Abstract

The non-destructive testing and diagnosis of transport infrastructures is essential because of the need to protect these facilities for mobility, and for economic and social development. The effective and timely assessment of structural health conditions becomes crucial in order to assure the safety of the transportation system and time saver protocols, as well as to reduce excessive repair and maintenance costs. Ground penetrating radar (GPR) is one of the most recommended non-destructive methods for routine subsurface inspections. This paper focuses on the on-site use of GPR applied to transport infrastructures, namely pavements, railways, retaining walls, bridges and tunnels. The methodologies, advantages and disadvantages, along with up-to-date research results on GPR in infrastructure inspection are presented herein. Hence, through the review of the published literature, the potential of using GPR is demonstrated, while the main limitations of the method are discussed and some practical recommendations are made.

Keywords:

ground penetrating radar; inspection; pavements; railways; bridges; tunnels; retaining walls; methodologies; limitations; benefits 1. Introduction

The deterioration and distress mechanisms that are active under the surface cannot be assessed with high accuracy using only traditional methods such as visual inspection, hammer sounding, chain dragging, and not even by destructive coring and test pits. Alternative methods are therefore required for a more complete inspection. Among other geophysical methods, ground penetrating radar (GPR) is widely recognized as one of the most powerful and versatile non-destructive testing (NDT) methods for routine subsurface inspections. GPR is a geophysical method that allows for the analysis of the propagation capacity of electromagnetic waves through media with different dielectric constants. A transmitting antenna emits an electromagnetic signal into the ground, which is partly reflected at the interface between two different media with sufficient dielectric contrast and partly transmitted into deeper layers. Then, the reflections produced are recorded from the receiving antenna, which is either in a separate antenna box or in the same antenna box as the transmitter. The strength (amplitude) of the reflected fields is proportional to the change in the magnitude of the dielectric constant. As the antenna is moved along the ground surface, a two-dimensional image (known as a radargram or B-scan) is obtained, which is an XZ graphic representation of the detected reflections. The x-axis represents the antenna displacement along the survey line, and the z-axis represents the two-way travel time of the pulse emitted and received. If the time required to propagate to a reflector and back is measured, and the velocity of the signal propagation in the medium is known, the depth of the reflector can therefore be determined. By using three-dimensional data acquisition and imaging techniques, the reflected signals recorded by the GPR can be transformed into 3D imaging, which allows for a better perception of the underground structures. A detailed description of the methodology along with a deep theoretical background can be found in [1,2,3]. GPR is a portable and fast data acquisition technique that provides dense and accurate data, with a much higher resolution compared with competing geophysical approaches.

The major strengths of GPR are that the method allows for the collection of data at high speed, continuously, using mobile acquisition units and in a non-contact mode. Furthermore, it enables one to keep the prospected transport infrastructure area in-service during the GPR assessment, thus reducing costs and discomfort to users. Conversely, the main limitations occur in the presence of high-conductivity materials (such as wet clay) and in heterogeneous conditions causing signal attenuation and complex scattering phenomena, respectively. Another drawback is that the interpretation of radargrams is generally non-intuitive and requires considerable expertise to properly process and understand the measurements.

A few international organizations have promoted recommendations to properly use GPR in transport infrastructures. The American Society for Testing and Materials (ASTM) has produced a standard guide, ASTM D6432-19, that summarizes the equipment and field procedures for GPR subsurface investigation, as well as processing methods used to interpret GPR data [4]. The British Highway Agency has published technical specifications (DMRB 3.1.7 and DMRB 7.3.2) regarding the use of GPR for testing highway structures (concrete and masonry bridges) [5] and for pavement assessment [6], respectively. In Europe, the EuroGPR has produced guidelines for pavement structural surveys [7] including limitations of GPR use on pavements, survey assessment, survey specification, location referencing, data quality and backup, and data reporting. In Italy, the Comitato Elettotecnico Italiano (CEI) published the Italian standard (CEI 306–8) for performing preliminary surveys with GPR before laying underground utilities and infrastructures [8].

The use of GPR in civil engineering applications began to appear in the mid-70s and early 80s, mainly focused on the detection of hidden utilities [9,10,11,12] and pavement inspection [13,14]. From these first studies, the number of applications and developments of the methodology increased remarkably, being nowadays successfully and widely employed for a great variety of tasks. A comprehensive overview on the civil engineering applications of GPR can be found in [15,16,17].

GPR surveys in pavements (rigid or flexible) are frequently applied as a complementary technique for the assessment of roads and airport pavements. GPR images provide valuable information about the continuity of layers and their thickness, which could be combined with falling weight deflectometer (FWD) tests. In addition, GPR inspection allows for the analysis of the pavement layer’s condition and locating defects, which is crucial in preserving the structure and its service life. In road assessment, the main analyses are focused on measuring layer thickness and detecting voids or delamination. Other, more recent studies are dedicated to the detection of water presence, mainly in the base and subgrade. Quality studies of the material density, water infiltration and cracking are also some examples of the applications that have been recently tested. Most of those researches are based on the analysis of the GPR images through the two-way travel time conversion into depths and the reflected wave amplitude analysis. However, during the last few years, several tests were prepared to determine additional parameters by studying frequencies.

For railway assessment, the main applications consist of ballast layer thickness measurement and detection of changes in track structure and substructure. During the last decade, a huge research effort has been carried out to improve the systematic application of GPR for ballast condition assessment, such as ballast fouling and moisture content.

In the study of retaining walls, GPR focuses on the detection of rebar in concrete retaining walls, detecting joints and dowels, and the location of damage and water infiltration. In some cases, the GPR analysis objective is the detection of the contact between the wall and the natural soil or between the wall and further restorations. Other applications are the detection and the analysis of the foundations. Those walls support high loads and the assessment of their state is important in maintaining or repairing parts of the structure.

Regarding masonry bridges, the main GPR applications comprehend the detection of unknown geometries such as hidden arches and ancient profiles, restorations and reconstructions in stonework, moisture content in masonry, bridge foundation, voids and cracks in masonry, filling distribution, and thickness of ashlars (e.g., voussoirs). Concerning concrete bridges, GPR evaluation encompasses the diagnosis of bridge–deck thickness, mapping rebar and tendon ducts, moisture content, corrosion assessment, and mapping delamination.

Finally, in tunneling inspection, the applications of GPR include the assessment of concrete segments and backfill grouting thickness, reinforcement, damages (e.g., cavities) in lining, moisture content and corrosion.

This paper presents a review of published works in the frame of GPR application in the evaluation of transport infrastructures, including roads, highways, airport runways, railways, retaining walls, concrete and masonry bridges, and tunnels. Although it has been demonstrated that GPR has significantly benefited the procedures for inspection and successfully solved some of the limitations of traditional methods, it also has some constraints. In order to maximize the benefit obtained through the use of GPR, it is important to be aware of these constraints and to be able to adapt the methodologies for testing and for analysis of the results to the job’s specific conditions. Thus, through the review of the methodologies shown by other authors in the literature, the present paper highlights some of these best practices and recommendations (type of antennas, setting parameters, acquisition mode, processing, etc.). Moreover, some recommendations are made in terms of best practices aiming to improve the application of GPR and to avoid the misinterpretation of results.

As Supplementary Materials, different tables are addressed with a compilation of interesting published works carrying out the on-site survey of transport infrastructures. Those present a synthesis on GPR equipment, inspection methodologies, and set parameters for data acquisition and data processing, as well as the most relevant results obtained and the drawbacks identified.

2. GPR Equipment for Transport Infrastructures Surveying

There are several GPR manufacturers and commercial equipment available, and some experimental prototypes also exist. Different GPR systems will have different capabilities according to the type of antennas and their frequency, which affect the operating speed, the resolution, the penetration and the sampling rate [17,18]. The frequency and depth of penetration are related, with higher frequency pulses achieving lower penetration, but better resolution. Impulse GPR systems are the most widely used, with two main groups of GPR antennas, dipole and horn antennas, and with frequencies nowadays ranging from 10 MHz to 6 GHz. Currently, the most commonly used technology is the time-domain impulse radar. Additionally, several investigations point to the step-frequency radar as a potential technology for broad resolution range, although these systems do not allow real-time visualization of data during acquisition.

It should be noted that there are technical standards regulating the electromagnetic emissions of GPR equipment. The following are the main standards in Europe, USA and Canada: European Telecommunications Standard Institute (ETSI) EN 203 066-1, ETSI EN 203 066-2, ETSI EN 203 489-32 and ETSI EG 202 730, USA regulations on UWB-GPR: Part 15 of Federal Communications Commission (FCC) Regulations, and Industry Canada Radio Standards Specification RSS-220 (Issue 1) “Devices Using Ultra-Wideband (UWB) Technology.

2.1. GPR with Horn Antennas

GPR horn antennas were specifically designed for use in transport infrastructures evaluation, since they can operate at traffic speed. In the last ten years, this type of equipment has evolved from prototype status to routine use in pavement evaluation studies.

Horn antennas have frequencies ranging from 1 to 2.5 GHz, corresponding to penetration depths in the order of 1 m to 0.4 m, respectively. The minimum layer thickness that can be detected is about 50 mm, for 1 GHz antennas and 25 mm, for the higher frequencies.

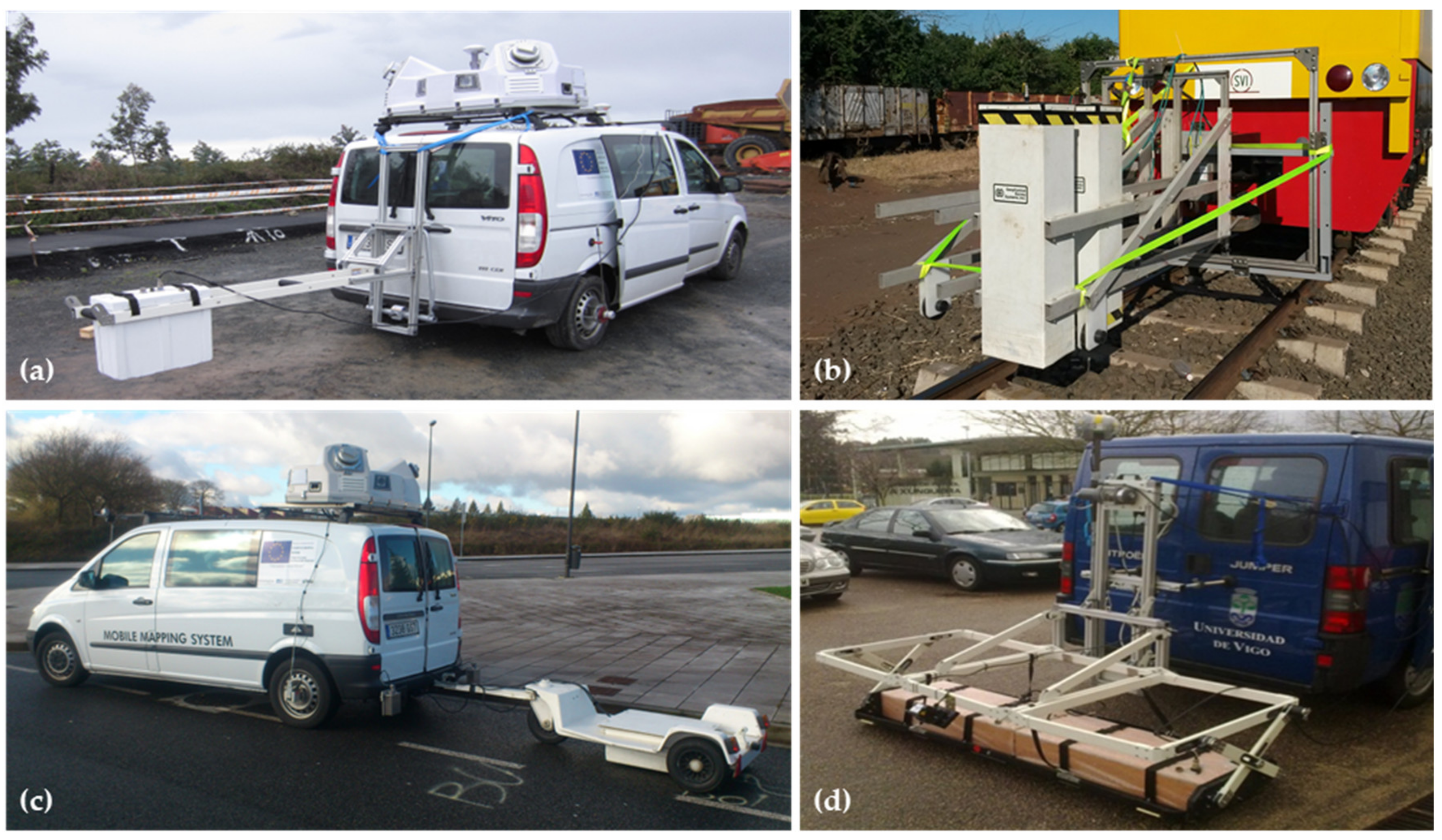

The antennas are “air-coupled”, and normally they work mounted on a mobile vehicle and are suspended at a certain distance from the surface (Figure 1a,b), typically ranging from 0.4 to 0.6 m. They perform measurements at traffic speeds (up to 80–120 km/h) without any interference with traffic, and therefore they are suitable for the evaluation of in-service pavements without major disturbance to road users.

