Engineered Metal Nanoparticles: A Possible Small Solution to Big Problems Associated with Toxigenic Fungi and Mycotoxins

Abstract

1. Introduction

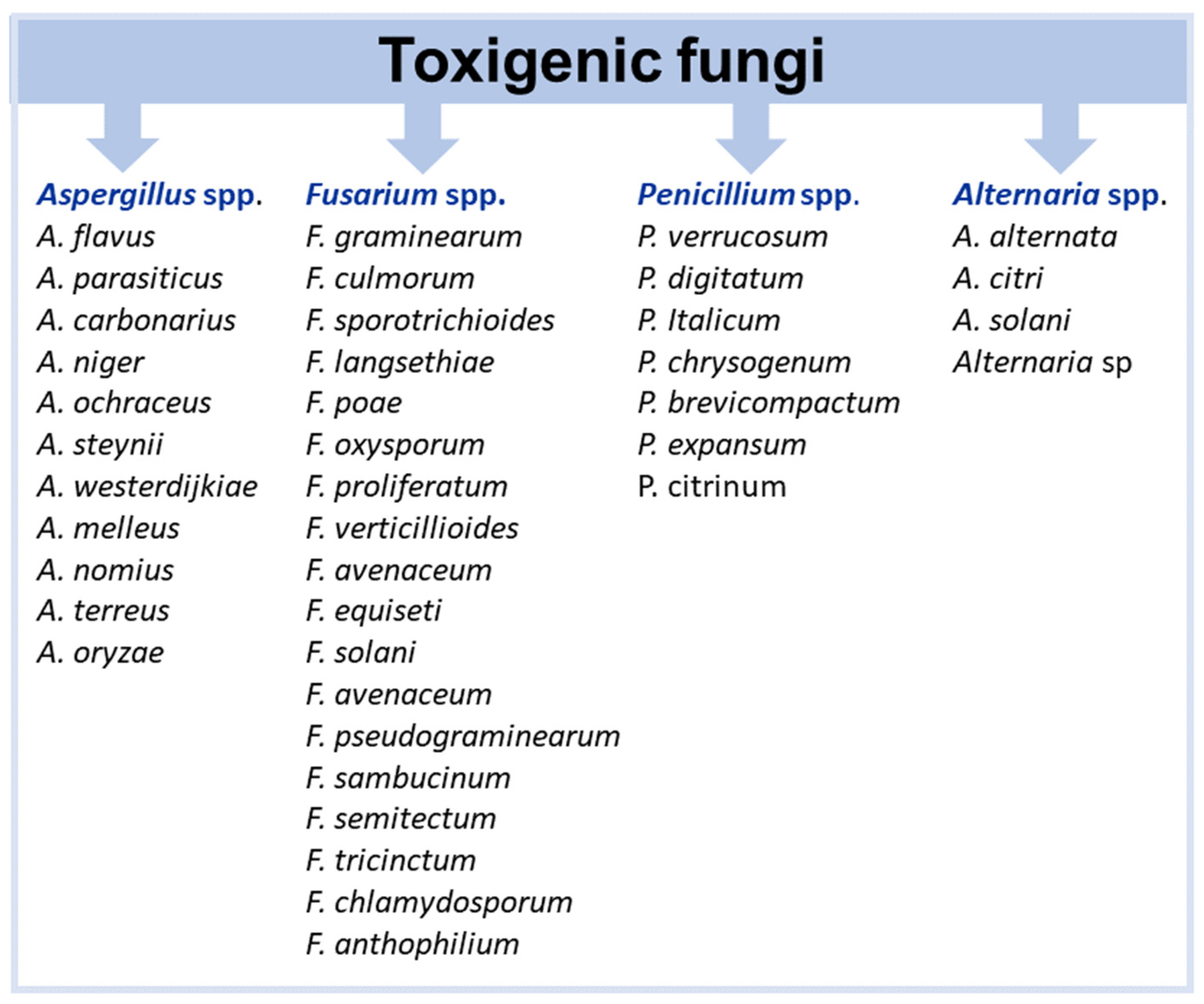

2. Engineered Nanomaterials Against Toxigenic Fungi and Mycotoxin Production

2.1. Definition of Nanoparticle

2.2. Engineered Nanoparticles as Antifungal Systems

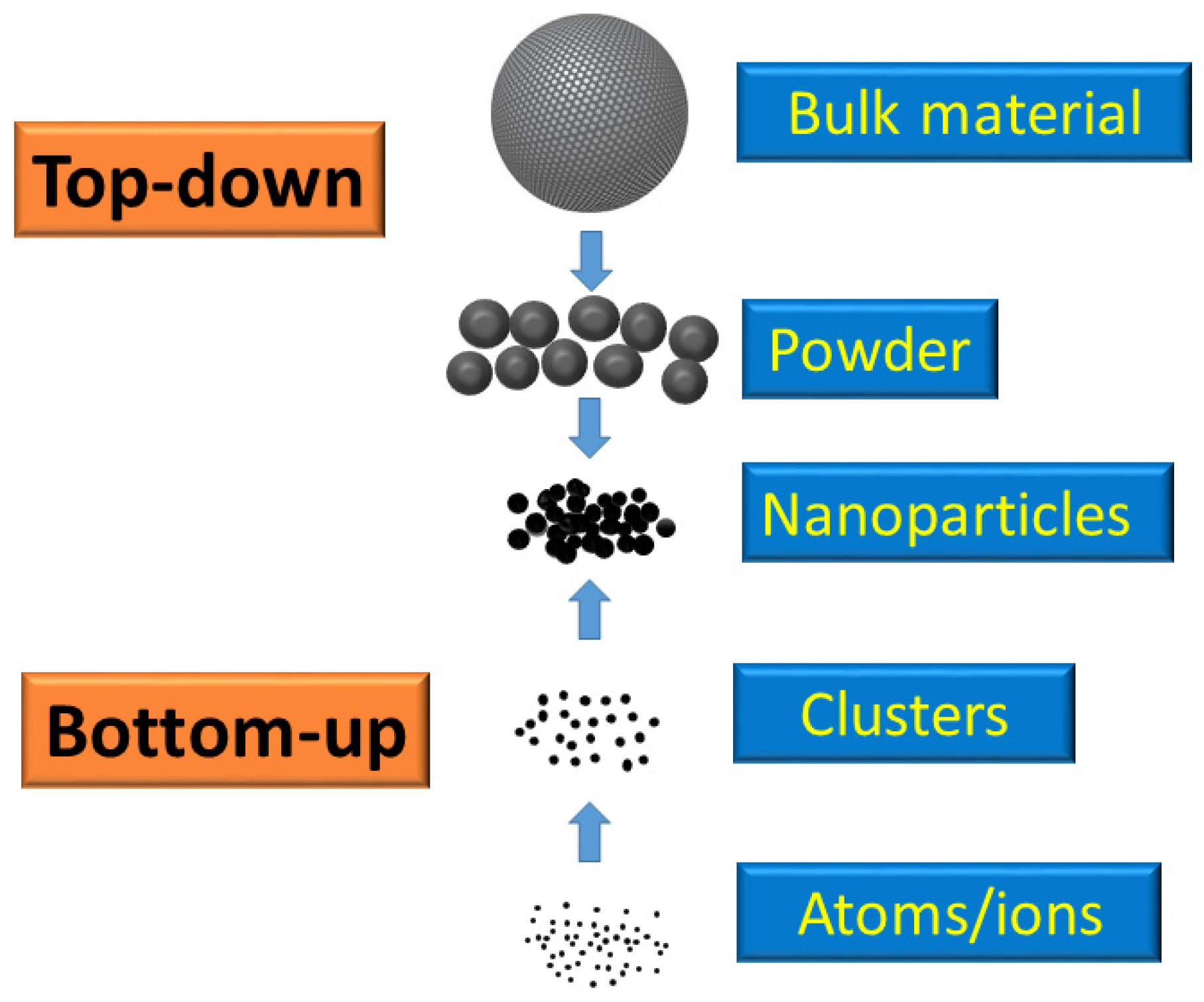

3. Synthesis of MNPs

3.1. Top-Down Methods

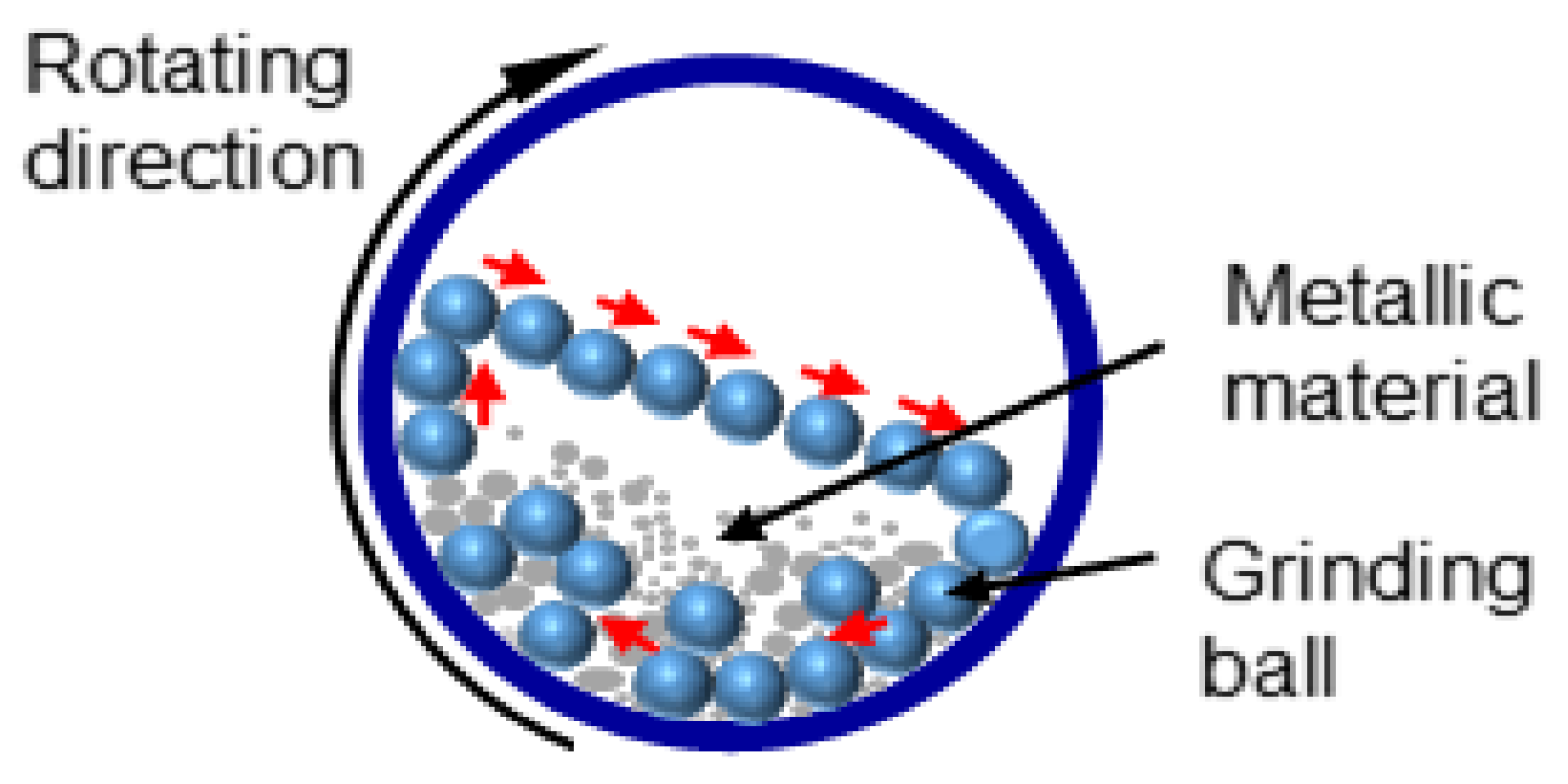

3.1.1. Mechanical Ball Milling

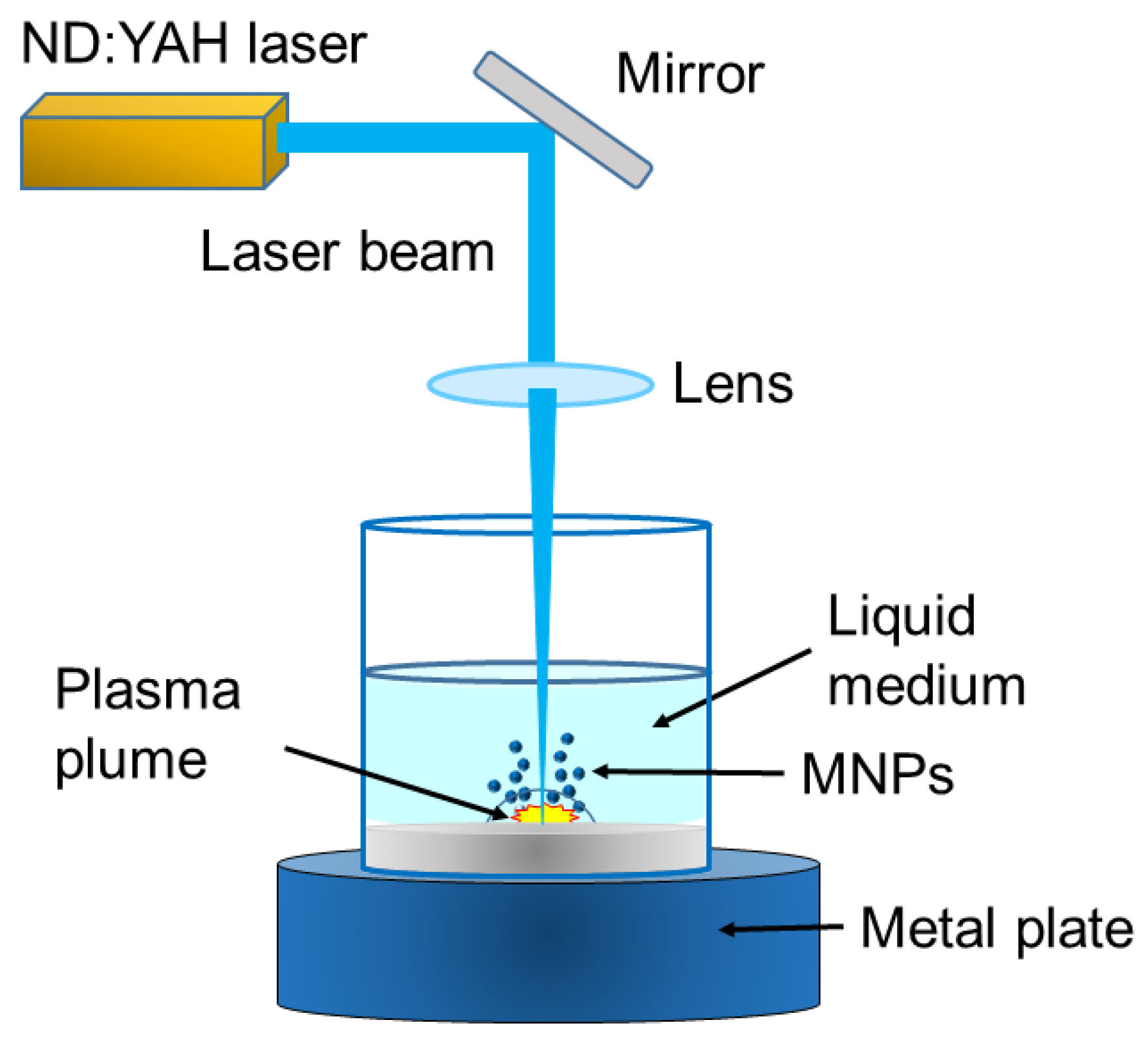

3.1.2. Laser Ablation

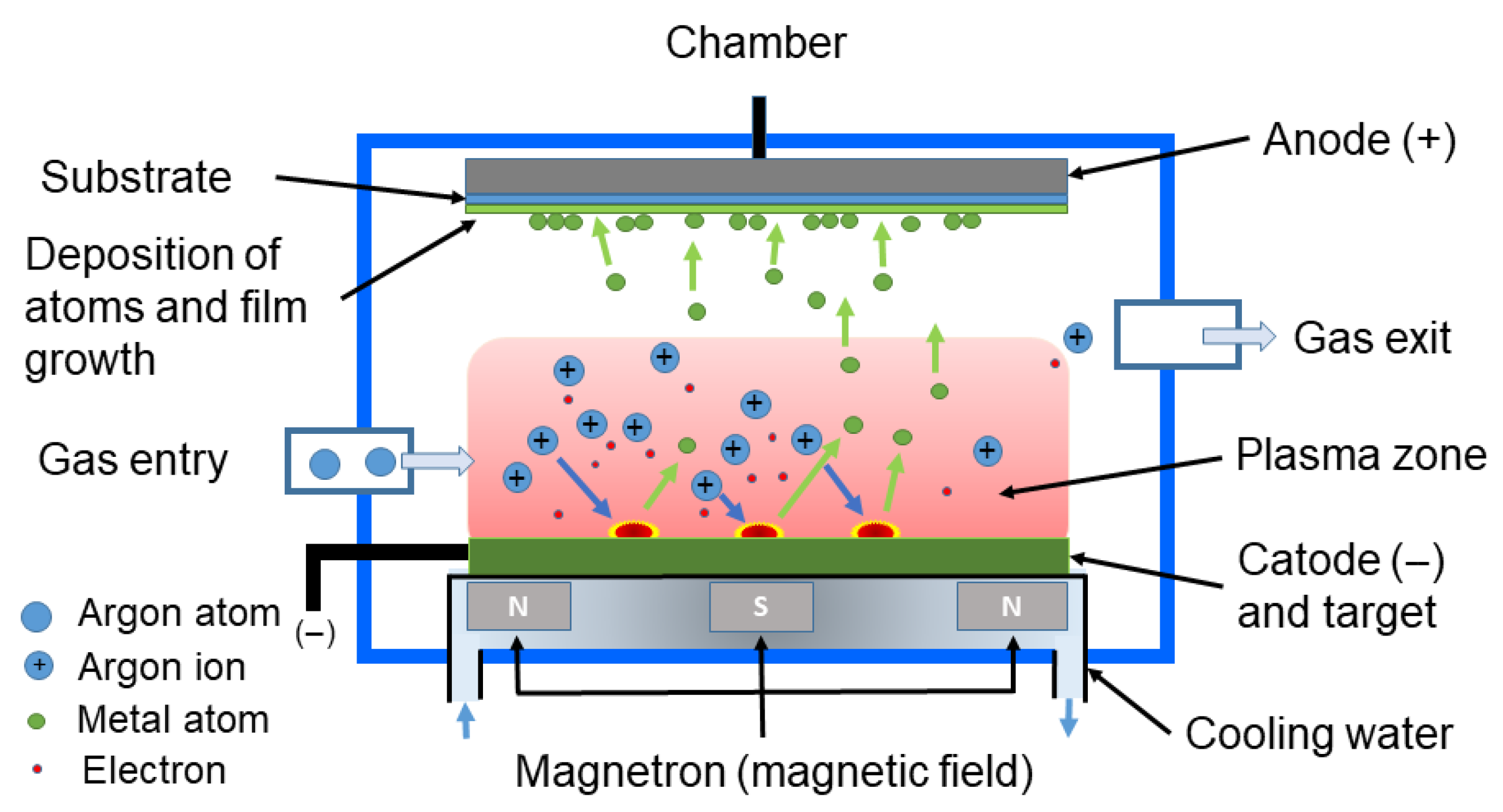

3.1.3. Sputtering

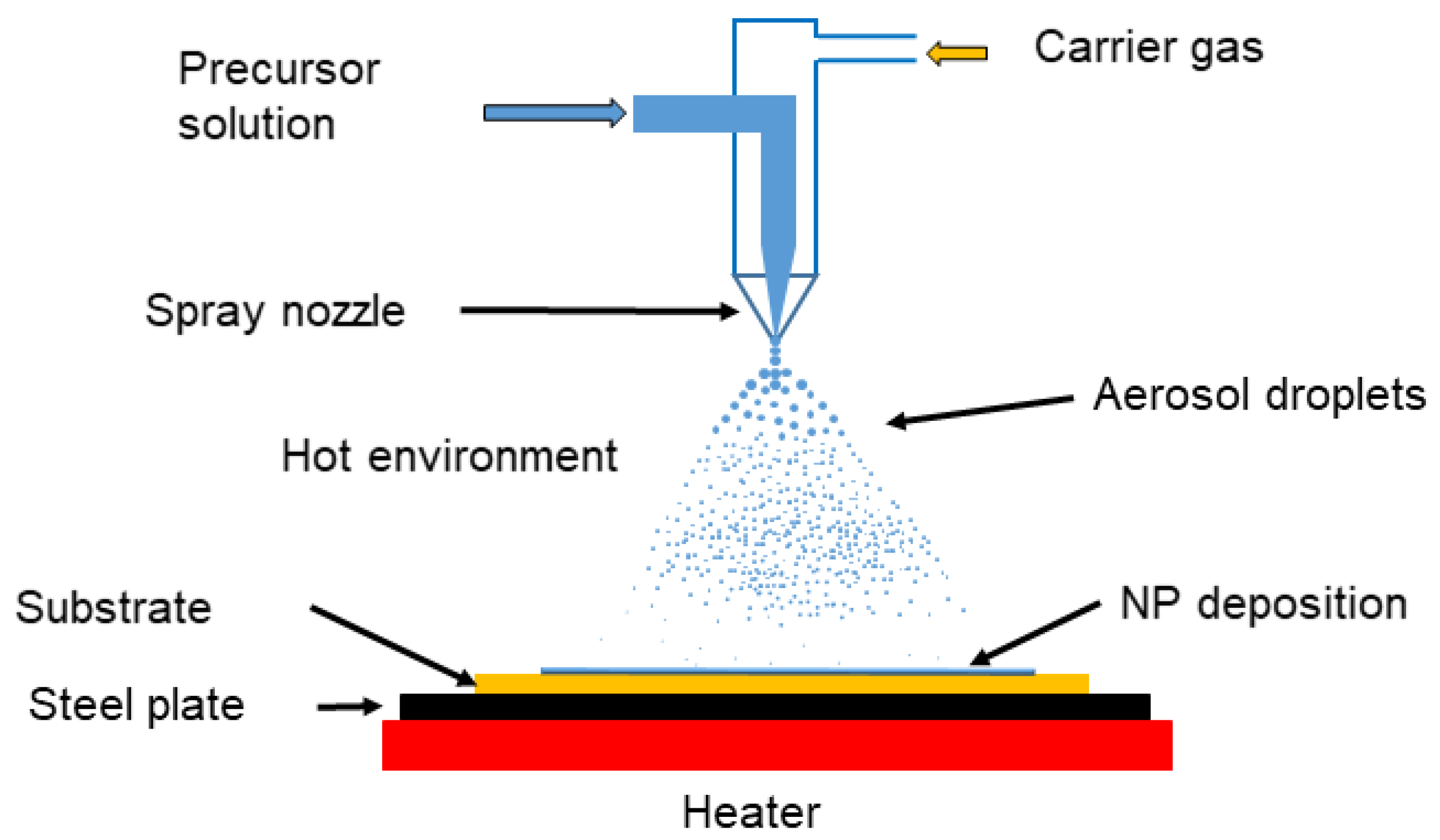

3.1.4. Spray Pyrolysis

3.1.5. Electrospray

3.2. Bottom-Up Methods

3.2.1. Physical Methods

Physical Vapor Deposition (PVD)

3.2.2. Chemical Methods

Sol–Gel Method

Chemical Vapor Deposition (CVD)

Atomic Layer Deposition (ALD)

Electrochemical Reduction

Chemical Reduction

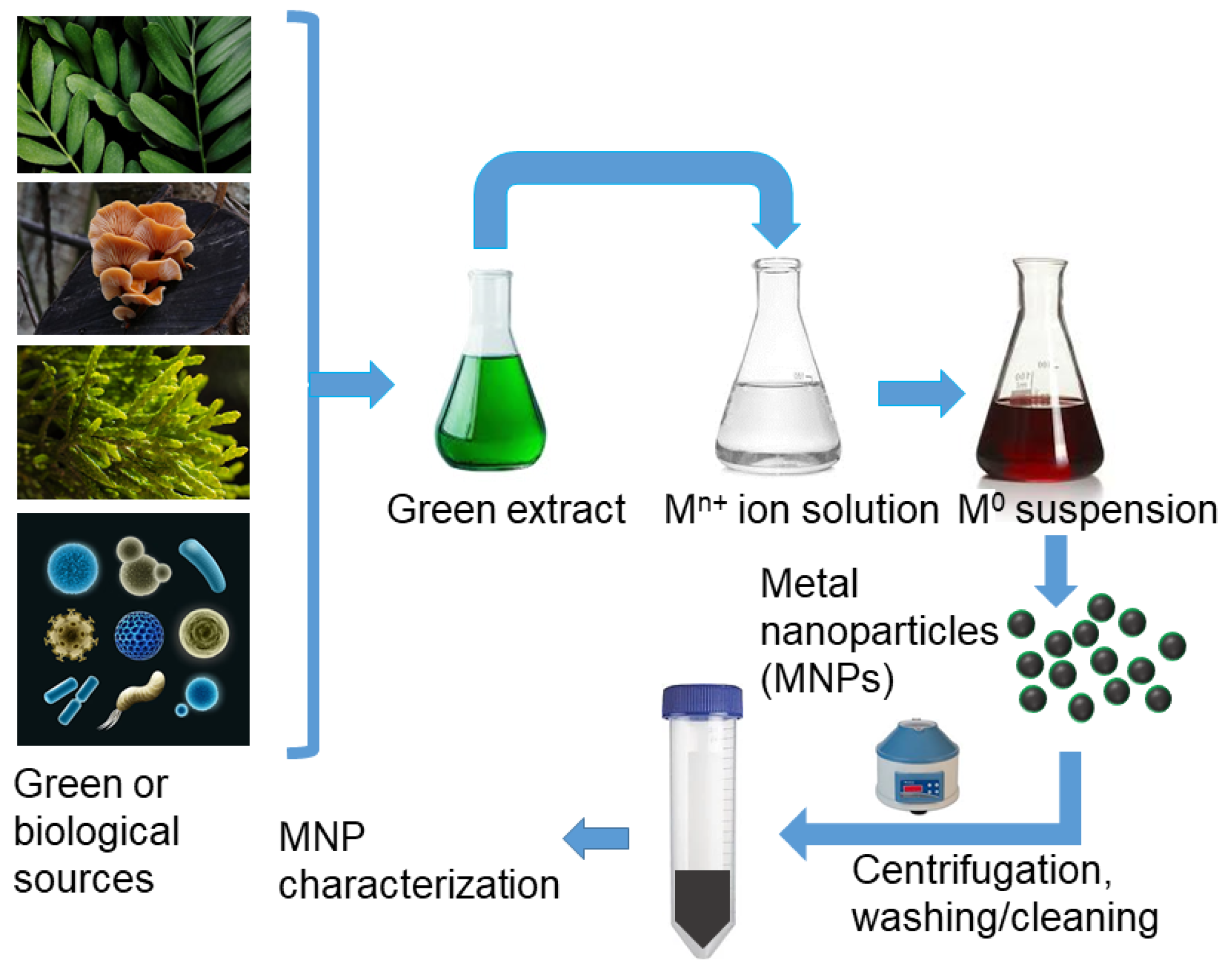

3.2.3. Biological or “Green” Synthesis

4. Antifungal Mechanisms of Metal Nanoparticles

- (a)

- The fungal cell wall undergoes changes and damage, including surface shrinkage, cell aggregation, pit and pore formation, and general deformation. Internalization of the NPs into fungal cells occurs through three principal mechanisms: (i) direct penetration of NPs through the cell wall, (ii) specific receptor-mediated adsorption followed by internalization, and (iii) uptake through ion transport proteins. During adsorption, NPs can embed within fungal cell walls, which induces morphological and functional changes [250]. Additionally, the NPs can release metal ions from the extracellular space. These ions can enter the fungal cell, thereby disrupting its biological processes [191].

- (b)

- The metal ions will contribute to the formation of NPs intracellularly through reduction processes by cellular organic compounds [251]. The fungal cell wall plays a critical role in various processes, including fungal growth and defense, morphogenesis, and biofilm formation. The primary functions of the cell include buffering fluctuations in osmotic pressure, sensing external stimuli, and protecting against detrimental conditions such as dryness, heat, and toxic molecules. The cell wall plays a pivotal role in the pathogenicity and virulence of pathogenic fungi, aiding in their invasion while protecting the fungus from host defense mechanisms [191]. The cell