3D printing has the potential to deeply affect the manufacture of mechatronic devices, shaping highly complex objects and embedding external components into complex structures. The additive processes provide a cost-effective way of using self-developed and individually designed mechatronic devices, with a completely customizable design that can combine optical, chemical, electronic, electromagnetic, fluidic, thermal, and acoustic features, potentially at a very low cost. Even if the conductivity of materials is still a challenge, due to the blending of conductive materials in a polymer matrix, typically made of dielectric materials, very recently a wide variety of composite materials have become available, with interesting conductive properties. Unfortunately, these composites are often critical for 3D printing due to their thermal expansion coefficient, glass transition temperature, and mechanical properties. These drawbacks actually limit the diffusion of 3D printing for mechatronic devices, and research in this field is very recent and limited to highly customized materials and machines.

Research Background

Traditionally fabricated sensors have some limitations, such as high production times, difficulty in producing elements with relatively small dimensions (micrometric features), difficulty in assembling micro components using imprecise and non-lasting fixing and/or gluing methods, high costs due to the miniaturization of the component, and poor large-scale reproducibility.

The additive manufacturing methods applied in the sensor industry seek to overcome some of these problems, guaranteeing lower production times and costs, with the possibility of embedding the transducers into structures (i.e., soft grippers) directly during the manufacturing.

In the current state of the art, additive manufacturing processes have proven to be an excellent alternative for the realization of customized sensors, while the traditional production methods are still the elective technology for high volume production.

3D printed sensors can be classified into three macro categories, including physical sensors, chemical sensors and biosensors [

1].