Figure 1.

Different ground penetrating radar (GPR) antennas: (a) air-coupled (horn) antennas, (b) multi-antenna system (horn), (c) ground-coupled (dipole) antennas in a trolley, and (d) array multi-channel (ground-coupled) antennas.

2.2. GPR with Dipole Antennas

Dipole antennas were primarily developed for use in geological survey, normally ground-coupled (Figure 1c). They have frequencies ranging between 10 MHz and 6 GHz. For transport infrastructure applications, the best results are obtained with antennas from 400 MHz to 2.5 GHz central frequency. In general, the higher the frequency, the lower the penetration depth and the higher the resolution is. For example, 1.5 GHz dipole antennas will give a penetration depth of 0.50 m, while the 400 MHz will give a penetration of 2.00 m [19].

Dipole antennas were mainly developed for use in contact with the surface, or suspended just above it (2–5 cm), and they are suitable for testing at maximum speeds of 20–30 km/h. In this condition, the radar signal is “ground-coupled”. Ground coupling introduces a stronger signal into the pavement, and therefore these antennas are normally employed for detailed studies over limited areas, as they allow one to obtain higher resolution [20].

2.3. GPR with Antennas Array Multi-Channel

GPR array multi-channel systems consist of a large number of closely-spaced antennas recording at the same time. Different multi-channel prototypes have recently been provided with different configurations, and they can include both air- and ground-coupled antennas (Figure 1b,d, respectively). Commonly, such multi-static systems are composed of 4–16 couples of transmitting and receiving channels mounted in a parallel broadside configuration with a cross-line trace spacing of 4–12 cm, depending on the manufacturer.

The main advantage is that they enable faster data collection by increasing the extension of the investigated area per time unit, and they make it easier for the operator to produce 3D images.

Generally, in transport infrastructure inspection, the antennas are mounted on a mobile vehicle to minimize traffic disruption. Mobile GPR is positioned connected to an external real-time kinematic (RTK) global navigation satellite system (GNSS) for trace tagging (georeferenced data) or to a distance measurement indicator (DMI) to control the distance trace-interval and to measure the travelled distance. The system also uses a computer navigation guided system to correctly follow profile direction and keep a constant overlap among parallel profiles without any physical marker on the ground surface.

3. Overview on GPR in Roads and Airports

Mobility and communications are the axis of our society’s development. Road transport and planes move population and merchandising, being crucial for the development of industry and the cities. The roads and airports are the infrastructures that support this high level of activity. The safety and the efficiency of the transport and communication routes require detailed maintenance plans. The plans must include detailed inspection of infrastructures and development of maintenance strategies based on this information. Damage due to age, traffic and weather highly affects this type of infrastructure and, without a careful conservation and maintenance strategies, can lead to significant financial losses and can cause accidents. Roads and airports are two types of pavement structures designed to support different kinds of vehicles. Generally, the pavement consists of several layers: the surface course (asphalt or concrete layer), the base course (usually an asphalt base layer) and the subbase course (an unbound aggregate layer). This structure is supported by the natural subsoil (subgrade layer). The number of layers and their thickness depend on the type of pavement, being different in the case of roads, airports and industrial and harbor platforms (slabs). The airport pavement layers’ thicknesses are always higher than in the roads. Depending on their structure, it is also possible to distinguish between rigid, flexible and semi-rigid pavements. In the first case, the surface layer is a reinforced concrete slab (although in some cases it is overlaid with an asphalt course, becoming a semi-rigid pavement) laid over a lean concrete layer. In the case of flexible pavements, the surface course is an asphalt layer. Differences in the structure of pavements yield on differences in the pavement behavior. Deformation in flexible pavements due to normal traffic loads is generally recoverable, whereas degradation due to excessive loads in rigid pavements are permanent. Changes in temperature also induce stress in rigid pavement and significantly affect the asphalt layers’ moduli that decrease with an increase in temperature, due to the viscoelastic characteristics of this material. However, the strength in the case of flexible pavements depends also on the strength and quality of the subgrade soil, whereas in the case of rigid pavements, this only depends on the concrete layer design. Therefore, rigid pavements are usually used in zones with soils that present an inadequate support condition, in bridges or to cross voids or failure zones.

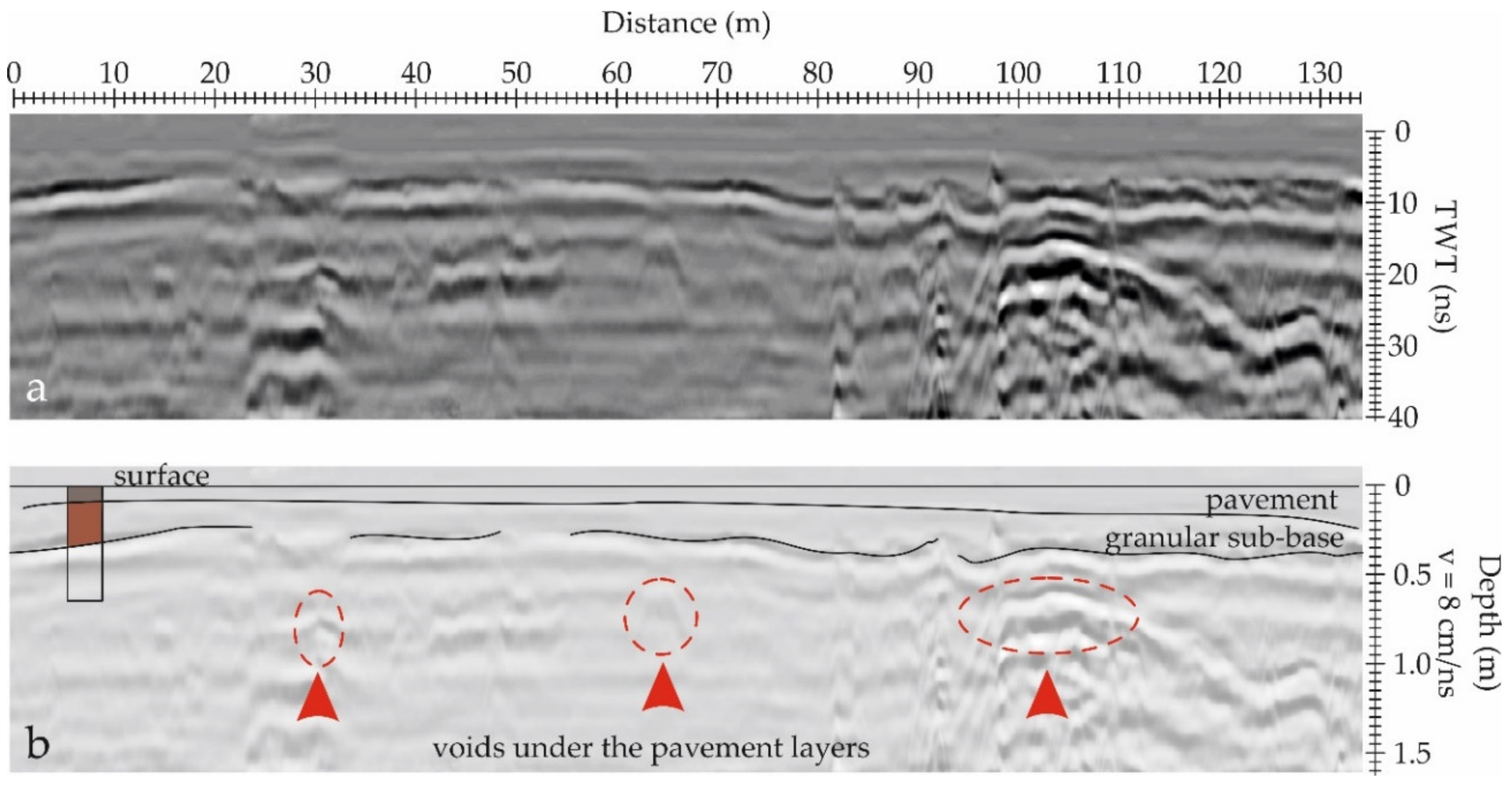

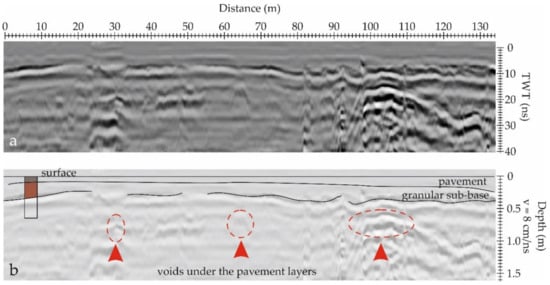

The requirement in many cases of surveying without interrupting the use of roads and airports forces the use of non-destructive tests that, at the same time, can be carried out without obstructing or disturbing the traffic [21,22]. GPR assessment in flexible pavement rehabilitation is recommended in the American Association of State Highway and Transportation Officials (AASTHO) guides [23], in combination with the use of FWD to obtain the thickness and the strength of each layer. In addition, GPR evaluation is frequently used to complement the studies about the structural conditions of pavements, detecting defects that affect their service life and preservation. The study of defects in pavements by means of GPR began at the end of the 20th century. The first studies allowed one to determine the contact between the asphalt and base layers, being difficult to distinguish thinner layers and details [24]. However, the studies about the relation between the GPR images and the material parameters [25,26,27] allowed for the application of the technique in the assessment, focused on particular aspects such as the material density for quality controls [28], control of layer thickness [29,30,31], detection of voids [32], measuring the depth to damage, and the detection of contact between rehabilitated (new) and old pavement [33]. Figure 2 presents an example of GPR data obtained in the assessment of roads with the objective of detecting possible voids in the ground, under the structure of the pavement.

Figure 2.

Detection of voids under the structure of the pavement with a 400 MHz center frequency antenna. Red arrows indicate the location of the anomalies associated to voids under the granular subbase, but the different layers of the pavement cannot be distinguished. (a) Radargram and (b) data interpretation.

More recent applications were focused on the damage and water infiltration detection in order to analyze the bearing capacity of the pavements, highly affected by the water content underneath the asphalt [34,35]. They also include the detection of pavement layers [36,37,38], the analysis of material density [39], cracking analysis [40,41,42], water detection [43,44,45], and the analysis of drainage structures under pavements [46]. Other recent studies have analyzed the effect of moisture in GPR amplitudes and frequencies [47,48] or delamination [47,49].

3.1. Roads

GPR application in roads is mainly focused on the assessment of flexible pavements as a complementary survey combined with more traditional methods: visual inspection, drilling and sampling, deflections and dynamic response monitoring systems. In some cases, GPR is also combined with infrared thermography, laser scanning and accelerometers. The application of this geophysical method in the assessment of pavements is regulated and recommended in the AASTHO guides [23]. Moreover, the guide ASTM D4748-98 [50] presents the procedures for the inspection of the upper layers of both bituminous and concrete pavements, using a short-pulse GPR. The methods included in this international standard are focused on the thickness evaluation of pavement layers. The report presents the functioning principles of a short-pulse radar and the test equipment configuration. Therefore, the guide includes technical topics such as calibration and standardization, procedures, calculation and reliability of the results. The document also emphasizes the importance of safety issues in GPR survey activities, since the apparatus involves potential microwave radiation hazard. However, the different characteristics of countries have driven the European Nordic countries to develop the Mara Nord Project, in order to provide recommendations and guidelines for the use of GPR in road construction quality control [51]. This project started in 2009 and involved several research units such as universities, national transport administrations, road rehabilitation and consultant companies, and GPR manufacturers from Finland, Sweden and Norway. The goal of this project was to define common criteria for the equipment standards and for the results requirements.

The European Cooperation in Science and Technology (COST) Action TU1208 has published some tests and recommendations for suitable GPR system performance compliance, obtained by scientists from Belgium (Belgium Road Research Center), Czech Republic (University of Pardubice), Portugal (National Laboratory for Civil Engineering), and Serbia (Faculty of Technical Sciences, Novi Sad) [52]. The D6087-08 standard, emitted by the ASTM [53], describes four procedures for the calibration of GPR systems equipped with air-coupled antennas. After a critical analysis of those procedures, four improved tests were proposed, which can be carried out to evaluate the signal-to-noise ratio, short-term stability, linearity in the time axis, and long-term stability of the GPR signal.

