Contamination of Zearalenone from China in 2019 by a Visual and Digitized Immunochromatographic Assay

Abstract

1. Introduction

2. Results and Discussion

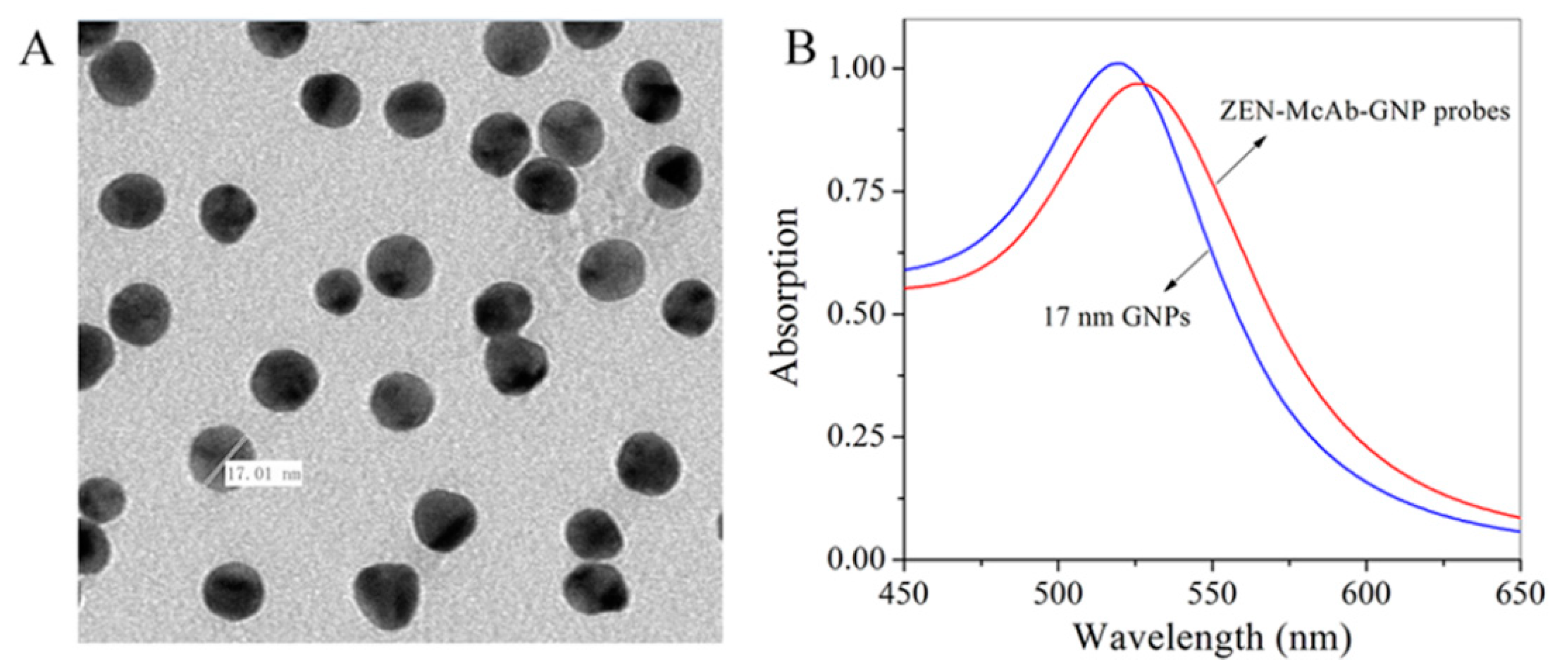

2.1. Identification of the Gold Nanoparticles

2.2. Key Parameters for the ICA

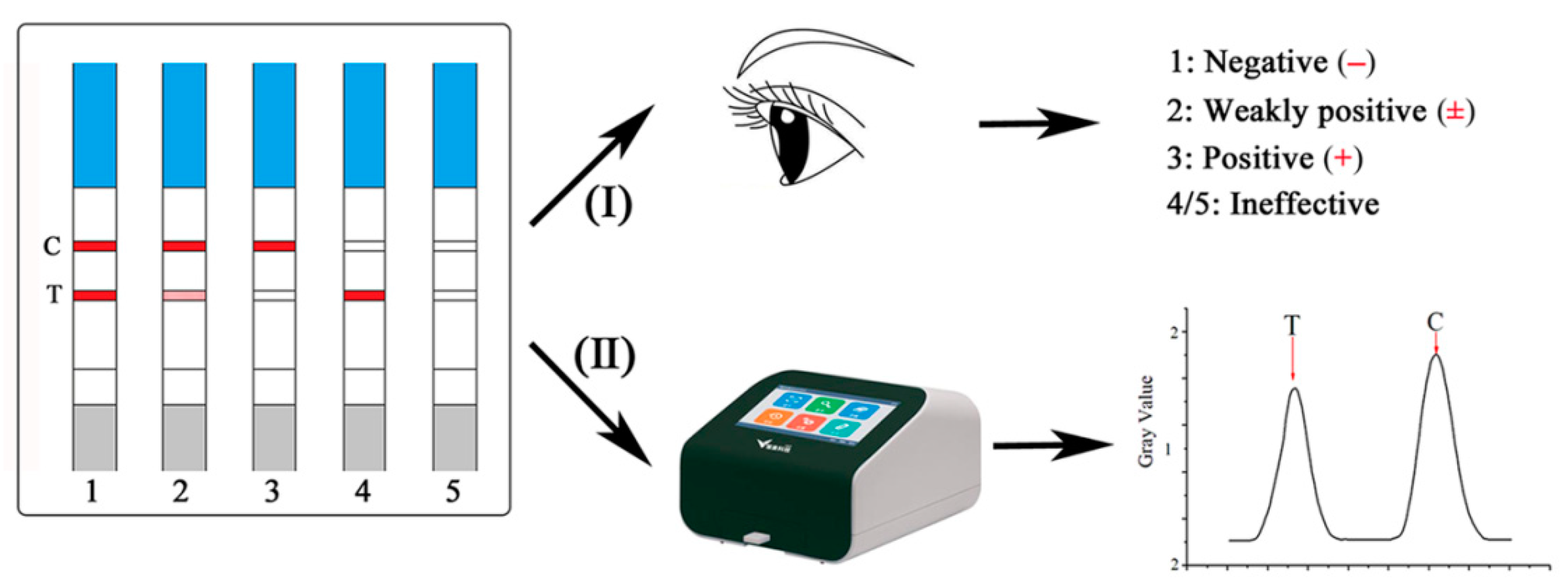

