Predicting Sugarcane Harvest Date and Productivity with a Drone-Borne Tri-Band SAR

Abstract

1. Introduction

2. Materials and Methods

2.1. SAR System

2.2. Investigation Stage

2.2.1. Experimental Area

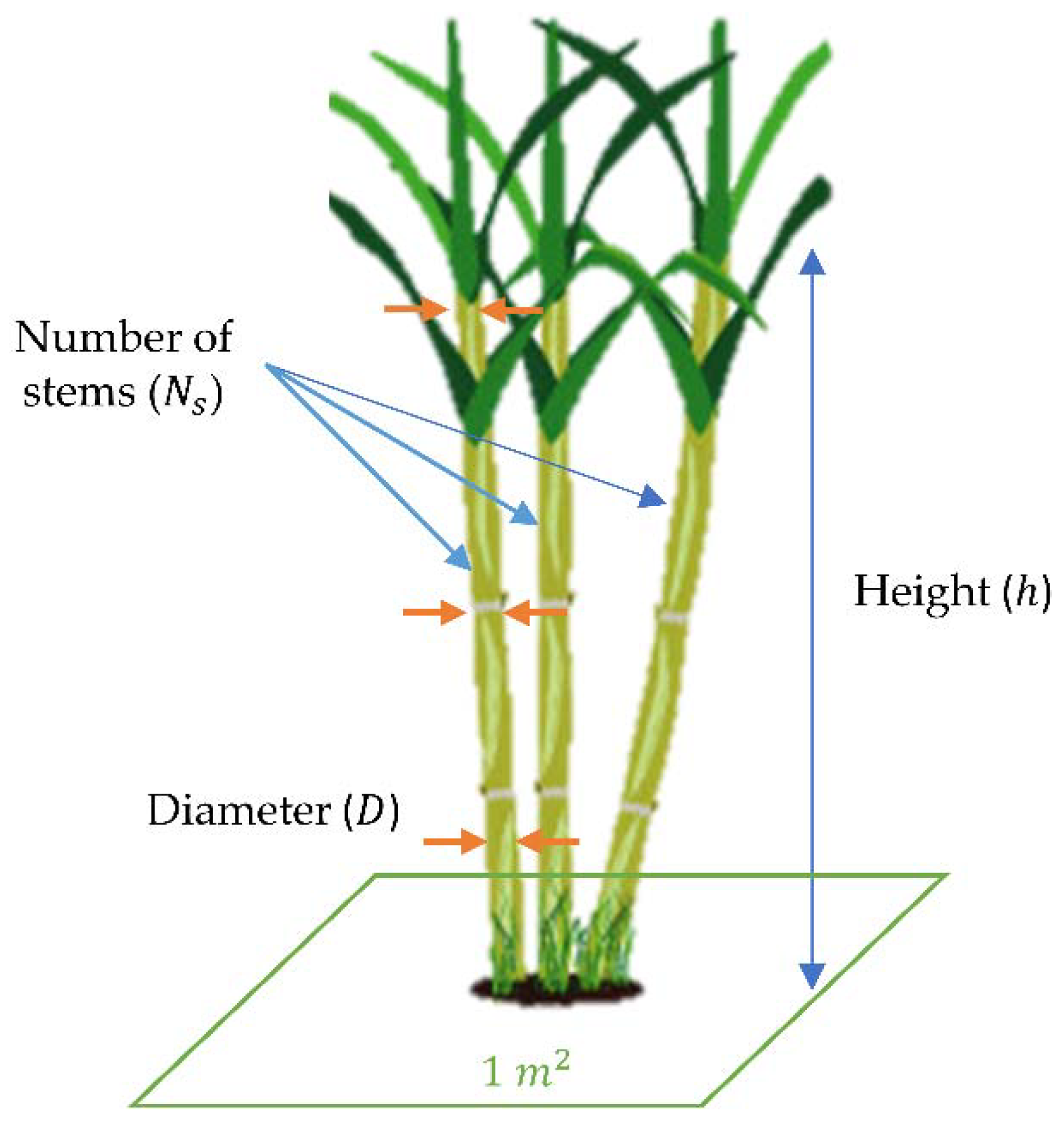

2.2.2. Sugarcane AGB Measurement

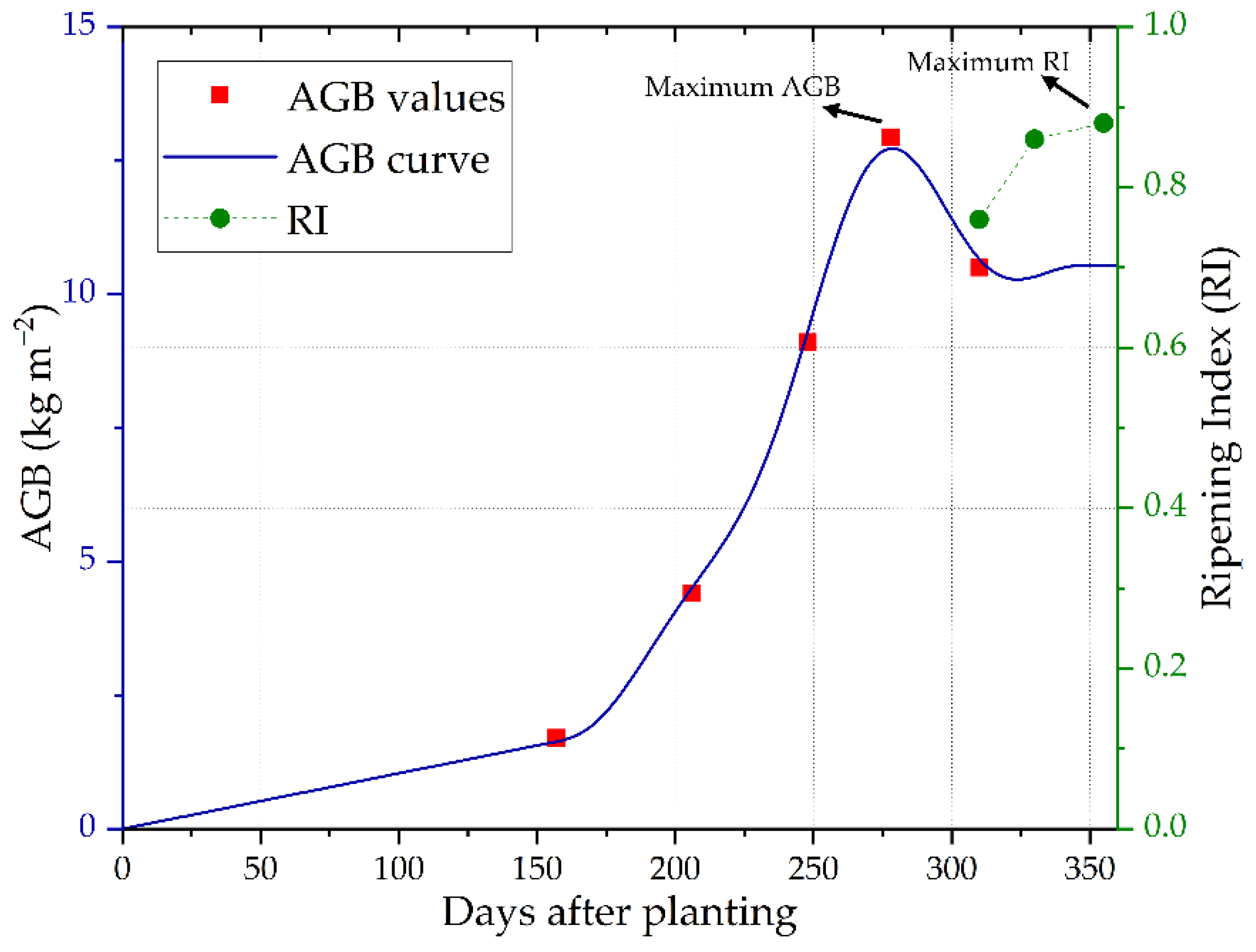

2.2.3. Ripening Index Measurement

2.2.4. Sugarcane AGB Estimation

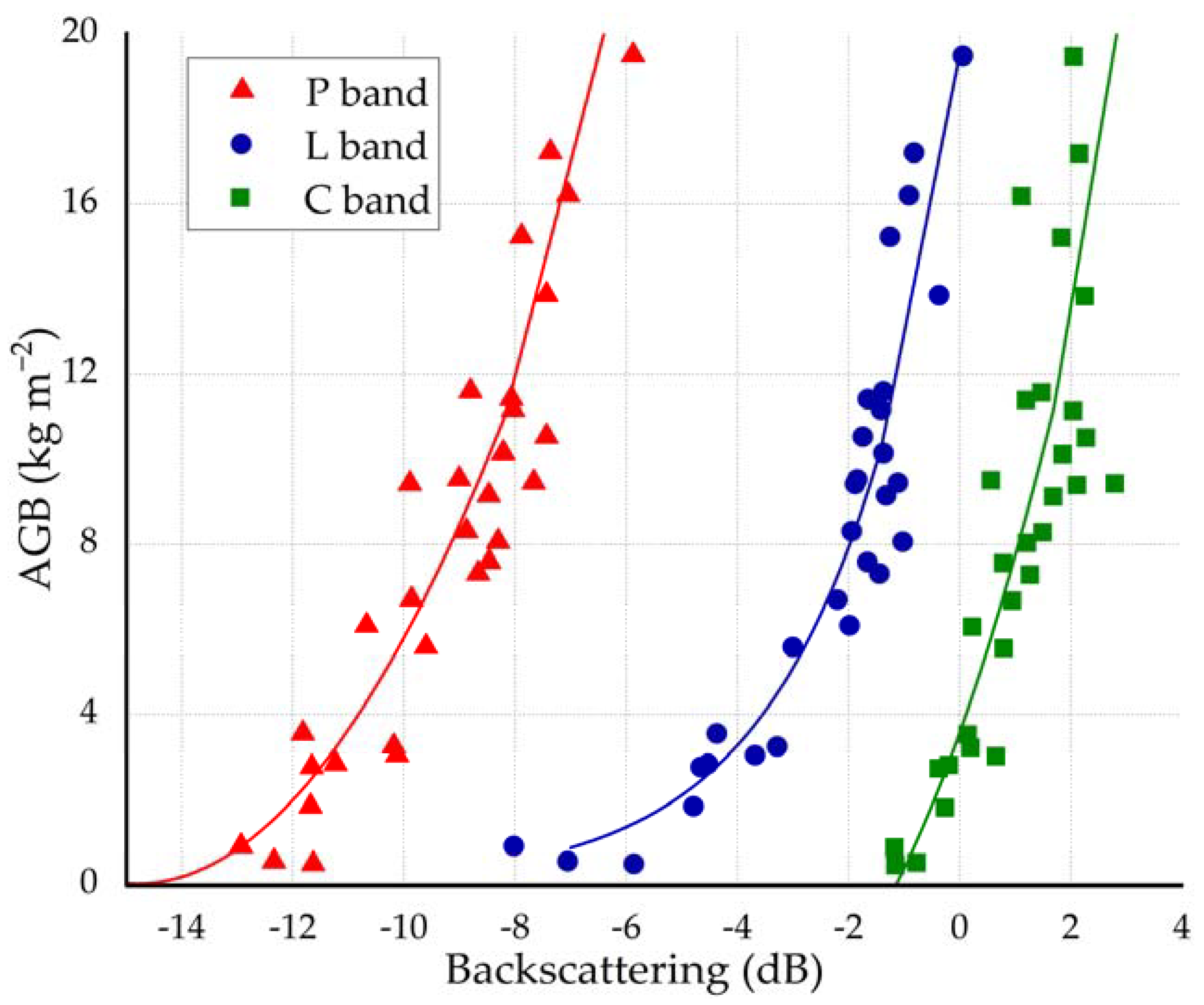

Single-Band AGB Models

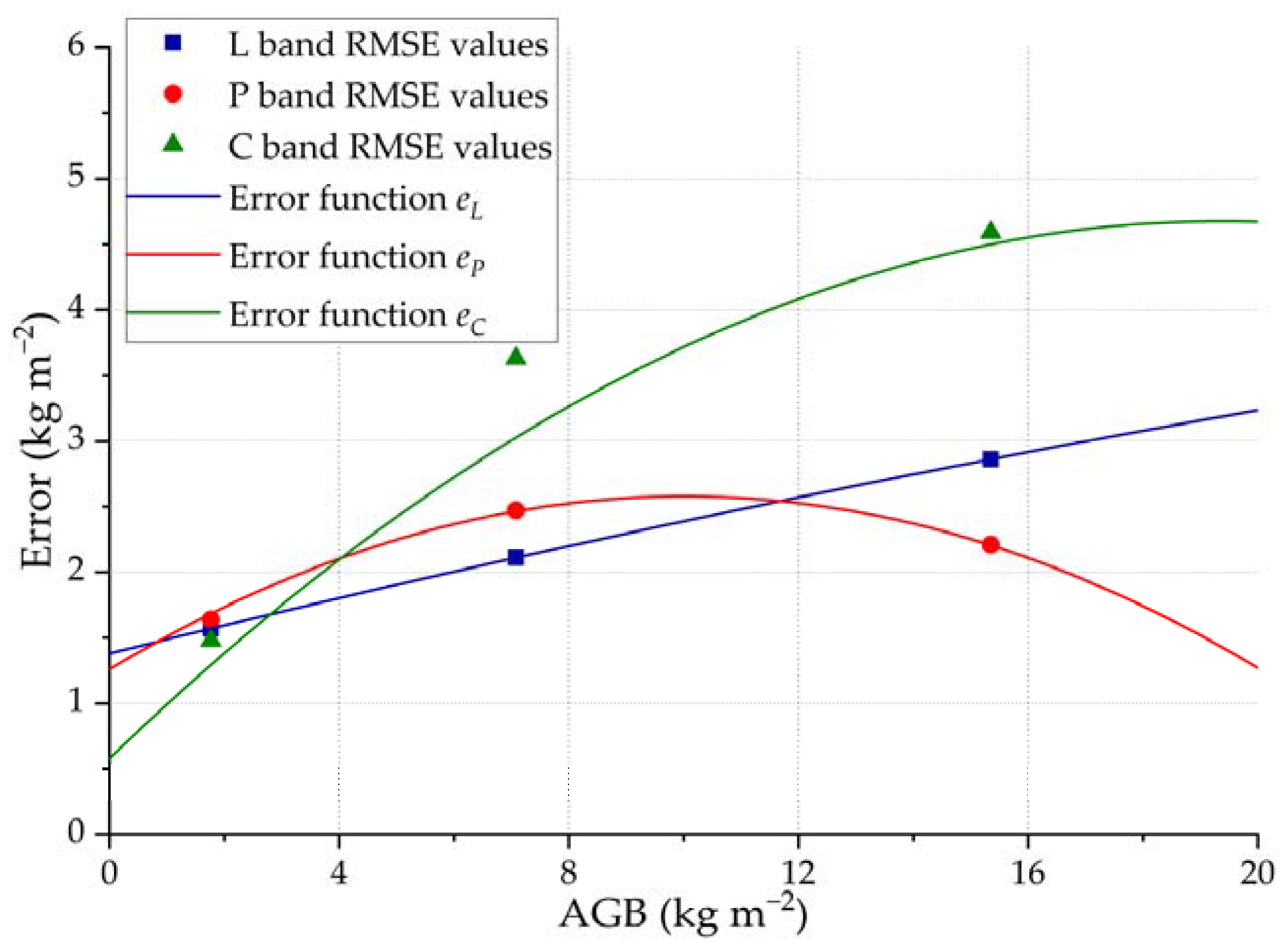

Band-Weighted AGB Model

2.3. Adjustment Stage

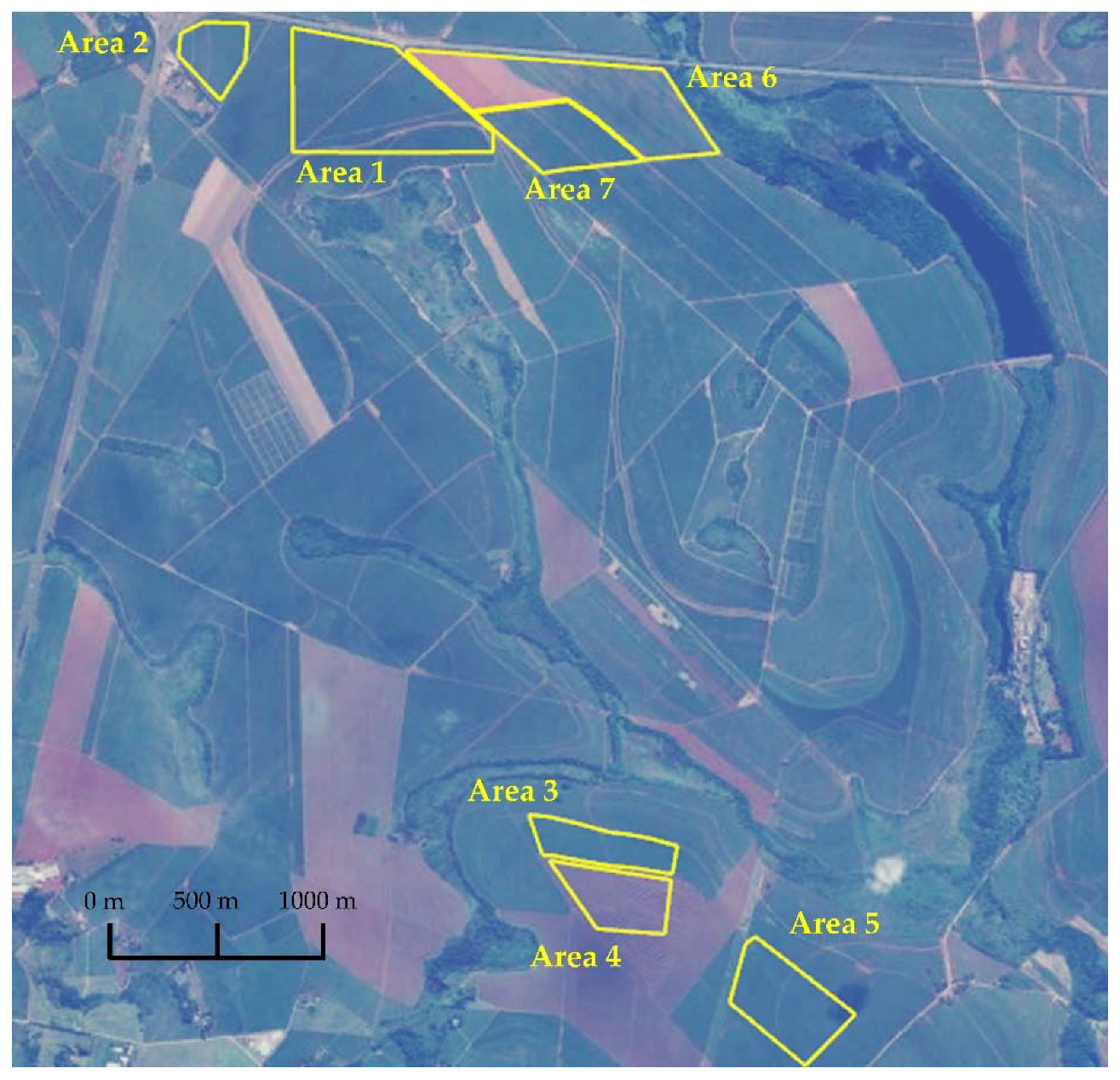

2.3.1. Test Site

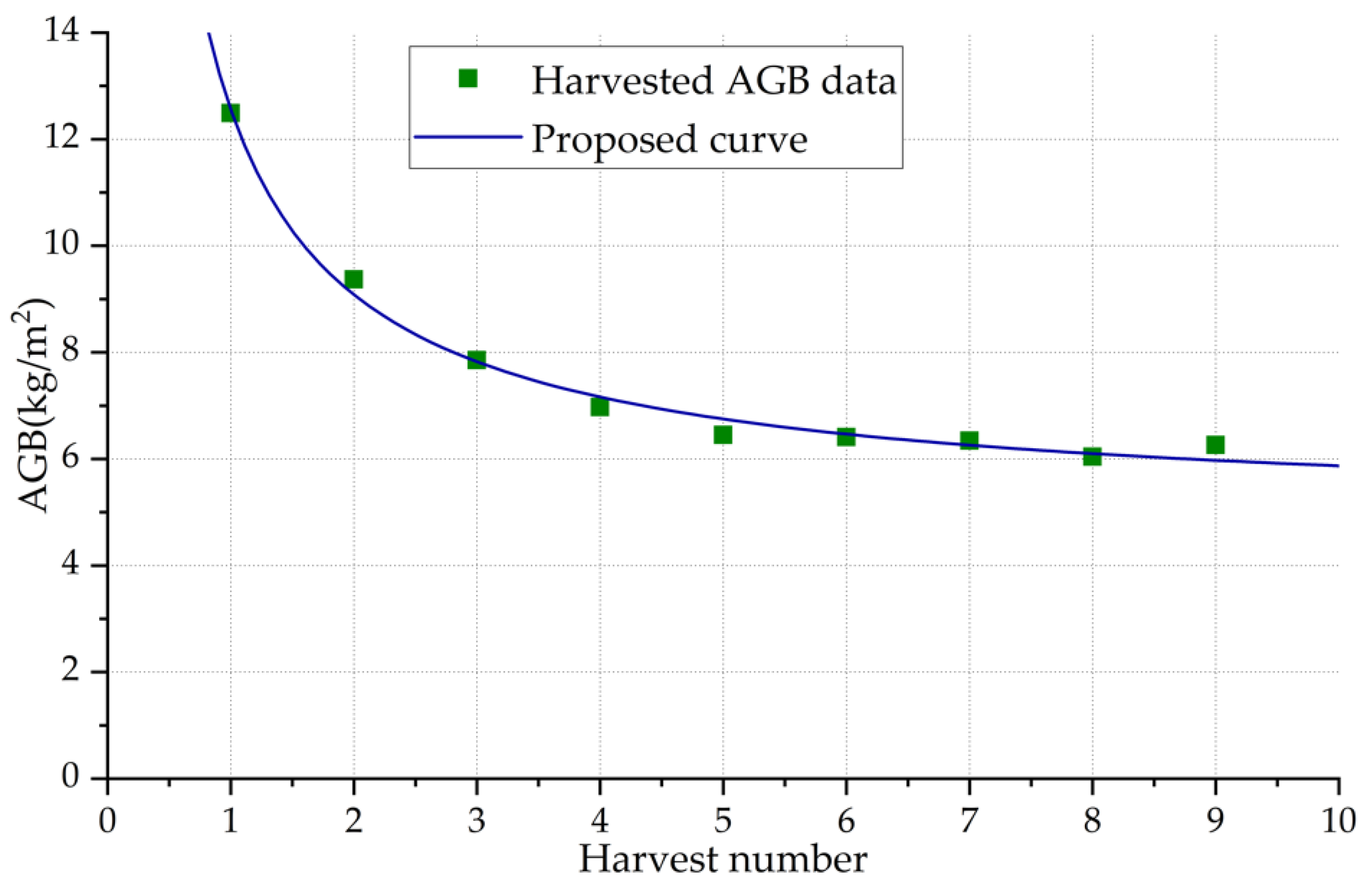

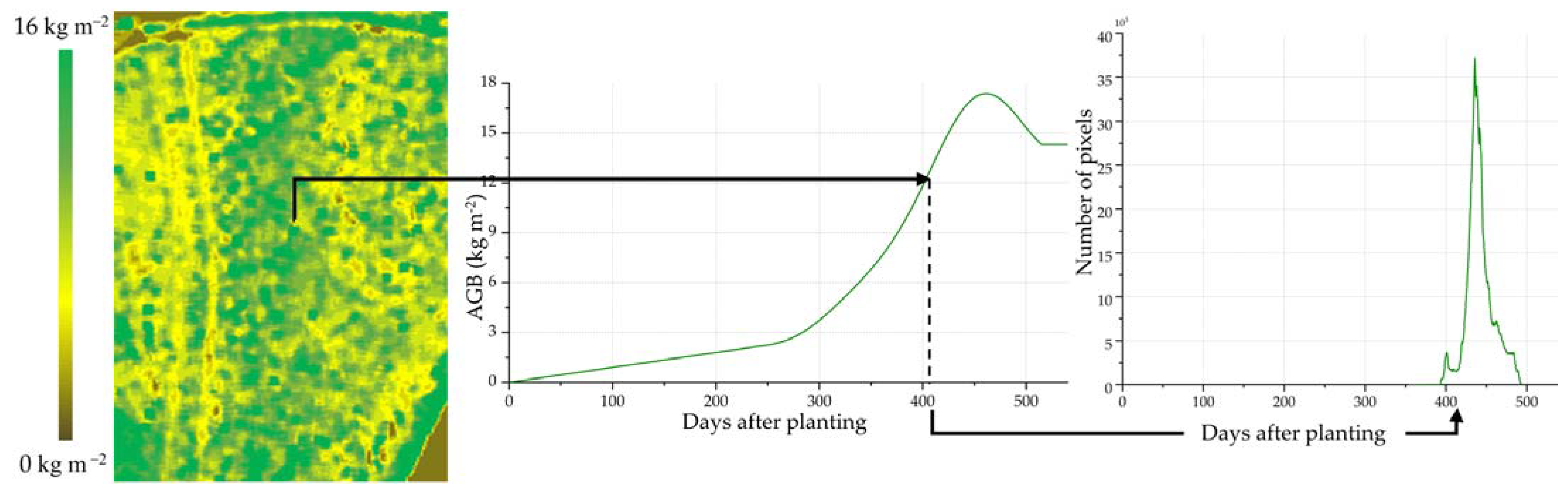

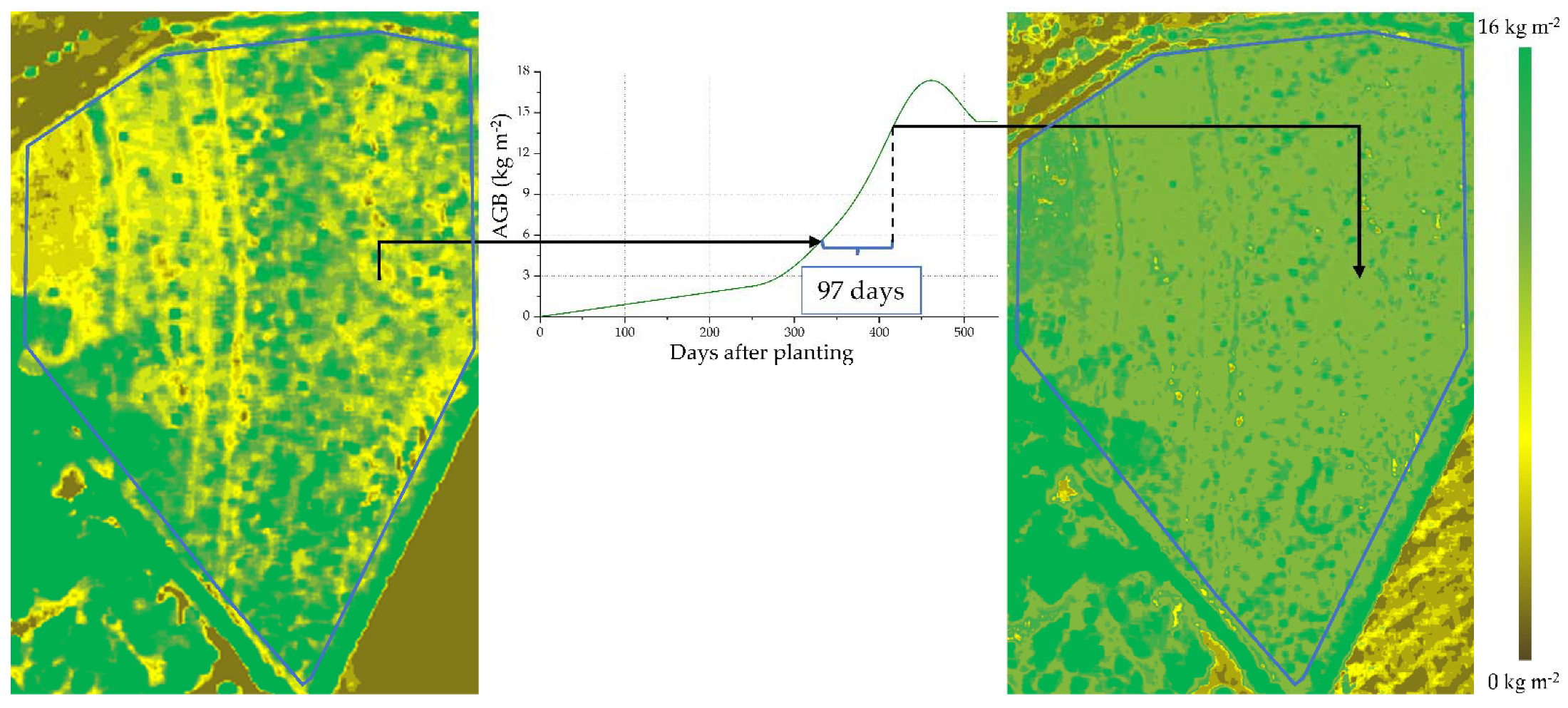

2.3.2. AGB Curve Adjustment

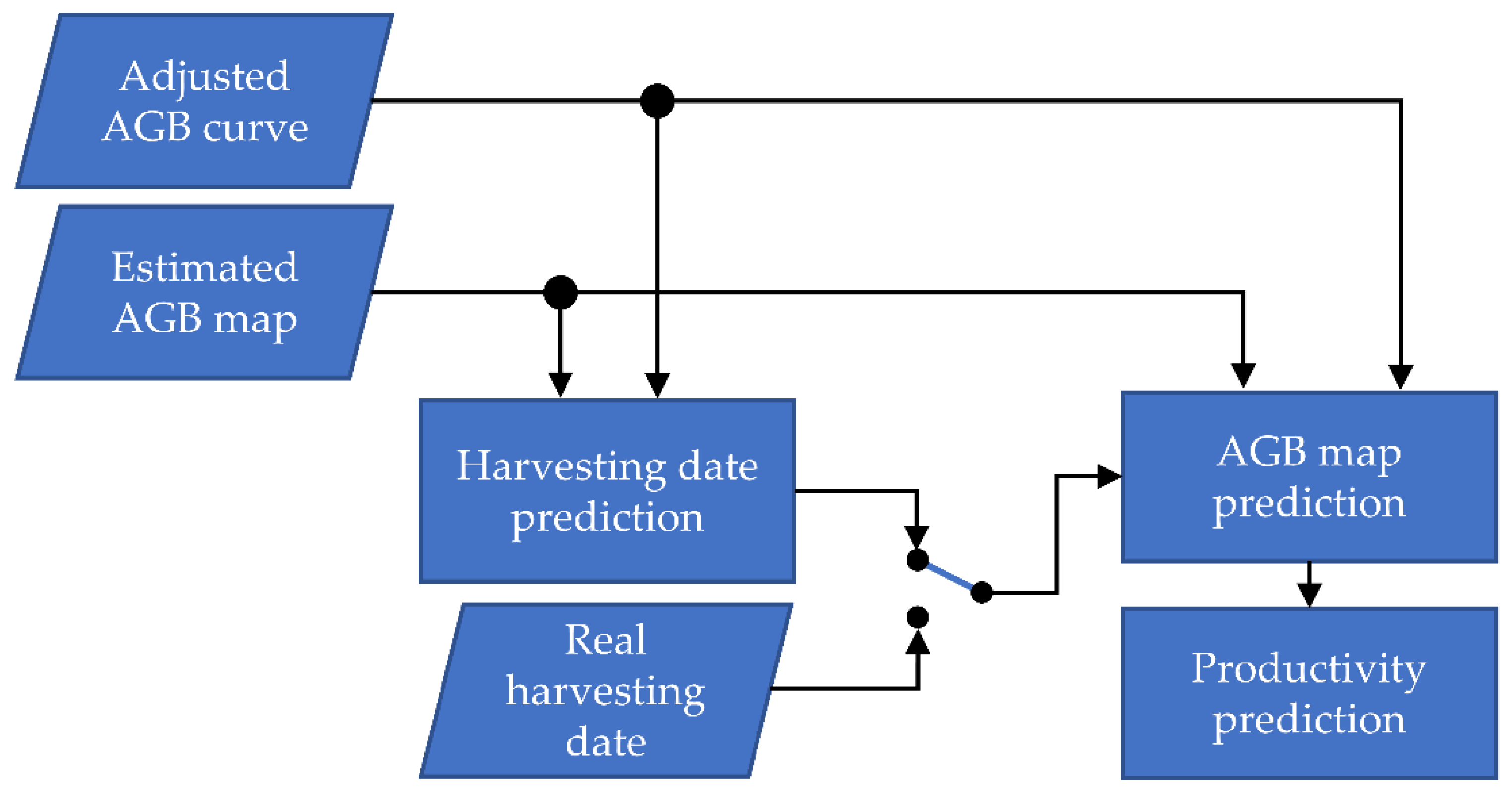

2.4. Prediction Stage

2.4.1. Harvesting Date Prediction

2.4.2. Productivity Prediction

3. Results

3.1. Imaging SAR

3.2. AGB Estimation

3.2.1. Single-Band AGB Models

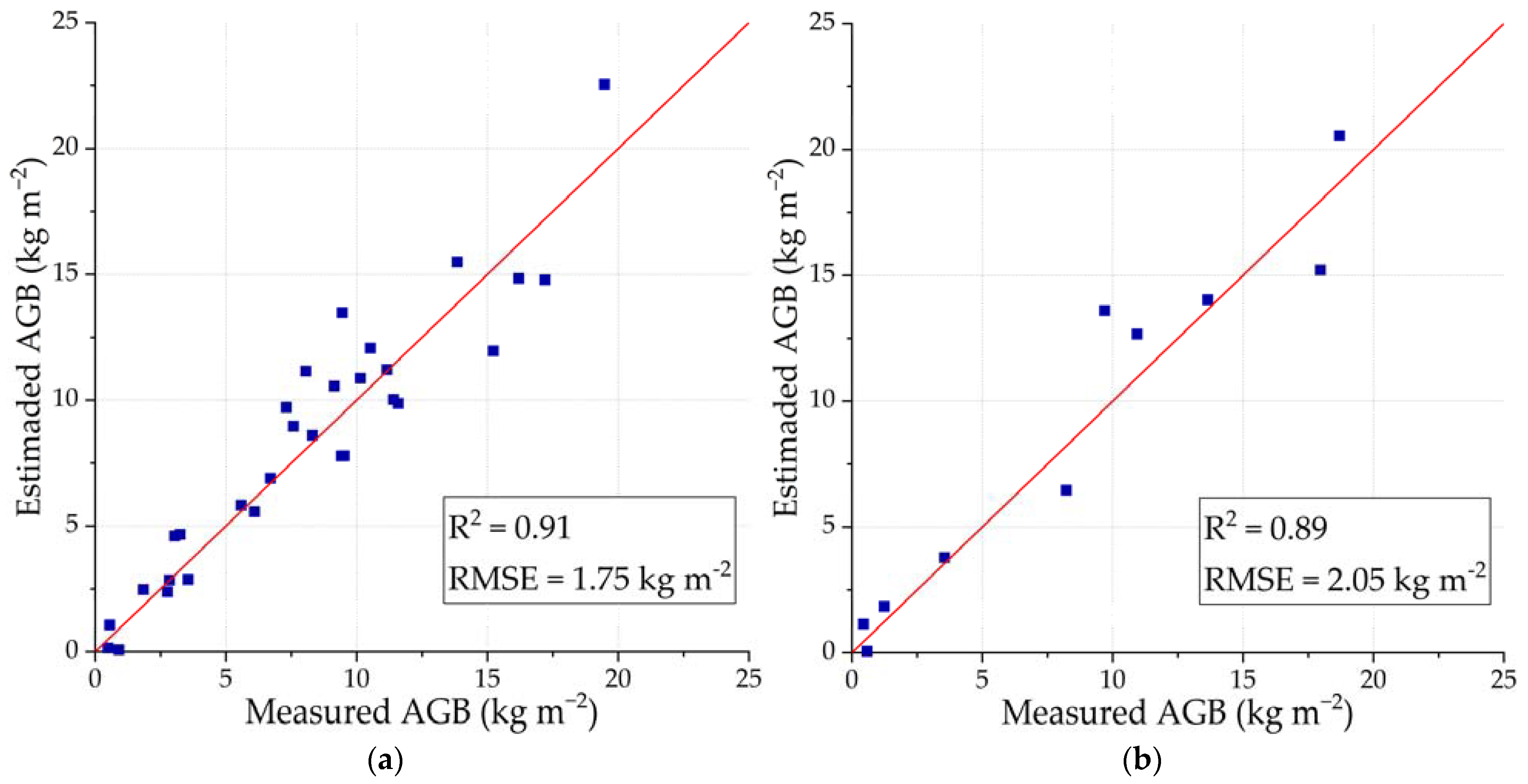

3.2.2. Band-Weighted AGB Model

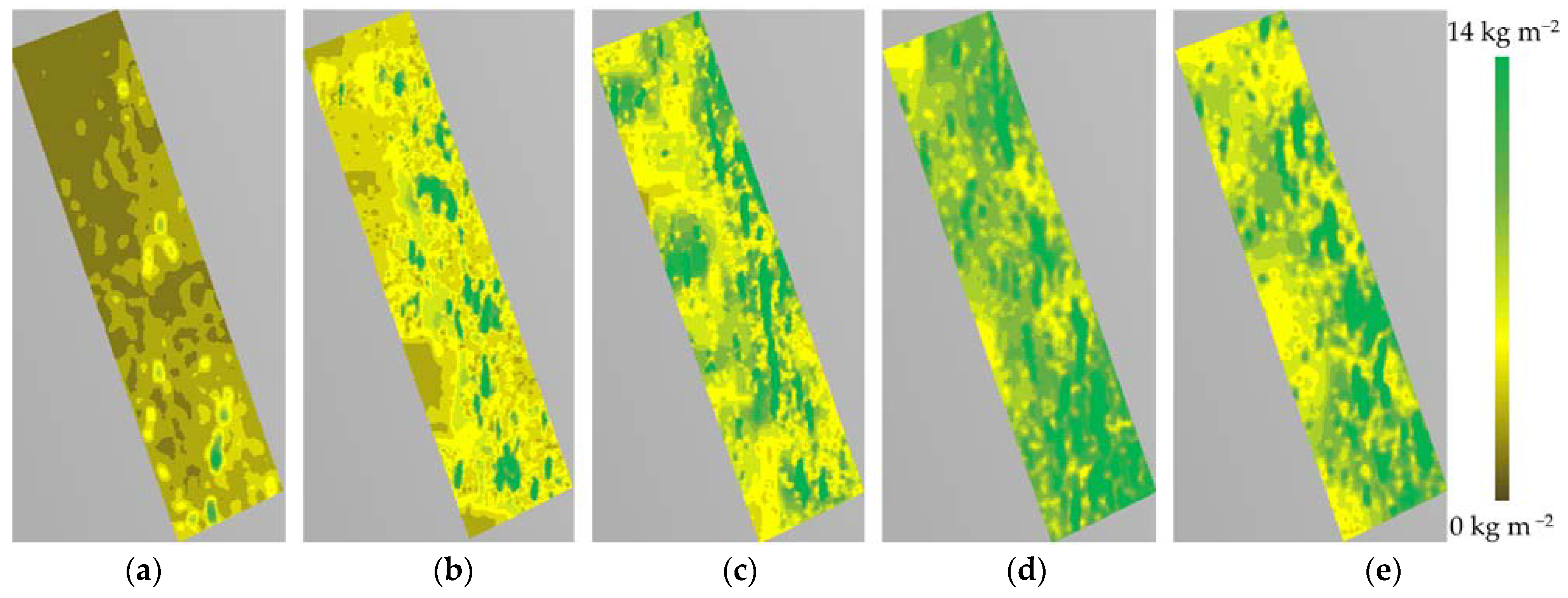

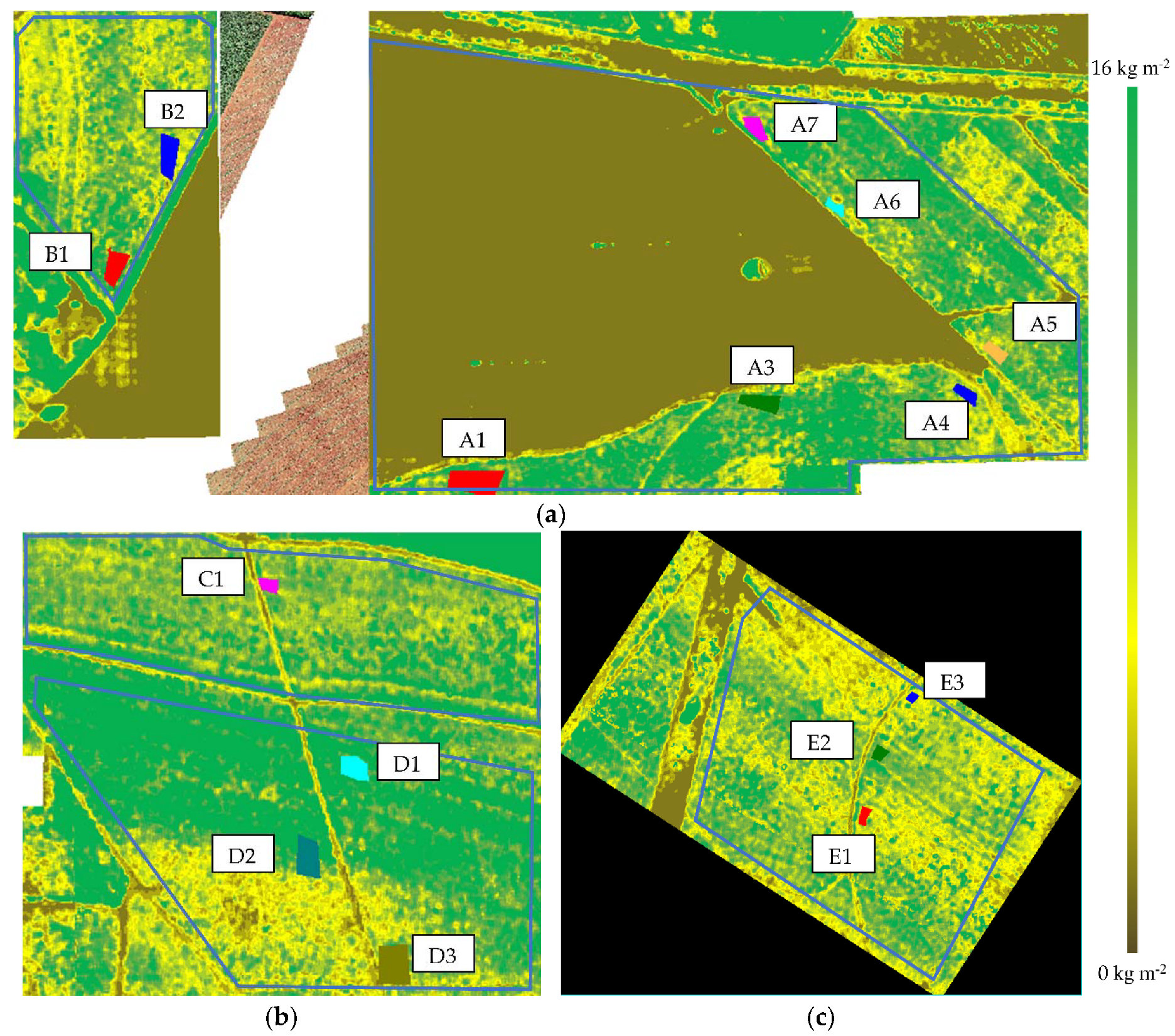

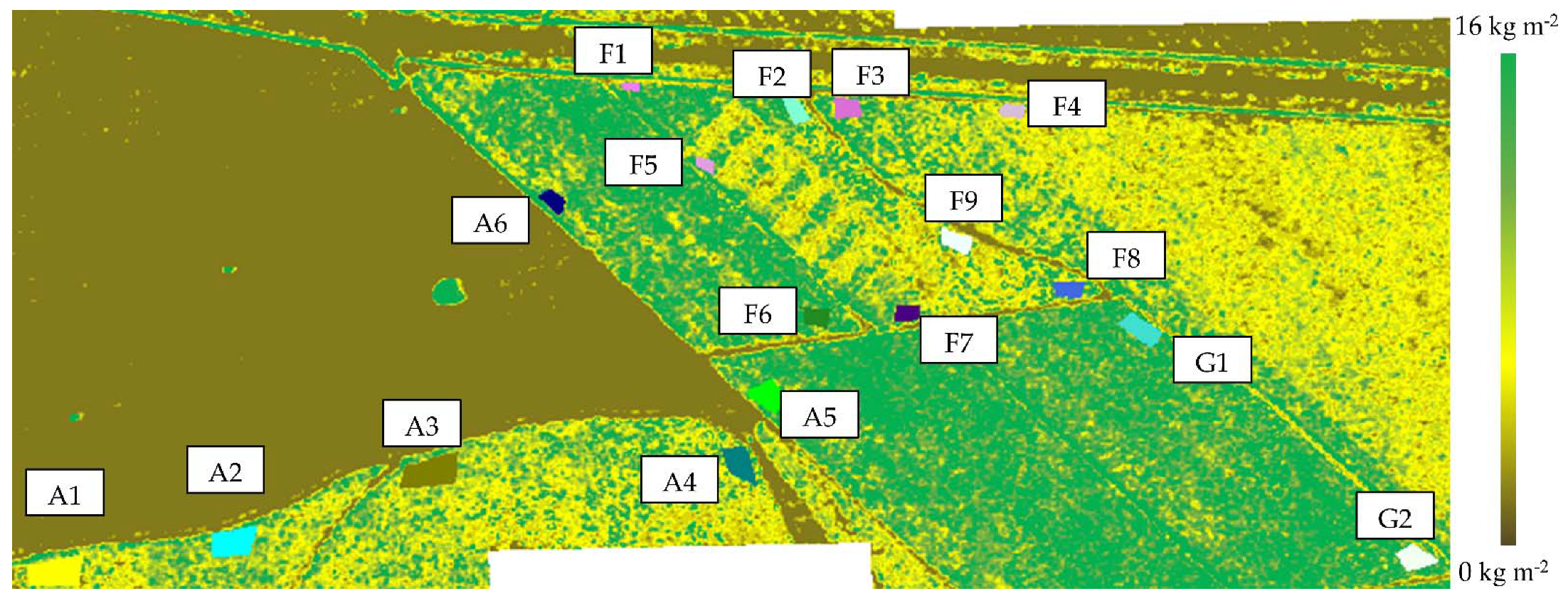

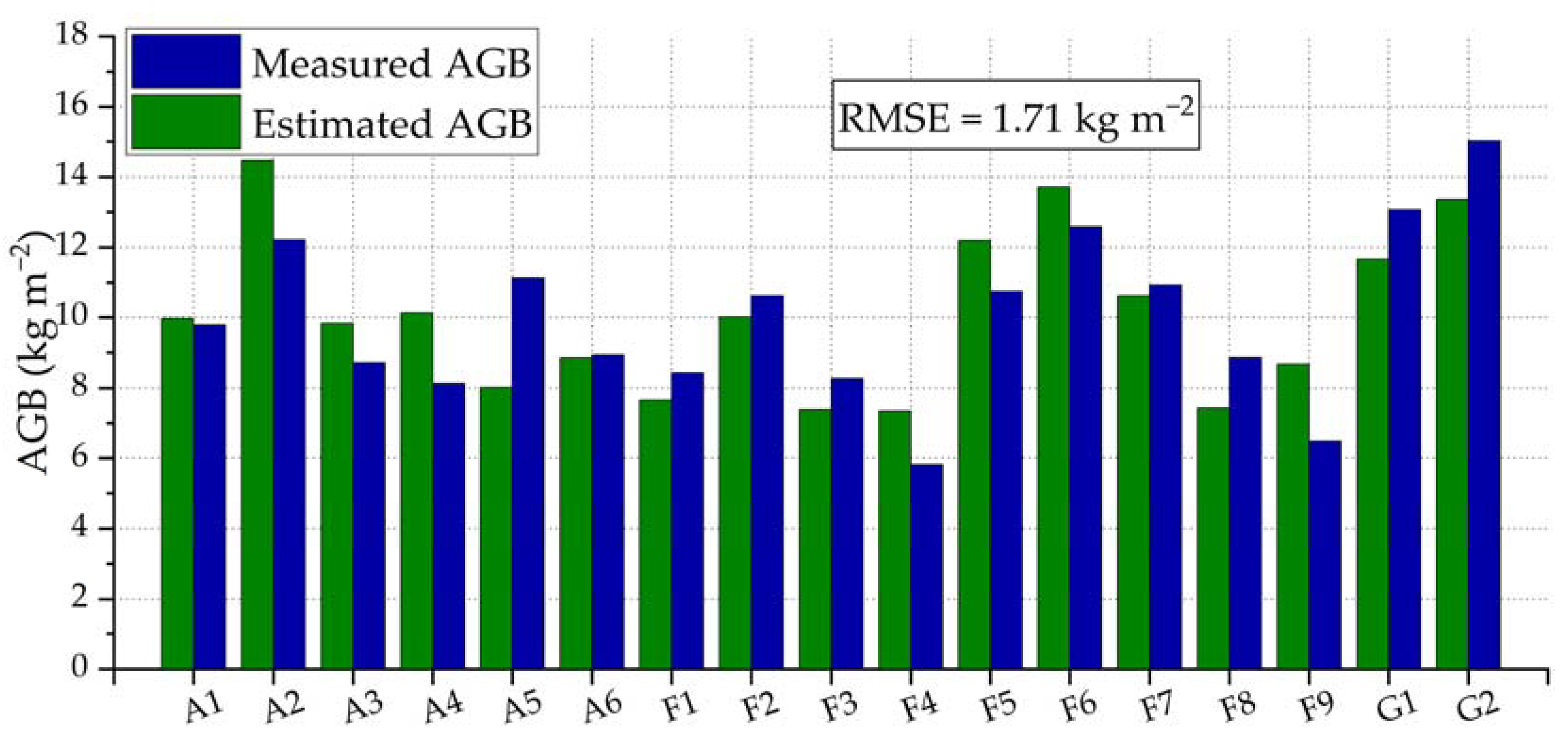

