Study on the Identification Method of Planar Geological Structures in Coal Mines Using Ground-Penetrating Radar

Abstract

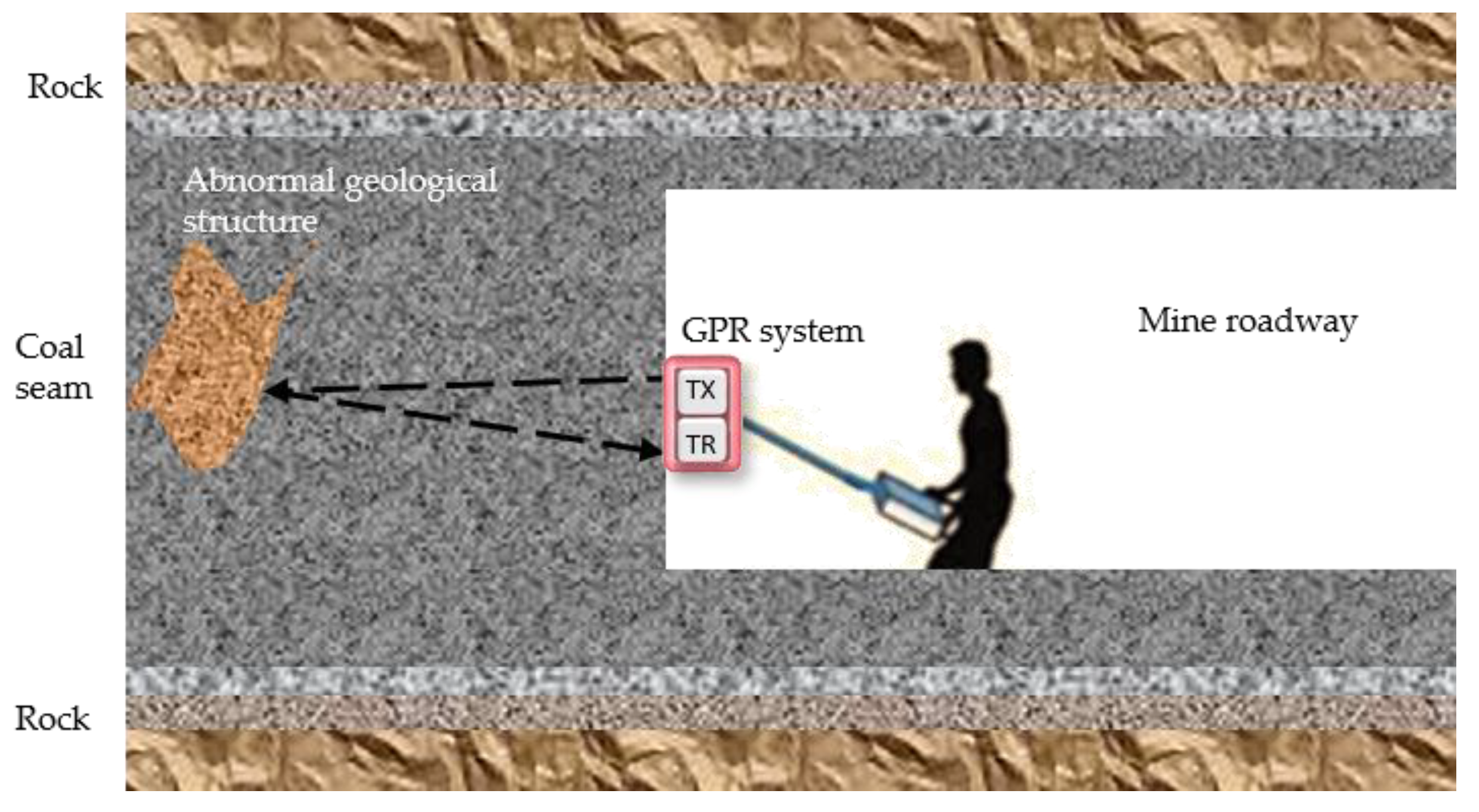

1. Introduction

2. Materials and Methods

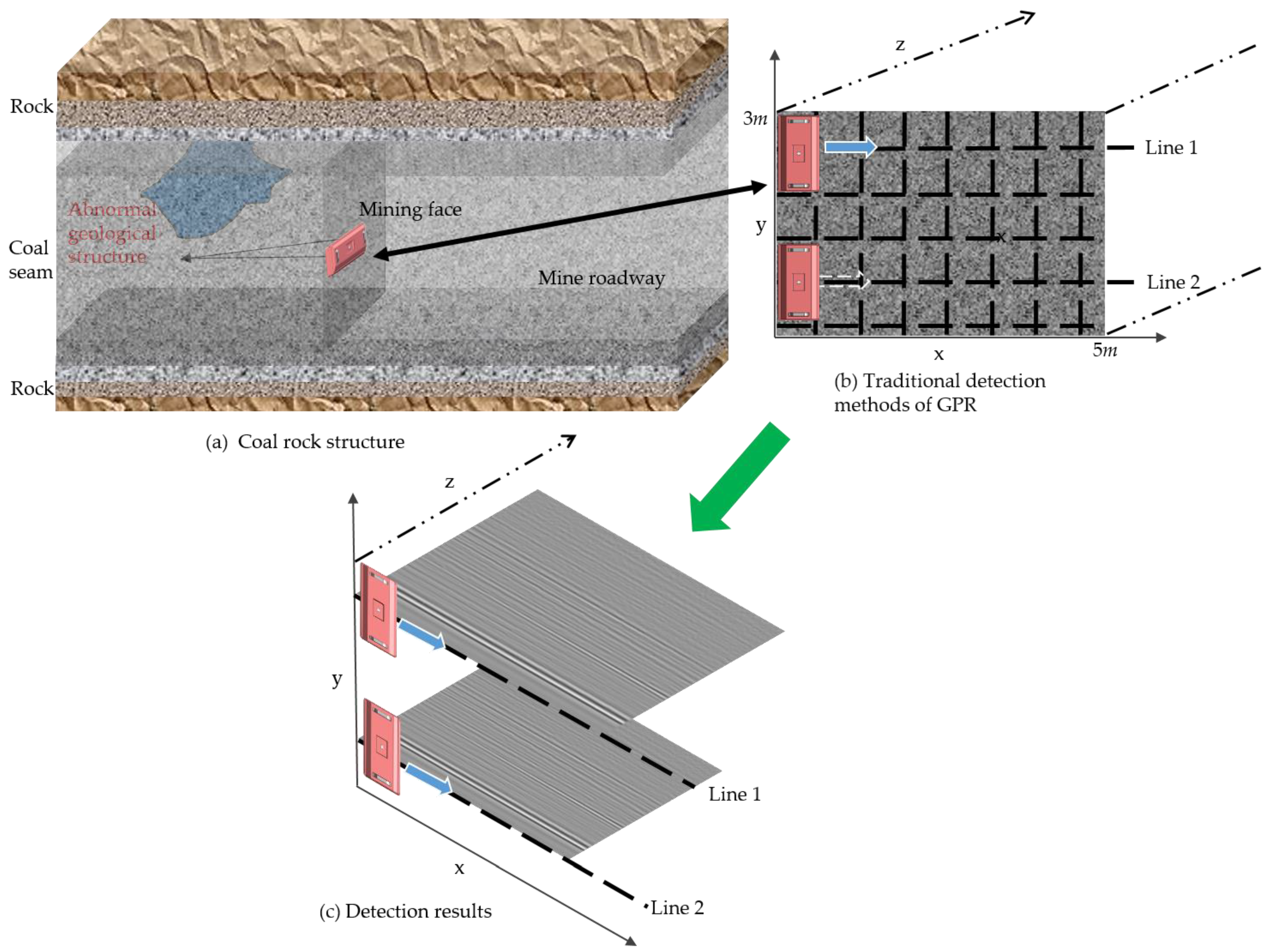

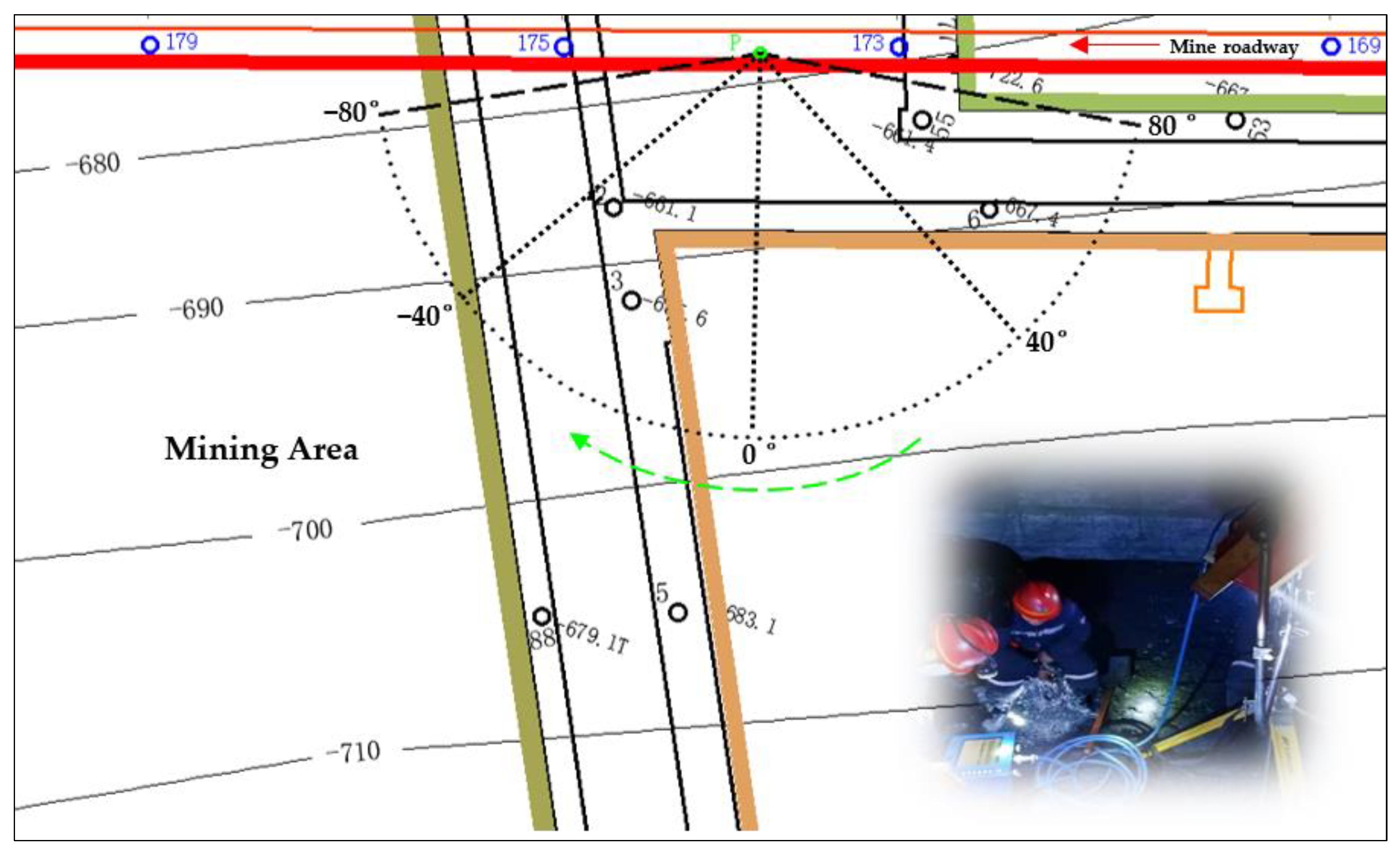

- Limited detection accuracy: As shown in Figure 2a, the coal mining face is a fully enclosed and confined space, with typical height and width dimensions of 3 m and 5 m, respectively. In extreme geological conditions, this space becomes even narrower, severely restricting the layout of survey lines. Due to these spatial constraints, only one or two survey lines can be arranged on the mining face, leading to highly limited spatial coverage and data acquisition (Figure 2c). This makes precise analysis of the unknown geological conditions ahead extremely difficult.

- Limited detection range: As shown in Figure 2b, the survey lines are positioned on the mining face, allowing for detection only in the direction of mining operations. However, it is ineffective in detecting potential geological hazards in areas beyond the observation range, such as the roof of the coal mine roadway (Figure 2a).

- Limited detection depth: While the theoretical detection depth of GPR in mine environments can reach tens of meters, the actual effective depth is limited to only a few meters to over ten meters. This is primarily due to the exponential attenuation of high-frequency electromagnetic waves as they propagate through the medium, weakening the strength of deep signals. Additionally, signals reflected by steel supports, metal mesh, and electromagnetic interference from mining equipment, along with scattered signals in confined spaces, are all captured by the receiving antenna, further reducing the signal-to-noise ratio of deep detections. In the absence of stable geological structure features and prior geological information, effectively distinguishing geological information from the interference signals becomes extremely difficult, presenting additional challenges for the processing, analysis, and interpretation of deep data.

- Limited spatial information on geological structures: GPR is based on the principle of electromagnetic wave reflection and detects geological structures according to differences in dielectric properties. When geological structures develop in horizontal or vertical directions and are either parallel or at steep angles to the mining direction, their reflected signals may be directed into unknown areas and cannot be captured by the receiving antenna. This can result in suboptimal detection of geological structures, making it challenging to obtain critical geological information such as spatial distribution and extension direction.