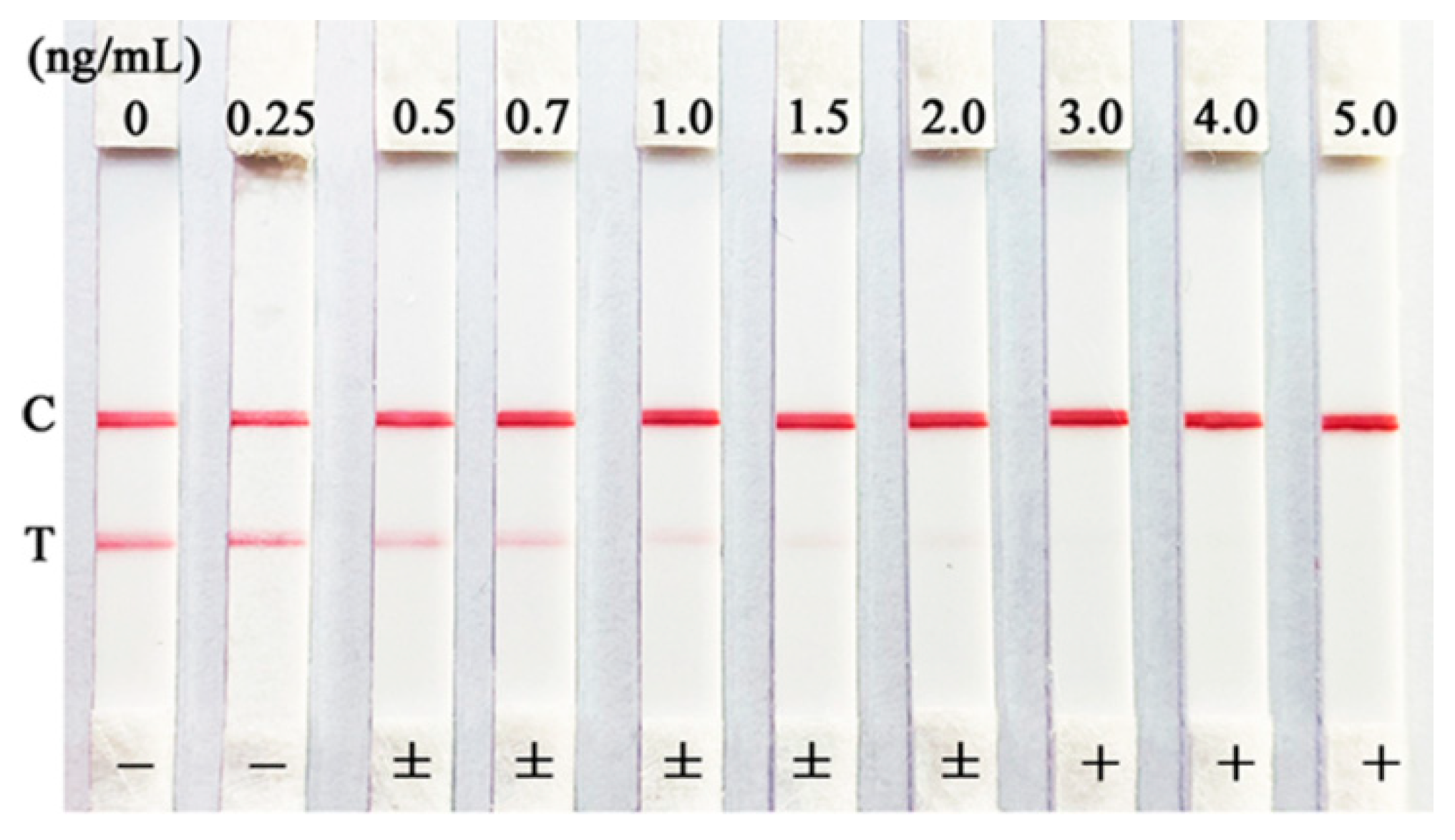

2.3. Semi-Quantitative Detection of the ICA

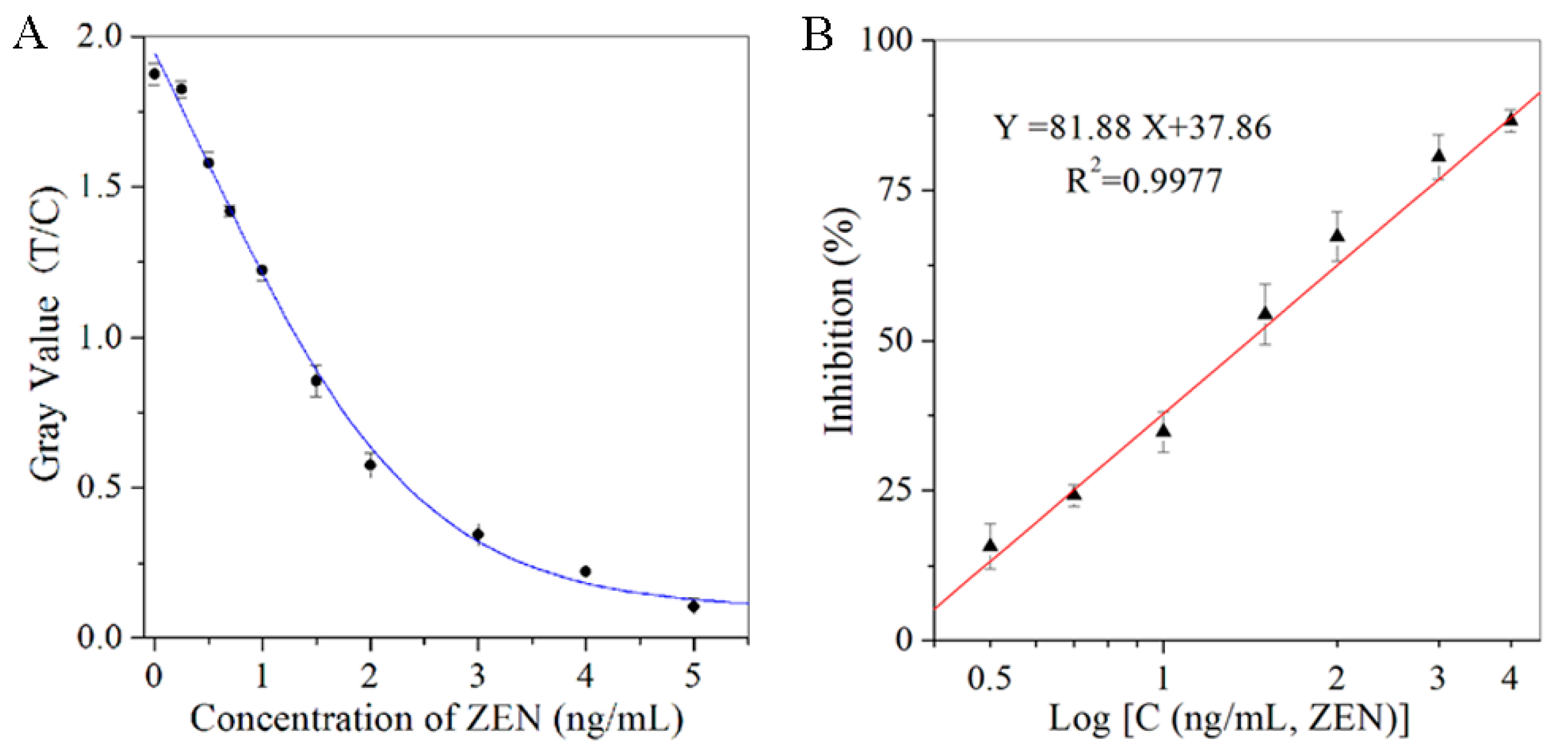

2.4. Quantitative Detection of the ICA

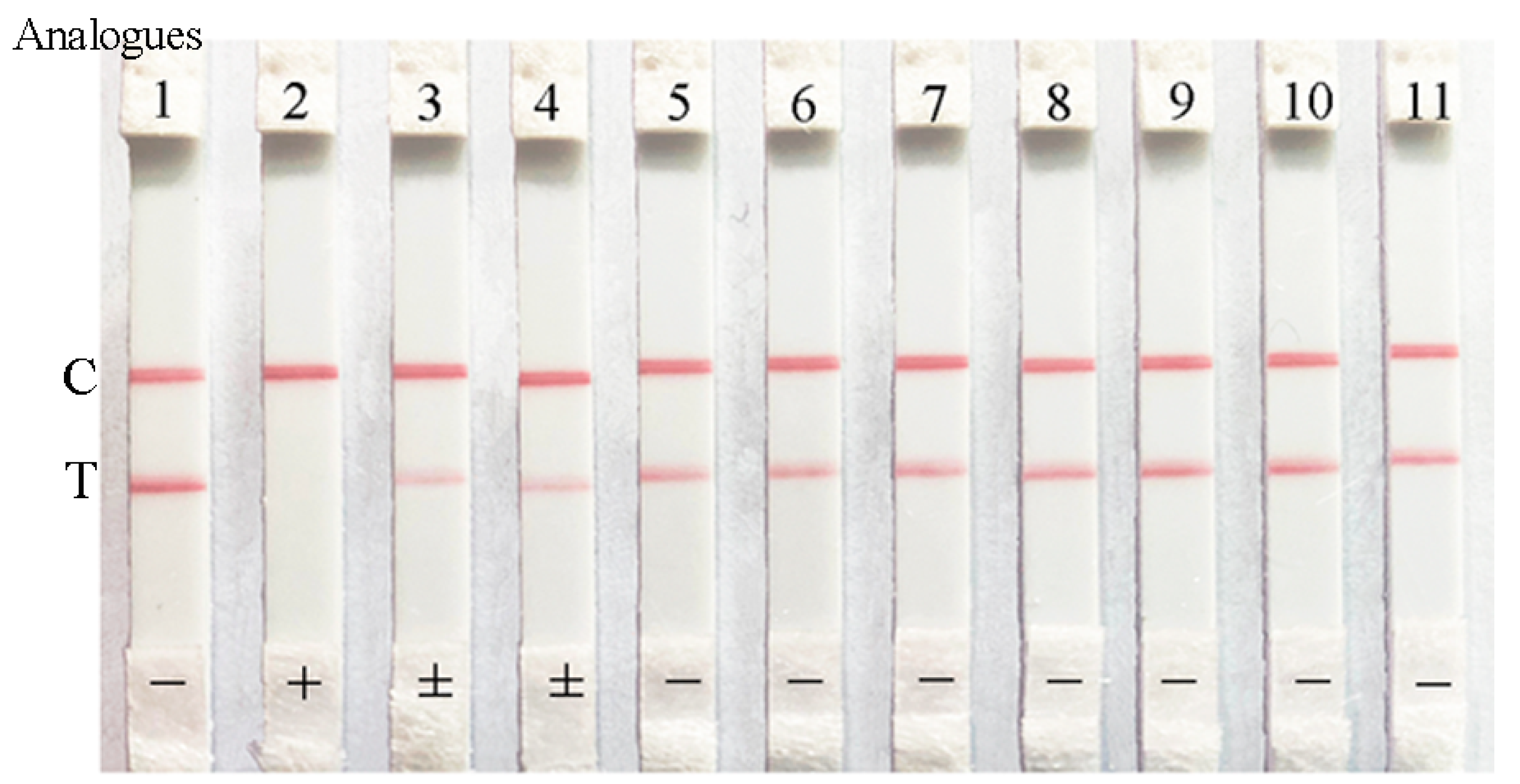

2.5. Specificity of the ICA

2.6. Stability of the ICA

2.7. Accuracy and Precision of the ICA