3.2.3. Test Site

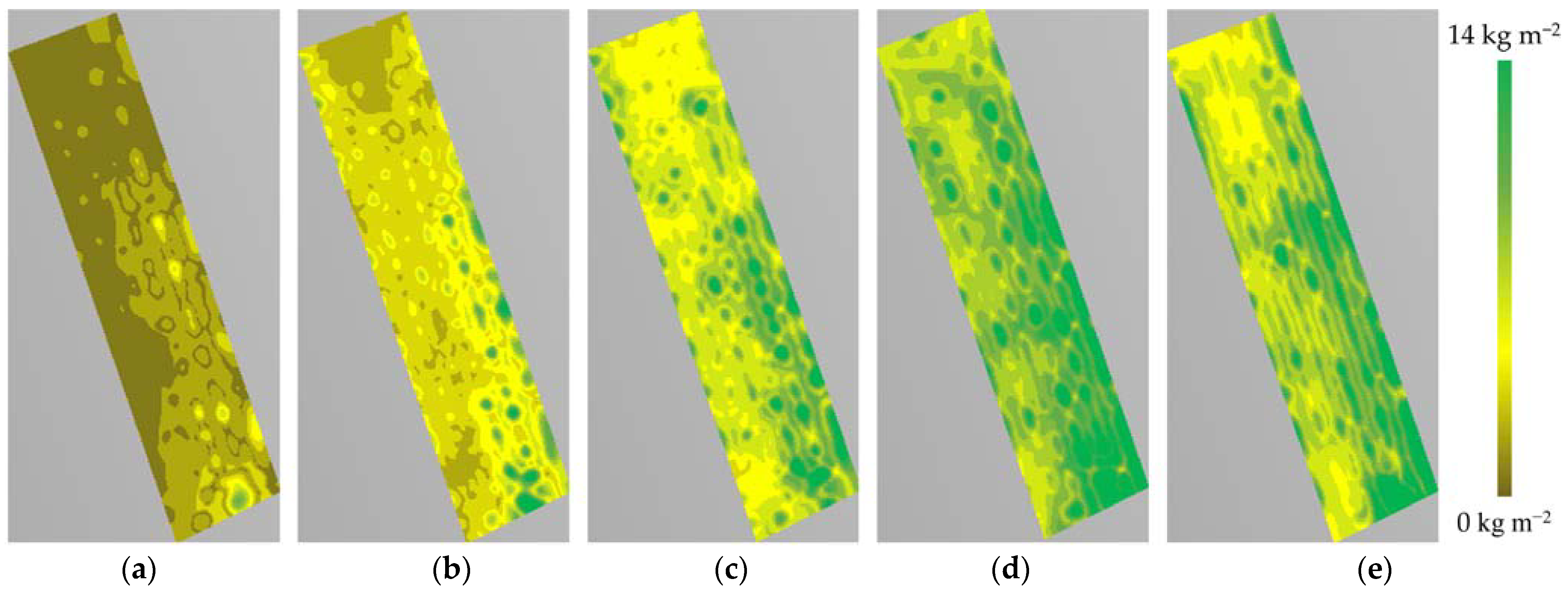

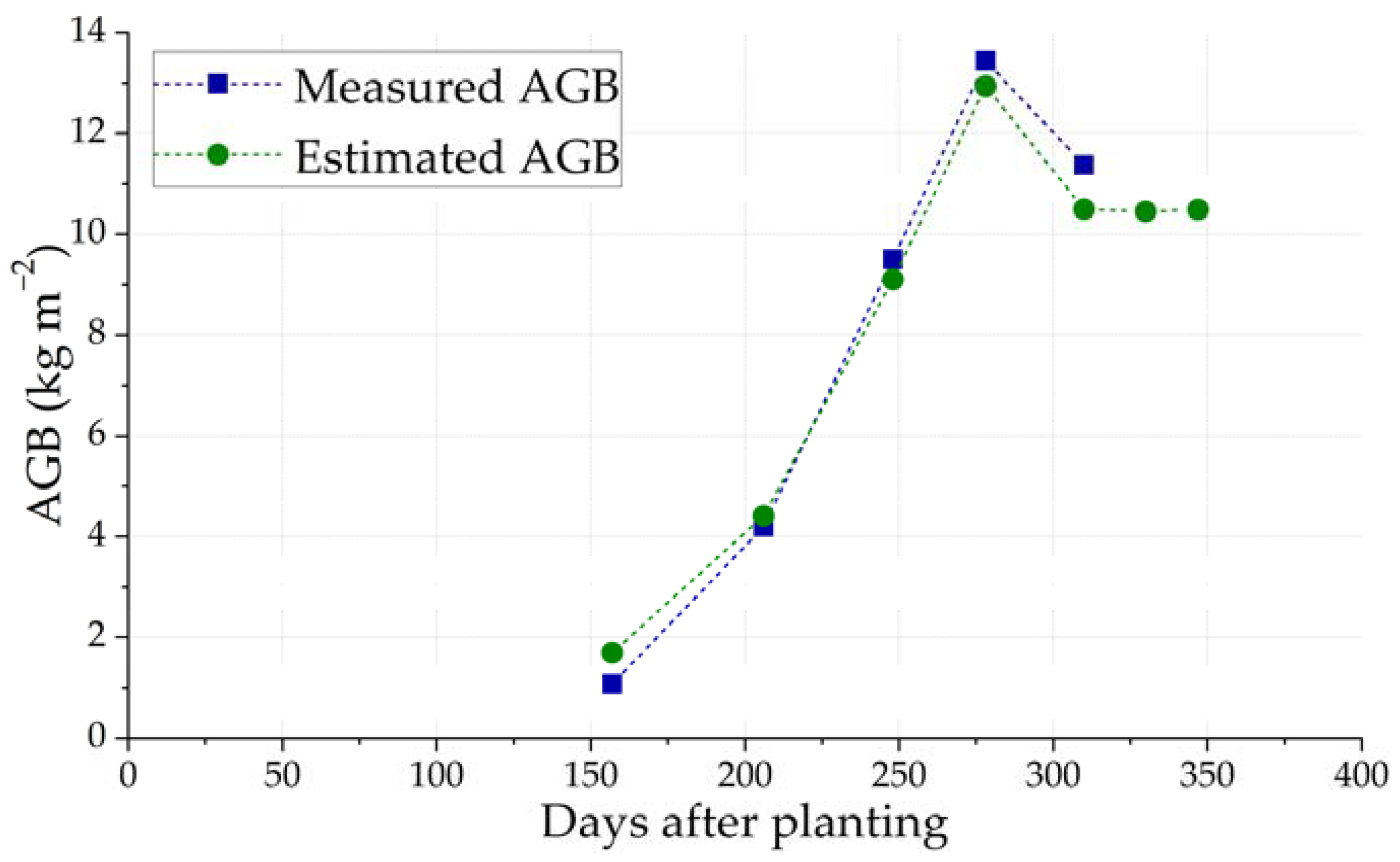

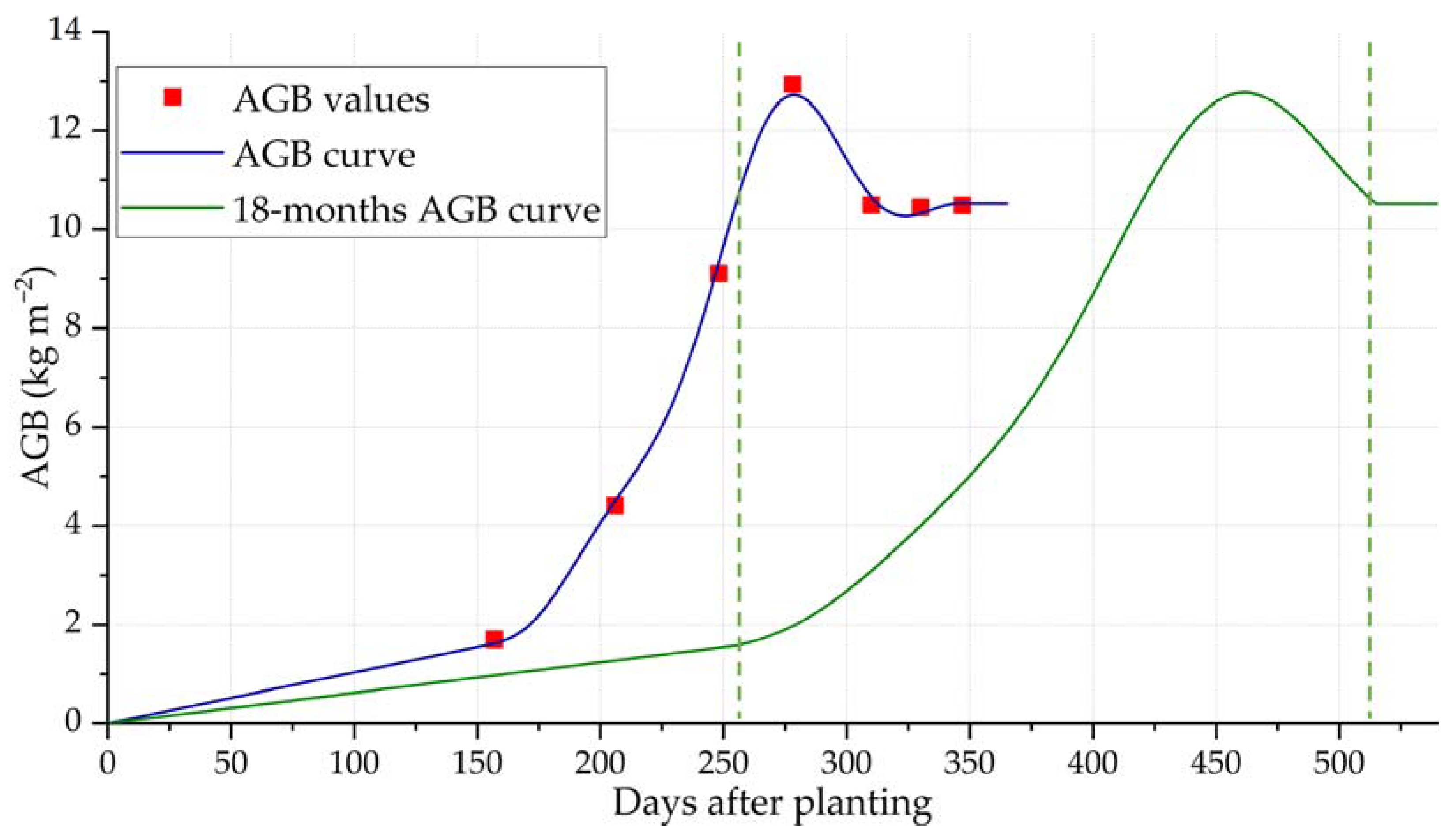

3.3. AGB Curve Adjustment

3.4. Prediction Methods

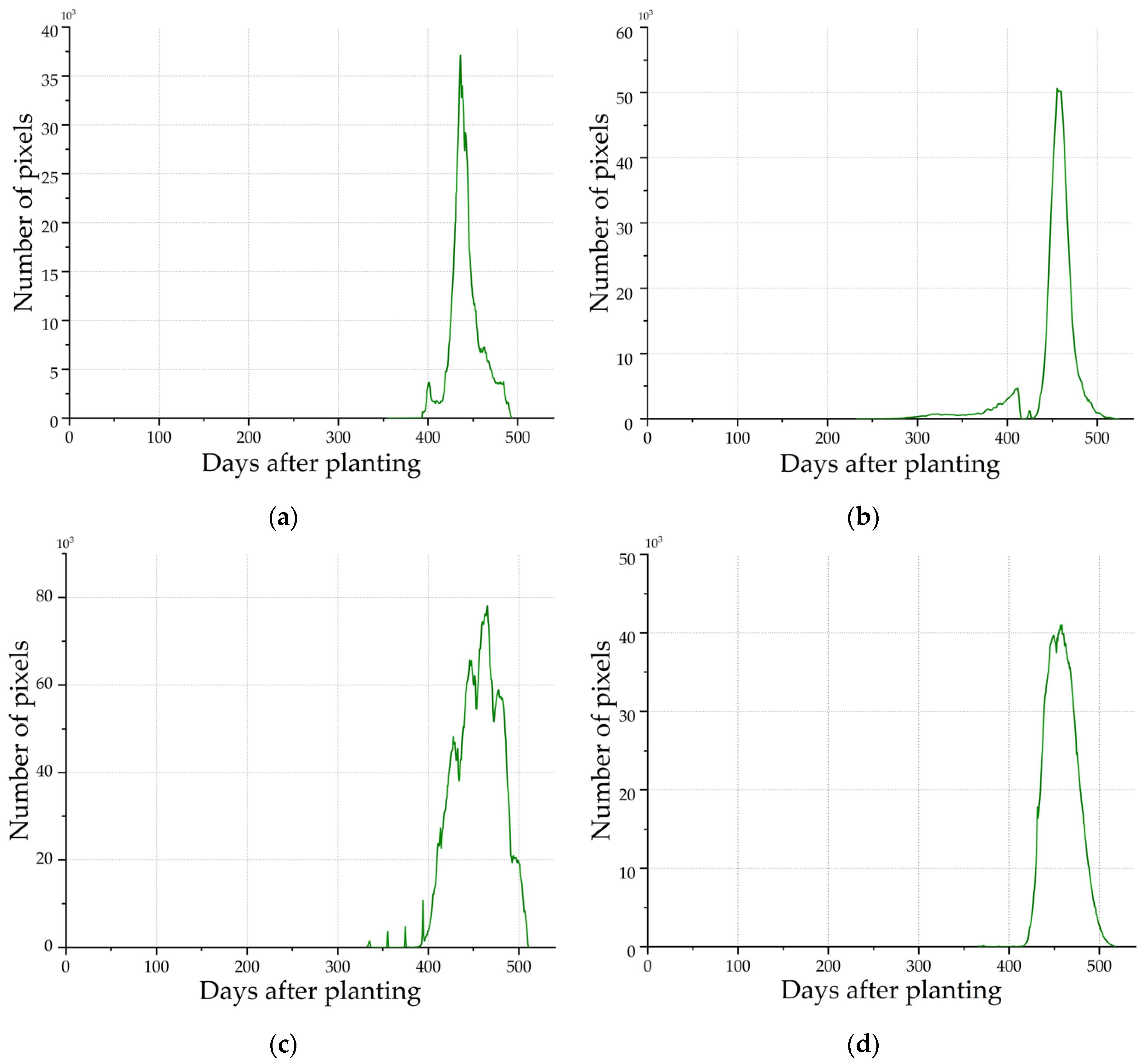

3.4.1. Harvesting Date Prediction

3.4.2. Productivity Prediction

4. Discussion

4.1. Comparision of AGB Estimation Methods

4.2. Comparision of Prediction Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, Y.; Ji, S.; Shao, X.; Tang, H.; Wu, W.; Yang, P.; Zhang, Y.; Ryosuke, S. Framework of SAGI agriculture remote sensing and its perspectives in supporting national food security. J. Integr. Agric. 2014, 13, 1443–1450. [Google Scholar] [CrossRef]

- Gilio, L.; Moraes, M. Sugarcane industry’s socioeconomic impact in São Paulo, Brazil: A spatial dynamic panel approach. Energy Econ. 2016, 58, 27–37. [Google Scholar] [CrossRef]

- Conab. Acompanhamento da Safra Brasileira Cana-de-Açúcar. V. 7, Safra 2019/20, n. 2, Segundo Levantamento; Conab: Brasília, Brazil, 2020. [Google Scholar]

- The World Bank. Agriculture, Forestry and Fishing, Value Added (% of GDP)—Brazil. Available online: https://data.worldbank.org/indicator/NV.AGR.TOTL.ZS?locations=BR (accessed on 24 October 2020).

