Silver Nanowires from Sonication-Induced Scission

Abstract

1. Introduction

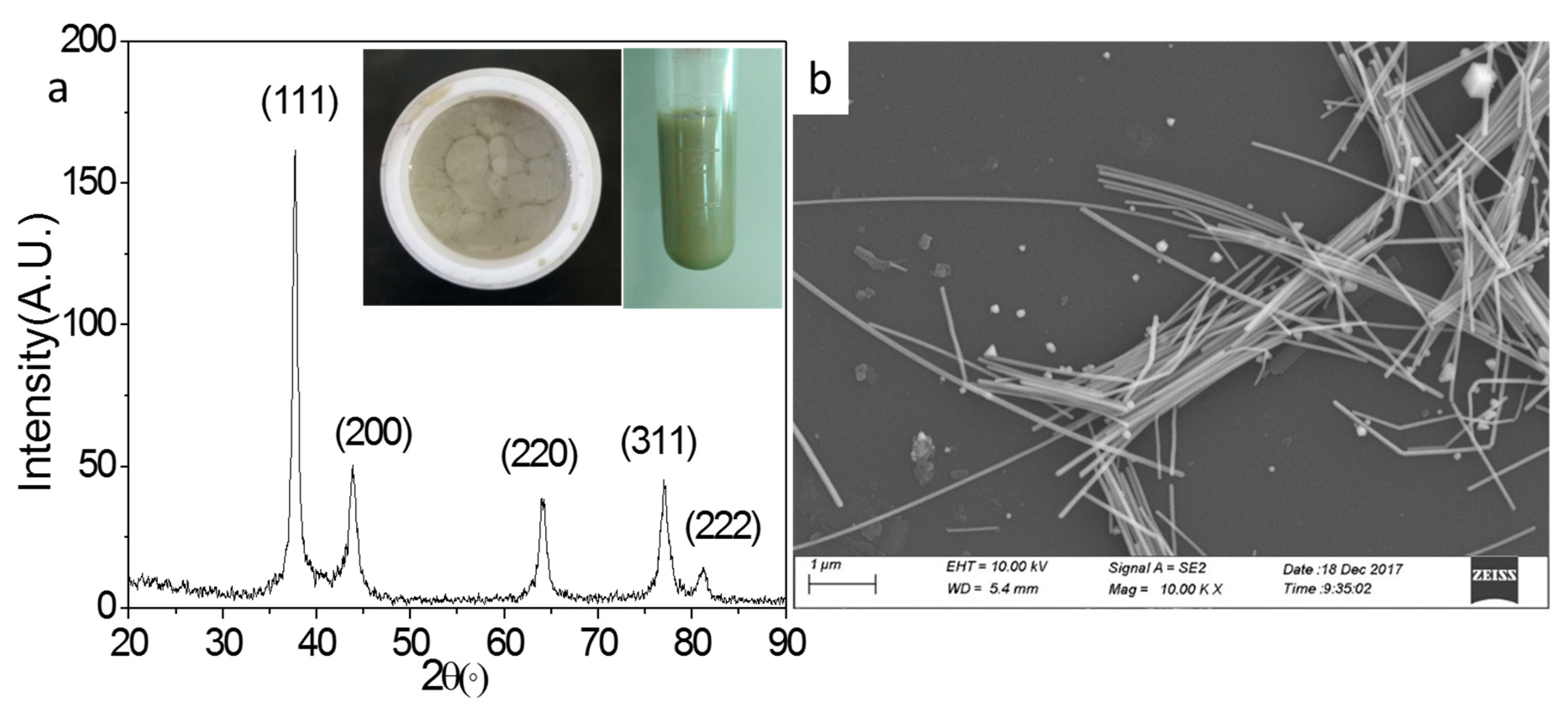

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation Method of Silver Nanowires

