Dual-Branch Diffusion Detection Model for Photovoltaic Array and Hotspot Defect Detection in Infrared Images

Abstract

1. Introduction

- (1)

- A UAV equipped with an infrared imager patrols the photovoltaic power station, capturing high-resolution infrared images of photovoltaic modules.

- (2)

- The images are uploaded to a local or remote server, where the PV array and hotspot detection model analyzes them.

- (3)

- The model processes the infrared images to detect and pinpoint the positions of photovoltaic strings and fault hotspots. By integrating GPS information from the images, precise fault locations are determined swiftly.

- (4)

- Armed with this detection information, maintenance personnel can promptly access and address identified faults, optimizing maintenance efficiency and minimizing downtime.

1.1. Related Works

1.2. Motivations and Novelties

1.2.1. Motivations

1.2.2. Novelties

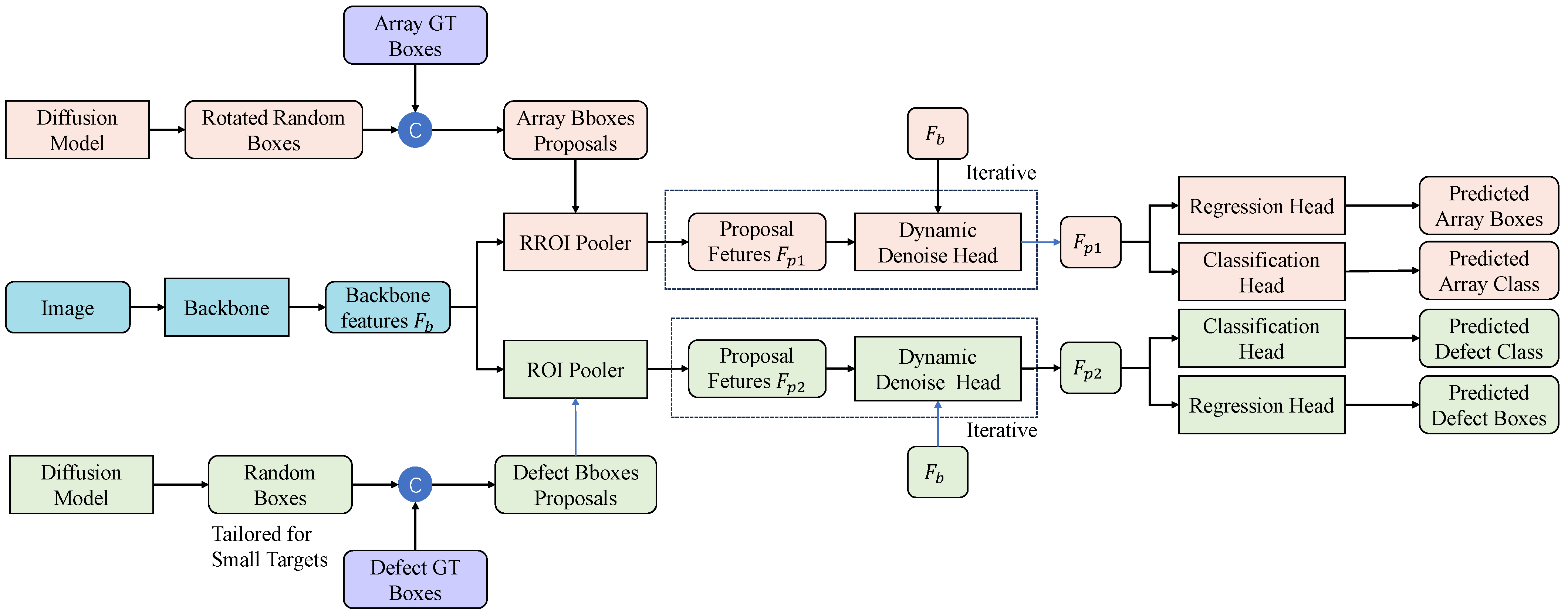

- A dual-branch detection network architecture is proposed. The proposed network includes two branches—one for PV arrays and the other for hotspot defects. The branches share low-level image features to model their correlations, while possessing independent detection heads to learn high-level semantic features. This separable architecture enhances the flexibility of the network, alleviating the class imbalance and scale disparity issues between arrays and hotspots.