- Caetano, J.M.; Casaroli, D. Sugarcane yield estimation for climatic conditions in the center of state of Goiás. Rev. Ceres Viçosa 2017, 64, 298–306. [Google Scholar] [CrossRef][Green Version]

- Cesnik, R.; Miocque, J. Melhoramento da Cana-de-Açúcar; Embrapa: Brasília, Brazil, 2004; ISBN 8573832827. [Google Scholar]

- Engelbrecht, J.; Kemp, J.; Inggs, M. The phenology of an agricultural region as expressed by polarimetric decomposition and vegetation indices. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium, Melbourne, Australia, 21–26 July 2013; pp. 1–4. [Google Scholar]

- Richards, M.; Scheer, J.; Holm., W. Principles of Modern Radar: Basic Principles; Scitech Publishing, Inc.: Raleigh, NC, USA, 2010; ISBN 9781891121524. [Google Scholar]

- Tsunoda, S.; Pace, F.; Stence, J.; Woodring, M.; Hensley, W.; Doerry, A.; Walker, B. Lynx: A high-resolution synthetic aperture radar. In Proceedings of the 2000 IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 25 March 2000; pp. 51–58. [Google Scholar]

- Koo, V.; Chan, Y.; Vetharatnam, G.; Chua, M.; Lim, H.; Lim, S.; Thum, C.; Lim, T.; Ahmad, Z.; Mahmood, K.; et al. A new unmanned aerial vehicle synthetic aperture radar for environmental monitoring. Prog. Electromagn. Res. 2012, 122, 245–268. [Google Scholar] [CrossRef]