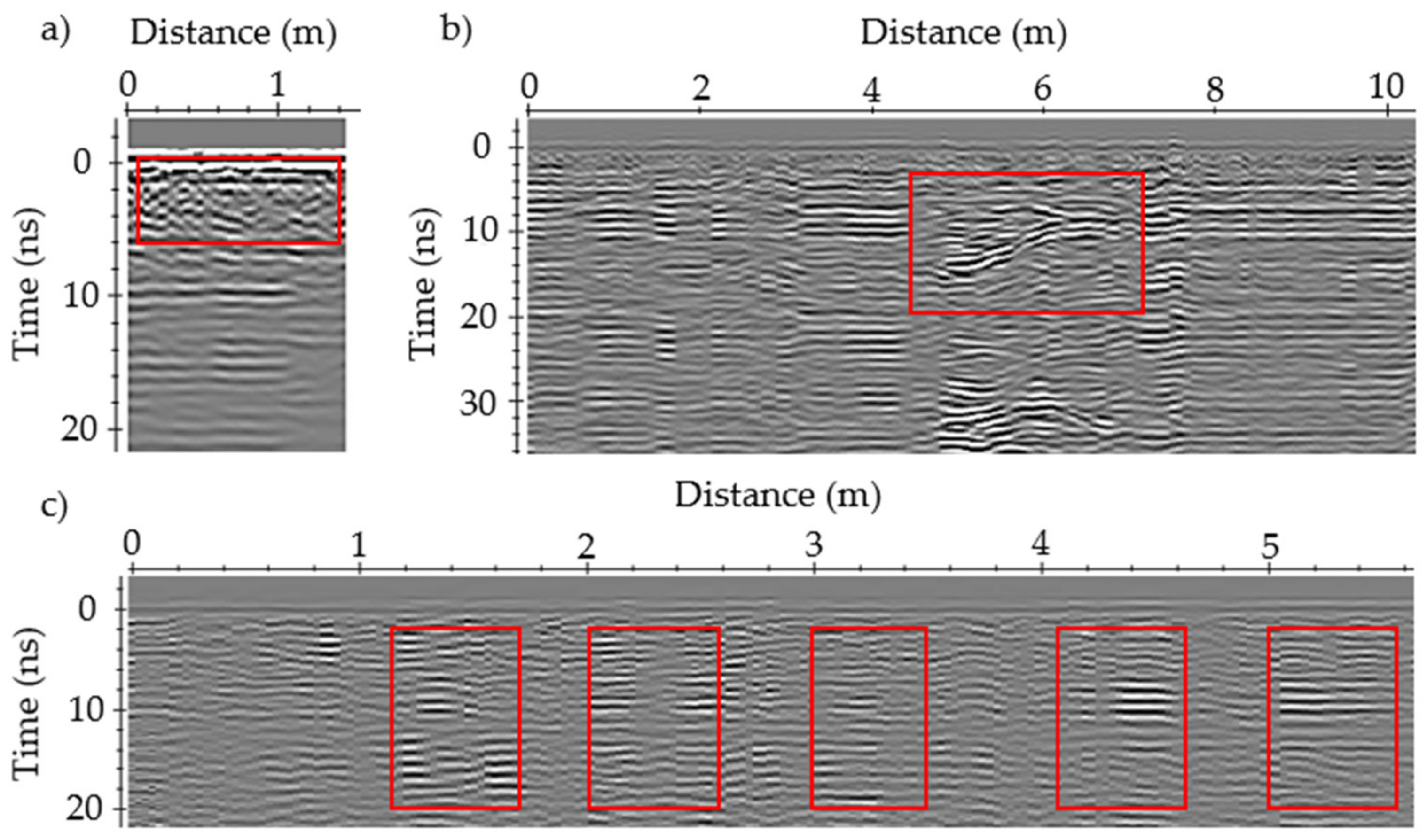

GPR is also applied in the assessment of rigid pavements, with one of the main objectives being the identification of metal bars and layers thickness [54], and measuring the rebar cover depth [55]. The assessment to detect damage such as cracking and voids is another application in rigid pavements [41,42], [56]. These studies are mainly focused on the detection of damage areas, but in some cases the origin of the damage is also investigated, including the effect of roots in pavements [57] and the impact of weather and load conditions. Figure 3 presents an example of GPR data acquired in a rigid pavement, showing the location of the rebar and the cover depth, besides the different layers and cracking.

Figure 3.

Results obtained in the study of rigid pavement. (a) Radargram. (b) Data interpretation highlighting the existence of cracks also visible at pavement surface (c) and cracks in the deeper layers, not yet visible. Moreover, image (b) shows the location of the rebar, the cover depth and the thickness of the different layers, obtaining a final model of the structure (d) (adapted from Rasol et al. [56]).

To summarize, GPR applications in pavement are mainly focused on:

- Measuring layer thickness [30,36,38,58,59,60,61,62,63].

- Detection of cracks and voids under the pavement, including the analysis of possible causes (weather, loads, roots, etc.) [40,56,57,64,65,66,67,68].

- Quality control of asphalt, mainly in the case of new pavement [69,70,71,72].

- Moisture and changes of water content detection [34,43,48,73,74].

Table S1, in Supplementary Materials, presents a compilation of the relevant on-site survey of roads.

3.2. Airports

The GPR assessment of airport infrastructure has the same objectives as road inspections. Most of them are focused on the detection of anomalies that could indicate damage in the airport runways, taxiways and apron pavements. The main difference between road and airport pavements is the layer thickness that in the case of an airport can be about 0.50 m, while in highways and roads is about 0.30 m [75]. The structure in airport pavements is composed of asphalt, concrete or reinforced concrete slabs. Moreover, the pavement of airport runways has a greater durability due to the higher content of asphalt bitumen. This infrastructure is designed to support the load due to the weight of the airplanes (between 70 Tn and 420 Tn). The highest loads are supported at the top (headland) of the runway where the airplanes accelerate when starting the take-off and stop after landing.

Despite the great loads supported by this infrastructure and its importance in communication and transport, the examples of GPR assessment of airports that can be found in the literature are less than those found on roads. In most of those examples, the objective is determining a procedure for the location of rebar and recognition of cracks and voids (in and under the concrete slab) [76,77,78,79,80]. Cracks wider than 1 mm are also detectable [81]. Other studies are focused on the detection of pavement structures and layers, detecting the dowels, joints and expansion joints [77] and different layers thickness [75,82,83,84]. GPR is also used to evaluate the quality of grouting treatments [78] applied to stabilize damaged pavements. GPR is also used in the assessment of the asphalt layers’ interfaces to detect debonding [75,85]. Other studies were focused on the analysis of airports under special conditions: (i) in the case of airports built over the sea, in order to detect the contact between the filled layers and the natural soil under the sea [86]; and (ii) in the study of airports in frozen areas, in order to detect the depth to the permafrost layer [87].

To summarize, the main applications in airport pavements are focused on:

- Measuring layer thickness [75,77,82,83,84].

- Detection of cracks and voids in pavement [76,79,81,88].

- Detection of thin cracks [81].

- Quality control of restoration treatments [78].

- Thickness of filling layers in special airports [86].

- Detection of debonding [75,85].

- Depth to permafrost layer [87].

- Structures in the pavement [77].

- Detection of rebar in reinforced concrete pavements [80].

Table S2, in Supplementary Materials, presents a compilation of the relevant on-site survey of airports.

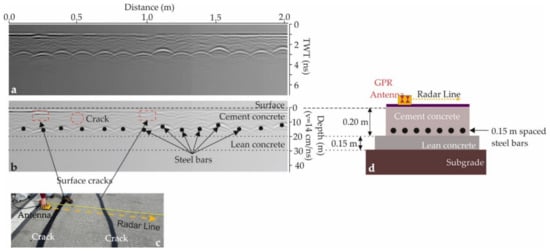

4. Overview on GPR in Railways

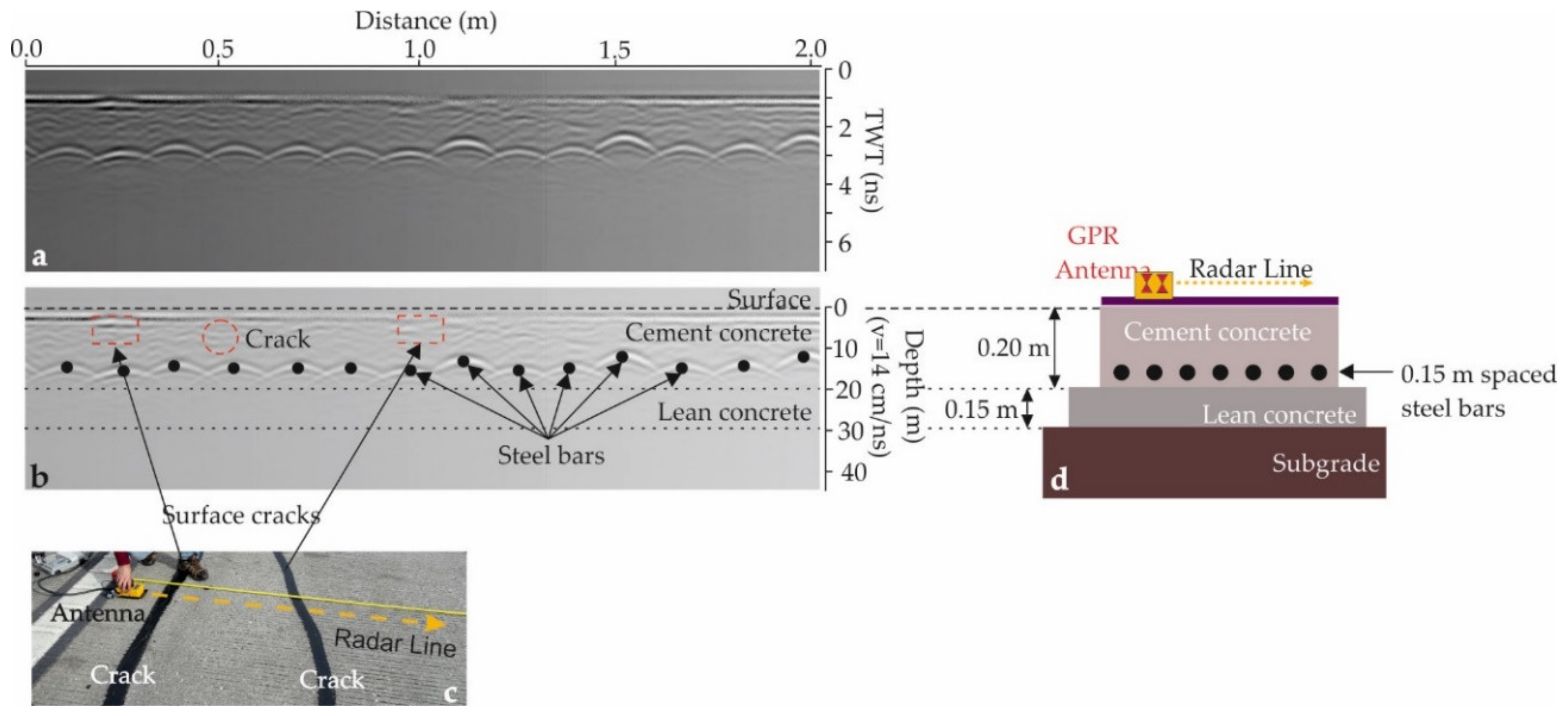

The railway (railroad in USA English) is a transport infrastructure energetically efficient and environmentally friendly, and it is gaining more and more importance for passengers and freight transport. The railway network use is increasing and, consequently, not only the deterioration under traffic load is higher, but also the time window available for monitoring and maintenance actions is becoming more restricted. The maintenance has to be well planned, due to the impact that it has on the railway users’ comfort and safety, and to enable it, a proper inspection is essential. In this context of efficient and expedient monitoring, NDT such as GPR represents a powerful tool to assess the track condition. The information gathered with GPR is generally used together with other track inspection results, such as track geometry and both rail shape and rail integrity measurements. While the track geometry and rail condition data give an indication of track deterioration, GPR survey provides the identification of the real cause of deterioration, such as changes in structure, settlements, ballast fouling and drainage problems. The information provided by GPR is therefore crucial for the definition of efficient maintenance action and depth of the intervention, mainly if the deterioration is due to substructure defects. Some examples of GPR application to railway assessment are shown in Figure 4.

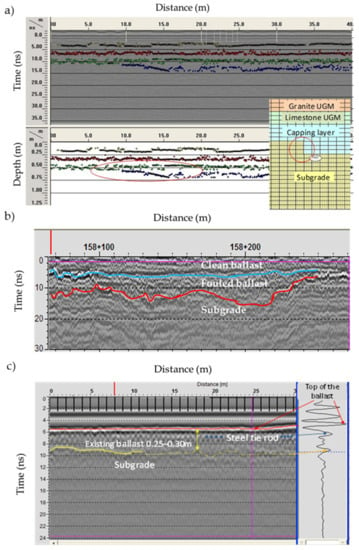

Figure 4.