wall, a structural component of cells, appears to be a rigid structure; nevertheless, it is dynamic and is subject to constant remodeling due to several factors. These include fungal growth, which encompasses processes such as expansion, sporulation, and branching, as well as environmental challenges. The process of binary fission, also known as the expansion of hyphae, is contingent upon the concurrent activity of anabolic and catabolic enzymes. Therefore, based on the composition of the fungal cell wall, it can be concluded that the structure provides an optimal target for antifungal MNPs [191].

- (c)

- The disruption of the cell membrane is a consequence of the interaction between MNPs and the fungal cell membrane, leading to structural damage. As Slavin’s hypothesis states [191], positively charged metal-based NPs establish a robust bond with cell membranes, thereby increasing membrane permeability. This process facilitates the diffusion of essential ions and molecules, ultimately resulting in the demise of fungal cells.

- (d)

- The internal membranes are distorted, and there is an alteration in the organelle disposition. This phenomenon is evidenced by an increase in the intracellular vesicle and vacuole count and a decrease in cytoplasmic content. The loss of intracellular structure results in the accumulation of cytoplasm within the cell, accompanied by an apparent absence of organelles. This complicates the process of distinguishing between the cytoplasm, plasma membrane, and cell wall boundaries after exposure to NPs.

- (e)

- The underlying mechanism of this complication is the alteration of these structures by NPs, thereby obscuring the boundaries [185,190,251,252,253]. The generation of reactive oxygen species (ROS) is an inherent process within the human body. In the cell, the presence of metal ions or NPs has been observed to trigger the generation of ROS, which includes superoxide radicals and hydrogen peroxide. It has been demonstrated that ROS play a critical role in the antifungal activity mechanism of NPs. These substances have been demonstrated to induce oxidative stress in fungal cells. The oxidative stress can suppress the antioxidant defense mechanism of the fungus against ROS. Subsequently, these metal ions have been demonstrated to interact with cellular structures, thereby inducing damage to cellular components such as proteins, lipids, and DNA, which ultimately results in cell death [254,255].