2.2.2. Sonication-Induced Scission of Silver Nanowires

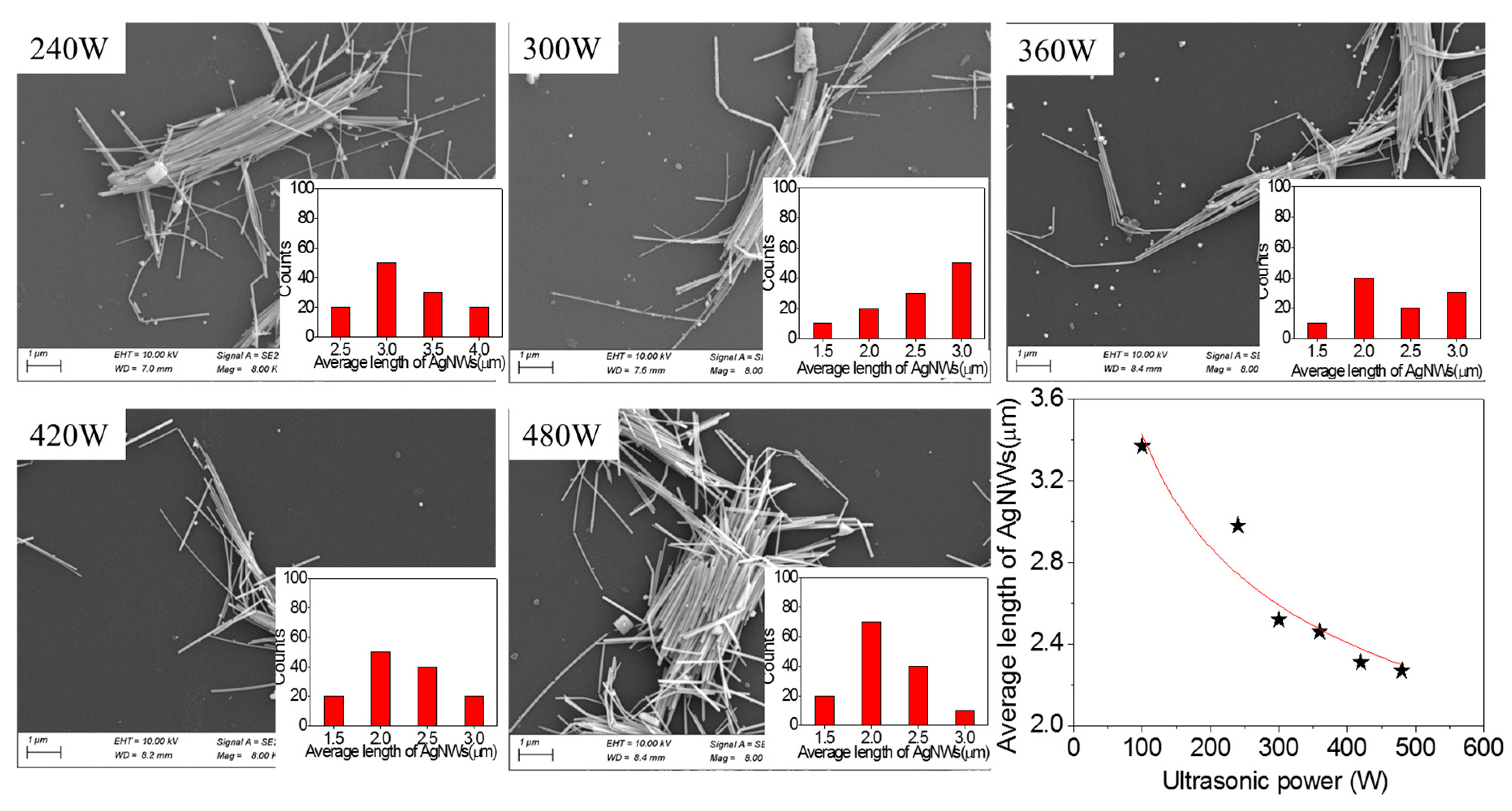

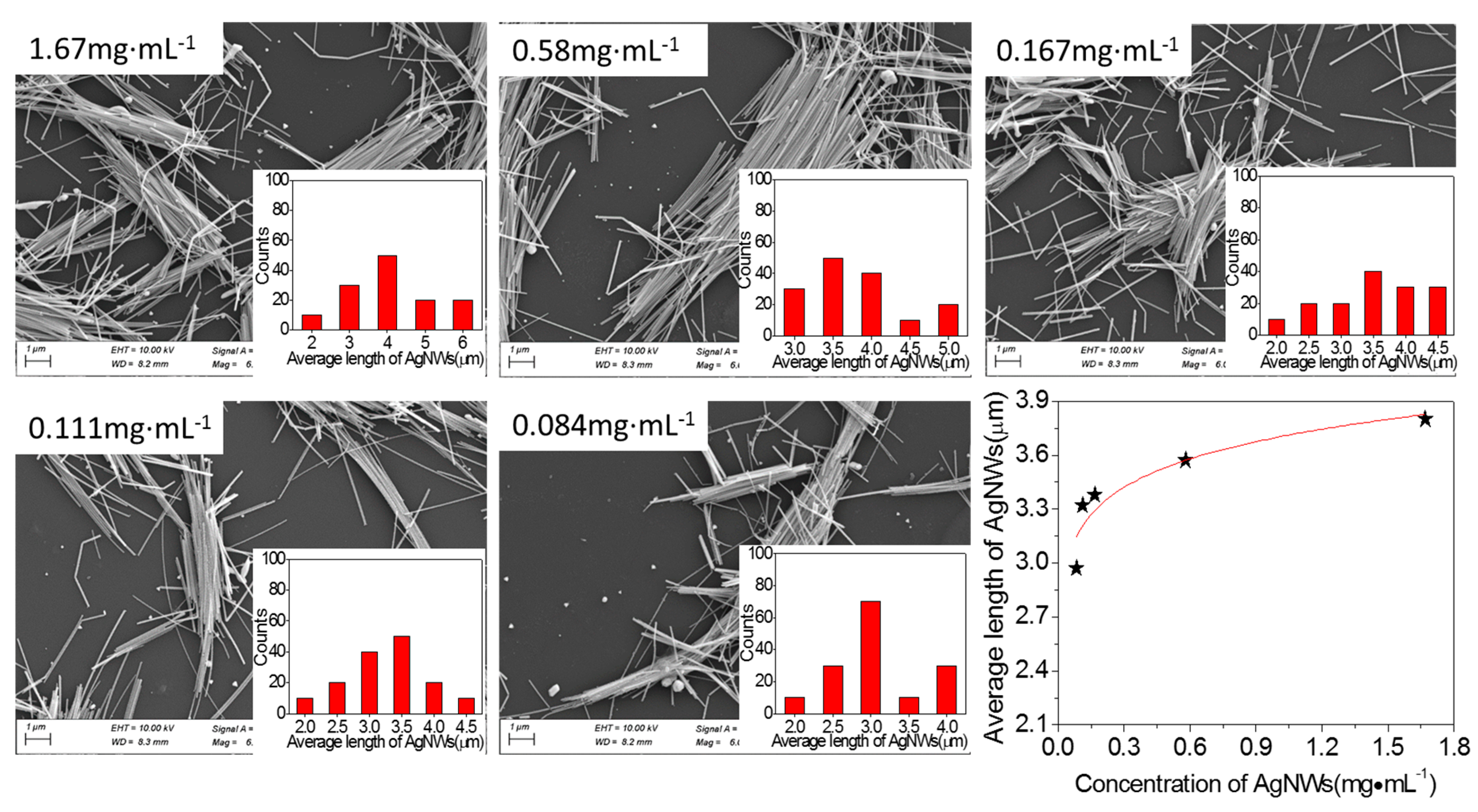

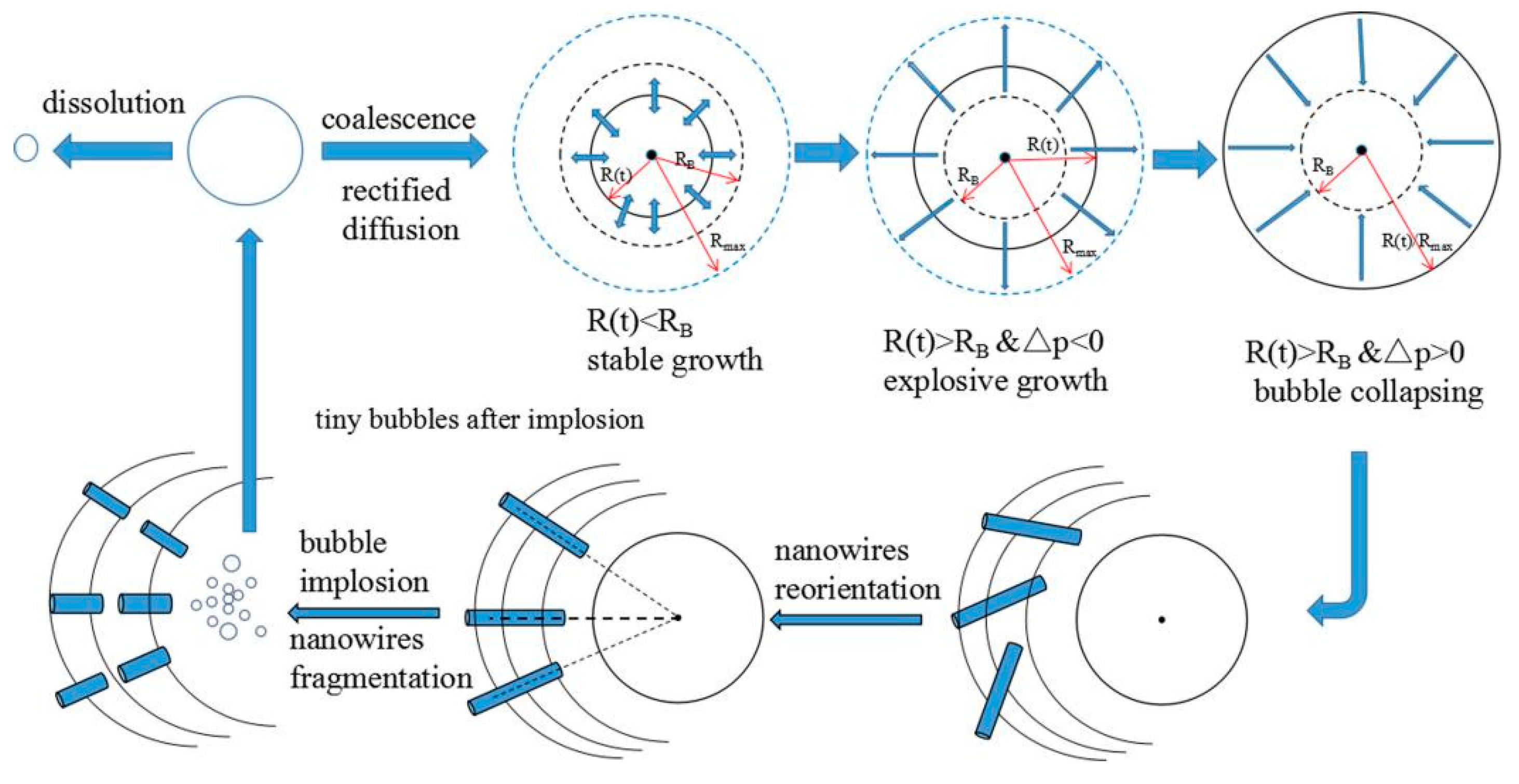

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jin, Y.X.; Wang, K.Q.; Cheng, Y.Q.; Pei, Q.B.; Xu, Y.X.; Xiao, F. Removable large-area ultrasmooth silver nanowire transparent composite electrode. ACS Appl. Mater. Interfaces 2017, 9, 4733–4741. [Google Scholar] [CrossRef] [PubMed]

- Du, H.W.; Wan, T.; Qu, B.; Cao, F.Y.; Lin, Q.R.; Chen, N.; Lin, X.; Chu, D.W. Engineering silver nanowire networks: From transparent electrodes to resistive switching devices. ACS Appl. Mater. Interfaces 2017, 9, 20762–20770. [Google Scholar] [CrossRef]

- Tiefenauer, R.F.; Dalgaty, T.; Keplinger, T.; Tian, T.; Shih, C.-J.; Vörös, J.; Aramesh, M. Monolayer Graphene Coupled to a Flexible Plasmonic Nanograting for Ultrasensitive Strain Monitoring. Small 2018, 1801187, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Secor, E.B.; Lim, S.; Zhang, H.; Frisbie, C.D.; Francis, L.F.; Hersam, M.C. Gravure printing of graphene for large-area flexible electronics. Adv. Mater. 2014, 26, 4533–4538. [Google Scholar] [CrossRef] [PubMed]