- A diffusion-based rotated bounding box detection branch is introduced for photovoltaic arrays, alongside a small-object detection branch for hotspot defects. The anchor-free nature of the diffusion-based approach improves sensitivity to rotation angles and adaptability to varying target scales.

- The inside-awareness loss function is developed for the dual-branch model to explicitly model the dependency distribution between arrays and defects. This loss function penalizes deviation in their internal and external relationships, guiding the model to learn from the bounding boxes for the hotspot defects located within arrays. The inside-awareness loss comprises two components—Inside IoU and Union-over-Convex-Hull loss. These terms guide the model to generate bounding boxes with compact scales and consistent scale ratios. The experimental results demonstrate that this loss significantly enhances the robustness of the detection model.

2. Preliminaries

3. Dual-Branch Photovoltaic Diagnose Network

3.1. Dual-Branch Architecture

3.2. The Array Branch

3.3. The Defect Branch

- Emphasizing internal inclusion: Unlike standard IoU, IIoU explicitly emphasizes whether is located inside , enhancing the model’s understanding of the internal layout of the bounding box.

- Focusing on small target boxes: By using as the denominator, IIoU inherently guides the model to prioritize learning small target boxes. This aligns with the nature of defect detection, where defects are generally small targets.

- Suppressing external expansion: UoC penalizes the excessive outward expansion of the defect box, guiding the model to suppress such behavior. As shown in Figure 5b,c, UoC decreases as the predicted box (green solid box) deviates farther from the ground truth (orange solid box). This, in turn, causes to increase, strengthening the penalization effect.

- Encouraging scale consistency: Leveraging the properties of the convex hull, UoC guides the model to predict boxes that are consistent in scale with the ground truth. For example, in Figure 5b, under the same outside position, the middle case whose , with a scale matching (), outperforms the right case with smaller predicted box (). Similarly, in Figure 5d, the left case with scale consistency () is preferred over the right case ().