- (f)

- Interaction with the fungal DNA is indicated herein. MNPs have been observed to penetrate fungal cells and interact with the DNA. The NPs can bind to the genetic material (which is negatively charged), resulting in structural damage, DNA fragmentation, or hindrance to DNA replication and transcription. This, in turn, disrupts the ability of the fungi to proliferate [191]. In addition, the NPs can induce mitochondrial DNA fragmentation, ribosome depolymerization, cellular dysfunction, and apoptosis [191]. The inhibition of enzyme activity is a consequence of the presence of MNPs within the fungal cell, thereby interfering with the function of the enzymes contained within. MNPs can bind to sulfhydryl groups on enzymes, thereby inhibiting their normal function and resulting in metabolic disruptions [118,256]. Metal ions have been observed to form strong coordination bonds with N, O, or S atoms. These atoms are found in abundance in organic compounds and biomolecules. Given the non-specific nature of the bond between metal ions and biomolecules, metal-based NPs typically demonstrate a broad spectrum of activities. It has been demonstrated that AgNPs exhibit reduced chemical reactivity in comparison to Ag+ ions. The interaction of Ag+ ions with a diverse array of biomolecules within the cell has been well documented, including nucleic acids, components of the cell wall, sulfhydryl groups of metabolic enzymes, and sulfur-containing cell components [257].

- (g)

5. Main Metal and Metal Oxide NPs Tested Against Toxigenic Fungi and Mycotoxin Production

5.1. Silver Nanoparticles

| Nanoparticle Properties | Antifungal Properties | |||||

|---|---|---|---|---|---|---|

| Synthesis Method | Size (nm) | Shape | Fungal Species | Methodology | Growth Reduction/(%)/Treatment | Ref. |

| Chemical | 14–100 (30) | Spherical | F. graminearum, F. culmorum, F. sporotrichioides, F. langsethiae, F. poae, F. oxysporum, F. proliferatum, F. verticillioides | Medium: Maize-based medium. Inoculum: From a spore suspension (1 × 105 spores/mL) previously treated with AgNPs for 2, 10, 20, and 30 h. AgNP concentration: 2, 5, 10, 15, 30, and 45 ppm. Incubation: 28–25 °C, 10 days. Fungal growth record: Spore viability (sv) and colony diameter (cd). | 100% (sv, cd)/2.0 ppm (30 h), 100% (sv, cd)/15.0 ppm (30 h), 100% (sv, cd)/10.0 ppm (30 h), 100% (sv, cd)/2.0 ppm (30 h), 100% (sv, cd)/2.0 ppm (30 h), 100% (sv, cd)/45.0 ppm (30 h), 100% (sv, cd)/30.0 ppm (30 h), 100% (sv, cd)/30.0 ppm (30 h). For each species, respectively | [275] |

| Chemical | 14–100 (30) | Spherical | A. flavus, A. parasiticus, A. carbonarius, A. niger, A. ochraceus, A. steynii, A. westerdijkiae, P. verrucosum | Medium: Maize-based medium. Inoculum: From a spore suspension (1 × 105 spores/mL) previously treated with AgNPs for 2, 10, 20, and 30 h. AgNP concentration: 2, 5, 10, 15, 30, and 45 ppm. Incubation: 20–37 °C, 10 days. Fungal growth record: Spore viability (sv) and colony diameter (cd). | 100% (sv, cd)/15.0 ppm (30 h), 100% (sv, cd)/30.0 ppm (30 h), 100% (sv, cd)/10.0 ppm (30 h), 100% (sv, cd)/15.0 ppm (30 h), 100% (sv, cd)/5.0 ppm (30 h), 100% (sv, cd)/5.0 ppm (30 h), 100% (sv, cd)/5.0 ppm (30 h), 100% (sv, cd)/15.0 ppm (30 h). For each species, respectively | [238] |

| Chemical | 20 | Spherical | A. parasiticus | Medium: Potato Dextrose Agar (PDA), Czapeck Dox Agar (CZA), Potato Dextrose Broth (PDB), and Czapeck Dox Broth (CZB). Inoculum: From a spore suspension (1 × 105 spores/mL) previously treated with AgNPs for 2, 10, 20, and 30 h. AgNP concentration: 25, 50, 100, and 200 ppm. Incubation: 28 °C, 7 days. Fungal growth record: Colony diameter (cd) and mycelium weight (mw). | 34% and 41% (cd)/200 ppm (in PDA and CZA, respectively) 92% (mw)/250 ppm (in both PDB and CZB) | [276] |

| Chemical | ∼7.5 | Spherical | Gibberella fujikuroi | Medium: PDA. Inoculum: From a spore suspension (7 × 104 spores/mL) previously treated with AgNPs for 1, 10, and 20 min. AgNP concentration: 0.00015, 0.0015, 0.015, 0.15, 1.5, 15, and 150 ppm. Incubation: 25 °C, 3 days. Fungal growth record: CFU. Medium: PDA. Inoculum: Rice seeds previously dipped in a spore suspension (5 × 105 spores/mL). AgNP concentration: Solution of 150 ppm (rice seeds previously infected with fungal spores are immersed in this solution for 1/6, 1/3, 1/2, 1, 3, 6, or 24 h). Incubation: 25 °C, 3 days. Fungal growth record: CFU (on seed surface). | 50% CFU/0.15–1.5 ppm (1 min) 100% CFU/≥ 1.5 ppm (1 min) 96.2% CFU/150 ppm (≥10 min) | [286] |

| Chemical | 25 ± 2.6 | Spherical | P. digitatum, P. italicum | Medium: PDA. Inoculum: From a spore suspension (1 × 106 spores/mL) previously treated with AgNPs for 24 h. AgNP concentration: 1–10 ppm. Incubation: 22 ± 1 °C, 4 days. Fungal growth record: CFU. Medium: Lemons. Inoculum: From a spore suspension (1 × 106 spores/mL) previously treated with AgNPs for 24 h. Concentration of AgNPs: 1–10 ppm. Incubation: 20 °C, 95% RH, 5–14 days. Fungal growth record: Lemon disease incidence. | 100% CFU/10 ppm (24 h) 100%/10 ppm/24 h) | [287] |

| Chemical | 17 ± 1.5 | Spherical | F. verticillioides | Medium: Nutrient Broth (according to CLSI for filamentous fungi). Inoculum: From a spore suspension (2 × 104 spores/mL). AgNP concentration: 5–200 ppm. Incubation: 25 °C, 48 h. Fungal growth record: MIC. | 100% (MIC)/75 ppm | [285] |

| Chemical | 12 ± 4 | F. avenaceum, F. equiseti | Medium: PDA. Inoculum: From a spore suspension (—) previously treated with AgNPs for 24–240 h. AgNP concentration: 2.5, 5, and 10 ppm. Incubation: 21 °C, 168 h. Fungal growth record: Colony diameter. | ∼25%/10 ppm (168 h) ∼43%/10 ppm (168 h) For each species, respectively | [270] | |

| Biological (Penicillium chrysogenum, Fusarium chlamydosporum) | 9–17.5 6–26 | Spherical Spherical | A. flavus, A. ochraceus | Medium: CZA. Inoculum: From a spore suspension (2 × 106 spores/mL). AgNP concentration: 10–50 ppm. Incubation: 30 °C, 16 h. Fungal growth record: Spore germination. | 100%/45–48 ppm 100%/47–51 ppm For each species, respectively | [284] |

| Biological (Aspergillus terreus) | 5–30 | Spherical | A. flavus (5 strains) | Medium: PDA. Inoculum: Agar plugs (6 mm) from a fungal culture. AgNP concentration: 50, 100, and 150 ppm. Incubation: 25 ± 2 °C, 7 days. Fungal growth record: Colony diameter. | 8.9–21.1%/50 ppm 43.3–54.8%/100 ppm 71.1–86.3%/150 ppm | [277] |

| Biological (Fusarium oxysporum) | 93 ± 11 | Spherical | A. flavus, A. melleus, A. nomius, A. ochraceus, A. parasiticus | Medium: Nutrient Broth and Sabouraud Dextrose Agar (SDA). Inoculum: From a spore suspension (1 × 105 spores/mL). AgNP concentration: 0.26–135 ppm. Incubation: 30 °C, 72 h. Fungal growth record: MIC and MFC (<3 colonies/plate). | MIC and MFC/8 and 64 ppm, MIC and MFC/4 and 16 ppm, MIC and MFC/8 and 32 ppm, MIC and MFC/4 and 16 ppm, MIC and MFC/8 and 32 ppm For each species, respectively | [288] |

| Biological (Malva parviflora L.) | 50.6 | Spherical | F. solani, F. oxysporum, A. alternata | Medium: PDA. Inoculum: Agar plugs (6 mm) from a fungal culture. AgNP concentration: 50,000 ppm. Incubation: 25 ± 2 °C, 7–9 days. Fungal growth record: Colony diameter. | 81.1%/50,000 ppm, 80.7%/50,000 ppm, 83.0%/50,000 ppm, For each species, respectively | [289] |

| Biological (Honeybee) | — | Cubic | F. avenaceum, F. culmorum, F. graminearum, F. oxysporum, F. poae, F. proliferatum, F. pseudograminearum, F. sambucinum, F. semitectum, F. sporotrichioides, F. verticillioides | Medium: PDA. Inoculum: From a spore suspension (2.5 × 103 spores/mL) (well diffusion method). AgNP concentration: 5, 25, 50, 75, and 100 ppm. Incubation: 25 ± 2 °C, 7 days. Fungal growth record: Growth reduction (%). | 3.3 ± 0.0–31.2 ± 0.0%/5–100 ppm, 2.2 ± 0.0–36.8 ± 0.3%/5–100 ppm, 2.2 ± 0.0–25.8 ± 0.1%/5–100 ppm, 1.1 ± 0.0–16.8 ± 0.2%/5–100 ppm, 2.2 ± 0.1–26.8 ± 0.2%/5–100 ppm, 2.2 ± 0.1–23.4 ± 0.2%/5–100 ppm, 4.4 ± 0.2–27.8 ± 0.1%/5–100 ppm, 4.4 ± 0.2–31.2 ± 0.2%/5–100 ppm, 3.3 ± 0.1–25.6 ± 0.2%/5–100 ppm, 2.2 ± 0.1–18.9 ± 0.3%/5–100 ppm, 2.2 ± 0.0–28.9 ±0.4%/5–100 ppm, For each species, respectively | [278] |

| Biological (Chaetomium globosum) | 11–14 | Spherical | F. oxysporum | Medium: PDA, Corn Meal Agar (CMA), and Malt Extract Agar (MEA). Inoculum: —. AgNP concentration: 50, 100, and 500 ppm. Incubation: 28–30 °C, 7 days. Fungal growth record: Colony diameter and CFU. Medium: Tomato seeds. Inoculum: —. AgNP concentration: 500 ppm. Incubation: 28–30 °C, 4 h. Fungal growth record: Seedlings wilt. | 88% (cd)/500 ppm 100% (CFU)/500 ppm Complete inhibition of seedlings wilt/500 ppm. | [290] |

| Biological (Epifocal nigrum) | 1–22 | Spherical | A. flavus | Medium: Nutrient Broth (documents M27-A, M38-A). Inoculum: From a spore suspension (2.5–5 ×103 spores/mL). AgNP concentration: 0.125–64 ppm. Incubation: 25 °C, 48 h. Fungal growth record: MIC (reduction of fungal growth by 80%). | 80%/5 ppm | [291] |

| Biological (Tropaeolum majus) | — | Spherical | A. niger | Medium: Nutrient Broth + resazurin indicator solution. Inoculum: From a spore suspension (5 × 106 spores/mL). AgNP concentration: 1–500 ppm. Incubation: —. Fungal growth record: At a glance. | 100%/≥ 31.2 ppm | [292] |

| Biological (Trichoderma harzianum) | — | — | F. moniliforme | Medium: PDA, CZA, Yeast Dextrose Agar (YES). Water Agar (WA). Inoculum: Agar plugs (5 mm) from a fungal culture. Concentrations of AgNPs: 0–800 ppm. Incubation: 25 ± 2 °C, 5 days. Fungal growth record: Colony diameter. | 0–60.04%/0–800 ppm | [293] |

| Biological (Geranium leaves) | 38.5 ± 18.5 | Spherical | F. oxysporum f. sp. lycopersici | Medium: PDA. Inoculum: Agar plugs (6 mm) from a fungal culture. AgNP concentration: 10, 20, 40, 75, and 150 ppm. Incubation: 27 ± 2 °C, 7 days. Fungal growth record: Colony diameter. Medium: PDB. Inoculum: From a spore suspension (1 × 104 spores/mL). AgNP concentration: 10, 20, 40, 75, and 150 ppm. Incubation: 27 ± 2 °C, 72 h. Fungal growth record: MIC. Medium: Tomatoes. Inoculum: From a spore suspension (1.5 × 105 spores/mL). AgNP concentration: 10, 20, 40, 75, and 150 ppm. Incubation: 27 ± 2 °C, 6 days. Fungal growth record: Tomato disease incidence. | 94.6%/150 ppm 100%/75 ppm 100%/10–100 ppm | [294] |

| Biological (Althaea officinalis, Thymus vulgaris, Mentha pulegium) | 50 50 50 | Spherical Spherical Spherical | A. flavus, P. chrysogenum | Medium: PDA. Inoculum: From a spore suspension (1 × 105 spores/mL, disk diffusion method). AgNP concentration: suspension 1 mM. Incubation: 26–27 °C, 60 h. Fungal growth record: Diameter inhibition zone. | 35–36 mm/1 mM 36–37 mm/1 mM For each species, respectively | [295] |

| Biological (Arthroderma fulvum) | 15.5 ± 2.5 | Spherical | A. flavus, A. terreus, F. solani, F. moniliforme, F. oxysporum | Medium: Nutrient broth (document M38-A2). Inoculum: From a spore suspension (1.0–2.0 × 104 spores/mL). AgNP concentration: 0.125–64 ppm. Incubation: 28 °C, 48 h. Fungal growth record: MIC (reduction of fungal growth by 80%). | 80%/2.00 ppm, 80%/1.00 ppm, 80%/2.00 ppm, 80%/4.00 ppm, 80%/2.00 ppm, For each species, respectively | [296] |

| Biological (Amaranthus retroflexus) | 10–32 | Spherical | A. alternata, F. oxysporum | Medium: PDA. Inoculum: Agar plugs (5 mm) from a fungal culture. AgNP concentration: 50, 100, 200, and 400 ppm. Incubation: 25 °C, 5 days. Fungal growth record: Colony diameter. | 50%/337.09 ± 19.72 ppm, 50%/328.05 ± 13.29 ppm, For each species, respectively | [297] |

| Biological (Phyllanthus urinaria, Pouzolzia zeylanica, Scoparia dulcis) | 28.3 26.7 <26.7 | Spherical Spherical, hexagonal, triangle, etc. Spherical | A. niger, A. flavus, F. oxysporum | Medium: PDA. Inoculum: Colonies from fungal cultures. AgNP concentration: 15, 30, and 45 ppm. Incubation: Room temperature, 4 days. Fungal growth record: Colony diameter. | 40–60%/45 ppm Depending on the fungal species | [298] |

| Biological (Aspergillus terreus) | 15–29 | Spherical | F. solani, A. alternata, A. flavus, A. ochraceus | Medium: CZA. Inoculum: –. AgNP concentration: 1 mM, 2 mM, 5 mM, 10 mM, and 20 mM (wells, 7 mm). Incubation: 28 °C, 3–5 days. Fungal growth record: Diameter inhibition zone. | 3–13 mm/0.84–1.68 ppm | [299] |

| Biological (Trichoderma longibrachiatum) | 5–30 (10) | Spherical | A. alternata, F. verticillioides, F. moniliforme, A. flavus, P. brevicompactum | Medium: PDA. Inoculum: From a spore suspension treated with 0.5 mM AgNPs. AgNP concentration: 0.5 mM. Incubation: 28 °C, 24 h. Fungal growth record: CFU. | 93.0%/0.5 mM, 96.4%/0.5 mM, 93.6%/0.5 mM, 86.7%/0.5 mM, 92.9%/0.5 mM, For each species, respectively | [300] |