Example of information obtained by GPR surveying on a ballasted track (1.0 GHz air-coupled antenna): (a) subballast thickness and continuity in the Alcácer Bypass (Portugal) showing an increase in capping layer thickness (red ellipse); (b) an in-service national railway line (Portugal) displaying the interfaces between the clean ballast/fouled ballast/subgrade where the settlement location is evident due to weak subgrade (adapted from Fontul et al. [95]); (c) GPR record of an in-service railway line showing the metal reflection of a steel tie rod. (UGM means Unbound Granular Material).

4.1. Ballasted Railways (Superstructure and Substructure)

One of the first studies of GPR application to railway was performed in late 90s by Sussmann [89]. Several studies were developed since then, some of them referred to herein. Nevertheless, there are only a few guides and standards for GPR application to railways [90].

On railways, a major limitation to the systematic application of GPR is the presence of the rails, as it is a metal, and consequently an ideal reflector that can shadow the information gathered in the subsurface. To overcome this, dedicated antennas and software were developed for railway assessment [91,92], which are discussed later in this paper.

The main applications of GPR for railway infrastructure evaluation are:

- Layer thickness measurement, mainly ballast [92,93,94,95,96].

- Investigation of embankment defects and moisture [92,94].

- Location of ballast pockets, subsidence and trapped water areas [92,93,95,97].

- Frost susceptible areas [98,99].

- Fouled ballast assessment [100,101,102,103,104].

In order to support the knowledge and to calibrate the on-site surveys, several laboratory and real scale tests were performed, such as:

- Track substructure assessment, layer thickness (experimental test sections) [105].

- Ballast condition characterization, fouling and fragmentation (experimental test sections) [101,106].

- Fouled ballast assessment (laboratory tests) [101,107,108,109,110].

- The influence of concrete sleepers on the assessment of ballast condition (laboratory tests) [111].

4.2. Ballastless Railways

The objectives of GPR application on a ballastless track are similar to other concrete reinforced structures, such as rigid pavements and bridge decks. The main applications are:

- Layer thickness measurement [112].

- Rebar detection [112].

- Mud detection under the slabs [113].

- Debonding between sleepers and slabs and between layers [112].

Table S3, in Supplementary Materials, presents a compilation of the relevant on-site survey of railways.

5. Overview on GPR in Retaining Walls

Retaining walls are structures prepared to support the soil laterally, in order to avoid landslides. Those structures retain the soil behind them and are designed to support high pressures due to the tones of the materials. The pressures, in most cases, are increased as a consequence of soil water content. This type of structure allows one to define different levels of soil, and in most cases are indispensable constructions in roads, bridges, tunnels or railways. Depending on the construction, there are different types of retaining walls. Some of the most usual types are:

- Gravity retaining walls, which are massive and require a significant gravity load to be stable under the soil horizontal pressures. These structures can be built with concrete, masonry, stone or precast concrete boxes filled with coarse material structures.

- Cantilever retaining walls that are usually built using concrete and reinforced with prestress concrete. These walls are composed of the stem and a base slab as a foundation. This is the most usual type.

- Anchored retaining walls, composed of the stem and cables anchored with concrete in the ground.

- Piled retaining walls, built with adjacent piles, making a wall.

As a consequence of aging, degradation of materials, changes in the loads (due to variations in the water content or in consequence of the construction of other structures) or changes in the temperature and moisture, the walls can suffer different levels of damage, leading even to the collapse of the structure. The detection of the pathologies reduces the possibility of the structure failure. The assessment of those walls requires the study of the structure and the analysis of the interaction between the structure and the soil. The inspection of the structures for retained soil requires the assessment of the wall that determines the decisions about the structure (repair, maintenance, change or frequency of future inspections). The assessment involves the visual inspection and simple sonic and thermographic tests. Depending on the results, more invasive tests could be needed.

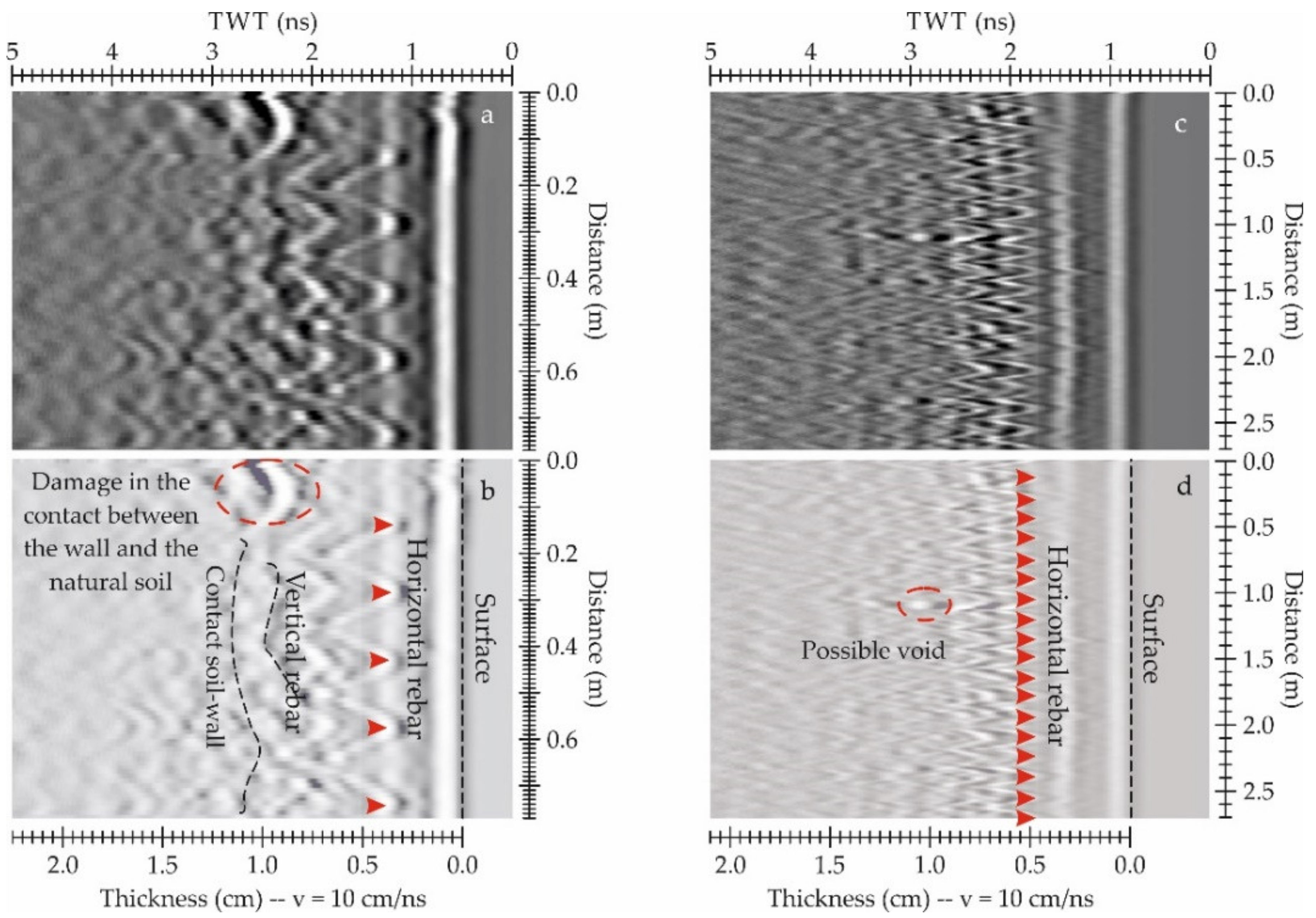

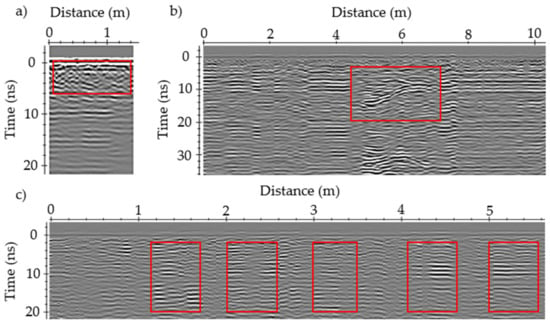

Non-destructive inspection techniques are currently applied to obtain valuable information about the state of the wall. GPR is a promising technique in this field. However, the application of GPR to vertical structures still requires development. The US Department of Transportation prepared a guide for retaining wall inspection [114], including GPR as a possible technique that requires further analysis and improvement. The assessment of those structures requires the analysis of the wall conditions (damage, moisture, rebar), the study of the soil (mainly water content) and the evaluation of the supporting structures (cables and anchors) and the foundations. Therefore, the GPR applications in retaining walls focus on the detection of the rebar in concrete retaining walls [115], detecting joints and dowels and obtaining high quality 3D models [116]. The studies define the limits of the method, showing a clear first layer of rebar and a low-quality image of the second rebar layer [117]. Figure 5 presents two examples of the reinforced wall inspections. In both cases, the rebar is detected and several anomalies highlight the existence of possible damage.

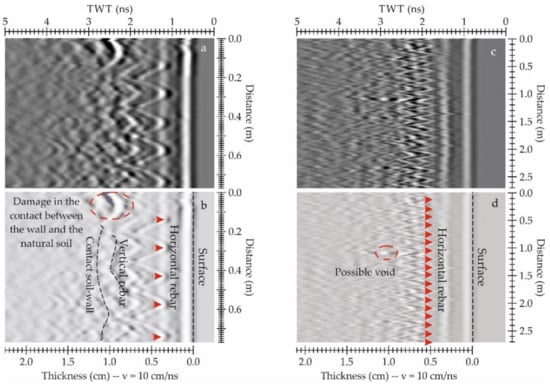

Figure 5.

Two examples of GPR images (a and c) obtained in reinforced retaining wall assessments with a 2.3 GHz antenna. Both cases focus on the detection of the rebar and the location of zones with possible damage (b and d).

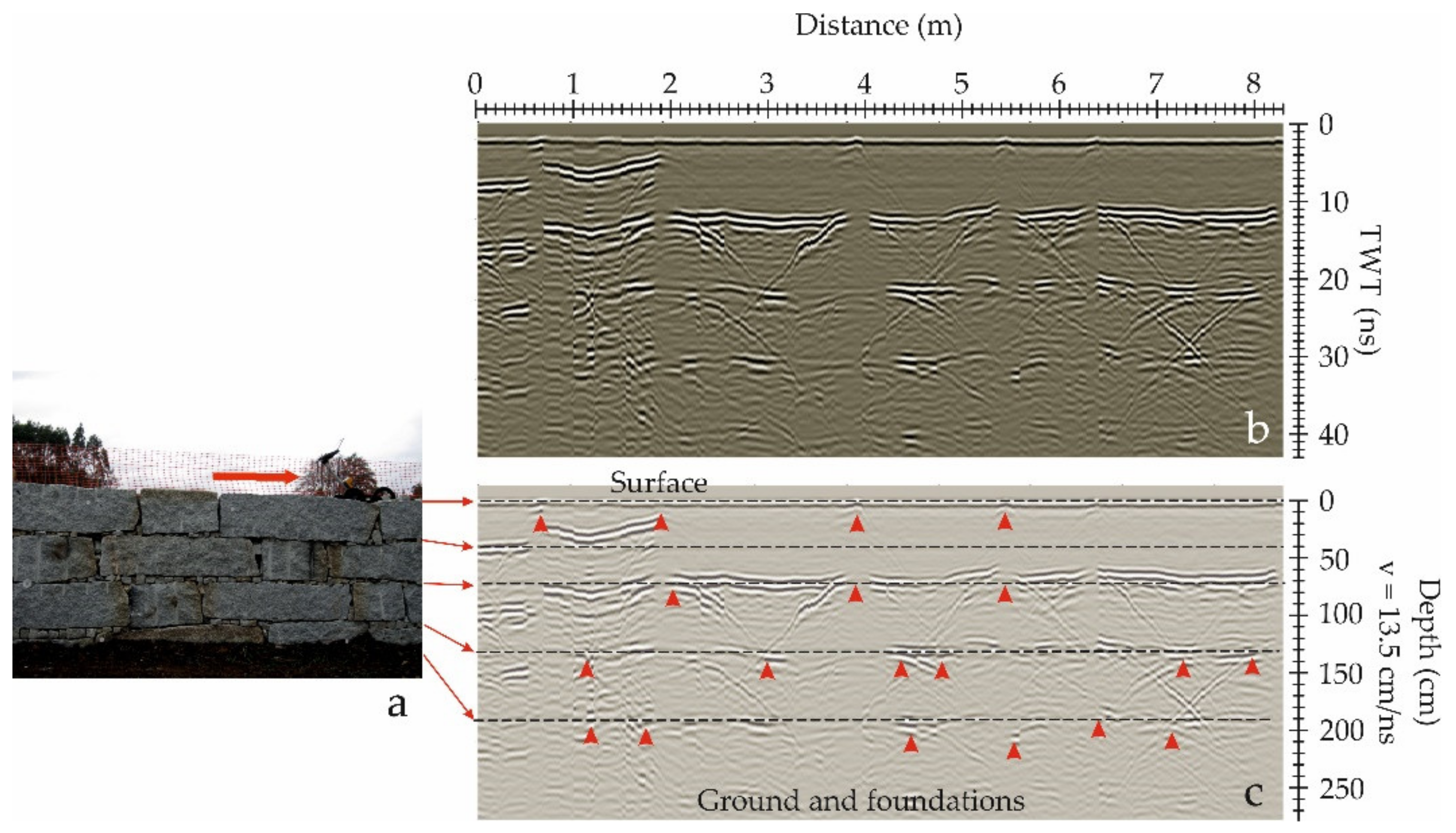

Only a few applications in masonry retaining walls can be found in the literature. Those applications are based on detecting the contact with the natural soil, estimating the thickness of the structure, and changes due to old repair works and the inner structure [118], including the foundations [119]. Although in many cases, GPR data is acquired with the antenna on the surface of the wall, in some cases, the analysis of the wall acquiring data from its top part (Figure 6) could provide information about the number of stone rows and the contact between ashlars [120]. Figure 6 shows the image and the interpretation of the GPR data. In the study of those walls, the velocity could be estimated from the hyperbolas produced at the contacts between stones.

