3D Food Printing: Principles of Obtaining Digitally-Designed Nourishment

Abstract

:1. Introduction

Background

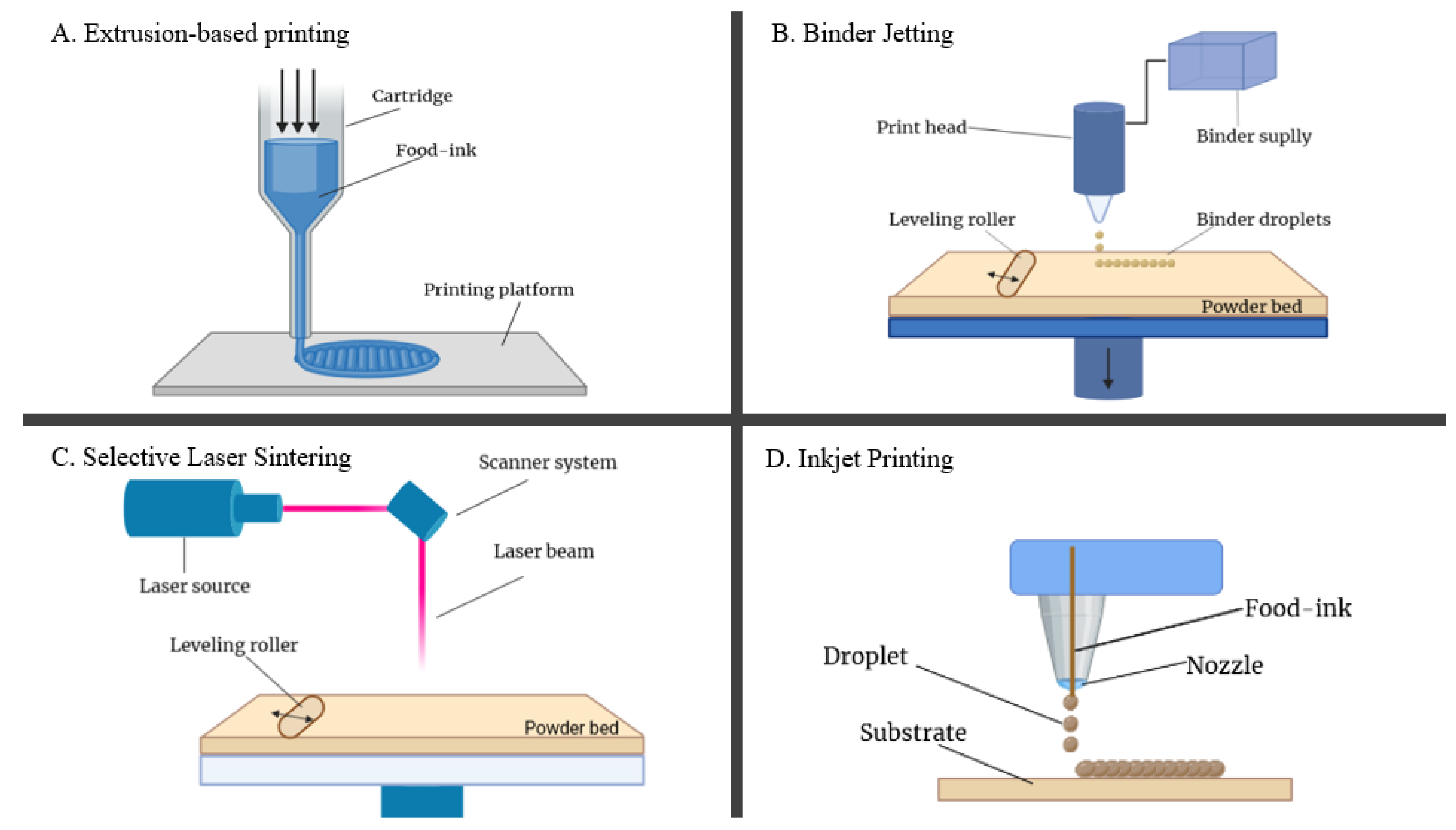

2. Technology of 3DFP

2.1. Extrusion Technology of 3DFP

2.2. Binder Jetting

2.3. Selective Laser Sintering (SLS)/Hot-Air Sintering (HAS)

2.4. Inkjet Printing

3. Sensory Properties of 3D-Printed Food Products

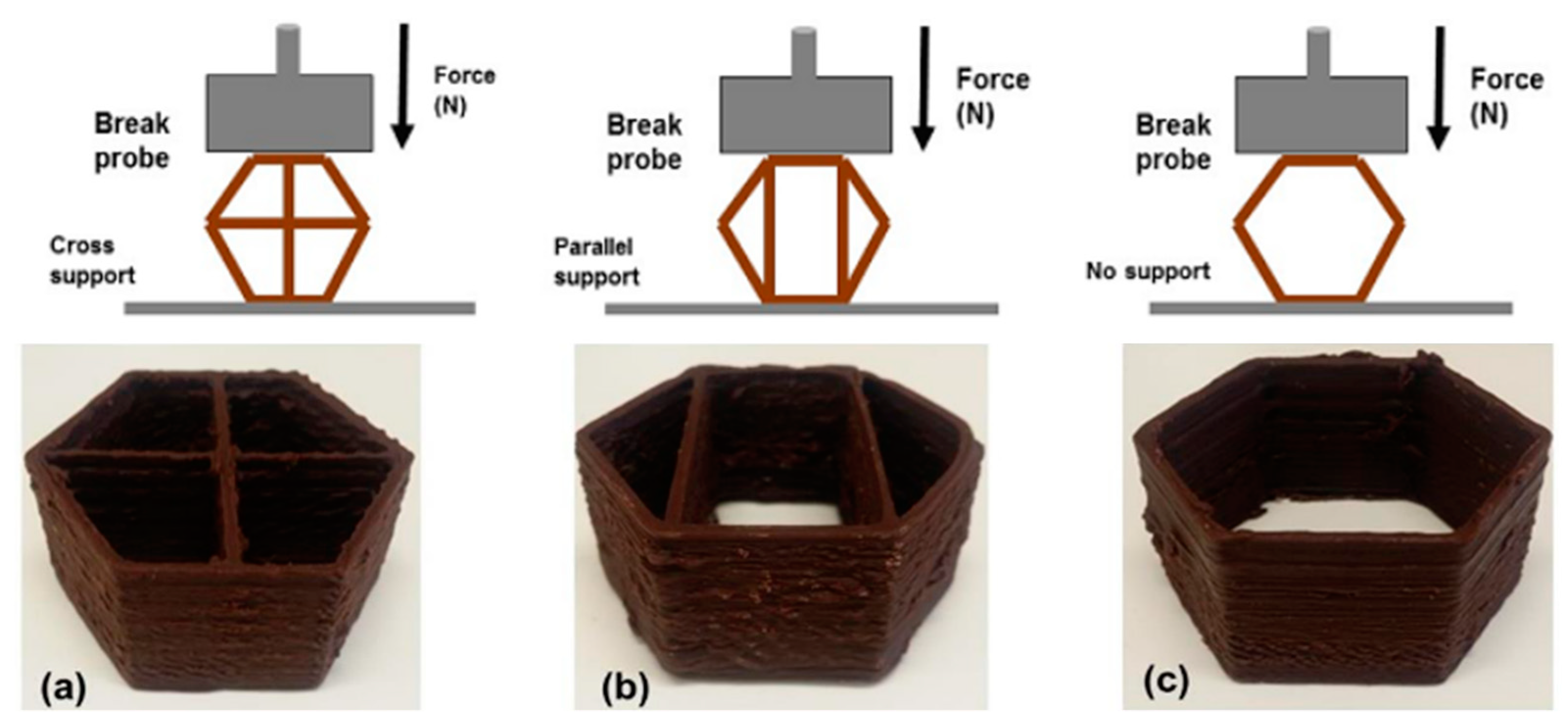

3.1. Texture and Structure

3.2. Rheological Properties

4. The Role of 3D-Printed Food Constituents

4.1. Binding Agents

4.1.1. Xanthan Gum

4.1.2. Pectin

4.1.3. Chitosan

4.2. Coloring Agents

4.2.1. Anthocyanins

4.2.2. Chlorophyll

4.2.3. Spirulina

4.3. Fortifying Constituents

4.3.1. Personalized 3D-Printed Food

Future Perspectives

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dankar, I.; Haddarah, A.; Omar, F.E.L.; Sepulcre, F.; Pujolà, M. 3D printing technology: The new era for food customization and elaboration. Trends Food Sci. Technol. 2018, 75, 231–242. [Google Scholar] [CrossRef]

- Mantihal, S.; Kobun, R.; Lee, B.B. 3D food printing of as the new way of preparing food: A review. Int. J. Gastron. Food Sci. 2020, 22, 100260. [Google Scholar] [CrossRef]