- Li, C.; Ling, H. Synthetic aperture radar imaging using a small consumer drone. In Proceedings of the IEEE International Symposium on Antennas and Propagation, Vancouver, BC, Canada, 19–24 July 2015; pp. 685–686. [Google Scholar]

- Li, C.; Ling, H. High-resolution, downward-looking radar imaging using a small consumer drone. In Proceedings of the IEEE International Symposium on Antennas and Propagation, Fajardo, PR, USA, 26 June–1 July 2016; pp. 2037–2038. [Google Scholar]

- Yan, J.; Guo, J.; Lu, Q.; Wang, K.; Liu, X. X-band mini SAR radar on eight-rotor mini-UAV. In Proceedings of the IGARSS, Beijing, China, 10–15 July 2016; pp. 6702–6705. [Google Scholar]

- Dill, S.; Schreiber, E.; Engel, M.; Heinzel, A.; Peichl, M. A drone carried multichannel synthetic aperture radar for advanced buried object detection. In Proceedings of the RadarConf, Boston, MA, USA, 22–26 April 2019; pp. 1–6. [Google Scholar]

- Deguchi, T.; Sugiyama, T.; Kishimoto, M. Development of SAR system installable on a drone. In Proceedings of the EUSAR, online, 29 March–1 April 2021; pp. 1–3. [Google Scholar]