- Biswas, C.; Lee, Y.H. Graphene versus carbon nanotubes in electronic devices. Adv. Funct. Mater. 2011, 21, 3806–3826. [Google Scholar] [CrossRef]

- Maisch, P.; Tam, K.C.; Lucera, L.; Egelhaaf, H.-K.; Scheiber, H.; Maier, E.; Brabec, C.J. Inkjet printed silver nanowire percolation networks as electrodes for highly efficient semitransparent organic solar cells. Org. Electron. 2016, 38, 139–143. [Google Scholar] [CrossRef]

- Fan, Z.; Yan, J.; Zhi, L.; Zhang, Q.; Wei, T.; Feng, J.; Zhang, M.; Qian, W.; Wei, F. A Three-Dimensional Carbon Nanotube/Graphene Sandwich and Its Application as Electrode in Supercapacitors. Adv. Mater. 2010, 22, 3723–3728. [Google Scholar] [CrossRef]

- Tao, Y.; Li, J.; Li, K.; Wang, H.; Chen, P.; Duan, Y.H.; Chen, Z.; Liu, Y.F.; Wang, H.R.; Duan, Y. Inkjet-printed Ag grid combined with Ag nanowires to form a transparent hybrid electrode for organic electronics. Org. Electron. 2017, 41, 179–185. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, D.M.; Liang, Y.T.; Zhang, D.D.; Yan, H.; Zhang, Y.Z. Flexible transparent and conductive films of reduced-graphene-oxide wrapped silver nanowires. Mater. Lett. 2017, 201, 50–53. [Google Scholar] [CrossRef]

- Chiang, K.M.; Huang, Z.Y.; Tsai, W.L.; Lin, H.W. Orthogonally weaved silver nanowire networks for very efficient organic optoelectronic devices. Org. Electron. 2017, 43, 15–20. [Google Scholar] [CrossRef]

- Aramesh, M.; Mayamei, Y.; Wolff, A.; Ostrikov, K. Superplastic nanoscale pore shaping by ion irradiation. Nat. Commun. 2018, 9, 835. [Google Scholar] [CrossRef] [PubMed]

- Zheng, K.; Wang, C.; Cheng, Y.Q.; Yue, Y.; Han, X.; Zhang, Z.; Shan, Z.; Mao, S.X.; Ye, M.; Yin, Y.; et al. Electron-beam-assisted superplastic shaping of nanoscale amorphous silica. Nat Commun. 2010, 1, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.J.; Zhu, Y. Gravure Printing of Water-based Silver Nanowire ink on Plastic Substrate for Flexible Electronics. Sci. Rep. 2018, 1, 15167. [Google Scholar] [CrossRef] [PubMed]

- Kwon, J.; Suh, Y.D.; Lee, J.; Lee, P.; Han, S.; Hong, S.; Yeo, J.; Lee, H.; Ko, S.H. Recent progress in silver nanowire based flexible/wearable optoelectronics. J. Mater. Chem. C 2018, 6, 7445–7461. [Google Scholar] [CrossRef]

- Jo, W.; Kang, H.S.; Choi, J.; Lee, H.; Kim, H.T. Plasticized polymer interlayer for low-temperature fabrication of a high-quality silver nanowire-based flexible transparent and conductive film. ACS Appl. Mater. Interfaces 2017, 9, 15114–15121. [Google Scholar] [CrossRef] [PubMed]

- Sorel, S.; Lyons1, P.E.; De1, S.; Dickerson, J.C.; Coleman, J.N. The dependence of the optoelectrical properties of silver nanowire networks on nanowire length and diameter. Nanotechnology 2012, 23, 185201. [Google Scholar] [CrossRef] [PubMed]

- Bergin, S.M.; Chen, Y.H.; Rathmell, A.R.; Charbonneau, P.; Li, Z.Y.; Wiley, B.J. The effect of nanowire length and diameter on the properties of transparent, conducting nanowire films. Nanoscale 2012, 4, 1996–2004. [Google Scholar] [CrossRef]

