Development of Micropatterns on Curved Surfaces Using Two-Step Ultrasonic Forming

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

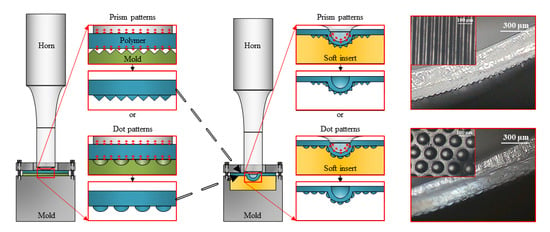

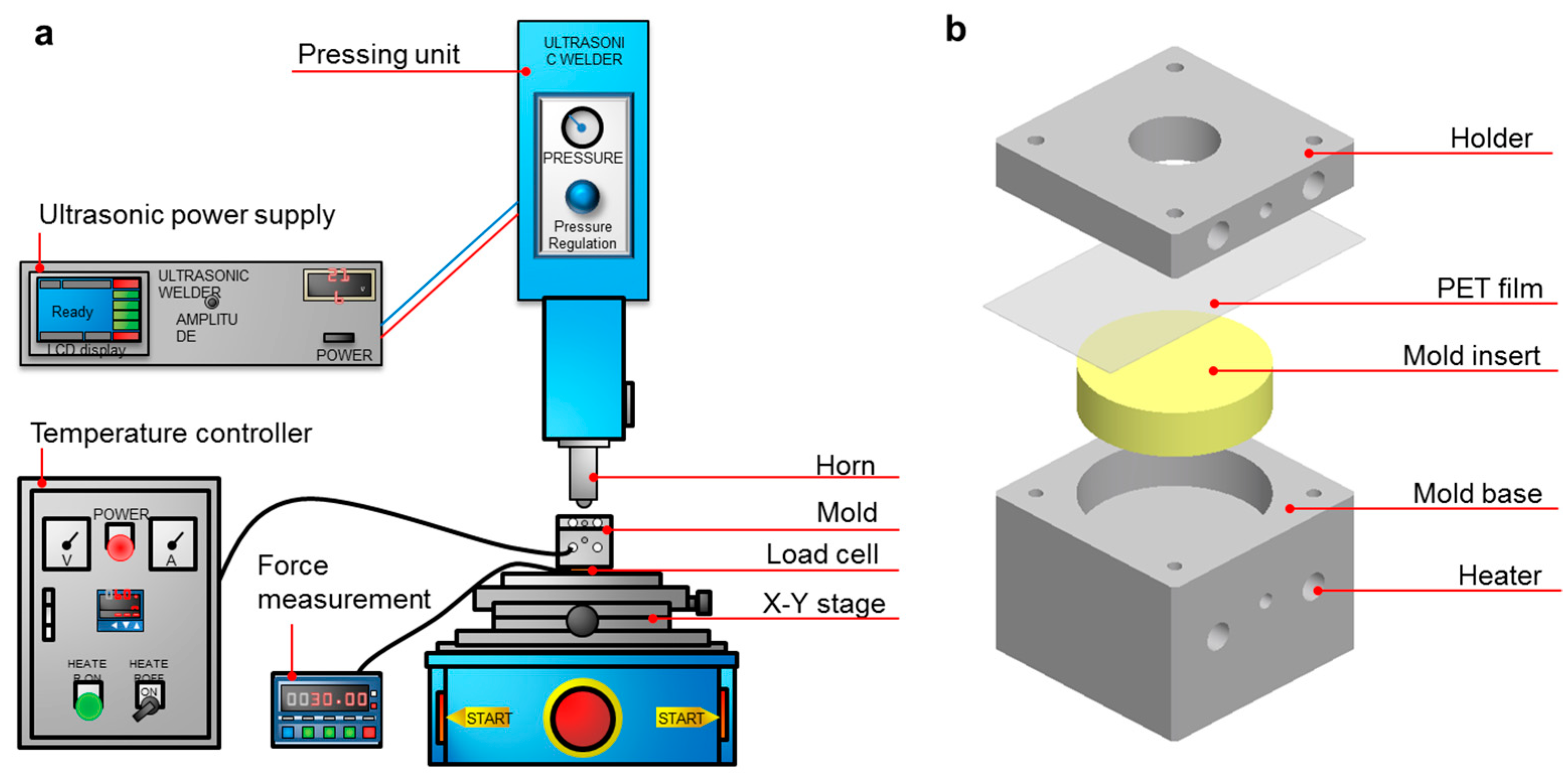

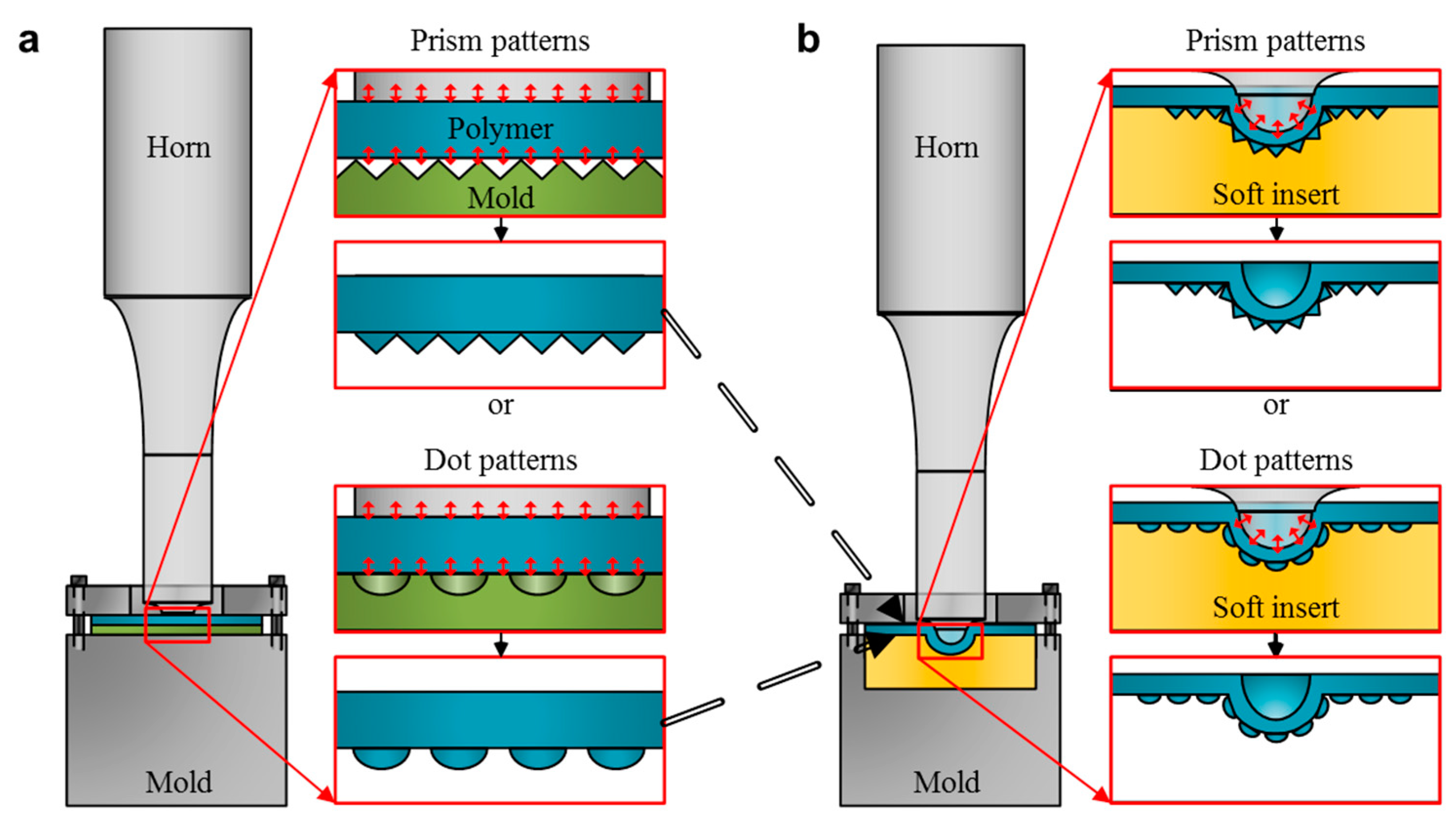

2.2. Two-Step Ultrasonic Forming

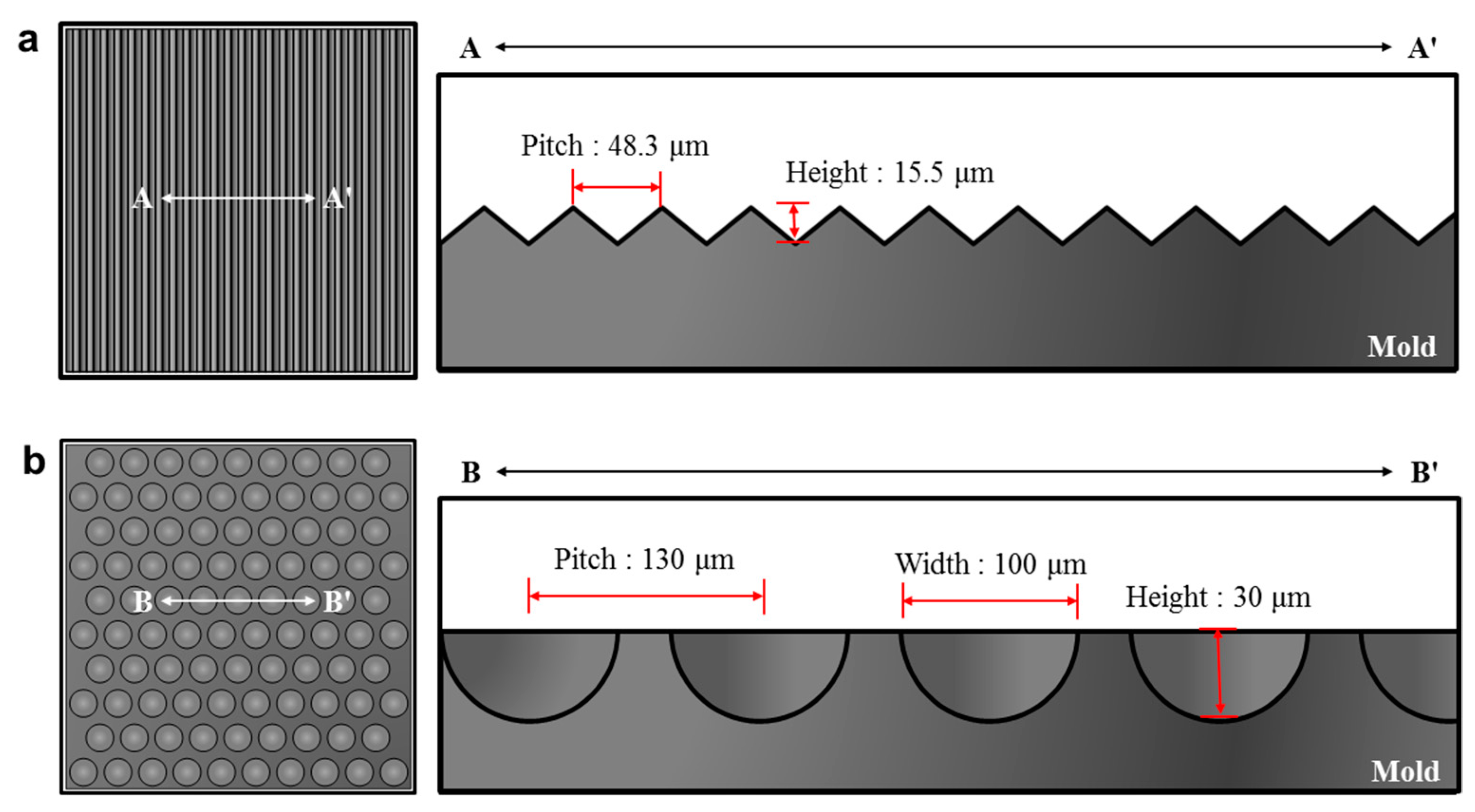