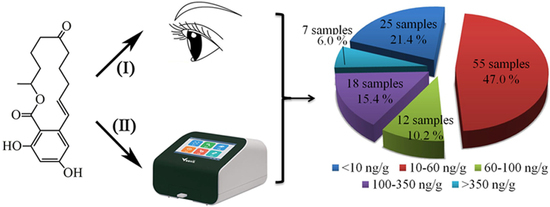

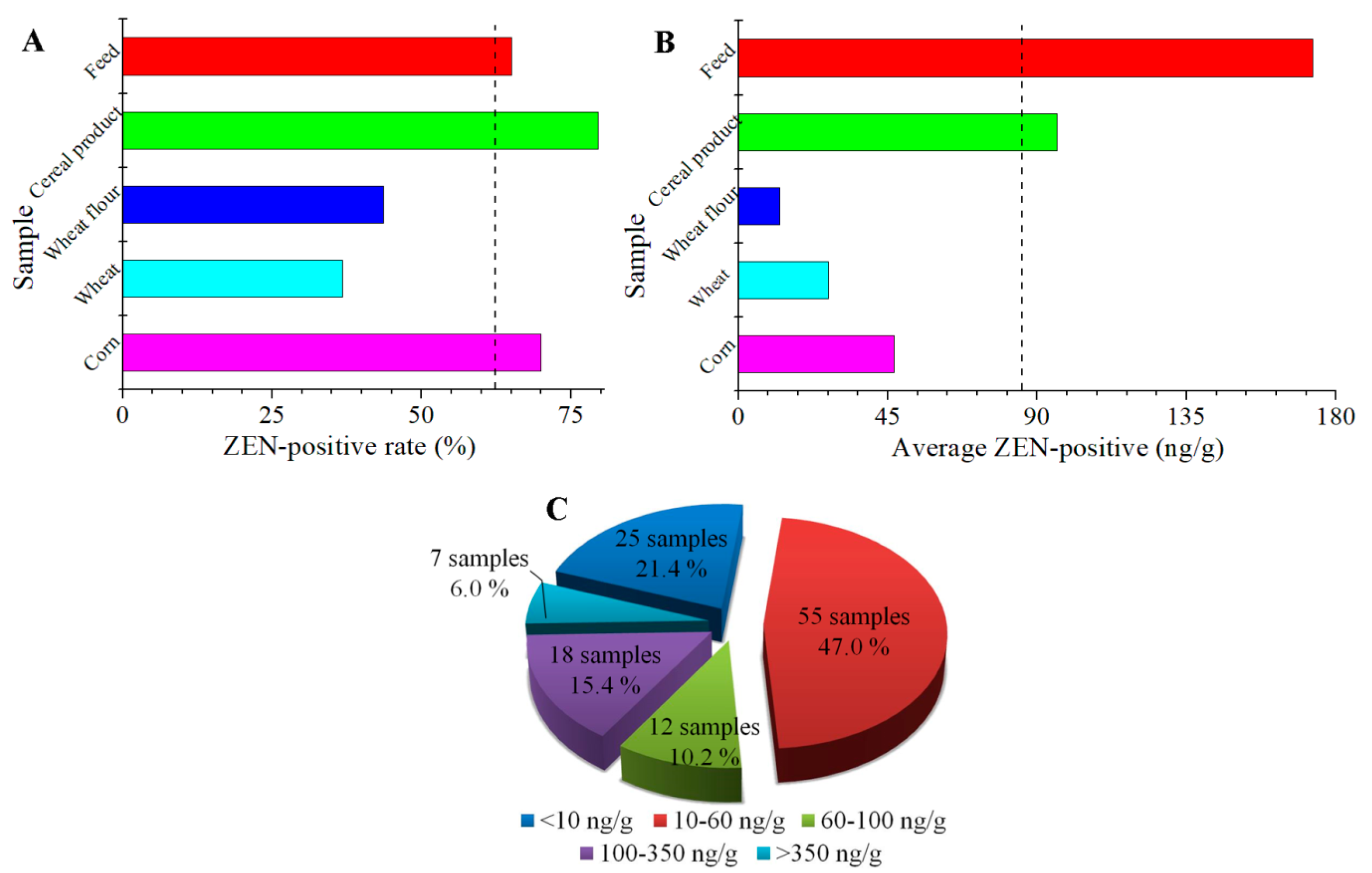

2.8. Investigation of Authentic Samples by the ICA and LC-MS/MS

3. Conclusions

4. Materials and Methods

4.1. Reagents and Materials

4.2. Preparation of the Nanoparticles

4.3. Preparation of the ZEN-McAb-GNP Probes

4.4. Preparation of the ICA Strip

4.5. Procedure and Judgment of the ICA

4.6. Optimization of the ICA

4.7. Evaluation of the ICA

4.8. Detection of Spiked and Authentic Samples

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Juan, C.; Oueslati, S.; Mañes, J.; Berrada, H. Multimycotoxin Determination in Tunisian Farm Animal Feed. J. Food Sci. 2019, 84, 3885–3893. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Yang, C.; Mao, Y.; Hong, X.; Du, D.-L. Zearalenone Contamination in Corn, Corn Products, and Swine Feed in China in 2016-2018 as Assessed by Magnetic Bead Immunoassay. Toxins 2019, 11, 451. [Google Scholar] [CrossRef]

