Assessment of Selected Parameters of the Automatic Scarification Device as an Example of a Device for Sustainable Forest Management

Abstract

:1. Introduction

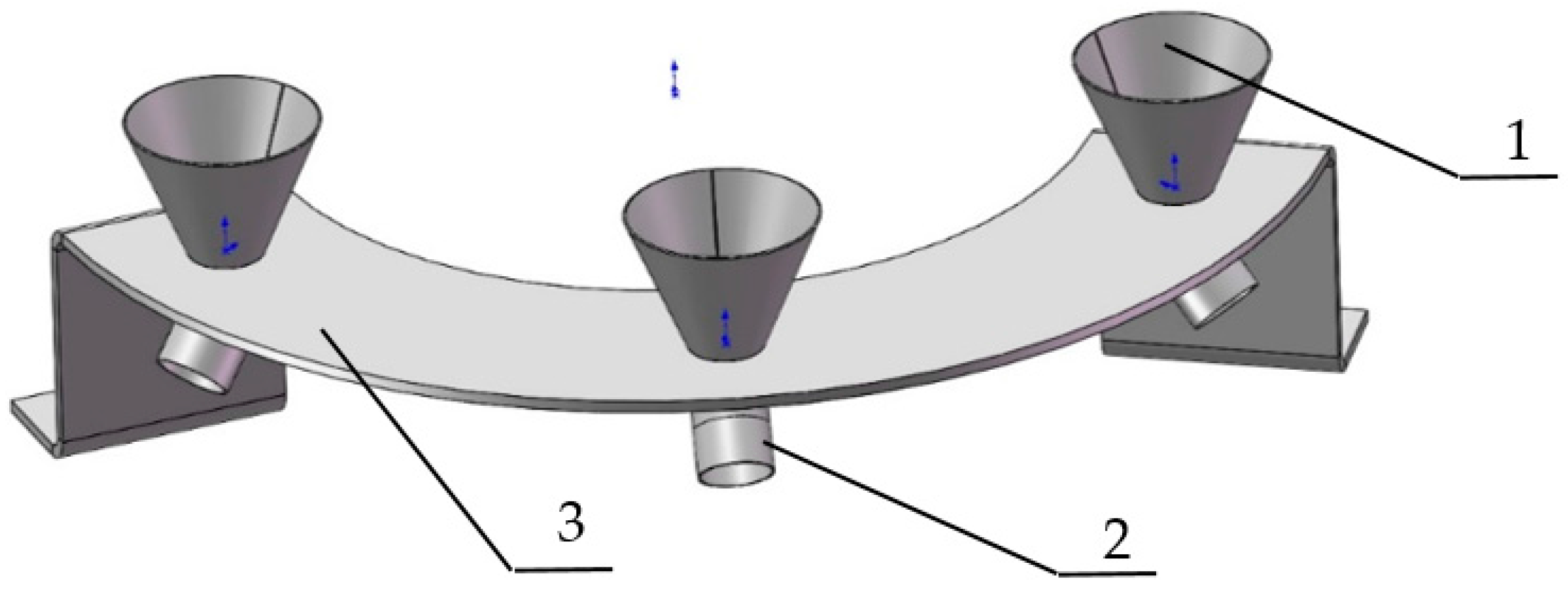

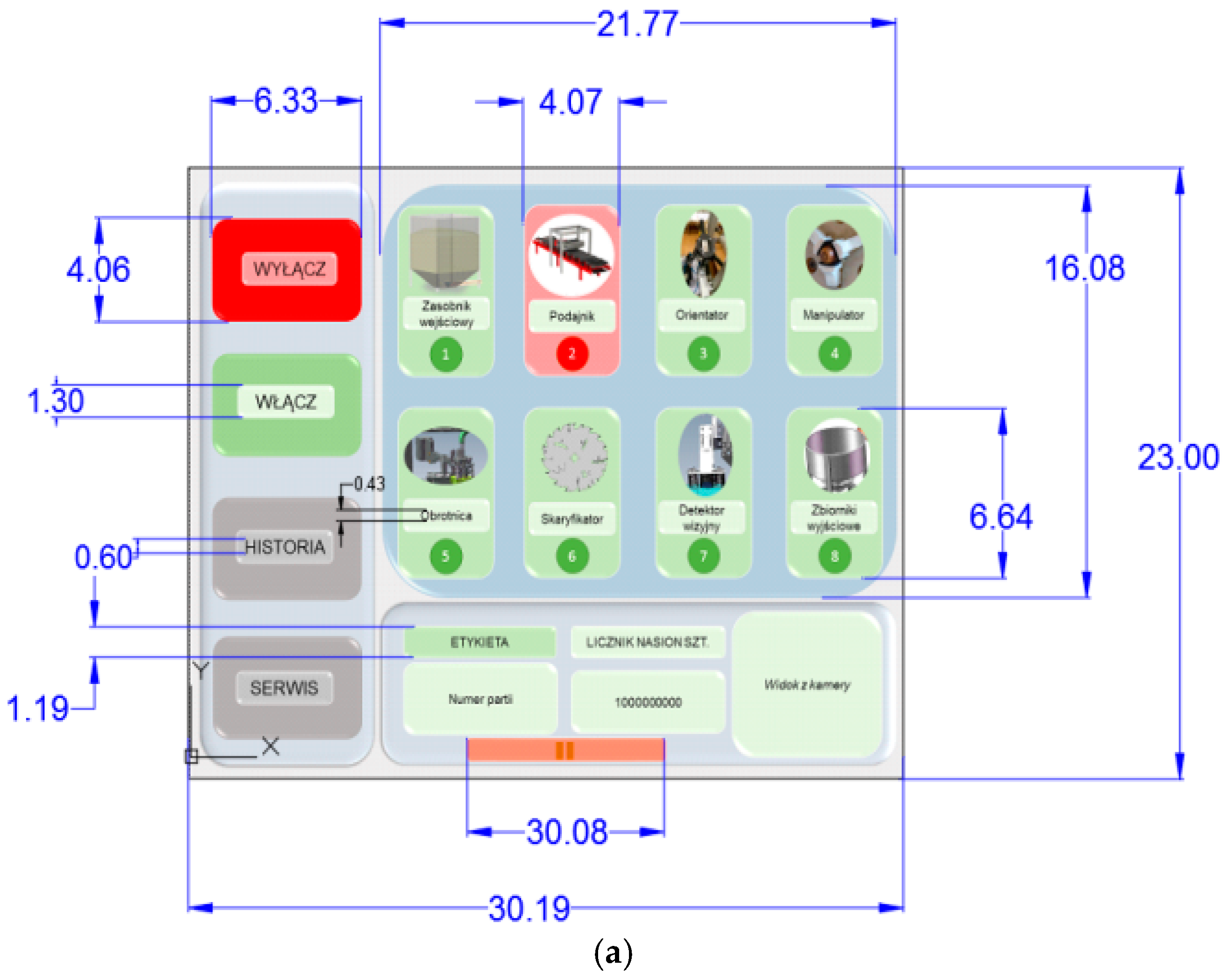

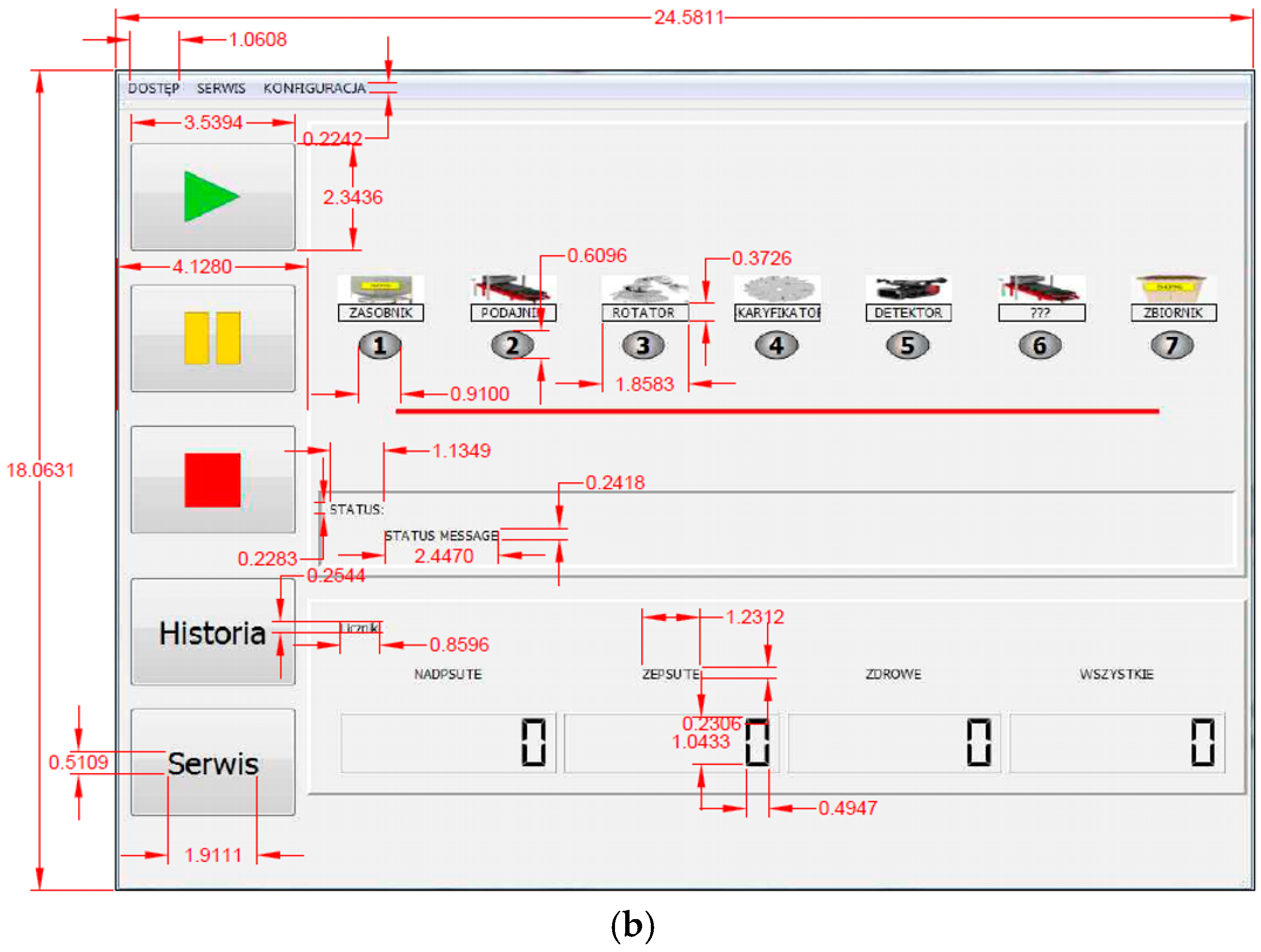

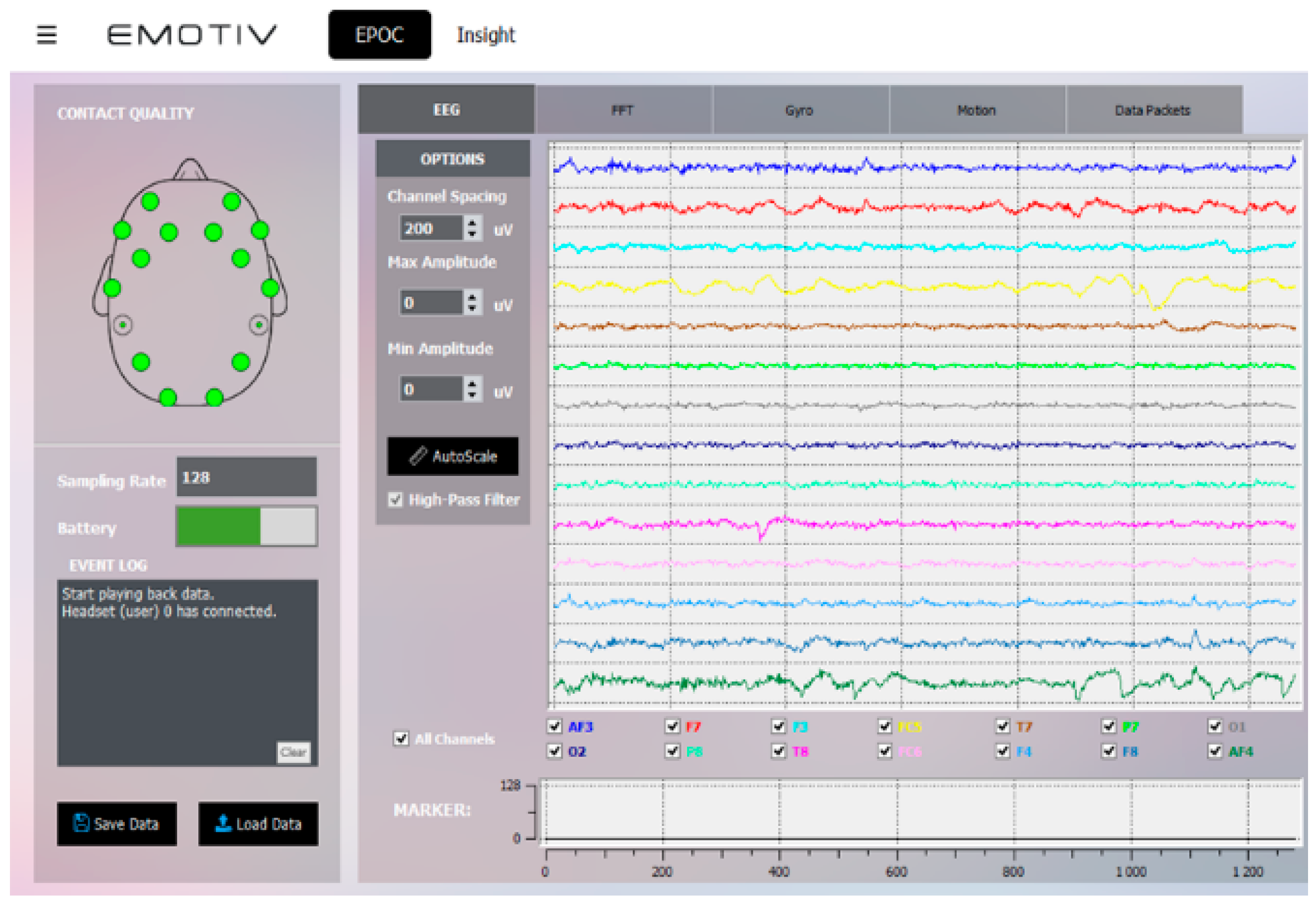

