Fabrication of Adhesive Resistance Surface with Low Wettability on Ti6Al4V Alloys by Electro-Brush Plating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.3. Characterization

3. Results and Discussion

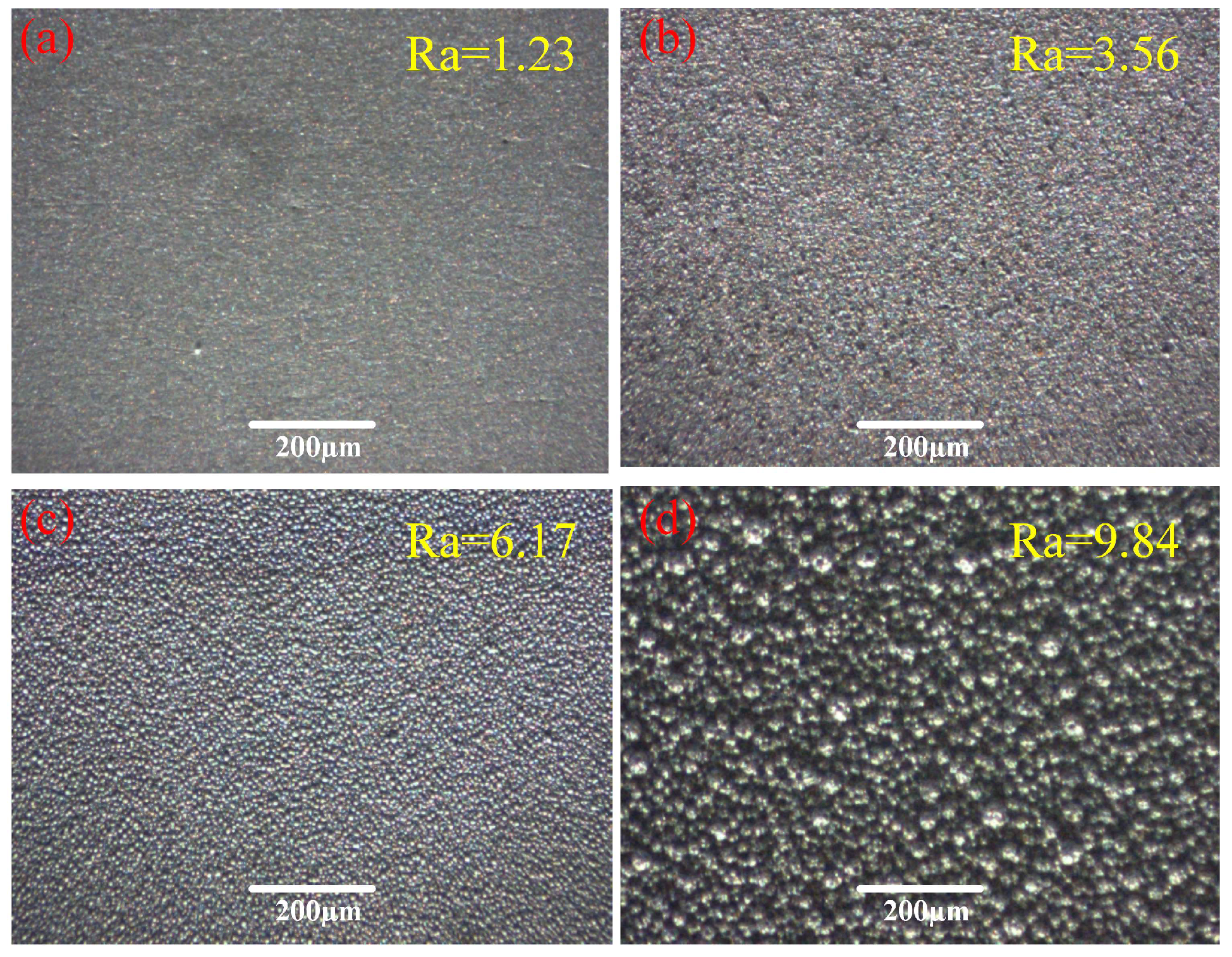

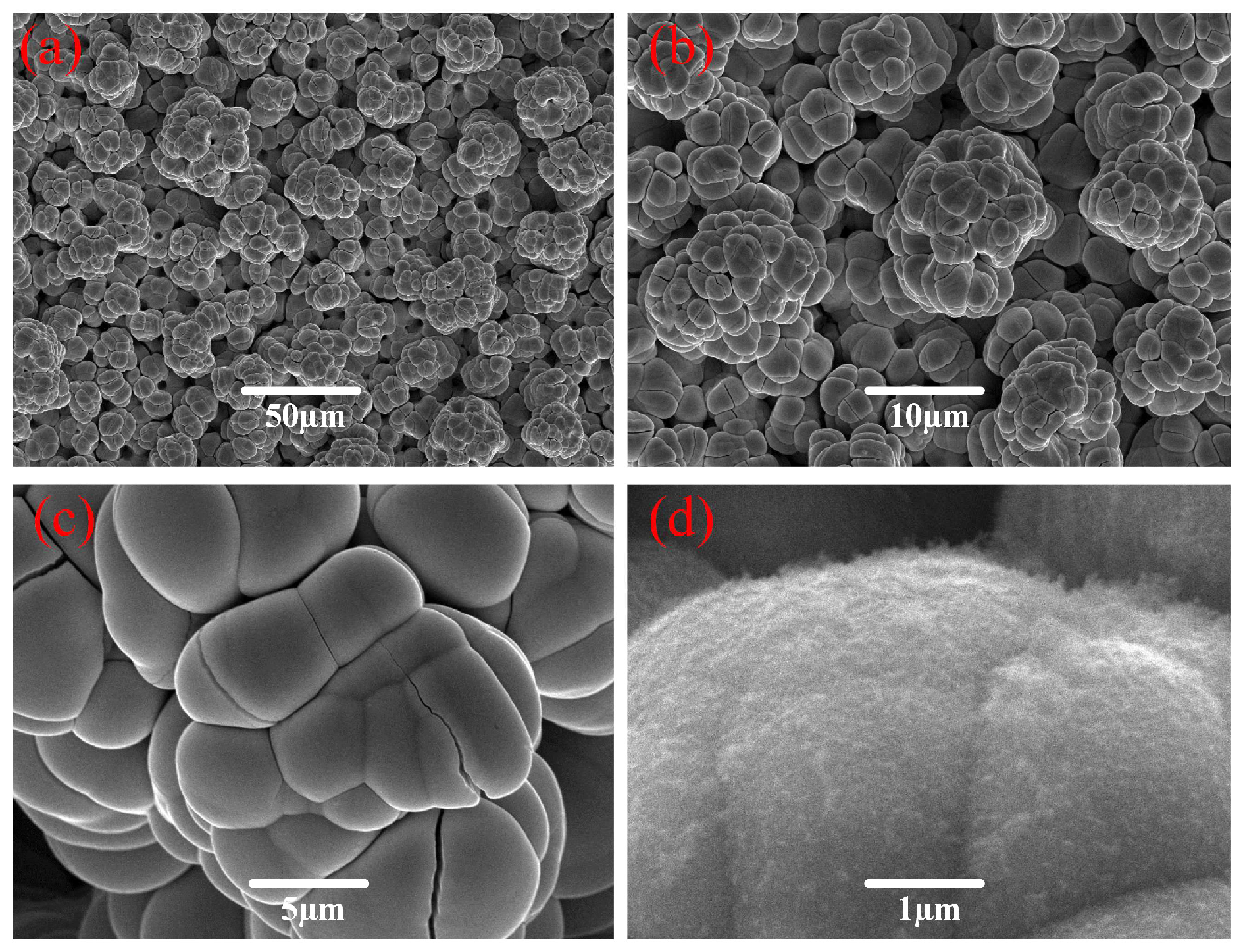

3.1. Surface Morphology

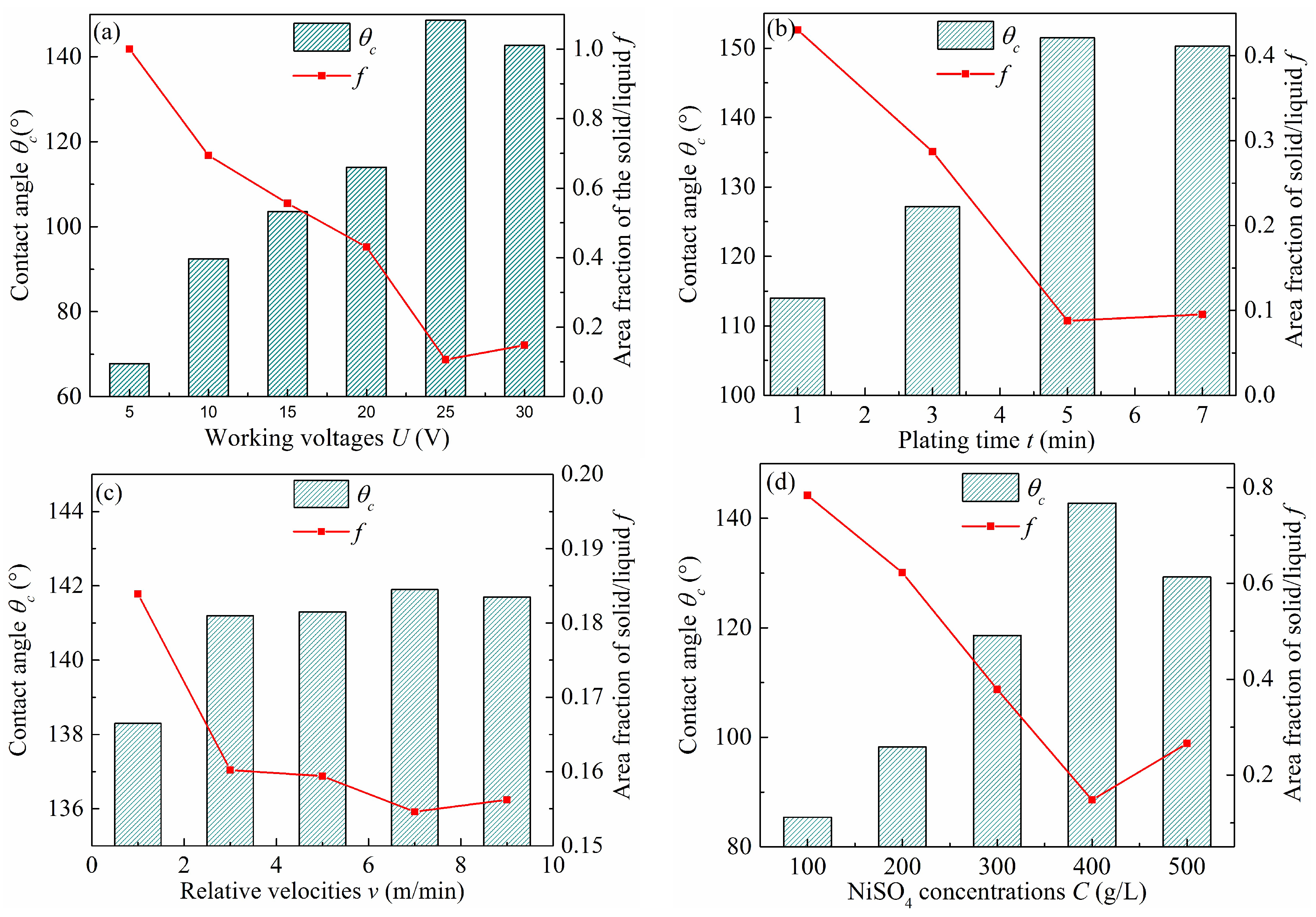

3.2. Surface Wettability