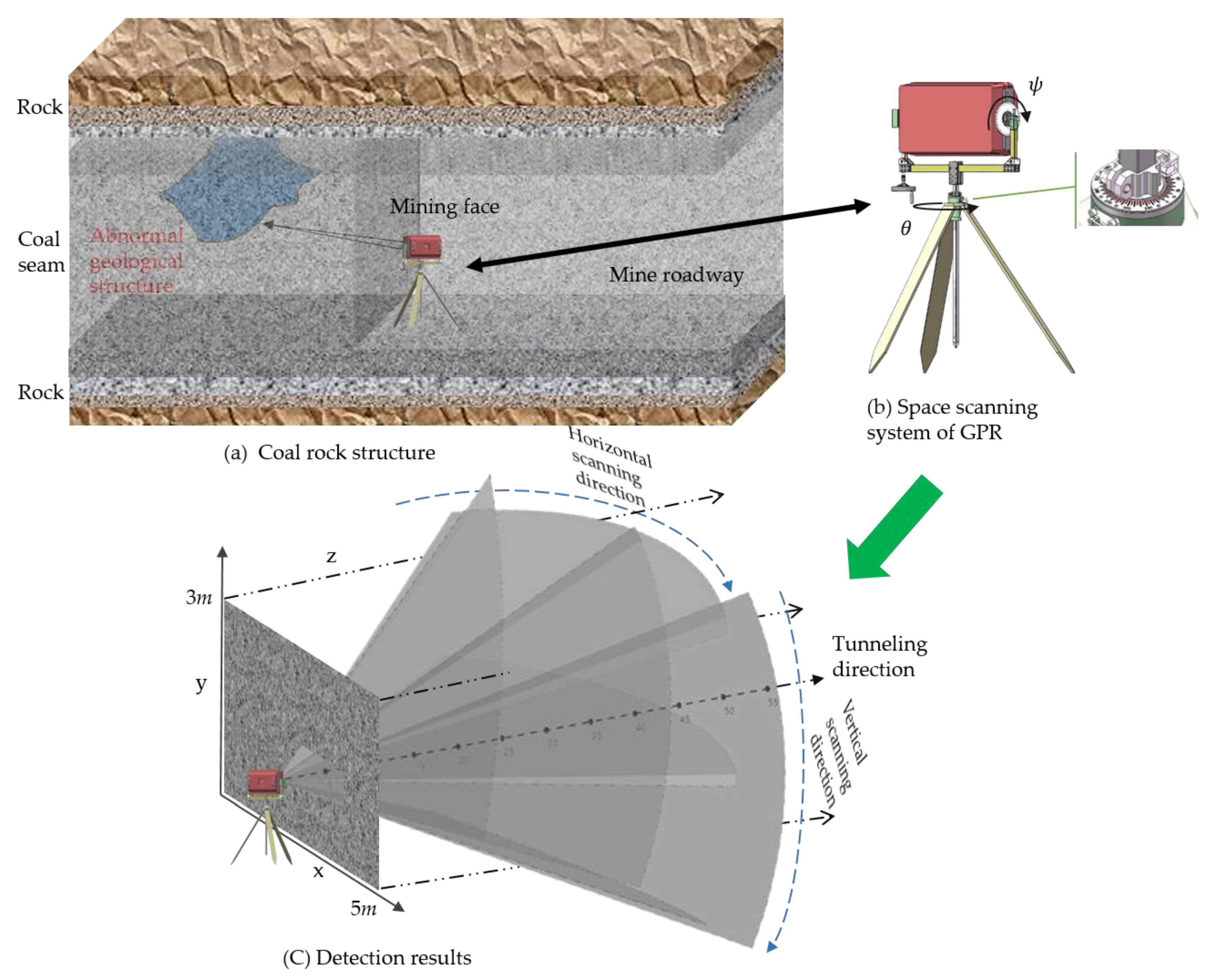

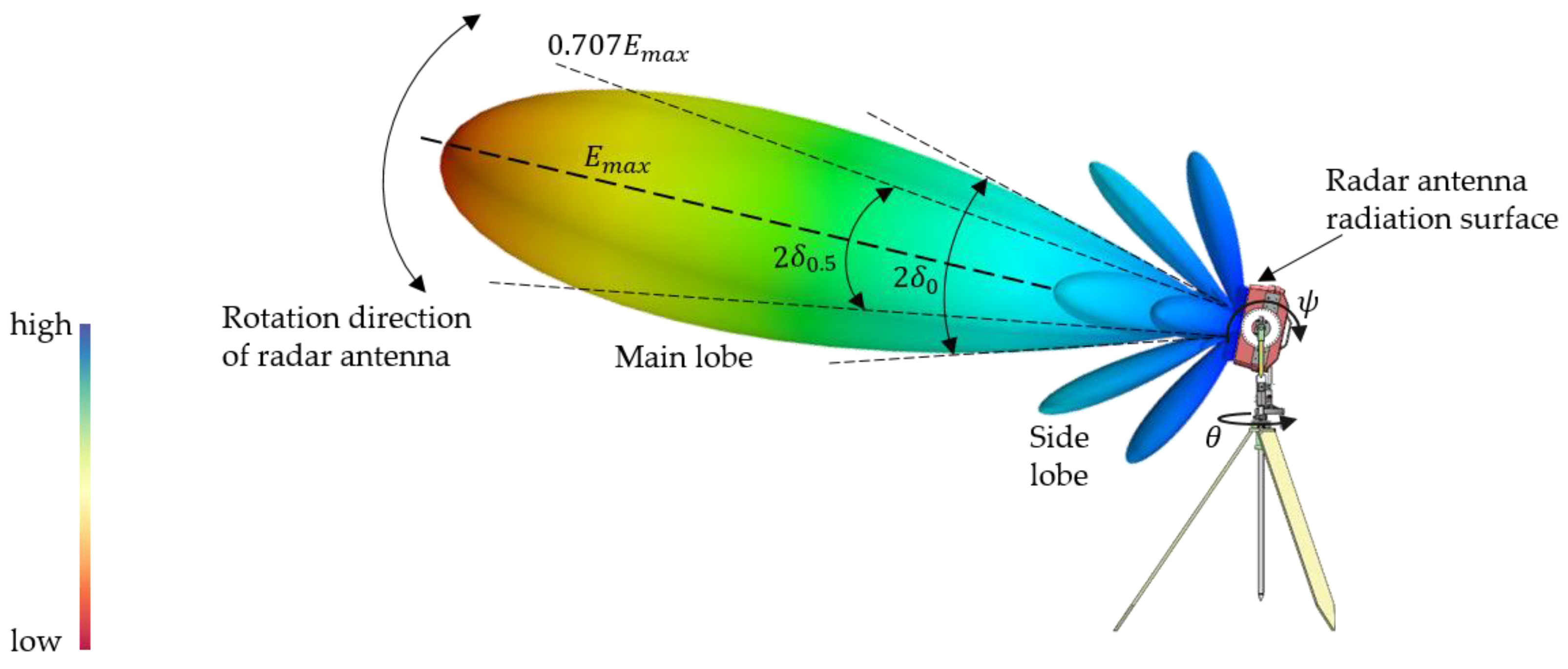

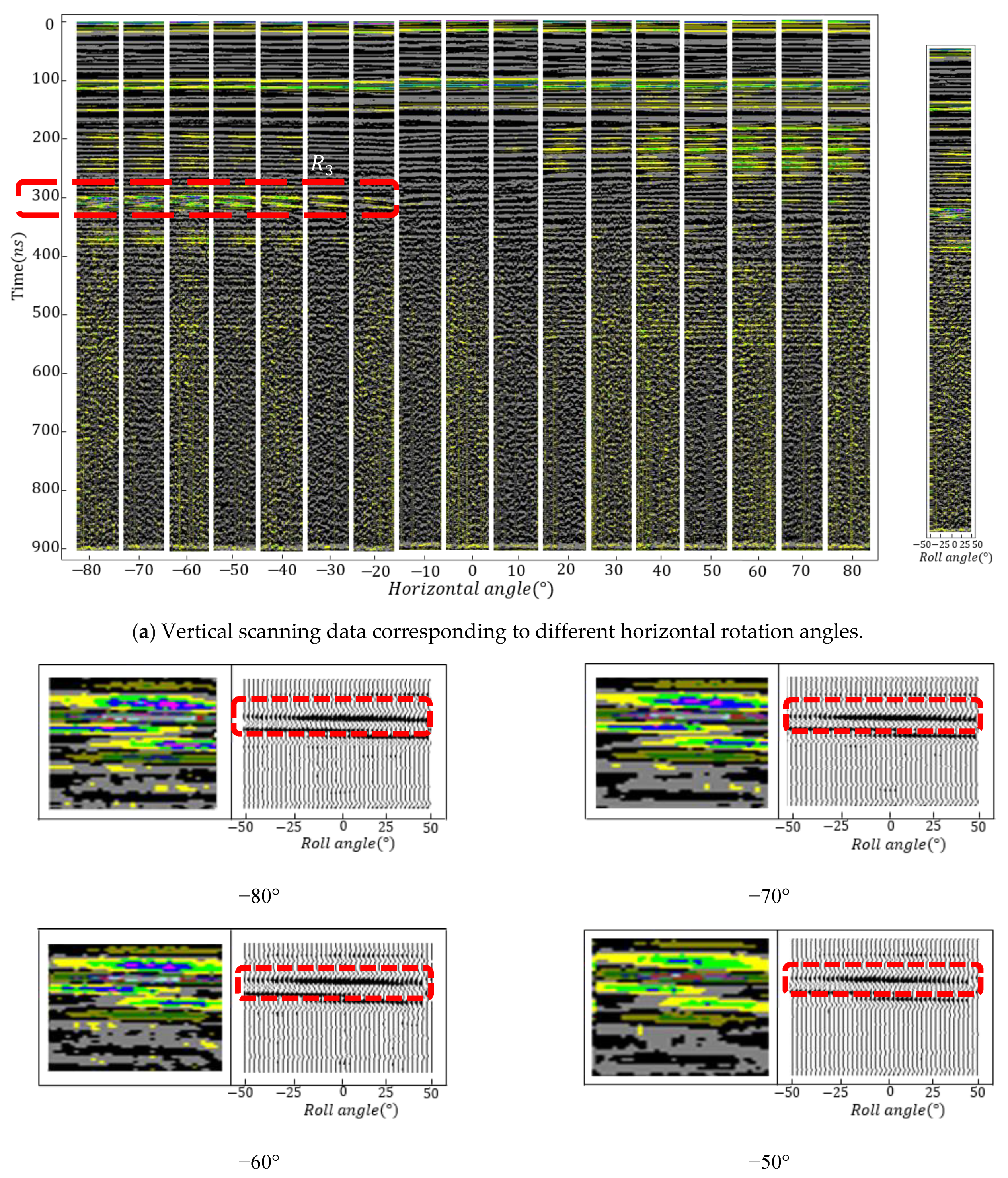

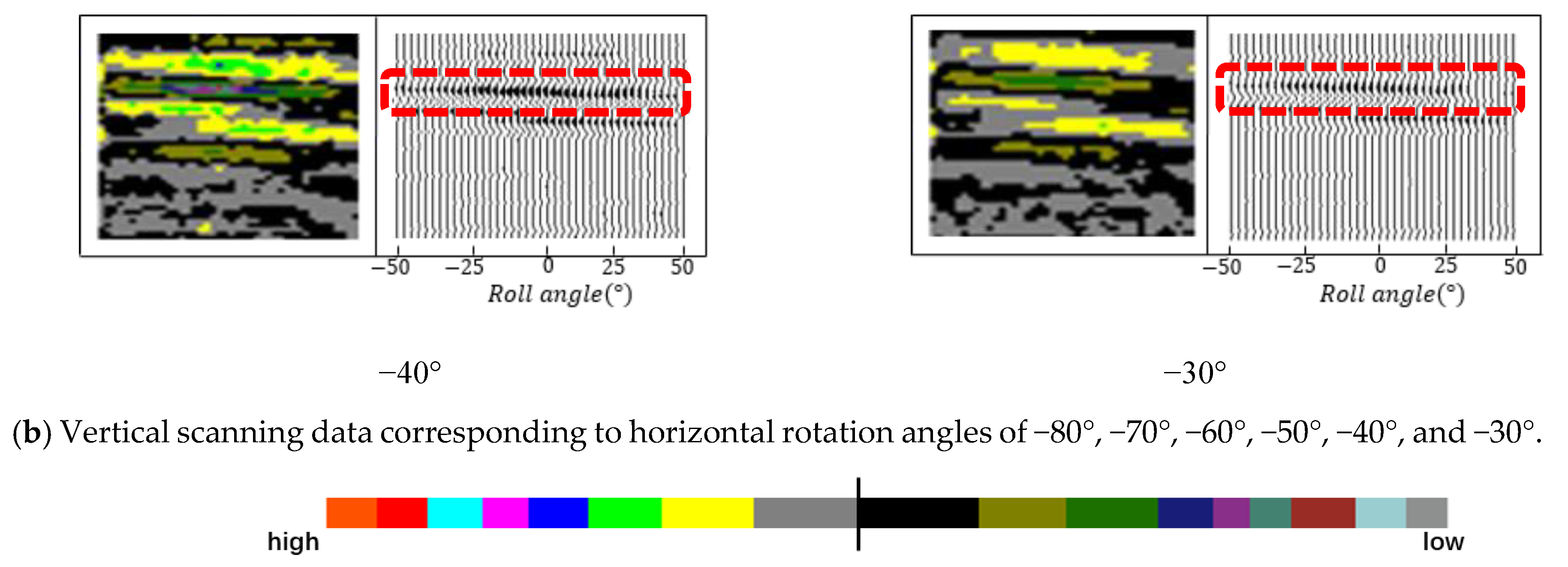

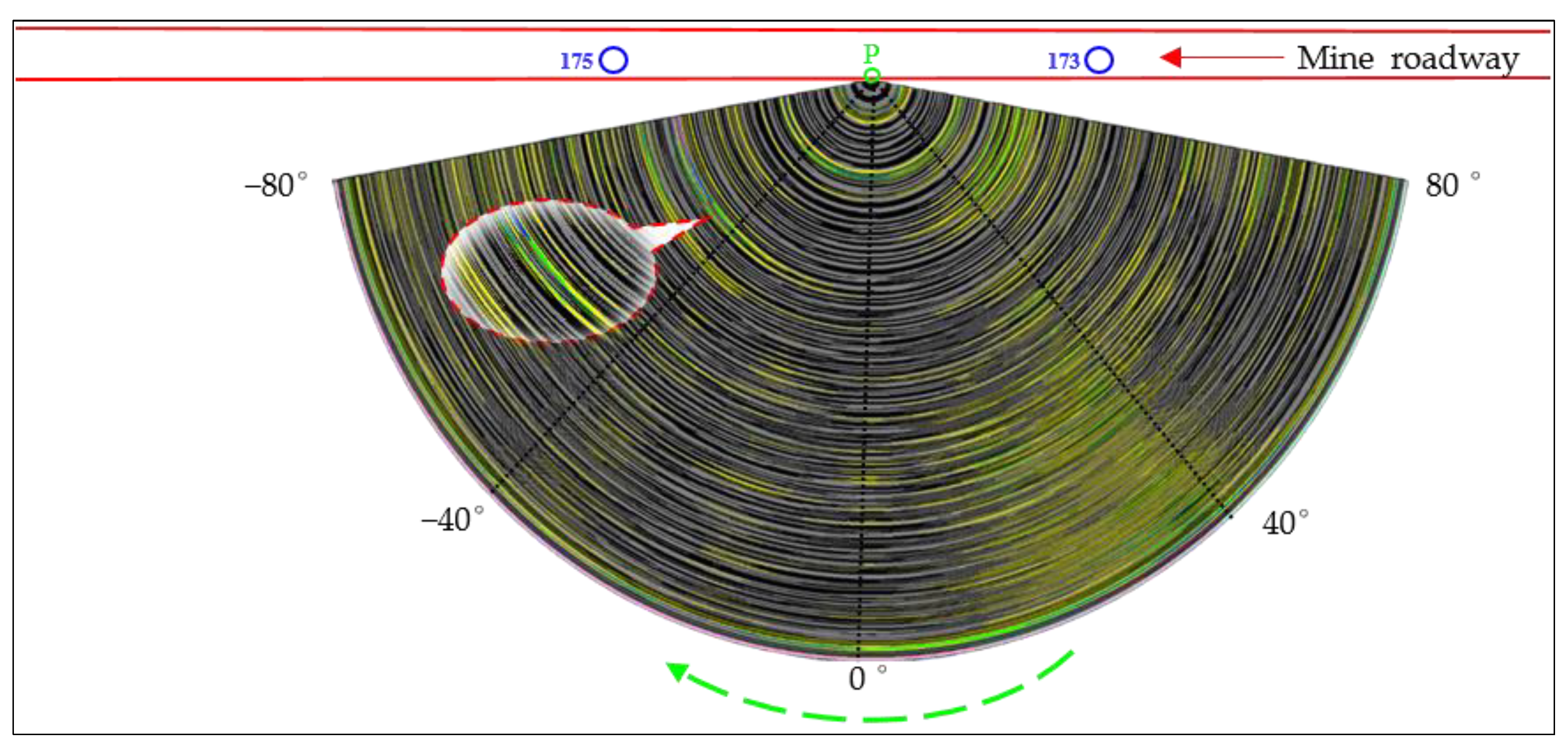

- Higher detection accuracy: During the spatial scanning process, the detection area is divided into sector scanning units, with the antenna transmitting and receiving signals at the center of each unit. As the rotation angles and are adjusted, the transmission points Tri, where I = , ,…, ,…, , ,…, , and the corresponding reception points Rei, change accordingly. This method allows for fine-grained management of the scanning space, significantly increasing the amount of spatial detection data (as shown in Figure 3c) and enhancing detection accuracy. Additionally, this detection approach eliminates the need for laying detection lines along the working face, thus freeing the detection equipment from the constraints of the working surface.