2. Materials and Methods

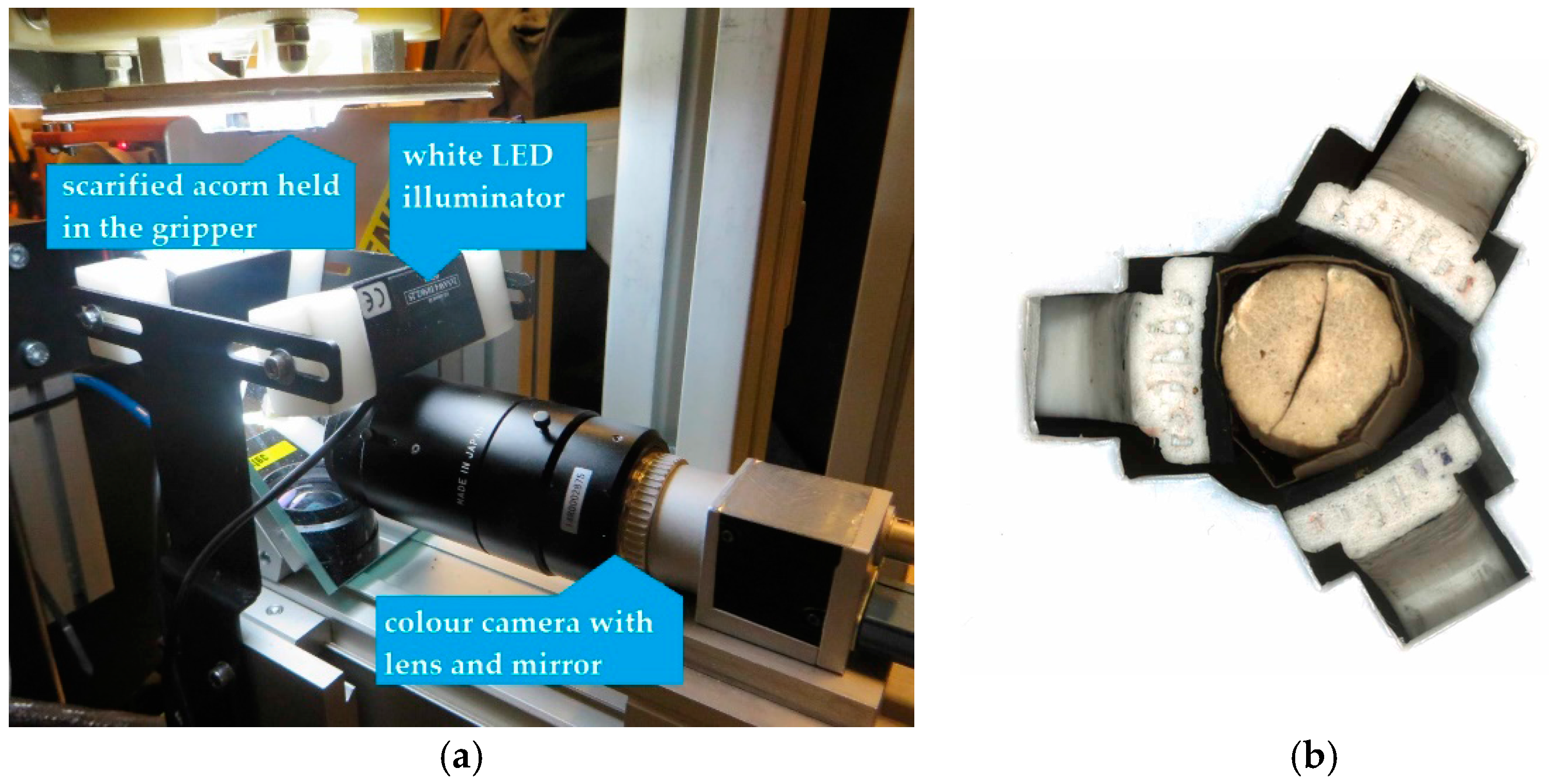

2.1. Vision-Based Separation of Acorns

2.2. Measures of the Effectiveness of Seed Health Assessment

2.3. Methods of Ergonomic Assessment of the User Interface

3. Results

- Gray—averaged gray levels determined according to the formula:Gray = 0.299R + 0.587G + 0.114B,

- R—averaged red component of section pixels,

- G—averaged green component of section pixels,

- B—averaged blue component of section pixels,

- H—averaged shade of section pixels,

- S—averaged saturation of section pixels,

- V—average brightness of section pixels,

- ExR—averaged red index,

- ExG—averaged green index.