| Biological (Momordica charantia, Psidium guajava) | 5–29 (17) 5–53 (25.7) | Spherical Spherical | A. niger, A. flavus, F. oxysporum | Medium: PDA. Inoculum: –. AgNP concentration: 20 and 40 ppm. Incubation: 30 °C, 24–96 h. Fungal growth record: Colony diameter. | <50%/40 ppm (96 h) | [301] |

| Biological (Cryptococcus laurentii, Rhodotorula glutinis) | 15–400 | Spherical | P. expansum, A. niger, Alternaria sp. | Medium: PDA. Inoculum: From a spore suspension (2.0 × 106 spores/mL) (wells of 3 mm). AgNP concentration: 3 ppm. Incubation: 28 ± 4 °C, 7 days. Fungal growth record: Diameter inhibition zone. | 11.1 ± 1.4 mm/3 ppm, 14.8 ± 2.2 mm/3 ppm, 11.3 ± 1.6 mm/3 ppm, For each species, respectively | [302] |

| Biological (Pseudomonas poae) | 19.8–44.9 | Spherical | F. graminearum | Medium: PDA and PDB. Inoculum: Agar plugs (5 mm) from a fungal culture. AgNP concentration: 5, 10, 15, and 20 ppm. Incubation: 28 °C, 5 days. Fungal growth record: Colony diameter in PDA and mycelium growth in PDB. | PDA: 45.56%/5 ppm 62.22%/10 ppm 72.78%/15 ppm 80.56%/20 ppm PDB: 48.56%/5 ppm 65.11%/10 ppm 75.50%/15 ppm 85.78%/20 ppm | [279] |

| Biological (Alternaria sp.) | 3–10 | Spherical | F. oxysporum, F. moniliforme, F. tricinctum, Alternaria sp. | Medium: PDA. AgNP concentration: 1000 ppm (25, 50, and 100 µL (wells 8 mm). Inoculum: —. Incubation: 28 ± 1 °C, 5 days. Fungal growth record: Diameter inhibition zone. | 14.7–21.3 mm/1000 ppm, 9–21.6 mm/1000 ppm, 11–21.2 mm/1000 ppm, 17.1–21.6 mm/1000 ppm, For each species, respectively | [303] |

| Biological (Penicillium verrucosum) | 10–12 | Spherical | A. flavus, F. chlamydosporum | Medium: PDA. Inoculum: Agar plugs (3 mm) from a fungal culture. AgNP concentration: 50, 100, 150, and 200 ppm. Incubation: 27 ± 2 °C, 7 days. Fungal growth record: Colony diameter. | 59.13%/200 ppm, 56.67%/200 ppm, For each species, respectively | [304] |

| Biological (Rhizoctonia solani, Cladosporium cladosporioides) | 80–100 | Spherical | A. flavus, P. citrinum, F. oxysporum | Medium: Sabouraud Dextrose Agar (SDA). Inoculum: —. AgNP concentration: 5000, 10,000, 15,000 ppm (wells 5 mm). Incubation: —. Fungal growth record: Diameter inhibition zone. | 15–21 mm/5000–15,000 ppm, 8–17 mm/5000–15,000 ppm, 8.33–13.33/5000–15,000 ppm, For each species, respectively | [305] |

| Biological (Trigonella foenum-graecum) | 20–25 | Spherical and cubic | A. alternata | Medium: PDA. Concentration of AgNPs: 100 ppm. Inoculum: —. Incubation: —. Fungal growth record: Colony diameter. | 40–50%/100 ppm | [306] |

| Biological (Nigrospora oryzae) | 3–13 | Spherical | F. sporotrichioides, F. oxysporum, F. moniliforme, F. solani, F. anthophilium | Medium: CZA and PDA. Inoculum: Agar plugs (4 mm) from a fungal culture. AgNP concentration: 50, 100, 150, and 200 ppm. Incubation. 28 ± 2 °C, 5 days. Fungal growth record: Colony diameter. | 50–70%/200 ppm Depending on the species | [307] |

| Biological (Allium cepa, Zingiber officinale, Allium sativum) | 1–9 1–6 2–10 | Spherical | F. graminearum, F. avenaceum, F. culmorum | Medium: PDB. Inoculum: —. AgNP concentration: 10, 30, 50, 70, 90, 110, 130, and 150 ppm. Incubation: 28 °C, 2 days. Fungal growth record: MIC. | 100%/90–110 ppm, 100%/90–110 ppm, 100%/110 ppm, For each species, respectively | [308] |

| Biological (Honey) | 9.9 | Spherical | A. parasiticus, A. ochraceus | Medium: PDA. Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 10, 20, 30, and 40 µg/well (well diffusion technique). Incubation: 28 °C, 3 days. Fungal growth record: Diameter inhibition zone. | 24.2 ± 0.77 mm/40 µg, 28.2 ± 1.04 mm/40 µg For each species, respectively | [280] |

| Biological (Penicillium expansum, Aspergillus terreus) | 14–25 10–18 | Spherical Spherical | A. ochraceus, A. parasiticus, A. niger | Medium: PDA. Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 3, 6, and 9 μg/well (5 mm). Incubation: 28 °C, 3 days. Fungal growth record: Diameter inhibition zone. | 16.33 ± 96 mm/9 μg/well, No detected, 10.1–11.3 mm/6–9 μg/well For each species, respectively | [281] |

| Biological (Viola odorata) | 18 | Spherical | F. oxysporum f. sp. radicis-lycopersici | Medium PDA. Inoculum: Agar plugs (5 mm) from a fungal culture. AgNP concentration: 600 ppm. Incubation: 28 °C, 7 days. Fungal growth record: Colony diameter. Medium: Tomato plants. Inoculum: From a spore suspension (1.5 × 104 spores/mL) (30 mL/plant). AgNP concentration: 60 ppm. Incubation: 24 °C ± 5 °C and photoperiod, 7 days. Fungal growth record: Percentage of plants that survive. | ∼50%/600 ppm 80%/solution of 60 ppm | [309] |

| Commercial | — | — | A. parasiticus | Medium: PDB. Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 60, 80, 100, 120, 140, 160, 180, and 200 ppm. Incubation: 28 °C, 96 h, 130 rpm. Fungal growth record: At a glance. | 100%/180 ppm | [282] |

| Commercial | 200– ≤0.65 | Spherical | P. verrucosum | Medium: Malt Extract Broth. Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 1–100 ppm. Incubation: 25 °C, 7 days. Fungal growth record: GNU Image Analysis Program GIMP 2.8.10. | 100% spore germination/>2 ppm (AgNPs 0.65 nm) 100% fungal growth/>5 ppm (AgNPs 5 nm) | [283] |

| Commercial | 2.0 | — | F. graminearum | Medium: PDA. Inoculum: Agar plugs (5 mm) from a fungal culture. AgNP concentration: 1, 1.5, 2, 3, 6, 8, and 10 ppm. Incubation: 25 °C, 2–3 days. Fungal growth record: Colony diameter. | 50%/1.88 ppm 90%/1.15 ppm | [186] |

| Commercial Argovit-1220 Argovit-1221 Argovit-C | 8–80 8.5 ± 3.3 14.95 ± 10.1 | Spherical, Pyramidal Spherical, Spherical | F. oxysporum f. sp. cubense | Medium: Mueller Hinton Broth + resazurin. Inoculum: From a spore suspension (1 × 104 spores/mL). AgNP concentration: 0.8, 1.6, 3.1, 6.3, 12.5, 25, 50, and 100 ppm. Incubation: 28 °C, 3 days. Fungal growth record: Mycelial growth. | 50%/3.1–6.3 ppm >90%/25–50 ppm Depending on commercial AgNPs | [310] |

| Commercial | 7–25 | A. alternata, F. oxysporum f. sp. cucumerinum, F. oxysporum f. sp. lycopersici, F. oxysporum, F. solani | Medium: PDA, MEA, and CMA (Corn Meal Agar). AgNP concentration: 10, 25, 50, and 100 ppm. Inoculum: Agar plugs (8 mm) from fungal cultures. Incubation: 28 ± 2 °C, 14 days. Fungal growth record: Colony diameter. | PDA 81.1%/100 ppm, 59.5%/100 ppm, 89.6%/100 ppm, 84.0%/100 ppm, 80.7%/100 ppm, For each strain, respectively MEA 65.35%/100 ppm, 36.5%/100 ppm, 26.5%/100 ppm, 21.2%/100 ppm, 52.9%/100 ppm, For each strain, respectively CMA 77.6%/100 ppm, 76.5%/100 ppm, 80.0%/100 ppm, 68.2%/100 ppm, 81.2%/100 ppm, For each strain, respectively | [311] | |

| Commercial | — | — | F. oxysporum | Medium: PDA. Inoculum: Agar plugs (3 mm) from a fungal culture. AgNP concentration: 5, 15, 25, and 35 ppm. Incubation: 22 °C, 14 days. Fungal growth record: Colony diameter. | 32.6%/35 ppm | [312] |

| Nanoparticle Properties | Anti-Mycotoxin Properties | |||||

|---|---|---|---|---|---|---|

| Synthesis Method | Size (nm) | Shape | Fungal Species (Mycotoxin Production) | Methodology | Mycotoxin/Reduction (%)/Treatment | Ref. |

| Chemical | 14–100 (30) | Spherical | F. graminearum (DON, 3-AcDON, ZEA), F. culmorum (DON, 3-AcDON, ZEA), F. sporotrichioides (T-2, HT-2), F. langsethiae (T-2, HT-2), F. poae (NIV), F. proliferatum (FB1, FB2), F. verticillioides (FB1, FB2) | Medium: Maize-based medium. Inoculum: From a spore suspension (1 × 105 spores/mL) previously treated with AgNPs for 2, 10, 20, and 30 h. AgNP concentration: 2, 5, 10, 15, 30, and 45 ppm. Incubation: 25–28 °C, 10 days. Mycotoxins analysis: UPLC-MS/MS. | DON/100%/2–15 ppm, 30 h, 3 AcDON/100%/2–15 ppm, 30 h, ZEA/100%/2–15 ppm. 30 h, T-2/100%/2 ppm, 30 h, HT-2/100%/2 ppm, 30 h, NIV/100%/2 ppm, 30 h, FB1/100%/30 ppm, 30 h, FB2/100%/30 ppm, 30 h, Depending on species and mycotoxin | [275] |

| Chemical | 14–100 (30) | Spherical | A. flavus (AFB1, AFB2), A. parasiticus (AFB1, AFB2, AFG1, AFG2), A. carbonarius (OTA), A. niger (OTA), A. ochraceus (OTA), A. steynii (OTA), A. westerdijkiae (OTA), P. verrucosum (OTA) | Medium: Maize-based medium. Inoculum: From a spore suspension (1 × 105 spores/mL) previously treated with AgNPs for 2, 10, 20, and 30 h. AgNP concentration: 2, 5, 10, 15, 30, and 45 ppm. Incubation: 20–37 °C, 10 days. Mycotoxins analysis: UPLC-MS/MS. | AFB1/100%/15–30 ppm, 30 h, AFB2/100%/15–30 ppm, 30 h, AFG1/100%/30 ppm, 30 h, AFG2/100%/30 ppm, 30 h, OTA/100%/5–15 ppm, 30 h, Depending on species and mycotoxin | [238] |

| Chemical | 20 | Spherical | A. parasiticus (AFB1, AFB2, AFG1, AFG2) | Medium: YES. Inoculum: From a spore suspension (1 × 105 spores/mL). AgNP concentration: 25, 50, 100, and 200 ppm. Incubation: 28–30 °C, 14 days. Aflatoxin analysis: HPLC. | AFB1/6%/200 ppm, AFB2/57.3%/200 ppm, AFG1/20.4%/200 ppm, AFG1/95.8%/200 ppm | [276] |

| Chemical | 17 ± 1.5 | Spherical | F. verticillioides (FB1) | Medium: Nutrient Broth (according to CLSI for filamentous fungi). Inoculum: From a spore suspension (2 × 104 spores/mL). AgNP concentration: 5–200 ppm. Incubation: 28 °C, 14 days. FB1 analysis: HPLC. | FB1/100%/75 ppm | [285] |

| Biological (Aspergillus terreus) | 5–30 | Spherical | A. flavus (AFB1) (5 strains) | Medium: SMKY broth. Inoculum: Agar plugs (6 mm) from a fungal culture. AgNP concentration: 50, 100, and 150 ppm. Incubation: 25 ± 2 °C, 20 days. Aflatoxin analysis: –. | AFB1/48.2–61.8%/50 ppm, AFB1/64.1–82.2%/100 ppm, AFB1/75.9–100%/150 ppm, Depending on the strain | [277] |

| Biological (Honeybee) | 20–60 | Cubic | F. avenaceum (DON), F. proliferatum (DON), F. sambucinum (DON), F. verticilliodes (DON), F. semitectum (DON), | Medium: SMKY broth. Inoculum: From a spore suspension (2.5 × 103 spores/mL). AgNP concentration: 5, 25, 50, 75, and 100 ppm. Incubation: 25 ± 2 °C, 10 days. DON analysis: ELISA. | DON/0.03–22%/5 ppm, DON/5.61–8.46%%/25 ppm, DON/25.40–34.44%/50 ppm, DON/25.75–34.60%/75 ppm, DON/25.49–34.89%/100 ppm, For each species, respectively | [278] |

| Biological (Pseudomonas poae) | 19.8–44.9 | Spherical | F. graminearum (DON) | Medium: GYEP. Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 5, 10, 15, and 20 ppm. Incubation: 28 °C, 7 days. DON analysis: ELISA. | DON/33%/5 ppm, DON/53%/10 ppm, DON/73%/15 ppm, DON/83%/20 ppm | [279] |

| Biological (Honey) | 9.9 | Spherical | A. parasiticus (AFB1, AFB2, AFG1, AFG2), A. ochraceus (OTA) | Medium: Yeast Extract Sucrose (YES). Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 10, 20, and 30 ppm. Incubation: 28 °C, 14 days. Aflatoxins B1, B2, G1 and G2, and OTA. analysis: HPLC. | AFB1/58.76%/30 ppm, AFB2/66.56%/30 ppm, AFG1/77.55%/30 ppm, AFG2/62.91%/30 ppm, OTA/79.85%/30 ppm | [280] |

| Biological (Penicillium expansum, Aspergillus terreus) | 14–25 10–18 | A. ochraceus (OTA) | Medium: YES Broth. Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 0.5, 1.1, and 2.2 ppm. Incubation: 28 °C, 14 days. OTA analysis: HPLC. | OTA/58.87–52·18%/2.2 ppm | [281] | |

| Biological synthesis (Green and black teas) | 10–20 | Spherical | A. flavus (Aflatoxins) A. parasiticus (Aflatoxins) | Medium: (CZA) Czapek’s Agar. Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 10, 25, 50, 100 ppm. Incubation: 25 ± 2 °C, 15 days. Aflatoxin analysis: HPLC. | Aflatoxins/100%/100 ppm | [313] |

| Biological synthesis (Syzygium cumini) | 11–19 | Spherical | A. flavus (Aflatoxins) A. parasiticus (Aflatoxins) | Medium: Czapek Dox Broth (CZB). Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 25, 50, 100 ppm. Incubation: 25 ± 2 °C, 15 days. Aflatoxin analysis: HPLC. | Aflatoxins/100%/100 ppm | [314] |

| Commercial | — | — | A. parasiticus (AFB1) | Medium: PDB. Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 45, 90, 100, 135, ppm. Incubation: 28 °C, 7 days, 130 rpm. AFB1 analysis: HPLC. | AFB1/50%/90 ppm AFB1/100%/100 ppm | [282] |

| Commercial | 200– ≤0.65 | Spherical | P. verrucosum (OTA, CIT) | Medium: MEA-liquid-medium. Inoculum: From a spore suspension (1 × 106 spores/mL). AgNP concentration: 1–100 ppm. Incubation: 25 °C, 7 days. OTA and CIT analysis: HPLC. | DON/100%/5 ppm (AgNPs 5 nm) CIT/100%/5 ppm (AgNPs 5 nm) | [283] |

| Commercial | 2.0 | — | F. graminearum (DON) | Medium: Toxin biosynthesis inducing (TBI) broth medium. Inoculum: Agar plugs (5 mm) from a fungal culture. AgNP concentration: 1, 1.5, 2, 3, 6, 8, and 10 ppm. Incubation: 25 °C, 2 + 6 days. DON analysis: kit Wis008 (Wise Science, Zhenjiang, China). | DON/Increase 50%/1.15 ppm DON/Increase > 50%/1.88 ppm | [185] |