- Hao, K.; Suryoprabowo, S.; Song, S.; Liu, L.; Kuang, H. Rapid detection of zearalenone and its metabolite in corn flour with the immunochromatographic test strip. Food Agric. Immunol. 2017, 29, 498–510. [Google Scholar] [CrossRef]

- Buszewska-Forajta, M. Mycotoxins, invisible danger of feedstuff with toxic effect on animals. Toxicon 2020, 182, 34–53. [Google Scholar] [CrossRef] [PubMed]

- Gadzała-Kopciuch, R.; Cendrowski, K.; Cesarz, A.; Kiełbasa, P.; Buszewski, B. Determination of zearalenone and its metabolites in endometrial cancer by coupled separation techniques. Anal. Bioanal. Chem. 2011, 401, 2069–2078. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, O.O.; Menkovska, M. The Nature, Sources, Detections and Regulations of Mycotoxins That Contaminate Foods and Feeds Causing Health Hazards for Both Human and Animals. J. Agric. Chem. Environ. 2019, 8, 33–57. [Google Scholar] [CrossRef]

- Rogowska, A.; Pomastowski, P.; Sagandykova, G.; Buszewski, B. Zearalenone and its metabolites: Effect on human health, metabolism and neutralisation methods. Toxicon 2019, 162, 46–56. [Google Scholar] [CrossRef]

- Złoch, M.; Rogowska, A.; Pomastowski, P.; Railean-Plugaru, V.; Walczak-Skierska, J.; Rudnicka, J.; Buszewski, B. Use of Lactobacillus paracasei strain for zearalenone binding and metabolization. Toxicon 2020, 181, 9–18. [Google Scholar] [CrossRef]

- Rogowska, A.; Pomastowski, P.; Walczak-Skierska, J.; Railean-Plugaru, V.; Rudnicka, J.; Buszewski, B.; Plugaru, R. Investigation of Zearalenone Adsorption and Biotransformation by Microorganisms Cultured under Cellular Stress Conditions. Toxins 2019, 11, 463. [Google Scholar] [CrossRef]

- Ji, J.; Zhu, P.; Li, J.; Pi, F.; Zhang, Y.; Li, Y.; Wang, J.-S.; Sun, X. The Antagonistic Effect of Mycotoxins Deoxynivalenol and Zearalenone on Metabolic Profiling in Serum and Liver of Mice. Toxins 2017, 9, 28. [Google Scholar] [CrossRef]

- European Commission Regulation, 2007; EC Regulation No. 1126/2007; Official Journal of the European Union: Brussels, Belgium, 2007.

- Zinedine, A.; Soriano, J.M.; Moltó, J.C.; Mañes, J. Review on the toxicity, occurrence, metabolism, detoxification, regulations and intake of zearalenone: An oestrogenic mycotoxin. Food Chem. Toxicol. 2007, 45, 1–18. [Google Scholar] [CrossRef] [PubMed]

- China National Standard, 2017; No. GB 2761-2017; Ministry of Health of P. R. China: Beijing, China, 2017.

- Drzymala, S.S.; Weiz, S.; Heinze, J.; Marten, S.; Prinz, C.; Zimathies, A.; Garbe, L.-A.; Koch, M. Automated solid-phase extraction coupled online with HPLC-FLD for the quantification of zearalenone in edible oil. Anal. Bioanal. Chem. 2015, 407, 3489–3497. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Deng, C.; Zhou, S.; Zhao, Y.; Wang, D.; Wang, X.; Gong, Y.Y.; Wu, Y. High-throughput and sensitive determination of urinary zearalenone and metabolites by UPLC-MS/MS and its application to a human exposure study. Anal. Bioanal. Chem. 2018, 410, 5301–5312. [Google Scholar] [CrossRef]

