Improving the Bearing Strength of Sandy Loam Soil Compressed Earth Block Bricks Using Sugercane Bagasse Ash

Abstract

:1. Introduction

2. Materials and Methods

| Mineral | Percentage (%) |

|---|---|

| SiO2 | 73 |

| Al2O3 | 6.7 |

| Fe2O3 | 6.3 |

| CaO | 2.8 |

| MgO | 3.2 |

| P2O5 | 4.0 |

| Na2O | 1.1 |

| K2O | 2.4 |

| Loss of Ignition | 0.9 |

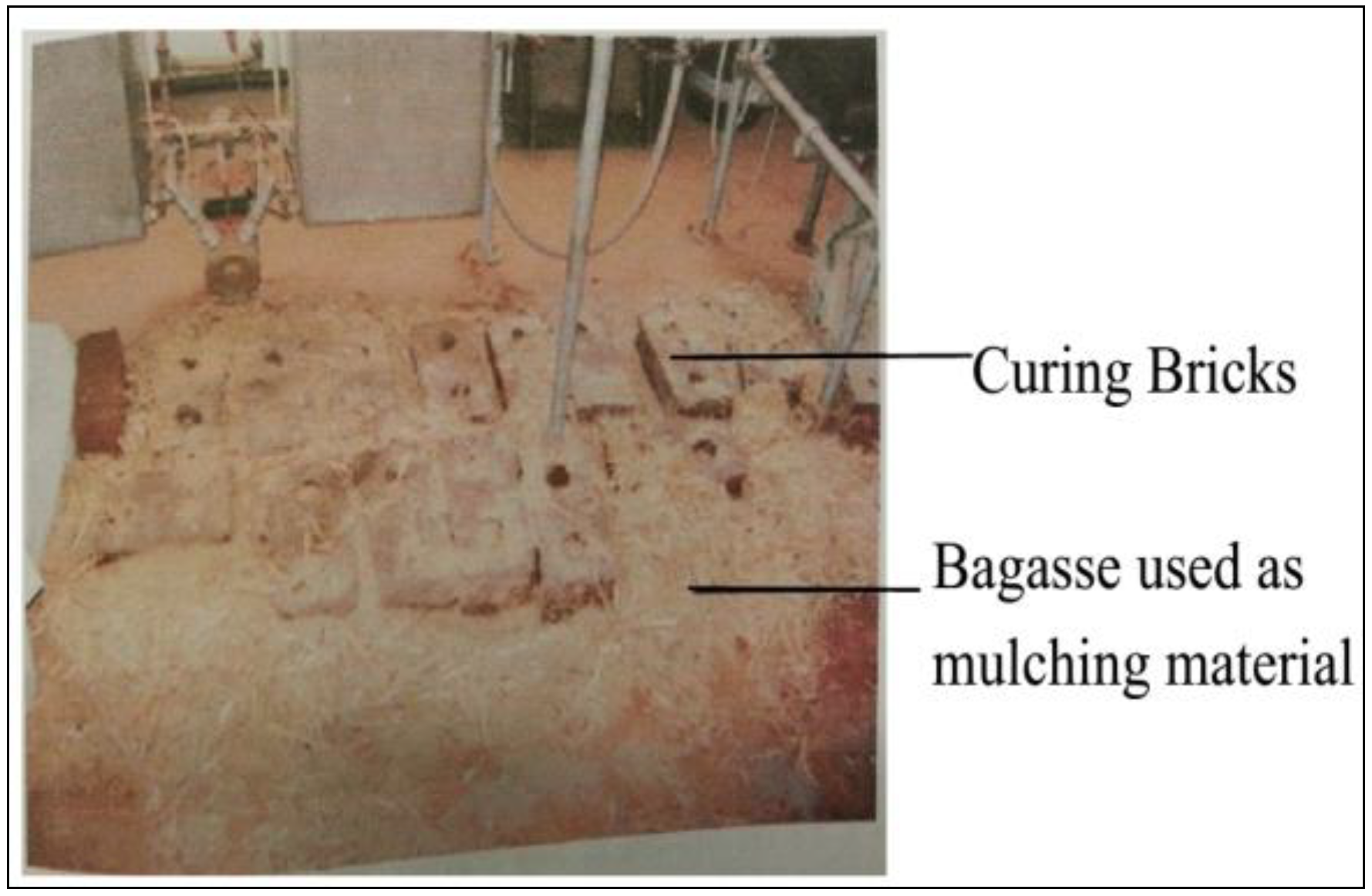

2.1. Mixture Proportion and Sample Preparation

| Sugar bagasse ash (%) | Soil | SCBA | Water |

|---|---|---|---|

| 0 | 6.0 | - | 2.04 |