5.2. Copper Nanoparticles

| Nanoparticle Properties | Antifungal Properties | |||||

|---|---|---|---|---|---|---|

| Synthesis Method | Size (nm) | Shape | Fungal Species | Methodology | Growth Reduction (%)/Treatment | Ref. |

| Chemical | 3–10 | Spherical | A. alternata, F. oxysporum | Medium: PDA. Inoculum: —. CuNP concentration: 20 μg/disc (disc diffusion method. Incubation: 28 °C, 2–3 days. Fungal growth record: Diameter inhibition zone. | 18 ± 1.1 mm/20 μg/disc, 24 ± 0.5 mm/20 μg/disc, For each species, respectively | [326] |

| Chemical | 100–500 | Flower | A. niger, F. moniliforme, F. culmorum, F. oxysporum, F. tricinctum | Medium: PDA. Inoculum: —. CuNP concentration: 100 mM (disc diffusion method). Incubation: 28 ± 2 °C, 2–3 days. Fungal growth record: Diameter inhibition zone. | ∼0–30 mm/100 mM Depending on the fungal species | [327] |

| Chemical | 14–37 | Truncated, octahedrons | F. oxysporum | Medium: PDA. Inoculum: From a spore suspension (1 × 106 spores/mL). CuNP concentration: 100, 250, and 500 ppm. Incubation: 29 °C, 6 days. Fungal growth record: Colony diameter. | 90–100%/500 ppm | [328] |

| Chemical | 50 | Spherical | A. flavus, P. chrysogenum | Medium: PDA. Inoculum: From a spore suspension (1 × 105 spores/mL). CuNP concentration: 1 mM. Incubation: 26–27 °C, 60 h. Fungal growth record: Diameter inhibition zone. | 24–27 mm/1 mM | [295] |

| Chemical | 20–50 | Spherical | Fusarium sp. | Medium: PDA (+ chloramphenicol). Inoculum: —. CuNP concentration: 300, 380, and 450 ppm. Incubation: —, 9 days. Fungal growth record: Colony diameter. | 67.38%/450 ppm (3 days) 93.98%/450 ppm (9 days) | [329] |

| Chemical | 200–500 | — | F. oxysporum f. sp. lycopersici | Medium: PDA. Inoculum: From a spore suspension (1 × 106 spores/mL). CuNP concentration 100, 250, 500, 750, and 1000 ppm. Incubation: 29 °C, 7 days. Fungal growth record: Colony diameter. Medium: Tomato plants. Inoculum: From a spore suspension (1 × 106 spores/mL). CuNP concentration: 500 ppm. Incubation: room temperature (June-August), 60 days. Fungal growth record: Ratio of leaves with symptoms/total leaves. | >80%/1000 ppm 70%/500 ppm | [325] |

| Chemical | 14 ± 2 | Spherical | A. niger, A. oryzae | Medium: PDA. Inoculum: From a spore suspension (—). CuNP concentration: 0.2, 0.4, 0.6, and 0.8 ppm (well diffusion method). Incubation: 28 ± 4 °C, 2 days. Fungal growth record: Diameter inhibition zone. | 17–24 mm/0.2–0.8 ppm. 15–20 mm/0.2–0.8 ppm. For each species, respectively | [330] |

| Chemical | 8 | Spherical | P. chrysogenum, A. alternata, F. solani, A. flavus | Medium: PDA. Inoculum: From a spore suspension (1 × 104 spores/mL). CuNP concentration: 20, 40, 60, 80, and 100 ppm. Incubation: 25 °C, 6 days. Fungal growth record: MIC. | 100%/40 ppm, 100%/60 ppm, 100%/60 ppm, 100%/80 ppm, For each species, respectively | [331] |

| Chemical | 53–174 | Spherical | F. oxysporum | Medium: PDA. Inoculum: — (well 4 mm). CuNP concentration: 5, 10, and 20 ppm. Incubation: 30 °C, 2–5 days. Fungal growth record: Diameter inhibition zone. | 49–72%/20 ppm | [332] |

| Chemical | 3–30 | Spherical | F. culmorum, F. oxysporum, F. equiseti | Medium: PDA. Inoculum: From a spore suspension (—). CuNP concentration: —. Incubation: 28 ± 2 °C, 3 days. Fungal growth record: Diameter inhibition zone. | 19 mm/—, 20 mm/—, 25 mm/—, For each species, respectively | [333] |

| Chemical | 200–500 | — | F. solani, F. oxysporum | Medium: PDA. Inoculum: From a spore suspension (1 × 106 spores/mL). CuNP concentration: 100, 250, 500, 750, and 1000 ppm. Incubation: 29 °C, 6 days. Fungal growth record: Colony diameter. | 95–97%/500 ppm | [334] |

| Chemical | 2.5 ± 0.3 | Spherical | F. verticillioides | Medium: Nutrient Broth (according to CLSI for filamentous fungi). Inoculum: From a spore suspension (2 × 104 spores/mL). CuNP concentration: 5–200 ppm. Incubation: 25 °C, 48 h. Fungal growth record: MIC. | 100%/125 ppm | [285] |

| Chemical | — | — | A. niger | Medium: PDA. Inoculum: —. CuNP concentration: 0.5, 1, and 1.5%. Incubation: 30 °C, 3 days. Fungal growth record: Colony diameter. | ∼35–100%/0.5–1.5% | [335] |

| Biological (Streptomyces capillispiralis Ca-1) | 3.6–59 | Spherical | Alternaria spp., A. niger, Fusarium spp. | Medium: PDA. Inoculum: Agar plugs (4 mm) from a fungal culture. CuNP Concentration: 5, 10, 15, and 20 mM. Incubation: 30 °C, 7 days. Fungal growth record: Colony diameter. | 57.14%/20 mM, 63.81%/20 mM, 42.61%/20 mM, For each species, respectively | [35] |

| Biological (Citrus medica Linn) | 10–60 (33) | Spherical | F. culmorum, F. oxysporum, F. graminearum | Medium: PDA. Inoculum: From a spore suspension (—). CuNP concentration: 2.18 × 108 particles/mL Incubation: 25 ± 2 °C, 52 h. Fungal growth record: Diameter inhibition zone. | ∼20–33 mm/2.18 × 108 particles/mL Depending on the fungal species | [336] |

| Biological (Talaromyces pinophilus) | 9 | Spherical | A. niger, A. terreus, A. fumigatus | Medium: Malt Extract Agar (MEA). Inoculum: From a spore suspension (1 × 107 spores/mL). CuNP concentration: 2000 ppm (wells 7.5 mm). Incubation: 30 °C, 72 h. Fungal growth record: Diameter inhibition zone. | 21.3 ± 0.58 mm/2000 ppm, 20.2 ± 1.26 mm/2000 ppm, 22.3 ± 1.53 mm/2000 ppm, For each species, respectively | [337] |

| Biological (Celastrus paniculatus leaves) | 2–10 | Spherical | F. oxysporum | Medium: PDA. Inoculum: Agar plugs (—) from a fungal culture. CuNP concentration: 0.12, 0.18, and 0.24%, w/v. Incubation: —. Fungal growth record: Colony diameter. | 76.29 ± 1.52%/0.24% 73.70 ± 1.52%/0.18% 59.25 ± 0.57%/0.12% | [338] |

| Commercial | 25 | — | A. alternata, F. solani, F. oxysporum f. sp. radicis lycopersici | Medium: PDA. Inoculum: Agar plug (5 mm) from a fungal culture. CuNP concentration: 0, 1, 10, 100, 500, 1000 ppm. Incubation: 25 °C, 4 days. Fungal growth record: Colony diameter. Medium: PDA. Inoculum: From a spore suspension (1 × 103 spores/mL). CuNP concentration: 0, 1, 2.5, 5, 10, 20, 50, 100 ppm. Incubation: 25 °C, 2 days. Fungal growth record: CFU. | 50%/296.56 ± 8.72 ppm 50%/261.16 ± 12.54 ppm 50%/328.12 ± 20.30 ppm For each species, respectively 50%/7.69 ± 1.00 ppm, 50%/18.84 ± 2.44 ppm, 50%/29.04 ± 4.32 ppm, For each species, respectively | [339] |

| Nanoparticle Properties | Antifungal Properties | |||||

|---|---|---|---|---|---|---|

| Synthesis Method | Size (nm) | Shape | Fungal Species | Methodology | Growth Reduction (%)/Treatment | Ref. |

| Biological (Morinda citrifolia) | 20–50 (29) | Spherical | A. flavus, A. niger | Medium: Sabouraud Dextrose agar (SDA). Inoculum: From a spore suspension (—). CuONP concentration: — (wells 5 mm). Incubation: 37 °C, 24 h. Fungal growth record: Diameter inhibition zone. | 7.6–13.1 mm/—, 9.2–14.7 mm/—, For each species, respectively | [340] |

| Biological (Penicillium chrysogenum) | 10.5–59.7 | Spherical | F. solani, F. oxysporum, A. terreus | Medium: PDA. Inoculum: —. CuONP concentration: 10,000 ppm (discs 7 mm). Incubation: 30 °C, 5 days. Fungal growth record: Diameter inhibition zone. | 31.66 ± 0.88 mm/10,000 ppm, 22.66 ± 0.66 mm/10,000 ppm, 28.66 ± 1.76 mm/10,000 ppm, For each species, respectively | [341] |

| Biological (Cissus quadrangularis) | 30 ± 2 | Spherical | A. niger, A. flavus | Medium: PDB. Inoculum: —. CuONP concentration: 500 and 1000 ppm. Incubation: —, 7 days. Fungal growth record: Fungal biomass. | 86%/1000 ppm, 85%/1000 ppm, For each species, respectively | [342] |

| Biological (Bougainvillea flower) | 5–20 (12 ± 4) | Spherical | A. niger | Medium: PDA. Inoculum: From a spore suspension (—). CuONP concentration: 5000 ppm. Incubation: 30 °C, 1 day. Fungal growth record: Diameter inhibition zone. | 80%/5000 ppm | [343] |

| Biological (Eichhornia crassipes) | 28 ± 4 | Spherical | F. culmorum, A. niger, A. flavus, F. oxysporum | Medium: PDA. Inoculum: —. CuONP concentration: 25, 50, 75, and 100 ppm. Incubation: Room temperature, 2 days. Fungal growth record: Diameter inhibition zone. | 21.26 ± 1 mm/100 ppm, 18.33 ± 1 mm/100 ppm, 16–18 mm/100 ppm, 15–17 mm/100 ppm, For each species, respectively | [344] |

| Biological (Aloe vera) | 11 ± 0.5 | Spherical | P. digitatum, P. italicum | Medium: PDA. Inoculum: From a spore suspension (1 × 106 spores/mL) (treated with CuONPs for 24 h). CuONP concentration: 100–1000 ppm. Incubation: 22 ± 1 °C, 4 days. Fungal growth record: CFU. Medium: Lemons. Inoculum: Steel rod previously immersed in conidial suspensions (treated with CuONPs for 24 h). CuONP concentration: 100–1000 ppm. Incubation: 20 °C, 95% RH, 5–14 days. Fungal growth record: Lemon disease incidence. | 100%/1000 ppm 100%/1000 ppm | [287] |

| Biological (Lemon peels extract) | 16.8 | Rounded, elongated spherical | A. citri | Medium: PDA. Inoculum: From a spore suspension (—). CuONP concentration: 10–100 ppm. Incubation: 28 °C, 5 days. Fungal growth record: Diameter inhibition zone. | 18.5–50 mm/10–100 ppm | [345] |

| Biological (Penicillium chrysogenum) | 9.7 | — | F. oxysporum, A. solani, A. niger, P. citrinum | Medium: Sabouraud Dextrose Agar. Inoculum: —. CuONP concentration: 250 ppm. Incubation: 28 °C, 5 days. Fungal growth record: Diameter inhibition zone. | 37.0 mm/250 ppm, 28.0 mm/250 ppm, 26.5 mm/250 ppm, 20.7 mm/250 ppm, For each species, respectively | [346] |

| Commercial | 46 | Spherical | F. oxysporum, A. solani | Medium: PDA. Inoculum: Agar plugs (5 mm) from a fungal culture. CuONP concentration: 100, 250, 500, 700, and 1000 ppm. Incubation: 25 ± 2 °C, 7–11 days. Fungal growth record: Colony diameter. | 31.48–95.57%/100–1000 ppm, 10.69–95.4%/100–1000 ppm, For each species, respectively | [347] |

| Nanoparticle Properties | Antifungal Properties | |||||

|---|---|---|---|---|---|---|

| Synthesis Method | Size (nm) | Shape | Fungal Species | Methodology | Mycotoxin/Reduction (%)/Treatment | Ref. |

| Chemical | 2.5 ± 0.3 | Spherical | F. verticillioides (FB1) | Medium: Nutrient broth (according to CLSI for filamentous fungi). Inoculum: From a spore suspension (2 × 104 spores/mL). CuNP Concentration: 5–200 ppm. Incubation: 28 °C, 14 days. Fumonisin B1 analysis: HPLC. | FB1/100%/100 ppm | [285] |

| Biological (Green and black tea leaves) | 26–40 | Spherical | A. flavus (Aflatoxins) A. parasiticus (Aflatoxins) | Medium: Czapek Dox agar Inoculum: From a spore suspension (1 × 106 spores/mL) CuNP Concentration: 10, 25, 50, and 100 ppm Incubation: 25 ± 2 °C, 15 days Aflatoxin analysis: HPLC | AFs/11.3 ± 1.2–83.1 ± 2.9/10–100 ppm | [313] |

| Biological (Syzygium cumini leaves) | 28−35 | Spherical | A. flavus (Aflatoxins) A. parasiticus (Aflatoxins) | Medium: Czapek Dox Liquid Inoculum: From a spore suspension (1 × 106 spores/mL) CuNP Concentration: 25, 50, and 100 ppm Incubation: 25 ± 2 °C, 15 days Aflatoxin analysis: HPLC | AFs/75.7± 3.2/100 ppm 80.0 ± 2.1/100 ppm | [314] |

5.3. Zinc Nanoparticles

5.4. Other Metal Oxide Nanoparticles

6. Engineered Metal and Metal Oxide NP as Antifungal Additives in Food

7. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hawksworth, D.L.; Lücking, R. Fungal Diversity Revisited: 2.2 to 3.8 Million Species. Microbiol. Spectr. 2017, 5, 10–1128. [Google Scholar] [CrossRef] [PubMed]

- Blackwell, M. The fungi: 1, 2, 3 ... 5.1 million species? Am. J. Bot. 2011, 98, 426–438. [Google Scholar] [CrossRef] [PubMed]

- Bongomin, F.; Gago, S.; Oladele, R.O.; Denning, D.W. Global and multi-national prevalence of fungal diseases—Estimate precision. J. Fungi 2017, 3, 57. [Google Scholar] [CrossRef] [PubMed]