- Gholamipour-shirazi, A.; Kamlow, M.; Norton, I.T.; Mills, T. How to Formulate for Structure and Texture via Medium of Additive Manufacturing—A Review. Foods 2020, 9, 497. [Google Scholar] [CrossRef] [Green Version]

- Álvarez-Castillo, E.; Oliveira, S.; Bengoechea, C.; Sousa, I.; Raymundo, A.; Guerrero, A. A rheological approach to 3D printing of plasma protein based doughs. J. Food Eng. 2021, 288, 110255. [Google Scholar] [CrossRef]

- Burke-Shyne, S.; Gallegos, D.; Williams, T. 3D food printing: Nutrition opportunities and challenges. Br. Food J. 2020. [Google Scholar] [CrossRef]

- Garcia-Segovia, P.; Garcia-Alcaraz, V.; Balasch-Parisi, S.; Martinez-Monzo, J. 3D printing of gels based on xanthan/konjac gums. Innov. Food Sci. Emerg. Technol. 2020, 64, 102343. [Google Scholar] [CrossRef]

- Nida, S.; Moses, T.A.J.A. 3D Printing of Grinding and Milling Fractions of Rice Husk. Waste Biomass Valorization 2020, 12, 81–90. [Google Scholar] [CrossRef]

- Portanguen, S.; Tournayre, P.; Sicard, J.; Astruc, T.; Mirade, P.S. Toward the design of functional foods and biobased products by 3D printing: A review. Trends Food Sci. Technol. 2019, 86, 188–198. [Google Scholar] [CrossRef] [Green Version]