4. Experimental Results and Analysis

4.1. Experimental Settings

4.1.1. Dataset

4.1.2. Evaluation Metrics

4.1.3. Implementation Details

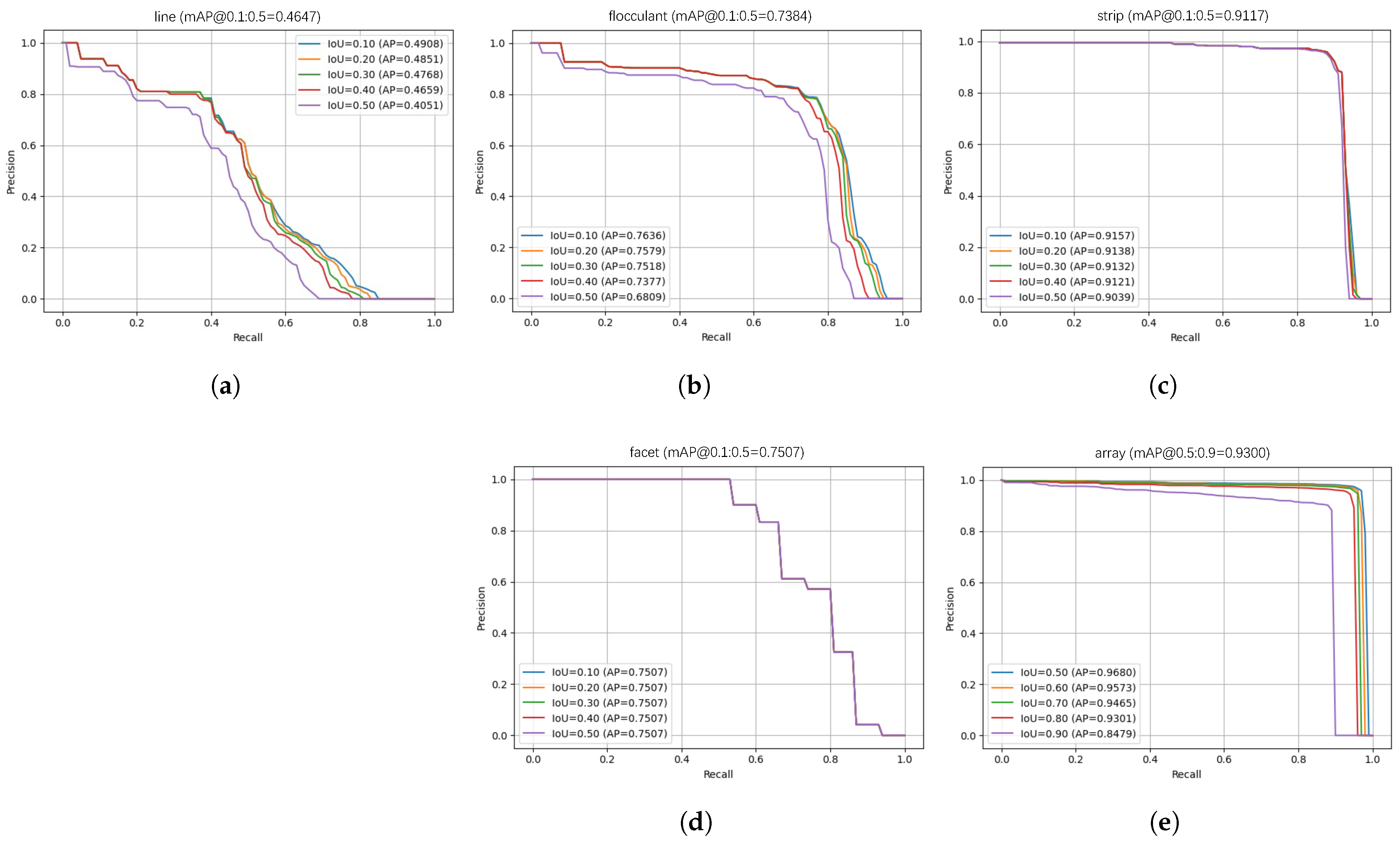

4.2. Qualitative Analysis

4.3. Quantitative Analysis

4.4. Comparative Analysis

4.4.1. Qualitative Comparison

4.4.2. Quantitative Comparison

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Čabo, F.G.; Marinić-Kragić, I.; Garma, T.; Nižetić, S. Development of thermo-electrical model of photovoltaic panel under hot-spot conditions with experimental validation. Energy 2021, 230, 120785. [Google Scholar] [CrossRef]

- Du, B.; Yang, R.; He, Y.; Wang, F.; Huang, S. Nondestructive inspection, testing and evaluation for Si-based, thin film and multi-junction solar cells: An overview. Renew. Sustain. Energy Rev. 2017, 78, 1117–1151. [Google Scholar] [CrossRef]

- Shengxue, T.; Yue, X.; Li, C.; Xiao, S.; Fang, Y. Study on suppressing strategy of hot spot in solar cell series. Acta Energiae Solaris Sin. 2022, 43, 226. [Google Scholar]

- Michail, A.; Livera, A.; Tziolis, G.; Candás, J.L.C.; Fernandez, A.; Yudego, E.A.; Martínez, D.F.; Antonopoulos, A.; Tripolitsiotis, A.; Partsinevelos, P.; et al. A comprehensive review of unmanned aerial vehicle-based approaches to support photovoltaic plant diagnosis. Heliyon 2024, 10, e23983. [Google Scholar] [CrossRef] [PubMed]

- Lofstad-Lie, V.; Marstein, E.S.; Simonsen, A.; Skauli, T. Cost-Effective Flight Strategy for Aerial Thermography Inspection of Photovoltaic Power Plants. IEEE J. Photovolt. 2022, 12, 1543–1549. [Google Scholar] [CrossRef]

- de Oliveira, A.K.V.; Aghaei, M.; Rüther, R. Automatic Inspection of Photovoltaic Power Plants Using Aerial Infrared Thermography: A Review. Energies 2022, 15, 2055. [Google Scholar] [CrossRef]

- Dotenco, S.; Dalsass, M.; Winkler, L.; Würzner, T.; Brabec, C.; Maier, A.; Gallwitz, F. Automatic detection and analysis of photovoltaic modules in aerial infrared imagery. In Proceedings of the 2016 IEEE Winter Conference on Applications of Computer Vision (WACV), Lake Placid, NY, USA, 7–10 March 2016; pp. 1–9. [Google Scholar] [CrossRef]