- Thambugala, K.M.; Daranagama, D.A.; Tennakoon, D.S.; Jayatunga, D.P.W.; Hongsanan, S.; Xie, N. Humans vs. Fungi: An Overview of Fungal Pathogens against Humans. Pathogens 2024, 13, 426. [Google Scholar] [CrossRef]

- Bastos, R.W.; Rossato, L.; Goldman, G.H.; Santos, D.A. Fungicide effects on human fungal pathogens: Cross-resistance to medical drugs and beyond. PLoS Pathog. 2021, 17, e1010073. [Google Scholar] [CrossRef]

- Denning, D.W. Global Incidence and Mortality of Severe Fungal Disease. Lancet Infect. Dis. 2024, 24, e428–e438. [Google Scholar] [CrossRef]

- Rokas, A. Evolution of the human pathogenic lifestyle in fungi. Nat. Microbiol. 2022, 7, 607–619. [Google Scholar] [CrossRef]

- Brown, G.D.; Denning, D.W.; Gow, N.A.R.; Levitz, S.M.; Netea, M.G.; White, T.C. Hidden killers: Human fungal infections. Sci. Transl. Med. 2012, 4, 165rv13. [Google Scholar] [CrossRef]

- Fisher, M.C.; Henk, D.A.; Briggs, C.J.; Brownstein, J.S.; Madoff, L.C.; McCraw, S.L. Emerging fungal threats to animal, plant and ecosystem health. Nature 2012, 484, 186–194. [Google Scholar] [CrossRef]

- Pangga, I.B.; Salvacion, A.R.; Cumagun, C.J.R. Climate Change and Plant Diseases Caused by Mycotoxigenic Fungi: Implications for Food Security. In Climate Change and Mycotoxins; Botana, L.M., Sainz, M.J., Eds.; De Gruyter: Berlin, Germany, 2015; pp. 1–28. [Google Scholar]

- Pitt, J.I.; Miller, D. A Concise History of Mycotoxin Research. J. Agric. Food Chem. 2017, 65, 7021–7033. [Google Scholar] [CrossRef]

- Stoev, S.D. Food security, underestimated hazard of joint mycotoxin exposure and management of the risk of mycotoxin contamination. Food Control 2024, 159, 110235. [Google Scholar] [CrossRef]

- Bezerra da Rocha, M.E.; Oliveira Freire, F.C.; Feitosa Maia, F.E.; Florindo Guedes, M.I.; Rondina, D. Mycotoxins and their effects on human and animal health. Food Control 2014, 36, 159–165. [Google Scholar] [CrossRef]

- Madalena, M.; Sobral, C.; Faria, M.A.; Cunha, S.C.; Ferreira, I. Toxicological interactions between mycotoxins from ubiquitous fungi: Impact on hepatic and intestinal human epithelial cells. Chemosphere 2018, 202, 538–548. [Google Scholar] [CrossRef] [PubMed]

- Dellafiora, L.; Dall’Asta, C.; Galaverna, G. Toxicodynamics of Mycotoxins in the Framework of Food Risk Assessment: An In Silico Perspective. Toxins 2018, 10, 52. [Google Scholar] [CrossRef] [PubMed]

- Freire, L.; Sant’Ana, A.S. Modified mycotoxins: An updated review on their formation, detection, occurrence, and toxic effects. Food Chem. Toxicol. 2018, 111, 189–205. [Google Scholar] [CrossRef] [PubMed]

- Berthiller, F.; Maragos, C.M.; Dall’Asta, C. Introduction to masked mycotoxins. In Masked Mycotoxins in Food: Formation, Occurrence and Toxicological Relevance; Dall’Asta, C., Berthiller, F., Eds.; Royal Society of Chemistry: London, UK, 2016; pp. 1–13. [Google Scholar]

- García-Esparza, M.Á.; Mateo, E.M.; Robles, J.A.; Capoferri, M.; Jiménez, M.; Soria, J.M. Unveiling the Neurotoxic Effects of Ochratoxin A and Its Impact on Neuroinflammation. Toxins 2025, 17, 264. [Google Scholar] [CrossRef]

- Moretti, A.T.; Logrieco, A.F.; Susca, A. Mycotoxin: An Underhand Food Problem. In Mycotoxigenic Fungi: Methods and Protocols; Moretti, A., Susca, A., Eds.; Humana Press: New York, NY, USA, 2017; pp. 3–12. [Google Scholar]

- Luo, S.; Du, H.; Kebede, H.; Liu, Y.; Xing, F. Contamination status of major mycotoxins in agricultural products and foodstuffs in Europe. Food Control 2021, 127, 108120. [Google Scholar] [CrossRef]

- Pandey, A.K.; Samota, M.K.; Kumar, A.; Silva, A.S.; Dubey, N.K. Fungal Mycotoxins in Food Commodities: Present Status and Future Concerns. Front. Sustain. Food Syst. 2023, 7, 1162595. [Google Scholar] [CrossRef]

- Johns, L.E.; Bebber, D.P.; Gurr, S.J.; Brown, N.A. Emerging health threat and cost of Fusarium mycotoxins in European wheat. Nat. Food 2022, 3, 1014–1019. [Google Scholar] [CrossRef]

- Eskola, M.; Kos, G.; Elliott, C.T.; Hajslova, J.; Mayar, S.; Krska, R. Worldwide contamination of food-crops with mycotoxins: Validity of the widely cited ‘FAO estimate’ of 25%. Crit. Rev. Food Sci. Nutr. 2020, 60, 2773–2789. [Google Scholar] [CrossRef]

- Ostry, V.; Malir, F.; Toman, J.; Grosse, Y. Mycotoxins as human carcinogens—The IARC Monographs classification. Mycotoxin Res. 2017, 33, 65–73. [Google Scholar] [CrossRef]

- Kamle, M.; Mahato, D.K.; Devi, S.; Lee, K.E.; Kang, S.G.; Kumar, P. Fumonisins: Impact on agriculture, food, and human health and their management strategies. Toxins 2019, 11, 328. [Google Scholar] [CrossRef]

- Leslie, J.F.; Moretti, A.; Mesterházy, Á.; Ameye, M.; Audenaert, K.; Singh, P.K.; Richard-Forget, F.; Chulze, S.N.; Ponte, E.M.D.; Chala, A.; et al. Key Global Actions for Mycotoxin Management in Wheat and Other Small Grains. Toxins 2021, 13, 725. [Google Scholar] [CrossRef]

- Fisher, M.C.; Hawkins, N.J.; Sanglard, D.; Gurr, S.J. Worldwide emergence of resistance to antifungal drugs challenges human health and food security. Science 2018, 360, 739–742. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Mahato, D.K.; Kamle, M.; Mohanta, T.K.; Kang, S.G. Aflatoxins: A Global Concern for Food Safety, Human Health and Their Management. Front. Microbiol. 2017, 7, 2170. [Google Scholar] [CrossRef] [PubMed]

- Sarmast, E.; Fallah, A.A.; Jafari, T.; Khaneghah, A.M. Occurrence and fate of mycotoxins in cereals and cereal-based products: A narrative review of systematic reviews and meta-analyses studies. Curr. Opin. Food Sci. 2021, 39, 68–75. [Google Scholar] [CrossRef]

- Yu, J.; Pedroso, I.R. Mycotoxins in Cereal-Based Products and Their Impacts on the Health of Humans, Livestock Animals and Pets. Toxins 2023, 15, 480. [Google Scholar] [CrossRef]

- Kolawole, O.; Siri-Anusornsak, W.; Petchkongkaew, A.; Elliott, C. A systematic review of global occurrence of emerging mycotoxins in crops and animal feeds, and their toxicity in livestock. Emerg. Contam. 2024, 10, 100305. [Google Scholar] [CrossRef]

- Khaneghah, A.M.; Fakhri, Y.; Gahruie, H.H.; Niakousari, M.; Sant’Ana, A.S. Mycotoxins in cereal-based products during 24 years (1983–2017): A global systematic review. Trends Food Sci. Technol. 2019, 91, 95–105. [Google Scholar] [CrossRef]

- Wang, J.; Sufar, E.K.; Bernhoft, A.; Seal, C.; Rempelos, L.; Hasanaliyeva, G.; Zhao, B.; Iversen, P.O.; Baranski, M.; Volakakis, N.; et al. Mycotoxin Contamination in Organic and Conventional Cereal Grain and Products: A Systematic Literature Review and Meta-Analysis. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13363. [Google Scholar] [CrossRef]

- Sá, S.V.M.; Monteiro, C.; Fernandes, J.O.; Pinto, E.; Faria, M.A.; Cunha, S.C. Emerging mycotoxins in infant and children foods: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 1707–1721. [Google Scholar] [CrossRef]

- Hassan, S.E.-D.; Salem, S.S.; Fouda, A.; Awad, M.A.; El-Gamal, M.S.; Abdo, A. New Approach for Antimicrobial Activity and Bio-Control of Various Pathogens by Biosynthesized Copper Nanoparticles Using Endophytic Actinomycetes. J. Radiat. Res. Appl. Sci. 2018, 11, 262–270. [Google Scholar] [CrossRef]

- Schabo, D.C.; Alvarenga, V.O.; Schaffner, D.W.; Magnani, M. A worldwide systematic review, meta-analysis, and health risk assessment study of mycotoxins in beers. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1351–1368. [Google Scholar] [CrossRef] [PubMed]

- Narváez, A.; Rodríguez-Carrasco, Y.; Castaldo, L.; Izzo, L.; Graziani, G.; Ritieni, A. Occurrence and Exposure Assessment of Mycotoxins in Ready-to-Eat Tree Nut Products through Ultra-High Performance Liquid Chromatography Coupled with High Resolution Q-Orbitrap Mass Spectrometry. Metabolites 2020, 10, 344. [Google Scholar] [CrossRef] [PubMed]

- González-Curbelo, M.Á.; Kabak, B. Occurrence of mycotoxins in dried fruits worldwide, with a focus on aflatoxins and ochratoxin A: A review. Toxins 2023, 15, 576. [Google Scholar] [CrossRef] [PubMed]

- Azaiez, I.; Font, G.; Mañes, J.; Fernández-Franzón, M. Survey of mycotoxins in dates and dried fruits from Tunisian and Spanish markets. Food Control 2015, 51, 340–346. [Google Scholar] [CrossRef]

- Abdallah, M.F.; Krska, R.; Sulyok, M. Occurrence of ochratoxins, fumonisin B2, aflatoxins (B1 and B2), and other secondary fungal metabolites in dried date palm fruits from Egypt: A mini survey. J. Food Sci. 2018, 83, 559–564. [Google Scholar] [CrossRef]

- Palumbo, J.D.; O’Keeffe, T.L.; Ho, Y.S.; Santillan, C.J. Occurrence of Ochratoxin a Contamination and Detection of Ochratoxigenic Aspergillus Species in Retail Samples of Dried Fruits and Nuts. J. Food Prot. 2015, 78, 836–842. [Google Scholar] [CrossRef]

- Rahimi, E.; Shakerian, A. Ochratoxin A in Dried Figs, Raisins, Apricots, and Dates on Iranian Retail Market. Health 2013, 5, 2077–2080. [Google Scholar] [CrossRef]

- Iqbal, S.Z.; Mehmood, Z.; Asi, M.R.; Shahid, M.; Sehar, M.; Malik, N. Co-occurrence of aflatoxins and ochratoxin A in nuts, dry fruits, and nutty products. J. Food Saf. 2018, 38, e12462. [Google Scholar] [CrossRef]

- Calderari, T.O.; Iamanaka, B.T.; Frisvad, J.C.; Pitt, J.I.; Sartori, D.; Pereira, J.L.; Fungaro, M.H.P.; Taniwaki, M.H. The Biodiversity of Aspergillus Section Flavi in Brazil Nuts: From Rainforest to Consumer. Int. J. Food Microbiol. 2013, 160, 267–272. [Google Scholar] [CrossRef]

- Russell, R.; Paterson, M.; Lima, N.; Taniwak, M.H. Coffee, mycotoxins and climate change. Food Res. Int. 2014, 61, 1–15. [Google Scholar] [CrossRef]

- Galarce-Bustos, O.; Alvarado, M.; Vega, M.; Aranda, M. Occurrence of ochratoxin A in roasted and instant coffees in Chilean market. Food Control 2014, 46, 102–107. [Google Scholar] [CrossRef]

- Vieira, T.; Cunha, S.; Casal, S. Mycotoxins in Coffee. Chapter 25. In Coffee in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: Cambridge, MA, USA; Elsevier: London, UK, 2015; pp. 225–233. [Google Scholar]

- Bessaire, T.; Perrin, I.; Tarres, A.; Bebius, A.; Reding, F.; Theurillat, V. Mycotoxins in green coffee: Occurrence and risk assessment. Food Control 2019, 96, 59–67. [Google Scholar] [CrossRef]

- Vecchio, A.; Mineo, V.; Planeta, D. Ochratoxin A in Instant Coffee in Italy. Food Control 2012, 28, 220–223. [Google Scholar] [CrossRef]

- Al Attiya, W.; Ul Hassan, Z.; Al-Thani, R.; Jaoua, S. Prevalence of toxigenic fungi and mycotoxins in Arabic coffee (Coffea arabica): Protective role of traditional coffee roasting, brewing and bacterial volatiles. PLoS ONE 2021, 16, e0259302. [Google Scholar] [CrossRef]

- Copetti, M.V.; Iamanaka, B.T.; Pitt, J.I.; Taniwaki, M.H. Fungi and Mycotoxins in Cocoa: From Farm to Chocolate. Int. J. Food Microbiol. 2014, 178, 13–20. [Google Scholar] [CrossRef]

- Pickova, D.; Ostry, V.; Malir, J.; Toman, J.; Malir, F.A. Review on Mycotoxins and Microfungi in Spices in the Light of the Last Five Years. Toxins 2020, 12, 789. [Google Scholar] [CrossRef]

- Kabak, B.; Dobson, A.D.W. Mycotoxins in spices and herbs—An update. Crit. Rev. Food Sci. Nutr. 2017, 57, 18–34. [Google Scholar] [CrossRef]

- El Darra, N.; Gambacorta, L.; Solfrizzo, M. Multimycotoxins Occurrence in Spices and Herbs Commercialized in Lebanon. Food Control 2019, 95, 63–70. [Google Scholar] [CrossRef]

- Cighir, A.; Curticăpean, A.; Mare, A.D.; Cighir, T.; Gabor, M.R.; Toma, F.; Man, A. Fungal and Mycotoxin Contamination of Green Leaf Spices Commercialized in Romania: A Food Choice Perspective. Sustainability 2023, 15, 16437. [Google Scholar] [CrossRef]

- Benkerroum, N. Mycotoxins in dairy products: A review. Int. Dairy J. 2016, 62, 63–75. [Google Scholar] [CrossRef]

- Flores-Flores, M.E.; Lizarraga, E.; López de Cerain, A.; González-Peñas, E. Presence of mycotoxins in animal milk: A review. Food Control 2015, 53, 163–176. [Google Scholar] [CrossRef]

- Leite, M.; Freitas, A.; Barbosa, J.; Ramos, F. Regulated and Emerging Mycotoxins in Bulk Raw Milk: What Is the Human Risk? Toxins 2023, 15, 605. [Google Scholar] [CrossRef]

- Becker-Algeri, T.A.; Castagnaro, D.; de Bortoli, K.; de Souza, C.; Drunkler, D.A.; Badiale-Furlong, E. Mycotoxins in bovine milk and dairy products: A review. J. Food Sci. 2016, 81, R544–R552. [Google Scholar] [CrossRef]