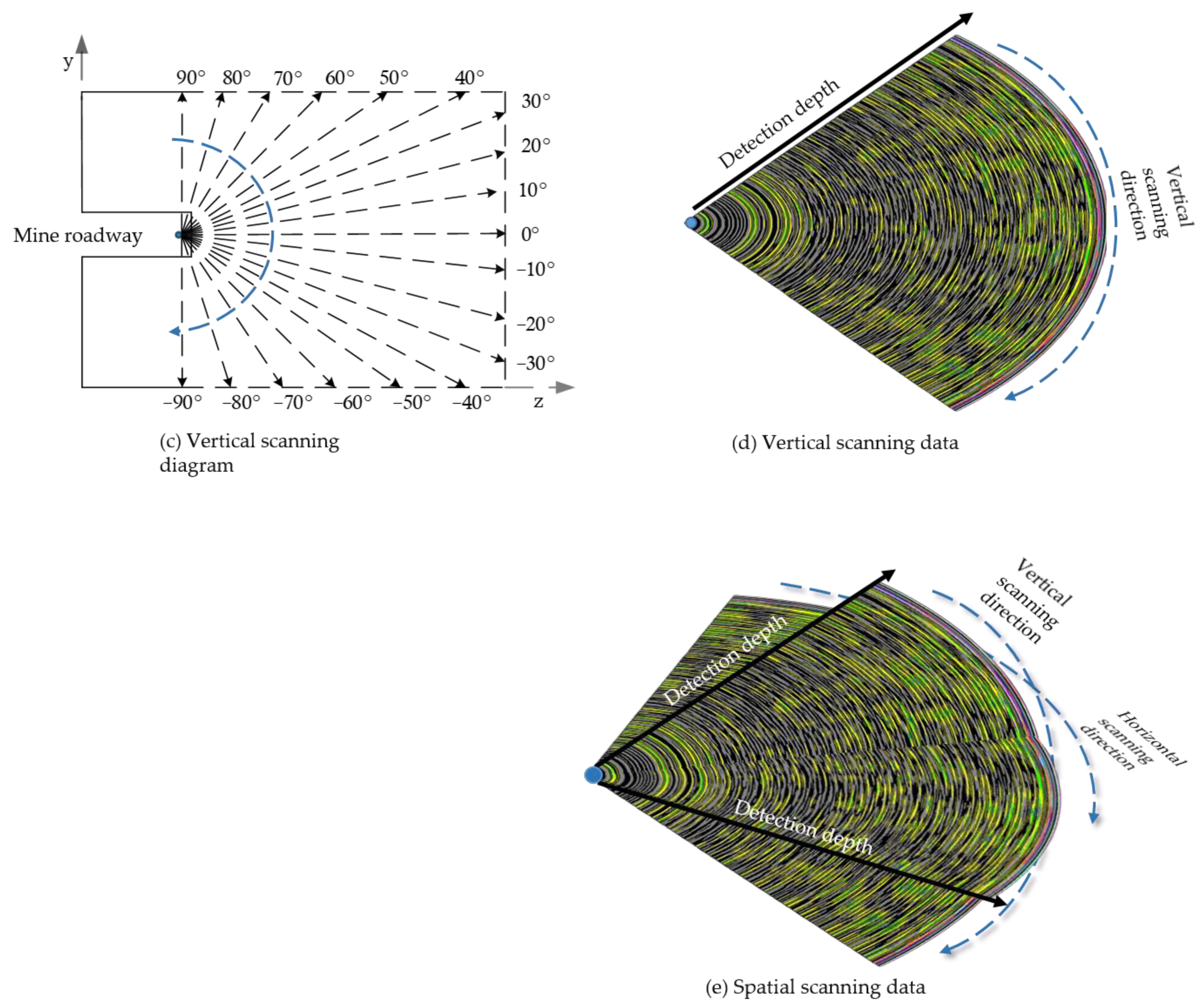

- Significant expansion of detection range: As illustrated in Figure 3a,b, there is no need to deploy survey lines above the mining working face for wall-attached detection, thereby removing spatial constraints imposed by the working face. By utilizing the spatial scanning system, comprehensive coverage from −90° to 90° in both horizontal and vertical directions (as shown in Figure 4a,d) can be achieved, facilitating the exploration of nearly all potential detection areas along the mining direction.

- Capacity for obtaining spatial distribution information of geological structures: This method is especially suitable for planar geological structures (such as faults, thin coal layers, etc.), which exhibit stable response characteristics. Through detailed analysis of energy variation characteristics, geological structures can be accurately identified amidst numerous interference signals. Moreover, crucial geological information, including spatial distribution, can be obtained based on changes in rotation angles during the detection process. The subsequent sections of this paper will delve into how this method significantly enhances detection accuracy and retrieval of spatial distribution information.