2.3. Fabrication of Micromolds for Ultrasonic Imprinting

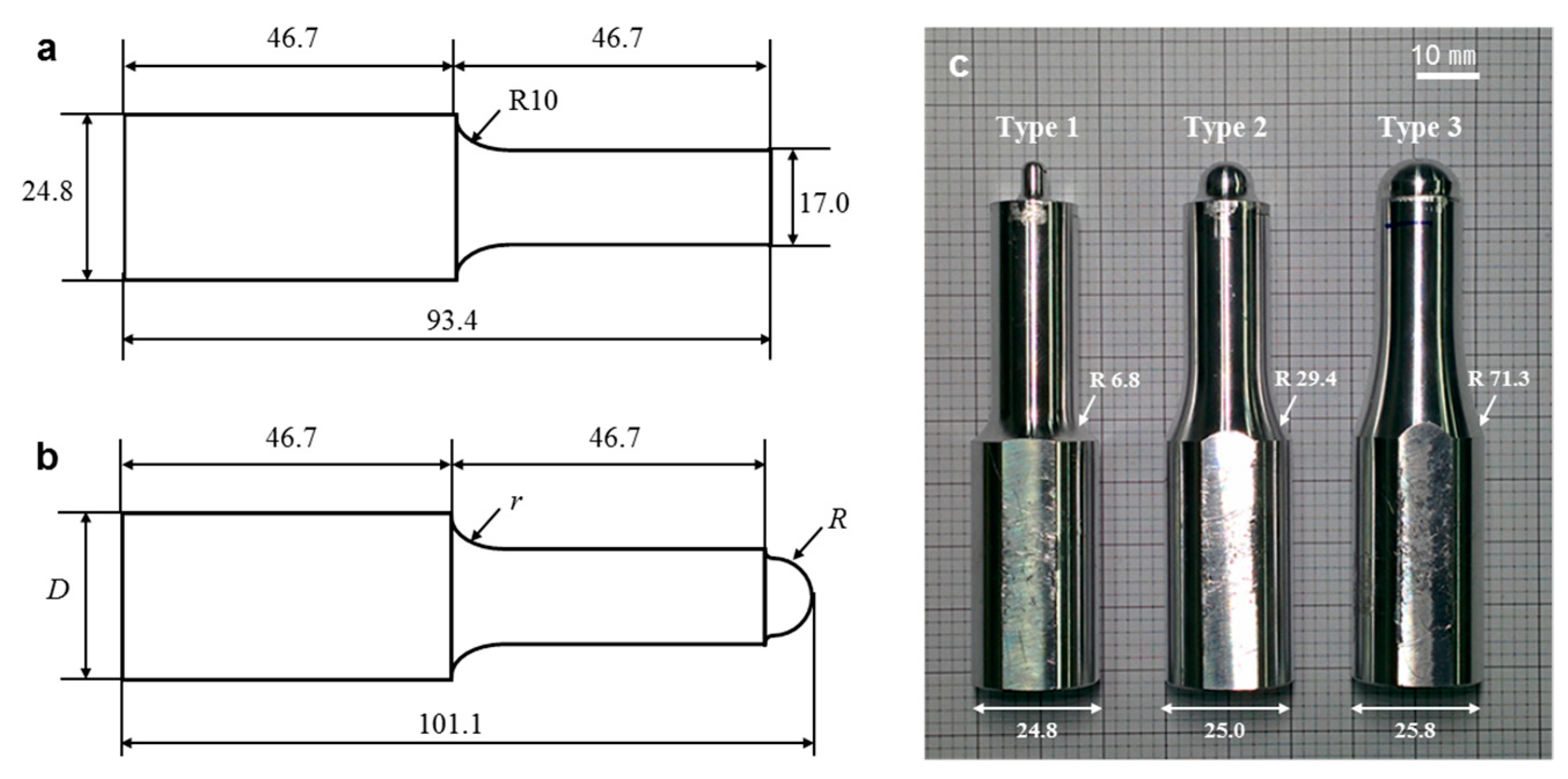

2.4. Design and Fabrication of the Ultrasonic Horns

2.5. Characterization

3. Results