- Hocking, A.D.; Leong, S.L.; Kazi, B.A.; Emmett, R.W.; Scott, E.S. Fungi and Mycotoxins in Vineyards and Grape Products. Int. J. Food Microbiol. 2007, 119, 84–88. [Google Scholar] [CrossRef]

- Kollia, E.; Kanapitsas, A.; Markaki, P. Occurrence of aflatoxin B1 and ochratoxin A in dried vine fruits from Greek market. Food Addit. Contam. Part B 2014, 7, 11–16. [Google Scholar] [CrossRef]

- Paterson, R.R.M.; Venâncio, A.; Lima, N.; Guilloux-Bénatier, M.; Rousseaux, S. Predominant Mycotoxins, Mycotoxigenic Fungi and Climate Change Related to Wine. Food Res. Int. 2018, 103, 478–491. [Google Scholar] [CrossRef]

- Mateo, F.; Tarazona, A.; Gavara, R.; Mateo, E.M. Bioactive Films with Essential Oils and Machine Learning for Controlling Aspergillus niger Growth and Fumonisin B2 Production In Vitro. Int. J. Food Microbiol. 2025, 439, 111251. [Google Scholar] [CrossRef]

- Rodrigues, P.; Silva, D.; Costa, P.; Abrunhosa, L.; Venâncio, A.; Teixeira, A. Mycobiota and mycotoxins in Portuguese pork, goat and sheep dry-cured hams. Mycotoxin Res. 2019, 35, 405–412. [Google Scholar] [CrossRef]

- Merla, C.; Andreoli, G.; Garino, C.; Vicari, N.; Tosi, G.; Guglielminetti, M.L.; Moretti, A.; Biancardi, A.; Arlorio, M.; Fabbi, M. Monitoring of Ochratoxin A and Ochratoxin-Producing Fungi in Traditional Salami Manufactured in Northern Italy. Mycotoxin Res. 2018, 34, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Abd El-Tawab, A.A.; El-Diasty, E.M.; Khater, D.F.; Al-baaly, Y.M. Mycological identification of some fungi isolated from meat products and spices with molecular identification of some Penicillium isolates. Adv. Anim. Vet. Sci. 2020, 8, 124–129. [Google Scholar] [CrossRef]

- Toman, J.; Pickova, D.; Rejman, L.; Ostry, V.; Malir, F. Investigation of ochratoxin A in air-dry-cured hams. Meat Sci. 2024, 217, 109605. [Google Scholar] [CrossRef] [PubMed]

- Lešić, T.; Zadravec, M.; Zdolec, N.; Vulić, A.; Perković, I.; Škrivanko, M.; Kudumija, N.; Jakopović, Ž.; Pleadin, J. Mycobiota and Mycotoxin Contamination of Traditional and Industrial Dry-Fermented Sausage Kulen. Toxins 2021, 13, 798. [Google Scholar] [CrossRef]

- Alkuwari, A.; Hassan, Z.U.; Zeidan, R.; Al-Thani, R.; Jaoua, S. Occurrence of mycotoxins and toxigenic fungi in cereals and application of yeast volatiles for their biological control. Toxins 2022, 14, 404. [Google Scholar] [CrossRef]

- Hassan, Z.U.; Al-Thani, R.F.; Migheli, Q.; Jaoua, S. Detection of Toxigenic Mycobiota and Mycotoxins in Cereal Feed Market. Food Control 2018, 84, 389–394. [Google Scholar] [CrossRef]

- Susca, A.; Villani, A.; Moretti, A.; Stea, G.; Logrieco, A. Identification of toxigenic fungal species associated with maize ear rot: Calmodulin as a single informative gene. Int. J. Food Microbiol. 2020, 319, 108491. [Google Scholar] [CrossRef]

- Commission Regulation (EU) 2023/915 of 25 April 2023 on maximum levels for certain contaminants in food and repealing Regulation (EC) No 1881/2006. Off. J. Eur. Union 2023, L 119, 103–157.

- Commission Regulation (EU) 2024/1022 of 8 April 2024 amending Regulation (EU) 2023/915 as regards maximum levels of deoxynivalenol in food. Off. J. Eur. Union 2024, L 1022, 1–4.

- Commission Regulation (EU) 2024/1038 of 9 April 2024 amending Regulation (EU) 2023/915 as regards maximum levels of T-2 and HT-2 toxins in food. Off. J. Eur. Union 2024, L 10, 1–5.

- Gruber-Dorninger, C.; Novak, B.; Nagl, V.; Berthiller, F. Emerging Mycotoxins: Beyond Traditionally Determined Food Contaminants. J. Agric. Food Chem. 2017, 65, 7052–7070. [Google Scholar] [CrossRef]

- Perrone, G.; Ferrara, M.; Medina, A.; Pascale, M.; Magan, N. Toxigenic Fungi and Mycotoxins in a Climate Change Scenario: Ecology, Genomics, Distribution, Prediction and Prevention of the Risk. Microorganisms 2020, 8, 1496. [Google Scholar] [CrossRef] [PubMed]

- Moretti, A.; Pascale, M.; Logrieco, A.F. Mycotoxin Risks under a Climate Change Scenario in Europe. Trends Food Sci. Technol. 2019, 84, 38–40. [Google Scholar] [CrossRef]

- Casu, A.; Leggieri, M.C.; Toscano, P.; Battilani, P. Changing Climate, Shifting Mycotoxins: A Comprehensive Review of Climate Change Impact on Mycotoxin Contamination. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13323. [Google Scholar] [CrossRef] [PubMed]

- Battilani, P.; Toscano, P.; Van Der Fels-Klerx, H.J.; Moretti, A.; Leggieri, M.C.; Brera, C.; Rortais, A.; Goumperis, T.; Robinson, T. Aflatoxin B1 contamination in maize in Europe increases due to climate change. Sci. Rep. 2016, 6, 24328. [Google Scholar] [CrossRef]

- Lv, C.; Jin, J.; Wang, P.; Dai, X.; Liu, Y.; Zheng, M.; Xing, F. Interaction of water activity and temperature on the growth, gene expression, and aflatoxin production by Aspergillus flavus on paddy and polished rice. Food Chem. 2019, 293, 472–478. [Google Scholar] [CrossRef]

- Al-Zaban, M.I. Impacts of temperature and water activity interactions on growth, aflatoxin B1 production and expression of major biosynthetic genes of AFB1 in Aspergillus flavus isolates. Microorganisms 2023, 11, 1199. [Google Scholar] [CrossRef]

- Kifer, D.; Jakšić, D.; Šegvić Klarić, M. Assessing the effect of mycotoxin combinations: Which mathematical model is (the most) appropriate? Toxins 2020, 12, 153. [Google Scholar] [CrossRef]

- Smith, M.C.; Madec, S.; Coton, E.; Hymery, N. Natural Co-occurrence of Mycotoxins in Foods and Feeds and their in vitro Combined Toxicological Effects. Toxins 2016, 8, 94. [Google Scholar] [CrossRef]

- Peijers, G.J.A.; Speijers, M.H.M. Combined Toxic Effects of Mycotoxins. Toxicol. Lett. 2004, 153, 91–98. [Google Scholar] [CrossRef]

- Venkatesh, N.; Keller, N.P. Mycotoxins in Conversation with Bacteria and Fungi. Front. Microbiol. 2019, 10, 403. [Google Scholar] [CrossRef]

- Assunção, R.; Silva, M.J.; Alvito, P. Challenges in risk assessment of multiple mycotoxins in food. World Mycotoxin J. 2016, 9, 791–811. [Google Scholar] [CrossRef]

- Nji, Q.N.; Babalola, O.O.; Ekwomadu, T.I.; Nleya, N.; Mwanza, M. Six Main Contributing Factors to High Levels of Mycotoxin Contamination in African Foods. Toxins 2022, 14, 318. [Google Scholar] [CrossRef] [PubMed]

- Hamad, G.M.; Mehany, T.; Simal-Gandara, J.; Abou-Alella, S.; Esua, O.J.; Abdel-Wahhab, M.A.; Hafez, E.E. A Review of Recent Innovative Strategies for Controlling Mycotoxins in Foods. Food Control 2023, 144, 109350. [Google Scholar] [CrossRef]

- Kabak, B. The fate of mycotoxins during thermal food processing. J. Sci. Food Agric. 2009, 89, 549–554. [Google Scholar] [CrossRef]

- Inglis, A.; Parnell, A.C.; Subramani, N.; Doohan, F.M. Machine Learning Applied to the Detection of Mycotoxin in Food: A Systematic Review. Toxins 2024, 16, 268. [Google Scholar] [CrossRef]

- Tarazona, A.; Mateo, E.M.; Gómez, J.V.; Romera, D.; Mateo, F. Potential use of machine learning methods in assessment of Fusarium culmorum and Fusarium proliferatum growth and mycotoxin production in treatments with antifungal agents. Fungal Biol. 2021, 125, 123–133. [Google Scholar] [CrossRef]

- Tarazona, A.; Mateo, E.M.; Gómez, J.V.; Gavara, R.; Jiménez, M.; Mateo, F. Machine learning approach for predicting Fusarium culmorum and F. proliferatum growth and mycotoxin production in treatments with ethylene-vinyl alcohol copolymer films containing pure components of essential oils. Int. J. Food Microbiol. 2021, 338, 109012. [Google Scholar] [CrossRef]

- Mateo, E.M.; Gómez, J.V.; Tarazona, A.; García-Esparza, M.A.; Mateo, F. Comparative Analysis of Machine Learning Methods to Predict Growth of F. sporotrichioides and Production of T-2 and HT-2 Toxins in Treatments with Ethylene-Vinyl Alcohol Films Containing Pure Components of Essential Oils. Toxins 2021, 13, 545. [Google Scholar] [CrossRef]

- Mateo, E.M.; Tarazona, A.; Jiménez, M.; Mateo, F. Lactic Acid Bacteria as Potential Agents for Biocontrol of Aflatoxigenic and Ochratoxigenic Fungi. Toxins 2022, 14, 807. [Google Scholar] [CrossRef]

- Mateo, E.M.; Tarazona, A.; Aznar, R.; Mateo, F. Exploring the Impact of Lactic Acid Bacteria on the Biocontrol of Toxigenic Fusarium spp. and Their Main Mycotoxins. Int. J. Food Microbiol. 2023, 387, 110054. [Google Scholar] [CrossRef] [PubMed]

- Mateo, F.; Gadea, R.; Mateo, E.M.; Jiménez, M. Multilayer Perceptron Neural Networks and Radial-Basis Function Networks as Tools to Forecast Accumulation of Deoxynivalenol in Barley Seeds Contaminated with Fusarium culmorum. Food Control 2011, 22, 88–95. [Google Scholar] [CrossRef]

- Wang, X.; Liu, C.; van der Fels-Klerx, H.J. Regional Prediction of Multi-Mycotoxin Contamination of Wheat in Europe Using Machine Learning. Food Res. Int. 2022, 159, 111588. [Google Scholar] [CrossRef]

- Aggarwal, A.; Mishra, A.; Tabassum, N.; Kim, Y.-M.; Khan, F. Detection of mycotoxin contamination in foods using artificial intelligence: A review. Foods 2024, 13, 3339. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2023: Sixth Assessment Report (AR6). The Synthesis Report Is Based on the Content of the Three Working Groups Assessment Reports: WGI–The Physical Science Basis, WGII—Impacts, Adaptation and Vulnerability, WGIII—Mitigation of Climate Change. Geneva, Switzerland. Available online: https://www.ipcc.ch/report/sixth-assessment-report-cycle (accessed on 3 May 2025).

- Waheed, A.; Haxim, Y.; Islam, W.; Ahmad, M.; Muhammad, M.; Alqahtani, F.M.; Hashem, M.; Salih, H.; Zhang, D. Climate Change Reshaping Plant-Fungal Interaction. Environ. Res. 2023, 238 Pt 2, 117282. [Google Scholar] [CrossRef]

- Lahlali, R.; Taoussi, M.; Laasli, S.E.; Gachara, G.; Ezzouggari, R.; Belabess, Z.; Aberkani, K.; Assouguem, A.; Meddich, A.; El Jarroudi, M.; et al. Effects of Climate Change on Plant Pathogens and Host-Pathogen Interactions. Crop Environ. 2024, 3, 159–170. [Google Scholar] [CrossRef]

- Liu, Y.; Yamdeu, J.H.G.; Gong, Y.Y.; Orfila, C. A review of postharvest approaches to reduce fungal and mycotoxin contamination of foods. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1521–1560. [Google Scholar] [CrossRef]

- Mateo, F.; Mateo, E.M.; Tarazona, A.; García-Esparza, M.Á.; Soria, J.M.; Jiménez, M. New Strategies and Artificial Intelligence Methods for the Mitigation of Toxigenic Fungi and Mycotoxins in Foods. Toxins 2025, 17, 231. [Google Scholar] [CrossRef]

- Brauer, V.S.; Rezende, C.P.; Pessoni, A.M.; De Paula, R.G.; Rangappa, K.S.; Nayaka, S.C.; Gupta, V.K.; Almeida, F. Antifungal Agents in Agriculture: Friends and Foes of Public Health. Biomolecules 2019, 9, 521. [Google Scholar] [CrossRef]

- Marín, P.; de Ory, A.; Cruz, A.; Magan, N.; González-Jaén, M.T. Potential effects of environmental conditions on the efficiency of the antifungal tebuconazole controlling Fusarium verticillioides and Fusarium proliferatum growth rate and fumonisin biosynthesis. Int. J. Food Microbiol. 2013, 165, 251–258. [Google Scholar] [CrossRef]

- Mateo, E.M.; Valle-Algarra, F.M.; Mateo, R.; Jiménez, M.; Magan, N. Effect of Fenpropimorph, Prochloraz and Tebuconazole on Growth and Production of T-2 and HT-2 Toxins by Fusarium langsethiae in Oat-Based Medium. Int. J. Food Microbiol. 2011, 151, 289–298. [Google Scholar] [CrossRef]

- Vitiello, A.; Ferrara, F.; Boccellino, M.; Ponzo, A.; Cimmino, C.; Comberiati, E.; Zovi, A.; Clemente, S.; Sabbatucci, M. Antifungal Drug Resistance: An Emergent Health Threat. Biomedicines 2023, 11, 1063. [Google Scholar] [CrossRef]

- Cui, X.; Wang, L.; Lü, Y.; Yue, C. Development and Research Progress of Anti-Drug Resistant Fungal Drugs. J. Infect. Public Health 2022, 15, 986–1000. [Google Scholar] [CrossRef]

- Hahn, M. The Rising Threat of Fungicide Resistance in Plant Pathogenic Fungi: Botrytis as a Case Study. J. Chem. Biol. 2014, 7, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Ribas, A.D.R.E.; Spolti, P.; Del Ponte, E.M.; Donato, K.Z.; Schrekker, H.; Fuentefria, A.M. Is the emergence of fungal resistance to medical triazoles related to their use in the agroecosystems? Braz. J. Microbiol. 2016, 47, 793–799. [Google Scholar] [CrossRef] [PubMed]

- Robbins, N.; Caplan, T.; Cowen, L.E. Molecular evolution of antifungal drug resistance. Annu. Rev. Microbiol. 2017, 71, 753–775. [Google Scholar] [CrossRef] [PubMed]

- European Food Safety Authority (EFSA); European Centre for Disease Prevention and Control (ECDC); European Chemicals Agency (ECHA); European Environment Agency (EEA); European Medicines Agency (EMA); European Commission’s Joint Research Centre (JRC). Impact of the use of azole fungicides, other than as human medicines, on the development of azole-resistant Aspergillus spp. EFSA J. 2025, 23, e9200. [Google Scholar]