- Baiano, A.; Baiano, A. 3D Printed Foods: A Comprehensive Review on Technologies, Nutritional Value, Safety, Consumer Attitude, Regulatory Framework, and Economic and Sustainability Issues; Taylor & Francis: Oxford, UK, 2020; ISBN 2019000547. [Google Scholar]

- Vancauwenberghe, V.; Mbong, V.B.M.; Vanstreels, E.; Verboven, P.; Lammertyn, J.; Nicolai, B. 3D printing of plant tissue for innovative food manufacturing: Encapsulation of alive plant cells into pectin based bio-ink. J. Food Eng. 2019, 263, 454–464. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Wang, Y. 3D printing: Printing precision and application in food sector. Trends Food Sci. Technol. 2017, 69, 83–94. [Google Scholar] [CrossRef] [Green Version]

- Derossi, A.; Caporizzi, R.; Paolillo, M.; Severini, C. Programmable texture properties of cereal-based snack mediated by 3D printing technology. J. Food Eng. 2020, 289, 110160. [Google Scholar] [CrossRef]

- Szabo, K.; Dulf, F.V.; Teleky, B.E.; Eleni, P.; Boukouvalas, C.; Krokida, M.; Kapsalis, N.; Rusu, A.V.; Socol, C.T.; Vodnar, D.C. Evaluation of the bioactive compounds found in tomato seed oil and tomato peels influenced by industrial heat treatments. Foods 2021, 10, 110. [Google Scholar] [CrossRef] [PubMed]

- Szabo, K.; Emőke Teleky, B.; Ranga, F.; Simon, E.; Lelia Pop, O.; Babalau-Fuss, V.; Kapsalis, N.; Cristian Vodnar, D. Bioaccessibility of microencapsulated carotenoids, recovered from tomato processing industrial by-products, using in vitro digestion model. LWT 2021, 152, 112285. [Google Scholar] [CrossRef]

- Szabo, K.; Dulf, F.V.; Diaconeasa, Z.; Vodnar, D.C. Antimicrobial and antioxidant properties of tomato processing byproducts and their correlation with the biochemical composition. LWT 2019, 116, 108558. [Google Scholar] [CrossRef]

- Landim Neves, M.I.; Silva, E.K.; Meireles, M.A.A. Natural blue food colorants: Consumer acceptance, current alternatives, trends, challenges, and future strategies. Trends Food Sci. Technol. 2021, 112, 163–173. [Google Scholar] [CrossRef]

- Uribe-wandurraga, Z.N.; Igual, M.; Reino-moyón, J.; García-segovia, P. Effect of Microalgae (Arthrospira platensis and Chlorella vulgaris) Addition on 3D Printed Cookies. Food Biophys. 2020, 16, 27–39. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Devahastin, S. Color/aroma changes of 3D-Printed buckwheat dough with yellow flesh peach as triggered by microwave heating of gelatin-gum Arabic complex coacervates. Food Hydrocoll. 2021, 112, 106358. [Google Scholar] [CrossRef]

- Keerthana, K.; Anukiruthika, T.; Moses, J.A.; Anandharamakrishnan, C. Development of fiber-enriched 3D printed snacks from alternative foods: A study on button mushroom. J. Food Eng. 2020, 287, 110116. [Google Scholar] [CrossRef]

- Varghese, C.; Wolodko, J.; Chen, L.; Doschak, M.; Srivastav, P.P.; Roopesh, M.S. Influence of Selected Product and Process Parameters on Microstructure, Rheological, and Textural Properties of 3D Printed Cookies. Foods 2020, 9, 907. [Google Scholar] [CrossRef]

- Pulatsu, E.; Su, J.; Lin, J.; Lin, M. Factors affecting 3D printing and post-processing capacity of cookie dough. Innov. Food Sci. Emerg. Technol. 2020, 61, 102316. [Google Scholar] [CrossRef]

- Liu, Y.; Saeed, A.; Lan, W. Properties of 3D printed dough and optimization of printing parameters. Innov. Food Sci. Emerg. Technol. 2019, 54, 9–18. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Wang, K.; Bao, Y.; Regenstein, J.M.; Zhou, P. Fabrication of gel-like emulsions with whey protein isolate using microfluidization: Rheological properties and 3D printing performance. Food Bioproc. Technol. 2019, 12, 1967–1979. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Zhang, M. Incorporation of probiotics (Bi fi dobacterium animalis subsp. Lactis) into 3D printed mashed potatoes: Effects of variables on the viability. Food Res. Int. 2020, 128, 108795. [Google Scholar] [CrossRef] [PubMed]

- Vicente, A.; Fuci, P.; Oliveira, S.M.; Fasolin, L.H. Printability, microstructure, and flow dynamics of phase-separated edible 3D inks. Food Hydrocoll. 2020, 109, 106120. [Google Scholar] [CrossRef]

- Jonkers, N.; Van Dommelen, J.A.W.; Geers, M.G.D. Experimental characterization and modeling of the mechanical behavior of brittle 3D printed food. J. Food Eng. 2020, 278, 109941. [Google Scholar] [CrossRef]