- Jiang, L.; Su, J.; Li, X. Hot spots detection of operating PV arrays through IR thermal image using method based on curve fitting of gray histogram. Matec Web Conf. 2016, 61, 06017. [Google Scholar] [CrossRef]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.Y.; Berg, A.C. SSD: Single Shot MultiBox Detector. In Proceedings of the Computer Vision—ECCV 2016, Amsterdam, The Netherlands, 11–14 October 2016; Leibe, B., Matas, J., Sebe, N., Welling, M., Eds.; Springer: Cham, Switzerland, 2016; pp. 21–37. [Google Scholar]

- Terven, J.; Córdova-Esparza, D.M.; Romero-González, J.A. A Comprehensive Review of YOLO Architectures in Computer Vision: From YOLOv1 to YOLOv8 and YOLO-NAS. Mach. Learn. Knowl. Extr. 2023, 5, 1680–1716. [Google Scholar] [CrossRef]

- Jocher, G.; Stoken, A.; Borovec, J.; Changyu, L.; Hogan, A.; Diaconu, L.; Ingham, F.; Poznanski, J.; Fang, J.; Yu, L.; et al. ultralytics/yolov5: v3. 1-bug fixes and performance improvements. Zenodo 2020. [Google Scholar]

- Wu, X.; Hao, X. SK-FRCNN: A Fault Detection Method for Hot Spots on Photovoltaic Panels. IEEE Access 2023, 11, 121379–121386. [Google Scholar] [CrossRef]

- Hao, S.; Li, J.; Ma, X.; Sun, S.; Tian, Z.; Li, T.; Hou, Y. A Photovoltaic Hot-Spot Fault Detection Network for Aerial Images Based on Progressive Transfer Learning and Multiscale Feature Fusion. IEEE Trans. Geosci. Remote Sens. 2024, 62, 4709713. [Google Scholar] [CrossRef]

- Qian, H.; Shen, W.; Xu, W.S. Hotspot defect detection for photovoltaic modules under complex backgrounds. Multimed. Syst. 2023, 29, 3245–3258. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, X.; Guan, A.H. Deeplab-YOLO: A method for detecting hot-spot defects in infrared image PV panels by combining segmentation and detection. J. Real-Time Image Process. 2024, 21, 52.1–52.11. [Google Scholar] [CrossRef]

- Zahradník, D.; Roučka, F.; Karlovská, L. Flat roof classification and leaks detections by Deep Learning. Stavebni Obz.-Civ. Eng. J. 2023, 32. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Wu, H.; Suzuki, S.; Namiki, A.; Wang, W. Design and Application of a UAV Autonomous Inspection System for High-Voltage Power Transmission Lines. Remote Sens. 2023, 15, 865. [Google Scholar] [CrossRef]

- Mei, B.; Han, R.; Jiang, X.; Wang, Y.; Yin, D. Failure Detection Of Infrared Thermal Imaging Power Equipment Based On Improved DenseNet. In Proceedings of the 2021 14th International Congress on Image and Signal Processing, BioMedical Engineering and Informatics (CISP-BMEI), Shanghai, China, 23–25 October 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Liao, K.C.; Liou, J.L.; Hidayat, M.; Wen, H.T.; Wu, H.Y. Detection and Analysis of Aircraft Composite Material Structures Using UAV. Inventions 2024, 9, 47. [Google Scholar] [CrossRef]

- Wyatt, J.; Leach, A.; Schmon, S.M.; Willcocks, C.G. AnoDDPM: Anomaly Detection with Denoising Diffusion Probabilistic Models Using Simplex Noise. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR) Workshops, New Orleans, LA, USA, 19–20 June 2022; pp. 650–656. [Google Scholar]

- Chen, S.; Sun, P.; Song, Y.; Luo, P. DiffusionDet: Diffusion Model for Object Detection. In Proceedings of the IEEE/CVF International Conference on Computer Vision (ICCV), Paris, France, 2–6 October 2023; pp. 19830–19843. [Google Scholar]

- Nag, S.; Zhu, X.; Deng, J.; Song, Y.Z.; Xiang, T. DiffTAD: Temporal Action Detection with Proposal Denoising Diffusion. In Proceedings of the IEEE/CVF International Conference on Computer Vision (ICCV), Paris, France, 2–6 October 2023; pp. 10362–10374. [Google Scholar]