- Pei, S.-C.; Lee, W.-J.; Zhang, G.; Hu, X.-F.; Eremin, S.A.; Zhang, L.-J. Development of anti-zearalenone monoclonal antibody and detection of zearalenone in corn products from China by ELISA. Food Control. 2013, 31, 65–70. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Z.; Zhang, Q.; Wang, Z.; Zhang, W.; Yu, L.; Li, H.; Jiang, J.; Li, P. Rapid and sensitive double-label based immunochromatographic assay for zearalenone detection in cereals. Electrophoresis 2018, 39, 2125–2130. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhang, Z.; Zhu, G.; Sun, J.; Zou, B.; Li, M.; Wang, J. Rapid screening of flonicamid residues in environmental and agricultural samples by a sensitive enzyme immunoassay. Sci. Total Environ. 2016, 551, 484–488. [Google Scholar] [CrossRef]

- Zhan, S.; Huang, X.; Chen, R.; Li, J.; Xiong, Y. Novel fluorescent ELISA for the sensitive detection of zearalenone based on H2O2-sensitive quantum dots for signal transduction. Talanta 2016, 158, 51–56. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Y.; Xue, Y.; Hong, X.; Cui, Y.; Liu, Z.; Du, D.-L. Simultaneous determination of β 2 -agonists clenbuterol and salbutamol in water and swine feed samples by dual-labeled time-resolved fluoroimmunoassay. Food Control. 2017, 73, 1039–1044. [Google Scholar] [CrossRef]

- Liu, R.; Shi, R.; Zou, W.; Chen, W.; Yin, X.; Zhao, F.; Yang, Z. Highly sensitive phage-magnetic-chemiluminescent enzyme immunoassay for determination of zearalenone. Food Chem. 2020, 325, 126905. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, M.; Cui, Y.; Hong, X.; Du, D. Using of Tyramine Signal Amplification to Improve the Sensitivity of ELISA for Aflatoxin B1 in Edible Oil Samples. Food Anal. Methods 2018, 11, 2553–2560. [Google Scholar] [CrossRef]

- Li, M.; Cui, Y.; Liu, Z.; Xue, Y.; Zhao, R.; Li, Y.; Du, D.-L. Sensitive and selective determination of butyl benzyl phthalate from environmental samples using an enzyme immunoassay. Sci. Total Environ. 2019, 687, 849–857. [Google Scholar] [CrossRef] [PubMed]

- Ji, F.; Mokoena, M.P.; Zhao, H.; Olaniran, A.O.; Shi, J. Development of an immunochromatographic strip test for the rapid detection of zearalenone in wheat from Jiangsu province, China. PLoS ONE 2017, 12, e0175282. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Duan, H.; Guo, L.; Leng, Y.; Lai, W.; Xiong, Y. Quantum dot nanobead-based multiplexed immunochromatographic assay for simultaneous detection of aflatoxin B1 and zearalenone. Anal. Chim. Acta 2018, 1025, 163–171. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Meng, C.; Wen, Y.; Fu, W.; He, P. Fluorometric lateral flow immunoassay for simultaneous determination of three mycotoxins (aflatoxin B1, zearalenone and deoxynivalenol) using quantum dot microbeads. Microchim. Acta 2019, 186, 748. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yu, X.; Wen, K.; Li, C.; Mari, G.M.; Jiang, H.; Shi, W.; Shen, J.; Wang, Z. Multiplex Lateral Flow Immunoassays Based on Amorphous Carbon Nanoparticles for Detecting Three Fusarium Mycotoxins in Maize. J. Agric. Food Chem. 2017, 65, 8063–8071. [Google Scholar] [CrossRef]

- Wu, S.; Liu, L.; Duan, N.; Li, Q.; Zhou, Y.; Wang, Z. Aptamer-Based Lateral Flow Test Strip for Rapid Detection of Zearalenone in Corn Samples. J. Agric. Food Chem. 2018, 66, 1949–1954. [Google Scholar] [CrossRef]

- Li, X.M.; Wang, J.; Yi, C.Q.; Jiang, L.L.; Wu, J.X.; Chen, X.M.; Shen, X.; Sun, Y.M.; Lei, H.T. A smartphone-based quantitative detection device integrated with latex microsphere immunochromatographic for on-site detection of zearalenone in cereals and feed. Sensor. Actuat. B-Chem. 2019, 290, 170–179. [Google Scholar] [CrossRef]

- Zeng, K.; Wei, W.; Jiang, L.; Zhu, F.; Du, D. Use of Carbon Nanotubes as a Solid Support To Establish Quantitative (Centrifugation) and Qualitative (Filtration) Immunoassays To Detect Gentamicin Contamination in Commercial Milk. J. Agric. Food Chem. 2016, 64, 7874–7881. [Google Scholar] [CrossRef]

- Jiang, L.; Wei, D.; Zenga, K.; Shao, J.; Zhu, F.; Du, D. An Enhanced Direct Competitive Immunoassay for the Detection of Kanamycin and Tobramycin in Milk Using Multienzyme-Particle Amplification. Food Anal. Methods 2018, 11, 2066–2075. [Google Scholar] [CrossRef]

- Zhu, F.; Mao, C.; Du, D. Time-resolved immunoassay based on magnetic particles for the detection of diethyl phthalate in environmental water samples. Sci. Total Environ. 2017, 601, 723–731. [Google Scholar] [CrossRef]

- China National Standard, 2016; No. GB 5009-209; Ministry of Health of P. R. China: Beijing, China, 2016.