- Cárdenas, J.; Martinez-Monzo, J.; Garcia-Segovia, P. Effect of Temperature on 3D Printing of Commercial Potato Puree. Food Biophys. 2019, 14, 225–234. [Google Scholar]

- Liu, Z.; Chen, H.; Zheng, B.; Xie, F.; Chen, L. Understanding the structure and rheological properties of potato starch induced by hot-extrusion 3D printing. Food Hydrocoll. 2020, 105, 105812. [Google Scholar] [CrossRef]

- Lee, C.P. 3D printing of milk-based product. RSC Adv. 2020, 10, 29821–29828. [Google Scholar] [CrossRef]

- Theagarajan, R.; Moses, J.A.; Anandharamakrishnan, C. 3D Extrusion Printability of Rice Starch and Optimization of Process Variables. Food Bioproc. Technol. 2020, 13, 1048–1062. [Google Scholar] [CrossRef]

- Caulier, S.; Doets, E.; Noort, M. An exploratory consumer study of 3D printed food perception in a real-life military setting. Food Qual. Prefer. 2020, 86, 104001. [Google Scholar] [CrossRef]

- Phuhongsung, P.; Zhang, M. Influence of Surface pH on Color, Texture and Flavor of 3D Printed Composite. Food Bioproc. Technol. 2020, 13, 1600–1610. [Google Scholar] [CrossRef]

- Zhu, S.; Stieger, M.A.; van der Goot, A.J.; Schutyser, M.A.I. Extrusion-based 3D printing of food pastes: Correlating rheological properties with printing behaviour. Innov. Food Sci. Emerg. Technol. 2019, 58, 102214. [Google Scholar] [CrossRef]

- Liu, L.; Ciftci, O.N. Effects of high oil compositions and printing parameters on food paste properties and printability in a 3D printing food processing model. J. Food Eng. 2021, 288, 110135. [Google Scholar] [CrossRef]

- Pant, A.; Lee, A.Y.; Karyappa, R.; Lee, C.P.; An, J.; Hashimoto, M.; Tan, U.X.; Wong, G.; Chua, C.K.; Zhang, Y. 3D food printing of fresh vegetables using food hydrocolloids for dysphagic patients. Food Hydrocoll. 2021, 114, 106546. [Google Scholar] [CrossRef]

- Derossi, A.; Husain, A.; Caporizzi, R.; Severini, C.; Derossi, A.; Husain, A.; Caporizzi, R.; Severini, C.; Derossi, A.; Husain, A.; et al. Manufacturing personalized food for people uniqueness. An overview from traditional to emerging technologies traditional to emerging technologies. Crit. Rev. Food Sci. Nutr. 2019, 60, 1141–1159. [Google Scholar] [CrossRef]

- Ejtahed, H.S.; Angoorani, P.; Soroush, A.R.; Atlasi, R.; Hasani-Ranjbar, S.; Mortazavian, A.M.; Larijani, B. Probiotics supplementation for the obesity management; A systematic review of animal studies and clinical trials. J. Funct. Foods 2019, 52, 228–242. [Google Scholar] [CrossRef]

- Mitrea, L.; Calinoiu, L.F.; Precup, G.; Bindea, M.; Rusu, B.; Trif, M.; Vodnar, D.C. Isolated microorganisms for bioconversion of biodiesel-derived glycerol into 1, 3-propanediol. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Food Sci. Technol. 2017, 74, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Dick, A.; Bhandari, B.; Prakash, S. Post-processing feasibility of composite-layer 3D printed beef. Meat Sci. 2019, 153, 9–18. [Google Scholar] [CrossRef]

- Siacor, F.D.C.; Chen, Q.; Zhao, J.Y.; Han, L.; Valino, A.D.; Taboada, E.B.; Caldona, E.B.; Advincula, R.C. On the additive manufacturing (3D printing) of viscoelastic materials and flow behavior: From composites to food manufacturing. Addit. Manuf. 2021, 45, 102043. [Google Scholar] [CrossRef]

- Kouzani, A.Z.; Adams, S.; Whyte, D.J.; Oliver, R.; Hemsley, B.; Palmer, S.; Balandin, S. 3D Printing of Food for People with Swallowing Difficulties. KnE Eng. 2017, 2, 23. [Google Scholar] [CrossRef]

- Severini, C.; Derossi, A.; Azzollini, D. Variables affecting the printability of foods: Preliminary tests on cereal-based products. Innov. Food Sci. Emerg. Technol. 2016, 38, 281–291. [Google Scholar] [CrossRef]

- Hamilton, C.A.; Alici, G.; in het Panhuis, M. 3D printing Vegemite and Marmite: Redefining “breadboards”. J. Food Eng. 2018, 220, 83–88. [Google Scholar] [CrossRef] [Green Version]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Bhandari, B.; Yang, C. Investigation on fish surimi gel as promising food material for 3D printing. J. Food Eng. 2018, 220, 101–108. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, M.; Bhandari, B.; Ye, Y. Use of potato processing by-product: Effects on the 3D printing characteristics of the yam and the texture of air-fried yam snacks. LWT 2020, 125, 109265. [Google Scholar] [CrossRef]