- Frey, O.; Werner, C. UAV-borne repeat-pass SAR interferometry and SAR tomography with a compact L-band SAR system. In Proceedings of the EUSAR, online, 29 March–1 April 2021; pp. 1–4. [Google Scholar]

- Lort, M.; Aguasca, A.; López-Martínez, C.; Martínez, T. Initial Evaluation of SAR Capabilities in UAV Multicopter Platforms. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2018, 11, 127–140. [Google Scholar] [CrossRef]

- Schartel, M.; Burr, R.; Mayer, W.; Waldschmidt, C. Airborne Tripwire Detection Using a Synthetic Aperture Radar. IEEE Geosci. Remote Sens. Lett. 2020, 17, 262–266. [Google Scholar] [CrossRef]

- Molijn, R.A.; Ianini, L.; Rocha, J.V.; Hanseen, R.F. Sugarcane productivity mapping through C-Band and L-Band SAR and optical satellite imagery. Remote Sens. J. 2019, 11, 1109. [Google Scholar] [CrossRef]

- Laneve, G.; Marzialetti, P.; Luciani, R.; Fusilli, L.; Mulianga, B. Sugarcane biomass estimate based on SAR imagery: A radar system comparison. In Proceedings of the IGARSS, Fort Worth, RX, USA, 23–28 July 2017; pp. 1–4. [Google Scholar]

- Lin, H.; Chen, J.; Pei, Z.; Zhang, S.; Hu, X. Monitoring sugarcane growth using ENVISAT ASAR data. IEEE Trans. Geosci. Remote Sens. 2009, 47, 2572–2580. [Google Scholar] [CrossRef]