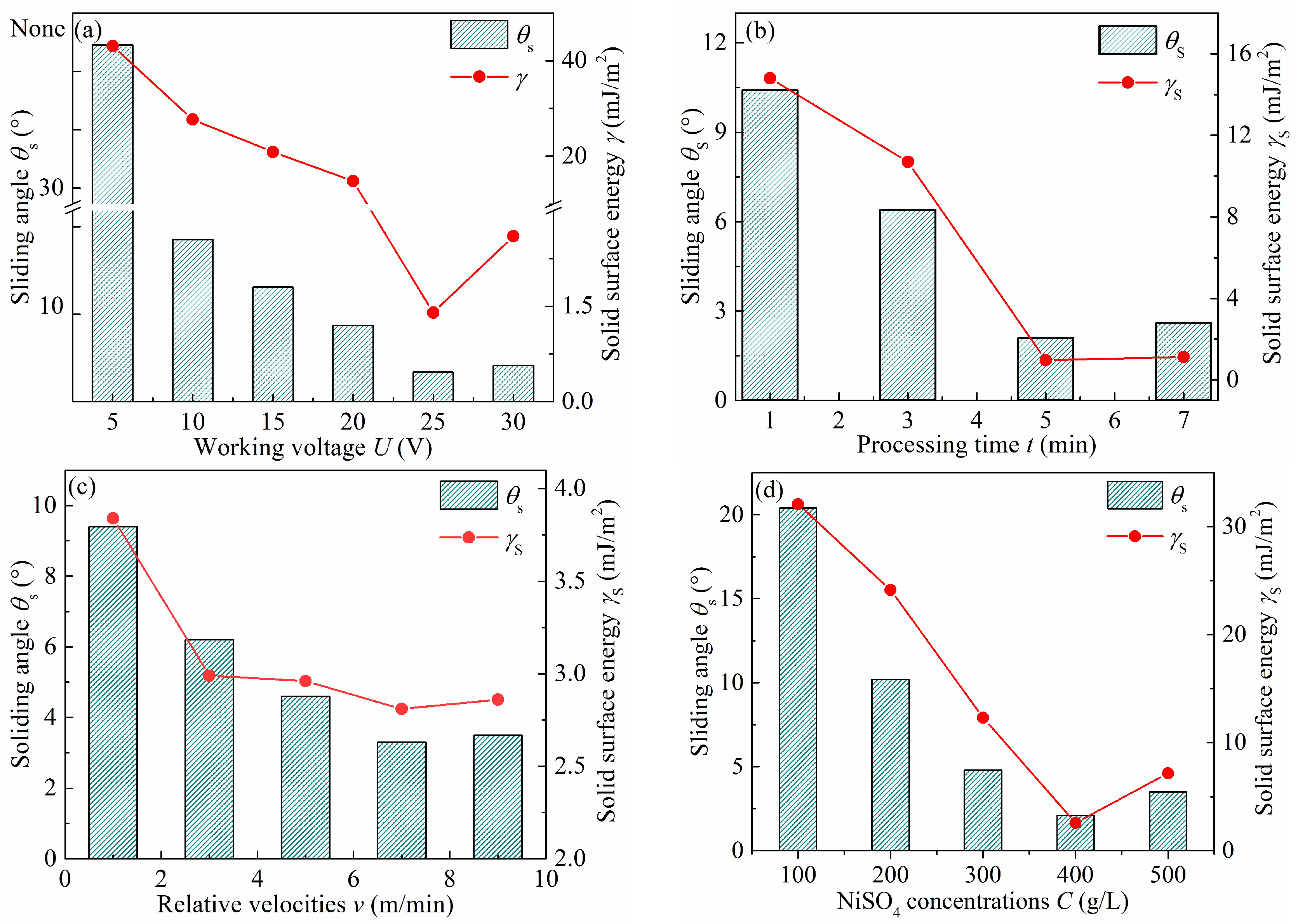

3.3. Surface Adhesive Resistance

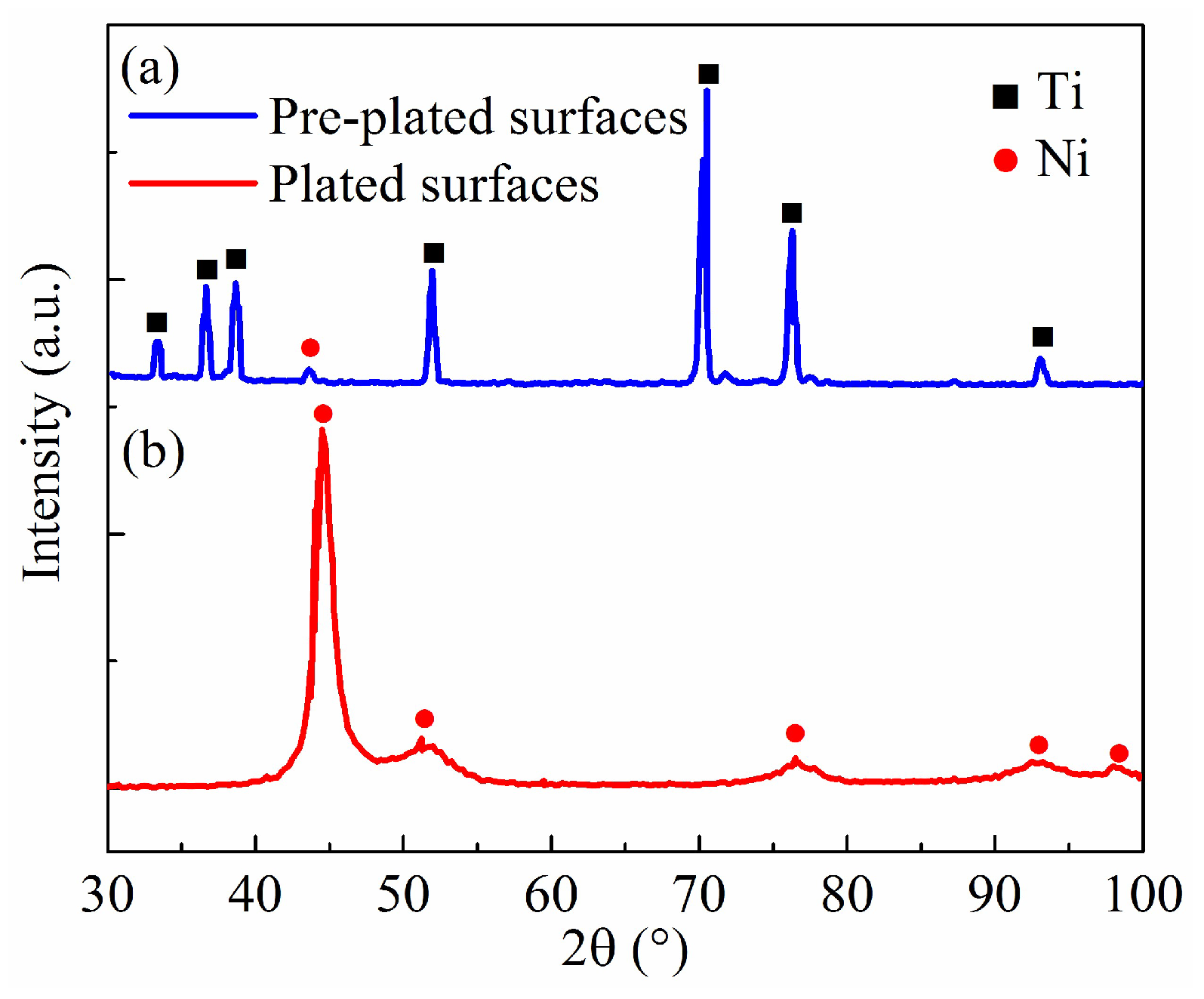

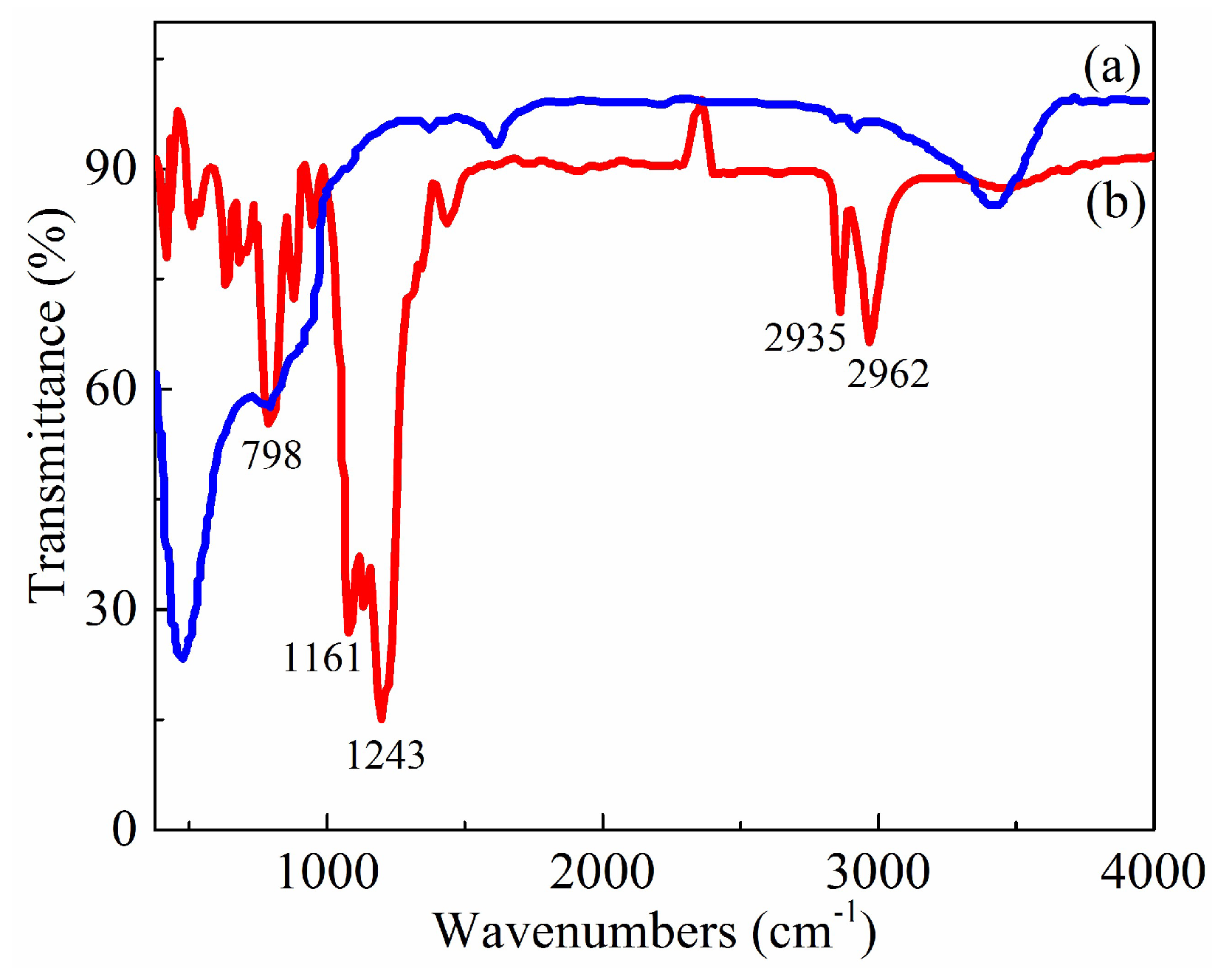

3.4. Chemical Composition

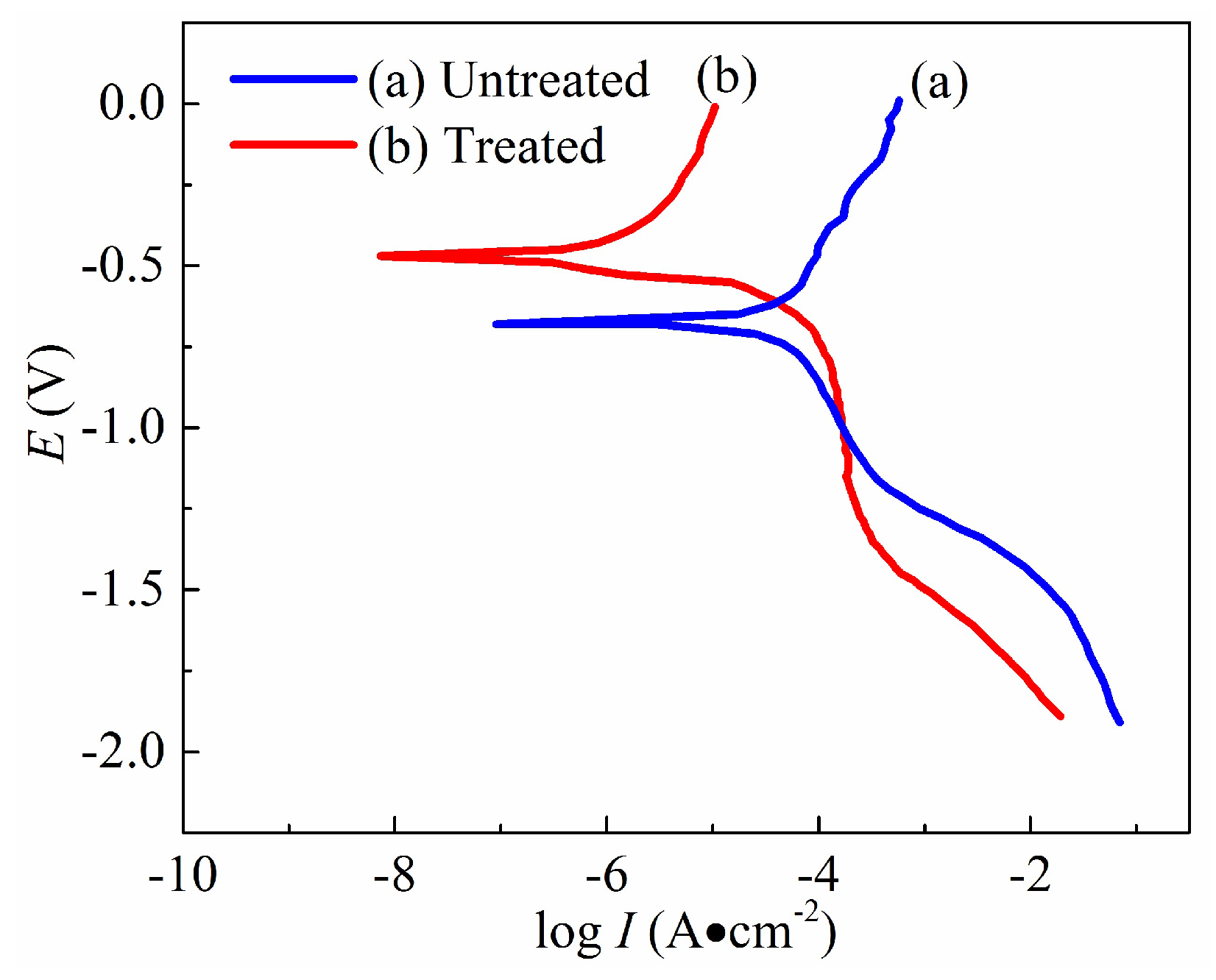

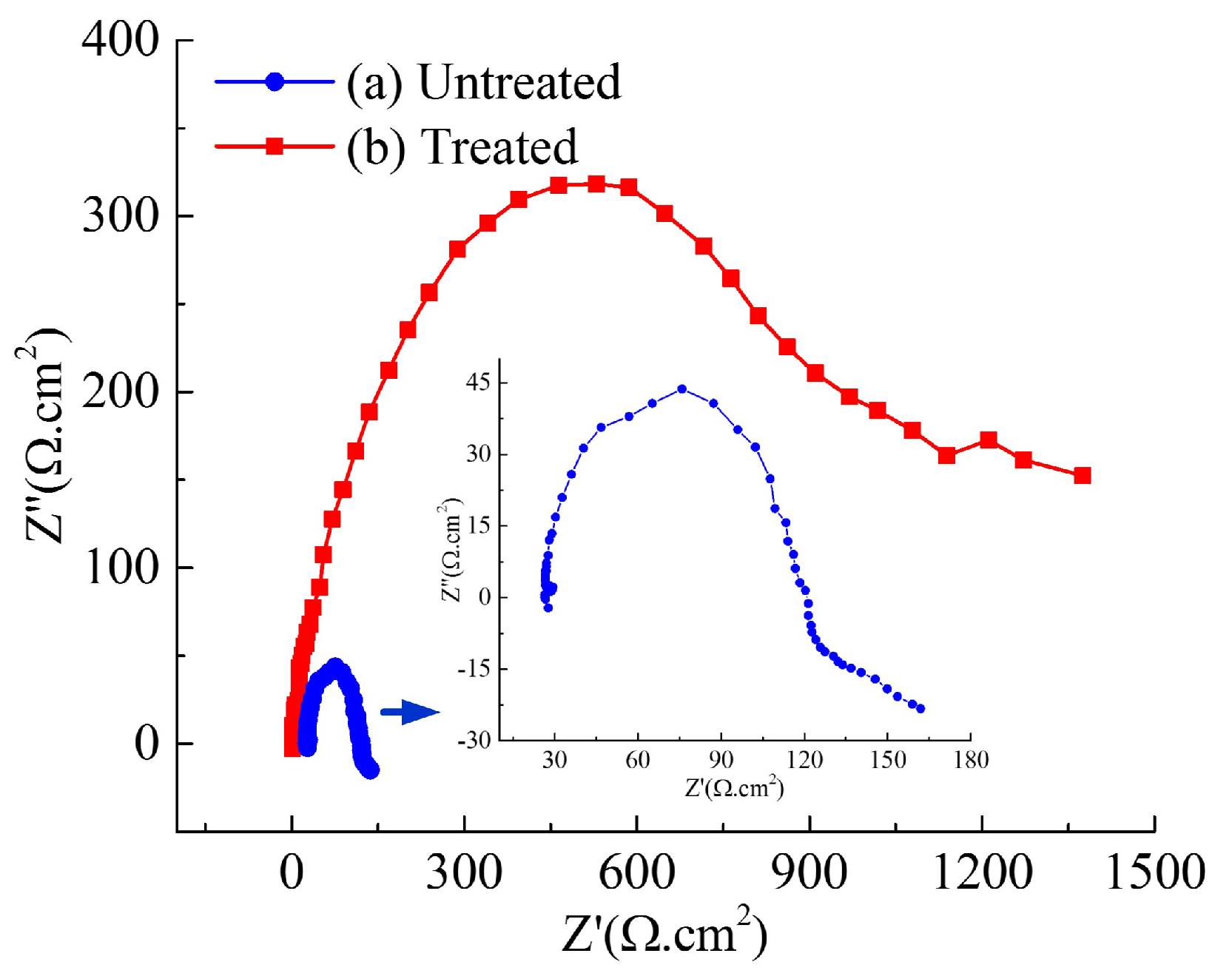

3.5. Surface Corrosion Resistance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yan, Y.D.; Chibowski, E.; Szczes, A. Surface