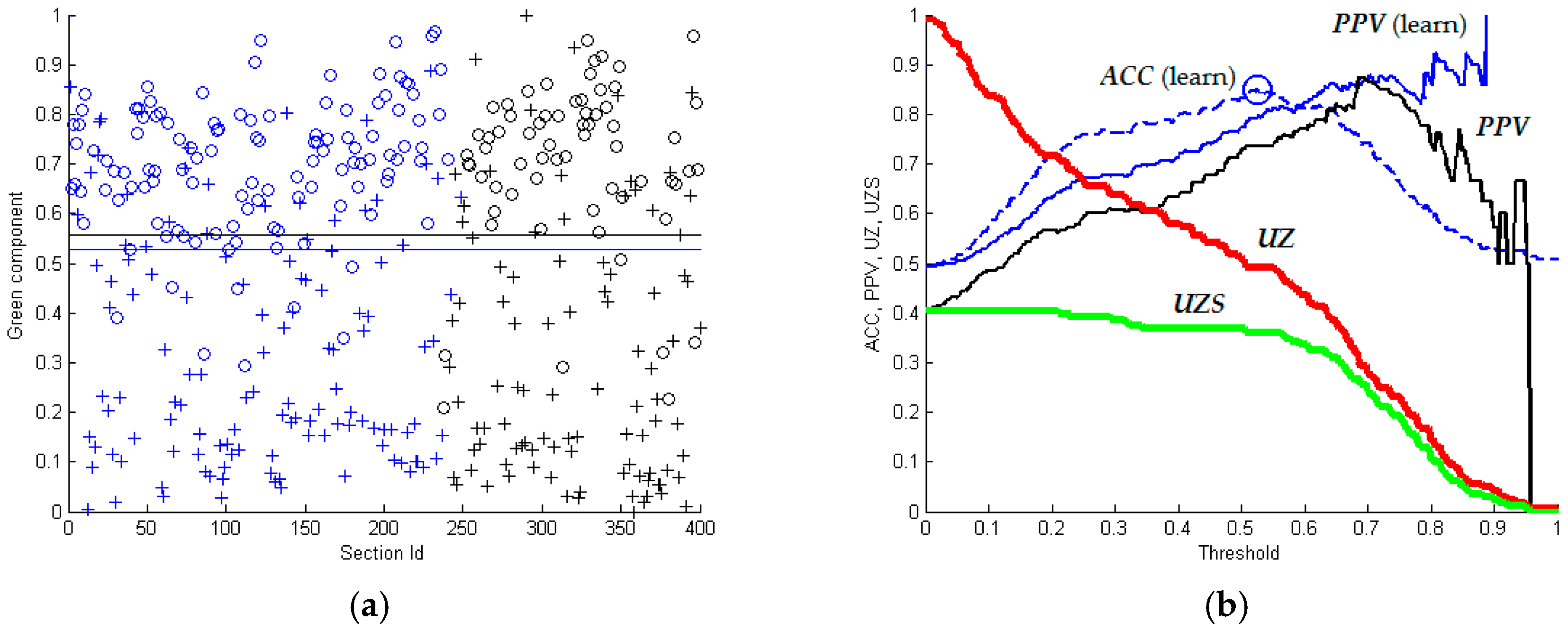

3.1. Evaluation of Selected Features for Separation of Acorns

3.2. Assessment of the Usefulness of Automatic Recognition

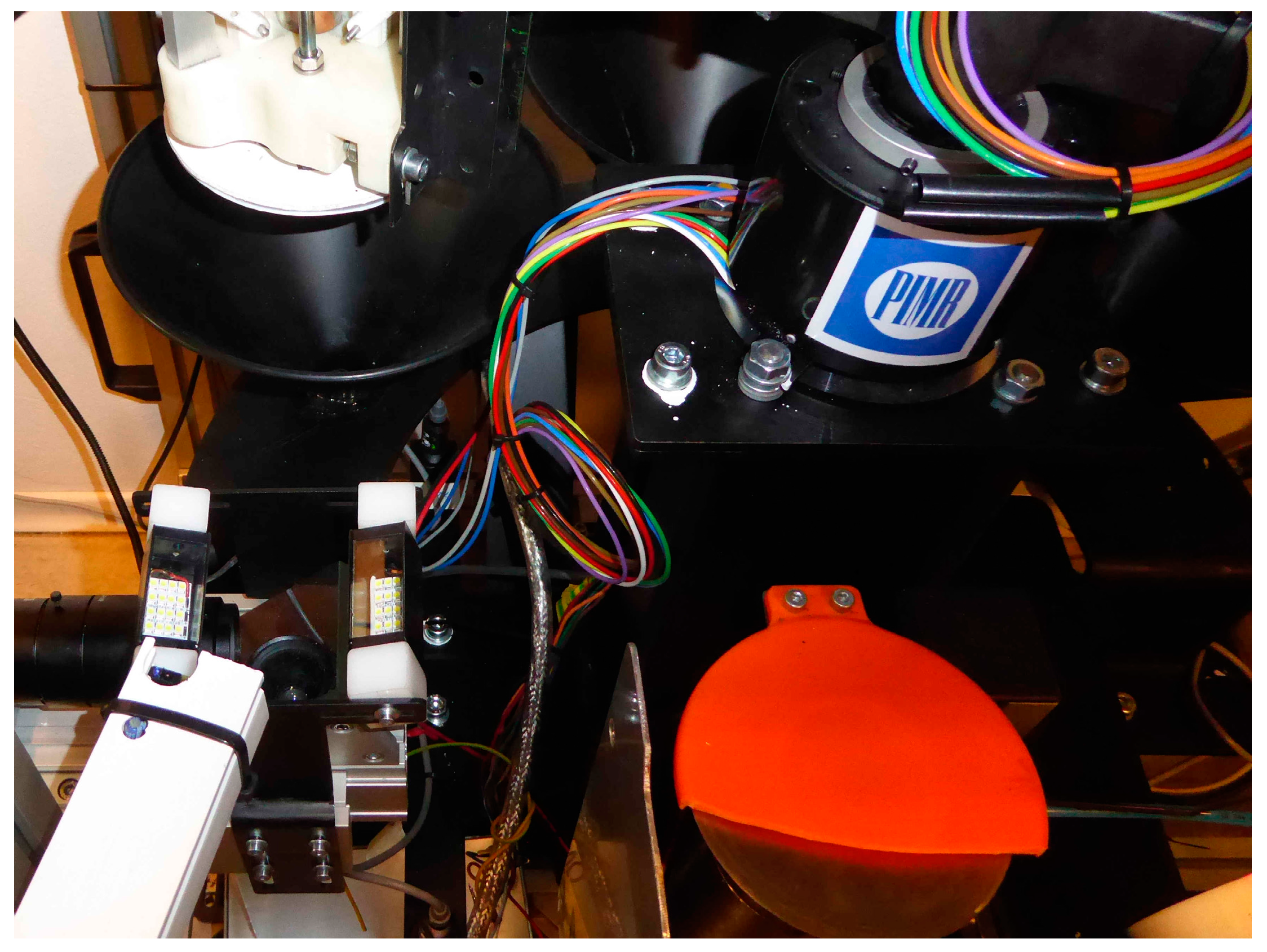

3.3. Implementation of the Acorn Separation Unit

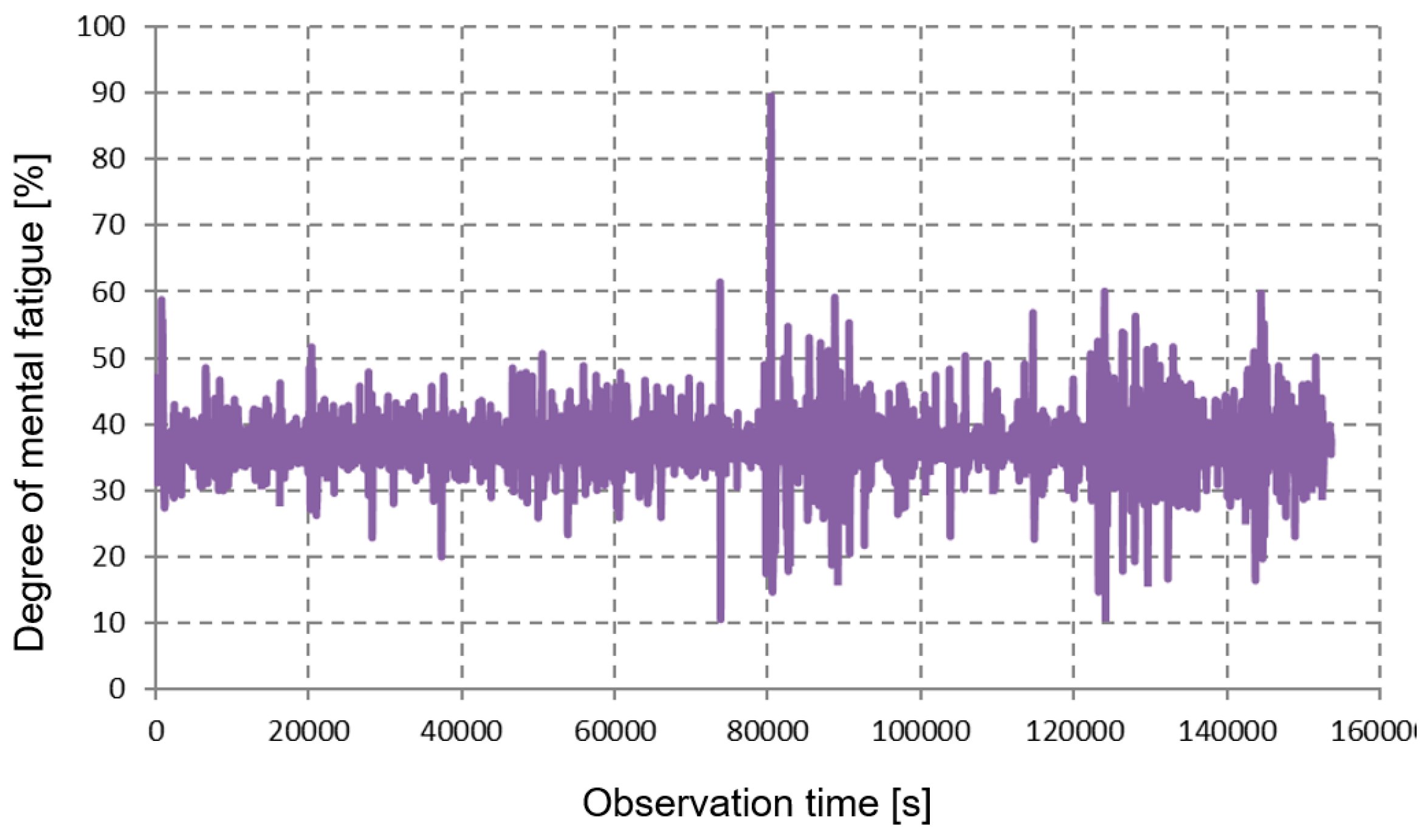