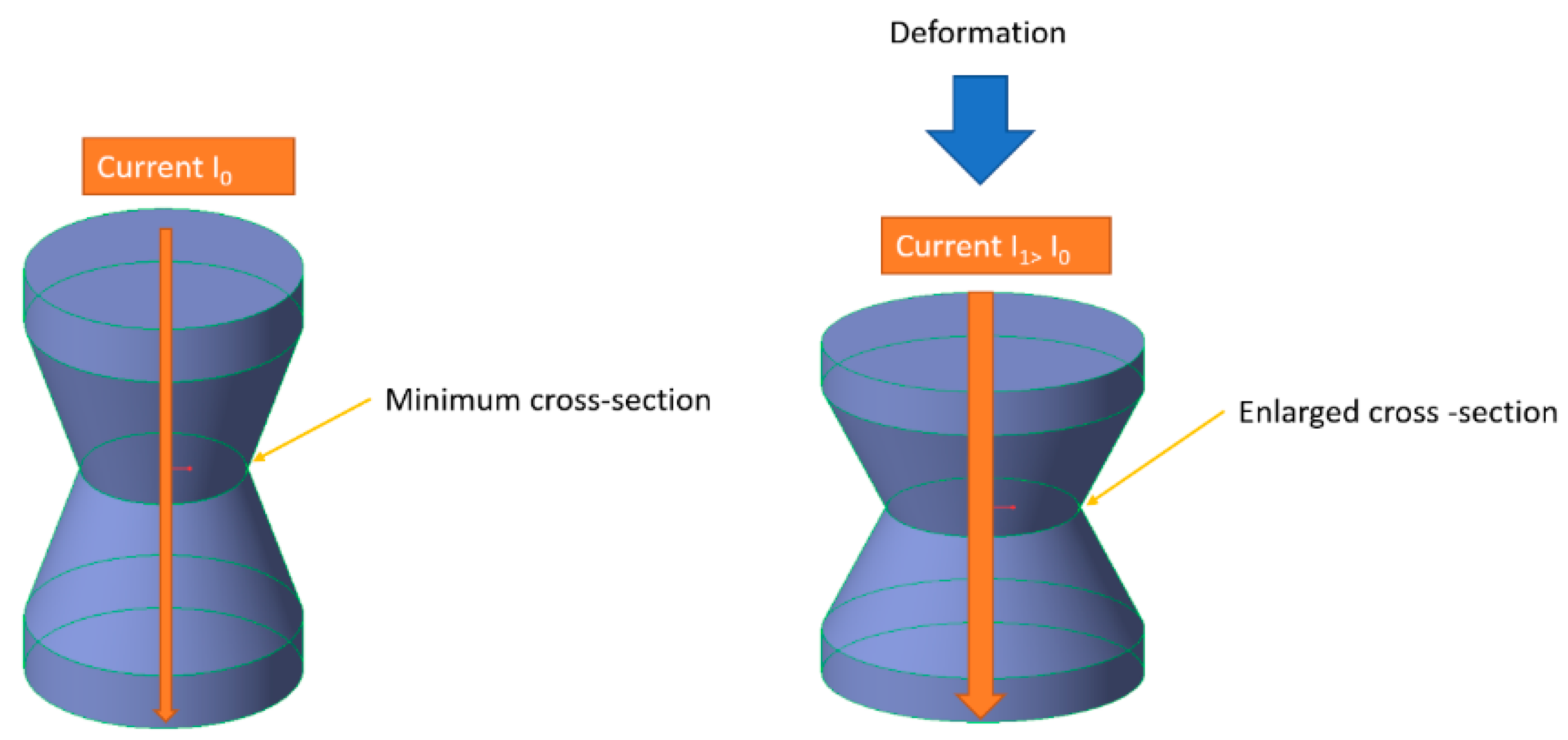

The physical sensors are used to detect the variation of one physical quantity, caused by physical effects, through the variation of the electrical resistance or capacity.

In the literature, most 3D-printed sensors are built by exploiting the mechanical properties of the most common filaments used in extrusion-based additive manufacturing. Polylactic acid (PLA) and thermoplastic polyurethane (TPU) are among the most commonly used materials in additive manufacturing. These materials can be coupled with one conductive material, typically thermoplastics doped with carbon nanotubes, which can be extruded and deposited. As a reference, the study in [

2] offers an overview of the commercially available electroconductive filaments, comparing the electrical features (resistance, conductivity and breaking point) to maximize the feasibility of industrial versions of the sensor and cross the threshold of large-scale production.

The use of an electroconductive ink is reported in [

3], where an extensimeter is realized, with a coplanar structure of a few millimeters thickness, starting from a simple rectangularly shaped elastomeric base and depositing a coil-shaped feature made of an electroconductive ink, suitable for detecting elongation and torsion in laboratory experiments. Unfortunately, the deposition of electroconductive inks forces the two materials, with such different features, to be coupled.

In the literature, mainly bending, torque, and tensile sensors have been studied, while to the best of the authors’ knowledge, no 3D-printed compressive sensors have been proposed.

One example is [

4], where a continuous conductive filament line is printed through a thin or hollow structure along the axis of the desired interaction. The bending sensors are therefore analog resistive sensors, where one end of the filament acts as an emitter, and the other, as a receiver. When the structure is bent, the carbon particles in the filament move away from each other. As a result, the resistance of the circuit increases proportionally.

The creation of 3D printed circuits is very interesting, and several solutions are proposed by some authors. Coupling and embedding extruded conductive materials into other materials is not a trivial task. A truly effective method for obtaining printed circuit production through additive manufacturing systems is not available yet, but it is self-evident that the potential advantages push research in this direction. Recently, a technique has been proposed for printing electronic flexural and capacitance sensors, thanks to a composite thermoplastic, as illustrated by [

5].

The crucial point in the realization of sensors with purely additive technology is the interaction between the different materials (elastomeric base and electrically conductive material). In fact, taking the case of fused deposition modeling (FDM) printing, the superimposition of successive layers requires adhesion between the materials. Attention must be paid to the phenomenon known as cross contamination, that is, the possible local, partial bending of the materials, leading to loose conductive properties.