properties of Ti-6Al-4V alloy part Ι: Surface roughness and apparent surface energy. Mater. Sci. Eng. 2017, 70, 207–215. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Wei, D.; Cao, J.; Feng, W.; Cheng, S.; Du, Q.; Li, B.; Wang, Y.; Jia, D.; Zhou, Y. Synergistic effect of surface chemistry and topologic structure from modified Microarc oxidation coatings on Ti implants for improving osseointegration. ACS Appl. Mater. Interfaces 2015, 7, 8932–8941. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.S.; Xie, L.S.; Chen, M.H.; Wang, N.; Wang, H. Surface characteristics and adhesive strength to epoxy of three different types of titanium alloys anodized in NaTESi electrolyte. Surf. Coat. Technol. 2015, 280, 122–128. [Google Scholar] [CrossRef]

- Gao, Y.Z.; Sun, Y.W.; Guo, D.M. Facile fabrication of superhydrophobic surfaces with low roughness on Ti–6Al–4V substrates via anodization. Appl. Surf. Sci. 2014, 314, 754–759. [Google Scholar] [CrossRef]

- Shen, Y.; Tao, J.; Tao, H.; Chen, S.; Pan, L.; Wang, T. Nanostructures in superhydrophobic Ti6Al4V hierarchical surfaces control wetting state transitions. Soft Matter 2015, 11, 3806–3811. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, H.; Song, J.; Sun, Y. Fast fabrication of superhydrophobic surfaces on Ti–6Al–4V substrates by deposition of lead. Surf. Coat. Technol. 2016, 302, 507–514. [Google Scholar] [CrossRef]

- Lu, Y.; Song, J.; Liu, X.; Xu, W.; Xing, Y.; Wei, Z. Preparation of superoleophobic and superhydrophobic titanium surfaces via an environmentally friendly electrochemical etching method. ACS Sustain. Chem. Eng. 2013, 1, 102–109. [Google Scholar] [CrossRef]

- Jiang, J.Y.; Xu, J.L.; Liu, Z.H.; Deng, L.; Sun, B.; Liu, S.D.; Wang, L.; Liu, H.Y. Preparation, corrosion resistance and hemocompatibility of the superhydrophobic TiO2 coatings on biomedical Ti-6Al-4V alloys. Appl. Surf. Sci. 2015, 347, 591–595. [Google Scholar] [CrossRef]

