A Study on User-Oriented and Intelligent Service Design in Sustainable Computing: A Case of Shipbuilding Industry Safety

Abstract

:1. Introduction

2. Literature Review on u-Business Service

2.1. u-Business Service Concept

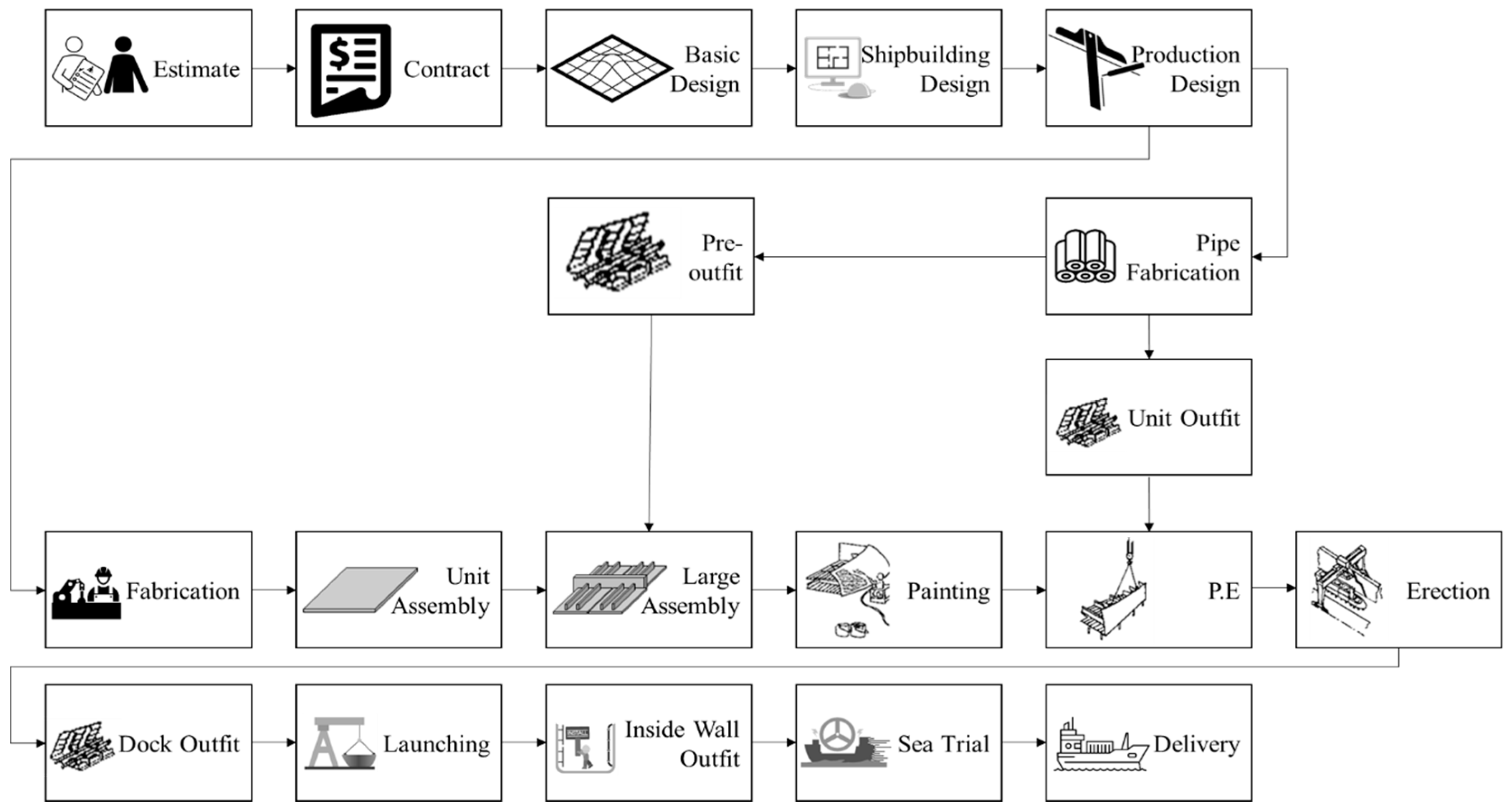

2.2. Analysis on Construction Processes in the Shipbuilding Industry

2.3. Features of the Shipbuilding Industry Sites

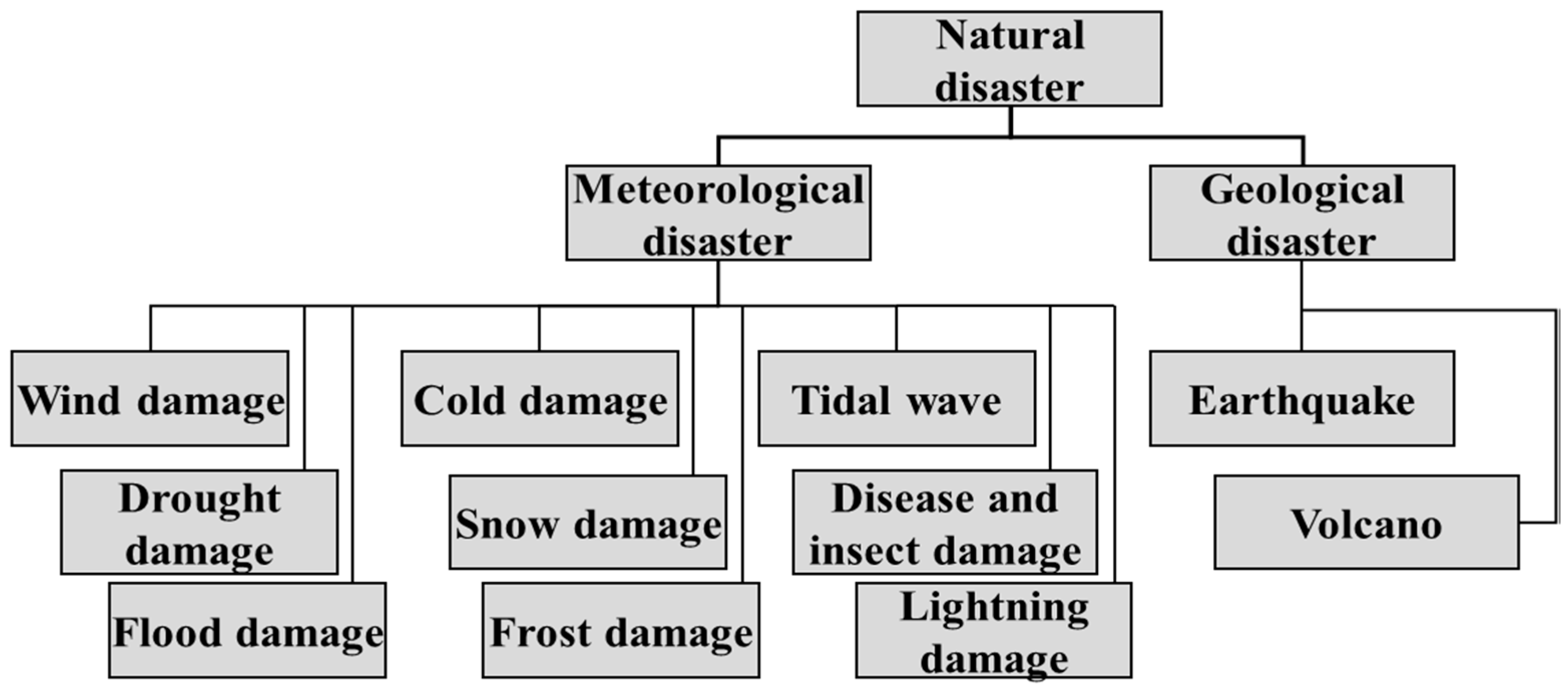

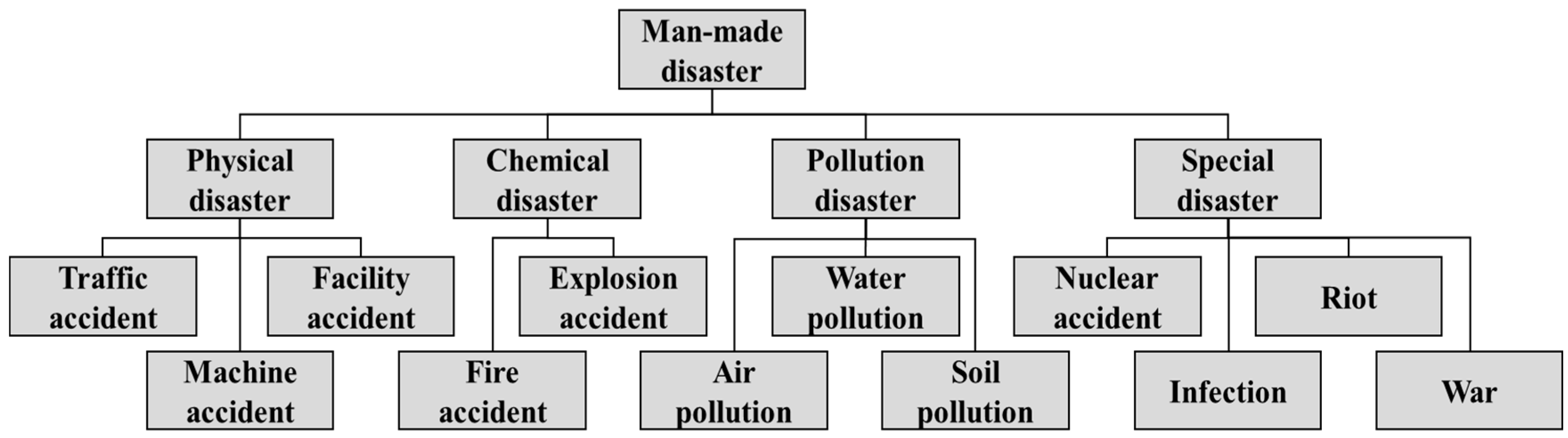

2.4. Definition and Classification of Industrial Accidents

2.5. Status of Accidents by Process in the Shipbuilding Industry (Cases in Korea)

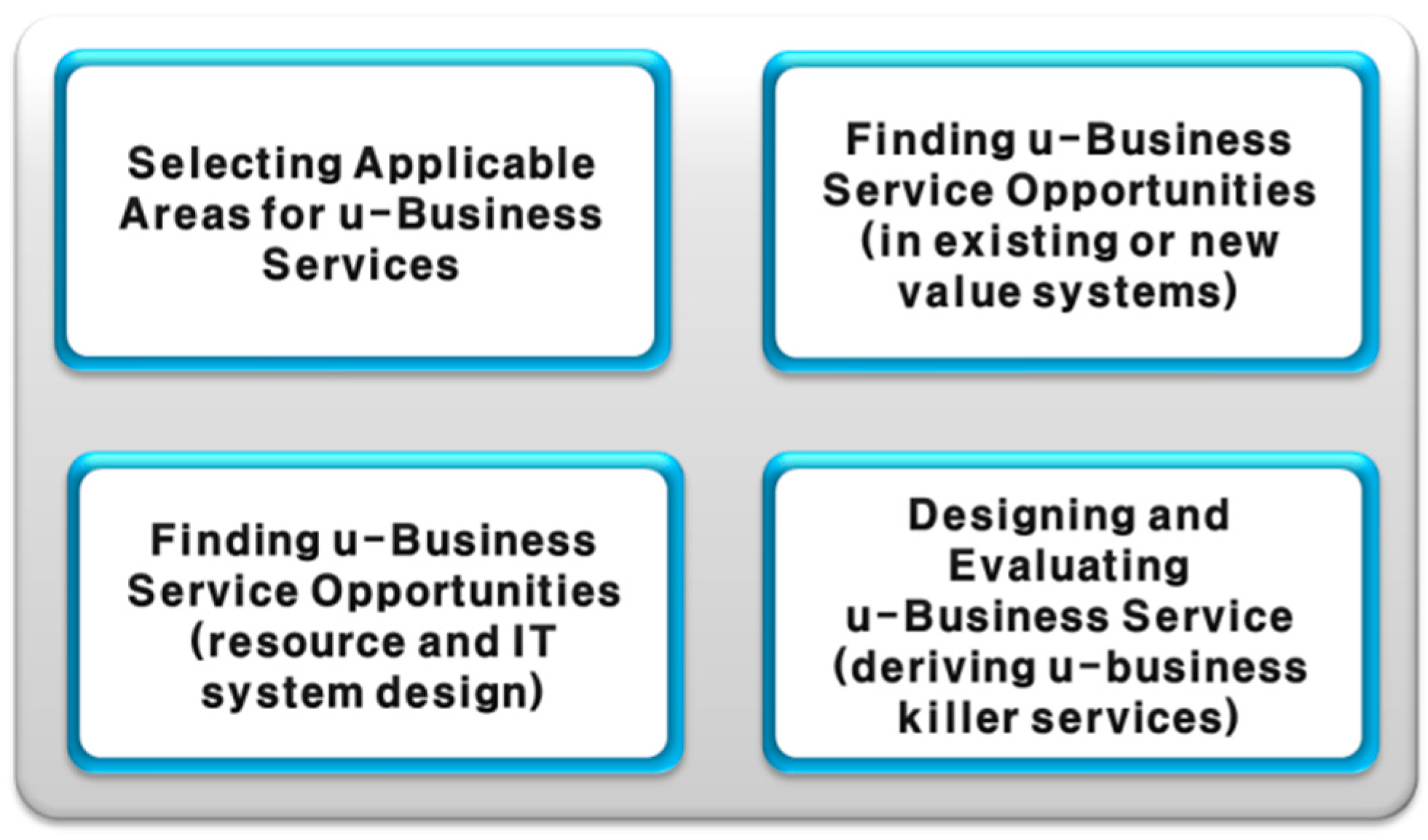

2.6. Methodology of Designing u-Business Service Model

3. Developing User-Centered u-Business Killer Services