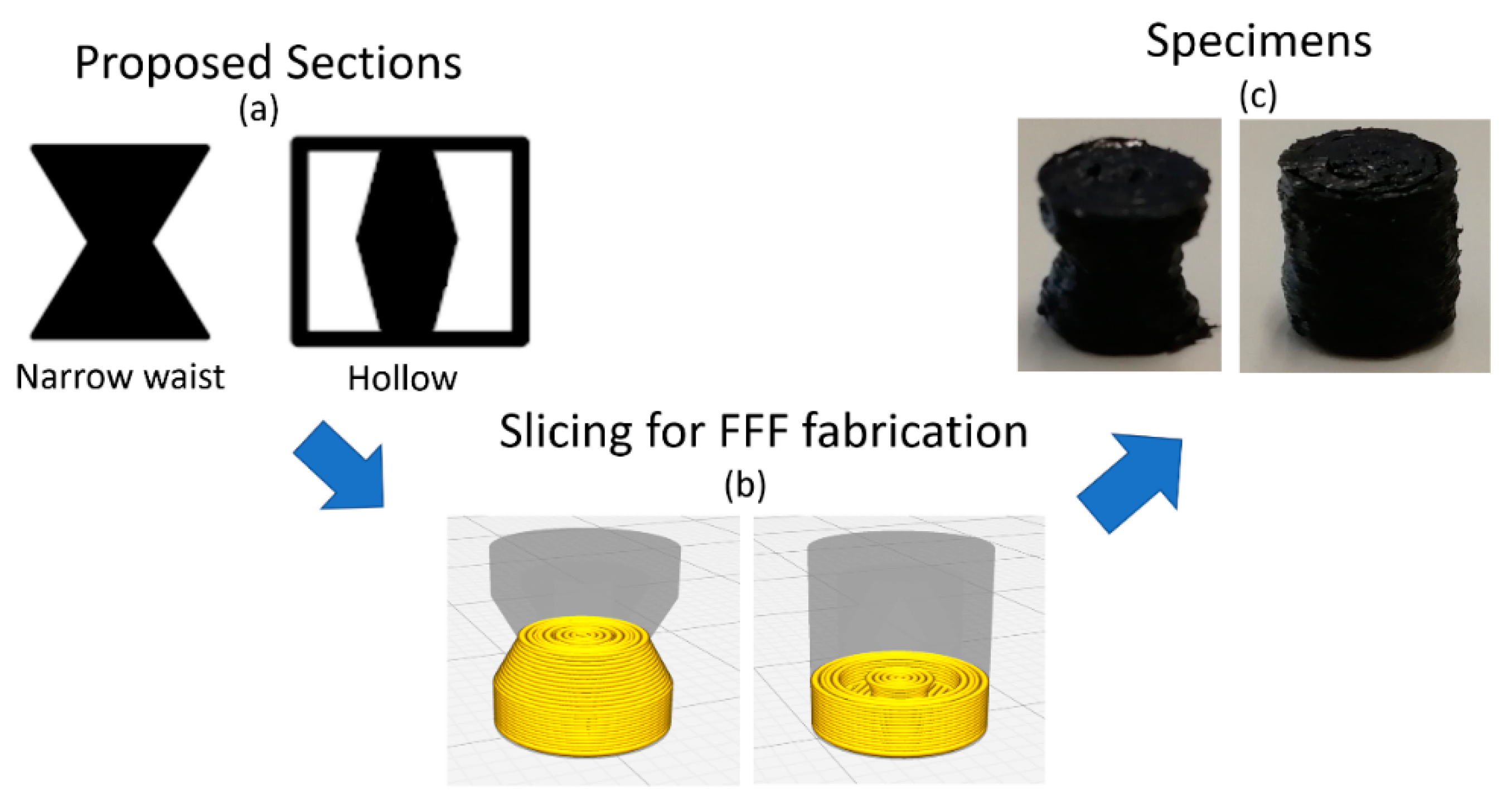

Concerning the typology of additive manufacturing processes, the reduced cost of the thermoplastic filaments and the attention they have received by the open source world have made filament freeform fabrication (FFF) the most widely used 3D printing technique, in spite of its low printing resolution and slow printing speed.

3D printing technology has been implemented either to completely produce sensors, or to carry out only a part of their production process, through the integration of different materials that embed active components [

6].

In the literature, customized and complex solutions have been proposed, such as [

7,

8] (for an exhaustive review of 3D-printed sensors please refer to [

9]).

Several patent applications relating to heterogeneous sensors in various fields have also been filed. One example is [

7], which proposes a microsensor for electrophysiology and electrochemistry studies in vitro and in vivo for the detection of electroactive neurotransmitters. Another example is [

8], which discloses a temperature sensor system based on a micro fluidic chip and a preparation method of the system.

Soft strain sensors are typically composed of a deformable conducting material patterned onto, attached to, or embedded in an inactive stretchable material, and this kind of sensor is eligible for 3D printing. On the market, conventional strain sensors are available. They are mainly piezoelectric sensors, often made of heterogeneous portions. However, the high standardization of manufacturing processes allows highly affordable sensors to be obtained.

However, such commercial sensors have substantially individual components, which need to be arranged mechanically in a structure or body under observation and be connected electrically to a measurement device.

When the miniaturization is particularly strong, the high affordability of individual commercial sensors is lost during their mechanical and electrical connection in defining a custom complex measurement system.