| 3 | 6.0 | 0.18 | 2.04 |

| 5 | 6.0 | 0.3 | 2.04 |

| 8 | 6.0 | 0.48 | 2.04 |

| 10 | 6.0 | 0.6 | 2.04 |

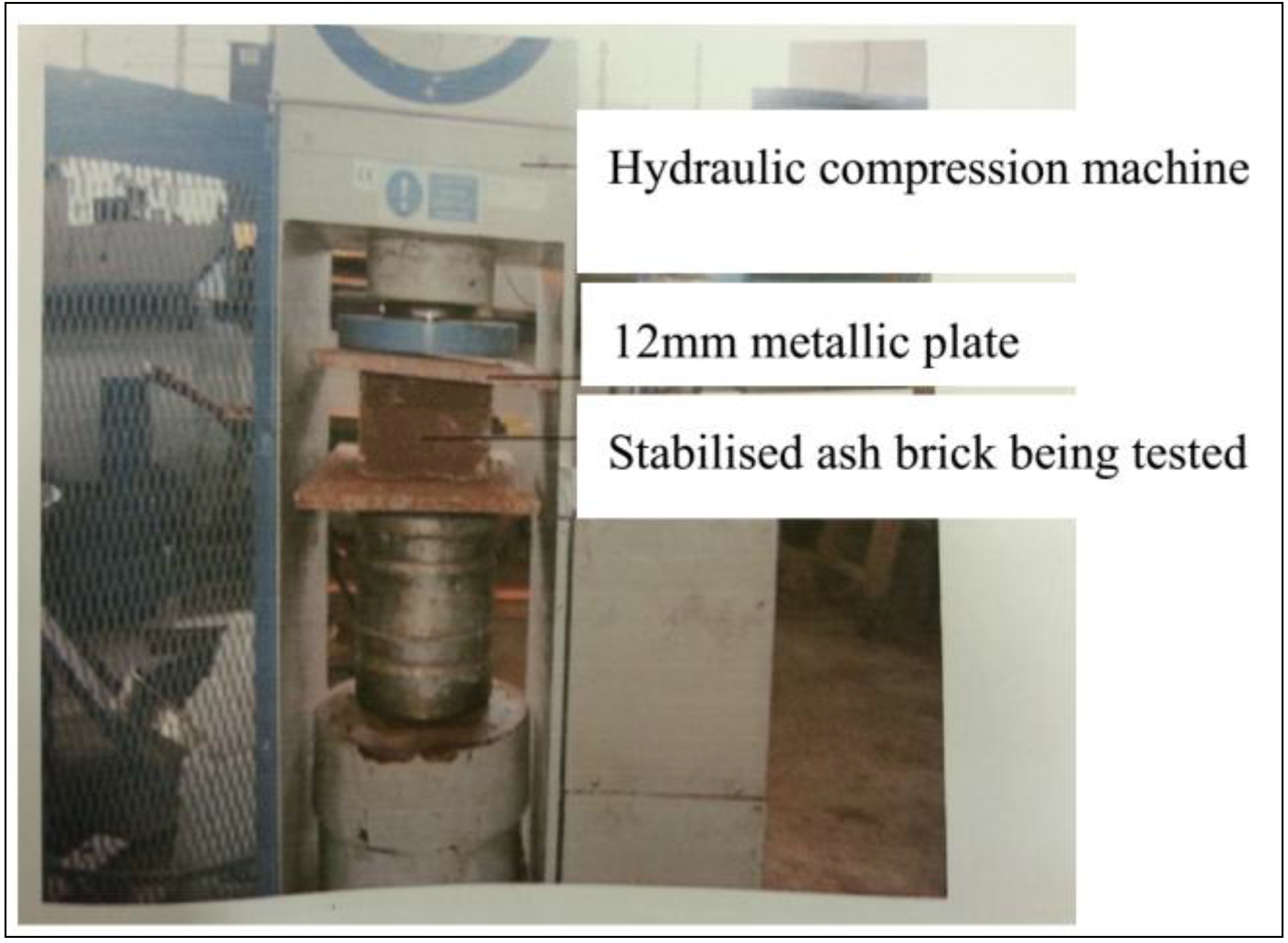

2.2. Compressive Strength Test

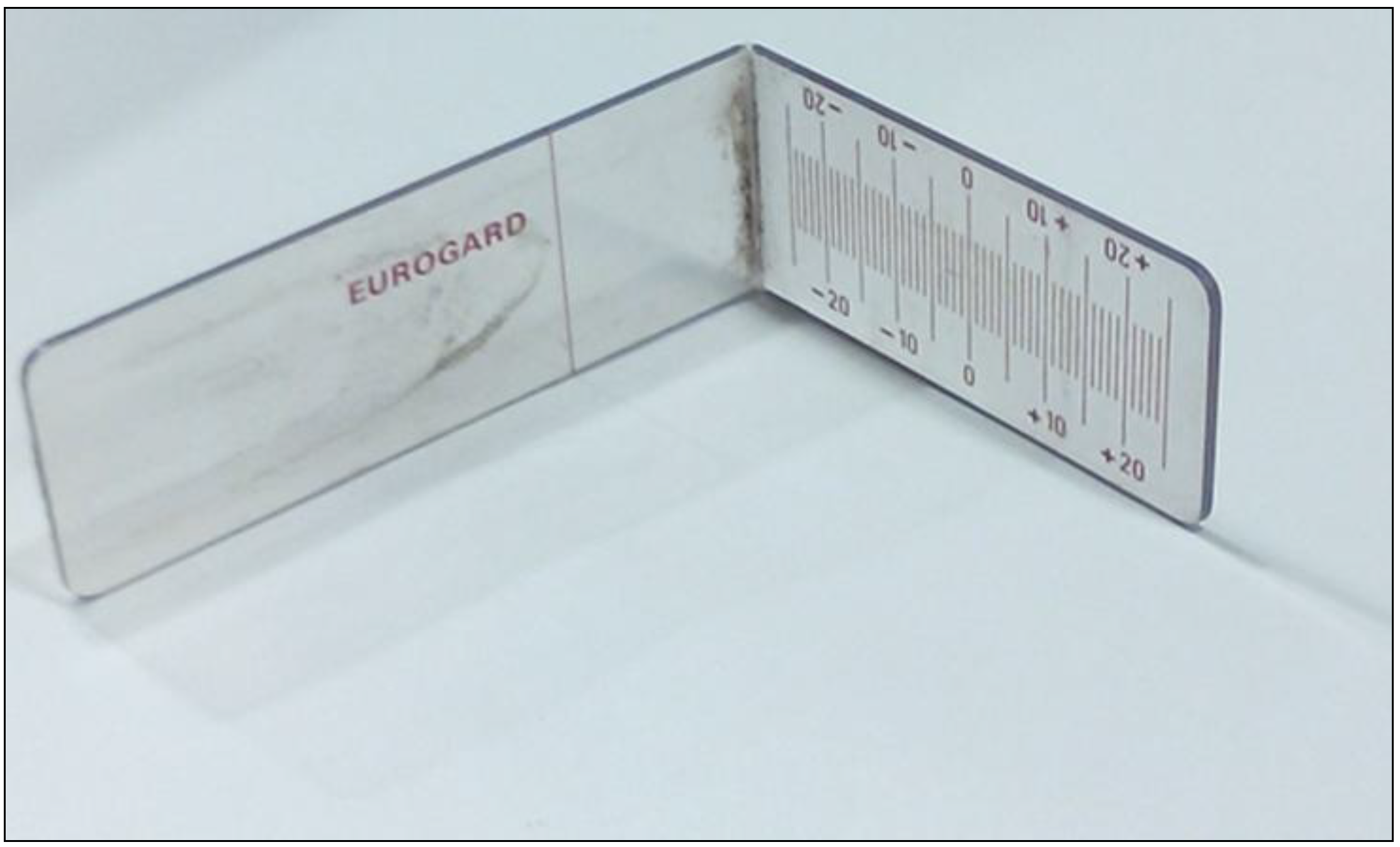

2.3. Shrinkage Cracks

3. Results and Discussions

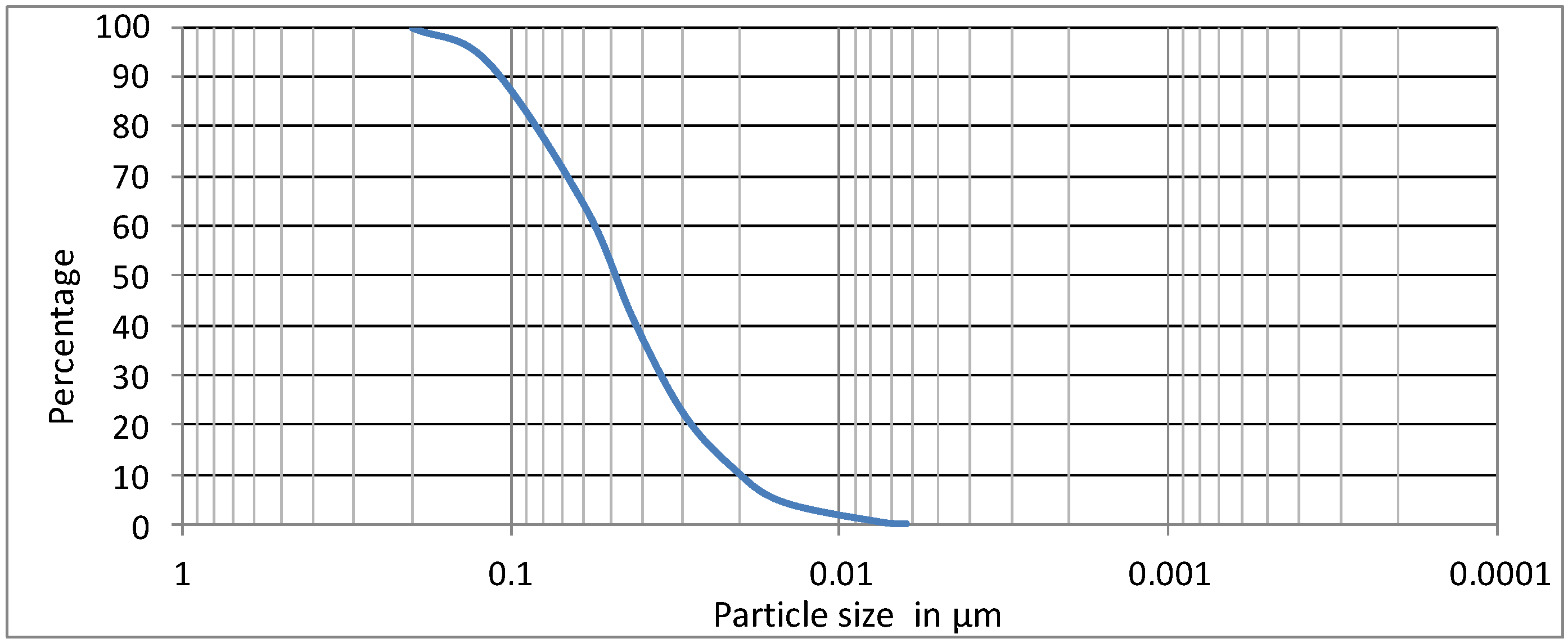

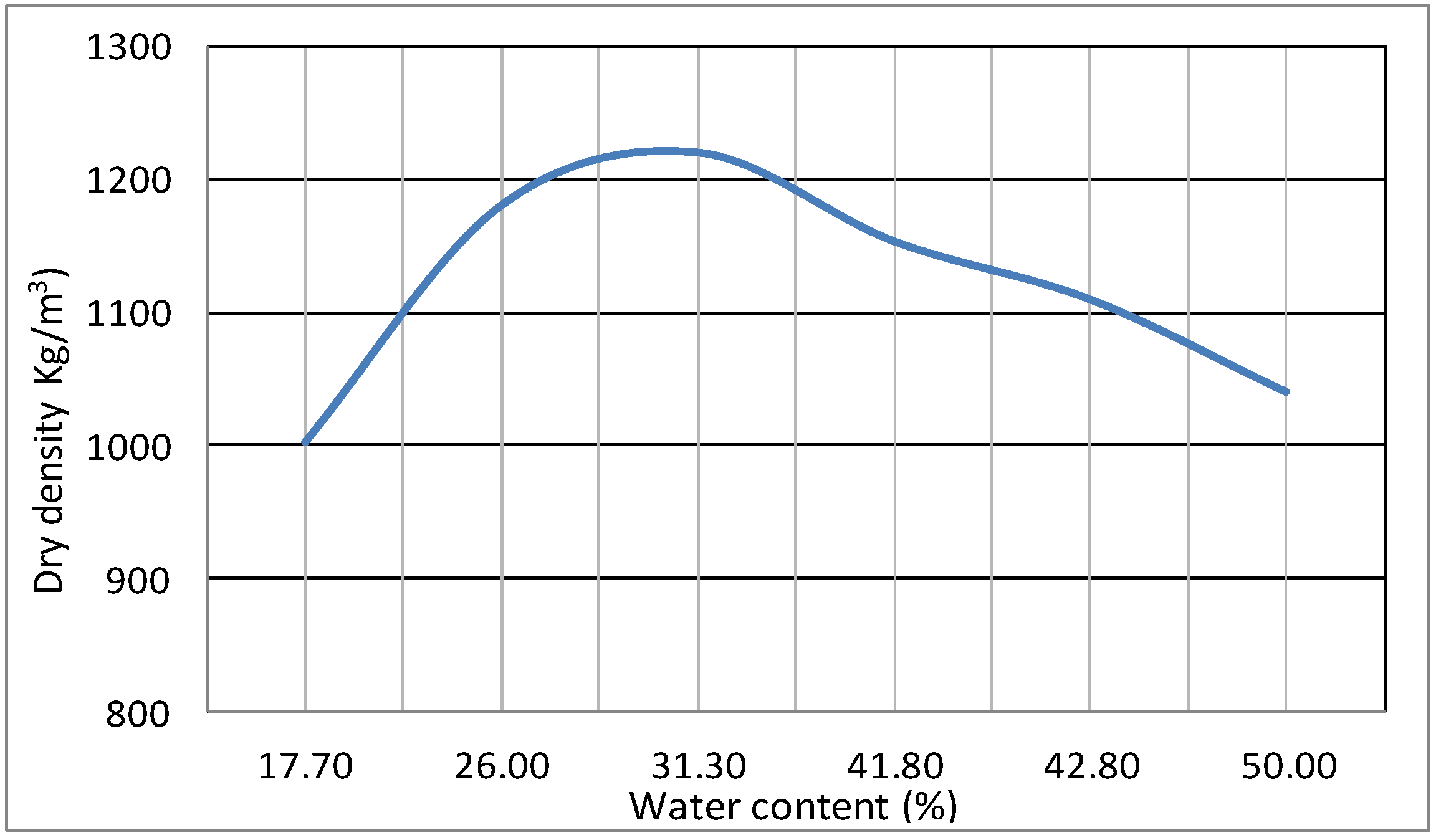

3.1. Soil Characteristics

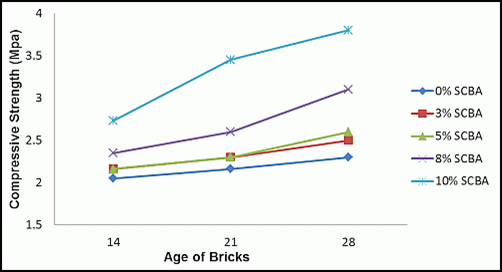

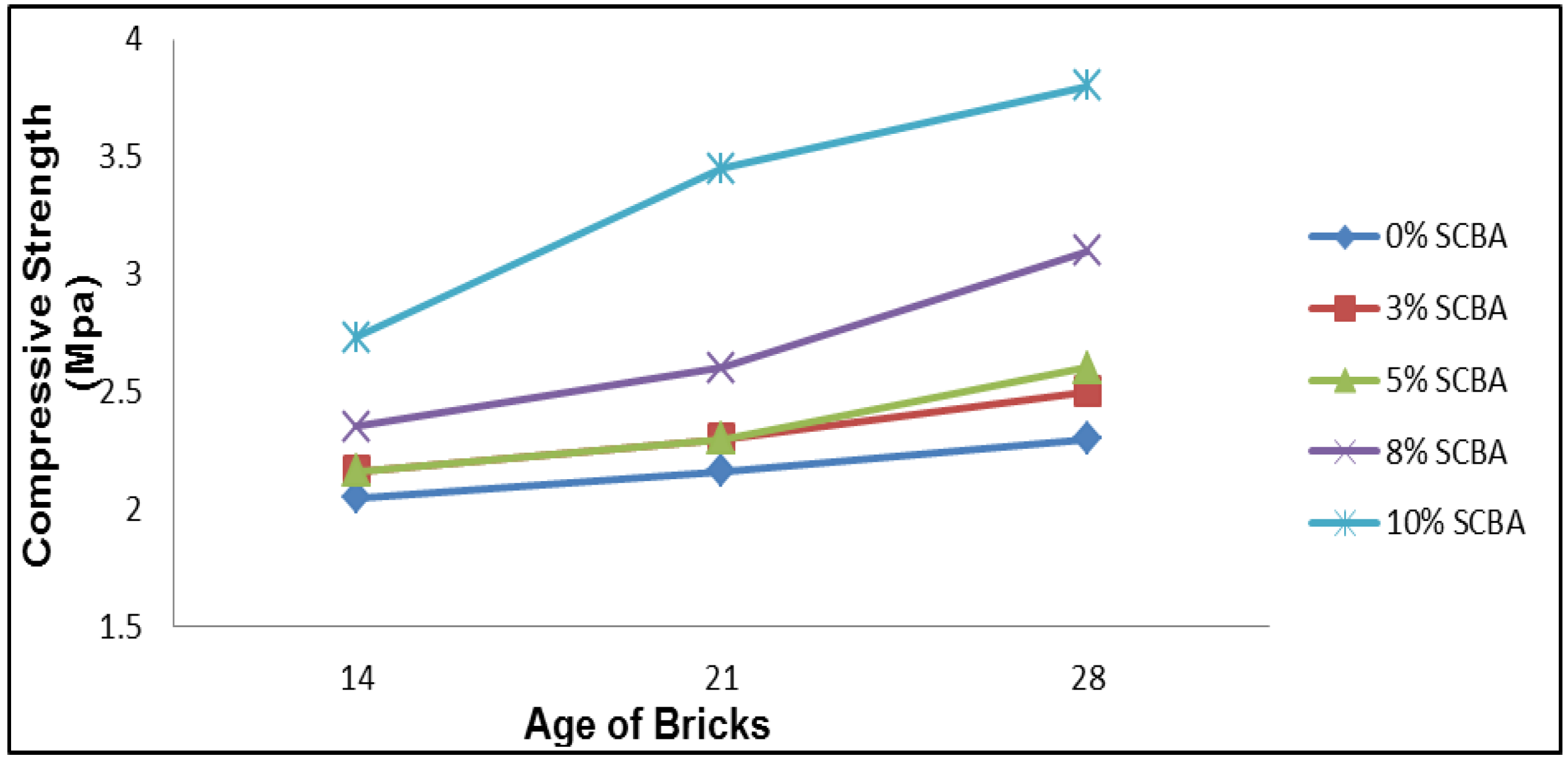

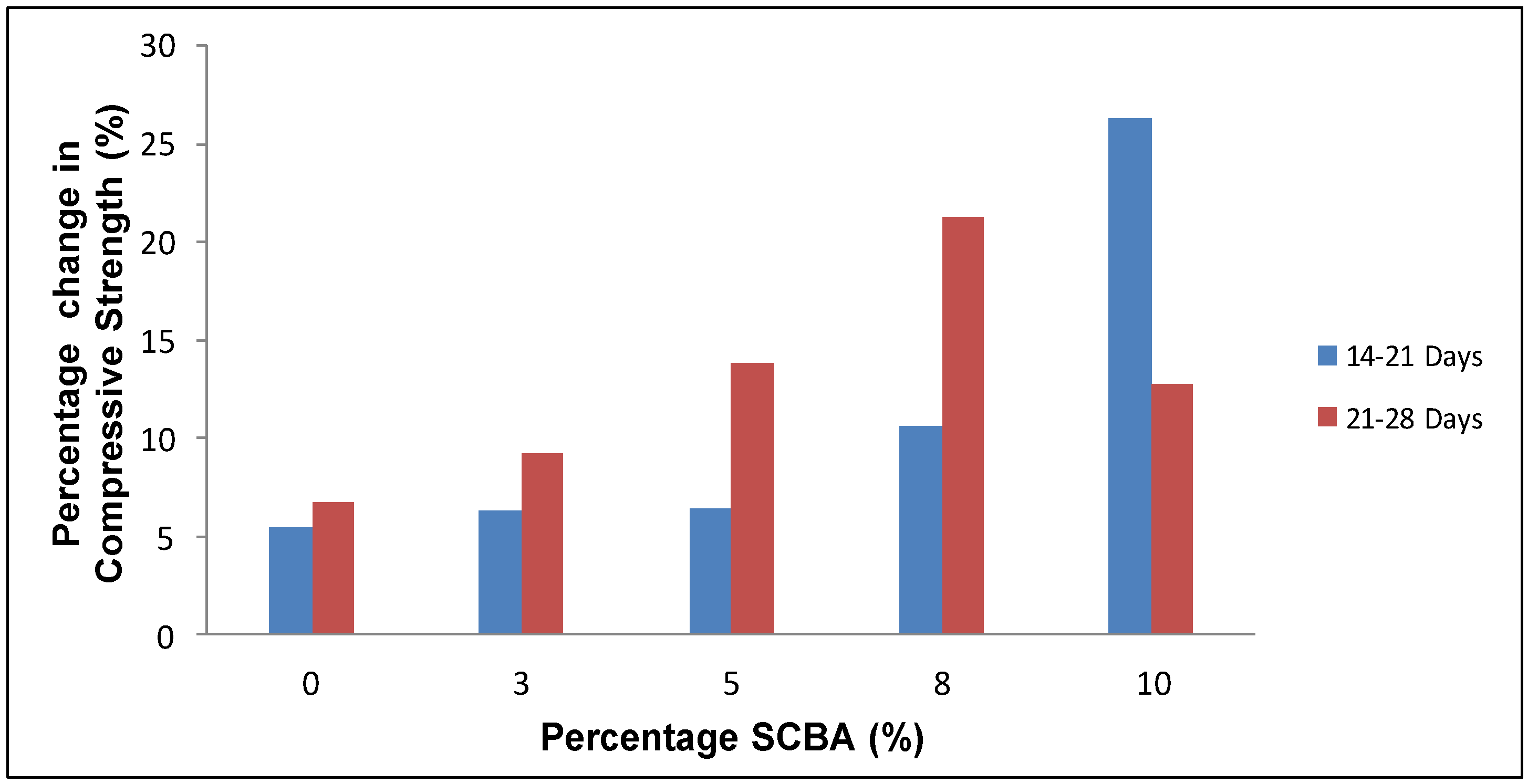

3.2. Compressive Strength