- Wu, A.-B.; Liu, N.; Yang, L.; Deng, Y.; Wang, J.; Song, S.; Lin, S.; Wu, A.; Zhou, Z.; Hou, J. Multi-mycotoxin analysis of animal feed and animal-derived food using LC–MS/MS system with timed and highly selective reaction monitoring. Anal. Bioanal. Chem. 2015, 407, 7359–7368. [Google Scholar] [CrossRef]

| Parameter | Concentration | Volume | Solvent |

|---|---|---|---|

| GAM-IgG | 13.1 mg/mL | 0.5 μL | 10 mmol/L PBS (containing 0.15 mol/L NaCl, pH 7.4) |

| ZEN-antigen | 8.8 mg/mL | 1.0 μL | 10 mmol/L PBS (containing 0.15 mol/L NaCl, pH 7.4) |

| ZEN-McAb | 1.0 mg/mL | 3.0 μL | 10 mmol/L PB |

| BSA | 10% | 100 μL | Purified water |

| K2CO3 | 0.2 mol/L | 2.3 μL | Purified water |

| Sample | Spiked (ng/g) | Dilution Times | Visualization a | Digitization (ng/g) | Quantitative Recovery ± SD (%, n = 5) b |

|---|---|---|---|---|---|

| Corn | 0 | 10 | − | ND c | ND |

| 3 | − | 3.4 | 113.3 ± 4.2 | ||

| 20 | ± | 18.6 | 93.0 ± 3.9 | ||

| 50 | + | 59.3 | 118.6 ± 5.5 | ||

| Wheat | 0 | 10 | − | ND | ND |

| 3 | − | 2.6 | 86.7 ± 4.6 | ||

| 20 | ± | 22.4 | 112.0 ± 3.7 | ||

| 50 | + | 45.2 | 90.4 ± 5.8 | ||

| Feed | 0 | 10 | − | ND | ND |

| 3 | − | 3.1 | 103.3 ± 4.9 | ||

| 20 | ± | 23.3 | 116.5 ± 6.2 | ||

| 50 | + | 56.4 | 112.8 ± 3.1 |

| Item | All | Corn | Wheat | Wheat Flour | Cereal Product | Feed |

|---|---|---|---|---|---|---|

| Total samples | 187 | 40 | 19 | 39 | 49 | 40 |

| ZEN-positive samples | 117 | 28 | 7 | 17 | 39 | 26 |

| ZEN-positive rate (%) | 62.6 | 70.0 | 36.8 | 43.6 | 79.6 | 65.0 |

| Average ZEN-positive (ng/g) | 85.0 | 46.8 | 27.1 | 12.4 | 95.9 | 173.0 |

| ZEN-positive range (ng/g) | 2.7–867.0 | 3.2–743.2 | 3.0–117.5 | 6.8–21.3 | 2.7–677.7 | 7.2–867.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, X.; Mao, Y.; Yang, C.; Liu, Z.; Li, M.; Du, D. Contamination of Zearalenone from China in 2019 by a Visual and Digitized Immunochromatographic Assay. Toxins 2020, 12, 521. https://doi.org/10.3390/toxins12080521

Hong X, Mao Y, Yang C, Liu Z, Li M, Du D. Contamination of Zearalenone from China in 2019 by a Visual and Digitized Immunochromatographic Assay. Toxins. 2020; 12(8):521. https://doi.org/10.3390/toxins12080521

Chicago/Turabian StyleHong, Xia, Yuhao Mao, Chuqin Yang, Zhenjiang Liu, Ming Li, and Daolin Du. 2020. "Contamination of Zearalenone from China in 2019 by a Visual and Digitized Immunochromatographic Assay" Toxins 12, no. 8: 521. https://doi.org/10.3390/toxins12080521

APA StyleHong, X., Mao, Y., Yang, C., Liu, Z., Li, M., & Du, D. (2020). Contamination of Zearalenone from China in 2019 by a Visual and Digitized Immunochromatographic Assay. Toxins, 12(8), 521. https://doi.org/10.3390/toxins12080521