- Marus, M.; Hubarevich, A.; Lim, R.J.W.; Huang, H.; Smirnov, A.; Wong, H.; Fan, W.J.; Sun, X.W. Effect of silver nanowire length in a broad range on optical and electrical properties as a transparent conductive film. Opt. Mater. Express 2017, 7, 1105–1112. [Google Scholar] [CrossRef]

- Yoo, B.; Kim, Y.; Han, C.J. Recyclable patterning of silver nanowire percolated network for fabrication of flexible transparent electrode. Appl. Surf. Sci. 2018, 29, 151–157. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, P.; Lee, D.; Lee, S.S.; Ko, S.H. Large-scale synthesis and characterization of very long silver nanowires via successive multistep growth. Cryst. Growth Des. 2012, 12, 5598–5605. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, J.N.; Xu, D.; Sun, Y.; Yan, F. One-pot synthesis and purification of ultra-long silver nanowires for flexible transparent conductive electrodes. ACS Appl. Mater. Interf. 2017, 9, 25465–25473. [Google Scholar] [CrossRef] [PubMed]

- Hemmati, S.; Barkey, D.P. Parametric study, sensitivity analysis, and optimization of polyol synthesis of silver nanowires. ECS J. Solid State Sci. Technol. 2017, 6, P132–P137. [Google Scholar] [CrossRef]

- Meléndrez, M.F.; Medina, C.; Solis-Pomar, F.; Flores, P.; Paulraj, M.; Pérez-Tijerina, E. Quality and high yield synthesis of Ag nanowires by microwave-assisted hydrothermal method. Nanoscale Res. Lett. 2015, 10, 48. [Google Scholar] [CrossRef] [PubMed]

- Natsuki, J.; Natsuki, T.; Hashimoto, Y. A review of silver nanoparticles: Synthesis methods, properties and applications. Int. J. Mater. Sci. Appl. 2015, 4, 325–332. [Google Scholar] [CrossRef]

- Zong, R.L.; Zhou, J.; Li, Q.; Du, B.; Li, B.; Fu, M.; Qi, X.W.; Li, L.T. Synthesis and optical properties of silver nanowires arrays embedded in anodic alumina membrane. J. Phys. Chem. B 2004, 108, 16713–16716. [Google Scholar] [CrossRef]

- Grossiord, N.; Regev, O.; Loos, J.; Meuldijk, J.; Koning, C.E. Time-dependent study of the exfoliation process of carbon nanotubes in aqueous dispersions by using UV-Visible Spectroscopy. Anal. Chem. 2005, 77, 5135–5139. [Google Scholar] [CrossRef]

- Elsner, H.I.; Lindblad, E.B. Ultrasonic degradation of DNA. DNA 1989, 8, 697–701. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Xiao, Z.W.; Wang, B. The exfoliation of SWCNT bundles examined by simultaneous Raman scattering and photoluminescence spectroscopy. Carbon 2009, 47, 3529–3537. [Google Scholar] [CrossRef]

- Lucas, A.; Zakri, C.; Maugey, M.; Pasquali, M.; Schoot, P.; Poulin, P. Kinetics of nanotube and microfiber scission under sonication. J. Phys. Chem. C 2009, 113, 20599–20605. [Google Scholar] [CrossRef]

- Heller, D.A.; Mayrhofer, R.M.; Baik, S.; Grinkova, Y.V.; Usrey, M.L.; Strano, M.S. Concomitant length and diameter separation of single-walled carbon nanotubes. J. Am. Chem. Soc. 2004, 126, 14567–14573. [Google Scholar] [CrossRef]

- Hennrich, F.; Krupke, R.; Arnold, K.; Stu1tz, J.A.R.; Lebedkin, S.; Koch, T.; Schimmel, T.; Kappes, M.M. The mechanism of cavitation-induced scission of single-walled carbon nanotubes. J. Phys. Chem. B 2009, 111, 1932–1937. [Google Scholar] [CrossRef] [PubMed]