3. Simulation Experiment and Result Analysis

3.1. Experimental Detection of Target Response Characteristics

3.1.1. Detection Process and Phenomena

3.1.2. Analysis of Detection Results

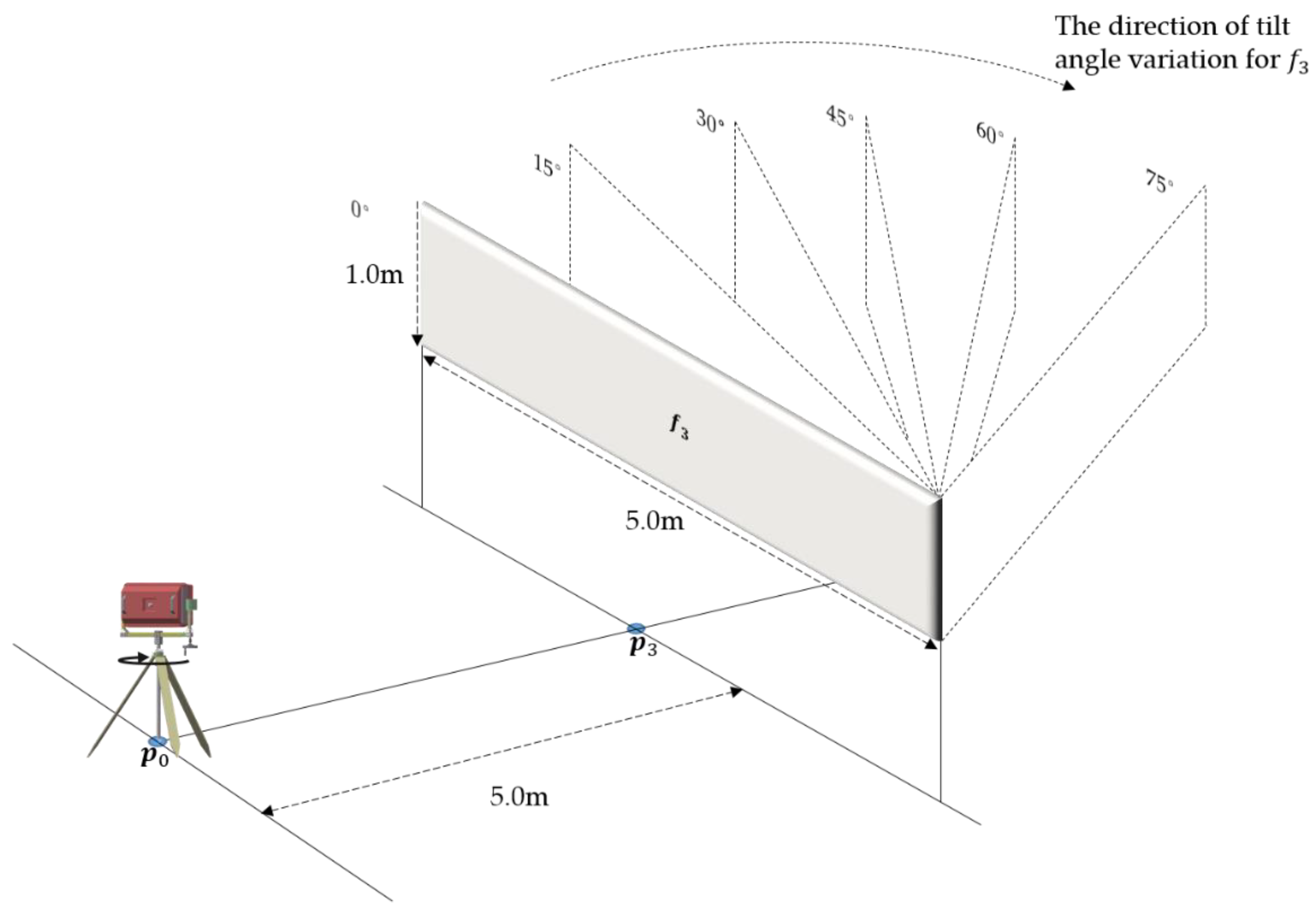

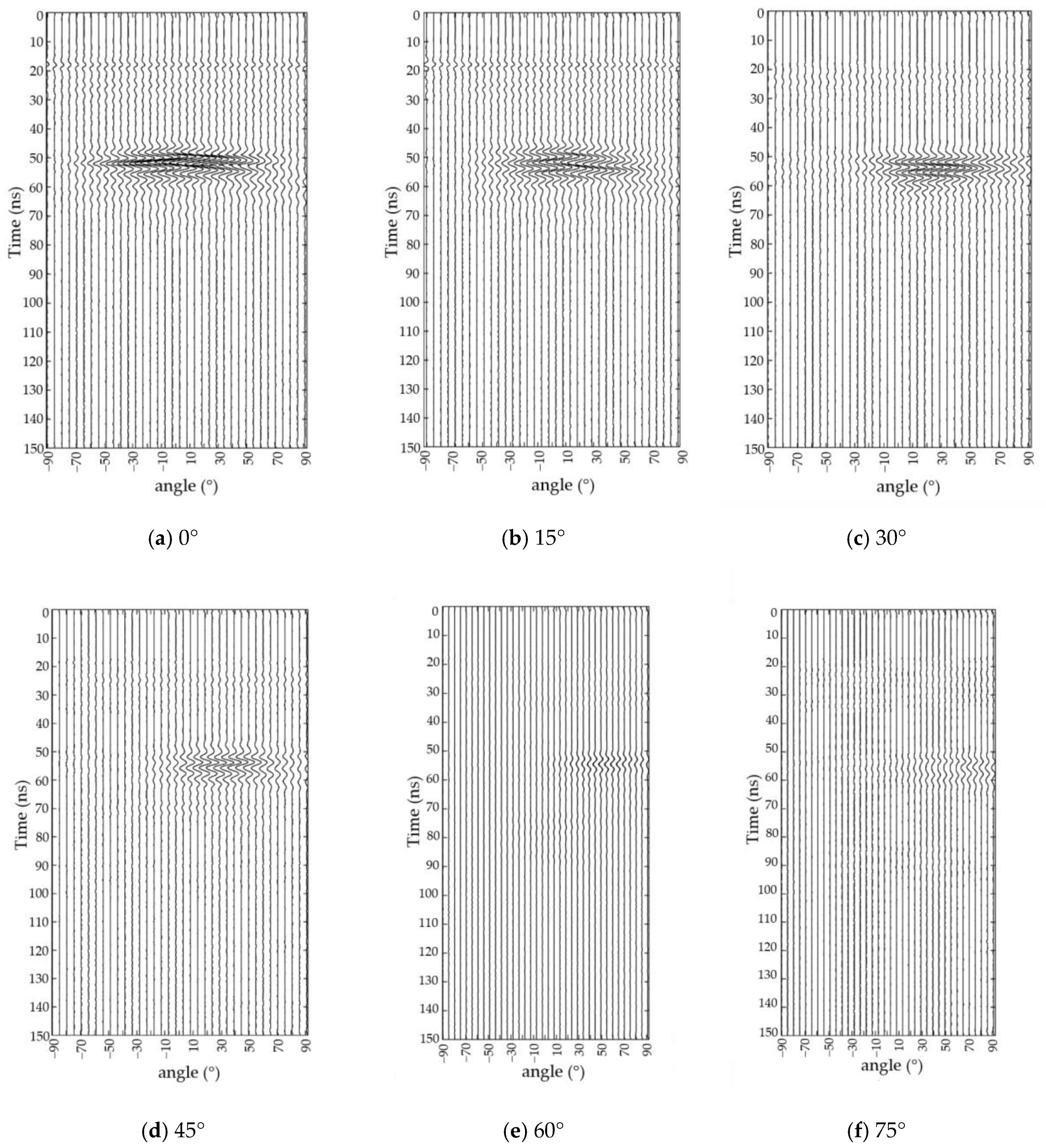

3.2. Experiment and Analysis of Target Spatial Distribution

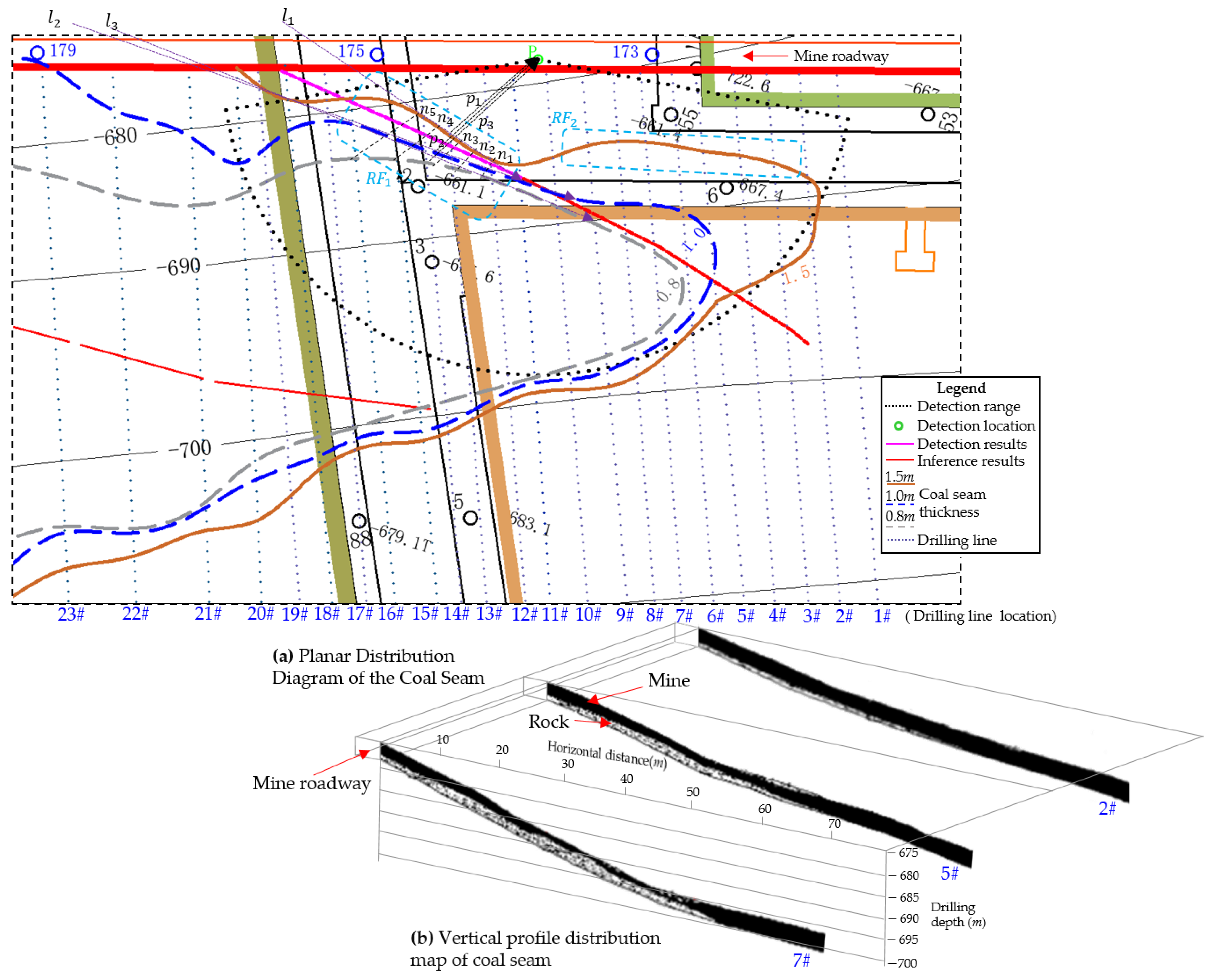

4. Experimental in Underground Coal Mine Environment

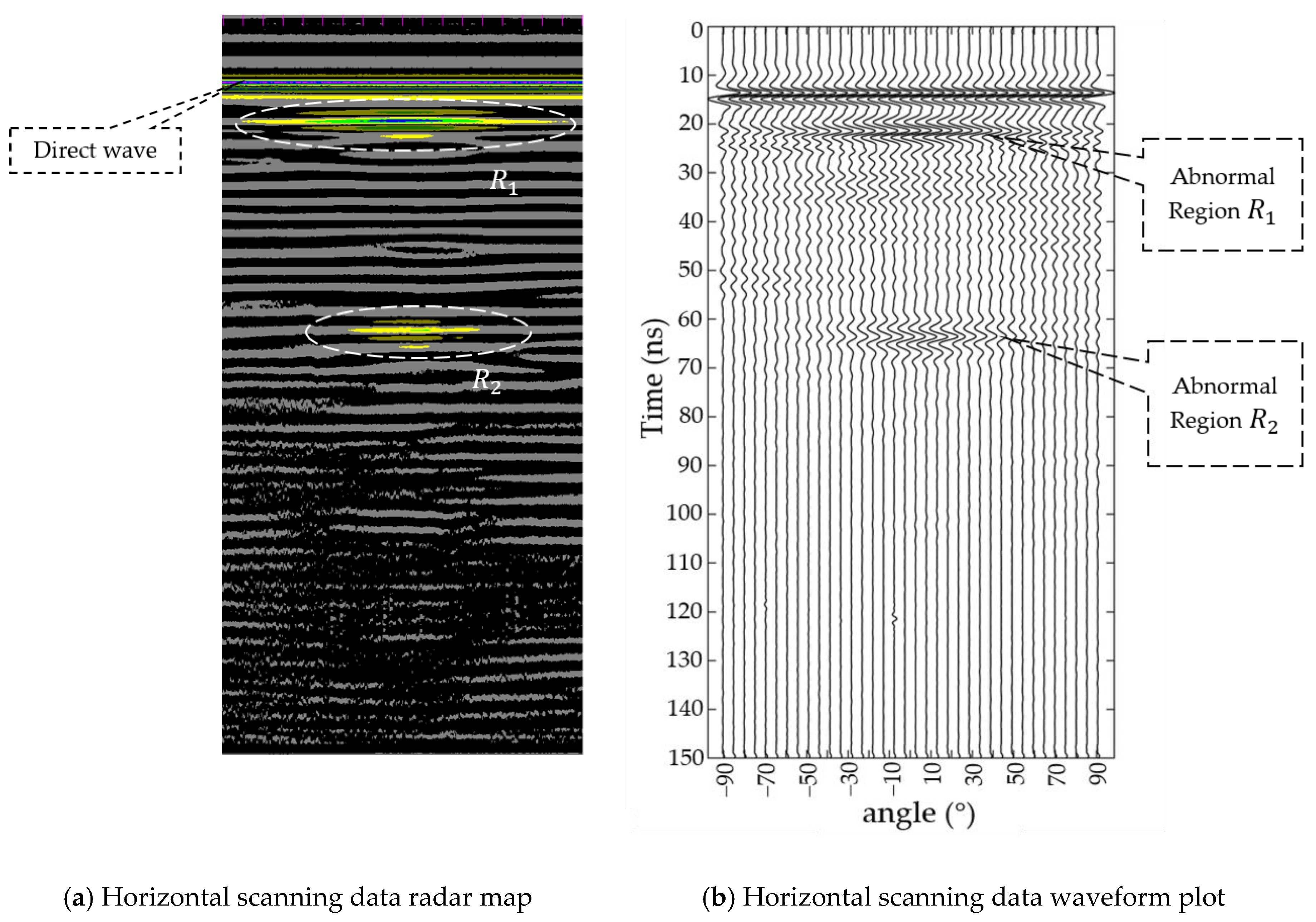

4.1. Detection Process and Phenomena

4.2. Analysis of Detection Results

5. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, D.; Hu, Z.; Yu, Y.; Zhang, F.; Sun, H. Assessing Ecological Impacts and Recovery in Coal Mining Areas: A Remote Sensing and Field Data Analysis in Northwest China. Remote Sens. 2024, 16, 2236. [Google Scholar] [CrossRef]

- Yuan, L.; Zhang, P.J. Key technology and path thinking of dynamic reconstruction of mine transparent geological model. J. China Coal Soc. 2023, 48, 1–14. [Google Scholar]

- Zhang, Q.; Zhang, R.; Liu, J.; Wang, C.; Zhang, H.; Tian, Y. Review on coal and rock identification technology for intelligent mining in coal mines. Coal Sci. Technol. 2022, 50, 1–26. [Google Scholar]

- Wang, G.; Xu, Y.; Ren, H. Intelligent and ecological coal mining as well as clean utilization technology in China: Review and prospects. Int. J. Min. Sci. Technol. 2019, 29, 161–169. [Google Scholar] [CrossRef]

- Cheng, J.; Li, F.; Peng, S. Research progress and development direction on advanced detection in mine roadway working face using geophysical methods. J. China Coal Soc. 2014, 39, 1742–1750. [Google Scholar]

- Siddiqui, M.A.H.; Akhtar, S.; Chattopadhyaya, S.; Sharma, S.; Kumar, A.; Abbas, M. 611 Universal Drilling Machine Reliability Modeling and Performance Evaluation in Subterranean Coal Mines. Rock Mech. Rock Eng. 2024, 57, 3559–3575. [Google Scholar] [CrossRef]