- Baghdadi, N.; Todoroff, P.; Zribi, M. Multitemporal observations of sugarcane by TerraSAR-X sensor. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium, Vancouver, BC, Canada, 24–29 July 2011; pp. 1401–1404. [Google Scholar]

- Gao, S.; Niu, Z.; Huang, N.; Hou, X. Estimating the Leaf Area Index, height and biomass of maize using HJ-1 and RADARSAT-2. Int. J. Appl. Earth Obs. Geoinf. 2013, 24, 1–8. [Google Scholar] [CrossRef]

- Wiseman, G.; McNairn, H.; Homayouni, S.; Shang, J. RADARSAT-2 polarimetric SAR response to crop biomass for agricultural production monitoring. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2014, 7, 4461–4471. [Google Scholar] [CrossRef]

- Hosseini, M.; McNairn, H.; Mitchell, S.; Davidson, A.; Robertson, L.D. Combination of optical and SAR sensors for monitoring biomass over corn fields. In Proceedings of the IGARSS, Valencia, Spain, 22–27 July 2018; pp. 5952–5955. [Google Scholar]

- Nizalapur, V.; Jha, C.; Madugundu, R. Estimation of above ground biomass in Indian tropical forested area using multi-frequency DLR-EASR data. Int. J. Geomat. Geosci. 2010, 1, 167–178. [Google Scholar]