3.1. Selecting Applicable Areas for u-Business Services

3.1.1. Shipbuilding Industry and Accidents

3.1.2. Characterizing Accidents in the Shipbuilding Industry

3.2. Finding Business Opportunities from Existing or New Value System

3.3. Designing and Evaluating the u-Business Service (Deriving u-Business Killer Services)

3.4. Developing a u-Business Killer Service Model (Designing Resource and IT Systems)

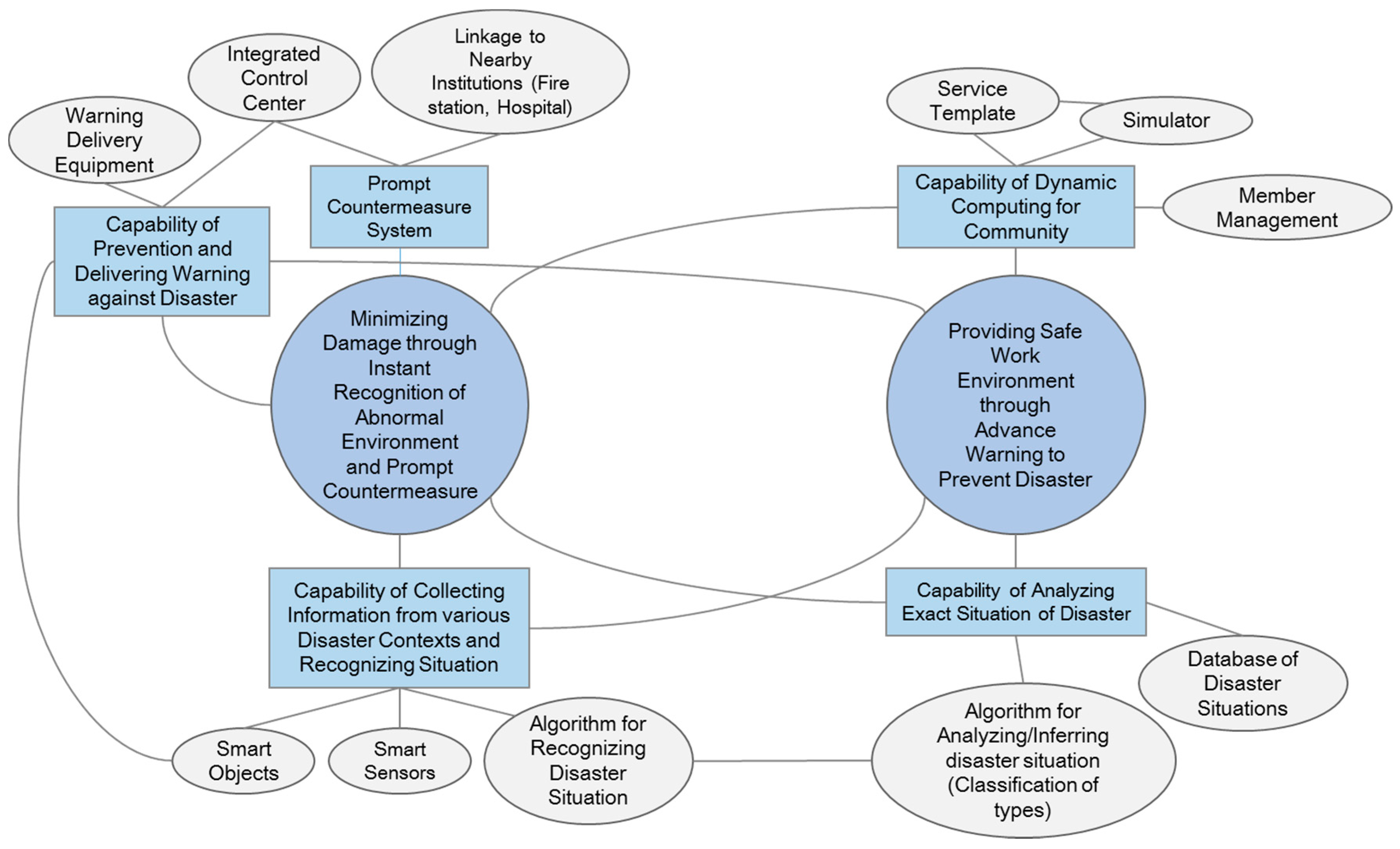

3.4.1. Value Proposition for u-Business Killer Services

3.4.2. Definition of Providing u-Business Killer Services

3.4.3. Designing the Resource System for a u-Business Killer Service

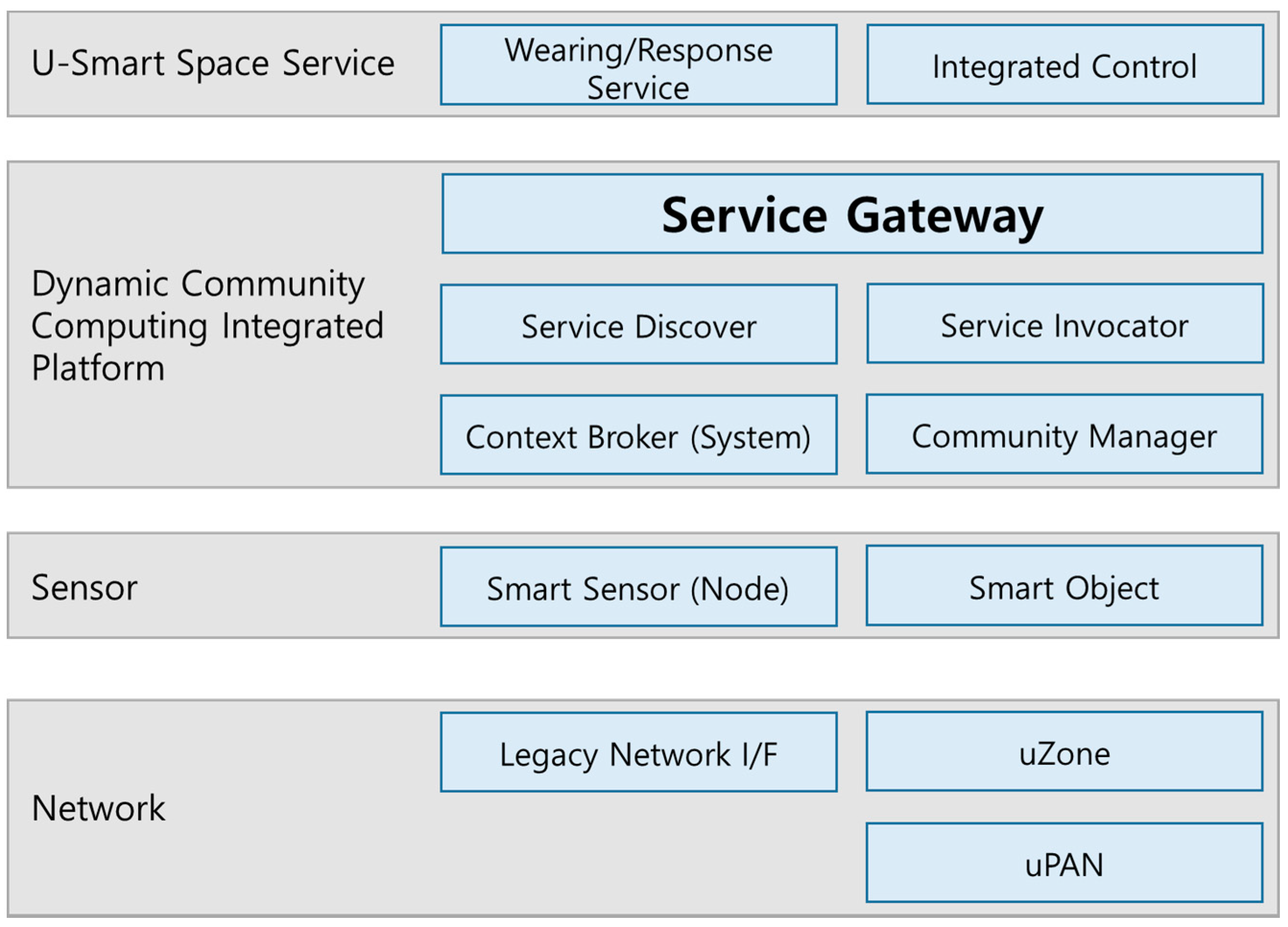

3.4.4. Designing a U-Business Killer Service IT System

- Scale-free uPAN: The WPAN (Wireless Personal Area Network) such as Bluetooth, Zigbee and UWB is often used as a Ubiquitous Computing network. For the WPAN, one of the high rate WPAN and the low rate WPAN is generally used according to the supporting distance, speed, power and lightweight degree required for providing services. The technology used here is a scale-free uPAN that recognizes various environment variables such as the object position, channel condition, type of data transmitted to serve self-regulated varying data transfer rate (from the minimum 20 kbps to the maximum 1 gbps).

- uZone: It is a network technology to support an intelligent ubiquitous space based on the community computing, which enables the converged intelligent network service.