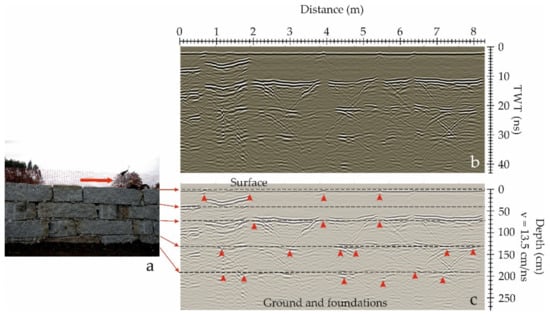

Figure 6.

GPR assessment of masonry walls composed by granite ashlars. (a) The data were acquired from the upper part of the retaining wall. (b) GPR image. (c) Interpreted radargram, showing the contact between the different rows of ashlars and the anomalies produced by the contact between stones (red arrows) (adapted from Solla et al. [120]).

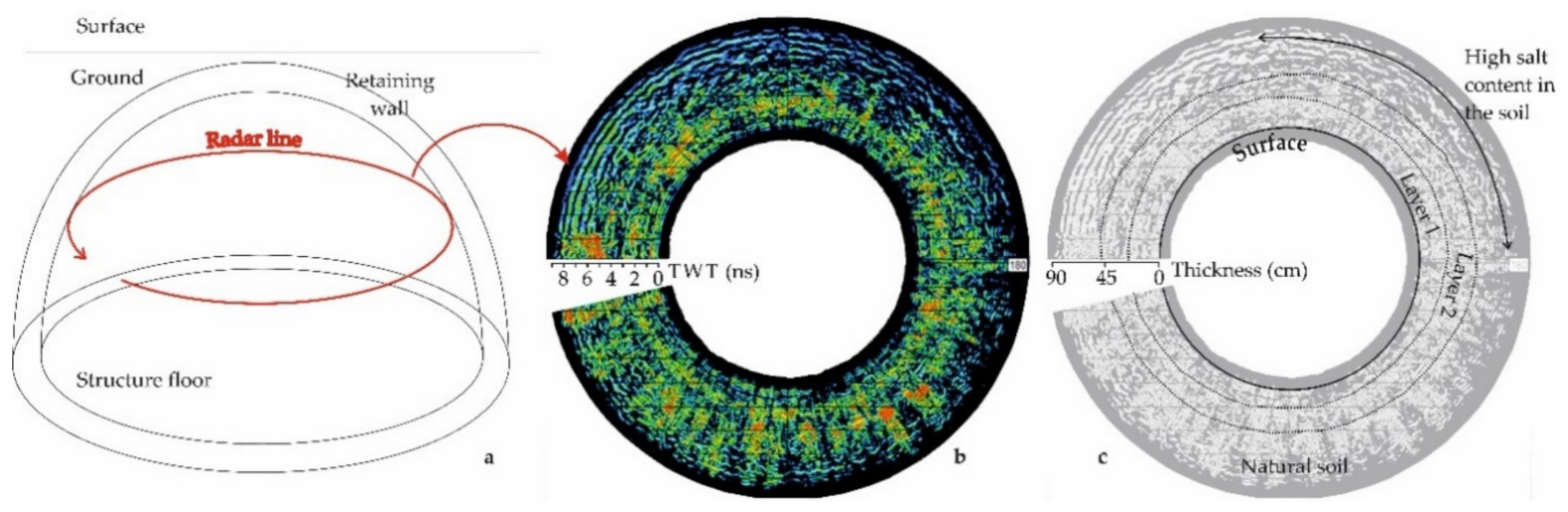

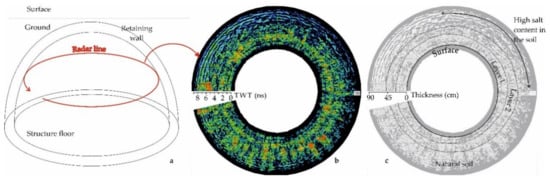

In some cases, the retaining walls are part of subterranean structures, as in the case of some Mycenaean tombs [121]. Those structures are composed of irregular stones, in two or more layers. Figure 7 is an example of the GPR images that can be obtained in this type of retaining wall. The different stone layers could be detected, and the irregular pattern of anomalies in the GPR images corresponds to the uneven stones. In addition, changes in the amplitudes could inform about the variations of physical of chemical properties of the ground or the structure, highlighting zones that could be damaged or that must be restored.

Figure 7.

GPR images from the study of the retaining walls in a subterranean tomb (adapted from Santos-Assunçao et al. [121]). (a) Scheme of the structure and location of the profile line (in red). (b) Processed GPR image. (c) Data interpretation. The wall is composed of two layers of uneven stones. The contact with the natural soil is detected and the changes in the amplitude denote changes in the soil salt content, which could affect the preservation of the structure.

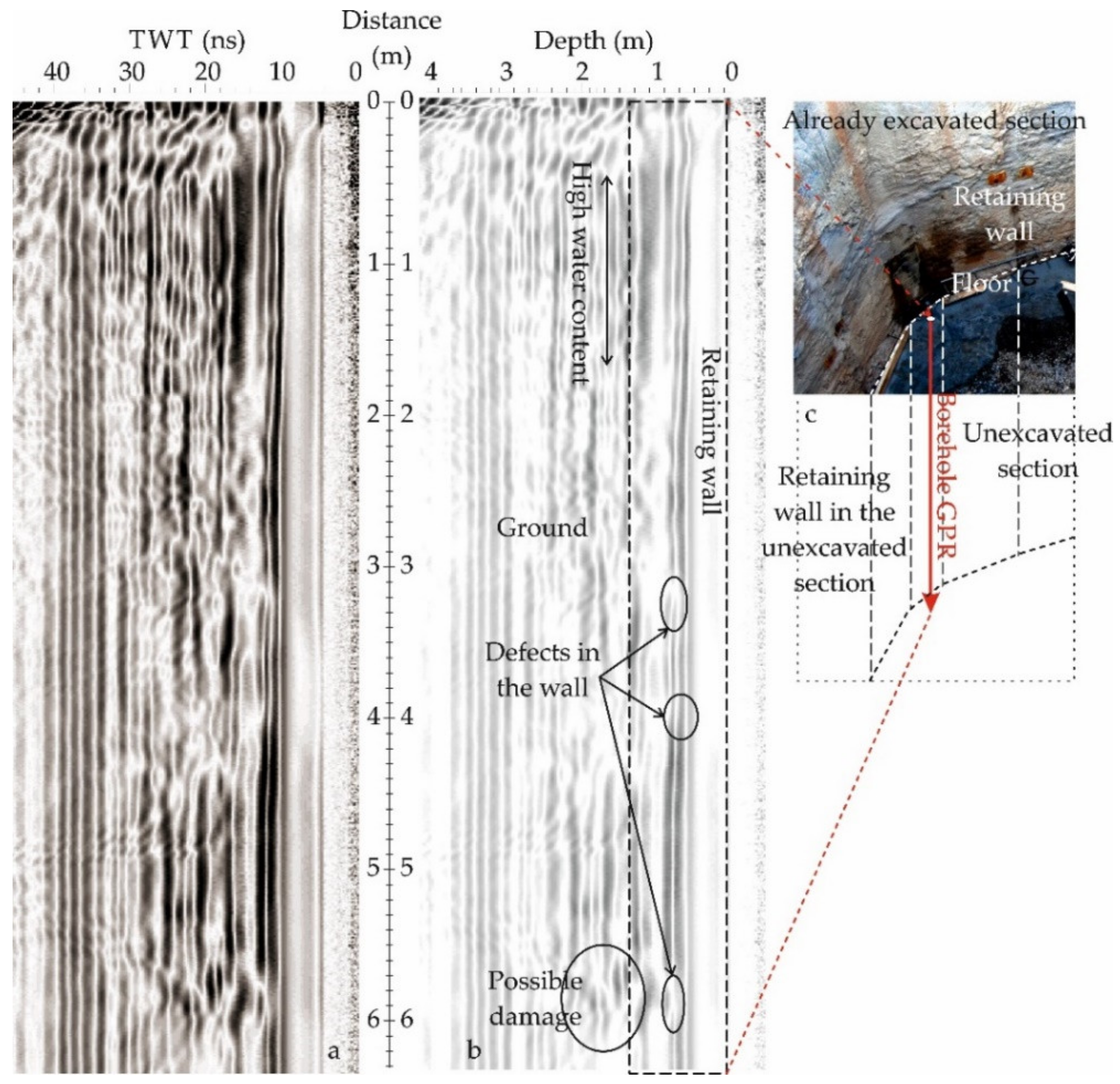

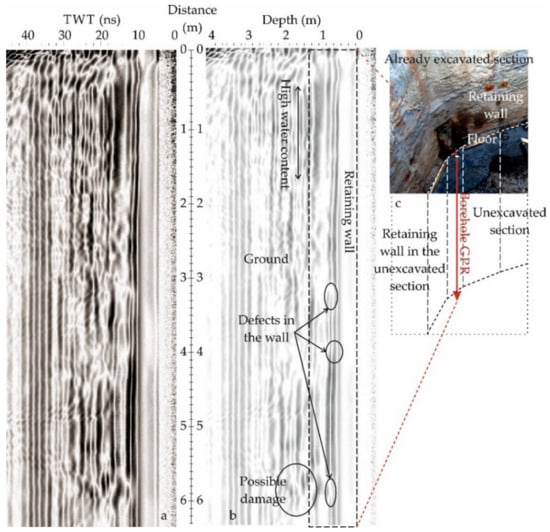

A particular type of retaining wall is used as a support system in deep excavations in the case of unstable soils or shallow water table. Those walls are built with concrete in different construction phases and in different sections inside the ground. The soil is excavated until the depth of the constructed section and, after that, the next section of the wall is built. This process continues until the excavation is complete. Prior to the excavation, the assessment of the already constructed wall section increases the safety of the process. Borehole GPR is a reliable method in this quality control process. The GPR images provide information about the integrity of the underground retaining wall, showing zones that must be repaired before excavation, such as damage or voids in the ground in contact with the structure that could lead to the collapse during the excavation procedure. Figure 8 shows an example of a borehole GPR image in the retaining wall during an excavation. The objective is the detection of both wall surfaces, the possible defects and voids in the concrete and in the ground behind the wall, and zones with possible changes in water content.

Figure 8.

Borehole GPR images. (a) Radargram. (b) Data interpretation. (c) The excavation and the position of the GPR borehole. The images allow one to determine the contact between the wall and the ground, as well as zones that must be repaired or reinforced before the excavation.

To summarize, the main applications in retaining walls depend on the type of the structure. However, the detection of the contact between the natural soil and the wall in order to identify possible voids, and changes in humidity or defects on the surface of the wall, is a common application in all types of walls. In masonry walls, the common objectives of surveying are the analysis of layers, the contact between blocks, and the assessment of foundations. Conversely, in concrete walls the main goal focuses on the detection of the rebar and possible defects that occurred during the construction of the wall.

Table S4, in Supplementary Materials, presents a compilation of the relevant on-site survey of retaining walls.

6. Overview on GPR in Bridges

Bridges are considered vital to human life because they connect different lands and facilitate economic, industrial and social development. However, a great majority of these structures, in operation within the transportation system, require desperate repair and maintenance strategies. The condition monitoring of bridges focuses on detecting material degradation and structural pathologies aiming to accurately assess the safety and service life of existing structures. Conventionally, diagnosis is accomplished by visual inspection and assessment can therefore be difficult as there is structural design and damage of the structure inaccessible and hidden from view. Indeed, the GPR method is one of the non-destructive techniques most used in internal bridge inspections [122,123,124,125,126], due to its high practicality in the field in a relatively quick time and with the minimum intervention without affecting the structure’s integrity. Internal damage detection can prevent the unpredictable and premature collapse of structures.