- Shugart, H.H.; Saatchi, S.; Hall, F.G. Importance of structure and its measurement in quantifying function of forest ecosystems. J. Geophys. Res. 2010, 115, 1–16. [Google Scholar] [CrossRef]

- Bombelli, A.; Balzter, H.; Avitabile, V.; Marchesini, L.B. BIOMASS Assessment of the Status of the Development of the Standards for the Terrestrial Essential Climate Variables; Global Terrestrial Observing System: Rome, Italy, 2009. [Google Scholar]

- Oliveira, G. Produtividade de Biomassa de Cana-de-Açúcar em Função dos íNdices de Vegetação Utilizando Técnicas de Monitoramento Remoto. Master’s Thesis, São Paulo State University, São Paulo, Brazil, 2015. [Google Scholar]

- Maimaitijiang, M.; Sagan, V.; Sidike, P.; Maimaitiyiming, M.; Hartling, S.; Peterson, K.; Maw, M.; Shakoor, N.; Mockler, T.; Fritschi, F. Vegetation index weighted canopy volume model (CVMVI) for soybean biomass estimation from unmanned aerial system-based RGB imagery. J. Photogramm. Remote Sens. 2019, 151, 27–41. [Google Scholar] [CrossRef]

- Yue, J.; Feng, H.; Jin, X.; Yuan, H.; Li, Z.; Zhou, C.; Yang, G.; Tian, Q. A comparison of crop parameters estimation using images from UAV-mounted snapshot hyperspectral sensor and high-definition digital camera. Remote Sens. 2018, 10, 1138. [Google Scholar] [CrossRef]