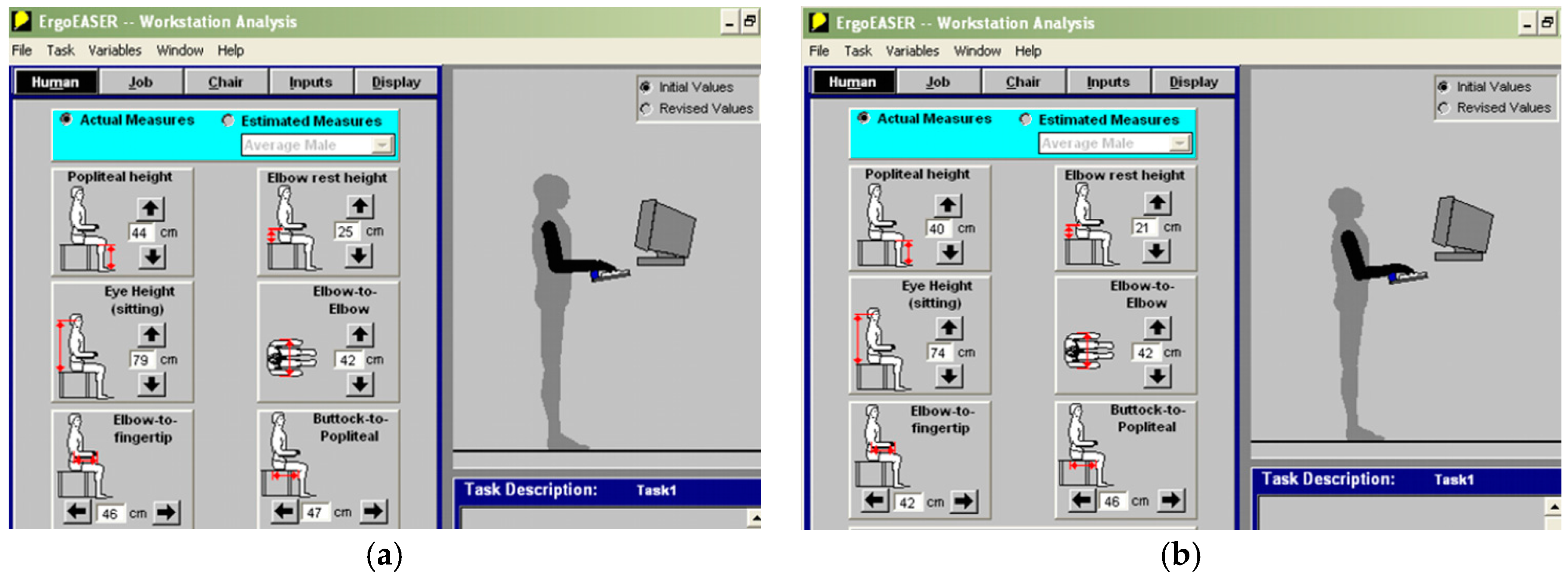

3.4. Ergonomic Assessment of the User Interface

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Andrzejczyk, T. Dąb Szypułkowy i Bezszypułkowy: Hodowla; Powszechne Wydawnictwo Rolnicze i Leśne (PWRiL): Warszawa, Poland, 2009; p. 328. ISBN 978-83-09-99017-8. [Google Scholar]