- Nachal, N.; Moses, J.A.; Karthik, P.; Anandharamakrishnan, C. Applications of 3D Printing in Food Processing. Food Eng. Rev. 2019, 11, 123–141. [Google Scholar] [CrossRef]

- Laureati, M.; Sandvik, P.; Almli, V.L.; Sandell, M.; Zeinstra, G.G.; Methven, L.; Wallner, M.; Jilani, H.; Alfaro, B.; Proserpio, C. Individual differences in texture preferences among European children: Development and validation of the Child Food Texture Preference Questionnaire (CFTPQ). Food Qual. Prefer. 2020, 80, 103828. [Google Scholar] [CrossRef]

- Fahmy, A.R.; Amann, L.S.; Dunkel, A.; Frank, O.; Dawid, C.; Hofmann, T.; Becker, T.; Jekle, M. Sensory design in food 3D printing—Structuring, texture modulation, taste localization, and thermal stabilization. Innov. Food Sci. Emerg. Technol. 2021, 72, 102743. [Google Scholar] [CrossRef]

- Rodriguez-Concepcion, M.; Avalos, J.; Bonet, M.L.; Boronat, A.; Gomez-Gomez, L.; Hornero-Mendez, D.; Limon, M.C.; Meléndez-Martínez, A.J.; Olmedilla-Alonso, B.; Palou, A.; et al. A global perspective on carotenoids: Metabolism, biotechnology, and benefits for nutrition and health. Prog. Lipid Res. 2018, 70, 62–93. [Google Scholar] [CrossRef] [Green Version]

- Derossi, A.; Caporizzi, R.; Azzollini, D.; Severini, C. Application of 3D printing for customized food. A case on the development of a fruit-based snack for children. J. Food Eng. 2018, 220, 65–75. [Google Scholar] [CrossRef]

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Optimization of chocolate 3D printing by correlating thermal and flow properties with 3D structure modeling. Innov. Food Sci. Emerg. Technol. 2017, 44, 21–29. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.S.; Zhang, M.; Bhandari, B. Assessing the 3D Printing Precision and Texture Properties of Brown Rice Induced by Infill Levels and Printing Variables. Food Bioprocess Technol. 2019, 12, 1185–1196. [Google Scholar] [CrossRef]

- Galanakis, C.M. Gastronomy and Food Science. In Gastronomy and Food Science; Academic Press: Cambridge, UK, 2021; ISBN 9780128200575. [Google Scholar]

- D’Angelo, G.; Hansen, H.N.; Hart, A.J. Molecular Gastronomy Meets 3D Printing: Layered Construction via Reverse Spherification. 3D Print. Addit. Manuf. 2016, 3, 153–159. [Google Scholar] [CrossRef] [Green Version]

- Nijdam, J.J.; LeCorre-Bordes, D.; Delvart, A.; Schon, B.S. A rheological test to assess the ability of food inks to form dimensionally stable 3D food structures. J. Food Eng. 2021, 291, 110235. [Google Scholar] [CrossRef]

- Corker, A.; Ng, H.C.H.; Poole, R.J.; García-Tuñón, E. 3D printing with 2D colloids: Designing rheology protocols to predict “printability” of soft-materials. Soft Matter 2019, 15, 1444–1456. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vancauwenberghe, V.; Katalagarianakis, L.; Wang, Z.; Meerts, M.; Hertog, M.; Verboven, P.; Moldenaers, P.; Hendrickx, M.E.; Lammertyn, J.; Nicolaï, B. Pectin based food-ink formulations for 3-D printing of customizable porous food simulants. Innov. Food Sci. Emerg. Technol. 2017, 42, 138–150. [Google Scholar] [CrossRef]

- Wang, Y.; Yi, S.; Lu, R.; Sameen, D.E.; Ahmed, S.; Dai, J.; Qin, W.; Li, S.; Liu, Y. Preparation, characterization, and 3D printing verification of chitosan/halloysite nanotubes/tea polyphenol nanocomposite films. Int. J. Biol. Macromol. 2021, 166, 32–44. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, M.; Bhandari, B.; Wang, Y.; Wang, B. Improvement of 3D printing properties of rose-sodium alginate heterogeneous gel by adjusting rose material. J. Food Process Eng. 2021, 44, e13583. [Google Scholar] [CrossRef]

- Uribe-Wandurraga, Z.N.; Zhang, L.; Noort, M.W.J.; Schutyser, M.A.I.; García-Segovia, P.; Martínez-Monzó, J. Printability and Physicochemical Properties of Microalgae-Enriched 3D-Printed Snacks. Food Bioprocess Technol. 2020, 13, 2029–2042. [Google Scholar] [CrossRef]

- Pérez-gálvez, A.; Viera, I.; Benito, I.; Roca, M. HPLC-hrTOF-MS study of copper chlorophylls: Composition of food colorants and biochemistry after ingestion. Food Chem. 2020, 321, 126721. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, S.M.; Gruppi, A.; Vieira, M.V.; Matos, G.S.; Vicente, A.A.; Teixeira, J.A.C.; Fuciños, P.; Spigno, G.; Pastrana, L.M. How additive manufacturing can boost the bioactivity of baked functional foods. J. Food Eng. 2021, 294, 110394. [Google Scholar]

- Scheele, S.C.; Hoque, M.N.; Christopher, G.; Egan, P.F. Printability and Fidelity of Protein-Enriched 3D Printed Foods: A Case Study Using Cricket and Pea Protein Powder. Available online: https://www.researchgate.net/publication/350710060_Printability_and_Fidelity_of_Protein-Enriched_3D_Printed_Foods_A_Case_Study_Using_Cricket_and_Pea_Protein_Powder (accessed on 11 August 2021).

