigation of molecular rarefaction effects in gas lubricated bearings at ultra-low clearances. J. Tribol. 1983, 105, 120–130. [Google Scholar] [CrossRef]

- Mitsuya, Y. Modified Reynolds equation for ultra-thin film gas lubrication using 1.5-order slip-flow model and considering surface accommodation coefficient. J. Tribol. 1993, 115, 289–294. [Google Scholar] [CrossRef]

- Fukui, S.; Kaneko, R. Analysis of ultra-thin gas film lubrication based on the linearized Boltzmann equation: Influence of accommodation coefficient. JMSE Int. J. 1987, 30, 1660–1666. [Google Scholar] [CrossRef]

- Fukui, S.; Kaneko, R. A database for interpolation of Poiseuille flow rates for high Knudsen number lubrication problems. J. Tribol. 1990, 112, 78–83. [Google Scholar] [CrossRef]

- Dowson, D.; Higginson, G. A numerical solution to the elasto-hydrodynamic problem. J. Mech. Eng. Sci. 1959, 1, 6–15. [Google Scholar] [CrossRef]

- O’Donoghue, J.; Brighton, D.; Hooke, C. The effect of elastic distortions on journal bearing performance. J. Lubr. Technol. 1967, 89, 409–415. [Google Scholar] [CrossRef]

- Oh, K.; Huebner, K. Solution of the elastohydrodynamic finite journal bearing problem. J. Lubr. Technol. 1973, 95, 342–351. [Google Scholar] [CrossRef]

- Ramanaiah, G.; Sundarammal, A. Effect of bearing deformation on the characteristics of a slider bearing. Wear 1982, 78, 273–278. [Google Scholar] [CrossRef]

- Malvano, R.; Vatta, F. Elastohydrodynamic lubrication in a plane slider bearing. Meccanica 1986, 21, 134–139. [Google Scholar] [CrossRef]

- Braun, M.; Dougherty, J. Hydrodynamic analysis and fluid-solid interaction effects on the behavior of a compliant wall (thick) journal bearing. Part 1: Theory. J. Tribol. 1989, 111, 70–79. [Google Scholar] [CrossRef]

- Braun, M.; Dougherty, J. Hydrodynamic analysis and fluid-solid interaction effects on the behavior of a compliant wall (thick) journal bearing. Part 2: Results. J. Tribol. 1989, 111, 80–86. [Google Scholar] [CrossRef]

- Sinhasan, R.; Goyal, K. Elastohydrodynamic studies of circular journal bearings with non-Newtonian lubricants. Tribol. Int. 1990, 23, 419–428. [Google Scholar] [CrossRef]

- Peng, J.P.; Carpino, M. Calculation of stiffness and damping coefficients for elastically supported gas foil bearings. J. Tribol. 1993, 115, 20–27. [Google Scholar] [CrossRef]

- Angra, S.; Mehta, N.; Rattan, S. Effects of elastic deformation of a bearing liner on performance of finite offset-halves pressure dam bearings. Tribol. Lett. 1996, 2, 273–285. [Google Scholar] [CrossRef]

- Lahmar, M.; Haddad, A.; Nicolas, D. Elastohydrodynamic analysis of one-layered journal bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 1998, 212, 193–205. [Google Scholar] [CrossRef]

- Ebrat, O.; Mourelatos, Z.P.; Vlahopoulos, N.; Vaidyanathan, K. Calculation of journal bearing dynamic characteristics including journal misalignment and bearing structural deformation©. Tribol. Trans. 2004, 47, 94–102. [Google Scholar] [CrossRef]

- Saber, E.; El-Gamal, H. Effect of Elastic Deformation of the Journal Bearing Shell on Its Dynamic Stability. In Proceedings of the IUTAM Symposium on Elastohydrodynamics and Micro-elastohydrodynamics, Cardiff, UK, 1–3 September 2004; pp. 121–131. [Google Scholar]

- Wang, Y.; Wang, Q.J.; Lin, C. A mixed-EHL analysis of effects of misalignments and elastic deformations on the performance of a coupled journal-thrust bearing system. Tribol. Int. 2006, 39, 281–289. [Google Scholar] [CrossRef]

- Nair, K.P.; Nair, V.S.; Jayadas, N. Static and dynamic analysis of elastohydrodynamic elliptical journal bearing with micropolar lubricant. Tribol. Int. 2007, 40, 297–305. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.; Yang, Q. Characteristics of micro gas journal bearings based on effective viscosity. J. Tribol. 2009, 131, 041707. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, H.; Liu, Y. Improved modified Reynolds equation for thin-film gas lubrication from an extended slip velocity boundary condition. Microsyst. Technol. 2016, 22, 2869–2875. [Google Scholar] [CrossRef]