- Rodriguez-Campos, A.; Diaz-Maroto, I.J.; Barcala-Perez, E.; Vila-Lameiro, P. Comparison of the autoecology of Quercus robur L. and Q. petraea (Mattuschka) Liebl. Stands in the Northwest of the Iberian Peninsula. Ann. For. Res. 2010, 53, 7–25. [Google Scholar]

- Schröder, T.; Kehr, R.; Procházková, Z.; Sutherland, J.R. Practical methods for estimating the infection rate of Quercus robur acorn seedlots by Ciboria batschiana. For. Pathol. 2004, 3, 187–196. [Google Scholar] [CrossRef]

- Kühne, C.; Bartsch, N. Germination of acorns and development of oak seedlings (Quercus robur L.) following flooding. J. For. Sci. 2007, 53, 391–399. [Google Scholar]

- Madsen, P.; Lof, M. Reforestation in southern Scandinavia using direct seeding of oak (Quercus robur L.). Forestry 2005, 1, 55–64. [Google Scholar] [CrossRef]

- Khasa, D.P.; Fung, M.; Logan, B. Early growth response of container-grown selected woody boreal seedlings in amended composite tailings and tailings sand. Bioresour. Technol. 2005, 96, 857–864. [Google Scholar] [CrossRef] [PubMed]

- Kormanek, M.; Banach, J.; Sowa, P. Effect of soil bulk density on forest tree seedlings. Int. Agrophys. 2015, 29, 67–74. [Google Scholar] [CrossRef]

- Banach, J.; Skrzyszewska, K.; Świeboda, Ł. Substrate influences the height of one- and two-year-old seedlings of silver fir and European beech growing in polystyrene containers. Leśn. Pr. Badaw. 2013, 74, 117–125. (In Polish) [Google Scholar] [CrossRef]

- Szabla, K.; Pabian, R. New Technologies and Techniques in the Container Nursery System; Centrum Informacyjne Lasów Państwowych (CILP): Warszawa, Poland, 2003; ISBN 8389-7448-05. (In Polish) [Google Scholar]

- Walczyk, J.; Tylek, P. Mechanizacja zabiegu sterowanej mikoryzacji sadzonek drzew leśnych i siewu punktowego. Sylwan 2009, 3, 197–202. [Google Scholar]

- Tylkowski, T.; Bujarska-Borkowska, B. Effect of acorn size and sowing depth on Quercus robur and Q. petraea seedling emergence and height. Sylwan 2011, 3, 159–170. (In Polish) [Google Scholar]

- Barzdajn, W. Wykorzystanie zmienności dębów w hodowli lasu. In Elementy Genetyki i Hodowli Selekcyjnej Drzew Leśnych, 1st ed.; Sabor, J., Ed.; Centrum Informacyjne Lasów Państwowych (CILP): Warszawa, Poland, 2006; pp. 231–240. ISBN 83-88478-21-4. [Google Scholar]

- Tylek, P. Wielkość i kształt jako cechy rozdzielcze nasion dębu szypułkowego (Quercus robur L.). Acta Agrophys. 2012, 19, 673–687. [Google Scholar]

- Kuc, T.; Aleksandrowicz-Trzcińska, M. Sterowana mikoryzacja i doglebowa aplikacja fungicydów w hodowli dębu szypułkowego. I. Kolonizacja mikoryzowa i wzrost sadzonek z zakrytym systemem korzeniowym w szkółce. Sylwan 2012, 10, 765–775. [Google Scholar]

- Szabla, K. Hodowlane i ekonomiczne aspekty produkcji materiału sadzeniowego z zakrytym systemem korzeniowym poddanego zabiegowi sterowanej mikoryzacji. Sylwan 2009, 153, 253–259. [Google Scholar]

- Kantorowicz, W. Half century of seed years in major tree species in Poland. Silvae Genet. 2000, 49, 245–249. [Google Scholar]

- Suszka, B.; Muller, C.; Bonnet-Masimbert, M. The Seeds of Deciduous Forest Trees from Their Harvesting to Sowing; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2000; ISBN 83011-33430. (In Polish) [Google Scholar]

- Kaliniewicz, Z.; Markowski, P.; Anders, A.; Tylek, P.; Krzysia, Z.; Fura, S. Wpływ wieku drzewostanu macierzystego na wybrane cechy fizyczne nasion świerka pospolitego. Sylwan 2017, 161, 548–557. [Google Scholar]

- Kaliniewicz, Z.; Tylek, P.; Markowski, P.; Anders, A.; Rawa, T.; Jóźwiak, K.; Fura, S. Correlations between the Germination Capacity and Selected Physical Properties of Scots Pine (Pinus sylvestris L.). Balt. For. 2013, 19, 201–211. [Google Scholar]

- Walczyk, J. Mechanizacja prac leśnych w ochronie bioróżnorodności. In Elementy Genetyki i Hodowli Selekcyjnej Drzew Leśnych; Sabor, J., Ed.; Centrum Informacyjne Lasów Państwowych (CILP): Warszawa, Poland, 2006; pp. 473–483. ISBN 83-88478-21-4. [Google Scholar]

- Kaliniewicz, Z.; Tylek, P.; Anders, A.; Markowski, P.; Rawa, T.; Oldakowski, M.; Wasowski, L. An Analysis of the Physical Properties of Seeds of Selected Deciduous Tree Species. Balt. For. 2016, 22, 169–174. [Google Scholar]

- Szumowski, B. Nowe technologie i techniki stosowane w Leśnym Banku Genów Kostrzyca. Postęp. Tech. Leśn. 2002, 82, 34–42. [Google Scholar]

- Tylek, P.; Kaliniewicz, Z.; Kiełbasa, P.; Zagrobelny, T. Mass and density as separation criteria of pedunculate oak (Quercus robur L.) seeds. Electron. J. Pol. Agric. Univ. Ser. For. 2015, 18. Available online: http://www.ejpau.media.pl/volume18/issue4/art-05.html (accessed on 17 December 2017).