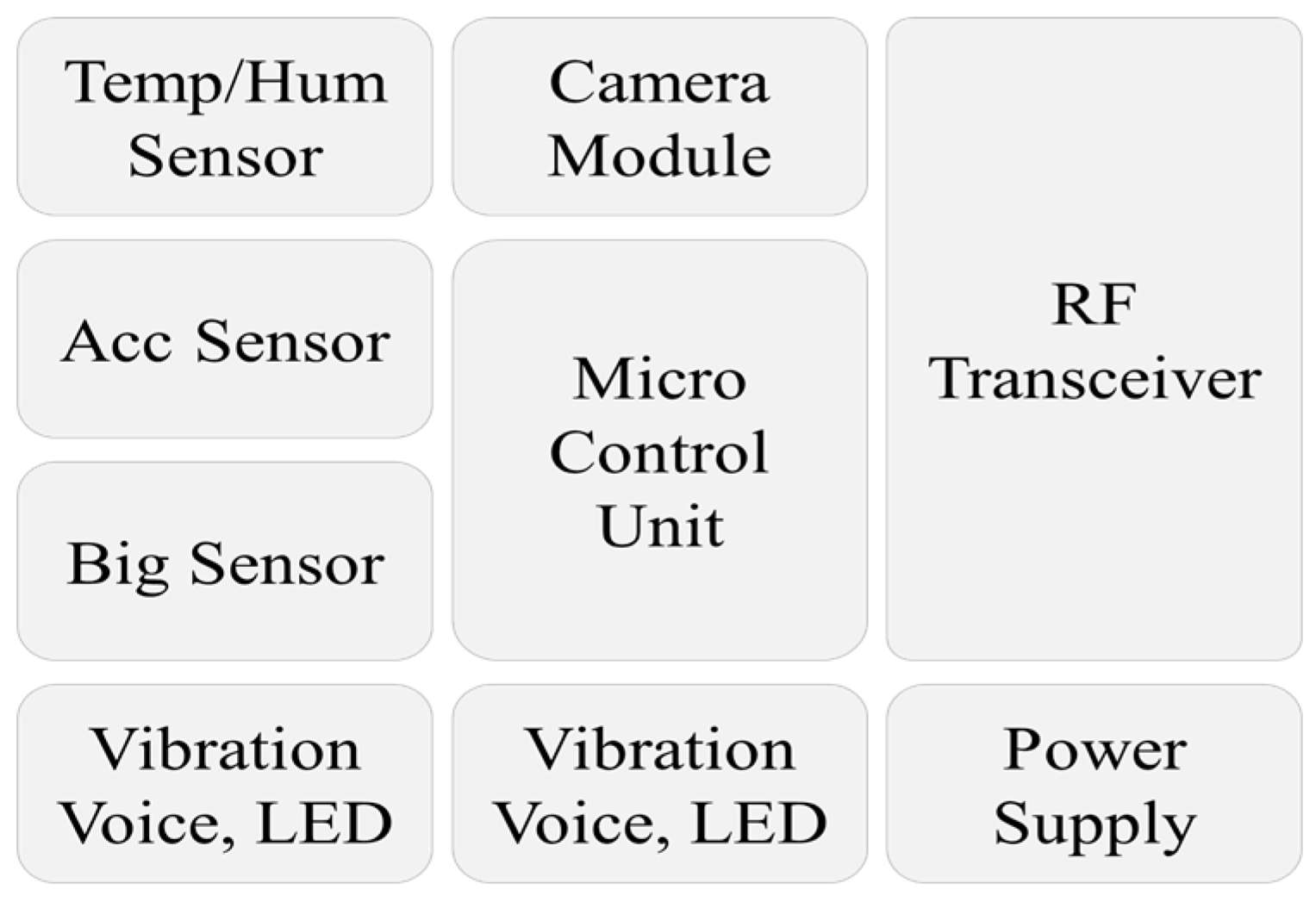

- Smart Object: It is that a sensing and alarm function is added to helmets, belts, gloves, etc. worn by workers in Figure 8. It can sense a variety of environmental data (temperature, humidity, illumination, current, image, and acceleration), recognize movements, positions and actions of workers, and generate an event (vibration, alarm and LED) depending on whether there is a dangerous situation. It can also send information on major emergency situations (video about a fire, etc.) to the integrated control center via a PAN or the existing wireless network, and additionally provide a danger alarm sharing functions between smart objects.