- Shi, Y.; Lin, Y.; Wei, P.; Xian, X.; Chen, T.; Lin, L. Diff-Mosaic: Augmenting Realistic Representations in Infrared Small Target Detection via Diffusion Prior. IEEE Trans. Geosci. Remote Sens. 2024, 62, 5004311. [Google Scholar] [CrossRef]

- Zhou, X.; Hou, J.; Yao, T.; Liang, D.; Liu, Z.; Zou, Z.; Ye, X.; Cheng, J.; Bai, X. Diffusion-Based 3D Object Detection with Random Boxes. In Proceedings of the Pattern Recognition and Computer Vision, Xiamen, China, 13–15 October 2023; Liu, Q., Wang, H., Ma, Z., Zheng, W., Zha, H., Chen, X., Wang, L., Ji, R., Eds.; Springer: Singapore, 2024; pp. 28–40. [Google Scholar]

- He, T.; Hao, S.; Zhang, X.; Ma, X.; Sun, S.; Yang, C. APM²Det: A Photovoltaic Hot-Spot Fault Detection Network Based on Angle Perception and Model Migration. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 2938–2946. [Google Scholar] [CrossRef]

- Wang, D.; Yan, P.; Yao, C.; Xiao, B.; Zhao, W.; Zhu, R. A lightweight joint metric detection approach on YOLO for hot spots in photovoltaic modules. J. Renew. Sustain. Energy 2024, 16, 053503. [Google Scholar] [CrossRef]

- Tan, H.; Guo, Z.; Zhang, H.; Chen, Q.; Lin, Z.; Chen, Y.; Yan, J. Enhancing PV panel segmentation in remote sensing images with constraint refinement modules. Appl. Energy 2023, 350, 121757. [Google Scholar] [CrossRef]

- Guo, Z.; Zhuang, Z.; Tan, H.; Liu, Z.; Li, P.; Lin, Z.; Shang, W.L.; Zhang, H.; Yan, J. Accurate and generalizable photovoltaic panel segmentation using deep learning for imbalanced datasets. Renew. Energy 2023, 219, 119471. [Google Scholar] [CrossRef]

- Ho, J.; Jain, A.; Abbeel, P. Denoising Diffusion Probabilistic Models. In Advances in Neural Information Processing Systems; Larochelle, H., Ranzato, M., Hadsell, R., Balcan, M., Lin, H., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2020; Volume 33, pp. 6840–6851. [Google Scholar]

- Song, J.; Meng, C.; Ermon, S. Denoising Diffusion Implicit Models. arXiv 2022, arXiv:2206.05564. [Google Scholar] [CrossRef]

- Rombach, R.; Blattmann, A.; Lorenz, D.; Esser, P.; Ommer, B. High-Resolution Image Synthesis With Latent Diffusion Models. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), New Orleans, LA, USA, 18–24 June 2022; pp. 10684–10695. [Google Scholar]

- Karras, T.; Aittala, M.; Aila, T.; Laine, S. Elucidating the Design Space of Diffusion-Based Generative Models. In Advances in Neural Information Processing Systems; Koyejo, S., Mohamed, S., Agarwal, A., Belgrave, D., Cho, K., Oh, A., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2022; Volume 35, pp. 26565–26577. [Google Scholar]

- Ding, X.; Wang, Y.; Zhang, K.; Wang, Z.J. CCDM: Continuous Conditional Diffusion Models for Image Generation. arXiv 2024, arXiv:22405.03546. [Google Scholar] [CrossRef]

- Rezatofighi, H.; Tsoi, N.; Gwak, J.; Sadeghian, A.; Reid, I.; Savarese, S. Generalized Intersection Over Union: A Metric and a Loss for Bounding Box Regression. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Long Beach, CA, USA, 15–20 June 2019. [Google Scholar]