- Abu Elella, M.H.; Goda, E.S.; Gab-Allah, M.A.; Hong, S.E.; Pandit, B.; Lee, S.; Gamal, H.; Rehman, A.U.; Yoon, K.R. Xanthan gum-derived materials for applications in environment and eco-friendly materials: A review. J. Environ. Chem. Eng. 2021, 9, 104702. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Prakash, S.; Mantihal, S.; Zhang, M. Linking rheology and printability of a multicomponent gel system of carrageenan-xanthan-starch in extrusion based additive manufacturing. Food Hydrocoll. 2019, 87, 413–424. [Google Scholar] [CrossRef]

- Pérez, B.; Nykvist, H.; Brøgger, A.F.; Barmar, M.; Fiilsøe, M. Impact of macronutrients printability and 3D-printer parameters on 3D-food printing: A review. Food Chem. 2019, 287, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Martau, G.A.; Mihai, M.; Vodnar, D.C. The use of chitosan, alginate, and pectin in the biomedical and food sector-biocompatibility, bioadhesiveness, and biodegradability. Polymers 2019, 11, 1837. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Q.; Ji, N.; Xiong, L.; Sun, Q. Rapid gelling, self-healing, and fluorescence-responsive chitosan hydrogels formed by dynamic covalent crosslinking. Carbohydr. Polym. 2020, 246, 116586. [Google Scholar] [CrossRef] [PubMed]

- Szabo, K.; Teleky, B.E.; Mitrea, L.; Călinoiu, L.F.; Martău, G.A.; Simon, E.; Varvara, R.A.; Vodnar, D.C. Active packaging-poly (vinyl alcohol) films enriched with tomato by-products extract. Coatings 2020, 10, 141. [Google Scholar] [CrossRef] [Green Version]

- Bergonzi, C.; Di Natale, A.; Zimetti, F.; Marchi, C.; Bianchera, A.; Bernini, F.; Silvestri, M.; Bettini, R.; Elviri, L. Study of 3D-printed chitosan scaffold features after different post-printing gelation processes. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Yi, W.; Liu, G.; Kang, N.; Ma, L.; Yang, G. Colour and chlorophyll level modelling in vacuum-precooled green beans during storage. J. Food Eng. 2021, 301, 110523. [Google Scholar] [CrossRef]

- Martău, G.A.; Călinoiu, L.F.; Vodnar, D.C. Bio-vanillin: Towards a sustainable industrial production. Trends Food Sci. Technol. 2021, 109, 579–592. [Google Scholar] [CrossRef]

- Mitrea, L.; Lavinia-florina, C.; Mart, G.; Rusu, A.; Szabo, K.; Teleky, B.; Mures, V. Polyols and Colored with Pigments Extracted from Tomato By-Products. Polymers 2020, 12, 532. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karimi, A.; Kazemi, M.; Samani, S.A.; Simal-Gandara, J. Bioactive compounds from by-products of eggplant: Functional properties, potential applications and advances in valorization methods. Trends Food Sci. Technol. 2021, 112, 518–531. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, C.; Huang, Z.; Lyu, L.; Li, J.; Li, W.; Wu, W. The Color Difference of Rubus Fruits is Closely Related to the Composition of Flavonoids including Anthocyanins. LWT 2021, 149, 111825. [Google Scholar] [CrossRef]

- Milenkovic, D.; Krga, I.; Dinel, A.; Morand, C.; Laye, S.; Castanon, N. Nutrigenomic modification induced by anthocyanin-rich bilberry extract in the hippocampus of ApoE-/- mice. J. Funct. Foods 2021, 85, 104609. [Google Scholar] [CrossRef]

- Cai, J.Q.; Liu, X.M.; Gao, Z.J.; Li, L.L.; Wang, H. Chlorophylls derivatives: Photophysical properties, assemblies, nanostructures and biomedical applications. Mater. Today 2021. [Google Scholar] [CrossRef]

- Sharifi, K.A.; Pirsa, S. Biodegradable film of black mulberry pulp pectin/chlorophyll of black mulberry leaf encapsulated with carboxymethylcellulose/silica nanoparticles: Investigation of physicochemical and antimicrobial properties. Mater. Chem. Phys. 2021, 267, 124580. [Google Scholar] [CrossRef]

- Soni, R.A.; Sudhakar, K.; Rana, R.S. Spirulina—From growth to nutritional product: A review. Trends Food Sci. Technol. 2017, 69, 157–171. [Google Scholar] [CrossRef] [Green Version]

- Vieira, M.V.; Oliveira, S.M.; Amado, I.R.; Fasolin, L.H.; Vicente, A.A.; Pastrana, L.M.; Fuciños, P. 3D printed functional cookies fortified with Arthrospira platensis: Evaluation of its antioxidant potential and physical-chemical characterization. Food Hydrocoll. 2020, 107, 105893. [Google Scholar] [CrossRef]