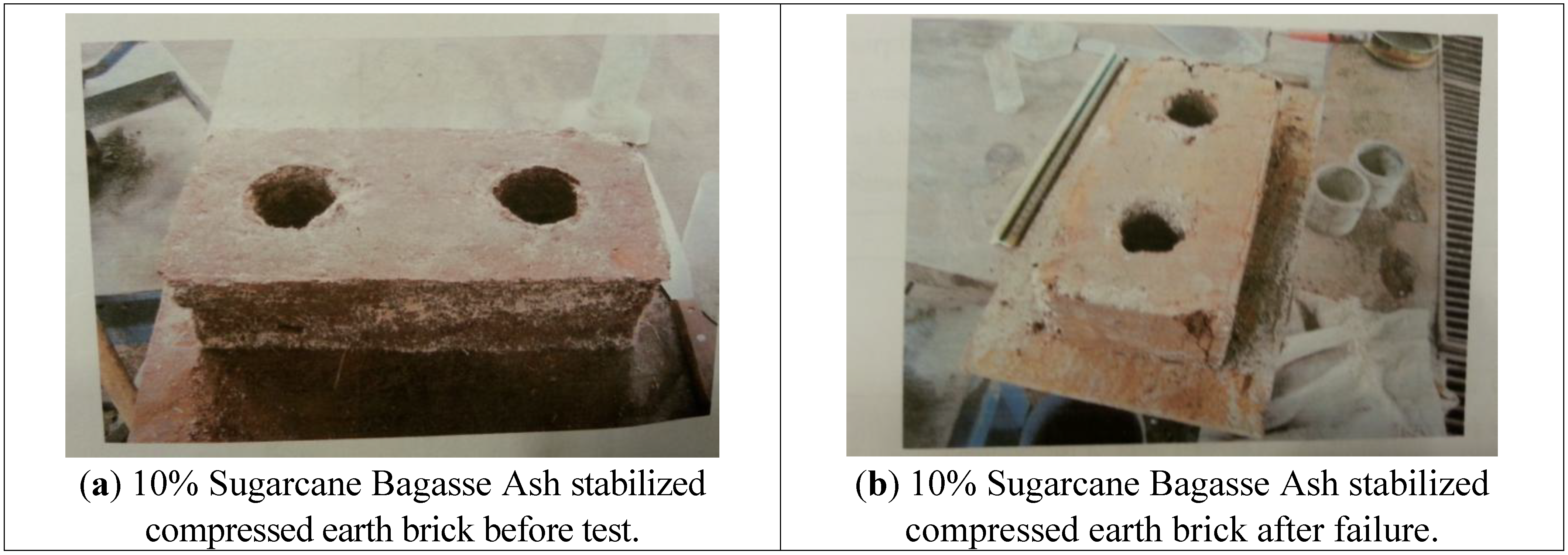

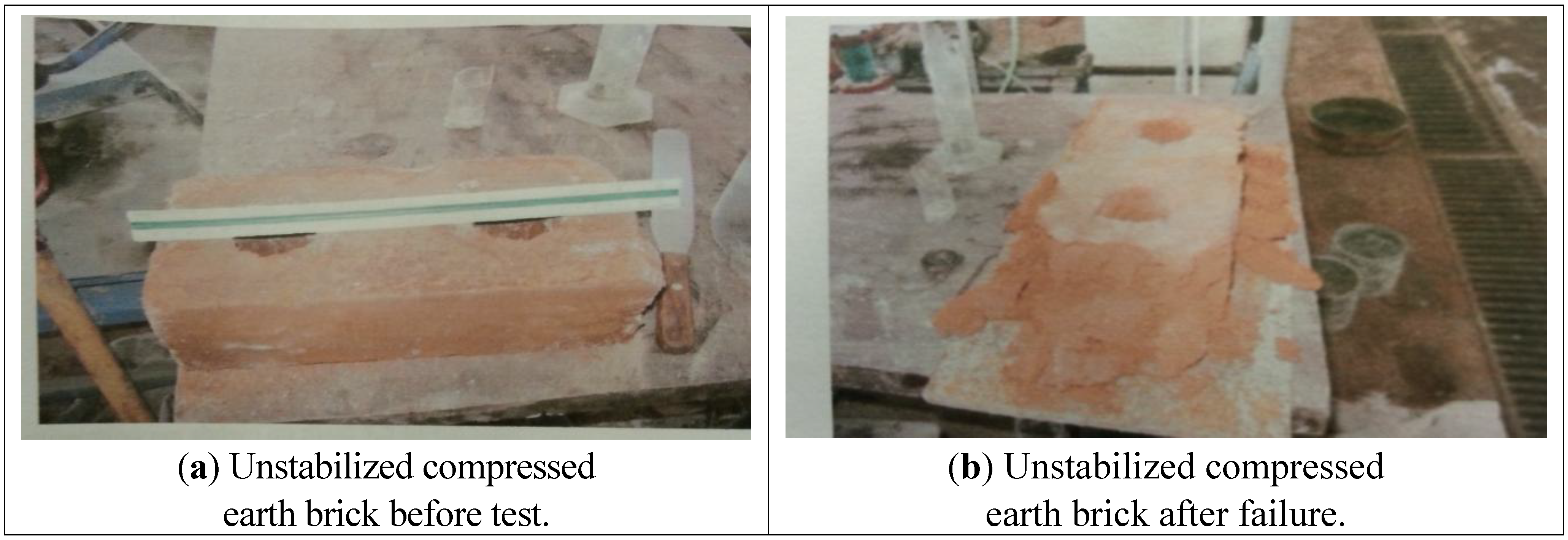

3.3. Failure Pattern

3.4. Shrinkage Cracks

| Sugarcane Bagasse Ash (%) | % Length of crack in direction parallel to cracks |

|---|---|

| 0 | 30 |

| 3 | 30 |

| 5 | 20 |

| 8 | 25 |

| 10 | 23 |

4. Conclusions

- The compressive strength of Sugarcane Bagasse Ash stabilized Compressed Earth Bricks increased with an increase in Sugarcane Bagasse Ash and was 65% higher than the control with the addition of 10 Sugarcane Bagasse Ash.