- Revie, N.M.; Iyer, K.R.; Robbins, N.; Cowen, L.E. Antifungal drug resistance: Evolution, mechanisms and impact. Curr. Opin. Microbiol. 2018, 45, 70–76. [Google Scholar] [CrossRef]

- Hokken, M.W.; Zwaan, B.J.; Melchers, W.J.; Verweij, P.E. Facilitators of Adaptation and Antifungal Resistance Mechanisms in Clinically Relevant Fungi. Fungal Genet. Biol. 2019, 132, 103254. [Google Scholar] [CrossRef]

- Habschied, K.; Krstanović, V.; Zdunić, Z.; Babić, J.; Mastanjević, K.; Šarić, G.K. Mycotoxins Biocontrol Methods for Healthier Crops and Stored Products. J. Fungi 2021, 7, 348. [Google Scholar] [CrossRef]

- Spanic, V.; Zdunić, Z.; Drezner, G.; Sarkanj, B. The Pressure of Fusarium Disease and Its Relation with Mycotoxins in the Wheat Grain and Malt. Toxins 2019, 11, 198. [Google Scholar] [CrossRef] [PubMed]

- Gomes, A.S.d.L.P.B.; Weber, S.H.; Luciano, F.B. Resistance of Transgenic Maize Cultivars to Mycotoxin Production—Systematic Review and Meta-Analysis. Toxins 2024, 16, 373. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Li, X.; Maier, M.; O’Brien-Simpson, N.M.; Heath, D.E.; O’Connor, A.J. Using Inorganic Nanoparticles to Fight Fungal Infections in the Antimicrobial Resistant Era. Acta Biomater. 2023, 158, 56–79. [Google Scholar] [CrossRef] [PubMed]

- Peters, R.; Brandhoff, P.; Weigel, S.; Marvin, H.; Bouwmeester, H.; Aschberger, K.; Rauscher, H.; Amenta, V.; Arena, M.; Moniz, F.B.; et al. Inventory of Nanotechnology Applications in the Agricultural, Feed and Food Sector. EFSA Support. Publ. 2014, 11, 621E. [Google Scholar] [CrossRef]

- Chen, J.; Guo, Y.; Zhang, X.; Liu, J.; Gong, P.; Su, Z.; Fan, L.; Li, G. Emerging Nanoparticles in Food: Sources, Application, and Safety. J. Agric. Food Chem. 2023, 71, 3564–3582. [Google Scholar] [CrossRef]

- Singh, S.; Chaurasia, P.K.; Bharat, S.L. Functional roles of essential oils as an effective alternative of synthetic food preservatives: A review. Bharat J. Food Process Preserv. 2022, 46, e16804. [Google Scholar] [CrossRef]

- Atanda, S.A.; Shaibu, R.O.; Agunbiade, F.O. Nanoparticles in agriculture: Balancing food security and environmental sustainability. Discov. Agric. 2025, 3, 26. [Google Scholar] [CrossRef]

- Dangi, K.; Verma, A.K. Efficient and Eco-friendly Smart Nano-pesticides: Emerging Prospects for Agriculture. Mater. Today Proc. 2021, 45, 3819–3824. [Google Scholar]

- Kopittke, P.M.; Lombi, E.; Wang, P.; Schjoerring, J.K.; Husted, S. Nanomaterials as fertilizers for improving plant mineral nutrition and environmental outcomes. Environ. Sci. 2019, 6, 3513–3524. [Google Scholar] [CrossRef]

- Santás-Miguel, V.; Arias-Estévez, M.; Rodríguez-Seijo, A.; Arenas-Lago, D. Use of metal nanoparticles in agriculture. A review on the effects on plant germination. Environ. Pollut. 2023, 334, 122222. [Google Scholar] [CrossRef]

- Mansoor, S.; Zahoor, I.; Baba, T.R.; Padder, S.A.; Bhat, Z.A.; Koul, A.M.; Jiang, L. Fabrication of silver nanoparticles against fungal pathogens. Front. Nanotechnol. 2021, 3, 679358. [Google Scholar] [CrossRef]

- Kaningini, A.G.; Nelwamondo, A.M.; Azizi, S.; Maaza, M.; Mohale, K.C. Metal nanoparticles in agriculture: A review of possible use. Coatings 2022, 12, 1586. [Google Scholar] [CrossRef]

- Jaskulski, D.; Jaskulska, I.; Majewska, J.; Radziemska, M.; Bilgin, A.; Brtnicky, M. Silver nanoparticles (AgNPs) in urea solution in laboratory tests and field experiments with crops and vegetables. Materials 2022, 15, 870. [Google Scholar] [CrossRef]

- Zahra, Z.; Habib, Z.; Chung, S.; Badshah, M.A. Exposure Route of TiO2 NPs from Industrial Applications to Wastewater Treatment and Their Impacts on the Agro-Environment. Nanomaterials 2020, 10, 1469. [Google Scholar] [CrossRef]

- Dey, S.; Ghosh, N.; Nath, S.; Gopal, G.; Paul, S.; Mukherjee, A.; Paul, S.; Kundu, R. Application of multi-metallic nanoparticles in agriculture: The more, the better? Biocatal. Agric. Biotechnol. 2024, 58, 103238. [Google Scholar] [CrossRef]

- Singh, R.P.; Handa, R.; Manchanda, G. Nanoparticles in sustainable agriculture: An emerging opportunity. J. Control. Release 2021, 329, 1234–1248. [Google Scholar] [CrossRef]

- Mgadi, K.; Ndaba, B.; Roopnarain, A.; Rama, H.; Adeleke, R. Nanoparticle Applications in Agriculture: Overview and Response of Plant-Associated Microorganisms. Front. Microbiol. 2024, 15, 1354440. [Google Scholar] [CrossRef]

- Su, C.; Chen, A.; Liang, W.; Xie, W.; Xu, X.; Zhan, X.; Zhang, W.; Peng, C. Copper-based nanomaterials: Opportunities for sustainable agriculture. Sci. Total Environ. 2024, 926, 171948. [Google Scholar] [CrossRef]

- Cruz-Luna, A.R.; Cruz-Martínez, H.; Vásquez-López, A.; Medina, D.I. Metal Nanoparticles as Novel Antifungal Agents for Sustainable Agriculture: Current Advances and Future Directions. J. Fungi 2021, 7, 1033. [Google Scholar] [CrossRef]

- Cruz-Luna, A.R.; Vásquez-López, A.; Rojas-Chávez, H.; Valdés-Madrigal, M.A.; Cruz-Martínez, H.; Medina, D.I. Engineered Metal Oxide Nanoparticles as Fungicides for Plant Disease Control. Plants 2023, 12, 2461. [Google Scholar] [CrossRef]

- Kutawa, A.B.; Ahmad, K.; Ali, A.; Hussein, M.Z.; Abdul Wahab, M.A.; Adamu, A.; Ismaila, A.A.; Gunasena, M.T.; Rahman, M.Z.; Hossain, M.I. Trends in Nanotechnology and Its Potentialities to Control Plant Pathogenic Fungi: A Review. Biology 2021, 10, 881. [Google Scholar] [CrossRef]

- Nguyen, N.N.; Nguyen, N.T.; Nguyen, P.T.; Phan, Q.N.; Le, T.L.; Do, H.D.K. Current and Emerging Nanotechnology for Sustainable Development of Agriculture: Implementation Design Strategy and Application. Heliyon 2024, 10, e31503. [Google Scholar] [CrossRef]

- Baker, S.; Volova, T.; Prudnikova, S.V.; Satish, S.; Prasad, M.N.N. Nanoagroparticles emerging trends and future prospect in modern agriculture system. Environ. Toxicol. Pharmacol. 2017, 53, 10–17. [Google Scholar] [CrossRef]

- Adisa, I.O.; Pullagurala, V.L.R.; Peralta-Videa, J.R.; Dimkpa, C.O.; Elmer, W.H.; Gardea-Torresdey, J.L.; White, J.C. Recent advances in nano-enabled fertilizers and pesticides: A critical review of mechanisms of action. Environ. Sci. Nano 2019, 6, 2002–2030. [Google Scholar] [CrossRef]

- Agrimonti, C.; Lauro, M.; Visioli, G. Smart agriculture for food quality: Facing climate change in the 21st century. Crit. Rev. Food Sci. Nutr. 2021, 61, 971–981. [Google Scholar] [CrossRef]

- Castro-Mayorga, J.L.; Cabrera-Villamizar, L.; Balcucho-Escalante, J.; Fabra, M.J.; López-Rubio, A. Applications of Nanotechnology in Agri-Food Productions. In Nanotoxicity; Rajendran, S., Mukherjee, A., Nguyen, T.A., Godugu, C., Shukla, R.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 319–340. [Google Scholar]

- Mishra, S.; Keswani, C.; Abhilash, P.C.; Fraceto, L.F.; Singh, H.B. Integrated Approach of Agri-nanotechnology: Challenges and Future Trends. Front. Plant Sci. 2017, 8, 471. [Google Scholar] [CrossRef]

- Tanwar, A.; Role, S. Role and Effects of Nanotechnology Used in Pesticides and Agriculture Field. AIP Conf. Proc. 2019, 2142, 5122581. [Google Scholar] [CrossRef]

- Siddique, S.; Chow, J.C. Gold nanoparticles for drug delivery and cancer therapy. Appl. Sci. 2020, 10, 3824. [Google Scholar] [CrossRef]

- Puttasiddaiah, R.; Basavegowda, N.; Lakshmanagowda, N.K.; Raghavendra, V.B.; Sagar, N.; Sridhar, K.; Dikkala, P.K.; Bhaswant, M.; Baek, K.-H.; Sharma, M. Emerging Nanoparticle-Based Diagnostics and Therapeutics for Cancer: Innovations and Challenges. Pharmaceutics 2025, 17, 70. [Google Scholar] [CrossRef]

- Islam, F.; Shohag, S.; Uddin, M.J.; Islam, M.R.; Nafady, M.H.; Akter, A.; Mitra, S.; Roy, A.; Emran, T.B.; Cavalu, S. Exploring the journey of zinc oxide nanoparticles (ZnO-NPs) toward biomedical applications. Materials 2022, 15, 2160. [Google Scholar] [CrossRef]

- Zhu, C.; Ji, Z.; Ma, J.; Ding, Z.; Shen, J.; Wang, Q. Recent Advances of Nanotechnology-Facilitated Bacteria-Based Drug and Gene Delivery Systems for Cancer Treatment. Pharmaceutics 2021, 13, 940. [Google Scholar] [CrossRef]

- Yetisgin, A.A.; Cetinel, S.; Zuvin, M.; Kosar, A.; Kutlu, O. Therapeutic Nanoparticles and Their Targeted Delivery Applications. Molecules 2020, 25, 2193. [Google Scholar] [CrossRef]

- Hofmann-Amtenbrink, M.; Grainger, D.W.; Hofmann, H. Nanoparticles in Medicine: Current Challenges Facing Inorganic Nanoparticle Toxicity Assessments and Standardizations. Nanomedicine 2015, 11, 1689–1694. [Google Scholar] [CrossRef]

- Lam, E.; Luong, J.H. Carbon Materials as Catalyst Supports and Catalysts in the Transformation of Biomass to Fuels and Chemicals. ACS Catal. 2014, 4, 3393–3410. [Google Scholar] [CrossRef]

- Rassaei, L.; Marken, F.; Sillanpää, M.; Amiri, M.; Cirtiu, C.M.; Sillanpää, M. Nanoparticles in electrochemical sensors for environmental monitoring. TrAC Trends Anal. Chem. 2011, 30, 1704–1715. [Google Scholar] [CrossRef]

- Khan, F.; Shahid, A.; Zhu, H.; Wang, N.; Javed, M.R.; Ahmad, N.; Xu, J.; Alam, M.A.; Mehmood, M.A. Prospects of algae-based green synthesis of nanoparticles for environmental applications. Chemosphere 2022, 293, 133571. [Google Scholar] [CrossRef]

- Rasheed, T.; Bilal, M.; Li, C.; Nabeel, F.; Khalid, M.; Iqbal, H.M.N. Catalytic Potential of Bio-Synthesized Silver Nanoparticles Using Convolvulus arvensis Extract for the Degradation of Environmental Pollutants. J. Photochem. Photobiol. B Biol. 2018, 181, 44–52. [Google Scholar] [CrossRef]

- Xiong, Y.; Li, W.; Wen, Q.; Xu, D.; Ren, J.; Lin, Q. Aptamer-Engineered Nanomaterials to Aid in Mycotoxin Determination. Food Control 2022, 135, 108661. [Google Scholar] [CrossRef]

- Rai, P.K.; Kumar, V.; Lee, S.S.; Raza, N.; Kim, K.-H.; Ok, Y.S.; Tsang, D.C.W. Nanoparticle-Plant Interaction: Implications in Energy, Environment, and Agriculture. Environ. Int. 2018, 119, 1–19. [Google Scholar] [CrossRef]

- Altammar, K.A. A review on nanoparticles: Characteristics, synthesis, applications, and challenges. Front. Microbiol. 2023, 14, 1155622. [Google Scholar] [CrossRef]

- Wasilewska, A.; Bielicka, M.; Klekotka, U.; Kalska-Szostko, B. Nanoparticle Applications in Food—A Review. Food Funct. 2023, 14, 2544–2567. [Google Scholar] [CrossRef]

- Horky, P.; Skalickova, S.; Baholet, D.; Skladanka, J. Nanoparticles as a Solution for Eliminating the Risk of Mycotoxins. Nanomaterials 2018, 8, 727. [Google Scholar] [CrossRef]

- Boholm, M.; Arvidsson, R. A definition framework for the terms nanomaterial and nanoparticle. Nanoethics 2016, 10, 25–40. [Google Scholar] [CrossRef]

- Zain, M.; Yasmeen, H.; Yadav, S.S.; Amir, S.; Bilal, M.; Shahid, A.; Khurshid, M. Applications of Nanotechnology in Biological Systems and Medicine. In Micro and Nano Technologies, Nanotechnology for Hematology, Blood Transfusion, and Artificial Blood; Denizli, A., Nguyen, T.A., Rajan, M., Alam, M.F., Rahman, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 215–235. [Google Scholar]

- Mitchell, M.J.; Billingsley, M.M.; Haley, R.M.; Wechsler, M.E.; Peppas, N.M.; Langer, R. Engineering Precision Nanoparticles for Drug Delivery. Nat. Rev. Drug Discov. 2021, 20, 101–124. [Google Scholar] [CrossRef] [PubMed]

- Commission Recommendation of 10 June 2022 on the definition of nanomaterial (Text with EEA relevance) (2022/C 229/01) (C/2022/3689). Off. J. Eur. Union 2022, C 229, 1–5.

- Commission Recommendation of 18 October 2011 on the definition of nanomaterial (Text with EEA relevance) (2011/696/EU). Off. J. Eur. Union 2011, L 275, 38–40.

- Commission Regulation (EU) 2015/2283 of the European Parliament and of the Council of 25 November 2015 on novel foods, amending Regulation (EU) No 1169/2011 and repealing Regulation (EC) No 258/97 and Commission Regulation (EC) No 1852/2001. Off. J. Eur. Union 2015, L 327, 1–22.

- Joudeh, N.; Linke, D. Nanoparticle classification, physicochemical properties, characterization, and applications: A comprehensive review for biologists. J. Nanobiotechnol. 2022, 20, 262. [Google Scholar] [CrossRef]

- Erdoğan, N.; Akkın, S.; Bilensoy, E. Nanocapsules for Drug Delivery: An Updated Review of the Last Decade. Recent Pat. Drug Deliv. Formul. 2019, 12, 252–266. [Google Scholar] [CrossRef]