The possibility of manufacturing printed sensors allows the production of each individual sensor to be embedded together with a complex custom measurement structure, in which the electric wires are also embedded additively through the same manufacturing procedure. Thus, the main challenge is to exclusively use 3D printing by avoiding the implementation of heterogeneous components, which are often adopted to realize concentrated measurements. However, the affordability of printed sensors must be investigated, before future implementation, by bearing in mind that the sole degree of freedom is the shape conferred on the sensor itself.

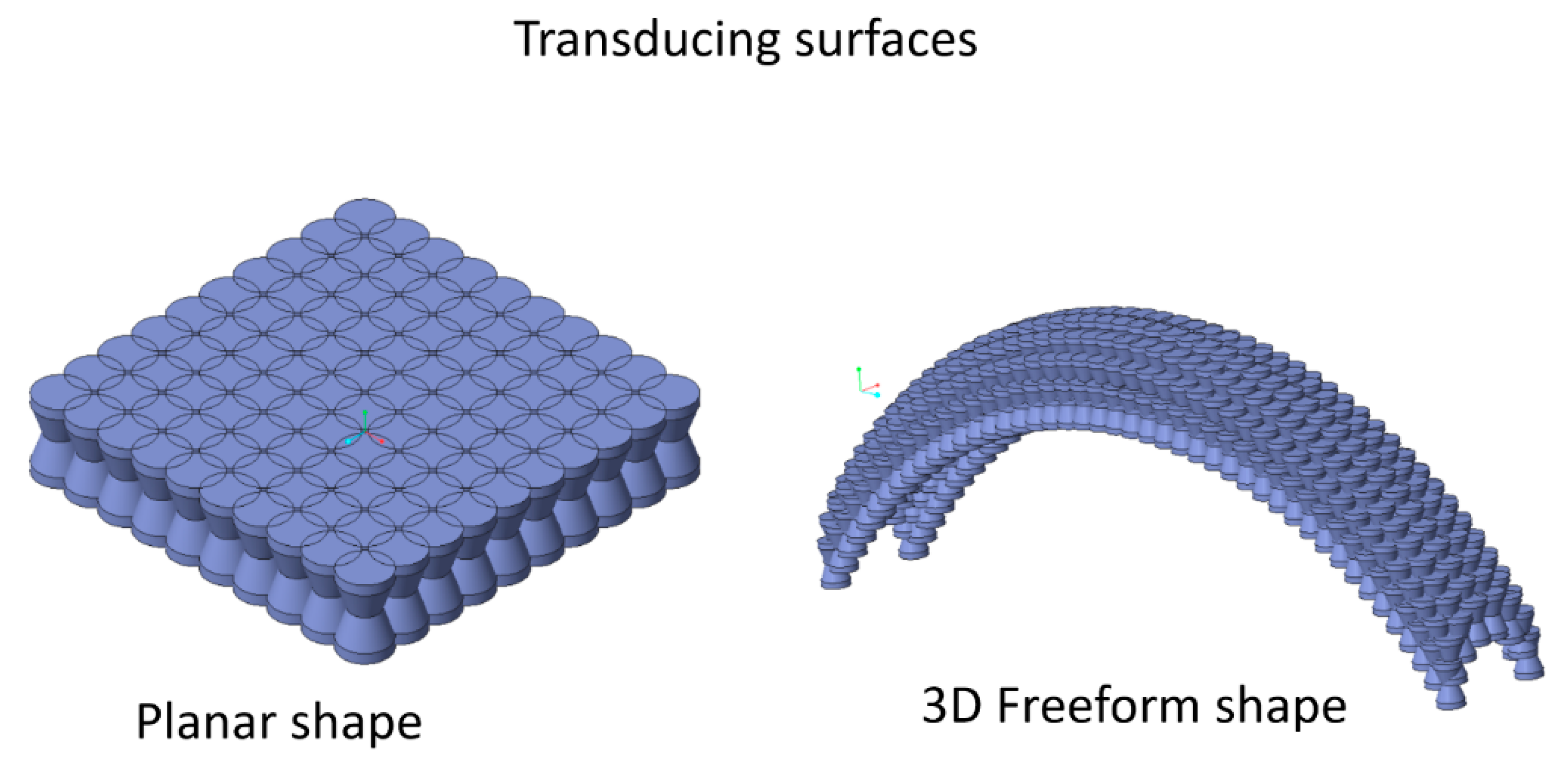