- Bąk-Badowska, J.; Żeber-Dzikowska, I.; Chmielewski, J. Evaluation of the degree of healthiness of the pedunculate oak (Quercus robur L.) acorns in the Włoszczowa-Jędrzejów Nature Park and its neighbouring area. Ochr. Srodowiska Zasobów Nat. 2017, 28, 14–19. [Google Scholar] [CrossRef]

- Knudsen, I.M.B.; Thomsen, K.A.; Jensen, B.; Poulsen, K.M. Effect of hot water treatment, biocontrol agents, disinfectants and a fungicide on storability of English oak acorns and control of the pathogen, Ciboria batschiana. For. Pathol. 2004, 1, 47–64. [Google Scholar] [CrossRef]

- Adamczyk, F.; Tylek, P.; Szczepaniak, J.; Szaroleta, M.; Walczyk, J.; Juliszewski, T.; Kiełbasa, P.; Tadeusiewicz, R.; Jabłoński, M.; Piłat, A. Automatyzacja skaryfikacji żołędzi jako metoda uszlachetniania materiału siewnego. In Wybrane Zagadnienia Ekologiczne we Współczesnym Rolnictwie. Monografia t. 10; Zbytek, Z., Ed.; Przemysłowy Instytut Maszyn Rolniczych: Poznań, Poland, 2017; pp. 75–84. ISBN 978-83-940788-8-1. [Google Scholar]

- Granitto, P.; Navone, H.; Verdes, P.; Ceccatto, H. Weed seeds identification by machine vision. Comput. Electron. Agric. 2002, 33, 91–103. [Google Scholar] [CrossRef]

- Giertych, M.J.; Suszka, J. Consequences of cutting off distal ends of cotyledons of Quercus robur acorns before sowing. Ann. For. Sci. 2011, 68, 433–442. [Google Scholar] [CrossRef]

- Jabłoński, M.; Tylek, P.; Walczyk, J.; Tadeusiewicz, R.; Piłat, A. Colour-based binary discrimination of scarified quercus robur acorns under varying illumination. Sensors 2016, 16, 1319. [Google Scholar] [CrossRef] [PubMed]

- Juliszewski, T.; Kiełbasa, P. Urządzenia Sygnalizacyjne Ciągników i Maszyn Rolniczych; Powszechne Wydawnictwo Rolnicze i Leśne (PWRiL): Poznań, Poland, 2010; ISBN 978-83-09-99034-5. [Google Scholar]

- Przybyło, J.; Kańtoch, E.; Jabłoński, M.; Augustyniak, P. Distant. Metrol. Meas. Syst. 2016, 23, 579–592. [Google Scholar]

- Złowodzki, M.; Juliszewski, T. Ergonomia Wobec Obciążeń measurement of plethysmographic signal in various lighting conditions using configurable frame-rate camera Praca Umysłową. In Obciążenie Psychiczne Pracą-Nowe Wyzwania Dla Ergonomii; Komitet Ergonomii PAN: Kraków, Poland, 2011; pp. 7–20. ISBN 978-83-61236-14-6. [Google Scholar]

- Grandjean, E. Physiologische Arbeitsgestaltung. Zeitschrift für Präventivmedizin 1958, 3, 253–260. [Google Scholar] [CrossRef]

- Tadeusiewicz, R.; Chaki, R.; Chaki, N. Exploring Neural Networks with C#; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2014; ISBN 978-1-4822-3339-1. [Google Scholar]

- Hagerer, P.; Köbsell, H. Erste systemergonomische Untersuchungen einer Arbeitsgestaltung beim Mähdrescher. Grundl. Landtech. 1986, 36, 87–93. [Google Scholar]

- Przybyło, J.; Jabłoński, M.; Pociecha, D.; Tadeusiewicz, R.; Piłat, A.; Walczyk, J.; Kiełbasa, P.; Szczepaniak, J.; Adamczyk, F. Application of model-based design in algorithms’ prototyping for experimental acorn scarification rig. J. Res. Appl. Agric. Eng. 2017, 62, 166–170. [Google Scholar]

- Jabłoński, M.P.; Tadeusiewicz, R. Vision-based detection of events using line-scan camera. In Proceedings of the 2016 Second International Conference on Event-based Control, Communication, and Signal Processing (EBCCSP), Krakow, Poland, 13–15 June 2016; pp. 1–3. [Google Scholar]

- Mangus, D.L.; Sharda, A.; Flippo, D.; Strasser, R.; Griffin, T. Development of high-speed camera hardware and software package to evaluate real-time electric seed meter accuracy of a variable rate planter. Comput. Electron. Agric. 2017, 142, 314–325. [Google Scholar] [CrossRef]

- Durand-Petiteville, A.; Vougioukas, S.; Slaughter, D.C. Real-time segmentation of strawberry flesh and calyx from images of singulated strawberries during postharvest processing. Comput. Electron. Agric. 2017, 142, 298–313. [Google Scholar] [CrossRef]

- Reyes, J.F.; Correa, C.; Zúñiga, J. Reliability of different color spaces to estimate nitrogen SPAD values in maize. Comput. Electron. Agric. 2017, 143, 14–22. [Google Scholar] [CrossRef]

- Tadeusiewicz, R.; Tylek, P.; Adamczyk, A.; Kiełbasa, P.; Jabłoński, M.; Pawlik, P.; Piłat, P.; Walczyk, J.; Szczepaniak, J.; Juliszewski, T.; et al. Automation of the acorn scarification process as a contribution to sustainable forest management. Case study: Common oak. Sustainability 2017, 9, 2276. [Google Scholar] [CrossRef]

- Smirnakou, S.; Ouzounis, T.; Radoglou, K.M. Continuous spectrum LEDs promote seedling quality traits and performance of quercus ithaburensis var. macrolepis. Front. Plant Sci. 2017, 8, 188. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization. Ergonomics of Human-System Interaction—Part 210: Human-Centred Design for Interactive Systems; ISO 9241-210:2010; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- International Organization for Standardization. Tractors and Machinery for Agriculture and Forestry—Serial Control and Communications Data Network—Part 6: Virtual Terminal; ISO 11783-6:2004; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- Załęski, A.; Aniśko, E.; Kantorowicz, W. Zasady oceny nasion w Lasach Państwowych. In Elementy genetyki i Hodowli Selekcyjnej Drzew Leśnych; Sabor, J., Ed.; Centrum Informacyjne Lasów Państwowych (CILP): Warszawa, Poland, 2006; pp. 317–326. ISBN 83-88478-21-4. [Google Scholar]

- Załęski, A. Zasady i Metodyka Oceny Nasion w Lasach Państwowych; Centrum Informacyjne Lasów Państwowych (CILP): Warszawa, Poland, 2000; ISBN 83-88478-14-1. [Google Scholar]

- Ch’ng, P.E.; Abdullah, M.H.R.O.; Mathai, E.J.; Yunu, N.A. Some physical properties of ginkgo nuts and kernels. Int. Agrophys. 2013, 27, 485–489. [Google Scholar] [CrossRef]