- Karadere, G. The effects of the total bearing deformation on the performance of hydrodynamic thrust bearings. Ind. Lubr. Tribol. 2010, 62, 207–213. [Google Scholar] [CrossRef]

- Yagi, K.; Sugimura, J. Elastic deformation in thin film hydrodynamic lubrication. Tribol. Int. 2013, 59, 170–180. [Google Scholar] [CrossRef]

- Su, B.; Huang, L.; Huang, W.; Wang, X. The load carrying capacity of textured sliding bearings with elastic deformation. Tribol. Int. 2017, 109, 86–96. [Google Scholar] [CrossRef]

- Chetti, B. Combined effects of turbulence and elastic deformation on the performance of a journal bearing lubricated with a couple stress fluid. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 1597–1603. [Google Scholar] [CrossRef]

- Zhou, C.; Xiao, Z. Stiffness and damping models for the oil film in line contact elastohydrodynamic lubrication and applications in the gear drive. Appl. Math. Model. 2018, 61, 634–649. [Google Scholar] [CrossRef]

- Schapery, R. Elastomeric bearing sizing analysis Part 2: Flat and cylindrical bearings. Int. J. Solids Struct. 2018, 152, 140–150. [Google Scholar] [CrossRef]

- Schapery, R. Elastomeric bearing sizing analysis Part 1: Spherical bearing. Int. J. Solids Struct. 2018, 152, 118–139. [Google Scholar] [CrossRef]

- Linjamaa, A.; Lehtovaara, A.; Larsson, R.; Kallio, M.; Söchting, S. Modelling and analysis of elastic and thermal deformations of a hybrid journal bearing. Tribol. Int. 2018, 118, 451–457. [Google Scholar] [CrossRef]

- Cercignani, C.; Pagani, C.D. Variational approach to boundary-value problems in kinetic theory. Phys. Fluids 2004, 9, 1167–1173. [Google Scholar] [CrossRef]

- Saraf, J. Rarefied gas flows based on variational principle. Appl. Sci. Res. 1973, 28, 27–36. [Google Scholar] [CrossRef]

- Abramowitz, M.; Stegun, I.A.; Romer, R.H. Handbook of mathematical functions with formulas, graphs, and mathematical tables. Am. J. Phys. 1988, 56, 958. [Google Scholar] [CrossRef]

- Hwang, C.C.; Fung, R.F.; Yang, R.F.; Weng, C.I.; Li, W.L. A new modified Reynolds equation for ultrathin film gas lubrication. IEEE Trans. Magn. 1996, 32, 344–347. [Google Scholar] [CrossRef]

- Duwensee, M. Numerical and Experimental Investigations of the Head/Disk Interface. Ph.D. Thesis, UC San Diego, San Diego, CA, USA, 2007. [Google Scholar]

- Yu, L.; Qi, S.; Geng, H. A generalized solution of elasto-aerodynamic lubrication for aerodynamic compliant foil bearings. Sci. China Ser. E Eng. Mater. Sci. 2005, 48, 414–429. [Google Scholar] [CrossRef]

- Yang, L.; Qi, S.; Yu, L. Numerical analysis on dynamic coefficients of self-acting gas-lubricated tilting-pad journal bearings. J. Tribol. 2008, 130, 011006. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Yang, L.; Xu, T.; Xu, H. Combined Effect of Rarefaction and Effective Viscosity on Micro-Elasto-Aerodynamic Lubrication Performance of Gas Microbearings. Micromachines 2019, 10, 657. https://doi.org/10.3390/mi10100657

Wu Y, Yang L, Xu T, Xu H. Combined Effect of Rarefaction and Effective Viscosity on Micro-Elasto-Aerodynamic Lubrication Performance of Gas Microbearings. Micromachines. 2019; 10(10):657. https://doi.org/10.3390/mi10100657

Chicago/Turabian StyleWu, Yao, Lihua Yang, Tengfei Xu, and Haoliang Xu. 2019. "Combined Effect of Rarefaction and Effective Viscosity on Micro-Elasto-Aerodynamic Lubrication Performance of Gas Microbearings" Micromachines 10, no. 10: 657. https://doi.org/10.3390/mi10100657

APA StyleWu, Y., Yang, L., Xu, T., & Xu, H. (2019). Combined Effect of Rarefaction and Effective Viscosity on Micro-Elasto-Aerodynamic Lubrication Performance of Gas Microbearings. Micromachines, 10(10), 657. https://doi.org/10.3390/mi10100657