3.1. Vibration Characteristics of the Ultrasonic Horns

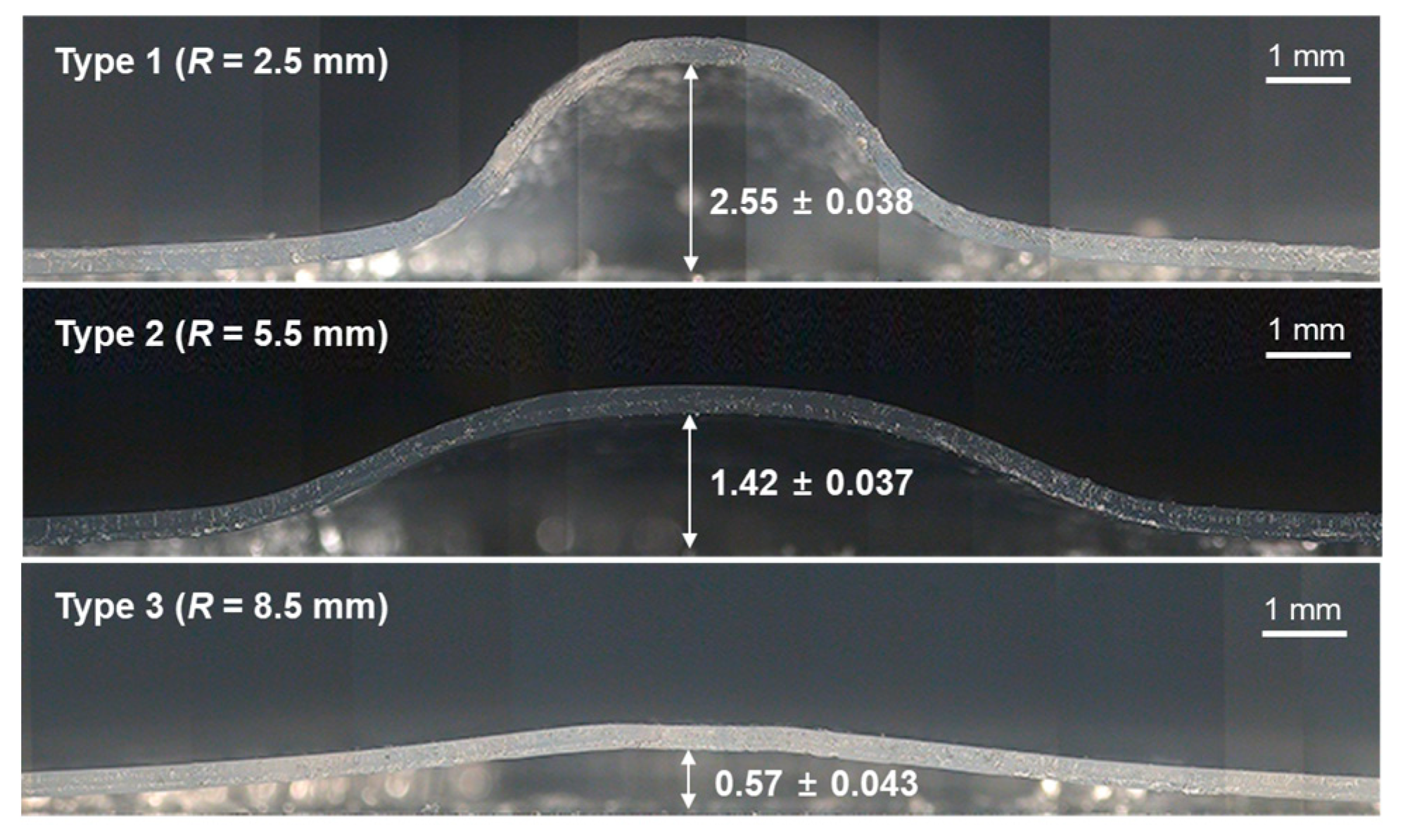

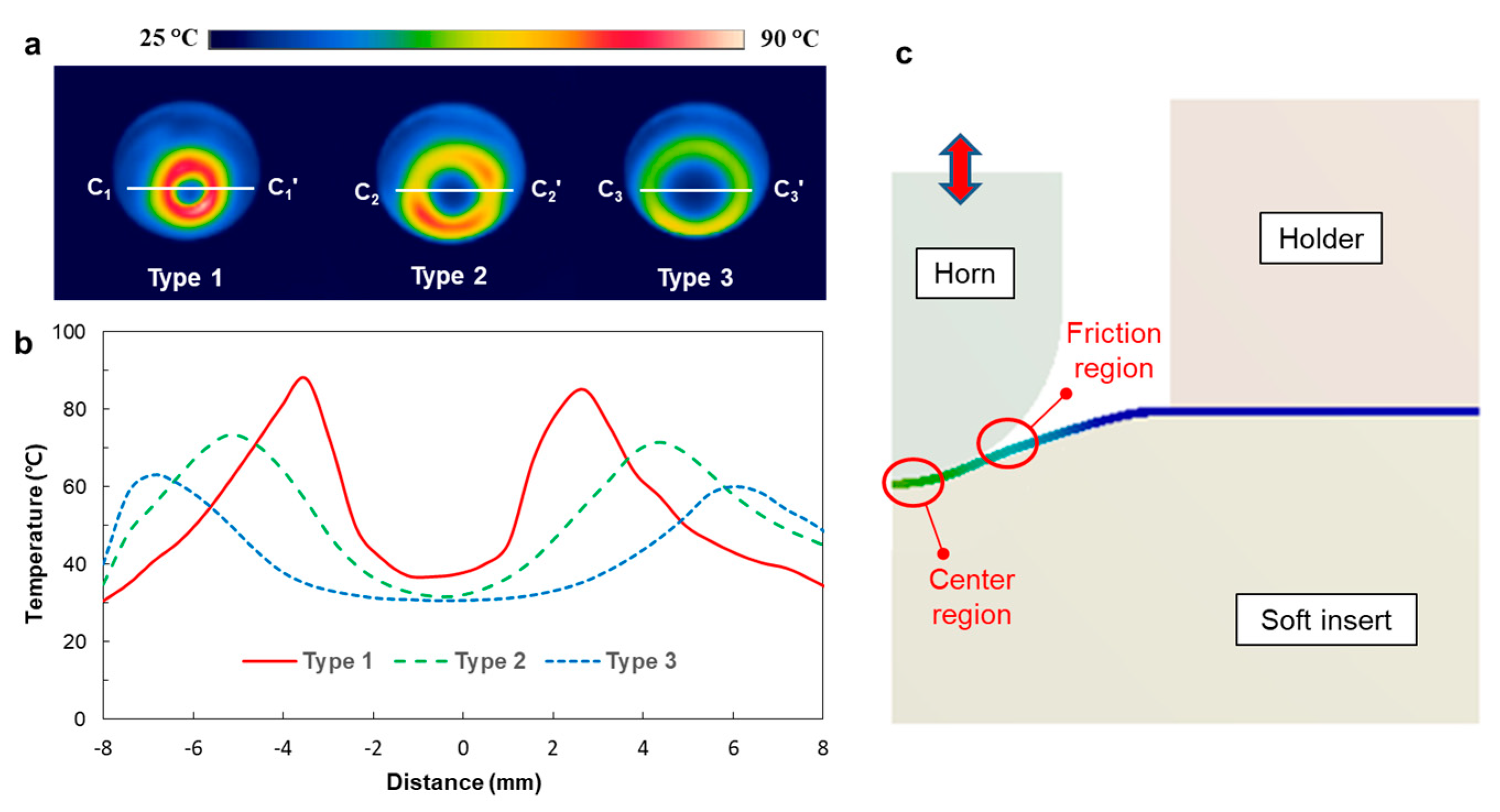

3.2. Formability of Curved Surface

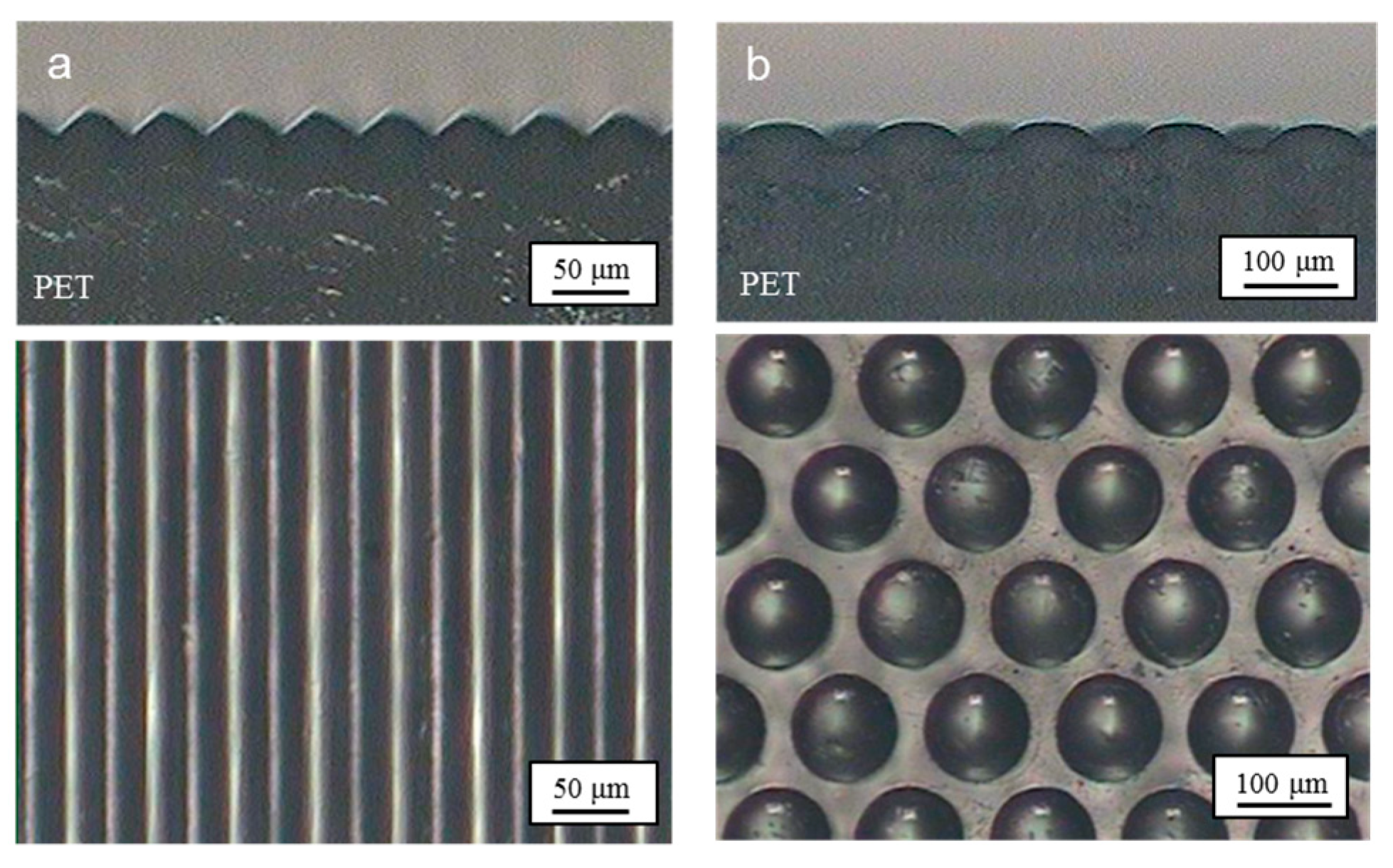