- Sinde-Gonzáles, I.; Gil-Docampo, M.; Arza-Garcia, M.; Grefa-Sanchez, J.; Yanez-Simba, D.; Perez-Guerrero, P.; Abril-Porras, V. Biomass estimation of pasture plots with multitemporal UAV-based photogrammetric surveys. Int. J. Appl. Earth Obs. Geoinf. 2021, 101, 102355. [Google Scholar] [CrossRef]

- Swayze, N.; Tinkham, W.; Vogeler, J.; Hudak, A. Influence of flight parameters on UAS-based monitoring of tree height, diameter, and density. Remote Sens. Environ. 2021, 263, 112540. [Google Scholar] [CrossRef]

- Poley, L.; McDermid, G. A systematic review of the factors influencing the estimation of vegetation aboveground biomass using unmanned aerial systems. Remote Sens. 2020, 12, 1052. [Google Scholar] [CrossRef]

- Masjedi, A.; Crawford, M. Prediction of sorghum biomass using time series UAV-based hyperspectral and LiDAR data. In Proceedings of the IGARSS, Waikoloa, HI, USA, 26 September–2 October 2020; pp. 3912–3915. [Google Scholar]

- Du., Y.; Wang, J.; Lin, Y.; Liu, Z.; Yu, H.; Yi, H. Estimating the aboveground biomass of phragmites australis (common reed) based on multi-source data. In Proceedings of the IGARSS, Valencia, Spain, 22–27 July 2018; pp. 9241–9244. [Google Scholar]

- Moreira, L.; Castro, F.; Góes, J.A.; Bins, L.; Teruel, B.; Fracarolli, J.; Castro, V.; Alcântara, M.; Oré, G.; Luebeck, D.; et al. A drone-borne multiband DInSAR: Results and Applications. In Proceedings of the RadarConf, Boston, MA, USA, 22–26 April 2019; pp. 1–6. [Google Scholar]

- Oré, G.; Alcântara, M.S.; Góes, J.A.; Oliveira, L.P.; Yepes, J.; Teruel, B.; Castro, V.; Bins, L.S.; Castro, F.; Luebeck, D.; et al. Crop Growth Monitoring with Drone-Borne DInSAR. Remote Sens. 2020, 12, 615. [Google Scholar] [CrossRef]

- Moreira, A.; Prats-Iraola, P.; Younis, M.; Krieger, G.; Hajnsek, I.; Papathanassiou, K. A tutorial on synthetic aperture radar. IEEE Geosci. Remote Sens. Mag. 2013, 1, 6–43. [Google Scholar] [CrossRef]

- Castro, F.H. Antenas para Radar de Abertura Sintética Embarcado em Drone. Master’s Thesis, University of Campinas, São Paulo, Brazil, 2018. [Google Scholar]

- Gray, A.L.; Vachon, P.W.; Livingstone, C.E.; Lukowski, T.I. Synthetic aperture radar calibration using reference reflectors. IEEE Trans. Geosci. Remote Sens. 1990, 28, 374–383. [Google Scholar] [CrossRef]

- Magro, F.; Takao, G.; Camargo, P.; Takamatsu, S. Biometria em Cana-de-Açúcar; Universidade de São Paulo, Escola Superior de Agricultura Luiz de Queiroz: Butanta, Brazil, 2011. [Google Scholar]

- Molijn, R.A.; Ianini, L.; Rocha, J.V.; Hanssen, R.F. Ground reference data for sugarcane biomass estimation in Sao Paulo state, Brazil. Sci. Data 2018, 5, 180150. [Google Scholar] [CrossRef] [PubMed]

- Gravois, K.; Orgeron, A. Estimating Brix Values to Improve Sugarcane Quality; LSU Ag. Center, Pub. 2888, 8/15; LSU AgCenter: Baton Rouge, LA, USA, 2020. [Google Scholar]

- Terr, D. Weighted Mean. From MathWorld—A Wolfram Web Resource. Available online: https://mathworld.wolfram.com/WeightedMean.html (accessed on 16 November 2020).

- Farr, T.; Rosen, P.; Caro, E.; Crippen, R.; Duren, R.; Hensley, S.; Kobrick, M.; Paller, M.; Rodriguez, E.; Roth, L.; et al. The shuttle radar topography mission. Rev. Geophys. 2007, 45, 1–33. [Google Scholar] [CrossRef]

- Shi, L.; Hu, S.; Zha, Y. Estimation of sugarcane yield by assimilating UAV and ground measurements via ensemble Kalman filter. In Proceedings of the IGARSS, Valencia, Spain, 22–27 July 2018; pp. 1–4. [Google Scholar]

- Wang, Y.; Zhang, K.; Tang, C.; Cao, Q.; Tian, Y.; Zhu, Y.; Cao, W.; Liu, X. Estimation of rice growth parameters based on linear mixed-effect model using multispectral images from fixed-wing unmanned aerial vehicles. Remote Sens. 2019, 11, 1371. [Google Scholar] [CrossRef]

- Han, L.; Yang, G.; Dai, H.; Xu, B.; Yang, H.; Feng, H.; Li, Z.; Yang, X. Modeling maize above-ground biomass based on machine learning approaches using UAV remote-sensing data. Plant Methods 2019, 15, 10. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Nie, S.; Xi, X.; Luo, S.; Sun, X. Estimating the biomass of maize with hyperspectral and LiDAR data. Remote Sens. 2017, 9, 11. [Google Scholar] [CrossRef]

- Stasolla, M.; Neyt, X. Applying Sentinel-1 time series analysis to sugarcane harvest detection. In Proceedings of the IGARSS, Yokohama, Japan, 24 July–2 August 2019; pp. 1–4. [Google Scholar]

- Priya, S.; Suresh, K. A study on pre-harvest forecast of sugarcane yield using climatic variables. Stat. Appl. 2009, 7, 1–8. [Google Scholar]

- Iizumi, T.; Shin, Y.; Kim, W.; Kim, M.; Choi, J. Global crop yield forecasting seasonal climate information from a muli-model ensemble. Clim. Serv. 2018, 11, 13–23. [Google Scholar] [CrossRef]

| Radar Parameters | L Band | P Band | C Band |

|---|---|---|---|

| Carrier wavelength | 22.8 cm | 70.5 cm | 5.6 cm |

| Bandwidth | 150 MHz | 50 MHz | 200 MHz |

| Polarization | HH | HH | VV |

| Antenna gain | 9.4 dB | 8.2 dB | 12.1 dB |

| Antenna aperture in azimuth | 58.5° | 55.9° | 32.5° |

| Antenna aperture in elevation | 79.8° | 69.3° | 51.3° |

| Drone average speed | 2 m/s | 2 m/s | 2 m/s |

| Drone average height | 120 m | 120 m | 120 m |

| Survey Dates | Days after Planting |

|---|---|

| 12 December 2019 | 165 |

| 25 January 2020 | 202 |

| 4 March 2020 | 241 |

| 10 April 2020 | 278 |

| 12 May 2020 | 310 |

| 1 June 2020 | 330 |

| 17 June 2020 | 346 |

| Band | Range 1: [0 to 4 kg m−2] | Range 2: [4 to 11 kg m−2] | Range 3: [11 to 21 kg m−2] |

|---|---|---|---|

| Sugarcane Harvest Season | Harvested AGB |

|---|---|

| 1st harvest season | 12.49 kg m−2 |

| 2nd harvest season | 9.37 kg m−2 |

| 3rd harvest season | 7.85 kg m−2 |

| 4th harvest season | 6.97 kg m−2 |

| 5th harvest season | 6.45 kg m−2 |

| 6th harvest season | 6.41 kg m−2 |

| 7th harvest season | 6.34 kg m−2 |

| 8th harvest season | 6.04 kg m−2 |

| 9th harvest season | 6.26 kg m−2 |

| Band | Range 1: [0 to 4 kg m−2] | Range 2: [4 to 11 kg m−2] | Range 3: [11 to 21 kg m−2] | Overall: [0 to 21 kg m−2] |

|---|---|---|---|---|

| 1.57 kg m−2 | 2.11 kg m−2 | 2.86 kg m−2 | 1.94 kg m−2 | |

| 1.64 kg m−2 | 2.47 kg m−2 | 2.21 kg m−2 | 2.11 kg m−2 | |

| 1.48 kg m−2 | 3.63 kg m−2 | 4.59 kg m−2 | 3.46 kg m−2 |

| Area | Harvested AGB (kg m−2) | Predicted AGB (kg m−2) | Harvest Season |

|---|---|---|---|

| Area 2 | 14.42 | 15.23 | 1st |

| Area 4 | 7.07 | 7.99 | 4th |

| Area 6 | 5.36 | 6.01 | 9th |

| Area 7 | 9.77 | 10.97 | 3rd |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oré, G.; Alcântara, M.S.; Góes, J.A.; Teruel, B.; Oliveira, L.P.; Yepes, J.; Castro, V.; Bins, L.S.; Castro, F.; Luebeck, D.; et al. Predicting Sugarcane Harvest Date and Productivity with a Drone-Borne Tri-Band SAR. Remote Sens. 2022, 14, 1734. https://doi.org/10.3390/rs14071734

Oré G, Alcântara MS, Góes JA, Teruel B, Oliveira LP, Yepes J, Castro V, Bins LS, Castro F, Luebeck D, et al. Predicting Sugarcane Harvest Date and Productivity with a Drone-Borne Tri-Band SAR. Remote Sensing. 2022; 14(7):1734. https://doi.org/10.3390/rs14071734

Chicago/Turabian StyleOré, Gian, Marlon S. Alcântara, Juliana A. Góes, Bárbara Teruel, Luciano P. Oliveira, Jhonnatan Yepes, Valquíria Castro, Leonardo S. Bins, Felicio Castro, Dieter Luebeck, and et al. 2022. "Predicting Sugarcane Harvest Date and Productivity with a Drone-Borne Tri-Band SAR" Remote Sensing 14, no. 7: 1734. https://doi.org/10.3390/rs14071734

APA StyleOré, G., Alcântara, M. S., Góes, J. A., Teruel, B., Oliveira, L. P., Yepes, J., Castro, V., Bins, L. S., Castro, F., Luebeck, D., Moreira, L. F., Cintra, R., Gabrielli, L. H., & Hernandez-Figueroa, H. E. (2022). Predicting Sugarcane Harvest Date and Productivity with a Drone-Borne Tri-Band SAR. Remote Sensing, 14(7), 1734. https://doi.org/10.3390/rs14071734