- The compressive strength of Sugarcane Bagasse Ash stabilized Compressed Earth Bricks increased with duration of curing. At 28 days, the control did not satisfy the requirement of KS02-1070 [21] while the 3%, 5%, 8% and 10% sugarcane bagasse stabilized Compressed Earth Bricks satisfied the minimum compressive strength requirement of the code.

- For the 10% Sugarcane Bagasse Ash stabilized compressed earth brick, the 14 to 21 day compressive strength growth rate was higher than the 21 to 28 day compressive strength growth rate, while for the control, 3%, 5% and 8% Sugarcane Bagasse Ash stabilized compressed earth brick the 21st to the 28th day compressive strength growth rate was higher than the 14 to 21 day growth rate.

- Stabilized soil bricks exhibited a similar failure pattern to concrete’s mode of failure while the unstabilized soil bricks in contrast disintegrated into smaller fragments.

- The stabilized and unstabilized Compressed Earth Bricks had crack width less than 0.3 mm. The control sample and the 3% stabilized compressed earth brick had higher crack length along the parallel block dimension than the 5% and 8% and 10% stabilized compressed earth brick.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shitote, S.M.; Nyomboi, T.; Muumbo, A.; Wanjala, R.S.; Khadambi, E.L.; Orowe, J.; Sakwa, F.; Apollo, A. A Pre-Cast Concrete Technology for Affordable Housing in Kenya. In Proceedings of the International conference on Advances in Engineering and Technology, Entebbe, Uganda, 16–19 July 2006; Mwakali, J.A., Taban-Wani, G., Eds.; Elsevier: Entebbe, Uganda, 2006; pp. 680–695. [Google Scholar]

- Wamukoya, M.B. An Investigation into the Suitability of Using Bagasse Ash in Stabilization of Soil Bricks; Moi University: Eldoret, Kenya, 2009. [Google Scholar]

- Rigassi, V.; CRATerre-EAG. Compressed Earth Bricks: Manual of Production; Deutsches Zentrum für Entwicklungstechnologien-GATE: Eschborn, Germany, 1985; Volume 1, pp. 1–143. [Google Scholar]

- Chan, C.-M.; Low, L.-P. Development of a Strength Prediction Model for “Green” Compressed Stabilised Earth bricks. J. Sustain. Dev. 2010, 3, 140–150. [Google Scholar]