3.3. Micropattern Replication Characteristics on Flat Surface

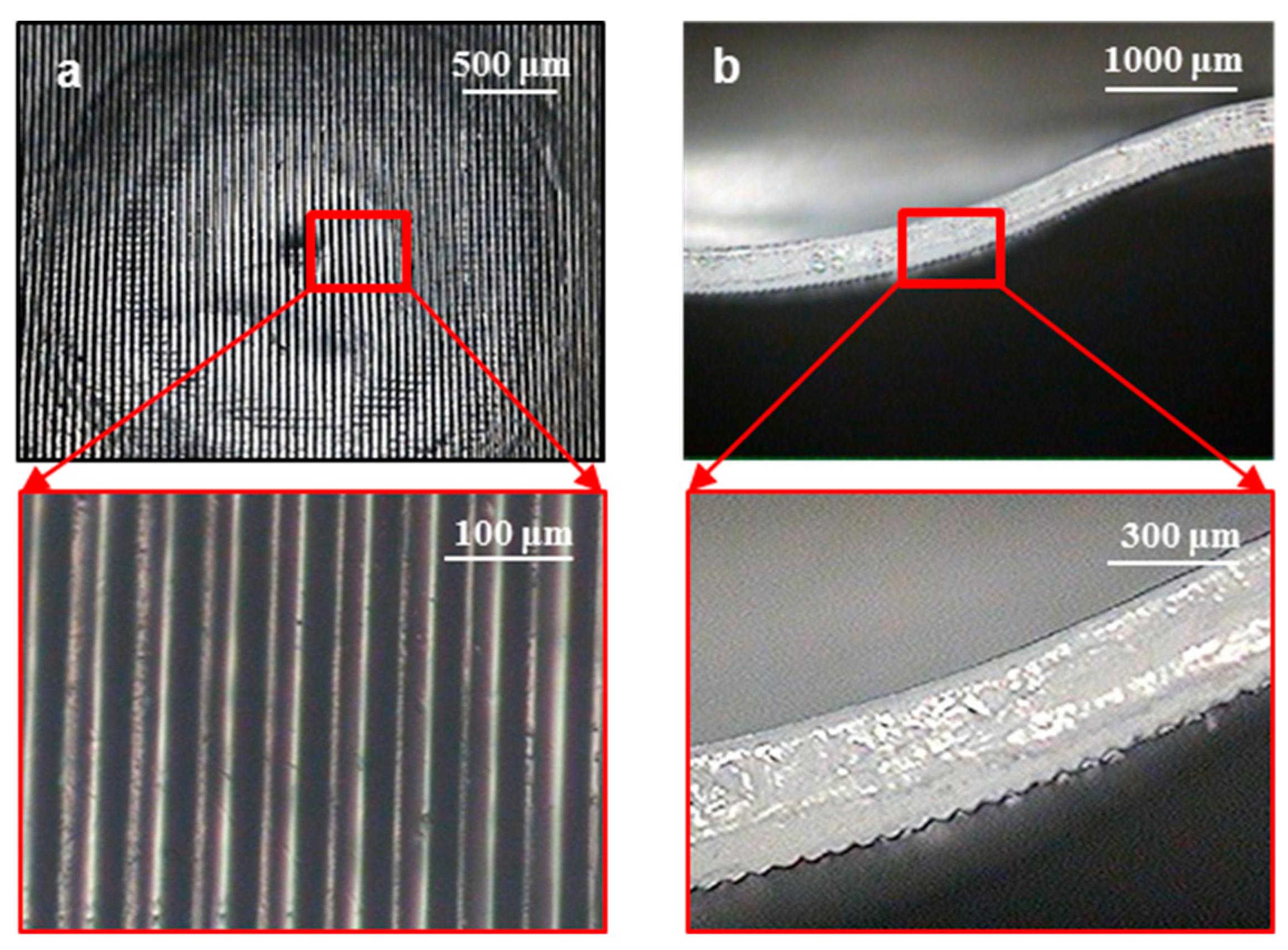

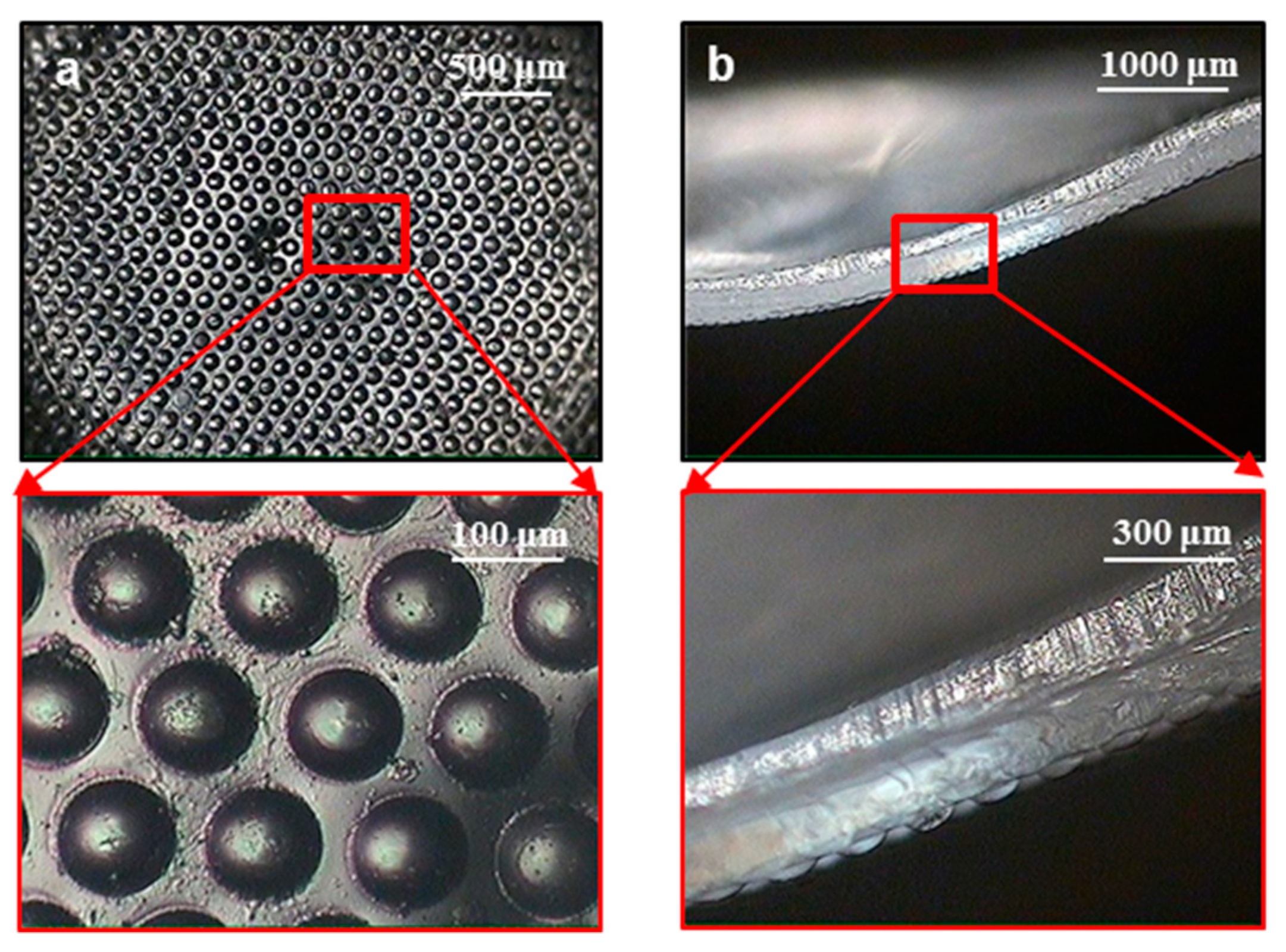