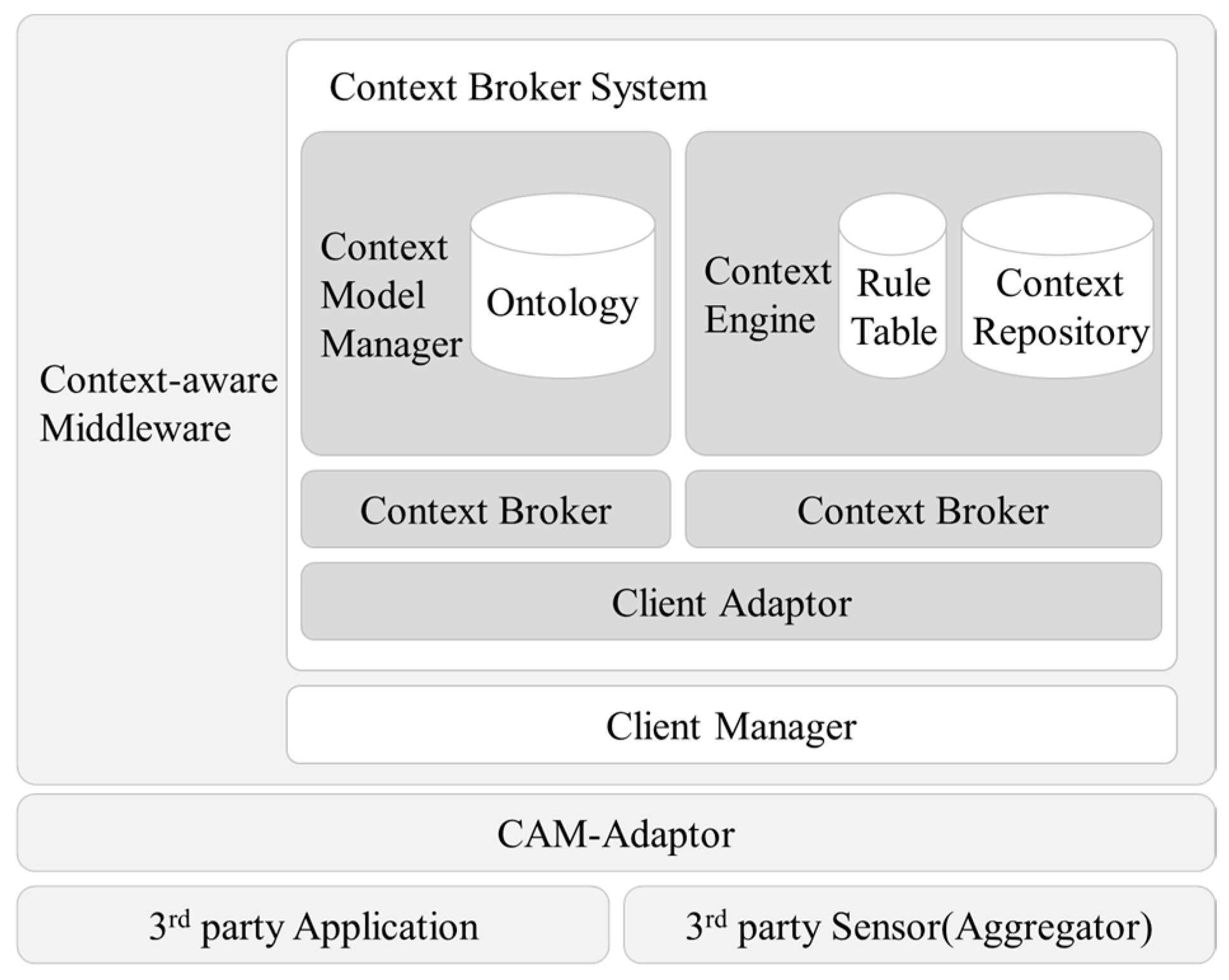

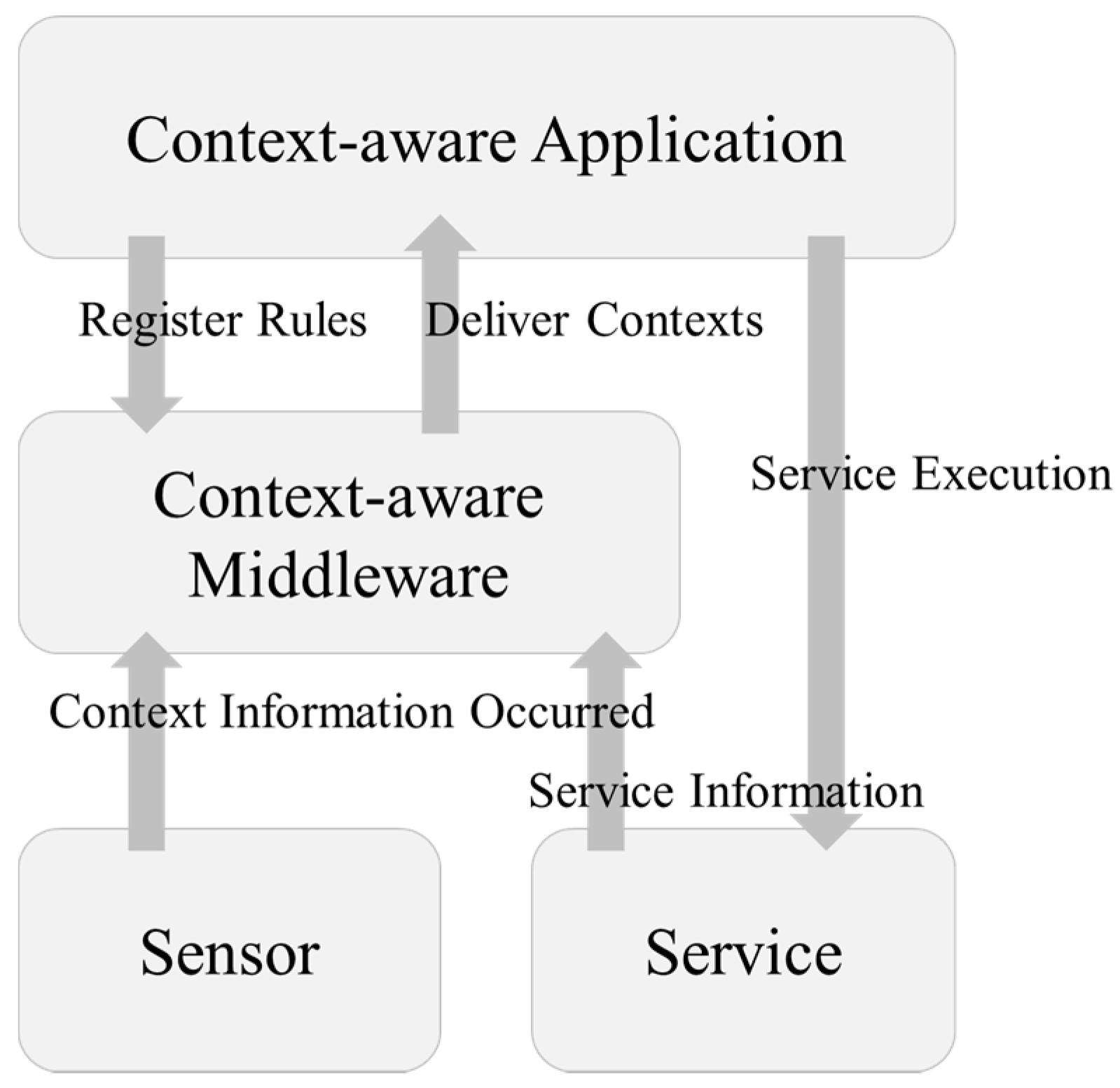

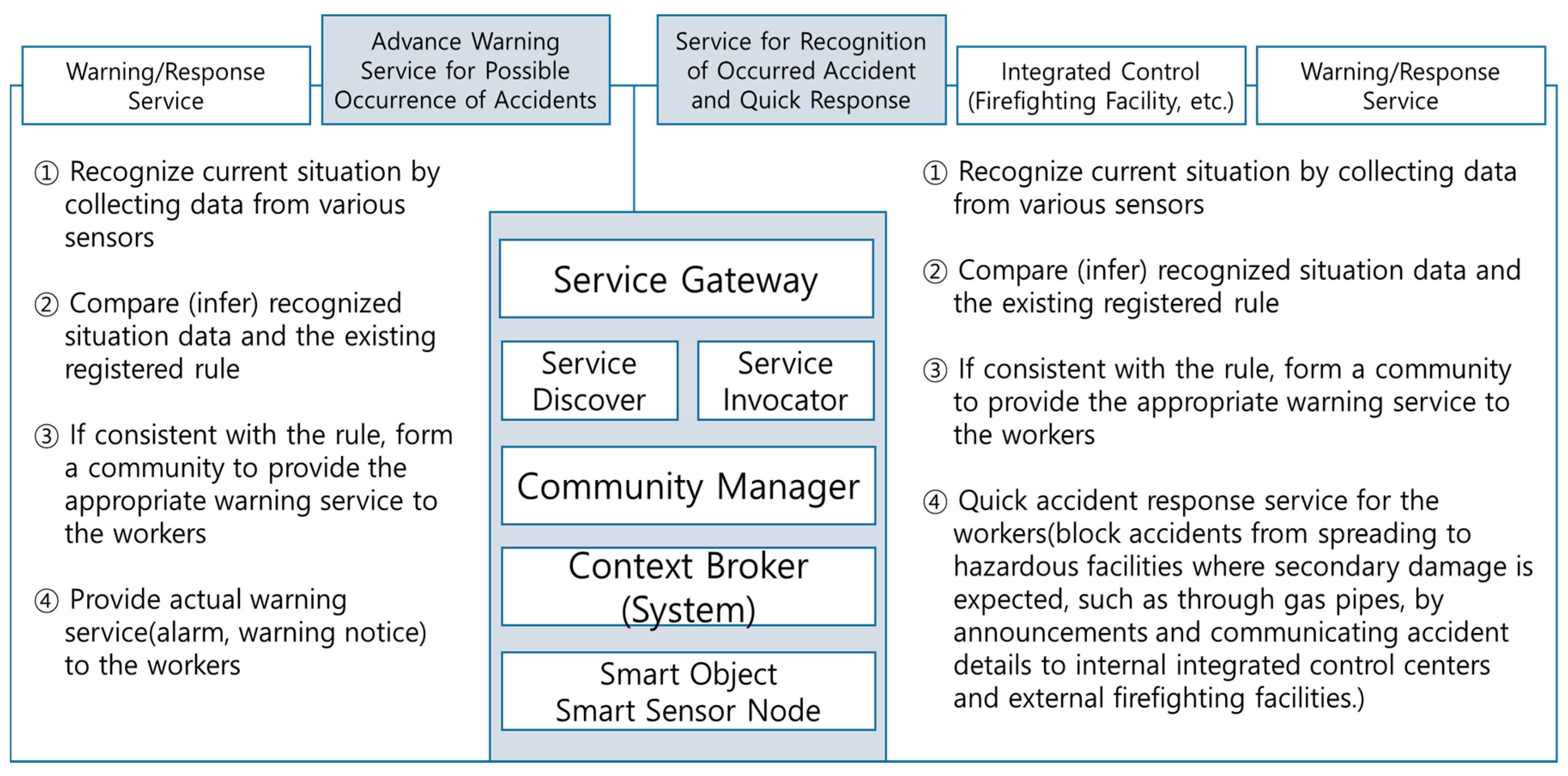

- Context broker (system): It operates as the event–condition–action method, which delivers context information to applications if there is a matched rule after comparing the occurred context information with the rules registered by the applications (integrated control center, etc.) in Figure 9 and Figure 10. Conversely, it plays a role in providing the corresponding context information delivered from the sensor when applications inquire the context information.