This section provides an overview of the main GPR applications on the condition monitoring of both masonry and concrete bridge structures.

6.1. Stone Masonry Arch Bridges

A large number of the existing masonry arch bridges still in use within the transportation network are ancient structures remaining from Roman and Mediaeval periods. In addition to their age, and environmental conditions, the stability of these bridges (both road and railway bridges) is questionable because of the actual loading, significantly higher than the estimate for their original design [127]. Consequently, they require periodic inspections of the changes in the structural condition, aiming to develop effective preventive and maintenance tasks.

The use of NDT technology becomes essential for the health assessment of these former structures in order to preserve their historical character and structural integrity. In this context, the GPR method has been demonstrated as effective for the diagnosis of masonry arch bridges, in which the detection of the following characteristics was possible:

- Unknown geometries remaining in the interior of the bridge such as hidden arches and ancient profiles (shape) of the structure [128,129,130].

- Evidences of restorations and/or reconstructions in stonework [130,131,132,133].

- Existence of cavities and fractures/cracking in masonry [131,134,135,136].

- Moisture in masonry [134,137,138].

- Bridge foundations [137,139,140,141].

- Filling distribution in masonry [130,136,139,140,141,142,143].

- Thickness of ashlars (pavement, ring arch, spandrel walls, etc.) [124,130,139,140,142,143,144,145,146].

There are different studies combining GPR with structural assessment on masonry arch bridges. The knowledge of the internal geometry and material characterization of the bridge allows engineers to perform more accurate numerical simulations and detailed assessment of the bridge’s structural load capacity and safety [136,139,140,142,143,145,146,147,148,149,150,151].

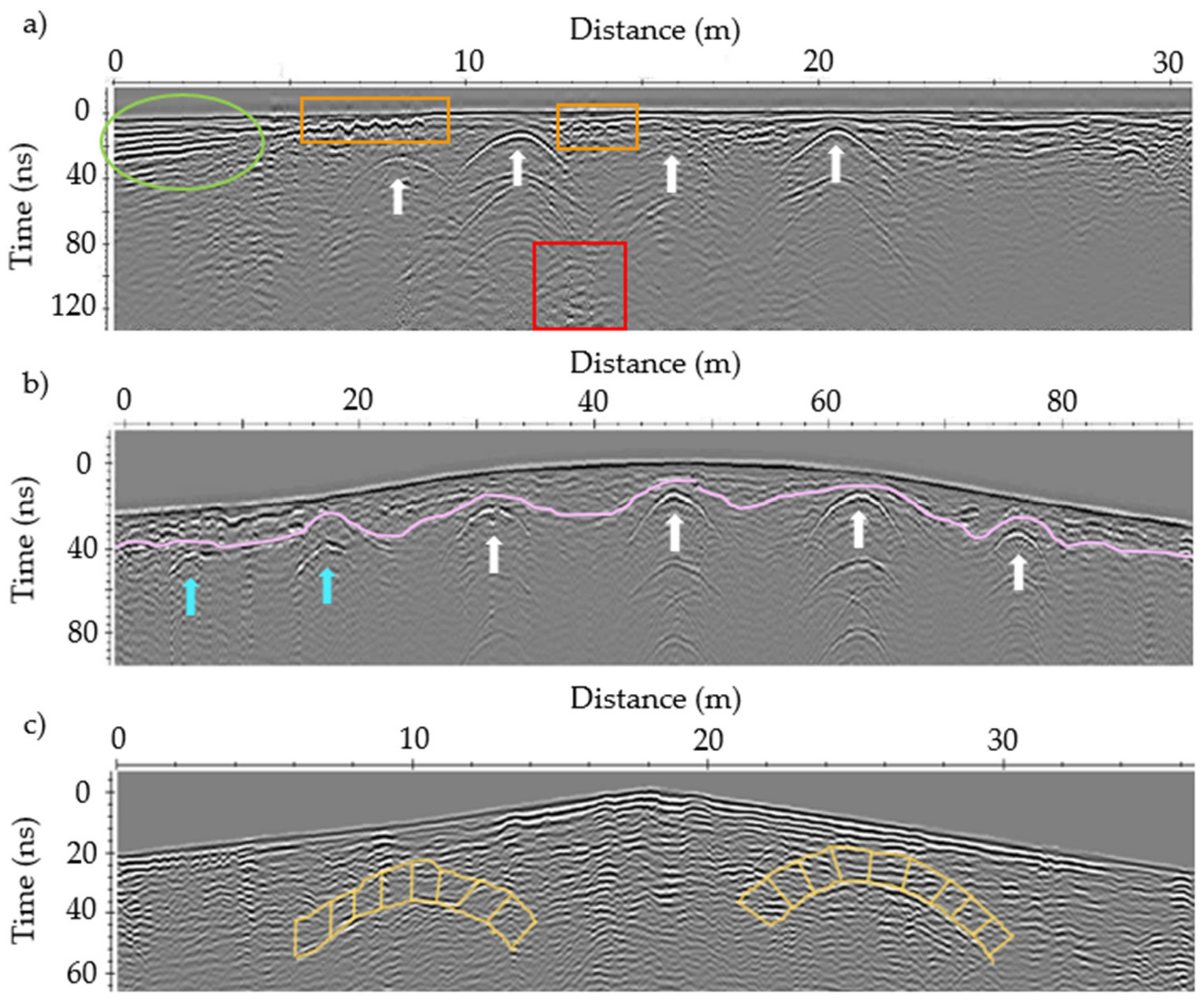

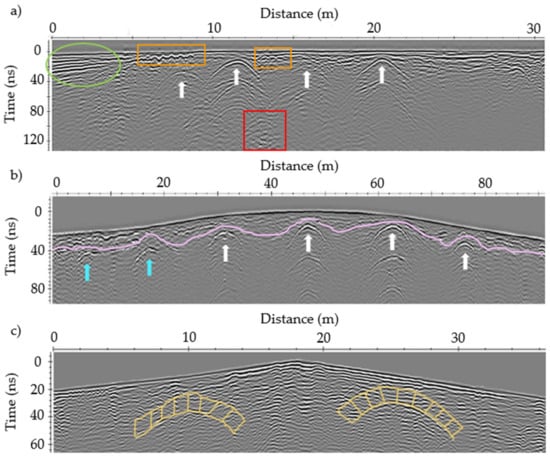

Figure 9 presents some GPR data obtained in three different masonry arch bridges, which demonstrate the feasibility of the technique for the documentation of previously unknown information from the interior of the structure.

Figure 9.

Examples of information obtained by GPR surveying on stone masonry arch bridges: (a) Traba bridge (Noia, Spain) showing an ancient profile (green ellipse), evidence of reinforced concrete used for restoration (orange rectangles) and presence of a void in a pier (red square); (b) Monforte bridge (Monforte de Lemos, Spain) displaying the interface between the original and the new backfill used for restoration (pink line) and the existence of two hidden arches (cyan arrows); (c) Vilanova bridge (Allariz, Spain) reproducing the voussoirs of the arch-ring (yellow lines).

6.2. Concrete Bridges

Bridge deck condition assessment is the most important part of concrete bridge health diagnostics and maintenance. Reinforced concrete bridges have steel bars, or rebar, which are embedded within the deck for structural strength. The corrosion of internal reinforcing bars is a major cause of concrete bridge deck deterioration and the most significant contributor to bridge deficiencies (with the formation of cracks and delamination). These deficiencies cause severe damage even on the top pavement layers, often having a crucial effect on driving safety and even structural failure. In order to prevent failure at early stages, extend the service life of concrete bridge decks, and reduce maintenance costs, proper inspection must be carried out periodically. GPR is seen predominantly as an effective NDT technique for deterioration assessment. The ASTM has a standard procedure, the ASTM D6087-08, that defines a methodology for using GPR to evaluate the condition of concrete bridge decks [53]. It is also important to mention the guidelines published by the European project—Mara Nord—for the use of GPR in bridge deck surveys [152], which describes GPR equipment, survey planning and performance, data processing and interpretation, and the reporting and delivery of results.

GPR has been successfully used in a wide range of applications in concrete bridge inspection, including:

- Estimation of concrete cover depth [153,154,155].

- Mapping reinforcing bars (deck and beams) [153,154,156,157,158,159,160,161,162].

- Location of cable ducts and other utilities such as deck joints or drain grate [154,158], [160,163].

- Damage detection on concrete (corrosion, cracking, spall, delamination, etc.) [157,158,160,161,164,165,166,167,168,169,170,171,172,173,174,175].

- Moisture detection and water content estimation [155,157,158,176].

When dealing with a GPR bridge inspection, a large amount of data are produced and extensive manual processing is required to extract useful information, in which the manual identification and localization of rebar is time-consuming and labor intensive. In such a context, some authors have developed algorithms for the automatic detection of rebar [157,173,174,176,177,178,179,180,181,182] and cracks/delamination [165,177,178].

Additionally, as in the case of stone masonry arch bridges, there are different studies that use GPR data to create structural models aiming to analyze the load-carrying capacity of concrete bridges [159,183].

Table S5, in Supplementary Materials, presents a compilation of the relevant on-site survey of masonry and concrete bridges.

7. Overview on GPR in Tunneling

Tunnels are essential civil engineering structures that constitute an important part of roadways, passages, sewer systems, utility networks and railways. There are various categories of tunnel construction, including bored, drill and blast, horizontal directional drilling, and pipe jacking/microtunnels. Moreover, the bored tunnel can be divided into two subcategories, controlled bored tunnels and tunnel boring machine (TBM) tunneling. Shield tunneling is the typical method used for railways, which is considered a more stable method than mining.

Tunnel distresses might not be visible, and it is therefore necessary to conduct regular inspections during its service life in order to ensure safety and long-term viability. Various processes and subsequent failures may cause damage to tunnel structural integrity; those that occur during construction (ground settlement) and after opening to service (aging, physical and chemical agents, etc.). Undoubtedly, the frequency of periodic inspection should be increased when the tunnel has become aged. If potential and hidden deficiencies of the tunnel are detected in advance, and treated in time, many accidents may be avoided, whereas excessive repair and maintenance costs can be saved. Firstly, the geological and hydro-geologic conditions in which tunneling occur are essential factors in the structural integrity. Secondly, more and more problems appear in the lining with aging, such as water leakage, cracks, spalling and voids behind the lining, which greatly affect the safety of the tunnel and the users. The thickness distribution of the grouting layer behind lining segments is a crucial factor to control the quality of the tunnel and it directly affects the overall bearing capacity and structural adhesion of the tunnel. Overall, based on the International Tunneling and Underground Space Association (ITA/AITES) [184], the stresses and settlements that appear at the surface of the lining are indicators of an inadequate TBM method on shield tunnels: (i) over-excavation, (ii) the ploughing/heading effect and steering, (iii) lining deformation and insufficient grouting and (iv) swelling/consolidation of the surrounding ground.