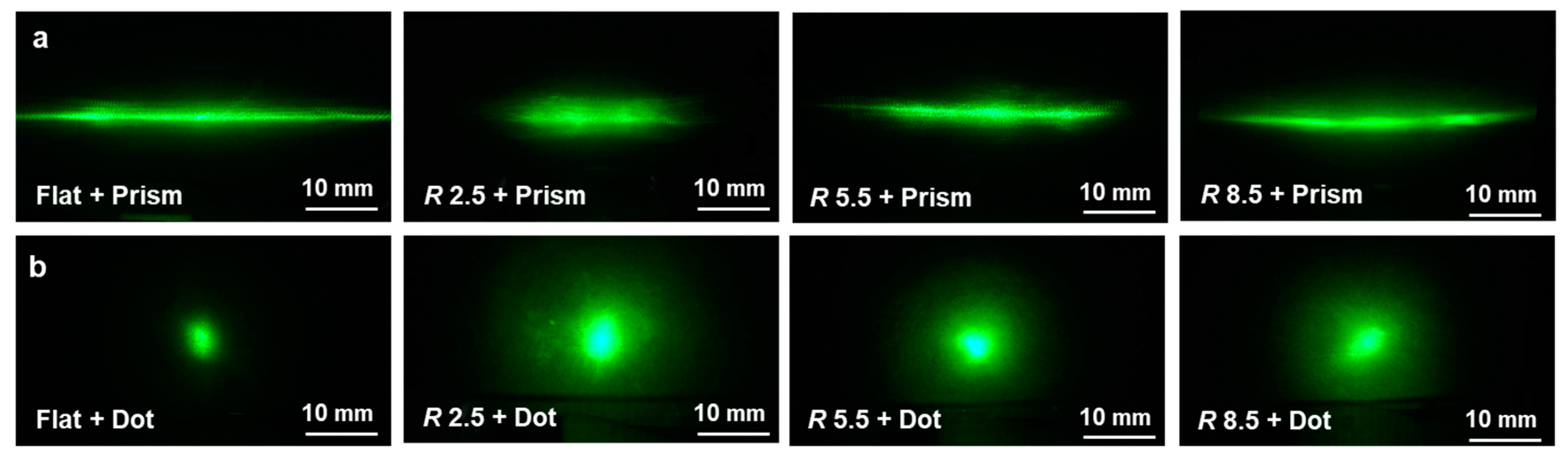

3.4. Development of Micropatterns on a Curved Surface

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Design No. | D (mm) | r (mm) | f (Hz) | γ |