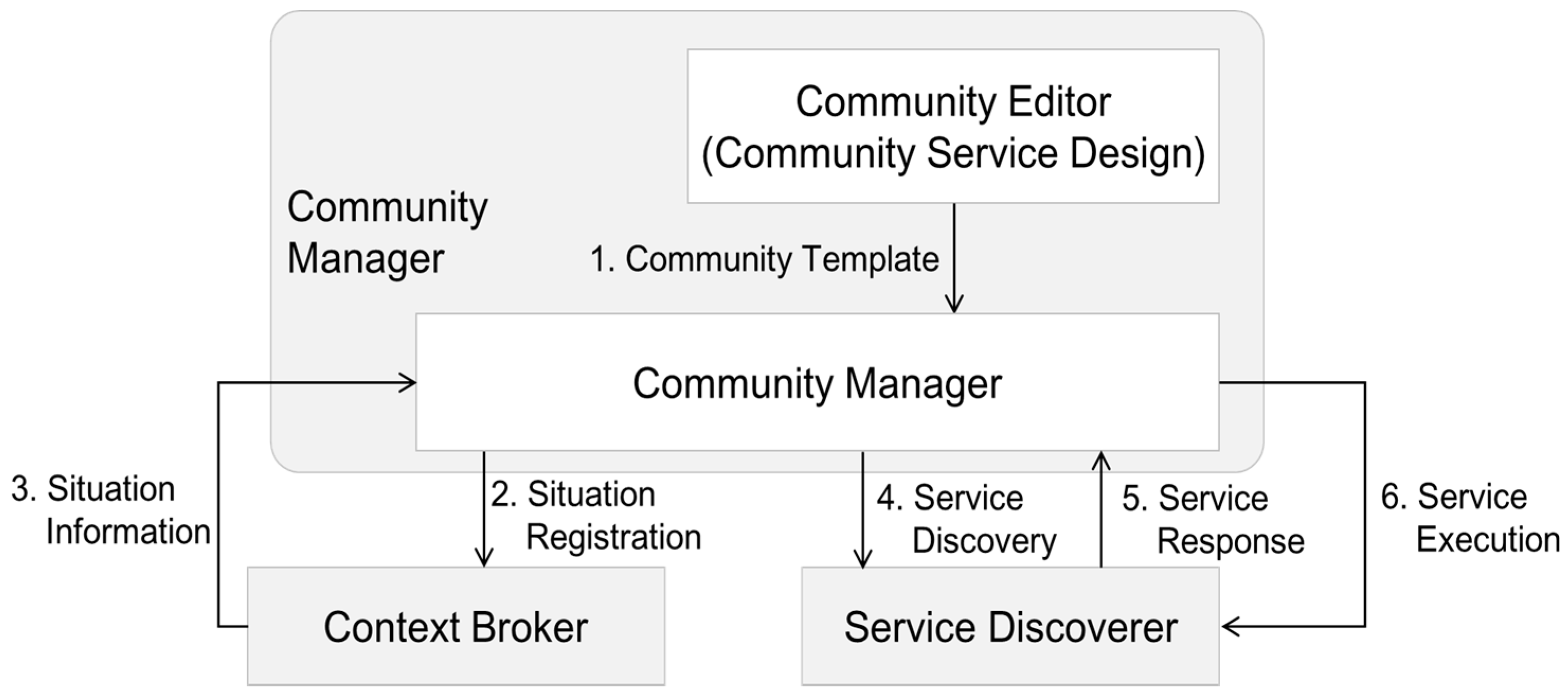

- Community manager: It supports dynamic community computing, which is composed of a community editor to support a design of service templates (definition of situations, goals, roles and procedures) through a community model, a community manager to dynamically select member services to construct a community according to the actual run time, and a USS simulator to provide the community service simulation support and member add/delete/deploy functions in a virtual space and interworking functions between context brokers and community managers in Figure 11.

- Service Discoverer: Repository where certain situation data and the corresponding services are connected

4. Conclusions and Future Study

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Petrova, K.; Wang, B. Location-based services deployment and demand: A roadmap model. Electron. Commer. Res. 2011, 11, 5–29. [Google Scholar] [CrossRef]

- Hallsteinsen, S.; Geihs, K.; Paspallis, N.; Eliassen, F.; Horn, G.; Lorenzo, J.; Mamelli, A.; Papadopoulos, G.A. A development framework and methodology for self-adapting applications in ubiquitous computing environments. J. Syst. Softw. 2012, 85, 2840–2859. [Google Scholar] [CrossRef]

- Qiao, X.-Q.; Li, X.-F.; Liang, S.-Q. Reference model of future ubiquitous convergent network and context-aware telecommunication service platform. J. China Univ. Posts Telecommun. 2006, 13, 50–56. [Google Scholar] [CrossRef]

- Kwon, O.; Yoo, K.; Suh, E. UbiDSS: A proactive intelligent decision support system as an expert system deploying ubiquitous computing technologies. Expert Syst. Appl. 2005, 28, 149–161. [Google Scholar] [CrossRef]

- Lee, S.; Kim, H.J.; Kwon, O.B. A study on the Multidimensional Service Scenario Evaluation Methodology for ITSM Construction Considering Ubiquitous Computing Technology. J. Soc. e-Bus. Stud. 2007, 12, 155–194. [Google Scholar]

- Klein, H.J. Shipbuilding trends in response to environmental issues. WMU J. Marit. Aff. 2007, 6, 167–175. [Google Scholar] [CrossRef]

- Borrajo, M.L.; Corchado, J.M.; Corchado, E.S.; Pellicer, M.A.; Bajo, J. Multi-agent neural business control system. Inform. Sci. 2010, 180, 799–1074. [Google Scholar]

- Asheim, B.T.; Isaksen, A. Regional Innovation Systems: The Integration of Local ‘Sticky’ and Global ‘Ubiquitous’ Knowledge. J. Technol. Transf. 2002, 27, 77–86. [Google Scholar] [CrossRef]

- Chang, H.; Kang, J.; Kim, Y.; Lim, J.; Na, Y. A Case Study on Cooperative Real-time Quality Monitoring Service Utilizing Sensor Networks. In Computer Science and Convergence; Lecture Notes in Electrical Engineering; Springer: Dordrecht, The Netherlands, 2012; pp. 203–210. [Google Scholar]

- Moschetta, E.; Antunes, R.S.; Barcellos, M.P. Flexible and secure service discovery in ubiquitous computing. J. Netw. Comput. Appl. 2010, 33, 128–140. [Google Scholar] [CrossRef]

- Taylor, D.G.; Davis, D.F.; Jillapalli, R. Privacy concern and online personalization: The moderating effects of information control and compensation. Electron. Commer. Res. 2009, 9, 203–223. [Google Scholar] [CrossRef]

- Yu, X.-Y.; Lin, R.-H.; Huang, P.-C. Research of a Ubiquitous-Computing Enabled Service Pattern in Converged Network. Adv. Intell. Soft Comput. 2012, 143, 715–722. [Google Scholar]

- Nylander, S.; Bylund, M.; Waern, A. Ubiquitous service access through adapted user interfaces on multiple devices. Pers. Ubiquitous Comput. 2005, 9, 123–133. [Google Scholar] [CrossRef]

- Baousis, V.A.; Kyriakakos, M.; Hadjiefthymiades, S.; Merakos, L. A Multiagent Platform for Ubiquitous Service Provision. J. Netw. Syst. Manag. 2009, 17, 371–396. [Google Scholar] [CrossRef]

- Baruque, B.; Corchado, E.; Mata, A.; Corchado, J.M. A forecasting solution to the oil spill problem based on a hybrid intelligent system. Inf. Sci. 2010, 180, 2029–2043. [Google Scholar] [CrossRef]

- Chua, H.-C.; Hwanga, G.-J.; Tsaib, C.-C. A knowledge engineering approach to developing mindtools for context-aware ubiquitous learning. Comput. Educ. 2010, 54, 289–297. [Google Scholar] [CrossRef]

- Petric, A.; Trzec, K.; Jurasovic, K.; Podobnik, V.; Jezic, G.; Kusek, M.; Ljubi, I. Agent-Based Support for Context-Aware Provisioning of IMS-Enabled Ubiquitous Services. In International Workshop on Service-Oriented Computing: Agents, Semantics, and Engineering; Springer: Berlin/Heidelberg, Germany, 2009; pp. 71–82. [Google Scholar]

- Lin, C.-C.; Lee, R.-G.; Hsiao, C.-C. A pervasive health monitoring service system based on ubiquitous network technology. Int. J. Med. Inform. 2008, 77, 461–469. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.-L.; Cho, C.-A. User-provided multimedia content distribution architecture in mobile and ubiquitous communication networks. J. Netw. Comput. Appl. 2011, 34, 121–136. [Google Scholar] [CrossRef]

- Eurich, M.; Oertel, N.; Boutellier, R. The impact of perceived privacy risks on organizations’ willingness to share item-level event data across the supply chain. Electron. Commer. Res. 2010, 10, 423–440. [Google Scholar] [CrossRef]

- Su, W.-T.; Kuo, Y.-H.; Huang, P.-C. A QoS-driven approach for service-oriented device anycasting in ubiquitous environments. Comput. Netw. 2008, 52, 3342–3357. [Google Scholar] [CrossRef]

- Cai, H.; Hu, X.; Lü, Q.; Cao, Q. A novel intelligent service selection algorithm and application for ubiquitous web services environment. Expert Syst. Appl. 2009, 36, 2200–2212. [Google Scholar] [CrossRef]

- Son, S.H.; Bae, S.M. Dissemination of Production Technology Using Manufacturing Knowledge Sharing Platform System. Adv. Sci. Lett. 2012, 13, 332–338. [Google Scholar] [CrossRef]