- Francisco, G.C.; Jordán, E.M.; Eustaquio, G.P. Influence of cotyledon removal on early seedling growth in Quercus robur L. Ann. For. Sci. 2003, 60, 69–73. [Google Scholar] [CrossRef]

- Hou, X.; Yi, X.; Yang, Y.; Liu, W. Acorn germination and seedling survival of Q. variabilis: Effects of cotyledon excision. Ann. For. Sci. 2010, 67, 711. [Google Scholar] [CrossRef]

- Liu, S.; Acosta-Gamboa, L.M.; Huang, X.; Lorence, A. Novel low cost 3d surface model reconstruction system for plant phenotyping. J. Imaging 2017, 3, 39. [Google Scholar] [CrossRef]

- Montagnoli, A.; Terzaghi, M.; Fulgaro, N.; Stoew, B.; Wipenmyr, J.; Ilver, D.; Rusu, C.; Scippa, G.S.; Chiatante, D. Non-destructive phenotypic analysis of early stage tree seedling growth using an automated stereovision imaging method. Front. Plant Sci. 2016, 7, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Grinblat, G.L.; Uzal, L.C.; Larese, M.G.; Granitto, P.M. Deep learning for plant identification using vein morphological patterns. Comput. Electron. Agric. 2016, 127, 418–424. [Google Scholar] [CrossRef]

- Ramcharan, A.; Baranowski, K.; McCloskey, P.; Ahamed, B.; Legg, J.; Hughes, D. Deep learning for image-based cassava disease detection. Front. Plant Sci. 2017, 8, 1852. [Google Scholar] [CrossRef] [PubMed]

- Gongal, A.; Amatya, S.; Karkee, M.; Zhang, Q.; Lewis, K. Sensors and systems for fruit detection and localization: A review. Comput. Electron. Agric. 2015, 116, 8–19. [Google Scholar] [CrossRef]

- Banyon, D.; Murray, D. Applying user modeling to human-computer interaction design. Artif. Intell. Rev. 1993, 7, 199–225. [Google Scholar] [CrossRef]

| Feature | Training Set | Feature | Test Set | ||||||

|---|---|---|---|---|---|---|---|---|---|

| ACC | PPV | UZ % | UZS % | ACC | PPV | UZ % | UZS % | ||

| Gray | 0.85 | 0.80 | 57 | 46 | Gray | 0.83 | 0.73 | 49 | 36 |

| R | 0.85 | 0.83 | 53 | 43 | R | 0.83 | 0.76 | 46 | 35 |

| G | 0.85 | 0.80 | 58 | 46 | G | 0.83 | 0.73 | 49 | 36 |

| B | 0.84 | 0.80 | 56 | 45 | B | 0.82 | 0.73 | 50 | 36 |

| H | 0.82 | 0.79 | 55 | 43 | H | 0.80 | 0.74 | 43 | 32 |

| S | 0.65 | 0.59 | 77 | 46 | S | 0.53 | 0.46 | 83 | 38 |

| V | 0.85 | 0.83 | 53 | 43 | V | 0.83 | 0.76 | 46 | 35 |

| ExR | 0.81 | 0.75 | 59 | 45 | ExR | 0.79 | 0.68 | 53 | 36 |

| ExG | 0.85 | 0.81 | 55 | 45 | ExG | 0.81 | 0.72 | 48 | 34 |

| Item No. | Interface Functionality Assessed | Assessment Result | |

|---|---|---|---|

| Positive | Negative | ||

| 1 | Visual clarity—the information displayed on the screen should be clear, well-organized, unambiguous, and legible | X | |

| 2 | Dialogue consistency—the system’s behavior and appearance should be consistent throughout its operation | X | |

| 3 | Conformity with expectations—the way it works should be consistent with the user’s habits and expectations | X | |

| 4 | Information confirmations—users should receive clear confirmations of what part of the system they are located in, what actions they had taken, whether the actions were successful, and what should be done next | X | |

| 5 | Transparency—the system and its structure should be transparent to the user | X | |

| 6 | System functionality—thanks to suitably matched functionality the system should meet the needs and requirements of the user while performing tasks | X | |

| 7 | Flexibility and control by the user—the system should be flexible in terms of structure, information presentation, and handling to meet the needs and requirements of different users and give them a sense of total control over the system | X | |

| 8 | The information displayed on the screen should be clear, well-organized, unambiguous, and legible; and the system should be designed so as to minimize the risk of user errors by using built-in mechanisms to detect and correct those errors that will occur. Users should be able to check the data entered, correct mistakes, or the information displayed on the screen should be clear, well-organized, unambiguous and legible | X | |

| 9 | User guide and support—the system should guide the user through the stages of the task and provide appropriate information support both on-line (from the system) and via printed documentation | X | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tadeusiewicz, R.; Tylek, P.; Adamczyk, F.; Kiełbasa, P.; Jabłoński, M.; Bubliński, Z.; Grabska-Chrząstowska, J.; Kaliniewicz, Z.; Walczyk, J.; Szczepaniak, J.; et al. Assessment of Selected Parameters of the Automatic Scarification Device as an Example of a Device for Sustainable Forest Management. Sustainability 2017, 9, 2370. https://doi.org/10.3390/su9122370

Tadeusiewicz R, Tylek P, Adamczyk F, Kiełbasa P, Jabłoński M, Bubliński Z, Grabska-Chrząstowska J, Kaliniewicz Z, Walczyk J, Szczepaniak J, et al. Assessment of Selected Parameters of the Automatic Scarification Device as an Example of a Device for Sustainable Forest Management. Sustainability. 2017; 9(12):2370. https://doi.org/10.3390/su9122370

Chicago/Turabian StyleTadeusiewicz, Ryszard, Paweł Tylek, Florian Adamczyk, Paweł Kiełbasa, Mirosław Jabłoński, Zbigniew Bubliński, Joanna Grabska-Chrząstowska, Zdzisław Kaliniewicz, Józef Walczyk, Jan Szczepaniak, and et al. 2017. "Assessment of Selected Parameters of the Automatic Scarification Device as an Example of a Device for Sustainable Forest Management" Sustainability 9, no. 12: 2370. https://doi.org/10.3390/su9122370

APA StyleTadeusiewicz, R., Tylek, P., Adamczyk, F., Kiełbasa, P., Jabłoński, M., Bubliński, Z., Grabska-Chrząstowska, J., Kaliniewicz, Z., Walczyk, J., Szczepaniak, J., Juliszewski, T., & Szaroleta, M. (2017). Assessment of Selected Parameters of the Automatic Scarification Device as an Example of a Device for Sustainable Forest Management. Sustainability, 9(12), 2370. https://doi.org/10.3390/su9122370