- Picciotti, U.; Massaro, A.; Galiano, A.; Garganese, F. Cheese Fortification: Review and Possible Improvements. Food Rev. Int. 2021, 1–27. [Google Scholar] [CrossRef]

- Ștefănescu, B.E.; Călinoiu, L.F.; Ranga, F.; Fetea, F.; Mocan, A.; Vodnar, D.C.; Crișan, G. Chemical composition and biological activities of the nord-west romanian wild bilberry (Vaccinium myrtillus L.) and lingonberry (Vaccinium vitisidaea L.) leaves. Antioxidants 2020, 9, 495. [Google Scholar] [CrossRef]

- Mostafai, R.; Nachvakc, S.M.; Mohammadi, R.; Rocha, R.S.; da Silva, M.C.; Esmerino, E.A.; Nascimento, K.O.; Cruz, A.G.; Mortazavian, A.M. Effects of vitamin D-fortified yogurt in comparison to oral vitamin D supplement on hyperlipidemia in pre-diabetic patients: A randomized clinical trial. J. Funct. Foods 2019, 52, 116–120. [Google Scholar] [CrossRef]

- Fazilah, N.F.; Ariff, A.B.; Khayat, M.E.; Rios-Solis, L.; Halim, M. Influence of probiotics, prebiotics, synbiotics and bioactive phytochemicals on the formulation of functional yogurt. J. Funct. Foods 2018, 48, 387–399. [Google Scholar] [CrossRef]

- Luo, D.; Lin, Z.; Li, S.; Liu, S.J. Effect of nutritional supplement combined with exercise intervention on sarcopenia in the elderly: A meta-analysis. Int. J. Nurs. Sci. 2017, 4, 389–401. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Prakash, S. 3D printing of meat. Meat Sci. 2019, 153, 35–44. [Google Scholar] [CrossRef]

- Vodnar, D.C.; Mitrea, L.; Teleky, B.E.; Szabo, K.; Călinoiu, L.F.; Nemeş, S.A.; Martău, G.A. Coronavirus disease (COVID-19) caused by (sars-cov-2) infections: A real challenge for human gut microbiota. Front. Cell. Infect. Microbiol. 2020, 10, 786. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Zhang, M.; Chitrakar, B.; Adhikari, B. Recent advances in functional 3D printing of foods: A review of functions of ingredients and internal structures. Crit. Rev. Food Sci. Nutr. 2020, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Dick, A.; Bhandari, B.; Prakash, S. Effect of reheating method on the post-processing characterisation of 3D printed meat products for dysphagia patients. LWT 2021, 150, 111915. [Google Scholar] [CrossRef]

- Urbina, P.; Marin, C.; Sanz, T.; Rodrigo, D.; Martinez, A. Effect of hhp, enzymes and gelatin on physicochemical factors of gels made by using protein isolated from common cricket (Acheta domesticus). Foods 2021, 10, 858. [Google Scholar] [CrossRef]

- Oyinloye, T.M.; Yoon, W.B. Stability of 3D printing using a mixture of pea protein and alginate: Precision and application of additive layer manufacturing simulation approach for stress distribution. J. Food Eng. 2020, 288, 110127. [Google Scholar] [CrossRef]

- Ross, M.M.; Crowley, S.V.; Crotty, S.; Oliveira, J.; Morrison, A.P.; Kelly, A.L. Parameters affecting the printability of 3D-printed processed cheese. Innov. Food Sci. Emerg. Technol. 2021, 72, 102730. [Google Scholar] [CrossRef]

- Piovesan, A.; Vancauwenberghe, V.; Aregawi, W.; Delele, M.A.; Bongaers, E.; de Schipper, M.; van Bommel, K.; Noort, M.; Verboven, P.; Nicolai, B. Designing Mechanical Properties of 3D Printed Cookies through Computer Aided Engineering. Foods 2020, 9, 1804. [Google Scholar] [CrossRef] [PubMed]

- Namsoo, P.K.; Abhilash, A.; Hyun-Jin, K.; Hee-Deung, P. Unique Approach of a Telemedicine System for CBD-Infused Foods. Processes 2021, 9, 936. [Google Scholar] [CrossRef]

| Food Products | Printing Method | Printer | Objectives/ Findings of the Study | Reference |

|---|---|---|---|---|

| 3D-printed cereal-snack bar | Extrusion | 3D printer Delta 2040 equipped with a clay extruder kit 2.0 |

| [12] |

| 3D-printed buckwheat dough with yellow flesh peach, enriched with complex coacervates microcapsules | Extrusion | SHINNOVE-D1 3D food printer |

| [18] |

| Button mushroom | Extrusion | 3D printer CARK |

| [19] |

| Cookies | Extrusion | A FoodBot 3D-printer |

| [20] |

| Cookie dough | Extrusion | Modified 3D printer by replacement of the nozzle with a digital air syringe dispenser. |

| [21] |

| Cookies with microalgae | Extrusion | 3D food printer equipped with a pasta extruder nozzle designed for food materials |

| [17] |

| Dough | Extrusion | Extrusion system with an air pump and an X-Y-Z position device. |