- Shuning, D.; Zaibin, L.; Jianyuan, C.; Baohui, C.; Zhenhua, D.; Dan, L. Technologies and prospect of geological guarantee for intelligent coal mining. Coal Geol. Explor. 2021, 49, 4. [Google Scholar]

- Peng, S. Current status and prospects of research on geological assurance system for coal mine safe and high efficient mining. J. China Coal Soc. 2020, 45, 2331–2345. [Google Scholar]

- Su, B.; Liu, S.; Deng, L.; Gardoni, P.; Krolczyk, G.M.; Li, Z. Monitoring direct current resistivity during coal mining process for underground water detection: An experimental case study. IEEE Trans. Geosci. Remote Sens. 2022, 60, 1–8. [Google Scholar] [CrossRef]

- Cheng, J.-L.; Song, G.-D.; Liu, T.-Y.; Hu, B.-X.; Wang, J.-Q.; Wang, J.-Y. High precision location of micro-seismic source in underground coal mine. Chin. J. Geophys. 2016, 59, 734–743. [Google Scholar]

- Anbazhagan, P.; Dixit, P.N.; Bharatha, T. Identification of type and degree of railway ballast fouling using ground coupled GPR antennas. J. Appl. Geophys. 2016, 126, 183–190. [Google Scholar] [CrossRef]

- Liu, C.; Song, C.; Lu, Q. Random noise de-noising and direct wave eliminating based on SVD method for ground penetrating radar signals. J. Appl. Geophys. 2017, 144, 125–133. [Google Scholar] [CrossRef]

- Song, J.; Wang, L.J. Study on the high precision detection of buried drill pipe by ground penetrating radar in the coal face. J. China Coal Soc. 2014, 39, 537–542. [Google Scholar]

- Wang, D.J.G.E. Ground penetrating radar and engineering geological exploration. Geophys. Equip. 2001, 11, 188–194. [Google Scholar]

- Li, S.C.; Zhou, Z.Q.; Ye, Z.H.; Li, L.P.; Zhang, Q.Q.; Xu, Z.H. Comprehensive geophysical prediction and treatment measures of karst caves in deep buried tunnel. J. Appl. Geophys. 2015, 116, 247–257. [Google Scholar] [CrossRef]

- Orlando, L.; Cardarelli, E.; Cercato, M.; De Donno, G.; Di Giambattista, L. Pavement testing by integrated geophysical methods: Feasibility, resolution and diagnostic potential. J. Appl. Geophys. 2017, 136, 462–473. [Google Scholar] [CrossRef][Green Version]