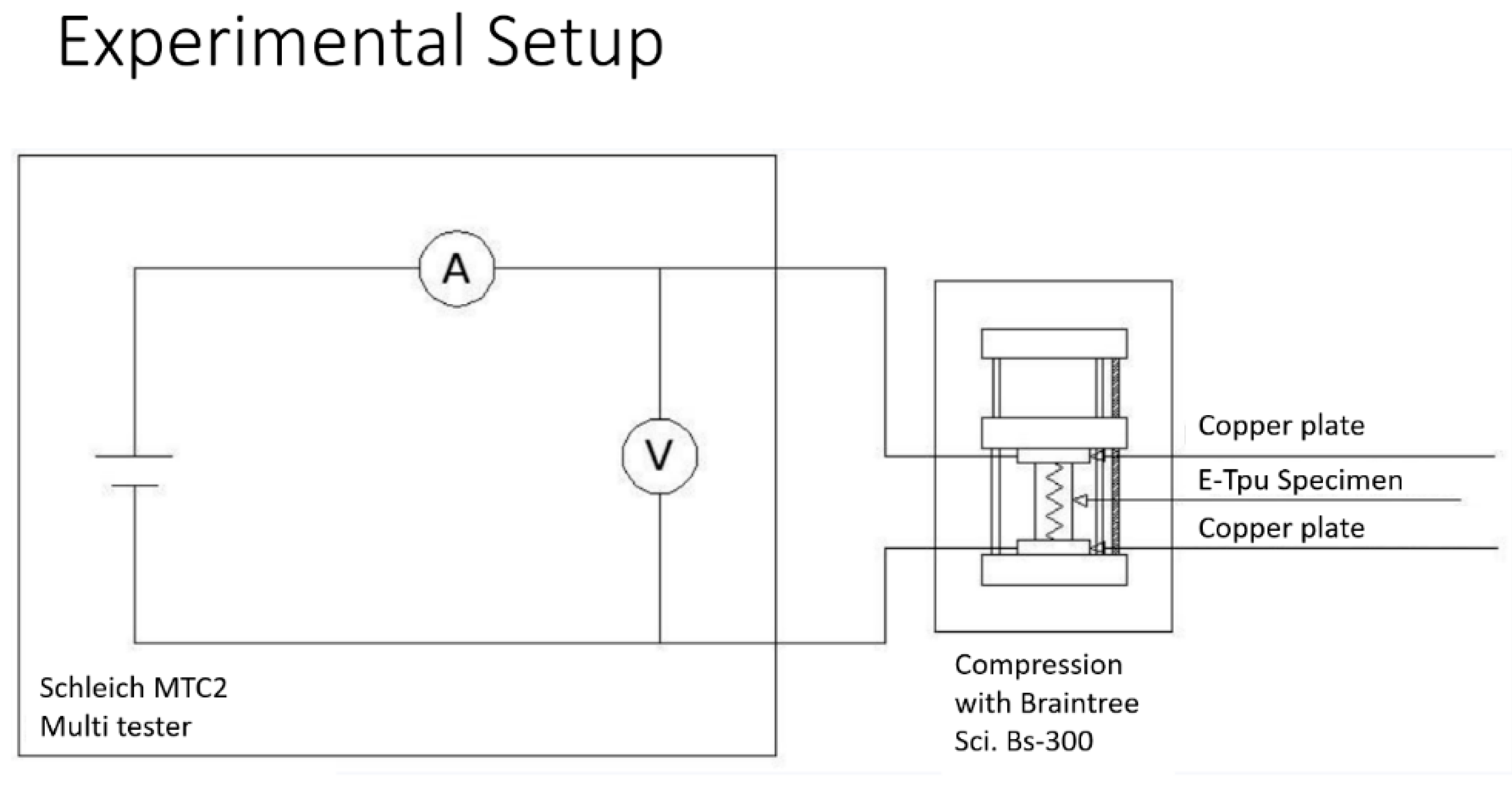

In this context, the present research aims to evaluate the commercially available materials and machines for fabricating multilayer, topologically optimized transducers, which can be embedded into mechanical devices, such as soft grippers. Preliminary tests on the possibility of fabricating 3D-printed transducers using a commercial conductive elastomeric filament are presented. To the best of the authors’ knowledge, no sensor applications using such a product are described in the literature. On the other hand, the exploitation of commercially available materials and machines could dramatically affect the diffusion of 3D additive manufacturing of mechatronic micro components.