- Stegen, J. Mechanics of carbon nanotube scission under sonication. J. Chem. Phys. 2104, 140, 244908. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Al-Milaji, K.N.; Zhao, H. Inkjet Printing of Silver Nanowires for Stretchable Heaters. ACS Appl. Nano Mater. 2018, 1, 4528–4536. [Google Scholar] [CrossRef]

- Finn, D.J.; Lotya, M.; Coleman, J.N. Inkjet Printing of Silver Nanowire Networks. ACS Appl. Mater. Interf. 2015, 7, 9254–9261. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.L.; Xie, H.; Jun, D.; Wang, Y.H.; Li, J.Z. A comprehensive study of transparent conductive silver nanowires films with mixed cellulose ester as matrix. J. Mater. Sci. Mater. Electron. 2015, 26, 6532–6538. [Google Scholar] [CrossRef]

- Yang, K.; Yi, Z.; Jing, Q.; Yue, R.; Jiang, W.; Lin, D. Sonication-assisted dispersion of carbon nanotubes in aqueous solutions of the anionic surfactant SDBS: The role of sonication energy. Chin. Sci. Bull. 2013, 58, 2082–2090. [Google Scholar] [CrossRef]

- Chen, S.Y.; Li, Y.; Jin, R.; Guan, Y.W.; Ni, H.T.; Wan, Q.H.; Li, L. A systematic and effective research procedure for silver nanowire ink. J. Alloys Compd. 2107, 706, 164–175. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Lee, J.; Kentish, S.; Grieser, F. Bubbles in an acoustic field: An overview. Ultrason. Sonochem. 2007, 14, 470–475. [Google Scholar] [CrossRef] [PubMed]

- Apfel, R.E. Acoustic cavitation inception. Ultrasonics 1984, 22, 167–173. [Google Scholar] [CrossRef]

- Chew, H.B.; Moon, M.W.; Lee, K.R.; Kim, K.S. Compressive dynamic scission of carbon nanotubes under sonication: Fracture by atomic ejection. Proc. R. Soc. A 2011, 467, 1270–1289. [Google Scholar] [CrossRef]

- Pagani, G.; Green, M.J.; Poulin, P.; Pasquali, M. Competing mechanisms and scaling laws for carbon nanotube scission by ultrasonication. Proc. Natl. Acad. Sci. USA 2012, 109, 11599–11604. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.Y.; Knowles, T.P.J.; Terentjev, E.M. Strength of nanotubes, filaments, and nanowires from sonication-induced scission. Adv. Mater. 2009, 21, 3945–3948. [Google Scholar] [CrossRef]

- Lee, J.; Ashokkumar, M.; Kentish, S.; Grieser, F. Determination of the size distribution of sonoluminescence bubbles in a pulsed acoustic field. J. Am. Chem. Soc. 2005, 127, 16810–16811. [Google Scholar] [CrossRef] [PubMed]

- Prosperetti, A. Bubble phenomena in sound fields: Part one. Ultrasonics 1984, 22, 69–77. [Google Scholar] [CrossRef]

- Guérin, G.; Wang, H.; Manners, I.; Winnik, M.A. Fragmentation of fiberlike structures: Sonication studies of cylindrical block copolymer micelles and behavioral comparisons to biological fibrils. J. Am. Chem. Soc. 2008, 130, 14763–14771. [Google Scholar] [CrossRef]

| Sample | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Ultrasonic power (W) | 240 | 300 | 360 | 420 | 480 |

| Ultrasonic energy (kJ) | 1296 | 1620 | 1944 | 2268 | 2592 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yang, X.; Du, D. Silver Nanowires from Sonication-Induced Scission. Micromachines 2019, 10, 29. https://doi.org/10.3390/mi10010029

Wang Y, Yang X, Du D. Silver Nanowires from Sonication-Induced Scission. Micromachines. 2019; 10(1):29. https://doi.org/10.3390/mi10010029

Chicago/Turabian StyleWang, Yuehui, Xing Yang, and Dexi Du. 2019. "Silver Nanowires from Sonication-Induced Scission" Micromachines 10, no. 1: 29. https://doi.org/10.3390/mi10010029

APA StyleWang, Y., Yang, X., & Du, D. (2019). Silver Nanowires from Sonication-Induced Scission. Micromachines, 10(1), 29. https://doi.org/10.3390/mi10010029