- Caterpillar. Introduction to Soil Stabilization; Caterpillar: Peoria, IL, USA, 2006; pp. 1–23. [Google Scholar]

- United States Department of the Army. Army, Military Soils Engineering; United States Department of the Army: Washington, DC, USA, 1992; pp. 9.1–9.23. [Google Scholar]

- The Housing and Building Research Institute (HABRI). Stabilised Soil Blocks (SSBs): Manual Selection, Testing and Production of SSB; University of Nairobi, HABI: Nairobi, Kenya, 2003. [Google Scholar]

- Republic of Kenya. National Report on the Review and Appraisal of the Implementation of the Habitat Agenda and the National Plan of Action on Shelter and Human Settlements to the (Istanbul +5); UN-Habitat: Istanbul, Turkey, 2000; pp. 1–143. [Google Scholar]

- Faria, K.C.P.; Gurgel, R.F.; Holanda, J.N.F. Recycling of sugarcane bagasse ash waste in the production of clay bricks. J. Environ. Manag. 2012, 101, 7–12. [Google Scholar] [CrossRef]

- Onchieku, J.M.; Chikamai, B.N.; Rao, M.S. Optimum Parameters for the Formulation of Charcoal Briquettes Using Bagasse and Clay as Binder. Eur. J. Sustain. Dev. 2012, 1, 477–492. [Google Scholar]

- Tantawy, M.A.; EL-Roudi, A.M.; Salem, A.A. Immobilization of Cr (VI) in bagasse ash blended cement pastes. Constr. Build. Mater. 2012, 30, 218–223. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Pozzolanic Activity and Filler Effect of Sugarcane Bagasse Ash in Portland Cement and Lime Mortars. Cem. Concr. Compos. 2008, 30, 410–418. [Google Scholar] [CrossRef]

- Keogh, B.T. Pozzolanic Products Produced from Bagasse Ash. U.S. Patent 4249954 A, 10 February 1981. [Google Scholar]

- Srinivasan, R.; Sathiya, K. Experimental Study on Bagasse Ash in Concrete. Int. J. Serv. Learn. Eng. 2010, 5, 60–66. [Google Scholar]

- Ganesan, K.; Rajagopal, K.; Thangave, K. Evaluation of Bagasse Ash as Supplementary Cementitious Material. Cem. Concr. Compos. 2007, 29, 515–524. [Google Scholar] [CrossRef]

- Onyelowe, K.C. Cement Stabilized Akwuete Lateritic Soil and the Use of Bagasse Ash as Admixture. Int. J. Sci. Eng. Invest. 2012, 1, 16–20. [Google Scholar]

- Alavez-Ramirez, R.; Montes-Garcia, P.; Martinez-Reyes, J.; Altamirano-Juarez, D.C.; Gochi-Ponce, Y. The Use of Sugarcane Bagasse Ash and Lime to Improve the Durability and Mechanical Properties of Compacted Soil Blocks. Constr. Build. Mater. 2012, 34, 296–305. [Google Scholar] [CrossRef]

- Khan, M.J.; Qasim, M. Integrated Use of Boiler Ash as Organic Fertilizer and Soil Conditioner with NPK in Calcareous Soil. Songklanakarin J. Sci. Technol. 2008, 30, 281–289. [Google Scholar]

- British Standard Institution. BS 1377-2:1990—Method of the Test for Soils for Civil Engineering Purposes. Classification tests. In BS 1377; British Standards Institution (BSI): London, UK, 1990. [Google Scholar]

- American Concrete Institute. State-of-the-Art Report on Soil-Cement; American Concrete Institute (ACI): Detroit, MI, USA, 1992. [Google Scholar]

- Kenya Bureau of Standards. KS02-1070, Kenya Standard Specification for Stabilized Soil Block; Kenya Bureau of Standards (KBS): Nairobi, Kenya, 1993. [Google Scholar]

- American Society for Testing and Materials. ASTM Standard D2487. In Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Adam, E.A.; Agib, A.R.A. Compressed Stabilised Earth Block Manufacture in Sudan; United Nations Educational, Scientific and Cultural Organization: Paris, France, 2001. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Salim, R.W.; Ndambuki, J.M.; Adedokun, D.A. Improving the Bearing Strength of Sandy Loam Soil Compressed Earth Block Bricks Using Sugercane Bagasse Ash. Sustainability 2014, 6, 3686-3696. https://doi.org/10.3390/su6063686

Salim RW, Ndambuki JM, Adedokun DA. Improving the Bearing Strength of Sandy Loam Soil Compressed Earth Block Bricks Using Sugercane Bagasse Ash. Sustainability. 2014; 6(6):3686-3696. https://doi.org/10.3390/su6063686

Chicago/Turabian StyleSalim, Ramadhan W., Julius M. Ndambuki, and David A. Adedokun. 2014. "Improving the Bearing Strength of Sandy Loam Soil Compressed Earth Block Bricks Using Sugercane Bagasse Ash" Sustainability 6, no. 6: 3686-3696. https://doi.org/10.3390/su6063686

APA StyleSalim, R. W., Ndambuki, J. M., & Adedokun, D. A. (2014). Improving the Bearing Strength of Sandy Loam Soil Compressed Earth Block Bricks Using Sugercane Bagasse Ash. Sustainability, 6(6), 3686-3696. https://doi.org/10.3390/su6063686