- Lian, S. Innovative Internet video consuming based on media analysis techniques. Electron. Commer. Res. 2011, 11, 75–89. [Google Scholar] [CrossRef]

- Zhou, B.; Shi, Q.; Merabti, M. Balancing intrusion detection resources in ubiquitous computing networks. Comput. Commun. 2008, 31, 3643–3653. [Google Scholar] [CrossRef]

- Leung, A.; Sheng, Y.; Cruickshank, H. The security challenges for mobile ubiquitous. Inf. Secur. Tech. Rep. 2007, 12, 162–171. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, F. Context-aware location discovery exchange in a ubiquitous environment. J. China Univ. Posts Telecommun. 2012, 19, 73–78. [Google Scholar] [CrossRef]

- Dong, H.; Hussain, F.K.; Chang, E. A framework for discovering and classifying ubiquitous services in digital health ecosystems. J. Comput. Syst. Sci. 2011, 77, 687–704. [Google Scholar] [CrossRef]

- Su, S.Y.W.; Meng, J.; Krithivasan, R.; Degwekar, S.; Helal, S. Dynamic Inter-Enterprise Workflow Management in a Constraint-Based E-Service Infrastructure. Electron. Commer. Res. 2003, 3, 9–24. [Google Scholar] [CrossRef]

- Rayport, J.; Jaworski, B. Introduction to E-Commerce; McGraw-Hill Inc.: New York, NY, USA, 2003. [Google Scholar]

- Cao, L. In-depth behavior understanding and use: The behavior informatics approach. Inform. Sci. 2010, 180, 3067–3380. [Google Scholar] [CrossRef]

- Qin Shiming, S.D.; Wang, G.-N. Interactive Genetic Algorithms for Optimal Assignment of Blocks into Workspaces of Shipbuilding Industry. Int. J. Appl. Evolut. Comput. 2016, 6, 19. [Google Scholar] [CrossRef]

| Items | e-Business Services | u-Business Services |

|---|---|---|

| Main Technology | Wired internet, web technology, etc. | Sensor network, wireless internet, self-reasoning and learning skills (Self Reasoning and Growing) |

| Business Area | Limited business improvement | Business process innovation, can generate new business |

| Business Activities | Passive (conscious) activities | Context-based autonomous activities |

| Business Characteristics | Expand offline business into online business | Integrate online and offline business |

| Features | Content |

|---|---|

| There are many movements between the working places due to the works’ characteristics. | There is high probability of human errors caused by repetitive works such as installation of structures and equipment and dismantling of the existing equipment due to frequent movements of the processes followed by block assembly → outfit work → painting work → erection, etc. |

| There are always elevated working places. | Because constructing ships are assembled with large steel structures, the height of working places is from 2 m to 10 m or more, many works are done in elevated places, and it is highly likely that a series of accidents take place due to a drop and falling objects, so it is more fatal than common accidents. |

| There are many narrow enclosed spaces because of its structure. | There is always potential dangerousness of serious accidents and suffocation possibly caused by the inadequacy of ventilation facilities due to excessive enclosed areas. |

| It is difficult to control such as adjustment of order between works. | The difficulty of control is involved due to frictions and interference of priorities between processes caused by the sequence control between works and processes, construction period, material amount fluctuation, frequent movement, and weather changes, etc. |

| Handling of many heavy weights. | When handling and moving heavy weights, there is always a main cause of serious accidents due to the excessive use of heavy equipment. |

| Very frequent manpower movement. | It is a labor intensive industry, which manpower movement is frequent due to the intensive manpower input of a unit project. |

| The working environment is diversified. | It is very difficult to respond to the working environment due to diversification of the constructing ship types in the frequently changed working environment. |

| The mixture of industries is inevitable within a limited space. | There is high probability of safety and health problems and serious accidents occur due to an inseparable relation of frictions or interferences between the work processes such as fire, painting, outfit and hull welding works within the same space. |

| Total | Processing/Assembly | Erection | Outfit | Painting | Support | Inspection/Test | Others |

|---|---|---|---|---|---|---|---|

| 1102 | 315 (28.6%) | 90 (8.2%) | 145 (13.2%) | 121 (11.0%) | 166 (15.1%) | 9 (0.8%) | 256 (23.2%) |

| Classifications | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Number of Workers | 168,114 | 180,661 | 186,226 | 215,833 | 233,730 |

| Number of Casualties | 1820 | 1760 | 1596 | 1349 | 1940 |

| Number of Deaths | 46 | 51 | 37 | 37 | 31 |

| Ship Manufacturing Process | Critical Types of Industrial Accidents |

| Stowing and Pretreatment of Raw Materials | Risk of collision between a vehicle and a worker |

| Risk of falling over or collapsing while unloading the steel materials | |

| Machine Cutting | Risk of falling over while transferring the steel plate or a body part getting caught during operation (Narrowness) |

| Small/Medium Block Assembly | Risk of falling over when securing the vertical beams |

| Large Block Assembly | Risk of the blocks colliding with each other or falling over |

| Painting | Risk of suffocation during the painting process in a sealed space |

| Ship Outfitting | Risk of fire while working wearing an air jacket with oxygen injection |

| Risk of falling when working on a high block | |

| Erection | Risk of dropping transporting materials due to defects in the shackles and lugs connected to the crane |

| Risk of falling through openings such as manholes | |

| Common | Risk of falling during scaffolding installation and disassembly, which are installed to allow working in high places |

| Critical Types of Industrial Accidents | u-Business Services Designed for Industrial Accident Prevention and Response |

|---|---|

| Risk of falling over or collapsing while unloading steel materials | The weight of raw materials, movement angles, and line strengths are sensed when transporting raw materials, and when they are greater than the permissible range, workers are warned to stop working (S1) |

| Risk of falling over while transferring a steel plate or a body part getting caught during operation (Narrowness) | |

| Risk of falling over when securing vertical beams | - |

| Risk of dropping transporting materials due to the defects in shackles and lugs connected to the crane | When monitoring the quality of components (degree of deterioration), the system alerts a worker when he uses a component that goes beyond the permissible range (S2) |

| Risk of the blocks colliding with each other or falling over | - |

| Risk of collision between a vehicle and a worker | Recognize objects (people) that approach from behind using a smart camera (sensor) and give a warning (S3) |

| Risk of falling when installing or disassembling scaffoldings that are installed to allow working in high places | Recognize those not wearing safety helmets (S4) By using smart objects (helmet, glove, belt), recognize the: (1) location/acceleration; (2) workers’ stress and fatigue levels; and (3) unstable posture of the workers to warn and respond (hospital service connection) (S5–S7) |

| Risk of falling when working on a high block | |

| Risk of falling through openings, including manholes | Recognize sudden changes in a worker’s location using smart objects and respond quickly (S5) |