- Cheng, J.; Lu, Z.; Xue, B.; Li, P.; Wang, P. The “long excavation and long exploration” technology of rapid excavation of coal mine roadway. J. China Coal Soc. 2022, 47, 404–412. [Google Scholar]

- Fernández-Álvarez, J.-P.; Rubio-Melendi, D.; Castillo, J.A.Q.; González-Quirós, A.; Cimadevilla-Fuente, D. Combined GPR and ERT exploratory geophysical survey of the Medieval Village of Pancorbo Castle (Burgos, Spain). J. Appl. Geophys. 2017, 144, 86–93. [Google Scholar] [CrossRef]

- Xu, X.; Peng, S.; Yang, F. Development of a ground penetrating radar system for large-depth disaster detection in coal mine. J. Appl. Geophys. 2018, 158, 41–47. [Google Scholar] [CrossRef]

- Xu, X.; Ma, Z.; Sun, T. A Whole closed space intrinsically safe GPR system for detection of geological hazard sources in coal mines. IEEE Geosci. Remote Sens. Lett. 2021, 19, 1–5. [Google Scholar] [CrossRef]

- Ma, Z.; Xu, X.; Peng, S.; Zhu, P.; Wang, Y. Development and application of air-coupled GPR antenna for coal-rock interface detection in mines. J. Appl. Geophys. 2023, 219, 105238. [Google Scholar] [CrossRef]

- Zhu, P.; Xu, X.; Ma, Z.; Wang, Y. Research on accuracy and error analysis of coal and rock strata detection based on air-coupled GPR. IEEE Geosci. Remote Sens. Lett. 2022, 19, 1–5. [Google Scholar] [CrossRef]

- Strange, A.D. Robust Thin Layer Coal Thickness Estimation Using Ground Penetrating Radar. Ph.D. Thesis, Queensland University of Technology, Brisbane, Australia, 2007. [Google Scholar]

- Strange, A.D.; Jecny, Z. Coal subsurface mapping for selective mining. In Proceedings of the 2018 17th International Conference on Ground Penetrating Radar (GPR), Rapperswil, Switzerland, 18–21 June 2018; pp. 1–4. [Google Scholar]

- Ralston, J.C.; Strange, A.D. An industrial application of ground penetrating radar for coal mining horizon sensing. In Proceedings of the 2015 International Symposium on Antennas and Propagation (ISAP), Hobart, Australia, 9–12 November 2015; pp. 1–4. [Google Scholar]

- Ralston, J.; Strange, A. 3D robotic imaging of coal seams using ground penetrating radar technology. In Proceedings of the 2016 16th International Conference on Ground Penetrating Radar (GPR), Hong Kong, China, 13–16 June 2016; pp. 1–6. [Google Scholar]

- Francke, J. Applications of GPR in mineral resource evaluations. In Proceedings of the XIII International Conference on Ground Penetrating Radar, Lecce, Italy, 21–25 June 2010; pp. 1–5. [Google Scholar]

- Ralston, J.C.; Hainsworth, D.W.; McPhee, R.J. Application of ground penetrating radar for coal thickness measurement. In TENCON'97 Brisbane-Australia. Proceedings of IEEE TENCON’97. IEEE Region 10 Annual Conference. Speech and Image Technologies for Computing and Telecommunications (Cat. No.97CH36162), Brisbane, QLD, Australia, 4 December 1997; IEEE: Piscataway, NJ, USA, 2002. [Google Scholar]

- Lai, W.W.; Chang, R.K.; Sham, J.F. A blind test of nondestructive underground void detection by ground penetrating radar (GPR). J. Appl. Geophys. 2018, 149, 10–17. [Google Scholar] [CrossRef]

- Yuan, W.; Liu, S.; Zhao, Q.; Deng, L.; Lu, Q.; Pan, L.; Li, Z. Application of Ground-Penetrating Radar with the Logging Data Constraint in the Detection of Fractured Rock Mass in Dazu Rock Carvings, Chongqing, China. Remote Sens. 2023, 15, 4452. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Zhang, T.; Yang, K.; Zhang, J.; Wang, X.J.S. A Study on Refraction Error Compensation Method for Underwater Spinning Laser Scanning Three-Dimensional Imaging. Sensors 2024, 24, 343. [Google Scholar] [CrossRef]

- Poljak, D.; Sesnic, S.; Susnjara, A.; Paric, D.; Drissi, K.E.K.; Lallechere, S. Direct time domain evaluation of the transient field transmitted into a lossy ground due to GPR antenna radiation. Eng. Anal. Bound. Elem. 2017, 82, 27–31. [Google Scholar] [CrossRef]

- Jiao, Y.; A McMechan, G.; Pettinelli, E. In situ 2-D and 3-D measurements of radiation patterns of half-wave dipole GPR antennas. J. Appl. Geophys. 2000, 43, 69–89. [Google Scholar] [CrossRef]

- Dhande, P. Antennas and Its Applications. DRDO Sci. Spectr. 2009, 66–78. [Google Scholar]

- Wang, W.; Hao, L.; Li, X.; Sun, J. Signal processing technology and its application research of ground penetrating radar (GPR). Proc. IOP Conf. Ser. Earth Environ. Sci. 2017, 69, 012077. [Google Scholar] [CrossRef]

- Abujarad, F. Ground Penetrating Radar Signal Processing for Landmine Detection; Otto-von-Guericke-Universität Magdeburg, Universitätsbibliothek: Magdeburg, Germany, 2007. [Google Scholar]

- Süsstrunk, S.; Buckley, R.; Swen, S. Standard RGB color spaces. In Proceedings of the Color and Imaging Conference, Scottsdale, AZ, USA, 16–19 November 1999; pp. 127–134. [Google Scholar]

| No. | Tilt Angle | Peak Energy Position | Half-Power Decay Range |

|---|---|---|---|

| 1 | 0° | −2° | −31.4°~30.8° |

| 2 | 15° | 14.4° | −18.8°~43° |

| 3 | 30° | 27.2° | 2.6°~47.6° |

| 4 | 45° | 41.8° | 19.4°~62° |

| 5 | 60° | 55.8° | 31.2°~68.6° |

| 6 | 75° | 72° | 48.8°~90° |

| No. | Medium | Conductivity (S/m) | Relative Permittivity (F/m) | Electromagnetic Wave Speed (m/ns) |

|---|---|---|---|---|

| 1 | Sand stone | 4 × 10−5 | 4.6 | 0.14 |

| 2 | Coking coal | 2.7 × 10−5 | 2.8 | 0.179 |

| 3 | Lean coal | 2.21 × 10−5 | 2.6 | 0.186 |

| 4 | Mud stone | 1 × 10−4 | 6.5 | 0.118 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Tang, X.; Yang, F.; Qiao, X.; Li, F.; Peng, S.; Huang, X.; Fang, Y.; Xu, M. Study on the Identification Method of Planar Geological Structures in Coal Mines Using Ground-Penetrating Radar. Remote Sens. 2024, 16, 3990. https://doi.org/10.3390/rs16213990

Liu J, Tang X, Yang F, Qiao X, Li F, Peng S, Huang X, Fang Y, Xu M. Study on the Identification Method of Planar Geological Structures in Coal Mines Using Ground-Penetrating Radar. Remote Sensing. 2024; 16(21):3990. https://doi.org/10.3390/rs16213990

Chicago/Turabian StyleLiu, Jialin, Xiaosong Tang, Feng Yang, Xu Qiao, Fanruo Li, Suping Peng, Xinxin Huang, Yuanjin Fang, and Maoxuan Xu. 2024. "Study on the Identification Method of Planar Geological Structures in Coal Mines Using Ground-Penetrating Radar" Remote Sensing 16, no. 21: 3990. https://doi.org/10.3390/rs16213990

APA StyleLiu, J., Tang, X., Yang, F., Qiao, X., Li, F., Peng, S., Huang, X., Fang, Y., & Xu, M. (2024). Study on the Identification Method of Planar Geological Structures in Coal Mines Using Ground-Penetrating Radar. Remote Sensing, 16(21), 3990. https://doi.org/10.3390/rs16213990