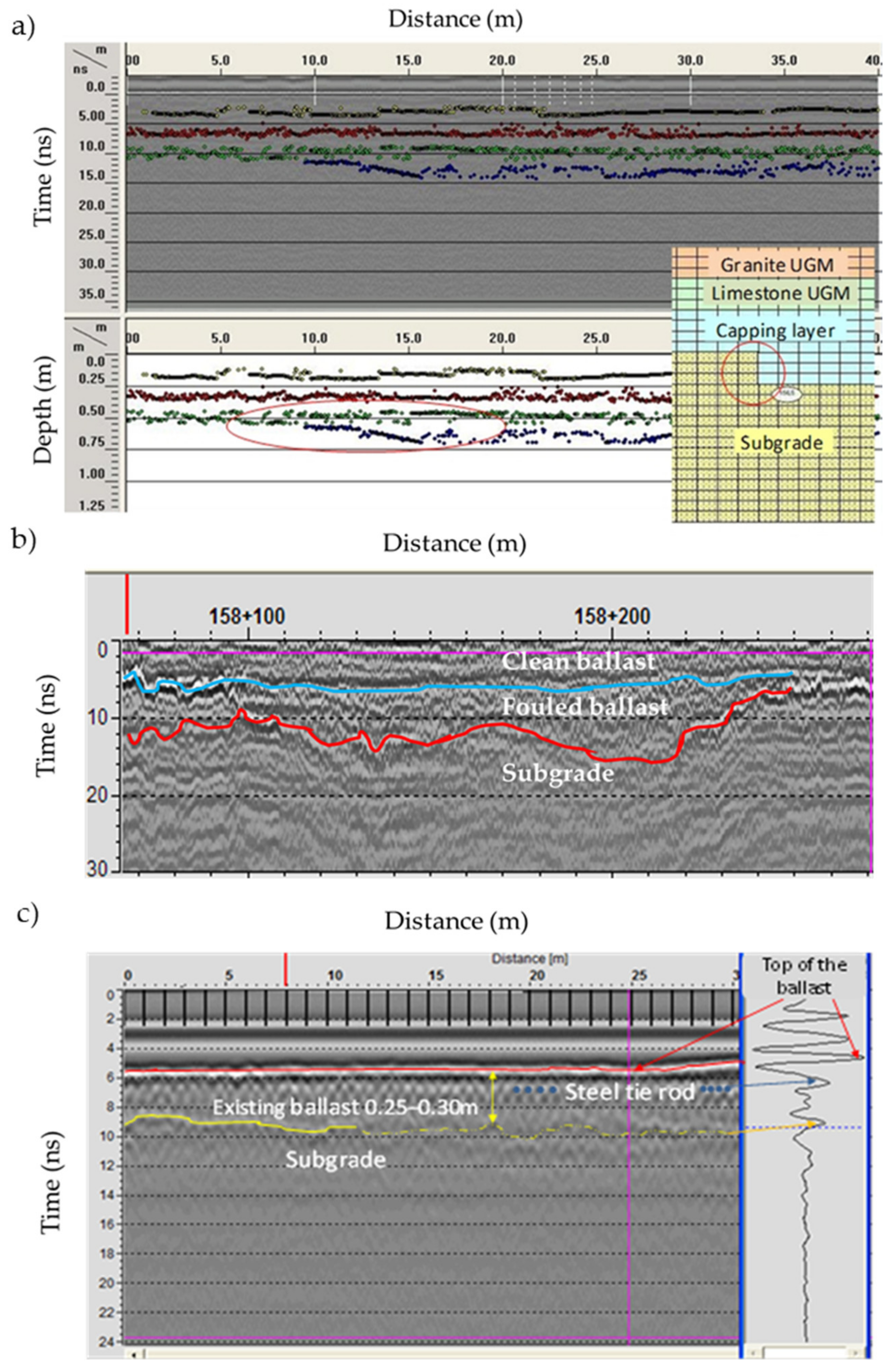

Conventional methods for tunnel assessment are destructive and have great limitations and uncertainties in obtaining a representative model of the overall structure. Nowadays, the stability of tunnels is being assessed more and more often through geophysical surveys. In fact, geophysical NDT technology is meant to obtain a rapid analysis of rock shearing and concrete lining quality. The ASTM produced a standard guide, ASTM D6429-99, to provide assistance in selecting the most appropriate geophysical method for a range of geologic, geotechnical, hydrologic, and environmental investigations [185]. Hence, the GPR method has demonstrated its reliability in quality testing, since it provides continuous measurements of grouting distribution. Some examples of GPR application to tunneling inspection are shown in Figure 10.

Figure 10.

Results obtained from a GPR tunneling inspection: (a) shotcrete layer, (b) cavity and (c) embedded steel arch (adapted from Prego et al. [204]).

This section provides an overview of the main GPR applications on the condition monitoring of tunnel structures. Currently, the most common applications include the following objectives:

- Thickness of concrete segment/lining [186,187,188,189,190,191,192,193,194,195,196,197,198,199].

- Thickness of the backfill grouting layer [187,189,193,196,198,199].

- Damages in concrete lining and grouting layer [186,188,192,194,196,200,201].

- Damages (e.g., cracks/fissures, fractures and voids) behind tunnel linings [188,195,197,200,201,202,203,204,205].

- Moisture/water content [186,188,195,203,204,206].

- Depth and location of reinforcement (rebar) [189,192,194,195,201,207,208].

- Inspection of other reinforced concrete structures (e.g., steel arch and shotcrete layer) [188,197,204,206,207,208].

- Location of immersion joints [207,208].

- Identification of depth and presence of insulation material [208].

Table S6, in Supplementary Materials, presents a compilation of relevant on-site survey of tunnels.

8. Discussion Table on Limitations and Best Practices

8.1. Roads and Airports

GPR surveys in pavements are most likely some of the most common and developed inspections. Generally, the main objectives are focused on the detection of layer thickness and damage in the pavement layers or under the road structure. Therefore, the application is included in several regulations [7,50,53,149]. The standard ASTM D4748 [50] defines the GPR test method for the determination of pavement layer thickness, advising of two potential complex scenarios (extremely wet pavement or saturated pavements, and high iron content in the aggregates) at which attenuation could affect the data interpretation. The ASTM D6087-08 [53] develops the test methods to assess the asphalt covering concrete decks with GPR. Both standards cover flexible and rigid pavements. However, these standards are only recommendations, and the application depends on the different countries’ regulations. In Europe, there are no specific common guidelines about the application of GPR in pavement surveys, even though some proposals are developed in different countries [209]. Examples of those guidelines are in the Mara Nord Project [51] and in the British [5,6] and Belgian [210] regulations. Many authors declare that an optimal pavement assessment requires a GPR calibration process. The studies demonstrate that the correct calibration causes an extreme decrease in the error in the estimation of the pavement thickness. The analysis of the uncertainty of GPR data interpretation in the study of pavements demonstrates that the calibrated data is closer to real data than non-calibrated data [211], being the results and the interpretation affected by the calibration process. The divergence between GPR data and real data is produced by several factors, such as: (i) the distance between the antenna and the pavement surface; (ii) the pavement age; (iii) the heterogeneity of the medium (changes in water content, presence of cracks, changes in density, etc.); (iv) the wave attenuation; (v) the scatters at the pavement surface (depending on its roughness); (vi) water, leaves or sand presence at pavement surface; (vii) changes in the time-zero; (viii) clutter; and (ix) changes in the data acquisition velocity [75,84,212]. The analysis of different calibration algorithms demonstrates that all of them diminish the systematic error during the data acquisition [212], and the tests allow one to evaluate the operation and the stability of the GPR system [213]. In some cases, calibration consists of comparing GPR data with cores, obtaining radar-wave velocities by comparing the thickness of each layer with the time to each continuous anomaly in the B-scans. In other cases, it consists of determining the dielectric permittivity of the surface layer comparing the amplitude of the reflected wave at the surface with the amplitude of the wave reflected on a metallic plate. However, in other cases, the dielectric permittivity of the layers can be determined with common mid-point (CMP) or wide-angle reflection and refraction (WARR) measurements. In the case of rigid pavements, the wave velocity in the concrete layers can be estimated considering the hyperbolic anomalies produced on GPR data as a consequence of reflections on the rebar [80]. An error less than 3% is observed in the thickness concrete layer estimation using this method [55].

Some of the authors use ground-coupled antennas [47,48,214]. In some cases, when surveying is dedicated to limited sections of the roads, the antenna is manually moved or mounted on a cart survey. Nevertheless, for large-scale surveying, the ground-coupled antenna is generally mounted on a vehicle that uses special devices and moves at a traffic speed. These devices are usually platforms or trailers that support the antenna at a certain distance from the surface of the road or the airport platform. The platforms are built with wood [84,215], plastics [21] or fiberglass [75] in order to reduce as much as possible clutter in the radar data. However, in some cases the survey is carried out using a platform in contact with the pavement, connected to the vehicle. The ground-coupled antenna is placed on that platform, assuring the maximum contact between the antenna and the pavement surface [216], and the maximum transmission of the wave into the medium. This type of data acquisition reduces the velocity of the vehicle during the survey, with the speed between 16 km/h [216] and 25 km/h [217], but increases the penetration depth, compared with a survey using the same frequencies but with the antenna suspended at a certain distance from the pavement surface. In general, surveys with ground-coupled antennas are designed to place the antenna as close as possible to the pavement surface. In most cases, pavements are surveyed with air-launched antennas [217]. These devices are suspended at a distance between 150 mm to 500 mm from the surface of the pavement [17,75,80,84,216]. Those devices provide clean GPR images, allowing surveys at a traffic speed (up to about 90 to 120 km/h) [75,84,218], but the penetration depth is less than in the case of ground-coupled antennas in contact with the surface of the medium. The comparison between the data obtained with each one of those antennas epitomizes the change in the direct and reflected wave, depending on the distance between the antenna and the surface of the pavement [75,219].

Some of the most recent assessments use an array of antennas, combining in many cases ground-coupled and air-launched antennas [216,220]. In [63] the use of a single transmitter and five receiver Vivaldi antennas is proposed, obtaining results in tests and pavement surveys with an error less than 10%, which is in the same level of other methods, including drilling. Other studies use a step-frequency array system [221] detecting shallow and deeper features. Dérobert et al. [222] demonstrate that a combination of UWB antennas, ranging from 500 MHz to 6 GHz central frequency, detected the second course in the base of the pavement structure and thin layers of about 2.5 cm. In addition, controlled tests based on the detection of pavement layers and damage conclude that GPR is a useful tool that could be implemented as a quality control tool during the construction of new pavements or in the assessment of already existing structures, indicating that survey speed during the data acquisition velocity must be different, depending on the antenna [218].

Even though in many of the applications the study is based on the analysis of anomalies in B-scans [82,86,87], in some cases those analyses are combined with other analyses from amplitudes and data obtained in CMP or WARR surveys [85], detection of reflections patterns in A-scans and B-scans [76], and velocity analysis [81]. In addition, many applications propose the use of arrays and multi-frequency antennas [77,81,83,85].

8.1.1. Soil Subgrade Assessment and the Detection of Bedrock

Some of the first studies in pavements were focused on the analysis of the soil subgrade. This layer is highly sensitive to the environmental changes, being also affected by the traffic loads [223]. Saarenketo [69] points to three applications:

- Analysis of new road alignments, studying the ground materials and the depth to the bedrock and to the water table, reaching in some cases a depth of about 5 m.

- Assessment of existing roads in order to detect filling materials [86], voids or weak zones under the pavement [40,56,64,65,66,67,68].

- Quality control of restorations [69,70,71,72].

One of the most important difficulties in the assessment of the subgrade is the wave attenuation. Two possible causes are the clay content in the soils and the existence of a significant water content [102,223], which recommends the use of different center frequency antennas to improve the data interpretation. In general, a combination of several assessment techniques is the most useful tool to detect the anomalous zones in the subgrade, being applicable in the quality control of roads under construction [223]. The tests presented by [223] are a clear example of the use of combined methodologies and types of antennas to enhance the final results. They conclude that air-coupled antennas are more appropriate in detecting interfaces between layers and with the subgrade; whereas the ground-coupled antennas are more appropriate in determining anomalous zones that could be associated with damage.

Related to the detection of the subgrade, there are two main types of studies: (i) the analysis of the ground under the pavement and (ii) the estimation of the depth to the bedrock. The location of the bedrock is essential, mainly in the design of road lines. In these applications, the attenuation causes an extreme decrease in the signal-to-noise ratio at higher depths, being difficult to distinguish clearly the contact with the bedrock or the existence of fractures and stratification in the ground under the pavement. These geological features could affect the stability of the road. Moreover, the data accuracy in the data interpretation depends on the precision in GPR wave velocity estimation [224], being a complex task in heterogeneous media. The studies presented in [224] propose the 450 MHz ground-coupled antenna as the most appropriate system, because it offers higher resolution than antennas between 100 MHz to 200 MHz central frequency. This result is a consequence of the GPR wave attenuation, allowing for the detection of discontinuities until a maximum depth of 5 m in all cases, based on the observation of different textures in the B-scans. The authors recommend the combination of GPR with electric resistivity tomography (ERT) in the case of: (i) bedrock at depths higher than 5 m and (ii) soils with superficial conductive clays. Those clays produce an extreme attenuation of the GPR signals. Other studies demonstrate that GPR is effective in determining the asphalt layers, being moderately successful in the detection of base thickness and shallow stratigraphy and is not applicable in the location of the near-surface bedrock [225]. However, other studies demonstrate that a 600 MHz center frequency antenna allows the detection of the bedrock contact and also changes in the compaction of the subgrade, locating areas under the pavement with poor soil compaction [226]. Low compaction of the subgrade soil could be the cause of road degradation, and GPR assessment could be a support in the strategies for road restorations. Saarenketo and Scullion [69] warn about the weak anomalies that could be associated with the bedrock contact depending on the dielectric properties of the pavement and the soil and the rock; hence concluding that the anomalies will probably be weak and non-continuous reflections.