- Russell, B.C.; Torralba, A.; Murphy, K.P.; Freeman, W.T. LabelMe: A Database and Web-Based Tool for Image Annotation. Int. J. Comput. Vis. 2008, 77, 157–173. [Google Scholar] [CrossRef]

| Category | Description | #Instances | Size | Rotation * |

|---|---|---|---|---|

| Line | Hotspot caused by PV module shielding, bubble, delamination, dirt, and gate line fracture. | 2283 | Small target within or | - |

| Flocculant | Hotspot caused by PV module occlusion, dirt, and rupture. | 3310 | Small target within | - |

| Strip | Hotspot caused by PV module occlusion, dirt, diode failure, and bracket deformation. | 3377 | Small target within or | - |

| Facet | Hotspot caused by PV module fragmentation, module failure, and module disconnection. | 168 | Small target within or | - |

| Array | A complete power-generating unit, consisting of any number of PV modules and panels. | 32,960 | Rotated rectangles with various sizes |

| Categories | Precision@0.1 | Precision@0.5 | Recall@0.1 | Recall@0.5 | AP@0.1:0.5 | AP@0.5:0.9 |

|---|---|---|---|---|---|---|

| Line Hotspot | 0.6091 | 0.5556 | 0.4900 | 0.4400 | 0.4647 | 0.1650 |

| Flo Hotspot | 0.7873 | 0.7302 | 0.7700 | 0.7200 | 0.7384 | 0.3697 |

| Strip Hotspot | 0.9219 | 0.9325 | 0.9000 | 0.8900 | 0.9117 | 0.5665 |

| Facet Hotspot | 0.8333 | 0.8333 | 0.6600 | 0.6600 | 0.7507 | 0.4930 |

| Average | 0.7879 | 0.7050 | 0.7629 | 0.6775 | 0.7164 | 0.3986 |

| PV Array | 0.9754 | 0.9671 | 0.9700 | 0.9600 | 0.9773 | 0.9300 |

| Categories | Models | AP@0.1:0.5 | AP@0.5:0.9 |

|---|---|---|---|

| Line Hotspot | Faster RCNN with RRPN | 0.1069 | 0.0114 |

| DiffusionDet with RRPN | 0.3843 | 0.1242 | |

| Ours | 0.4647 | 0.1650 | |

| Flo Hotspot | Faster RCNN with RRPN | 0.6456 | 0.3091 |

| DiffusionDet with RRPN | 0.6851 | 0.3336 | |

| Ours | 0.7384 | 0.3697 | |

| Strip Hotspot | Faster RCNN with RRPN | 0.8733 | 0.5360 |

| DiffusionDet with RRPN | 0.8120 | 0.4921 | |

| Ours | 0.9117 | 0.5665 | |

| Facet Hotspot | Faster RCNN with RRPN | 0.2825 | 0.1495 |

| DiffusionDet with RRPN | 0.6663 | 0.3365 | |

| Ours | 0.7507 | 0.4930 | |

| Average | Faster RCNN with RRPN | 0.4618 | 0.2402 |

| DiffusionDet with RRPN | 0.6523 | 0.3447 | |

| Ours | 0.7164 | 0.3986 | |

| PV Array | Faster RCNN with RRPN | 0.8581 | 0.7782 |

| DiffusionDet with RRPN | / | / | |

| Ours | 0.9773 | 0.9300 |

| Models | Parameters (M) | Time (s) | FPS |

|---|---|---|---|

| Faster RCNN with RRPN | 85.817 | 0.0833 | 12 |

| DiffusionDet with RRPN | 70.0398 | 0.0513 | 19 |

| Ours | 111.8674 | 0.0571 | 18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Yan, W.; Xia, C. Dual-Branch Diffusion Detection Model for Photovoltaic Array and Hotspot Defect Detection in Infrared Images. Remote Sens. 2025, 17, 1084. https://doi.org/10.3390/rs17061084

Li R, Yan W, Xia C. Dual-Branch Diffusion Detection Model for Photovoltaic Array and Hotspot Defect Detection in Infrared Images. Remote Sensing. 2025; 17(6):1084. https://doi.org/10.3390/rs17061084

Chicago/Turabian StyleLi, Ruide, Wenjun Yan, and Chaoqun Xia. 2025. "Dual-Branch Diffusion Detection Model for Photovoltaic Array and Hotspot Defect Detection in Infrared Images" Remote Sensing 17, no. 6: 1084. https://doi.org/10.3390/rs17061084

APA StyleLi, R., Yan, W., & Xia, C. (2025). Dual-Branch Diffusion Detection Model for Photovoltaic Array and Hotspot Defect Detection in Infrared Images. Remote Sensing, 17(6), 1084. https://doi.org/10.3390/rs17061084