- Chen, T.; Ge, S.; Liu, H.; Sun, Q.; Zhu, W.; Yan, W.; Qi, J. Fabrication of low adhesive superhydrophobic surfaces using nano Cu/Al2O3 Ni-Gr composited electro-brush plating. Appl. Surf. Sci. 2015, 356, 81–90. [Google Scholar] [CrossRef]

- Quere, D. Wetting and roughness. Annu. Rev. Mater. Res. 2008, 38, 71–99. [Google Scholar] [CrossRef]

- Li, J.; Jing, Z.; Zha, F.; Yang, Y.; Wang, Q.; Lei, Z. Facile spray-coating process for the fabrication of tunable adhesive superhydrophobic surfaces with heterogeneous chemical compositions used for selective transportation of microdroplets with different volumes. ACS Appl. Mater. Interfaces 2014, 6, 8867–8877. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.L.; Sundararajan, S. Superhydrophobic engineering surfaces with tunable air-trapping ability. J. Micromech. Microeng. 2008, 18, 035024. [Google Scholar] [CrossRef]

- Ueda, E.; Levkin, P.A. Emerging applications of superhydrophilic—Superhydrophobic micropatterns. Adv. Mater. 2013, 25, 1234–1247. [Google Scholar] [CrossRef] [PubMed]

- Meng, J.; Dong, X.; Zhou, H.; Liu, W.; Yin, Z. Investigation of adhesive resistance of aluminum alloy by sandblasting and electrochemical machining. Micromachines 2017, 8, 91. [Google Scholar] [CrossRef]

- Ohkubo, Y.; Tsuji, I.; Onishi, S.; Ogawa, K. Preparation and characterization of super-hydrophobic and oleophobic surface. J. Mater. Sci. 2010, 45, 4963–4969. [Google Scholar] [CrossRef]

- Li, D.; Neumann, A. Equation of state for interfacial tensions of solid-liquid systems. Adv. Colloid Interface Sci. 1992, 39, 299–345. [Google Scholar] [CrossRef]

- Wang, C.Q.; He, X.N. Effect of atmospheric pressure dielectric barrier discharge air plasma on electrode surface. Appl. Surf. Sci. 2006, 253, 926–929. [Google Scholar] [CrossRef]

| Solution | Composition | Value | pH | Temperature (°C) | Time (min) |

|---|---|---|---|---|---|

| Degreasing Solution | Na2CO3 | 30 g/L | 12 | 80 | 10 |

| NaOH | 35 g/L | ||||

| Na3PO4∙12H2O | 30 g/L | ||||

| Na2SiO3 | 5 g/L | ||||

| Washing Solution | HF (40%) | 20 mL/L | 0.6 | 25 | 1 |

| HCl (36%) | 50 mL/L | ||||

| Activation Solution | HF (40%) | 50 mL/L | 4 | 25 | 5 |

| HNO3 (65%) | 50 mL/L | ||||

| H2O2 (30%) | 100 mL/L | ||||

| Pre-plating Solution | NiSO4∙6H2O | 40 g/L | 5 | 25 | 10 |

| NaH2PO2∙H2O | 20 g/L | ||||

| CH3COONa | 10 g/L | ||||

| NH4Cl | 10 g/L | ||||

| Plating Solution | NiSO4∙6H2O | 100–500 g/L | 3–4 | 60 | 1–5 |

| NiCl2∙6H2O | 40 g/L | ||||

| Na3C6H5O7·2H2O | 15 g/L | ||||

| C6H11NaO7 | 12 g/L | ||||

| H3BO3 | 35 g/L |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Meng, J.; Zhou, H.; Xu, R.; Bai, X.; Zhang, H. Fabrication of Adhesive Resistance Surface with Low Wettability on Ti6Al4V Alloys by Electro-Brush Plating. Micromachines 2019, 10, 64. https://doi.org/10.3390/mi10010064

Dong X, Meng J, Zhou H, Xu R, Bai X, Zhang H. Fabrication of Adhesive Resistance Surface with Low Wettability on Ti6Al4V Alloys by Electro-Brush Plating. Micromachines. 2019; 10(1):64. https://doi.org/10.3390/mi10010064

Chicago/Turabian StyleDong, Xiaojuan, Jianbing Meng, Haian Zhou, Rufeng Xu, Xue Bai, and Haiyun Zhang. 2019. "Fabrication of Adhesive Resistance Surface with Low Wettability on Ti6Al4V Alloys by Electro-Brush Plating" Micromachines 10, no. 1: 64. https://doi.org/10.3390/mi10010064

APA StyleDong, X., Meng, J., Zhou, H., Xu, R., Bai, X., & Zhang, H. (2019). Fabrication of Adhesive Resistance Surface with Low Wettability on Ti6Al4V Alloys by Electro-Brush Plating. Micromachines, 10(1), 64. https://doi.org/10.3390/mi10010064