|---|---|---|---|---|

| 1 | 25.0 | 6.5 | 26,973 | 2.15 |

| 2 | 24.0 | 6.0 | 26,958 | 1.98 |

| 3 | 26.0 | 6.0 | 26,891 | 2.32 |

| 4 | 24.0 | 7.0 | 27,025 | 1.98 |

| 5 | 26.0 | 7.0 | 26,994 | 2.32 |

| 6 | 25.0 | 5.8 | 26,910 | 2.15 |

| 7 | 26.4 | 6.5 | 26,930 | 2.39 |

| 8 | 25.0 | 7.2 | 27,029 | 2.15 |

| 9 | 23.6 | 6.5 | 26,998 | 1.91 |

| Design No. | D (mm) | r (mm) | f (Hz) | γ |

|---|---|---|---|---|

| 1 | 24.8 | 30.0 | 26,987 | 2.05 |

| 2 | 25.0 | 29.5 | 27,002 | 2.08 |

| 3 | 25.2 | 29.0 | 27,016 | 2.12 |

| 4 | 25.2 | 30.0 | 27,041 | 2.11 |

| 5 | 25.2 | 29.5 | 27,039 | 2.13 |

| 6 | 25.0 | 28.8 | 26,985 | 2.09 |

| 7 | 24.8 | 29.5 | 26,965 | 2.04 |

| 8 | 24.8 | 29.0 | 26,964 | 2.05 |

| 9 | 25.0 | 30.2 | 27,019 | 2.08 |

| Design No. | D (mm) | r (mm) | f (Hz) | γ |

|---|---|---|---|---|

| 1 | 25.0 | 71.5 | 26,822 | 2.00 |

| 2 | 25.0 | 70.8 | 26,813 | 2.00 |

| 3 | 24.0 | 71.0 | 26,599 | 1.87 |

| 4 | 26.4 | 71.5 | 27,144 | 2.18 |

| 5 | 25.0 | 72.2 | 26,830 | 1.99 |

| 6 | 26.0 | 71.0 | 27,041 | 2.13 |

| 7 | 26.0 | 72.0 | 27,055 | 2.12 |

| 8 | 24.0 | 72.0 | 26,609 | 1.86 |

| 9 | 23.6 | 71.5 | 26,518 | 1.81 |

References

- Koch, K.; Bhushan, B.; Barthlott, W. Multifunctional surface structures of plants: An inspiration for biomimetics. Prog. Mater. Sci. 2009, 54, 137–178. [Google Scholar] [CrossRef]

- Lafuma, A.; Quéré, D. Superhydrophobic states. Nature Mater. 2003, 2, 457–460. [Google Scholar] [CrossRef] [PubMed]

- Kaless, A.; Schulz, U.; Munzert, P.; Kaiser, N. NANO-motheye antireflection pattern by plasma treatment of polymers. Surf. Coat. Technol. 2005, 200, 58–61. [Google Scholar] [CrossRef]

- Gao, X.; Yan, X.; Yao, X.; Xu, L.; Zhang, K.; Zhang, J.; Jiang, L. The dry-style antifogging properties of mosquito compound eyes and artificial analogues prepared by soft lithography. Adv. Mater. 2007, 19, 2213–2217. [Google Scholar] [CrossRef]

- Parker, A.R.; Lawrence, C.R. Water capture by a desert beetle. Nature 2001, 414, 33–34. [Google Scholar] [CrossRef] [PubMed]

- Lan, H.; Ding, Y.; Liu, H.; Lu, B. Review of the wafer stage for nanoimprint lithography. Microelec. Eng. 2007, 84, 684–688. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Nanoimprint lithography. J. Vacuum Sci. 1996, 14, 4129–4133. [Google Scholar] [CrossRef]

- Heckel, M.; Schomburg, W.K. Review on micro molding of thermoplastic polymers. J. Micromech. Microeng. 2004, 14, R1. [Google Scholar] [CrossRef]

- Guo, L.J. Nanoimprint lithography: Methods and material requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef]

- Kooy, N.; Mohamed, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale Res. Lett. 2014, 9, 320. [Google Scholar] [CrossRef]

- Sackmann, J.; Burlage, K.; Gerhardy, C.; Memering, B.; Liao, S.; Schomburg, W.K. Review on ultrasonic fabrication of polymer micro devices. Ultrasonics 2015, 56, 189–200. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.H.; Chen, R. Ultrasonic nanoimprint lithography: A new approach to nanopatterning. J. Micro/Nanolithogr. MEMS MOEMS 2006, 5, 011003. [Google Scholar] [CrossRef]

- Lin, C.H.; Chen, R. Effects of mold geometries and imprinted polymer resist thickness on ultrasonic nanoimprint lithography. J. Micromech. Microeng. 2007, 17, 1220. [Google Scholar] [CrossRef]

- Mekaru, H.; Takahashi, M. Ultrasonic nanoimprint on poly(ethylene terephthalate) at room temperature. Jpn. J. Appl. Phys. 2008, 47, 5178–5184. [Google Scholar] [CrossRef]

- Mekaru, H.; Takahashi, M. Ultrasonic nanoimprint on engineering plastics. J. Vacuum Sci. Technol. A 2009, 27, 785–792. [Google Scholar] [CrossRef]

- Cho, Y.H.; Seo, Y.S.; Moon, I.Y.; Kim, B.H.; Park, K. Facile fabrication of superhydrophobic poly(methyl methacrylate) substrates using ultrasonic imprinting. J. Micromech. Microeng. 2013, 23, 055019. [Google Scholar] [CrossRef]

- Jung, W.; Park, K. Selective ultrasonic imprinting for micropattern replication on predefined area. Ultrasonics 2014, 54, 1495–1503. [Google Scholar] [CrossRef] [PubMed]

- Jung, W.; Lee, H.J.; Park, K. Micropattern replication characteristics in selective ultrasonic imprinting using negative masks. Int. J. Precis. Engng. Manuf. 2015, 16, 1999–2004. [Google Scholar] [CrossRef]

- Lee, H.J.; Park, K. Variable wettability control of a polymer surface by selective ultrasonic imprinting and hydrophobic coating. Collids Polym. Sci. 2016, 294, 1413–1423. [Google Scholar] [CrossRef]

- Lee, H.J.; Park, K. Development of composite micro-patterns on polymer film using repetitive ultrasonic imprinting. Int. J. Precis. Engng. Manuf. Green Technol. 2014, 1, 341–345. [Google Scholar] [CrossRef] [Green Version]

- Baker, K.M. Highly corrected close-packed microlens arrays and moth-eye structuring on curved surfaces. Appl. Opt. 1999, 38, 352–356. [Google Scholar] [CrossRef] [PubMed]