8.1.2. Pavement Layer Thickness Analysis

Pavement is usually assessed with GPR in combination with FWD [223,226,227,228]. In these studies, one of the most common analysis is the determination of layer thickness [30,36,38,58,59,60,61,62,63,75]. This analysis requires high-frequency antennas, in all cases with a central frequency higher than 800 MHz. For example, [36] uses a 2 GHz antenna, while [229] reports the application of a 1.5 GHz ground-coupled antenna for the layer thickness determination, and [48] compares the results obtained with two antennas with 800 MHz and 900 MHz central frequency. The detection of the contact between layers is observed in the B-scans as a continuous anomaly produced by the reflection of the radar-wave at the interface between two media with different dielectric permittivity. The studies point to the easier detection of boundaries in the case of asphalt layers than in the case of concrete layers [17,84,228]. The results indicate that the error in the layer thickness determination is higher in the case of thinner layers and deteriorated structures. Errors less than 10% are reported in several works referring to new pavements [36,63,75]. Another analysis observes an error of about 12% in the surface asphalt layer with a common data processing method, but about 3% when the deconvolution is applied to separate the anomalies [60]. The analysis developed by [230] obtains the following results: (i) with air-coupled antennas of 1.8 GHz central frequency and the CMP (common mid-point) survey, the error in thinner asphalt layers ranges between 6% and 18%; and (ii) with ground-coupled antennas of 1.5 GHz central frequency and the CO (common offset) mode, the error ranges between 1% and 26%. This study highlights the importance of the data processing for the proper picking of anomalies associated with reflections in the base of thin layers. It is noticeable that both methods introduce the same error (an average value of 7%) in the case of thicker layers. This study also notices the influence of dust or sand on the surface of the pavement for the analysis of the dielectric permittivity using ground-coupled antennas, although the error depends on the thickness and the depth to the layer. In [216] an average error of 6.8% was reported for pavement thickness layers ranging from 280 to 350 mm, while for pavement thickness layers ranging from 100 mm to 200 mm the error was 3.8%. Other authors also conclude that the error in the bituminous layer differs from the error in the granular layer. In [231] an average error of 7.5% was obtained for asphalt surface layers ranging from 5 mm to 500 mm thick, but this error increased until it was 12% in the case of granular base layers ranging from 150 mm to 330 mm thick. A higher error was also obtained in [230] for thinner layers, observing a correlation between the thickness of the layer and the error in the case of CO surveys. However, no correlation was observed in the case of CMP surveys.

Additionally, the error depends on the quality and homogeneity of the layers. Al-Qadi et al. [232] observe lower errors in the case of plain concrete layers; whereas the studies in old pavements [216] and in new pavements [217], show an important change in the error comparing both studies in new and old pavements.

The error diminishes in the case of a proper calibration using several cores [36], [214], [223], although the accuracy depends on the number of cores. The results obtained without calibration present higher errors and demonstrate that the GPR used as a unique NDT assessment of the pavement is only useful for a quick and rough evaluation, being nonetheless a satisfactory technique.

8.1.3. Damage Assessment: Detection of Voids and Cracks

In most surveys, the objective is determining a procedure for the recognition of cracks and under-slab voids, as well as the rebar location in reinforced concrete slabs [76,77,78,79,80,81], [88], being mostly used the CO acquisition mode and determining anomalies in B-scans. However, Yi et al. [81] observed that thin cracks are not detected using the common reflection analysis, and propose a 3D CMP using an array of antennas in order to determine slight changes in the radar-wave velocity that could be associated with zones affected by cracks wider than 1 mm.

On-site measurements compared with cores highlight that clear images of cracks in the B-scans correspond to large fissures (several centimeters wide), in many cases filled with foreign material [42,56]. Early fissures are not visible in GPR images because the anomaly is masked with the anomalies produced in the grains and heterogeneities of the layers [66]. However, zones affected by many smaller early cracks produce in some cases blurred images in GPR B-scans. This effect can be used to select possible zones with early damage. The effect of internal small cracks is also visible in the frequency spectrum. The heterogeneity due to the existence of cracks, mainly in the subgrade, increases the energy dispersion and subsequently attenuates the signal, generating an irregular image [81] with vague boundaries [66]. The radar-wave velocity in damaged areas differs slightly from the radar-wave velocity in undamaged asphalt [81]. In addition, the amplitude of the frequency spectrum decreases, which denotes the existence of possible anomalous zones [47].

Several tests report that 1 GHz center frequency antenna [40,41], [65], or even larger frequency antennas [66], are valuable systems to characterize vertical pavement cracks. However, lower frequency antennas, for example 250 MHz, are in many cases more effective for detecting cracks because the larger wavelength is less affected by the heterogeneities and the aggregates grading of the layers [65]. In consequence, most pavements are assessed with antennas presenting a range of frequencies. For example, the studies in [68] explore depths between 50 mm to 160 mm using antennas with central frequency between 2.5 GHz and 700 MHz; [233] obtains details of the top structure and the subgrade soil with 1.5 GHz and 400 MHz center frequency antennas, respectively; [234] explores the bituminous layer with a 1.6 GHz center frequency antenna and the underneath structure (base, subbase and subgrade) with a 600 MHz center frequency antenna; [235] combines 800 MHz and 500 MHz center frequency antennas to detect subsidence in a port area, showing visible deterioration in paving blocks and loss of filling; and [221] uses an array of antennas with central frequencies ranging between 50 MHz and 3050 MHz.

Many works are devoted to laboratory tests and controlled measurements in order to determine the limits in the detection of cracks. The laboratory tests described by [56] in specimens representing rigid pavements are focused on detecting the bottom of the cracks depending on its width, length, and filling material. The results conclude that it is possible to detect 2 mm wide cracks, and the presence of material filling the crack increases its detectability, being possible to determine the bottom of the cracks: (i) wider than 5 mm and filled with saturated sand; and (ii) wider than 15 mm and filled with dry sand. The detection also depends on the depth of the crack and its position in the pavement structure. The controlled field studies described in [65] also present the detection of the bottom of the cracks in asphalt pavements, concluding that the stronger anomaly is obtained when the bottom of the crack intersects the bottom of the asphalt pavement. The results obtained in the laboratory experiments presented in [67] highlight that the stronger response depends on the contrast between adjacent layers in the case of cracks crossing the entire upper layer. The analysis presented in [40] determines an error of about 5.5% in the estimation of the length of the cracks when the bottom is detected. In those experimental tests, additional computational methods (e.g., finite-difference time-domain (FDTD) modelling) were applied to compare synthetic data with laboratory and controlled measurements.

To summarize, different authors point to the applicability of GPR in the detection of cracks and voids inside different layers of the pavement structure. The method provides clear images in the case of large cracks, although small cracks (until 2 mm) can be detected in the upper layers. The existence of zones with a large number of thin or early cracks can be also detected because of the changes in the radar-wave velocity with respect to the velocity in undamaged pavement. In addition, the bottom of the cracks can be also detected in the case of large and superficial cracks or in the case of cracks filled with water or saturated sand. The dielectric permittivity of those materials differs strongly from the dielectric permittivity of the pavement layer materials. More heterogeneous layers, presenting different grading, make the detection of cracks or voids more difficult. Cracks crossing one entire layer are more detectable, especially in the case of a large contrast in their dielectric permittivity.

8.1.4. Damage Assessment: Debonding

The loss of adhesion between adjacent pavement layers produces a change in the behavior of the pavement, which can contribute to its early failure, producing permanent deformations or superficial cracks and adversely affecting its performance. This problem is considerably severe in the case of airport pavements that undergo high shear stresses during the landing and take-off of the planes. The early detection of debonding is therefore crucial for pavement assessment. The application of GPR in the detection of debonding is usually combined with FWD analysis [75,85], with consistent results validating each other. In addition, the analysis of the GPR signal frequency indicates that the spectrum is sensitive to the structural condition of the pavement, correlating the results with the standardized deflection tests [47] in roads: when comparing damaged zones with undamaged zones, the spectrum bandwidth reduces while the amplitude and the central frequency decreases. However, the clear detection of debonding is only possible in the case of water presence in the debonded zone. Another analysis focused on the assessment of airport pavements [85] refers that the identification of such damage is difficult because it is usually produced at the shallow zone of the pavement structure (within the first several centimeters). However, GPR lateral wave in the CMP data acquisition is highly sensitive to the material properties, and the amplitude maps have proved to be efficient in determining debonding zones in which the high amplitude corresponds with the damaged zones detected by acoustic sounding methods. Methodologies based on linear prediction and supported by vector regression have been proposed and tested using a 10 GHz bandwidth antenna in an accelerated pavement testing facility [236], providing promising results in the detection of thin debonding. Another proposal was the application of a support vector machine to the A-scans, allowing for the detection of horizontally stratified debonding and geotextiles between the two upper pavement layers [237].

8.1.5. Damage Assessment: Moisture

The analysis of changes in water content in the different pavement layers of the substrate was analyzed in a laboratory [238], in controlled field tests [43], and in specific zones of roads [48,73,74]. Some results epitomize the ability of GPR to reveal variations in the water content in the pavement layers beneath the asphalt layer. Comparing GPR data with direct measurements of gravimetric water content reveals the ability of GPR to detect changes in moisture and also to assess the functionality of the drainage layers [34]. The results presented in [74] compare 1 GHz and 2 GHz center frequency antennas, concluding that, although data was similar in both cases, the higher penetration depth with the 1 GHz center frequency antenna makes it more appropriate for detecting zones affected by moisture. In addition, the existence of high water content in fractures [42] and debonding [47,48] between layers is a particular condition for the best detection of those damages. The representation of A-scan datasets in time-domain and in frequency-domain, obtained in wet and dry parts of the pavements, illustrates the great difference in amplitude due to the difference in dielectric permittivity contrast. In many assessments, the moisture damage is detected by observing the amplitude of the maximum peak in the time-domain. However, Zhang et al. [45] propose the use of more properties of the dataset to detect wet zones, considering statistical properties that are affected by moisture, selected with linear discriminant analysis. The comparison of results from GPR tests and passive microwave radiometry demonstrates that GPR is able to detect water content at higher depths, enabling the detection of water table in the soil under the structure [237]. Nevertheless, the identification in the B-scans of the anomaly associated with water table can require different seasonal measurements in order to determine the permanent and variable reflectors, which allows one to distinguish between natural layers or pavement structures, and water table.

The central frequency of the antennas recommended for the detection of moisture ranges from 900 MHz (to analyze moisture in the ground under the pavement [239]) to higher frequencies such as 2.5 GHz (to determine the existence of water in porous layers of the pavement structure [45], between those layers or inside cracks and voids).

The frost susceptibility is another issue to be treated in pavements placed in zones with extreme temperature changes. It is related to water content and drainage of the subgrade. In roads affected by frozen water, a strong reflection is produced at the interface between frozen and non-frozen sections when the subgrade presents high dielectric permittivity and subsequent high frost susceptibility [69].

8.1.6. Quality Control of New Structures: Asphalt Air Void Content and Segregation

Quality control is important in the construction of new pavements and in the restoration of already existing roads and airfields [78,240,241]. The analysis requires the improvement of signal-to-noise ratio of the GPR scans. Bianchini Ciampoli et al. [240] present and discuss a processing flow to improve the GPR images during the quality control of structures. In these applications, a previous calibration is required to obtain accurate results [217].

Quality control involves the thickness control during pavement construction [217], the quality analysis of the layer bonding [209,242], the porosity of the materials [71] and the analysis of thin layers overlaid on old and rehabilitated pavements [217].

The existence of thin layers over the pavements, added as a rehabilitation of damaged zones, produces an overlap between the wave reflected on the surface and the wave reflected on the contact between the thin layer and the old pavement, making the detection of the anomaly and the thickness estimation of the rehabilitated layer difficult. The existence of those thin layers considerably degrades the accuracy of the GPR interpretation of the layer’s thickness and, therefore, accurate signal processing can be required. GPR surveys provide precise results in the estimation of the layer’s thickness when used to assess the quality control of flexible pavements during their construction, allowing traffic speed velocities during the data acquisition (up to 90 km/h with air-coupled antennas and 25 km/h with ground-coupled antennas [217]). Nevertheless, the use of air-coupled antennas is highly recommended [217].

The analysis of quality in the pavement layer bonding is based on the water accumulated in the debonded zones. GPR is an efficient tool because of its sensitivity to changes in water content. Furthermore, it has been observed that GPR is also sensitive to changes in the quality of the material in the case of new pavements [242]. These changes are perceived mainly as a consequence of changes in the travel wave velocity. However, it is difficult to discern between the real cause of changes in the wave travel time: changes in the material conditions or variations in the layer thickness.

The void content in the asphalt pavement is related to the dielectric permittivity values that are obtained when calibrating the wave velocity by comparing GPR data to cores [72]. Dielectric permittivity ranges between 4.5 and 6.5 in dry aggregates while the asphalt permittivity varies between 2.6 and 2.8 [71]. Saarenketo [71] introduces an empirical relationship between the air voids content and the measured dielectric values from GPR data, with an accuracy of about 90%. The uncertainty in these kind of studies can be reduced by comparing GPR data to cores [28]. The analysis presented in [71] also detects the damage in pavements as a consequence of segregation, which is produced in small zones of the shallow layers of pavements with low density materials. This segregation is also associated with an excess of coarse aggregates. The proposed analysis is based on the estimation of the surface dielectric permittivity using GPR data, in which extremely low values could be associated with segregated zones [69]. Computational methods corroborate the occurrence of changes in the GPR signal when variation exists in the pavement density. The A-scan’s amplitude increases when the asphalt pavement density increases because of the higher dielectric permittivity, also showing an augment in the amplitude of the frequency range [243].

8.1.7. Rebar Detection and Corrosion