| [22] |

| Emulsion with whey protein isolate and soy oil | Extrusion | 3D food printer |

| [23] |

| Gels based on xanthan/ konjac gums | Extrusion | Commercial 3D printer equipped with a paste extruder nozzle to work with food ingredients |

| [6] |

| Grinding and milling fractions of rice husk with the addition of guar gum | Extrusion | 3D food printer CARK |

| [7] |

| Mashed potatoes with probiotics (Bifidobacterium animalis subsp. Lactis) | Extrusion | Two-nozzle printer |

| [24] |

| Mixture of whey protein isolate and gellan gum (GG) | Extrusion | Focus 3D food printer (byFlow) |

| [25] |

| Mixture of 50% native wheat starch + 40% maltodextrin + 10% palm oil powder | Selective laser sintering | - |

| [26] |

| Potato puree | Extrusion | Commercial 3D printer equipped with a paste extruder nozzle to work with food ingredients |

| [27] |

| Potato starch | Extrusion —hot | SHINNOVE-S2 printer |

| [28] |

| Powdered milk | Extrusion —cold | Pneumatic Direct Ink writing (DIW) printer |

| [29] |

| Rice starch | Extrusion | 3D printer CARK |

| [30] |

| Snack bars (Acceptance study) |

| [31] | ||

| Soy protein isolate, pumpkin, and beetroot mixture | Extrusion | 3D-printing system |

| [32] |

| Tomato paste | Extrusion | ByFlow 3D printer |

| [33] |

| High-oil-content (up to 37%) pastes | Extrusion | ByFlow 3D printer |

| [34] |

| Fresh and frozen vegetables with addition of hydrocolloids | Extrusion | FOODINI |

| [35] |

| Type of Product | Printing Parameters | Reference | ||||||

|---|---|---|---|---|---|---|---|---|

| Nozzle Diameter | Nozzle Height | Nozzle Moving Speed | Extrusion Rate | Printing Pressure | Temperature | Time | ||

| Surimi gel | 2 mm | 5 mm | 28 mm/s | 0.003 cm3/s | NS | 25 °C | NS | [45] |

| Plasma protein-based doughs | 1.5 mm | NS | NS | 0.0024 mL/s | NS | 20 °C | 6.5 min | [4] |

| Buckwheat dough with yellow flesh peach | 1.2 mm | NS | 20 mm/s | 35 mm3/s | NS | 25 °C | NS | [18] |

| Vegemite and Marmite | NS | NS | NS | NS | 15 psi (103 kPa) | 25 °C | NS | [43] |

| Yam-Potato by-product paste | 1.2 mm | NS | 20 mm/s | 22 mm3/s | NS | 23 ± 1 °C | NS | [46] |

| 15–25% potato starch | 0.8 mm | 1.0 mm | 30 mm/s | NS | NS | 70 °C | NS | [28] |

| Beef | N1 = 2 mm/N2 = 1 mm | NS | 20 mm/s | NS | NS | 23± 1 °C | 6.37 min, up to 10 min | [39] |

| Function | Constituent | Source | Application | Reference |

|---|---|---|---|---|

| Binding agent | Xanthan gum | Xanthomonas campestris | Printable gels based on xanthan gum. | [6] |

| Pectin | Fruits and vegetable pomaces (e.g., apple, sugar beet pulp, etc.) | 3D-printed objects from pectin-based food-ink. | [58] | |

| Chitosan | Shellfish, fungi, insects | 3D-printed chitosan/halloysite nanotubes/tea polyphenol nanocomposite films. | [59] | |

| Coloring agent | Anthocyanins | Flowers and fruits of plants (e.g., raspberry, eggplant, etc.) | 3D-printed snack food with the addition of rose petals. | [60] |

| Chlorophyll | Plants, algae and bacteria | 3D-printed cereal snack with the addition of Chlorella. | [61] | |

| Spirulina | Blue-green algae | Cookie dough with spirulina extract. | [62] | |

| Fortifying constituents | Bioactive compounds (polyphenols, antioxidants, and essential oils) | Plants | Cookies enriched with encapsulated polyphenols. | [63] |

| Protein | Meat, eggs, dairy products, etc. | Incorporated cricket and pea protein powder in 3DP mashed potatoes formulations. | [64] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varvara, R.-A.; Szabo, K.; Vodnar, D.C. 3D Food Printing: Principles of Obtaining Digitally-Designed Nourishment. Nutrients 2021, 13, 3617. https://doi.org/10.3390/nu13103617

Varvara R-A, Szabo K, Vodnar DC. 3D Food Printing: Principles of Obtaining Digitally-Designed Nourishment. Nutrients. 2021; 13(10):3617. https://doi.org/10.3390/nu13103617

Chicago/Turabian StyleVarvara, Rodica-Anita, Katalin Szabo, and Dan Cristian Vodnar. 2021. "3D Food Printing: Principles of Obtaining Digitally-Designed Nourishment" Nutrients 13, no. 10: 3617. https://doi.org/10.3390/nu13103617

APA StyleVarvara, R.-A., Szabo, K., & Vodnar, D. C. (2021). 3D Food Printing: Principles of Obtaining Digitally-Designed Nourishment. Nutrients, 13(10), 3617. https://doi.org/10.3390/nu13103617