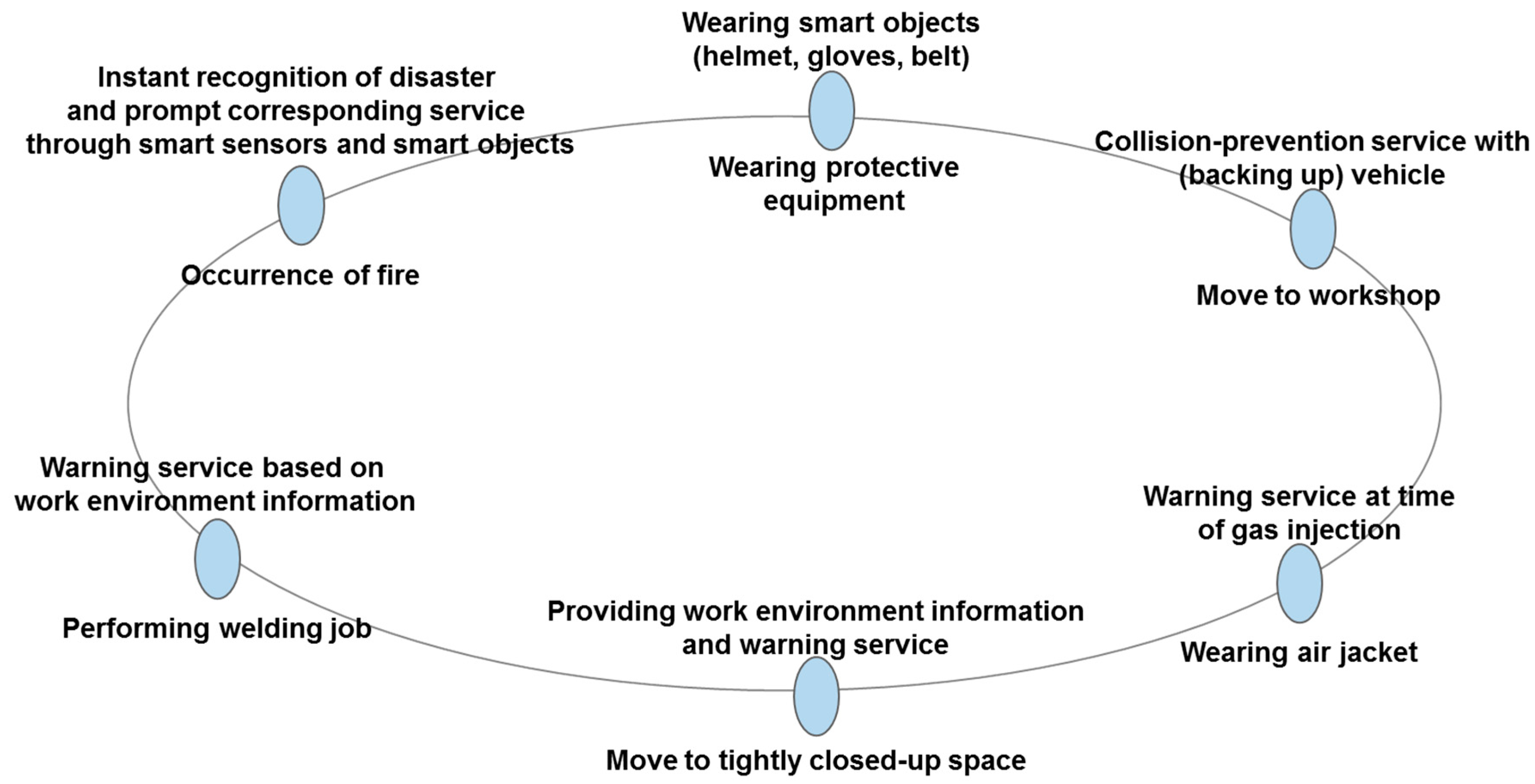

| Risk of fire while working, wearing the air jacket with oxygen injection | Warning by recognizing the oxygen concentration in the air jacket (S8) Advance warning of accidents that occur frequently (S9) |

| Risk of suffocation when painting in a sealed space | Detect the oxygen and combustibility concentrations and illumination and humidity intensities; when they are greater than the permissible range, notify the entry way/nearby workers and automatically open or close the windows (S10) |

| Classification | u-Business Service Scenario |

|---|---|

| S1 | When transporting raw materials, the weight of the raw materials, swaying motion angle, and line strength are recognized. If the recognized data are outside of the (safe) permissible range, workers are warned to stop transporting the raw materials. |

| S2 | The quality (degree of deterioration) of the components is identified by recognizing the degree of usage and wear. If the condition of the component used by the worker is outside of the (safe) permissible range, the worker is notified to stop using the component. Additionally, the number of deteriorated components is automatically determined so that this information can be used when ordering the component from its suppliers in the future. |

| S3 | Smart sensors are mounted on the back of the vehicles (truck, forklifts, or excavators). The mounted smart sensors notify the driver and stop the vehicle when a person approaches within a certain distance while driving the vehicle. |

| S4 | Smart cameras installed at the construction site automatically recognize people not wearing (yellow) safety helmets, zoom in to photograph, and send the person’s location and photo to the integrated control center, as well as use the nearby speaker to warn the worker to wear the helmet. |

| S5 | When a hazardous situation (fire, explosion, or fallen worker) occurs near the workers, the smart helmet immediately recognizes this and notifies workers and the integrated control server. This provides a quick response in an emergency situation by notifying the nearby workers and giving instructions for handling the accident or giving the location of fire extinguishers and emergency exits through the smart helmets. |

| S6 | Measure the stress levels of workers before starting work (or on a regular basis). If that level is outside of the permissible range or deviates greatly from the worker’s normal levels, it is recommend that the worker take a break. When the stress level is serious, take responsive actions, including contacting the emergency center at local hospitals. |

| S7 | Workers who work on high blocks are to wear smart gloves at all times. The smart gloves recognize when the worker exhibits careless (unsafe) behavior/posture (for example, working while holding heavy equipment in both hands) and notify the worker and the integrated control center. |

| S8 | Automatically recognize the oxygen and flammable gas concentrations in the air jacket to automatically shut off the gas supply device and prevent the worker from inhaling the wrong type of gas. |

| S9 | Gather data about the situations (time period, location, or work contents) in which accidents occur. Based on the collected data, safety warnings are provided to workers in advance for the accident-prone work situations. |

| S10 | Recognize the flammable gas and oxygen concentrations, temperature, humidity, and illumination in the enclosed space, indicate warning light/warning signs at the entryway, and automatically open the window when outside the permissible range. The smart cameras installed in the workspace detect fires and notify the integrated control center when there is a fire by sending a video of it. The integrated control center responds by transferring the facts about the fire to the nearby hazard facility to take safety measures and contacts the fire department when necessary. |

| Effect | Value | F | Hypothesis Degree of Freedom | Error Degree of Freedom | p-Value | |

|---|---|---|---|---|---|---|

| Intercept | Trace of Pillai Intercept Lambda of Wilks Trace of Hotelling Max Val. of Roy | 0.929 0.071 13.135 13.135 | 599.852(a) 599.852(a) 599.852(a) 599.852(a) | 3.000 3.000 3.000 3.000 | 137.000 137.000 137.000 137.000 | 0.000 0.000 0.000 0.000 |

| Service | Trace of Pillai Service Lambda of Wilks Trace of Hotelling Max Val. of Roy | 0.339 0.684 0.429 0.339 | 1.967 2.061(a) 2.155 5.236(b) | 27.000 27.000 27.000 9.000 | 417.000 400.753 407.000 139.000 | 0.003 0.002 0.001 0.000 |

| Service | Usability | Reliability | Versatility and Extensibility | Total | Ranking |

|---|---|---|---|---|---|

| S1 | 4467 | 4200 | 4533 | 4400 | 7 |

| S2 | 6200 | 6067 | 4333 | 5533 | 1 |

| S3 | 4600 | 4133 | 4467 | 4400 | 7 |

| S4 | 3667 | 3533 | 3467 | 3556 | 10 |

| S5 | 4800 | 4733 | 4733 | 4756 | 4 |

| S6 | 5267 | 5133 | 4933 | 5111 | 2 |

| S7 | 4571 | 4643 | 4571 | 4595 | 5 |

| S8 | 4067 | 4067 | 4133 | 4089 | 9 |

| S9 | 5133 | 4867 | 4667 | 4889 | 3 |

| S10 | 4667 | 4467 | 4200 | 4444 | 6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joe, T.; Chang, H. A Study on User-Oriented and Intelligent Service Design in Sustainable Computing: A Case of Shipbuilding Industry Safety. Sustainability 2017, 9, 544. https://doi.org/10.3390/su9040544

Joe T, Chang H. A Study on User-Oriented and Intelligent Service Design in Sustainable Computing: A Case of Shipbuilding Industry Safety. Sustainability. 2017; 9(4):544. https://doi.org/10.3390/su9040544

Chicago/Turabian StyleJoe, Taehee, and Hangbae Chang. 2017. "A Study on User-Oriented and Intelligent Service Design in Sustainable Computing: A Case of Shipbuilding Industry Safety" Sustainability 9, no. 4: 544. https://doi.org/10.3390/su9040544

APA StyleJoe, T., & Chang, H. (2017). A Study on User-Oriented and Intelligent Service Design in Sustainable Computing: A Case of Shipbuilding Industry Safety. Sustainability, 9(4), 544. https://doi.org/10.3390/su9040544