- Jackman, R.J.; Wilbur, J.L.; Whitesides, G.M. Fabrication of submicrometer features on curved substrates by microcontact printing. Science 1995, 269, 664–666. [Google Scholar] [CrossRef] [PubMed]

- Ruchhoeft, P.; Colburn, M.; Choi, B.; Nounu, H.; Johnson, S.; Bailey, T.; Damle, S.; Stewart, M.; Ekerdt, J.; Sreenivasan, S.V.; et al. Patterning curved surfaces: Template generation by ion beam proximity lithography and relief transfer by step and flash imprint lithography. J. Vacuum Sci. Technol. B 1999, 17, 2965–2969. [Google Scholar] [CrossRef]

- Paul, K.E.; Prentiss, M.; Whitesides, G.M. Patterning spherical surfaces at the two-hundred-nanometer scale using soft lithography. Adv. Func. Mater. 2003, 13, 259–263. [Google Scholar] [CrossRef]

- Farshchian, B.; Amirsadeghi, A.; Hurst, S.M.; Wu, J.; Lee, J.; Park, S. Soft UV-nanoimprint lithography on non-planar surfaces. Microelectron. Eng. 2011, 8, 3287–3292. [Google Scholar] [CrossRef]

- Park, J.; Fujita, H.; Kim, B. Fabrication of metallic microstructure on curved substrate by optical soft lithography and copper electroplating. Sens. Actuator A Phys. 2011, 168, 105–111. [Google Scholar] [CrossRef]

- Mukherjee, R.; Patil, G.K.; Sharma, A. Solvent vapor-assisted imprinting of polymer films coated on curved surfaces with flexible PVA stamps. Ind. Engng. Chem. Res. 2009, 48, 8812–8818. [Google Scholar] [CrossRef]

- Farshchian, B.; Park, S.; Choi, J.; Amirsadeghi, A.; Lee, J.; Park, S. 3D nanomolding for lab-on-a-chip applications. Lab Chip 2012, 12, 4764–4771. [Google Scholar] [CrossRef]

- Park, H.J.; Son, C.; Park, S.H. Fabrication of micro-scale wrinkles on a curved surface using weak-polymerization and surface shrinkage. Int. J. Precis. Engng. Manuf. 2014, 15, 2469–2471. [Google Scholar] [CrossRef]

- Huang, W.M.; Yang, R.K.; Su, G.D.J. Variable focus microlens array with curved electrodes. J. Micromech. Microeng. 2017, 27, 055003. [Google Scholar] [CrossRef]

- Park, J.K.; Kim, S. Three-dimensionally structured flexible fog harvesting surfaces inspired by Namib Desert Beetles. Micromachines 2019, 10, 201. [Google Scholar] [CrossRef] [PubMed]

- Köpplmayr, T.; Häusler, L.; Bergmair, I.; Mühlberger, M. Nanoimprint lithography on curved surfaces prepared by fused deposition modelling. Surf. Topogr. Metrol. Prop. 2015, 3, 024003. [Google Scholar] [CrossRef]

- Mielonen, K.; Suvanto, M.; Pakkanen, T.A. Curved hierarchically micro-micro structured polypropylene surfaces by injection molding. J. Micromech. Microeng. 2017, 27, 015025. [Google Scholar] [CrossRef]

- Chen, H.T.; Trefilov, D.; Cui, Y.S.; Yuan, C.S.; Ge, H.X.; Hu, X.; Cui, B. Flexible nanoimprint mold based on a commercial SEBS thermoplastic elastomer. In Proceedings of the International Conference on Materials Science, Energy Technology and Environmental Engineering, MSETEE, Zhuhai, China, 28–29 May 2016. [Google Scholar]

- Park, Y.M.; Kim, B.H.; Seo, Y.H. Three-dimensional antireflective hemispherical lens covered by nanoholes for enhancement of light transmission. Appl. Phys. Express 2013, 6, 115202. [Google Scholar] [CrossRef]

- Liu, F.; Diao, X.; Li, L.; Hao, Y.; Jiao, Z. Fabrication and characterization of inhomogeneous curved artificial compound eye. Micromachines 2018, 9, 238. [Google Scholar] [CrossRef] [PubMed]

- Bae, H.J.; Park, K. Design and analysis of ultrasonic horn for polymer sheet forming. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 49–54. [Google Scholar] [CrossRef]

- Park, J.H. Freeform Forming of Polymer Sheets Using Ultrasonic Vibration Energy. Master’s Thesis, Seoul National University of Science and Technology, Seoul, Korea, 2015. [Google Scholar]

- Bae, H.J.; Lee, H.J.; Park, K. Ultrasonic assisted thermoforming for rapid fabrication of a microspeaker diaphragm. Microsyst. Technol. 2017, 23, 1677–1686. [Google Scholar] [CrossRef]

| Horn Type | R (mm) | D (mm) | r (mm) |

|---|---|---|---|

| Type 1 | 2.5 | 24.8 | 6.8 |

| Type 2 | 5.5 | 25.0 | 29.4 |

| Type 3 | 8.5 | 25.8 | 71.3 |

| Horn Type | R (mm) | f (Hz) | δo (μm) | γ |

|---|---|---|---|---|

| Type 1 | 2.5 | 27,008 | 33.1 ± 1.0 | 2.02 ± 0.06 |

| Type 2 | 5.5 | 26,989 | 33.4 ± 0.4 | 2.04 ± 0.02 |

| Type 3 | 8.5 | 27,035 | 34.1 ± 0.8 | 2.08 ± 0.05 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.-H.; Park, K. Development of Micropatterns on Curved Surfaces Using Two-Step Ultrasonic Forming. Micromachines 2019, 10, 654. https://doi.org/10.3390/mi10100654

Park J-H, Park K. Development of Micropatterns on Curved Surfaces Using Two-Step Ultrasonic Forming. Micromachines. 2019; 10(10):654. https://doi.org/10.3390/mi10100654

Chicago/Turabian StylePark, Jong-Han, and Keun Park. 2019. "Development of Micropatterns on Curved Surfaces Using Two-Step Ultrasonic Forming" Micromachines 10, no. 10: 654. https://doi.org/10.3390/mi10100654

APA StylePark, J.-H., & Park, K. (2019). Development of Micropatterns on Curved Surfaces Using Two-Step Ultrasonic Forming. Micromachines, 10(10), 654. https://doi.org/10.3390/mi10100654